Patents

Literature

307 results about "Pitchstone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pitchstone is a dull black glassy volcanic rock formed when felsic lava or magma cools quickly. It is similar to obsidian but is defined by the International Union of Geological Sciences as having a higher water content. It is a volcanic glass; however, unlike a glass, pitchstone has an irregular hackly fracture not a conchoidal fracture. That is due to its coarser (than obsidian) crystal structure. Pitchstone has a resinous lustre, or silky in some cases, and a variable composition. Its colour may be mottled, streaked, or uniform brown, red, green, gray, or black. It is an extrusive rock that is very resistant to erosion.

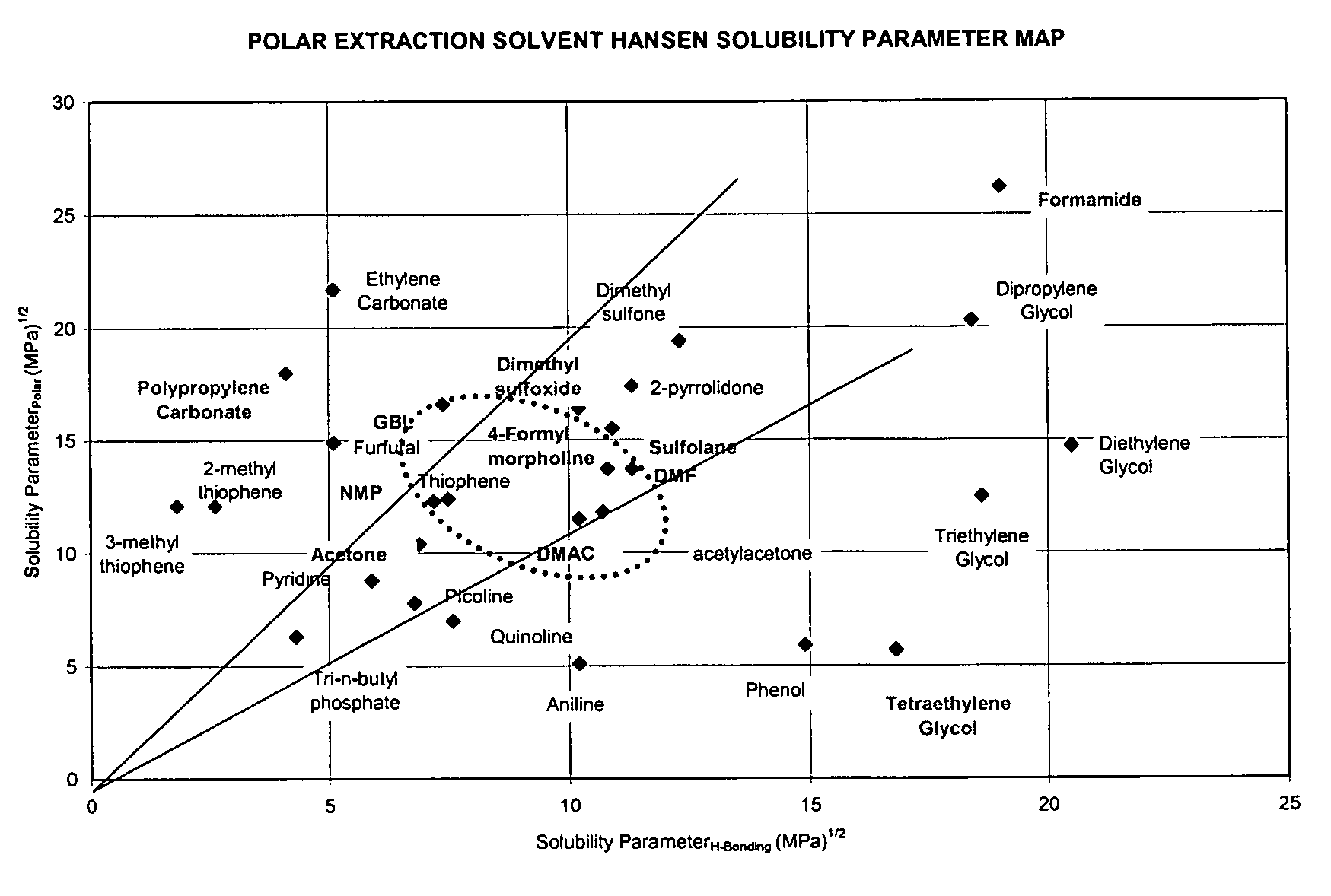

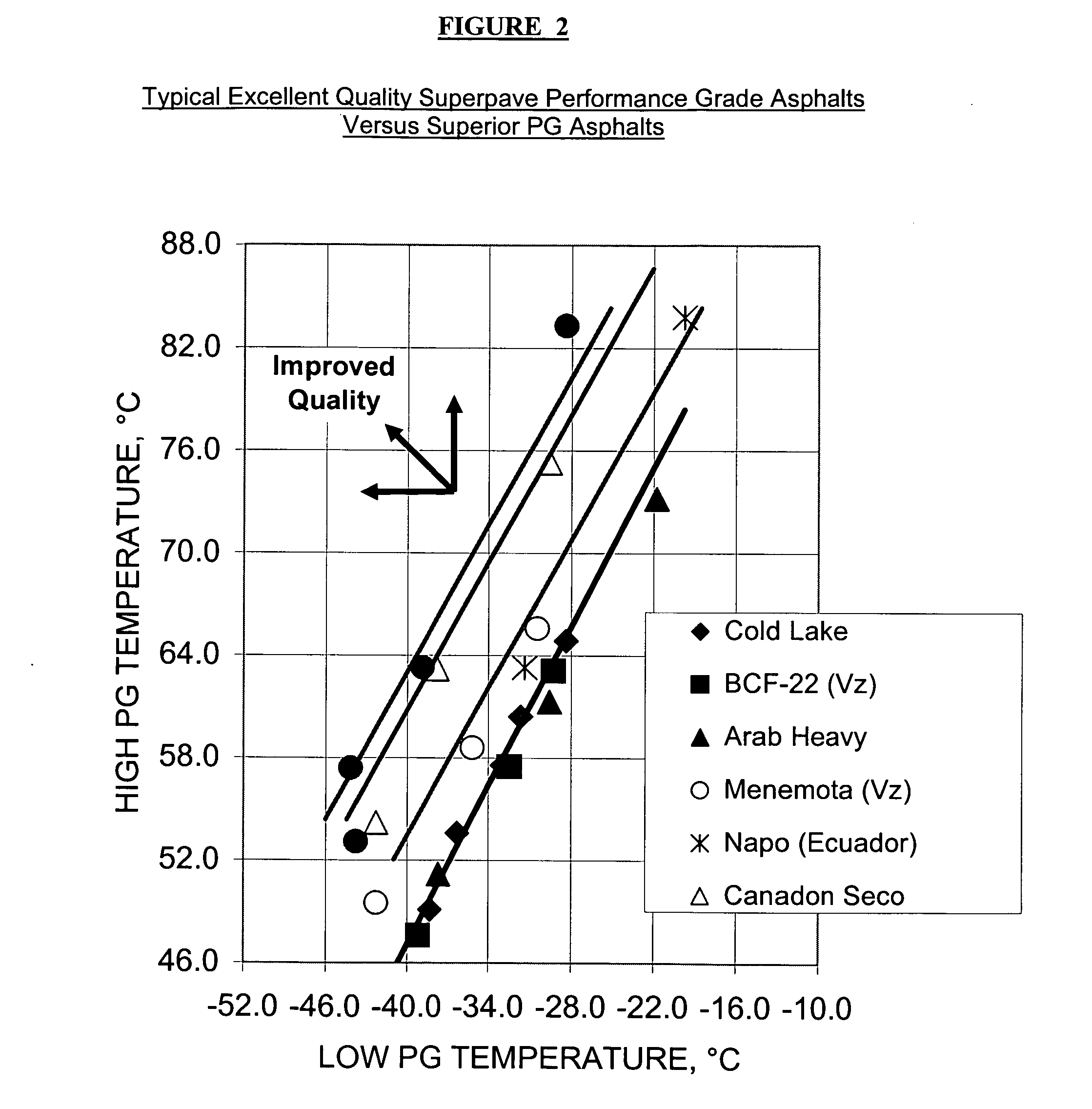

Dearomatized asphalt

InactiveUS20080006561A1Improving neat asphalt propertyHigh-temperature stiffnessWorking-up pitch/asphalt/bitumen by selective extractionSolid sorbent liquid separationSolventAsphalt

This invention relates to a dearomatized asphalt. More particularly, an asphalt is extracted with a aromatic extraction solvent to produce an asphalt-rich phase and a solvent rich phase. The asphalt rich phase is stripped of solvent to produce dearomatized asphalt that has superior properties for paving and roofing applications.

