Patents

Literature

31results about How to "Good heat preservation and energy saving effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

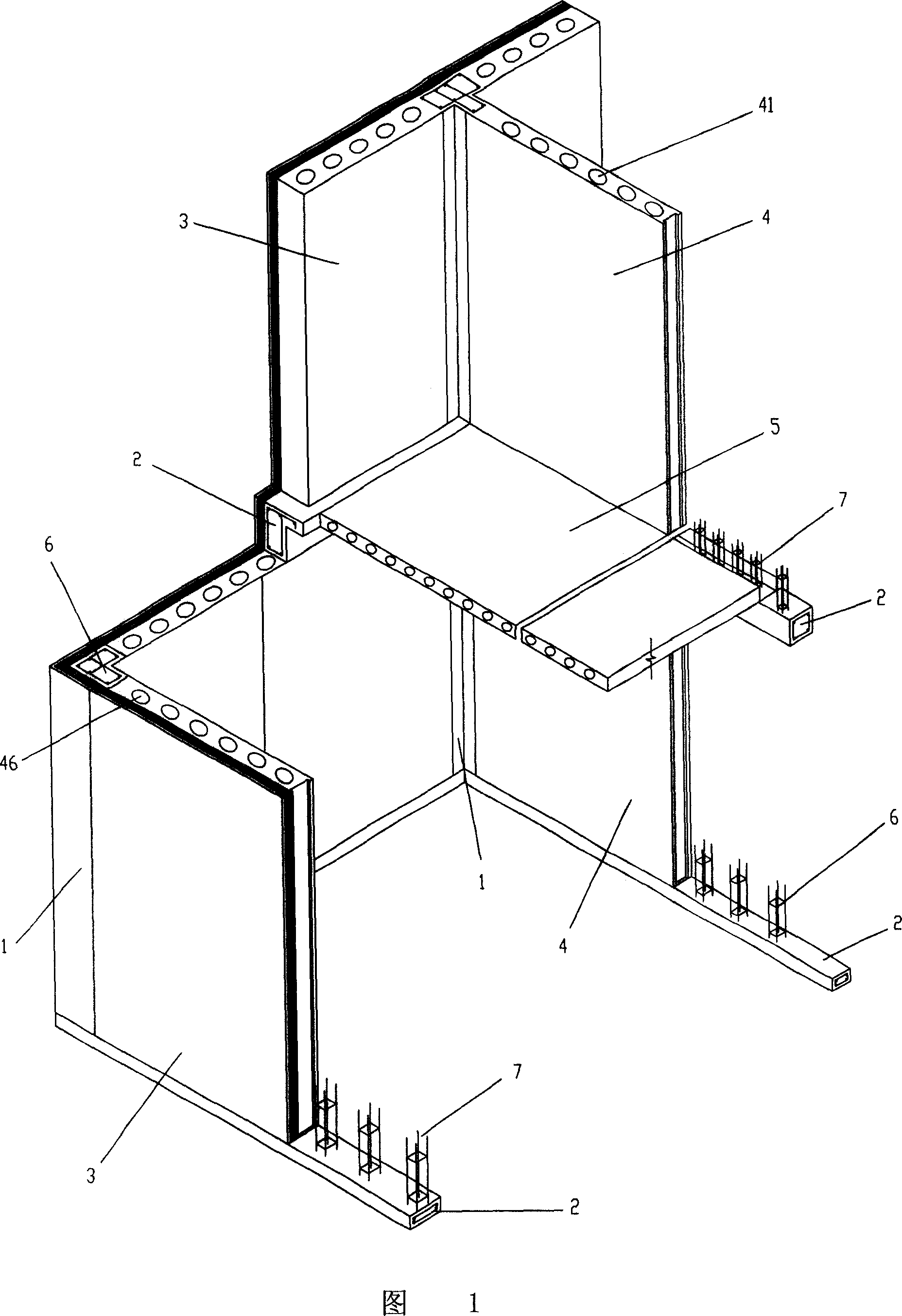

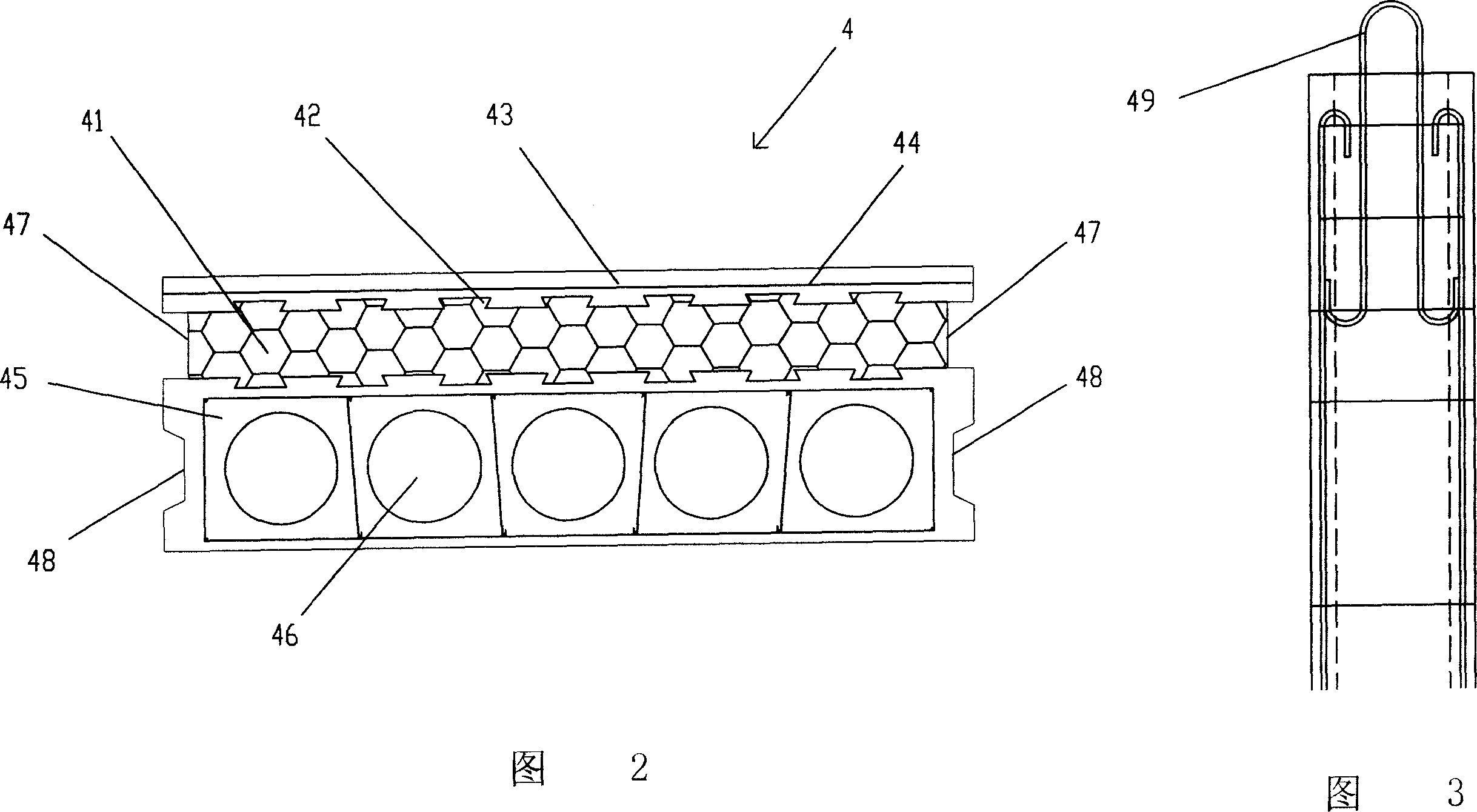

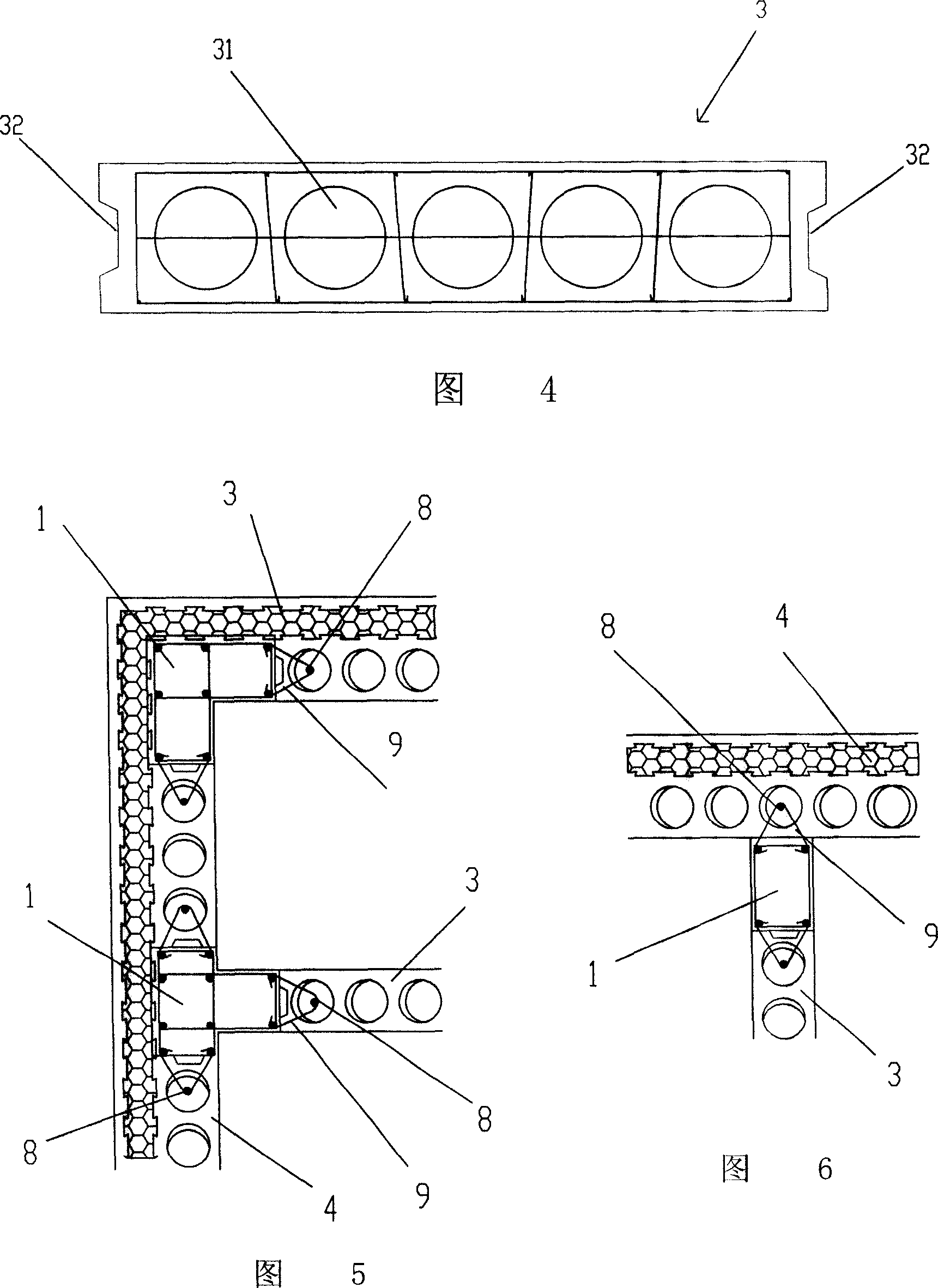

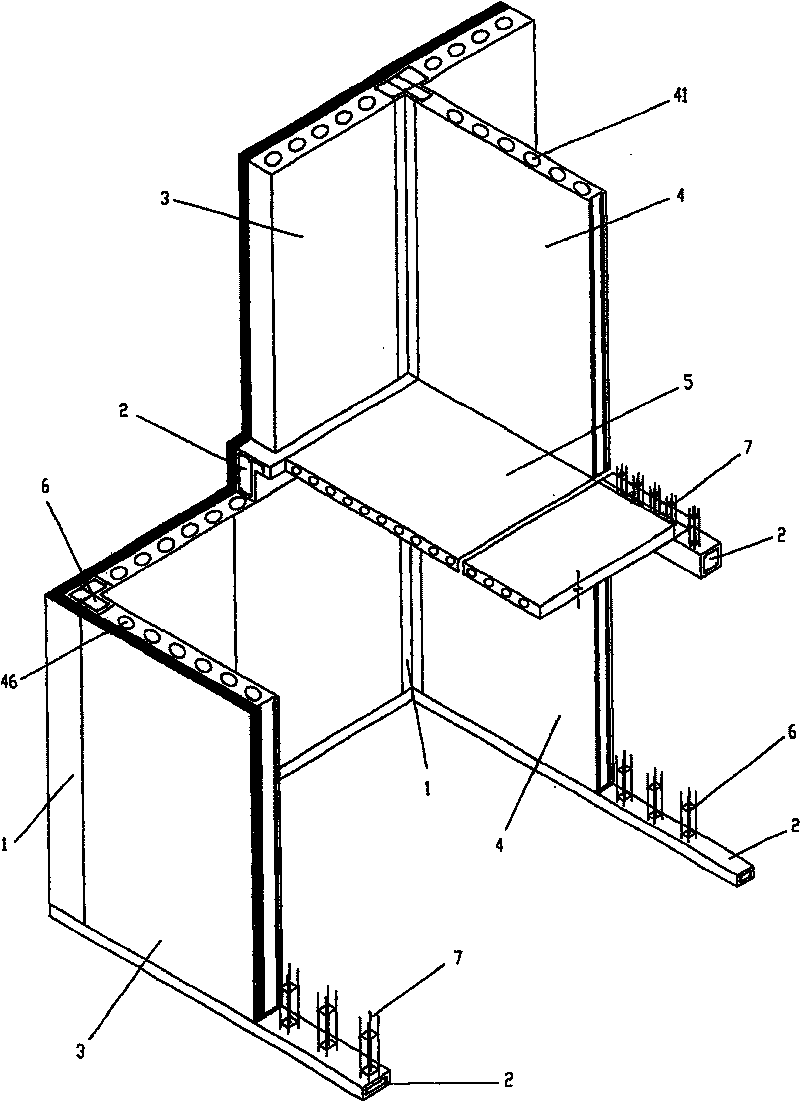

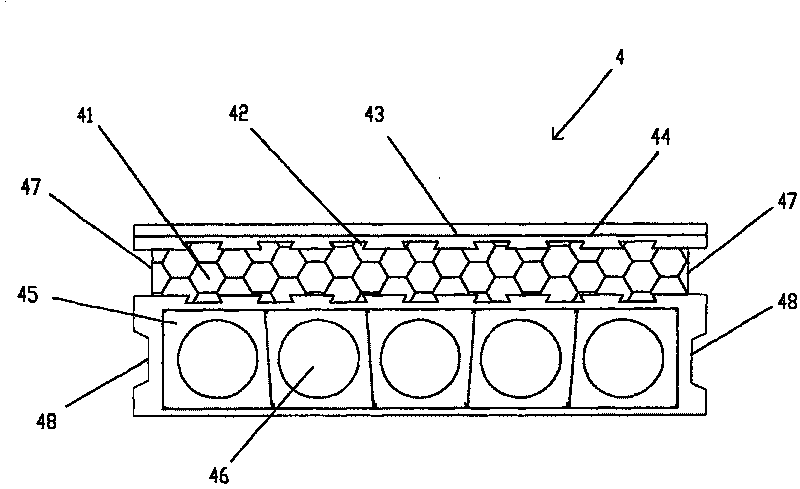

Architectural structure system of preformed hollow load-bearing wall panel and construction method

The invention relates to an architecture systematism and a construction method for a precast hollow load-bearing wall panel comprising a column and a collar beam of cast-in-situ armored concrete, a precast interior or external wall panel and a floor slab equipped in between the column and the collar beam, and a roof slab equipped on the most top, characterized in that the external wall panel is a bearing plate with heat-retaining function, and the interior wall panel is a bearing plate of lightweight armored concrete, while the inside of the interior and external wall panel is equipped with hollow holes whose upper and lower ends are inserted and casting fixed with anchor concrete bars preformed on the collar beam concrete bars. The first hollow hole on the side adjacent the column of the interior and external wall panel is vertical interval inserted the anchor concrete bars on the column concrete bars, and fully pours the concrete. The invention can build a high-rise building with 6 floors and 18 meter height in an anti-seismic prevention region with 8 degrees, or a high-rise building with 7 floors and 21 meter height in an anti-seismic prevention region with 7 degrees, or a high-rise building with 8 floors and 24 meter height in an anti-seismic prevention region with 6 degrees.

Owner:冯葆纯 +1

Architectural structure system of preformed hollow load-bearing wall panel and construction method

The invention relates to an architecture systematism and a construction method for a precast hollow load-bearing wall panel comprising a column and a collar beam of cast-in-situ armored concrete, a precast interior or external wall panel and a floor slab equipped in between the column and the collar beam, and a roof slab equipped on the most top, characterized in that the external wall panel is abearing plate with heat-retaining function, and the interior wall panel is a bearing plate of lightweight armored concrete, while the inside of the interior and external wall panel is equipped with hollow