Architectural structure system of preformed hollow load-bearing wall panel and construction method

A technology of building structure and load-bearing structure, which is applied in the direction of building components, building structure, construction, etc., can solve problems such as inability to adapt, high cost, and few types of specifications, and achieve strong integrity, low engineering cost, and fast construction speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

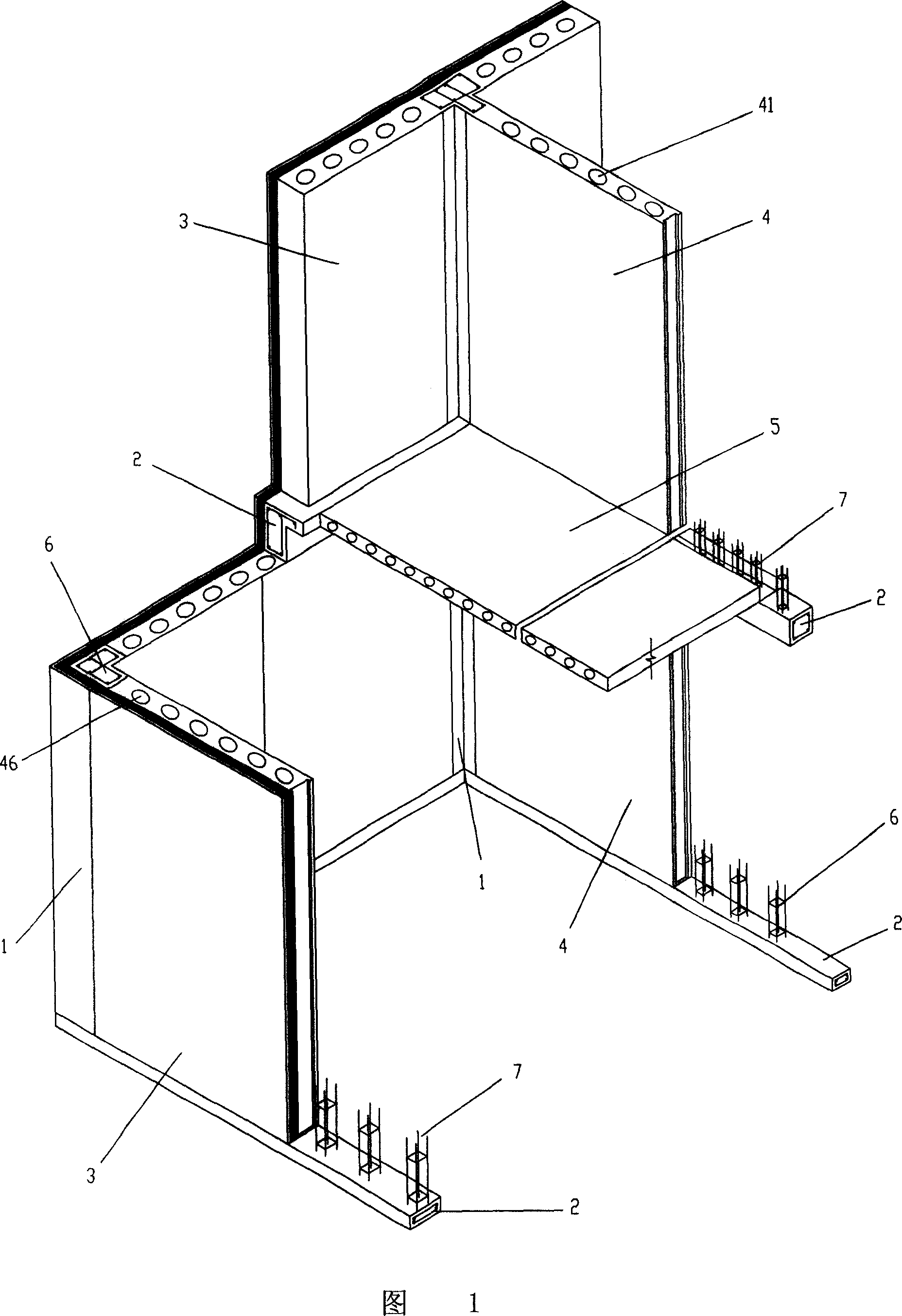

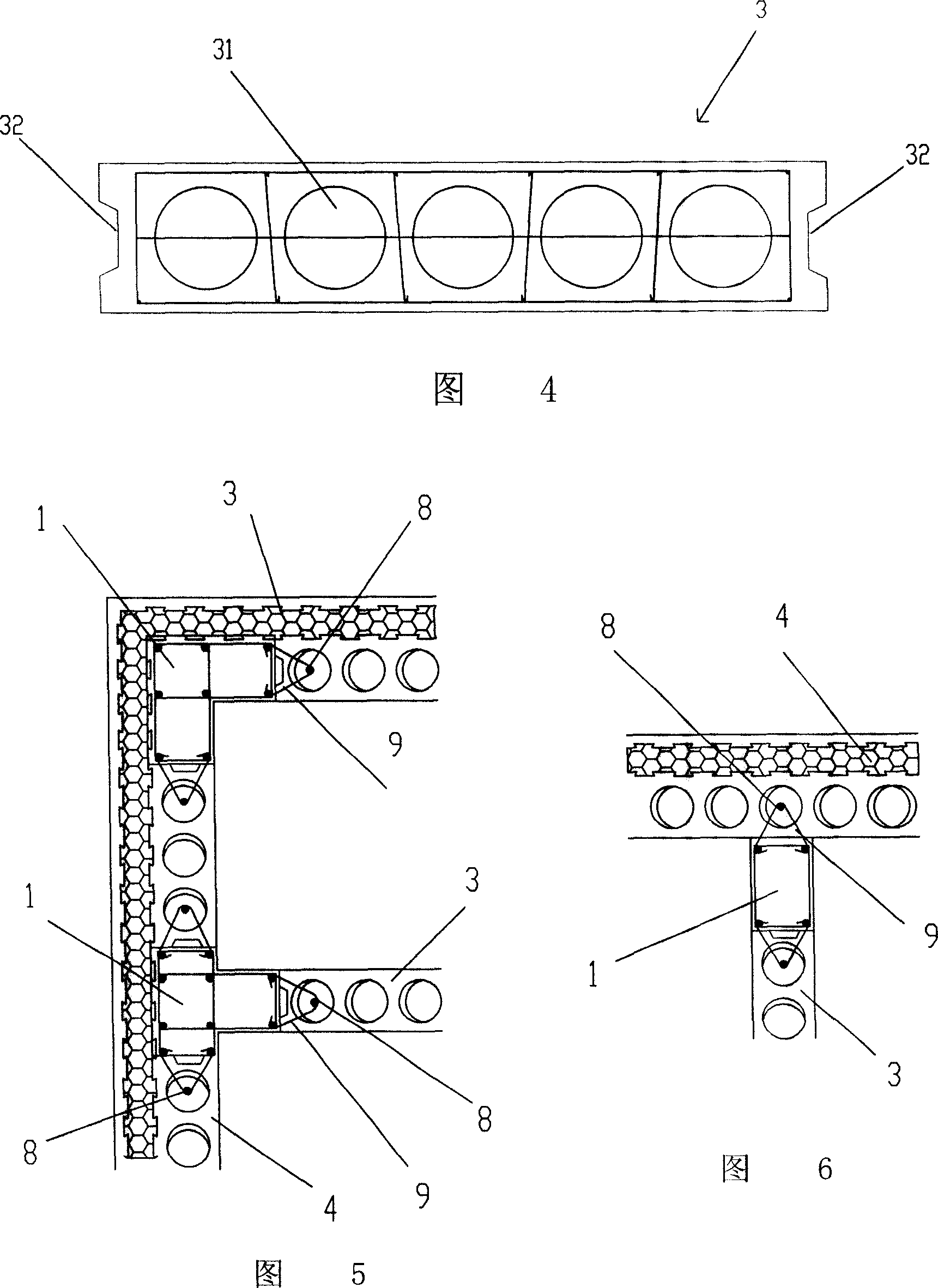

[0019] As shown in Fig. 1, the building structure system of the present invention comprises cast-in-situ reinforced concrete upper column 1, ring beam 2, prefabricated inner and outer wall panels 3, 4 and floor slabs 5 arranged between column 1 and ring beam 2 , and the top roof panel (not shown).