Owner:MORAN LYLE E +1

Rosin cation asphalt emulgent

InactiveCN1861721AReduce manufacturing costGood emulsificationTransportation and packagingMixingRosinAsphalt

The invention relates to a rosin cationic bitumen emulsifier. The rosin intermediate is reacted by the rosin and the polyethylene polyamine, then to condensate with the different types of the quaternary ammonium salt to get the emulsifier. The emulsifier can be used to produce the normal cationic emulsifying asphalt or the SBR modified emulsifying asphalt for the road priming oil and the felting oil. The character of the invention is to use the nature resin rosin as the material, so the cost has decreased and it meets the environment need. The emulsifying asphalt can reach the need of the standard of the China ministry of communications and the America ASTMD2397.

Owner:DALIAN UNIV OF TECH

Microwave-absorbing asphalt concrete pavement material composition

InactiveCN101736671ASimple preparation processIncreased heating rate by microwave heatingIn situ pavingsMicrowaveSnow melting

The invention discloses a road asphalt concrete pavement material composition which is applicable to microwave absorption. Magnetic powder is added for replacing all or part of limestone mineral powder in the traditional asphalt concrete raw material; magnetic sand or silicon carbide sand is adopted for replacing all or part of natural aggregate in the traditional asphalt concrete raw material, wherein the weight of the magnetic powder accounts for 3-15% of the total weight of the composition; the weight of the magnetic sand or the silicon carbide sand accounts for 2-50% of the total weight of the composition; the weight of asphalt accounts for 5-10% of the total weight of the composition; the weight of the limestone mineral powder accounts for 0-5% of the total weight of the composition; and the weight of the natural aggregate accounts for 20-90% of the total weight of the composition, and the microwave-absorbing asphalt concrete pavement material composition is finally obtained. Compared with the traditional asphalt concrete, the microwave-absorbing asphalt concrete can improve the microwave heating rate by a plurality of times to dozens of times. The composition can greatly improve the microwave de-icing and snow-melting efficiency, and be extensively applied in a variety of asphalt concrete highway pavements, parking aprons of airports, factories, offices, schools, troops and other units for use.