holes whose upper and lower ends are inserted and casting fixed with anchor concrete bars preformed on the collar beam concrete bars. The first hollow hole on the side adjacent the column of theinterior and external wall panel is vertical interval inserted the anchor concrete bars on the column concrete bars, and fully pours the concrete. The invention can build a high-rise building with 6 floors and 18 meter height in an anti-seismic prevention region with 8 degrees, or a high-rise building with 7 floors and 21 meter height in an anti-seismic prevention region with 7 degrees, or a high-rise building with 8 floors and 24 meter height in an anti-seismic prevention region with 6 degrees.

Owner:冯葆纯 +1

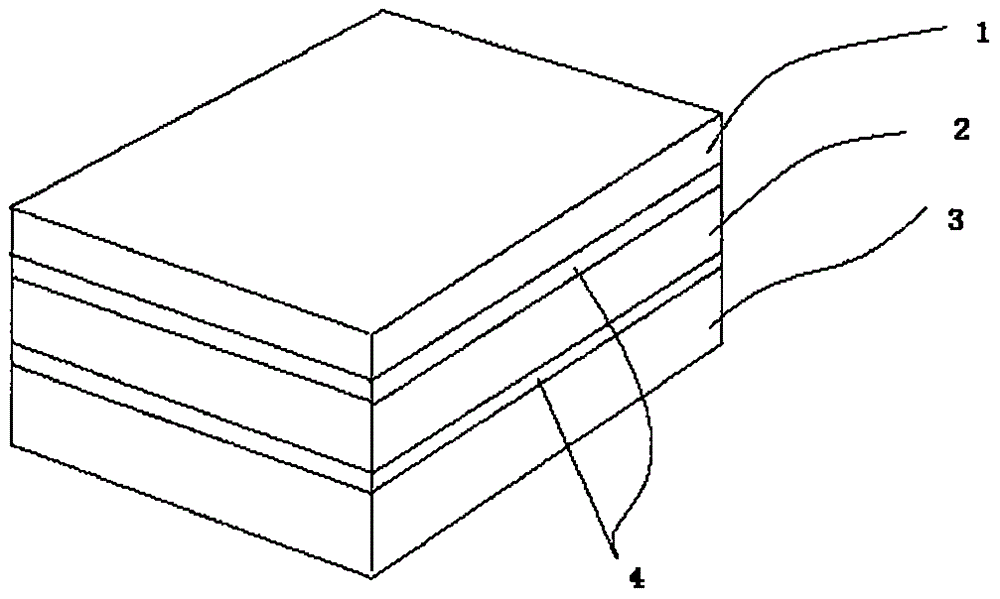

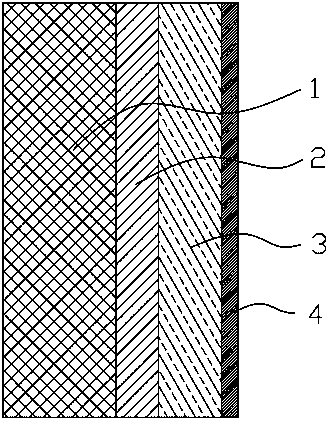

Multifunctional green building materials

ActiveCN105220779AGood thermal insulation performanceGood heat preservation and energy saving effectSynthetic resin layered productsHeat proofingThermal insulationCorrosion resistant

The invention discloses multifunctional green building materials with functions of fire prevention, thermal insulation and sound insulation and aims to overcome the defect that current building materials are poor in thermal insulation and sound insulation effects. The green building materials comprise an inner fire preventing layer, an outer sound insulation layer and a thermal insulation layer between the inner fire preventing layer and the outer sound insulation layer, wherein the thermal insulation layer is connected with the fire preventing layer through an adhering layer, and the thermal insulation layer is connected with the sound insulation layer through an adhering layer. The multifunctional green building materials have the advantages that the building materials are good in thermal insulation performance, the heat conductivity coefficient of the building materials is 0.01-0.05W / (m*K), the building materials are good in thermal insulation and energy saving effects and good in fire preventing performance, the fire resistance duration of the building materials is larger than 3 hours, an A-level fire preventing standard can be reached, good fire resistance is achieved, a good sound insulation performance is achieved, noise influence can be reduced greatly, good durability is achieved, and the building materials are resistant to high temperature and low temperature and good in corrosion resistance and weather resistance.