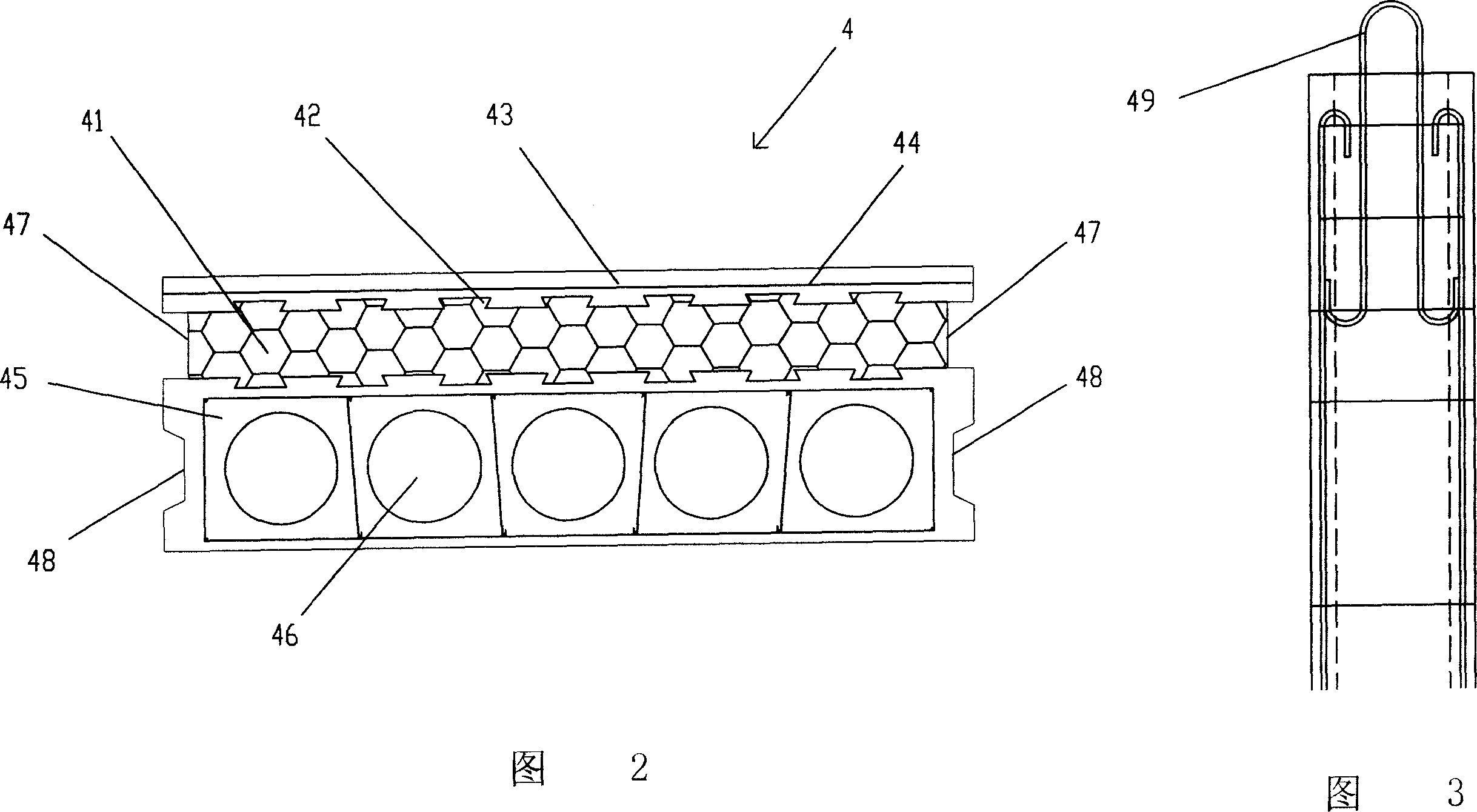

[0020] As shown in Fig. 2 and Fig. 3, the outer wall panel 4 of the present invention is a prefabricated load-bearing board with heat preservation function, which includes a foamed plastic insulation layer 41, and a number of vertically spaced inner and outer surfaces of the insulation layer 41 are arranged The dovetail groove 42 that passes through. A reinforced lightweight concrete surface layer 43 embedded in the dovetail groove 42 is poured on the outer surface of the insulation layer 41 , and a layer of steel wire mesh or short glass fiber mesh is sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com