Owner:CHANGAN UNIV

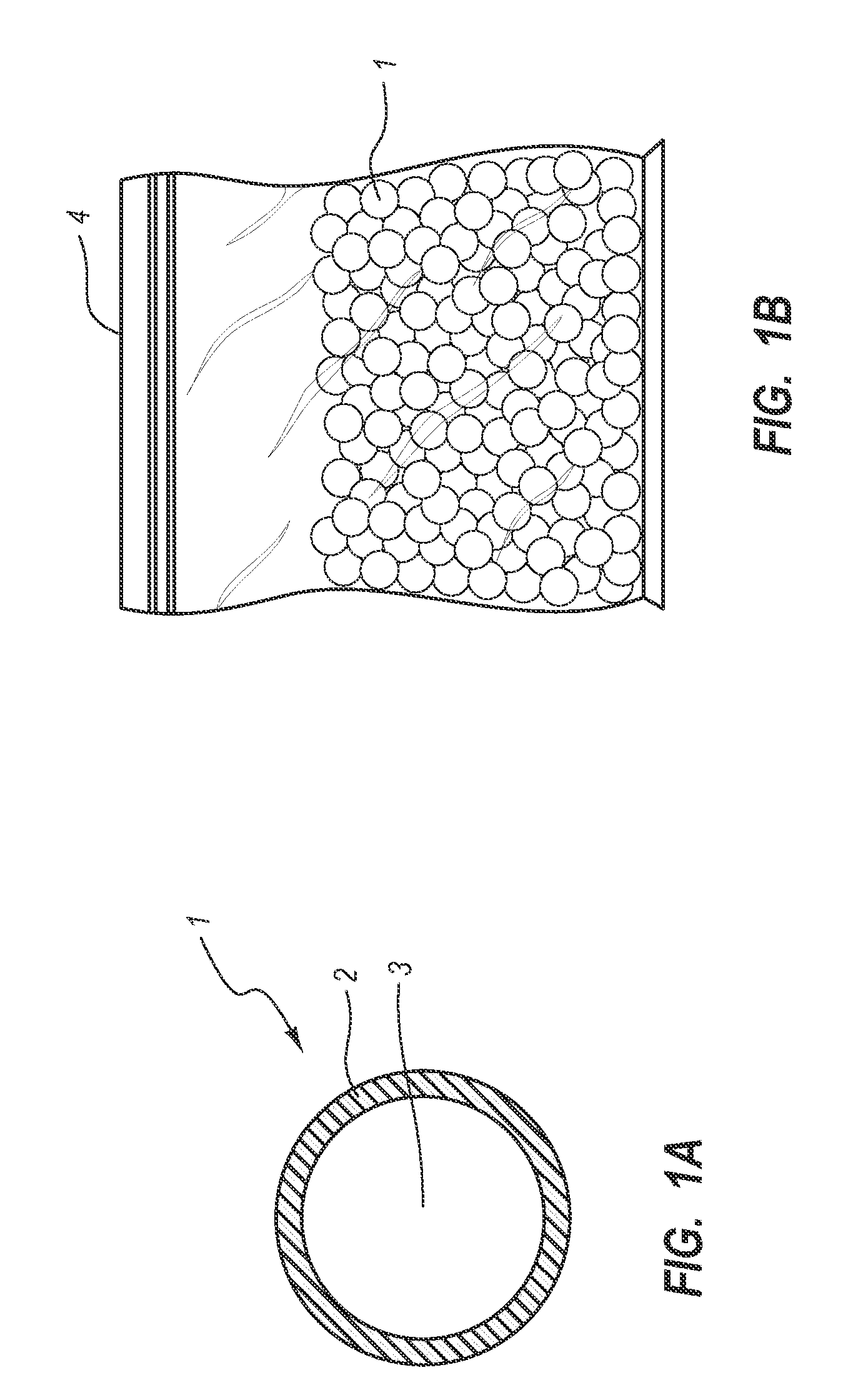

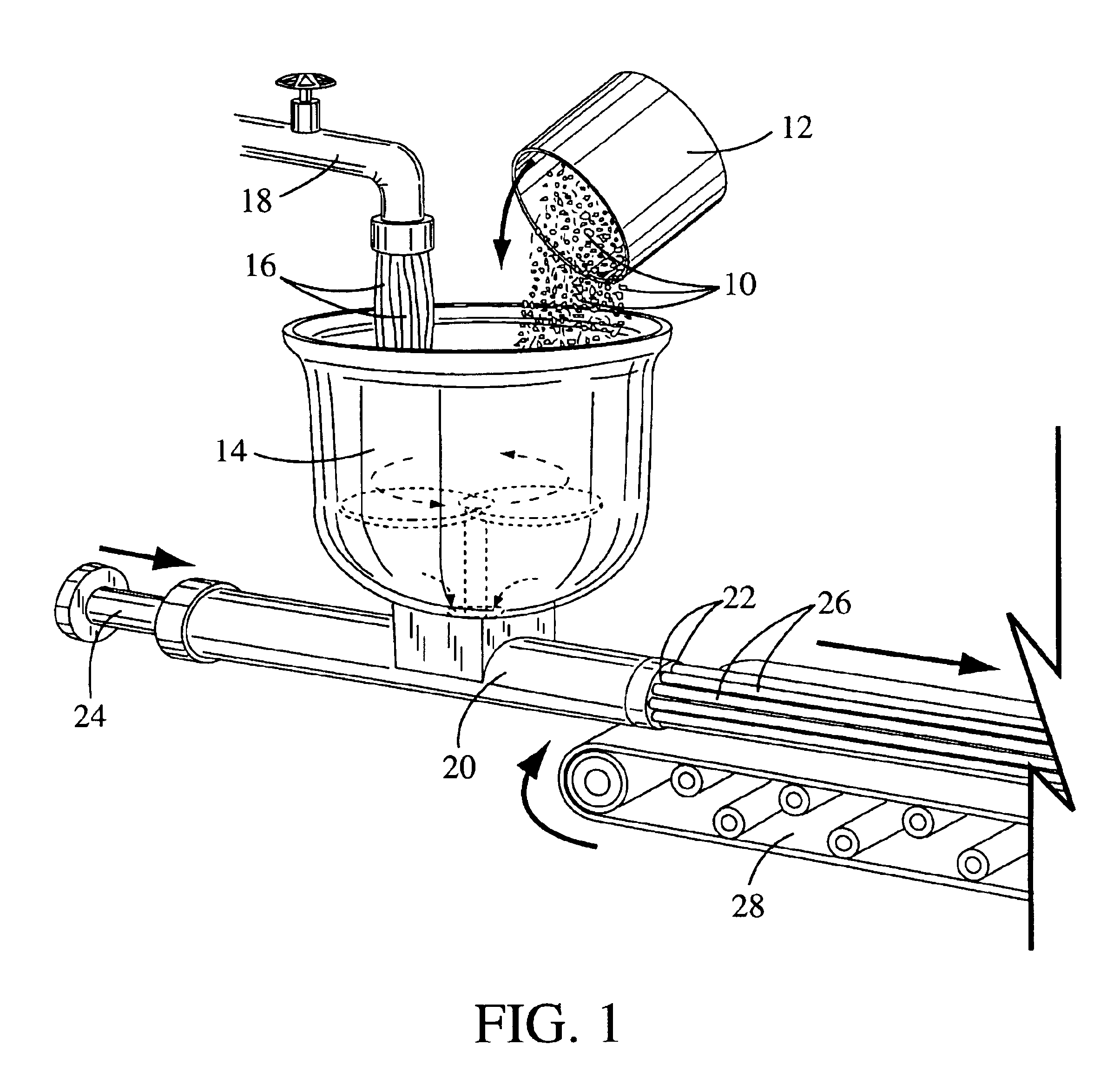

Rubberized asphalt pellets

A storage-stable rubberized asphalt paving pellet can include fines in the core. The core can be an asphalt-based binder at about 70% to about 95% by weight of the core. The asphalt-based binder can include: ground tire rubber from about 15% to about 30% by weight of the asphalt-based binder, and pavement grade asphalt from about 85% to about 70% by weight of the asphalt based binder. The core can include fines at about 30% to about 1% by weight of the core. The shell coating the core can provide the pellet with a maximum dimension of about 1 / 16 inch to about 2 inches. The shell can include a water-resistant polymer or wax, or a coating of fines. In one aspect, the fines are lime fines or ground asphalt pavement fines. Optionally, the fines can be mineral or rock fines as described herein.