Owner:FENGLIN ENVIRONMENTAL PROTECTION TECH CO LTD

Efficient energy-saving kervit microbead insulated sand slurry

The invention is a high-efficiency, energy-saving, vitrified microball thermal insulation mortar thermal insulation system, comprising: cement, vitrified microballs, re-dispersible latex powder, composite fibers, methyl cellulose ether and air-entraining agent, where the composite fibers include tensile fiber, PP fiber and wood fiber. The invention has antiaging and fireproofing properties, not hollow swelling and cracking, and having high intensity and good binding property, and having heat conductivity coefficient of 0.05W / m.k-0.06W / m.k, saving energy consumption of buildings, applied to new buildings and existing buildings. As constructing, the invention is simple to operate, and the quality is easy to control, able to largely raise construction efficiency and convenient to large-scale spreading and application.

Owner:李珠

Method for producing liquid wood integral door

The invention discloses a method for producing a liquid wood integral door, which comprises the following steps of: 1) preparing liquid wood, namely (1) drying and grinding raw materials; (2) mixing the raw materials to obtain a mixture; and (3) generating the liquid wood, wherein the liquid wood comprises the following raw materials in part by weight: 100 parts of polyvinyl chloride, 40 parts of calcium carbonate, 60 parts of wood fiber powder, 4.5 parts of stabilizer, 8 parts of chlorinated polyethylene (CPE), 5 parts of acrylamide (ACR), 3 parts of H530, 0.5 part of polyethylene (PE) wax, 0.6 part of stearic acid, and 1 part of pigment; and 2) performing extrusion molding on the liquid wood at one time to obtain the integral door. In the method, the raw materials are molded at one time at a high temperature and under high pressure, do not contain formaldehyde, and are subjected to surface treatment by adopting thermal transfer technology; the integral door is free of paint, has no any toxic harmful gas and smell release in the production and use process, is environmental-friendly and has practicality.

Owner:杨华

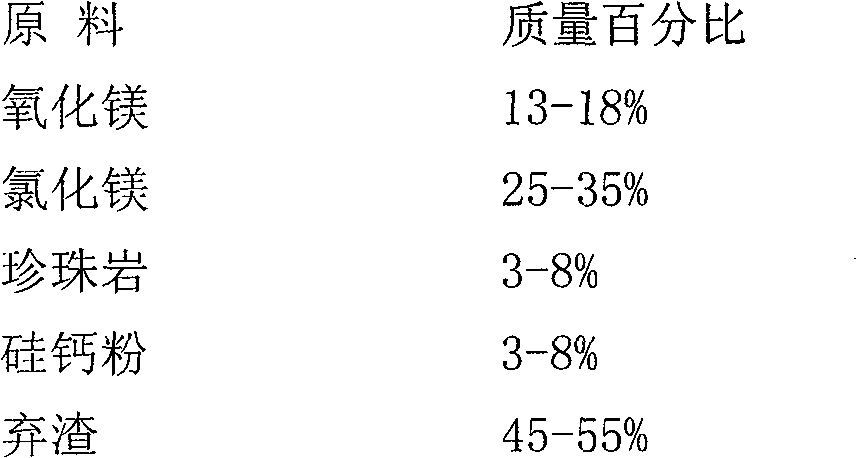

Baking-free building block produced by utilizing nonmetallic waste slag and preparation method

The invention discloses a baking-free building block produced by utilizing nonmetallic waste slag and a preparation method. The baking-free building block is produced by magnesium oxide, magnesium chloride, perlite, silicon-calcium powder and waste slag according to a certain proportion. The preparation method comprises the following steps: 1, waste slag with abundant resources is selected under specific conditions, and materials are prepared according to a state requirement; 2, integrated feeding is carried out according to the mixture ratio of a formulation; 3, the mixture is uniformly stirred by a stirrer; 4, compression moulding forming is carried out by a special brick making machine; 5, prehardening conservation is carried out by a supporting plate; 6, the supporting plate is removed, and natural curing conservation is carried out by stacking; 7, classification warehousing is carried out after detection; and 8, the product is sold and used. The invention has reasonable formulation, simple operation and low cost, and the building block is energy-saving and environmental-friendly and does not need sintering and steam pressure maintenance.

