Composite water-proof layer for ballast track concrete bridge deck and construction method of composite water-proof layer

A technology of concrete and waterproof layer, applied in coatings, bridges, bridge parts, etc., can solve the problems of water channeling at the interface between the concrete bridge deck and the coil, cracking and powdering of the concrete protective layer, loss of protective effect, etc. Strong, save engineering costs, reduce the effect of water channeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

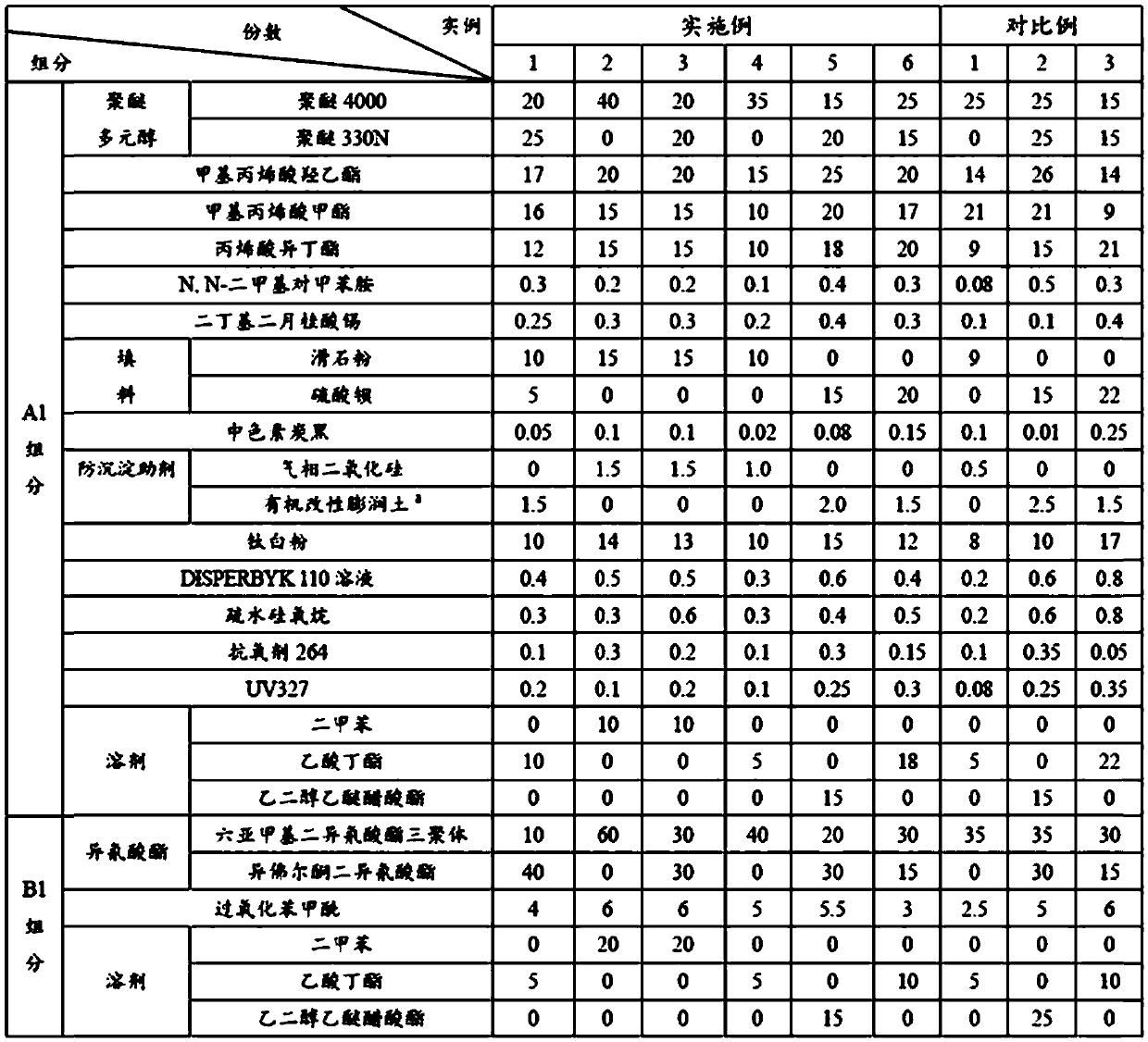

[0076] Embodiment 1~6: a kind of polyurethane composition I

[0077] The polyurethane composition I raw material composition of embodiment 1~6 is as shown in table 1, is prepared by the following method:

[0078] (1) Prepare the raw materials of A1 component and B1 component according to the mass proportion;

[0079](2) Put the solvent and polyether polyol of the A1 component in a container, add the filler under stirring at 100-140 rpm, stir and disperse for 5-10 minutes, and then stir at 1000-1400 rpm After adding hydroxyethyl methacrylate, methyl methacrylate, isobutyl acrylate, N,N-dimethyl-p-toluidine and dibutyltin dilaurate, keep stirring and dispersing for 30-45 minutes at a constant speed, and then continue After adding fillers, anti-sedimentation additives, wetting and dispersing agents, defoamers, light stabilizers, and ultraviolet absorbers, continue to stir and disperse at high speed for 45-65 minutes, grind until the material fineness is below 50 μm, and dischar...