Owner:BILLIAN I P

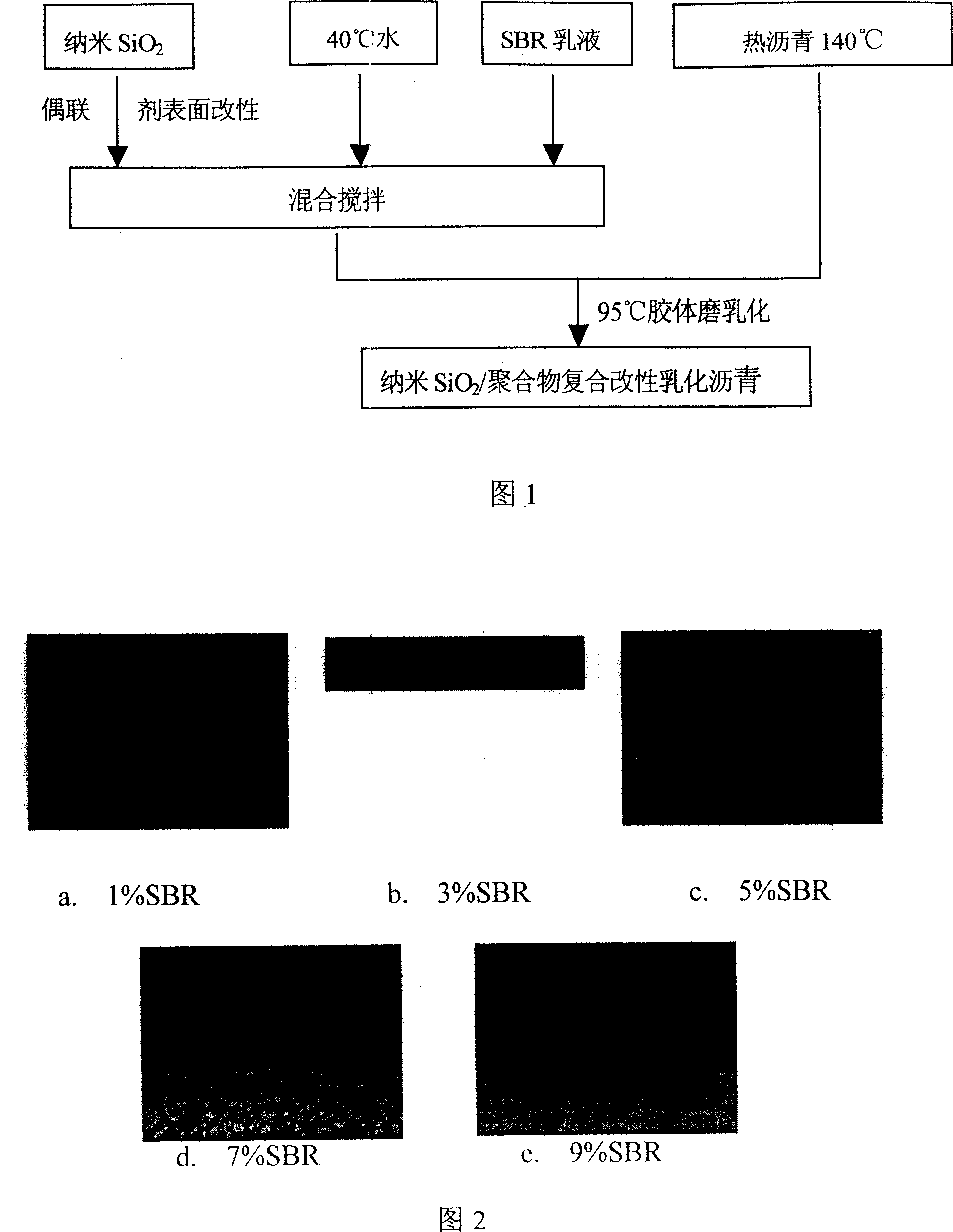

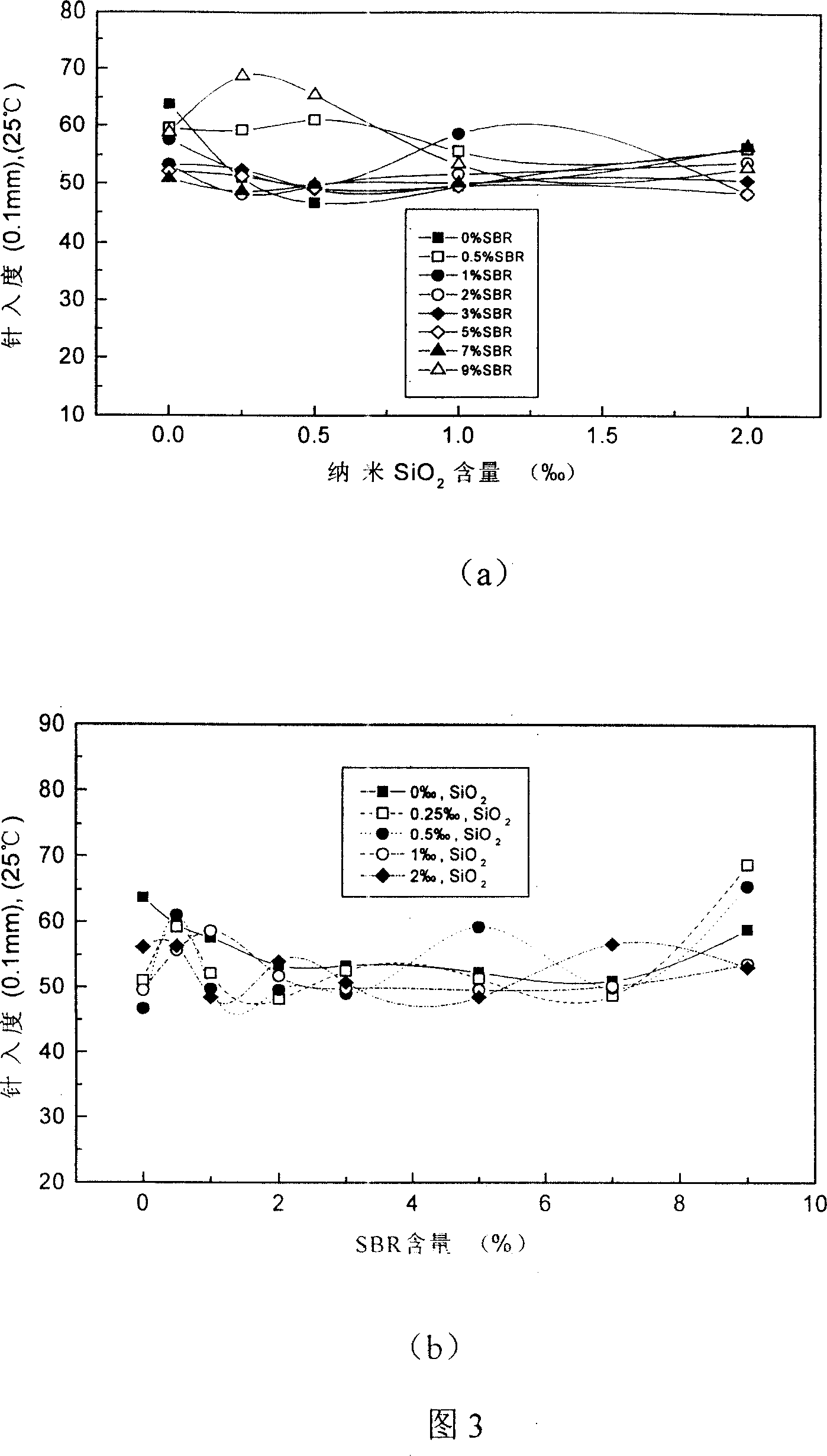

Inorganic nano particle and polymer composite modified emulsified asphalt

InactiveCN101143967AGood resistance to UV agingImprove heat aging performanceBuilding insulationsPolymer scienceButadiene-styrene rubber