Owner:王福生

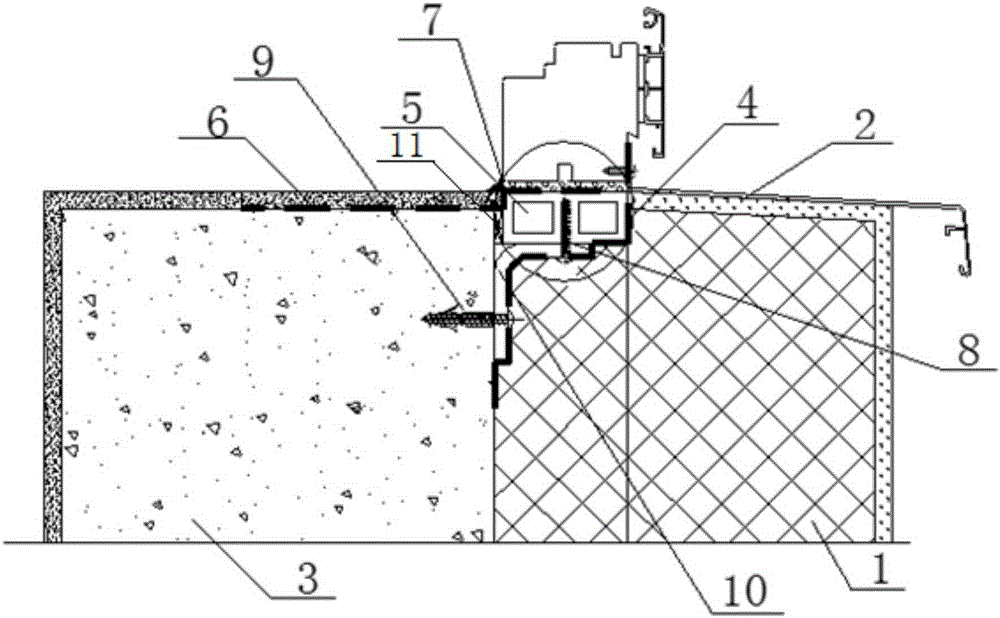

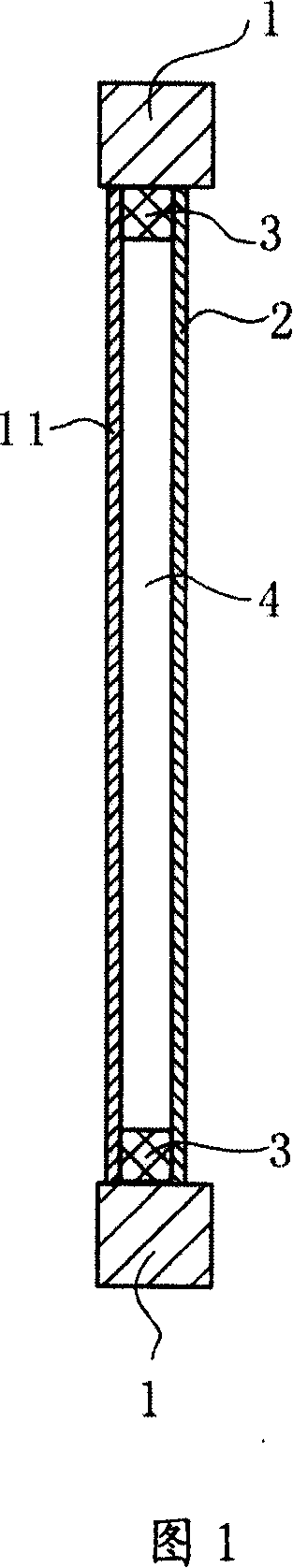

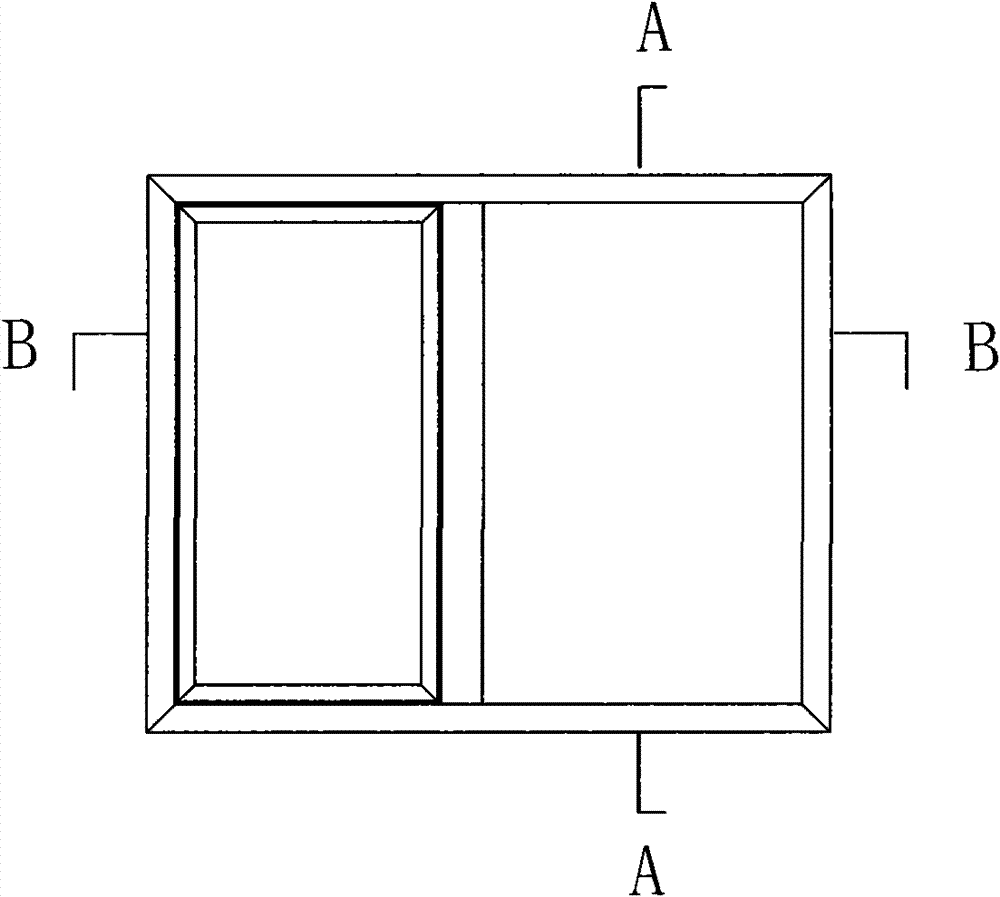

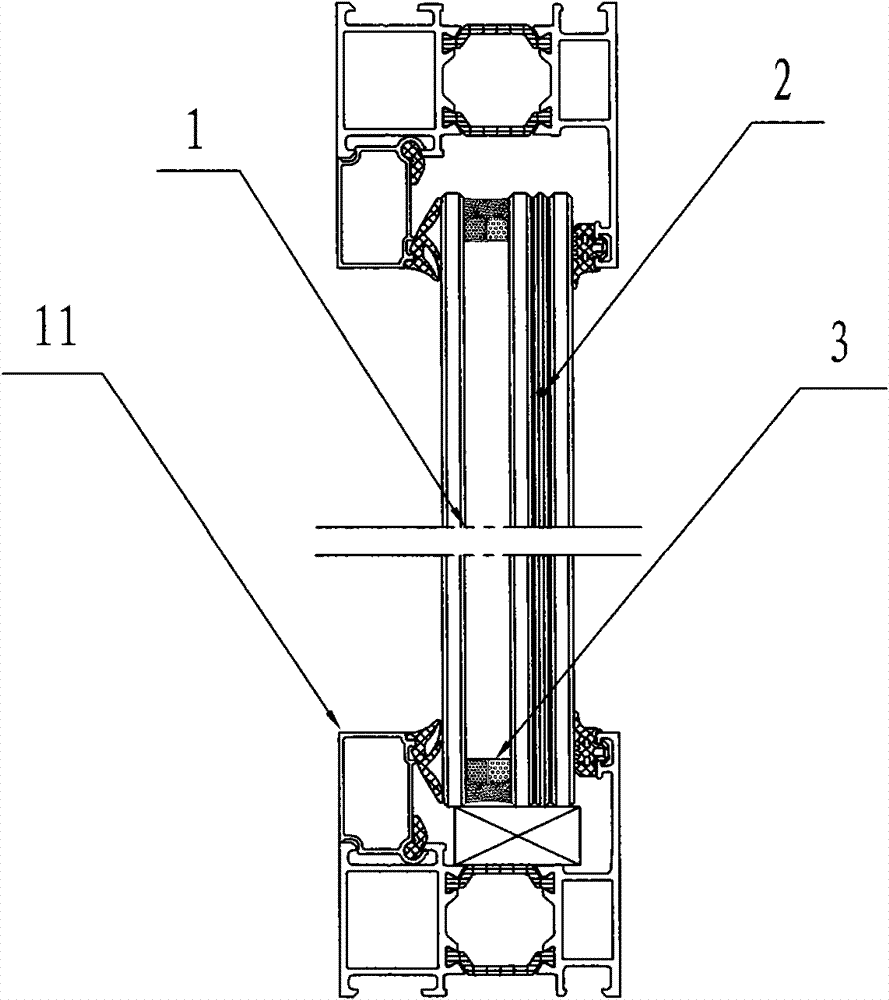

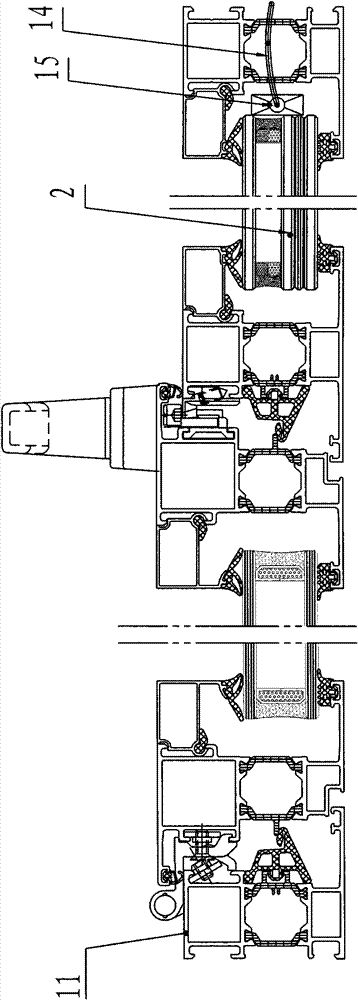

Passive window with auxiliary frame and installation method thereof

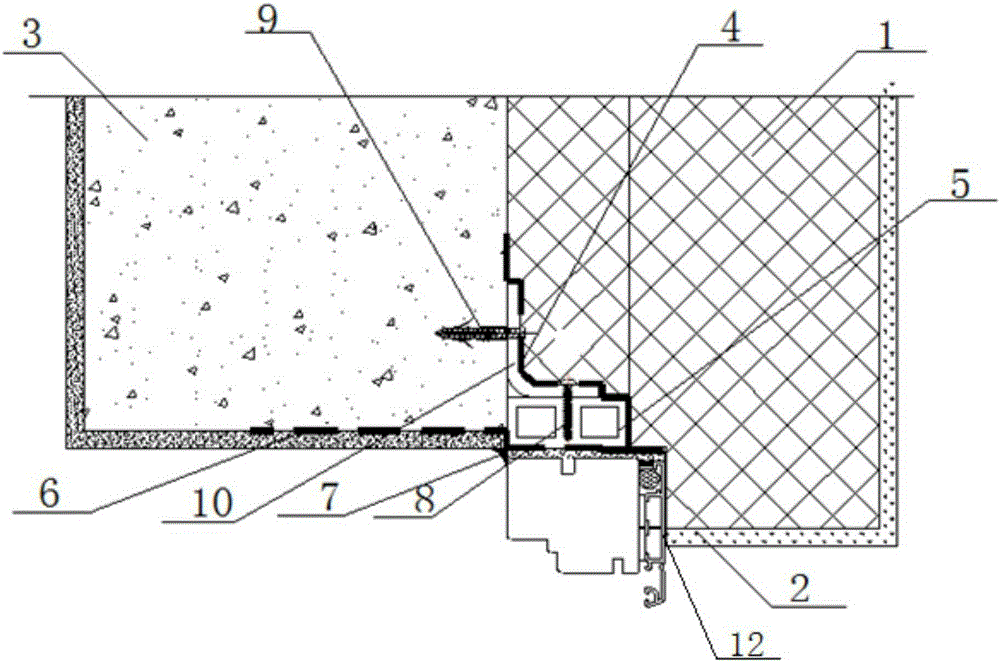

InactiveCN105201335ATo overcome the defect that the maintenance needs to remove the wallGuaranteed air tightnessFrame fasteningBase framesWindow openingEngineering

The invention discloses a passive window structure with an auxiliary frame and an installation method thereof. The installation method comprises the following steps: (1) installing the auxiliary frame on a wall at the outer side of a window opening, embedding in an outer insulating layer, and enabling four sides of the auxiliary frame to be respectively consistent with the window opening in verticality and levelness; (2) after the auxiliary frame is installed, sticking a waterproof and breathable membrane on the outer surface of the auxiliary frame, sticking a waterproof and gas-isolated membrane on the front of the auxiliary frame, and installing positioning lines on the outside top surface and two side surfaces of the auxiliary frame; and (3) connecting the auxiliary frame with the passive window to finish installation. After the auxiliary frame of the passive window is adopted, the passive window disclosed by the invention is simpler in structure, can completely meet the energy-saving requirement, is more reasonable in design, is energy-saving and environment-friendly, is reduced in cost, convenient in installation and standardized in installation, thoroughly solves the connection problem of passive window installation and external insulation construction, and is increased in installation yield.