Embodiment 7~12

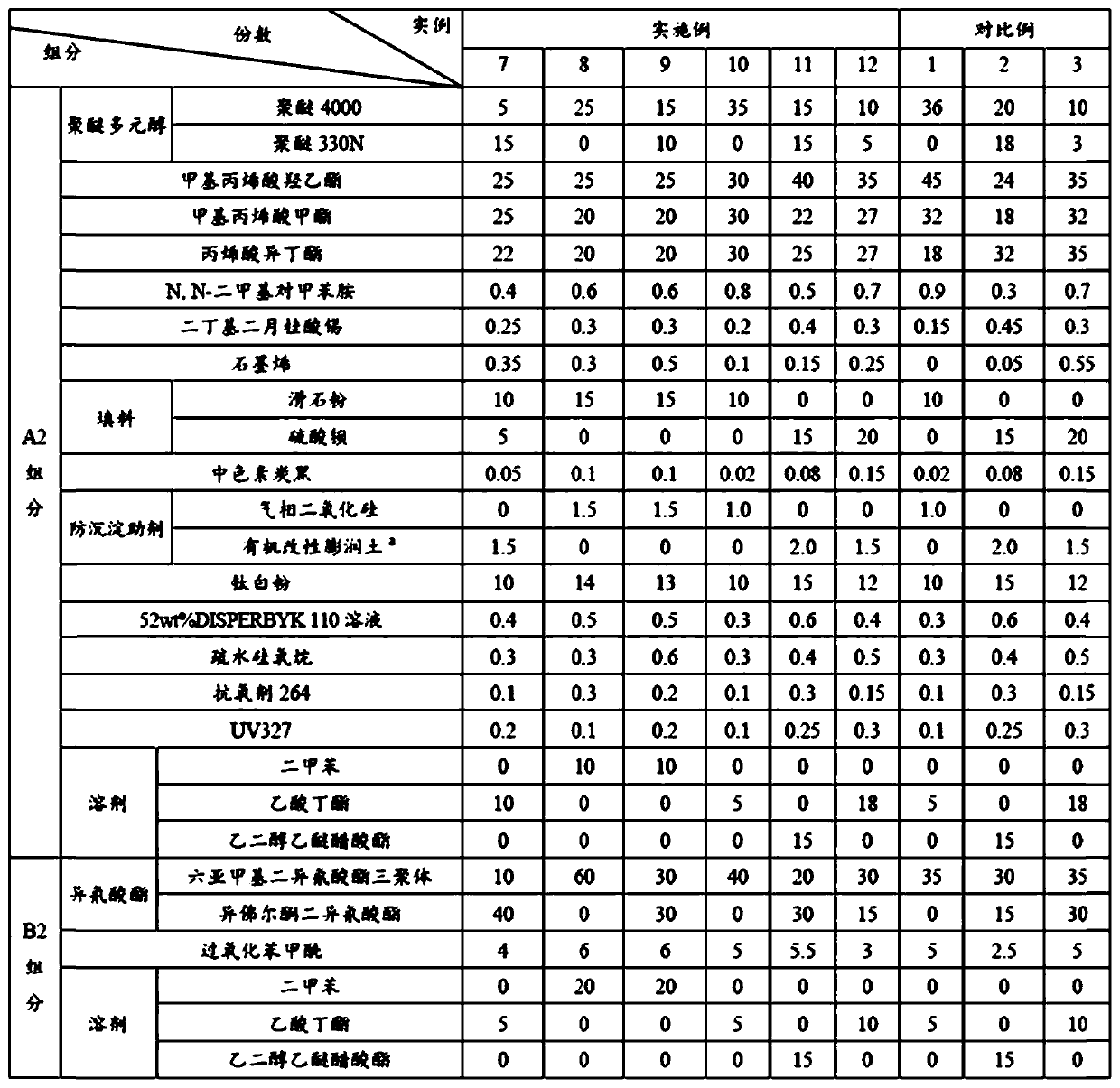

[0099] Embodiment 7~12 a kind of polyurethane composition II

[0100] The raw material composition of the polyurethane composition II of Examples 7-12 is as shown in Table 2, prepared by the following method:

[0101] (1) Prepare the raw materials of A2 component and B2 component according to the mass proportion;

[0102] (2) Put the solvent and polyether polyol of the A2 component in a container, add the filler under stirring at 100 to 140 rpm, stir and disperse for 5 to 10 minutes, and then stir at 1000 to 1400 rpm After adding hydroxyethyl methacrylate, methyl methacrylate, isobutyl acrylate, N,N-dimethyl-p-toluidine, dibutyltin dilaurate and graphene, keep stirring and dispersing for 30-45 minutes at a constant speed ,, and then continue to add fillers, anti-sedimentation additives, wetting and dispersing agents, defoamers, light stabilizers, ultraviolet absorbers, continue to stir and disperse at high speed for 45 to 65 minutes, grind until the material fineness reache...

Embodiment 13~18

[0113] Embodiments 13-18 Composite waterproof layer of railway ballasted track concrete bridge deck

[0114] The railway ballasted track concrete bridge deck composite waterproof layer described in embodiments 13 to 18 comprises from top to bottom: a modified polyurethane composite topcoat layer, a modified polyurethane composite primer layer and a sealing primer layer, wherein each layer Both are closely bonded to adjacent layers; construction is completed by the following methods:

[0115] (1) After the base surface of the concrete bridge deck is cleaned and dried, apply an epoxy sealing primer (produced by Langfang Santong Chemical Industry Co., Ltd.), and the consumption of the epoxy sealing primer is 0.2~0.4Kg / m 2 ;

[0116] (2) After coating the seal primer 24h, on the seal primer layer formed, coat the polyurethane composition I shown in Table 5 (prepared according to the method described in Example 1), the modified polyurethane compound formed The dry film thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com