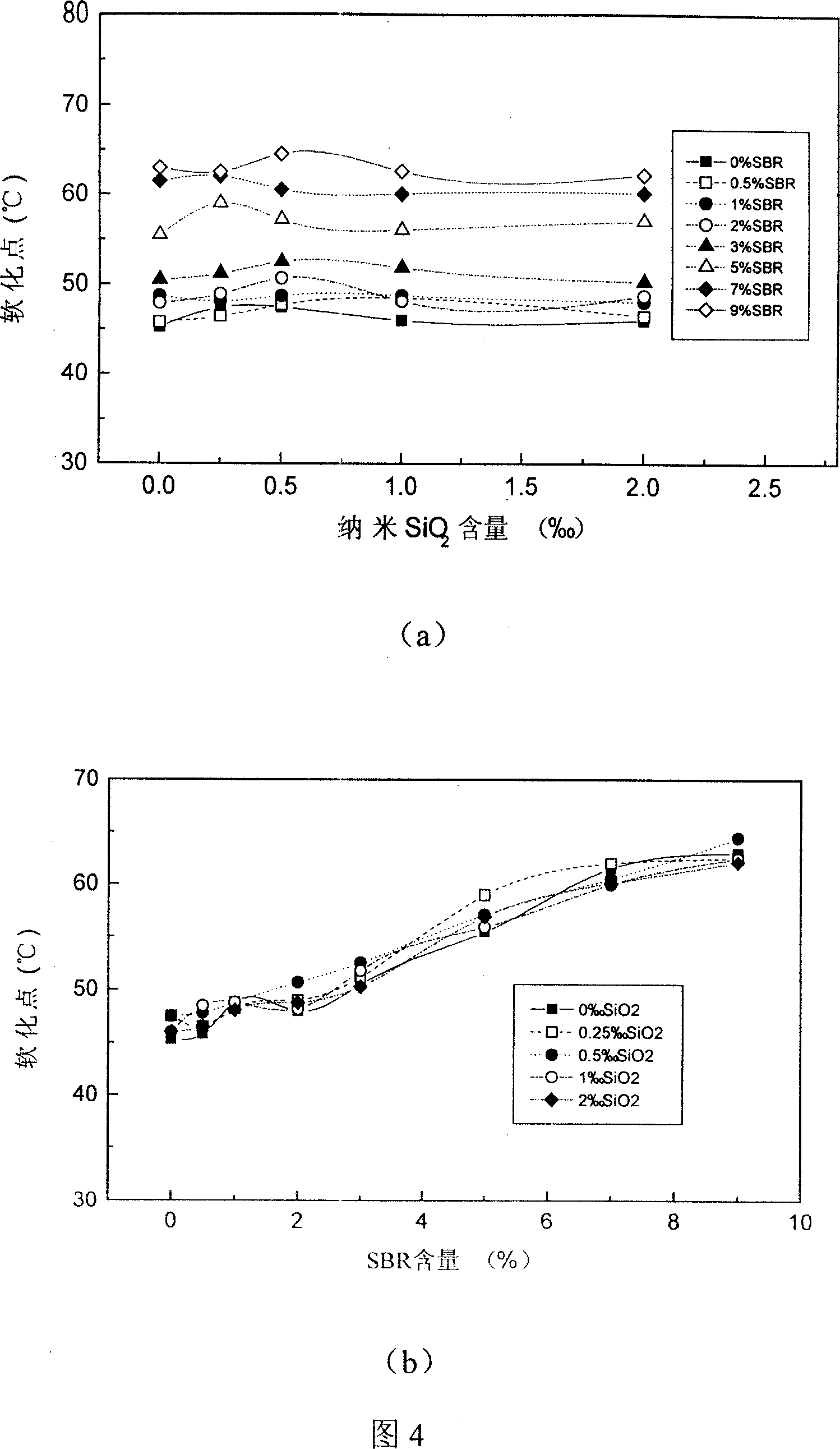

A modified emulsion asphalt compounded by inorganic nano-particles and polymer contains 200-700 parts by weight of asphalt, 2-80 parts by weight of modified inorganic nano-particles, 5-50 parts by weight of styrene-butadiene rubber latex, and 170-793 parts by weight of water, wherein the modified inorganic nano-particles is prepared by mixing 95-98 parts by weight of inorganic nano-particles with 2-5 parts by weight of coupling agent, and each components are mixed, followed by normal emulsion treatment to get the emulsion asphalt. The invention utilizes unique surface effect, small size effect and macroscopic quantum tunneling effect etc. of the inorganic nano-particles to give the product comprehensive properties, such as good wear resistance, intensity sum, anti-aging property and fine waterproof effect etc. Using the invention can increase the road maintenance cycle and decrease the cost. Furthermore, the water-proof cost of construction industry is greatly decreased.