Owner:常州玖洲联横建材有限公司

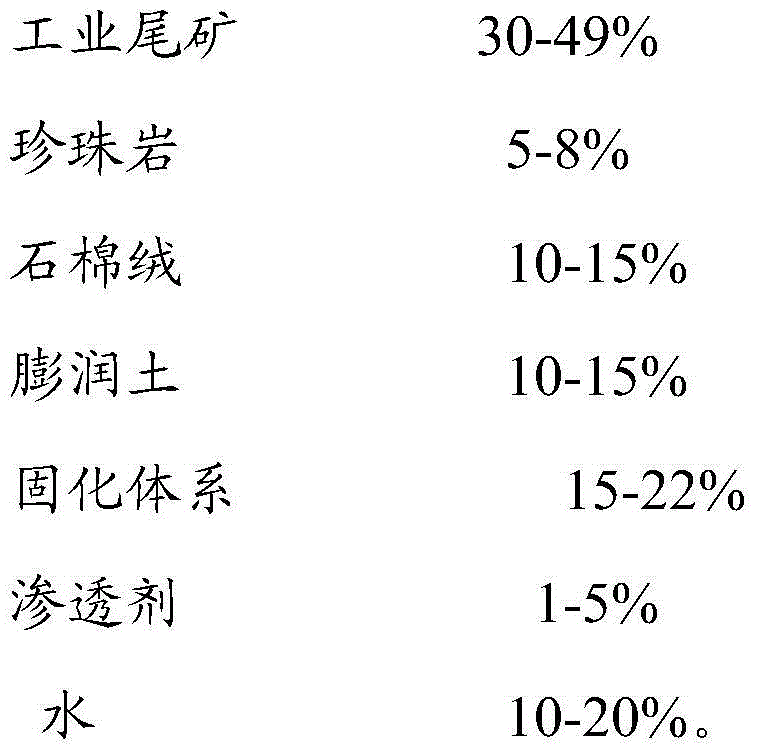

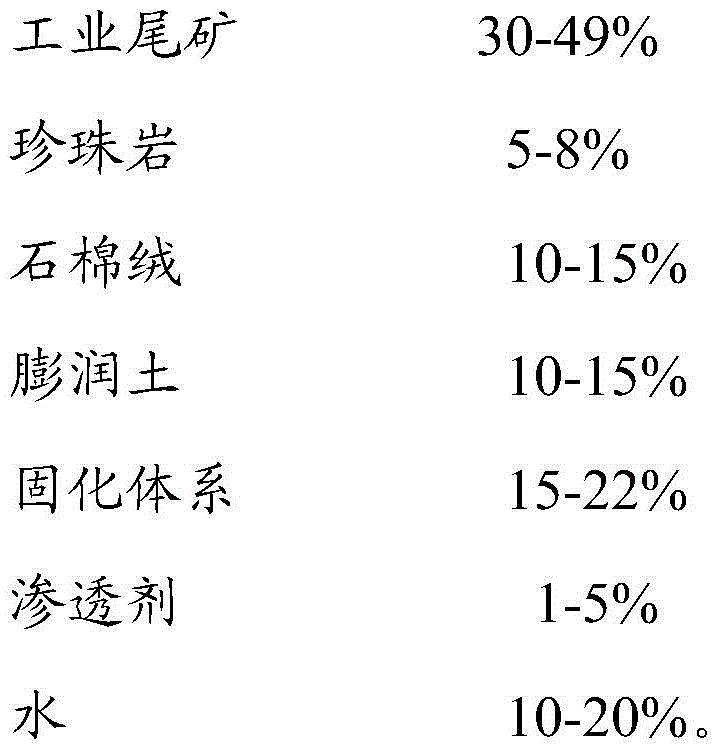

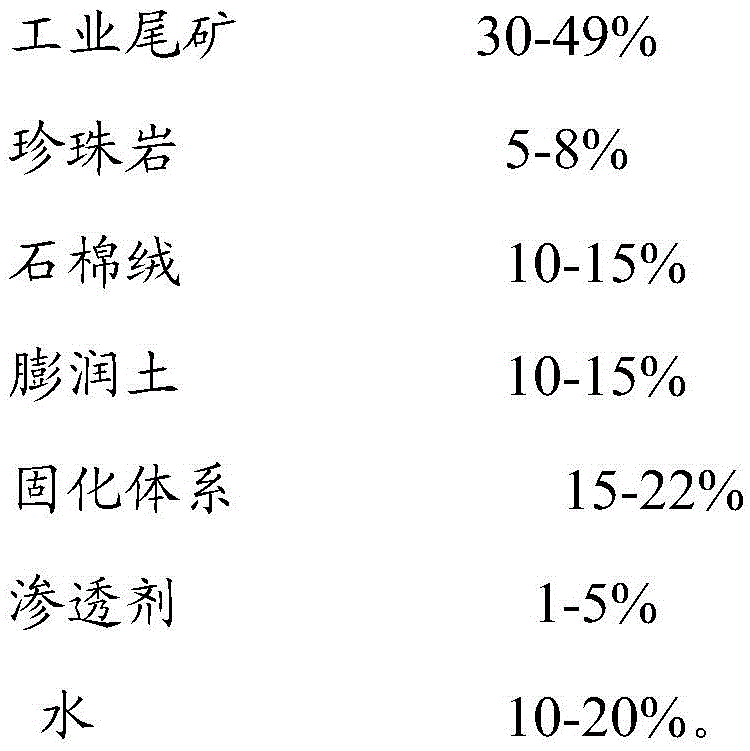

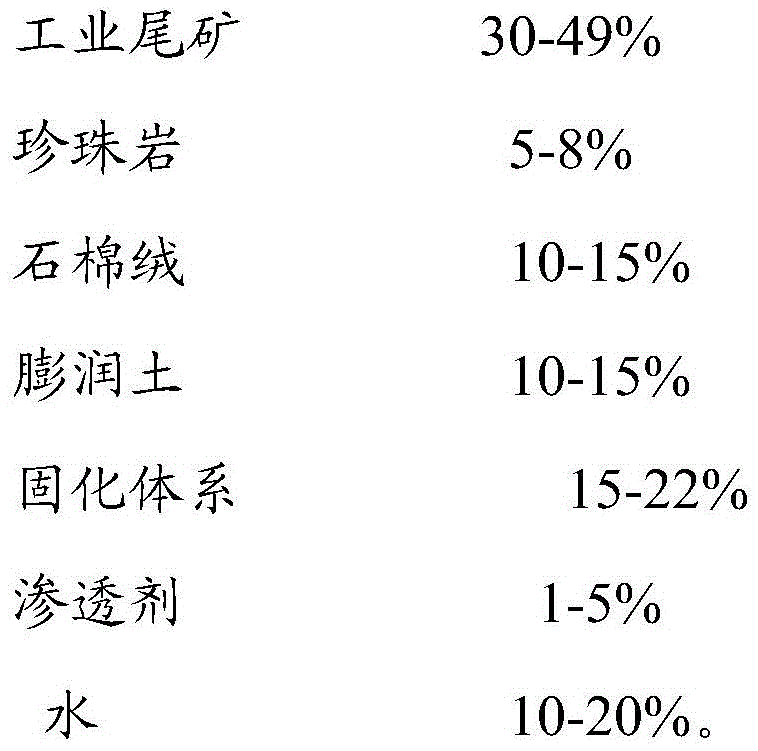

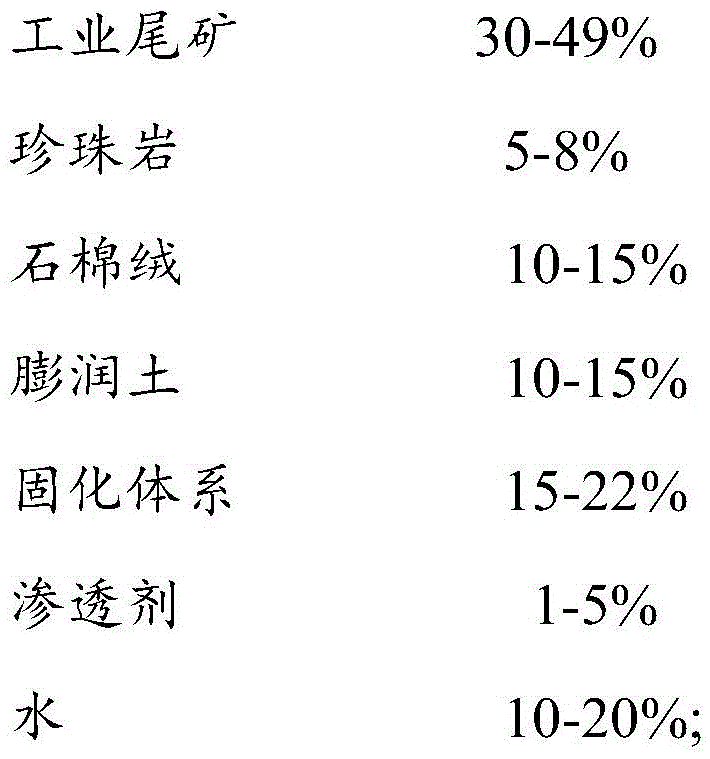

High-temperature-resistant thermal-insulation material prepared with industrial tailings and preparation method thereof

ActiveCN104649647ALow thermal conductivityAvoid crackingSolid waste managementThermal insulationMaterials science

The invention discloses a high-temperature-resistant thermal-insulation material prepared with industrial tailings, which includes following components, by weight: 30-49% of the industrial tailings, 5-8% of perlite, 10-15% of asbestos wool, 10-15% of bentonite, 15-22% of a solidifying system, 1-5% of a penetrant, and 10-20% of water. The thermal-insulation material is low in thermal conductivity coefficient, is not liable to crack and fall off, and is good in sealing performance. The invention also discloses a preparation method of the high-temperature-resistant thermal-insulation material with the industrial tailings, which comprises steps of: weighing the raw materials, mixing the raw materials and sealing and storing the mixed raw materials. The preparation method is simple and convenient to carry out, is low in cost and is suitable for industrial production.

Owner:GEM CO LTD

Anti-cracking thermal insulation mortar and preparation method thereof

ActiveCN104193239AGood adhesionGood heat preservation and energy saving effectPerliteAluminium salts

The invention discloses anti-cracking thermal insulation mortar. The anti-cracking thermal insulation mortar is prepared from the following raw materials in parts by weight: 4-6 parts of aluminum sulfate, 2-4 parts of alum, 14-17 parts of wood charcoal, 230-250 parts of perlite, 20-25 parts of pitchstone, 34-38 parts of obsidian, 30-40 parts of coal slime, 30-50 parts of coal ash, 3-4 parts of urea, 3-5 parts of monopotassium phosphate, 180-200 parts of cement, 40-50 parts of sepiolite fabric, 100-120 parts of sand, a proper amount of water and 20-25 parts of auxiliaries. The mortar has the advantages of good adhesiveness, water-retaining property and thermal-insulation and heat-insulation performance, outstanding thermal-insulation energy-saving effects, and further has excellent anti-cracking performance by use of the sepiolite fabric, is suitable for masonry and plastering construction of a wall material. By use of the auxiliaries adopted by the anti-cracking thermal insulation mortar, the compressive strength and the breaking strength of the mortar are improved, and the peaceability, the flow sagging resistance, the thixotropy and the settling resistance of the mortar are improved.

Owner:长治市中宝建材股份有限公司

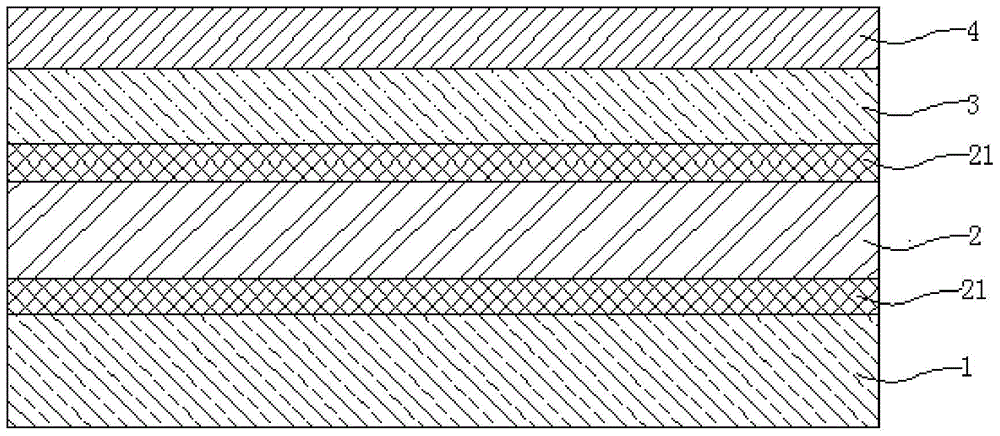

Pre-coating film for thermal insulation of buildings and thermal insulation material coated with pre-coating film

InactiveCN103362225AEasy to useGood heat preservation and energy saving effectClimate change adaptationPassive housesPolyesterThermal insulation

The invention discloses a pre-coating film for the thermal insulation of buildings, which comprises a hot melt adhesive layer, a base film layer and a metal layer in sequence, wherein the hot melt adhesive layer is made of ethylene-vinyl acetate (EVA), the base film layer is a biaxially-oriented polypropylene (BOPP) film and a biaxially-oriented polyester (BOPP) film; the metal layer is an aluminium layer evaporated on the base layer. The invention further discloses a thermal insulation material coated with the pre-coating film on the surface, and comprises a thermal insulation layer, the hot melt adhesive layer, the base film layer and the metal layer in sequence from interior to exterior. The invention provides the anti-ultraviolet and flame-retardant pre-coating film applicable to the building field, which can be used for thermal insulation of an external wall and a roof; the aluminum plated pre-coating film is pasted on the outer surface of the thermal insulation material, so that the building thermal insulation material is convenient to use, superior in thermal insulation and energy saving effects, easy to assemble and disassemble and low in cost.

