Oil-soluble hydrogen sulfide-proof corrosion inhibitor

A technology of anti-hydrogen sulfide and corrosion inhibitor, which is applied in the direction of wellbore/well components, earthwork drilling and production, etc., can solve the problems of low corrosion inhibition rate, easy failure, unsatisfactory corrosion inhibition performance, etc., to improve corrosion inhibition rate, Corrosion inhibition and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

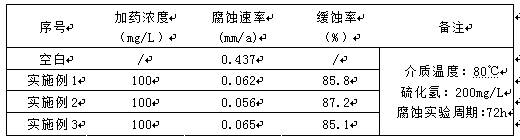

Examples

Embodiment 1

[0024] Mix 20g of sorbitan monooleate (Span80), 10g of nonylphenoxyacetic acid, 5g of octyl phosphate, and 65g of 260# special kerosene solvent, and stir evenly to prepare oil-soluble corrosion inhibitor 1.

Embodiment 2

[0026] Mix 25g of sorbitan monooleate (Span80), 15g of nonylphenoxyacetic acid, 8g of octyl phosphate, and 52g of 260# special kerosene solvent, and stir evenly to prepare oil-soluble corrosion inhibitor 2.

Embodiment 3

[0028] Mix 30g of sorbitan monooleate (Span80), 20g of nonylphenoxyacetic acid, 10g of octyl phosphate, and 40g of 260# special kerosene solvent, and stir evenly to prepare oil-soluble corrosion inhibitor 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com