Owner:ANHUI GUOFENG PLASTIC

Lightweight composite building energy-saving heat-insulation material

ActiveCN104773985AEasy to processReduce processing costsCeramicwareThermal insulationSuperplasticizer

A fire-proof non-combustible composite heat-insulation material with good energy saving effect, good water proofing effect and better mechanical spraying construction effect is prepared by mixing and stirring ordinary Portland 42.5R cement with different weights, fiber brucite, magnesium silicate long fiber, wood fiber, light weight magnesium oxide, polypropylene fiber, an organic active waterproof agent, ultra light nano expansion beads, urea formaldehyde particles or polystyrene particles, adhesives, a foaming agent, a procoagulant regulating agent, silicon micropowder and a poly carboxylic acid superplasticizer, and has the appearance of dry and powdery fiber. The material can be directly spared on external walls, interior walls, roofs and staircase rooms of buildings according to a certain thickness after addition of water for mixing and stirring, has the characteristics of being thermal-insulation, energy-saving, non-combustible, environmentally-friendly, waterproof, and simple and quick in construction, is applicable to heat insulation of a variety of houses and buildings, and can achieve high efficiency and energy saving effect.

Owner:营口天瑞新型建筑材料有限公司

Method for remaking common window into thermal insulation energy saving window

InactiveCN101089354AGood heat preservation and energy saving effectEasy to transformUnits with parallel planesThermal insulationAgricultural engineering

The present invention discloses a method for remaking general window into heat-insulating energy-saving window. Said method is characterized by that said method includes the following steps: cutting a soft glass into the general window glass size, sticking adhesive strip on the periphery of said soft glass, then making the soft glass be stuck on the general window glass. The thickness of said adhesive strip is 12-16 mm, and the described soft glass is coated colored soft glass or transparent colorless soft glass.

Owner:SHANGHAI SHENGE HIGH SCHOOL

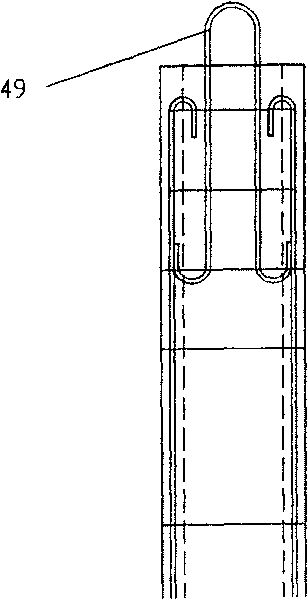

Steel structure integrated system

InactiveCN104695661AImprove thermal insulationLow smoke productionPhotovoltaic supportsCovering/liningsSurface layerThermal insulation

The invention relates to a steel structure integrated system which comprises a structure layer, wherein a thermal insulation layer and a surface layer are arranged on an outer side of the structure layer in sequence from inside to outside. The steel structure integrated system integrates functions of structure, decoration, energy conservation and thermal insulation, saves energy, protects environment, can finish structure, thermal insulation and decoration constructions by one step, is short in construction cycle and low in comprehensive manufacturing cost, and radically eliminates the influence of crossed construction caused by multiple conventional constructions of thermal insulation, decoration and the like.

Owner:SHENZHEN ZHUOBAO TECH

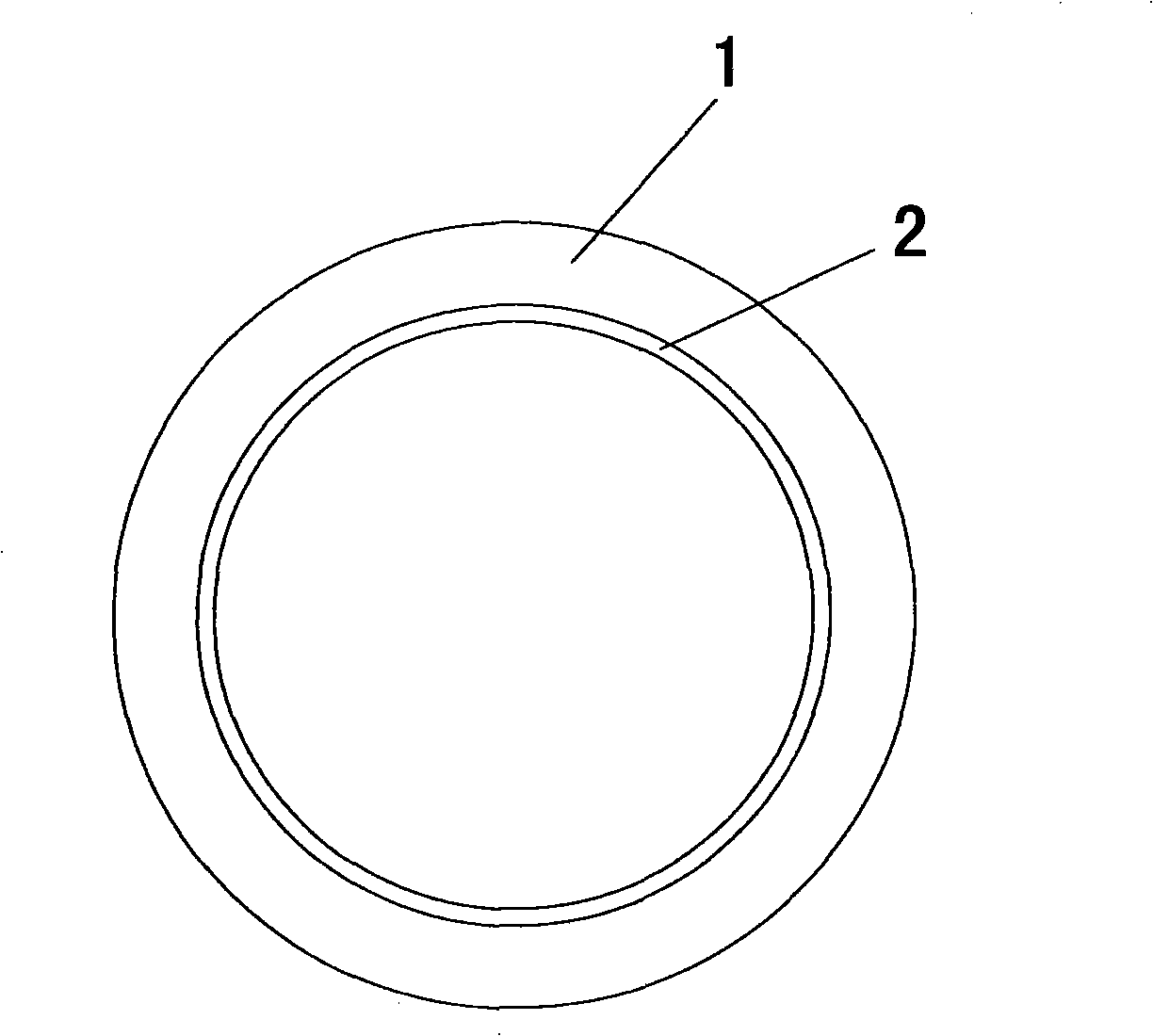

Novel antimicrobial PE tube

InactiveCN101270833AGood heat preservation and energy saving effectImprove toughnessRigid pipesThermal coefficientEngineering

A novel antibacterial PE pipe relates to construction pipes. The outer layer is PE pipe. The invention is characterized in that the inner wall of the PE pipe is provided with a layer of inorganic antibacterial layer by co-extrusion. In the invention, the thickness of the pipe wall of the PE pipe is between 2mm and 10mm. The thickness of the inorganic antibacterial layer is between 0.3mm and 1.0mm. The invention has the beneficial effect that the novel antibacterial PE pipe integrates antibacterial property, energy saving, sanitation and self-cleaning, which can be directly applied to the transportation system of purified water. The invention is a novel green and environmentally-friendly construction material. The thermal coefficient is only 2 percent of the metal pipe and the hot-water pipe has excellent heat insulating and energy saving effects. Adopting the consubstantial hot melt connection, the tubes and the pipes have the advantages of no leakiness, high toughness and strong heat resistance and creep resistance. When used under normal pressure and temperature, the service life of the tubes and the pipes can be 50 years.

Owner:SHANGHAI RUIHE ENTERPRISE GRP

Novel efficient energy-saving fireproof heat insulation concrete and preparation method thereof

A novel efficient energy-saving fireproof thermal insulation concrete and a preparation method thereof. The thermal insulation concrete is composed of cement, redispersible latex powder, composite fiber, methyl cellulose ether, glazed hollow bead and an air entraining agent. The concrete has the characteristics of fire resistance, water resistance, thermal insulation resistance, severe cold resistance and light weight, and is suitable for all base materials of walls and insulation of various complex shapes of walls, and is all closed, seamless, cavity-free and free of hot and cold bridge. The concrete has coefficient of thermal conductivity in the range of 0.05 W / m.k-0.06 W / m.k, saves the energy consumption of buildings, and is applicable to all types of buildings. The concrete not only can be applied to external thermal insulation of external wall as well as interior thermal insulation of external wall, or external and interior thermal insulation of external wall, roof heat insulation and geothermal insulation layer. The concrete not only can replace traditional mixed plastering mortar but also can substitute on-site composite wall insulation construction of complex paste warming plate, due to its good heat insulation and energy saving effect. The invention has the advantages of simple construction operation, easy quality control and high construction efficiency, and is convenient for large-scale popularization and application.

Owner:李聪

Composite insulating material

The composite heat insulating material is fibrous thick paste produced with aluminum silicate fiber 10-18 weight portions, pearlite 12-16 weight portions, asbestos fiber 8-12 weight portions, bentonite 10-15 weight portions, permeating agent 1-3 weight portions and proper amount of clear water. The present invention has the advantages of low heat conducting coefficient, high heat insulating performance, no crack, high sealing performance and less falling, and is especially suitable for use in pipeline, apparatus, furnace and kiln in complicated shape.

Owner:邱日平 +1

Efficient energy-saving kervit microbead insulated sand slurry

The invention is a high-efficiency, energy-saving, vitrified microball thermal insulation mortar thermal insulation system, comprising: cement, vitrified microballs, re-dispersible latex powder, composite fibers, methyl cellulose ether and air-entraining agent, where the composite fibers include tensile fiber, PP fiber and wood fiber. The invention has antiaging and fireproofing properties, not hollow swelling and cracking, and having high intensity and good binding property, and having heat conductivity coefficient of 0.05W / m.k-0.06W / m.k, saving energy consumption of buildings, applied to new buildings and existing buildings. As constructing, the invention is simple to operate, and the quality is easy to control, able to largely raise construction efficiency and convenient to large-scale spreading and application.

Owner:李珠

Construction method for bonding pearlite insulation board

InactiveCN108589950AGuaranteed stabilityImproved bonding reliabilityHeat proofingPolymer modifiedAdhesive

The invention discloses a construction method for bonding a pearlite insulation board. According to the characteristics of pearlite insulation board materials, a magnesium-based adhesive is prepared.Through polymer modification, magnesium-based inorganic adhesive crystals form an organic-inorganic interpenetrating network structure, and a certain bridging role is played, so that the bonding strength of the materials is increased. At the same time, emulsion solidifies into a film, the pores in perlite of the insulation board are blocked, hole walls are connected, the fit degree between the adhesive and the perlite insulation board is enhanced, and the stability of the insulation board after bonding is ensured. At the same time, an integral and tight operation mode is adopted aiming at slabjoints and door and window holes, gaps between slabs are reduced, and the phenomenon of swelling and slab warping is avoided. Compared with traditional insulation mortar, the smoothness is higher, and the construction is convenient. The application of the adhesive increases the bonding fastness and reliability of the insulation board, prevents the shedding and prolongs the service life, and thengood insulation and energy saving effects are achieved.

Owner:马鞍山市金韩防水保温工程股份有限公司

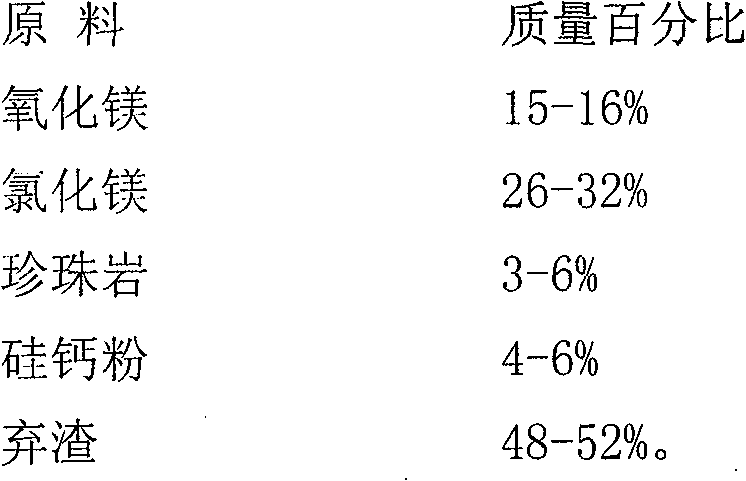

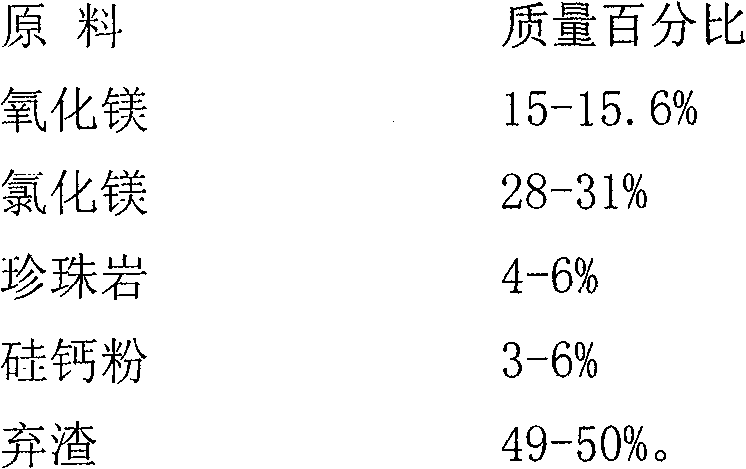

Baking-free building block produced by utilizing nonmetallic waste slag and preparation method

The invention discloses a baking-free building block produced by utilizing nonmetallic waste slag and a preparation method. The baking-free building block is produced by magnesium oxide, magnesium chloride, perlite, silicon-calcium powder and waste slag according to a certain proportion. The preparation method comprises the following steps: 1, waste slag with abundant resources is selected under specific conditions, and materials are prepared according to a state requirement; 2, integrated feeding is carried out according to the mixture ratio of a formulation; 3, the mixture is uniformly stirred by a stirrer; 4, compression moulding forming is carried out by a special brick making machine; 5, prehardening conservation is carried out by a supporting plate; 6, the supporting plate is removed, and natural curing conservation is carried out by stacking; 7, classification warehousing is carried out after detection; and 8, the product is sold and used. The invention has reasonable formulation, simple operation and low cost, and the building block is energy-saving and environmental-friendly and does not need sintering and steam pressure maintenance.

Owner:王福生

Lightweight composite building energy-saving thermal insulation material

ActiveCN104773985BEasy to processReduce processing costsCeramicwareThermal insulationSuperplasticizer

A fire-proof non-combustible composite heat-insulation material with good energy saving effect, good water proofing effect and better mechanical spraying construction effect is prepared by mixing and stirring ordinary Portland 42.5R cement with different weights, fiber brucite, magnesium silicate long fiber, wood fiber, light weight magnesium oxide, polypropylene fiber, an organic active waterproof agent, ultra light nano expansion beads, urea formaldehyde particles or polystyrene particles, adhesives, a foaming agent, a procoagulant regulating agent, silicon micropowder and a poly carboxylic acid superplasticizer, and has the appearance of dry and powdery fiber. The material can be directly spared on external walls, interior walls, roofs and staircase rooms of buildings according to a certain thickness after addition of water for mixing and stirring, has the characteristics of being thermal-insulation, energy-saving, non-combustible, environmentally-friendly, waterproof, and simple and quick in construction, is applicable to heat insulation of a variety of houses and buildings, and can achieve high efficiency and energy saving effect.

Owner:营口天瑞新型建筑材料有限公司

Light high-strength rock ballast powder concrete energy-saving building block and manufacturing method thereof

Owner:丰泽区新安江新型建筑材料厂 +2

A kind of anti-crack thermal insulation mortar and preparation method thereof

The invention discloses anti-cracking thermal insulation mortar. The anti-cracking thermal insulation mortar is prepared from the following raw materials in parts by weight: 4-6 parts of aluminum sulfate, 2-4 parts of alum, 14-17 parts of wood charcoal, 230-250 parts of perlite, 20-25 parts of pitchstone, 34-38 parts of obsidian, 30-40 parts of coal slime, 30-50 parts of coal ash, 3-4 parts of urea, 3-5 parts of monopotassium phosphate, 180-200 parts of cement, 40-50 parts of sepiolite fabric, 100-120 parts of sand, a proper amount of water and 20-25 parts of auxiliaries. The mortar has the advantages of good adhesiveness, water-retaining property and thermal-insulation and heat-insulation performance, outstanding thermal-insulation energy-saving effects, and further has excellent anti-cracking performance by use of the sepiolite fabric, is suitable for masonry and plastering construction of a wall material. By use of the auxiliaries adopted by the anti-cracking thermal insulation mortar, the compressive strength and the breaking strength of the mortar are improved, and the peaceability, the flow sagging resistance, the thixotropy and the settling resistance of the mortar are improved.

Owner:长治市中宝建材股份有限公司

Crack-resistant warm mortar and preparing method thereof

InactiveCN106517899AGood adhesionGood heat preservation and energy saving effectSilica fumeAluminium salts

The invention provides a crack-resistant warm mortar and a preparing method thereof. The mortar is prepared from 5-8 parts of aluminum sulfate, 2-5 parts of alum, 15-19 parts of charcoal, 240-260 parts of perlite, 21-26 parts of pitchstone, 35-39 parts of obsidian, 31-42 parts of coal slime, 30-52 parts of coal ash, 4-6 parts of urea, 3-6 parts of monopotassium phosphate, 180-210 parts of cement, 41-53 parts of sepiolite fabric, 110-130 parts of grid, 41-52 parts of silica fume, 2-5 parts of dodecyl trimethyl ammonium chloride and 41-53 parts of bentonite. According to the crack-resistant warm mortar and the preparing method thereof, the mortar is good in adhesiveness, water-retaining property and heat preservation and insulation performance and remarkable in heat preservation and energy conservation effect; by the use of the sepiolite fabric, the mortar further has good crack-resistant performance, and is applicable to masonry and plastering construction of wall body material; by using auxiliary, compression and fracture resistant strength of the mortar is improved, and peaceability, anti-sagging property, thixotropy and anti-subsidence performance are improved.

Owner:GUANGXI UNIV

Solar photovoltaic high heat insulating window

ActiveCN101881123BImprove power generation efficiencyImprove reliabilityDoor/window applicationsUnits with parallel planesMolecular sieveBuilding integration

Owner:沈阳金都铝业装饰工程有限公司

Thermal insulation concrete hollow block and preparation method thereof

InactiveCN100540502CLow thermal conductivityLower heat transfer coefficientSolid waste managementThermal insulationPolystyrene particle

The invention relates to a thermal- insulating concrete hollow building-block, comprising cement, stone fragment powder, polystyrene particle, adhesion promoter and water. The weight proportions of said raw material are follows: cement: stone fragment powder: polystyrene particle: adhesion promoter: water= 1: 6- 9: 0.005- 0.05: 0.01- 0.02: 0.35- 0.5. The raw material is stirred, shaped, stewed for one hour, and produced to hollow building-block. The proper amount of polystyrene particle in the block makes the thermal conductivity coefficient of block concrete be reduced to 0.5 (W / m. K), the thermal conductivity coefficient of block-work partition be reduced to 1.8 W / (m2. K), the average thermal resistance of wall be reduced to 0.30 m2.K / W, and the thermal inert index be maintained at about 6.0.

Owner:丰泽区新安江新型建筑材料厂 +2

Broken bridge heat insulation and energy saving decorative integrated board

Owner:SHANGQIU POLYTECHNIC +6

A kind of high temperature resistant heat insulation material using industrial tailings and its preparation method

ActiveCN104649647BLow thermal conductivityAvoid crackingSolid waste managementSodium BentoniteThermal insulation

The invention discloses a high-temperature-resistant thermal-insulation material prepared with industrial tailings, which includes following components, by weight: 30-49% of the industrial tailings, 5-8% of perlite, 10-15% of asbestos wool, 10-15% of bentonite, 15-22% of a solidifying system, 1-5% of a penetrant, and 10-20% of water. The thermal-insulation material is low in thermal conductivity coefficient, is not liable to crack and fall off, and is good in sealing performance. The invention also discloses a preparation method of the high-temperature-resistant thermal-insulation material with the industrial tailings, which comprises steps of: weighing the raw materials, mixing the raw materials and sealing and storing the mixed raw materials. The preparation method is simple and convenient to carry out, is low in cost and is suitable for industrial production.

Owner:GEM CO LTD

Broken bridge heat insulation energy saving decoration integrated board

Owner:SHANGQIU POLYTECHNIC +6

Geopolymer-based foamed concrete for filling lightweight steel keel composite walls based on straw and solid waste

The invention discloses geopolymer-based foam concrete based on straw and solid waste for light steel keel composite wall filling. The geopolymer-based foam concrete comprises, by weight, 96.2-112.1 parts of solid waste powder, 11.4-28.4 parts of alkali activator, 1.1-10.2 parts of cementitious material enhancer, 0-142.0 parts of ceramsite, 1.0-10.0 parts of surface modified straw, 3.8-9.0 parts of iron powder expansion agent, 3.2-6.0 parts of admixture and 35.8-78.6 parts of water, and 0.25-1.84 L of foam is added into the raw materials per kg or more. The geopolymer-based foam concrete is prepared by using the crop straw and the solid waste as the raw materials, the concrete is high in fluidity retention rate and great in stability, and phenomena of stratification, segregation, bleedingand collapse cannot occur. The straw is uniformly distributed, and the geopolymer-based foam concrete is good in filling performance, low in thermal conductivity, great in thermal insulation performance and especially suitable for light steel keel composite wall filling.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

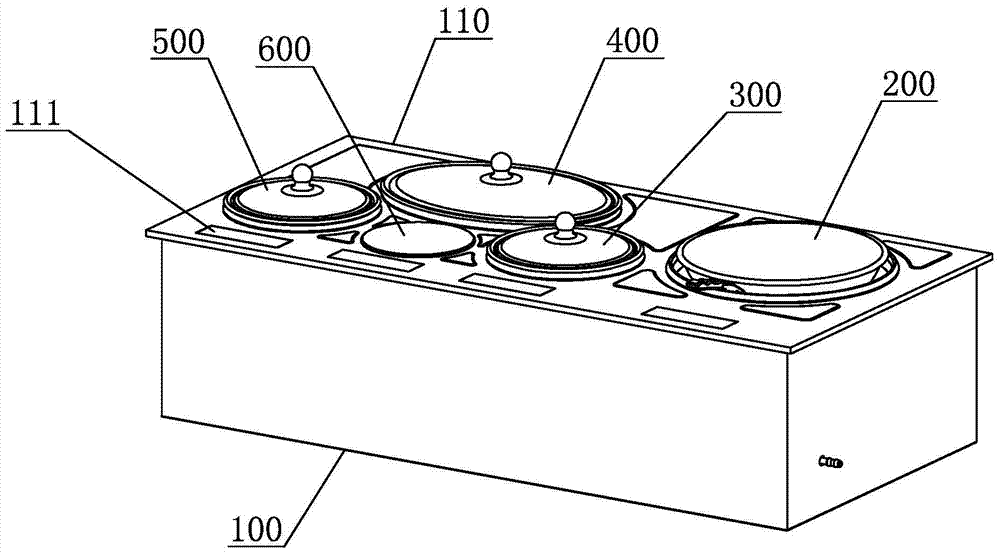

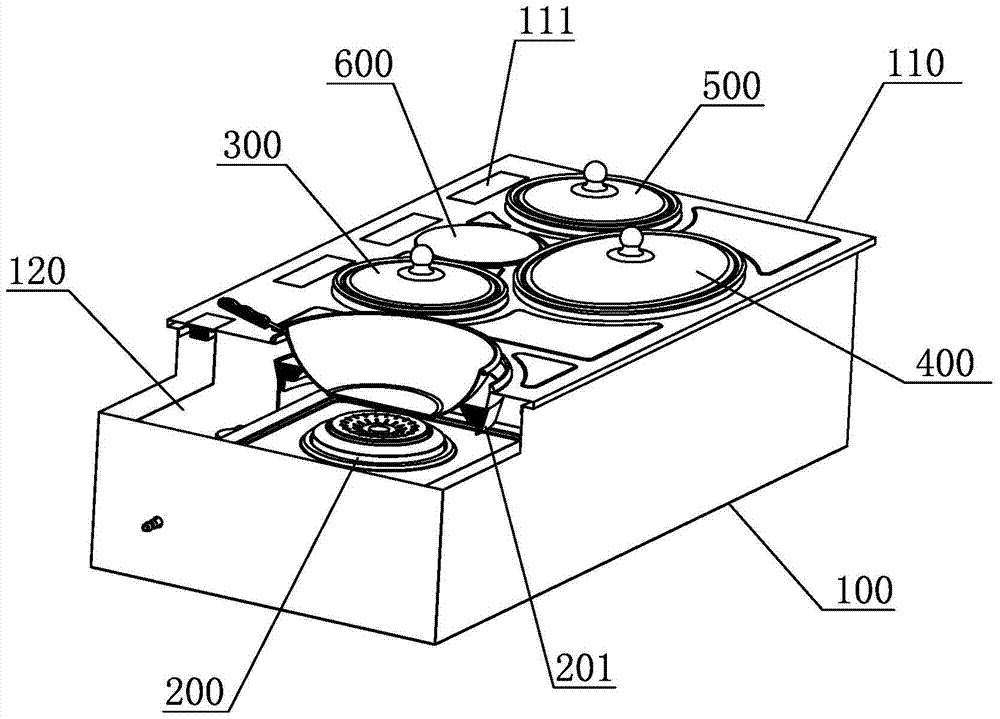

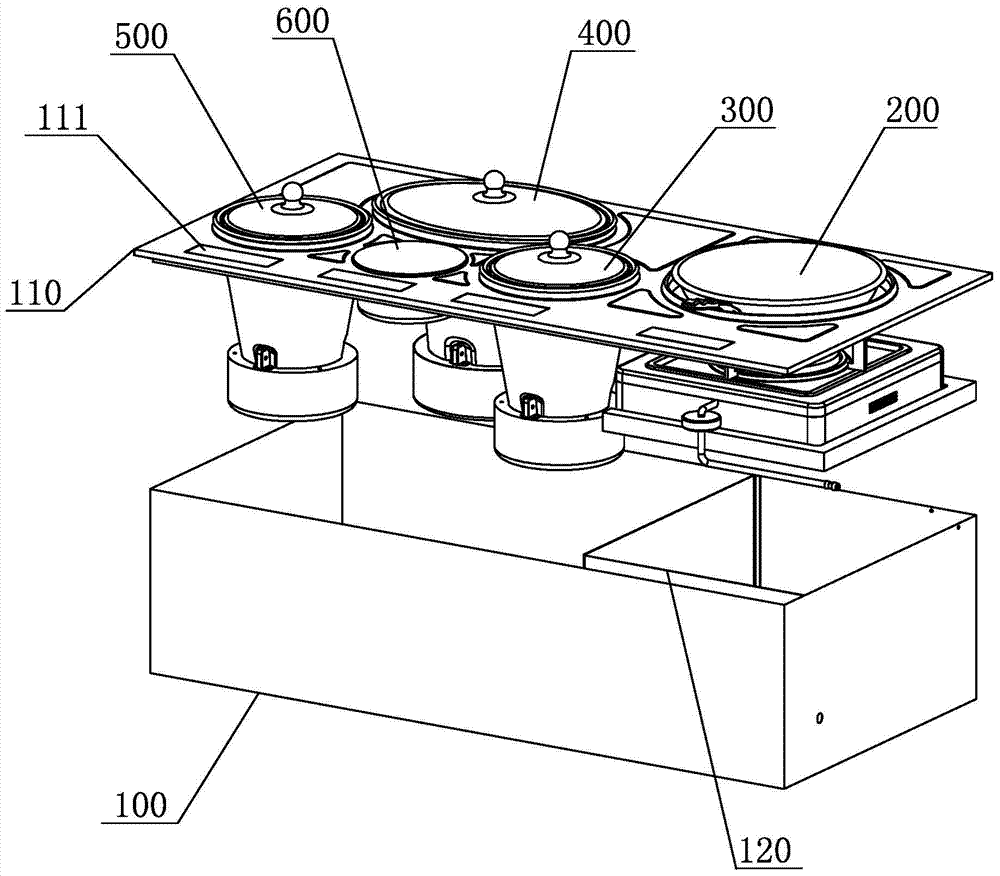

A multifunctional integrated built-in cooker

ActiveCN105212733BPrevent dumpingTake advantage ofCooking-vessel lids/coversMultiple-unit cooking vesselsEmbedded technologyElectricity

The invention discloses a multifunctional integrated embedded cooker, which comprises a metal outer cover, and the top of the metal outer cover is set as a cooking platform, and a plurality of sunken cooking pots are arranged on the cooking platform. The heating part of the cooking pot is located inside the metal cover; the metal cover is provided with a sensor for detecting the state of the cooking pot, and the cooking platform is provided with a display control connected to the cooking pot and the sensor panel. The multifunctional integrated embedded cooking utensil of the present invention integrates electric rice cooker, electric saucepan, electric steamer, gas stove, etc. by embedded technology, and has various cooking functions; the cooking utensil adopts submerged installation , At the same time, the space is fully utilized, and there will be no scalding accidents caused by dumping during cooking, and the safety factor is extremely high; at the same time, various sensors can be set in the metal outer cover, which is convenient for closed-loop feedback control and program control.

Owner:贵州爱卡电器科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com