Owner:HUNAN UNIV

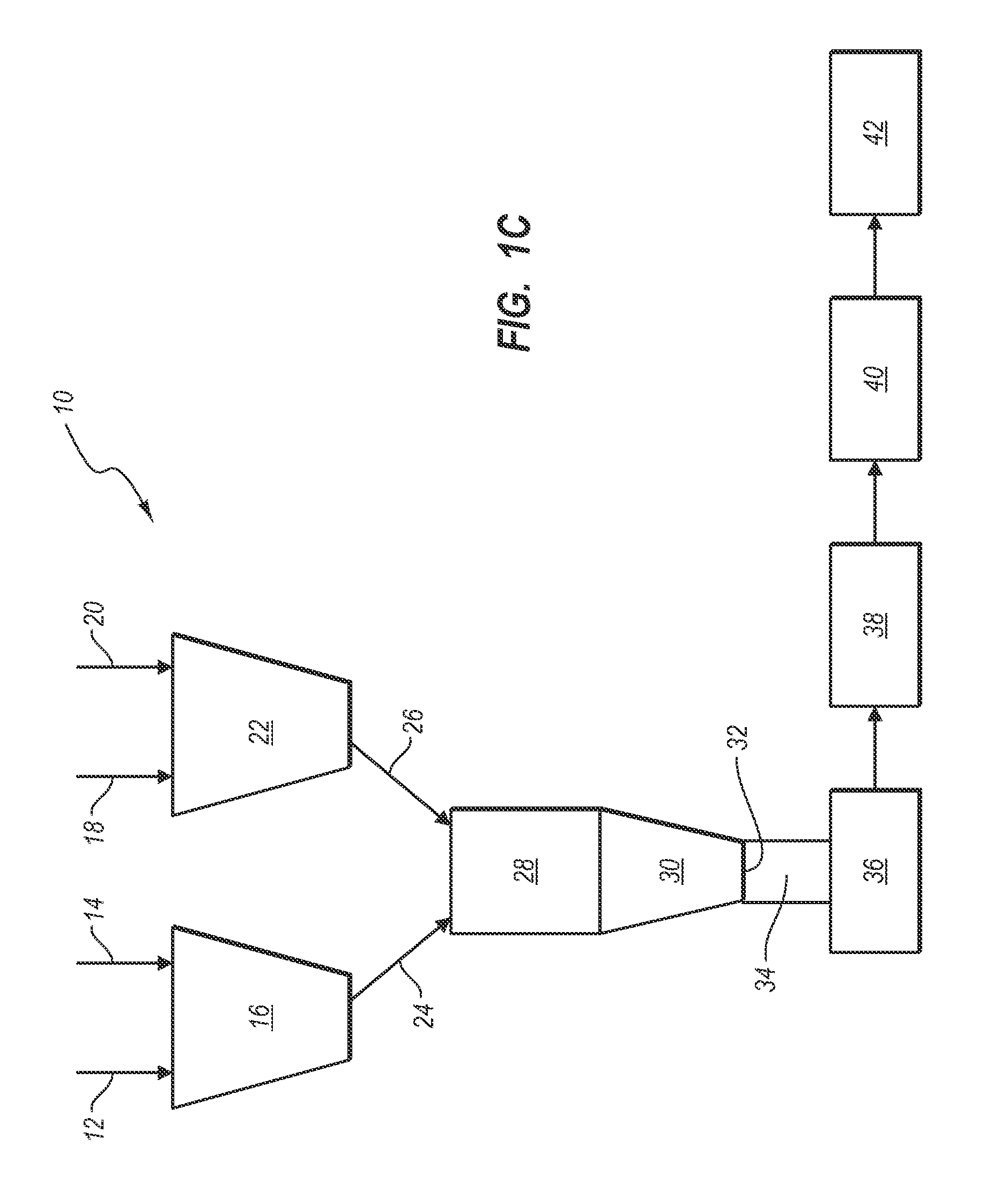

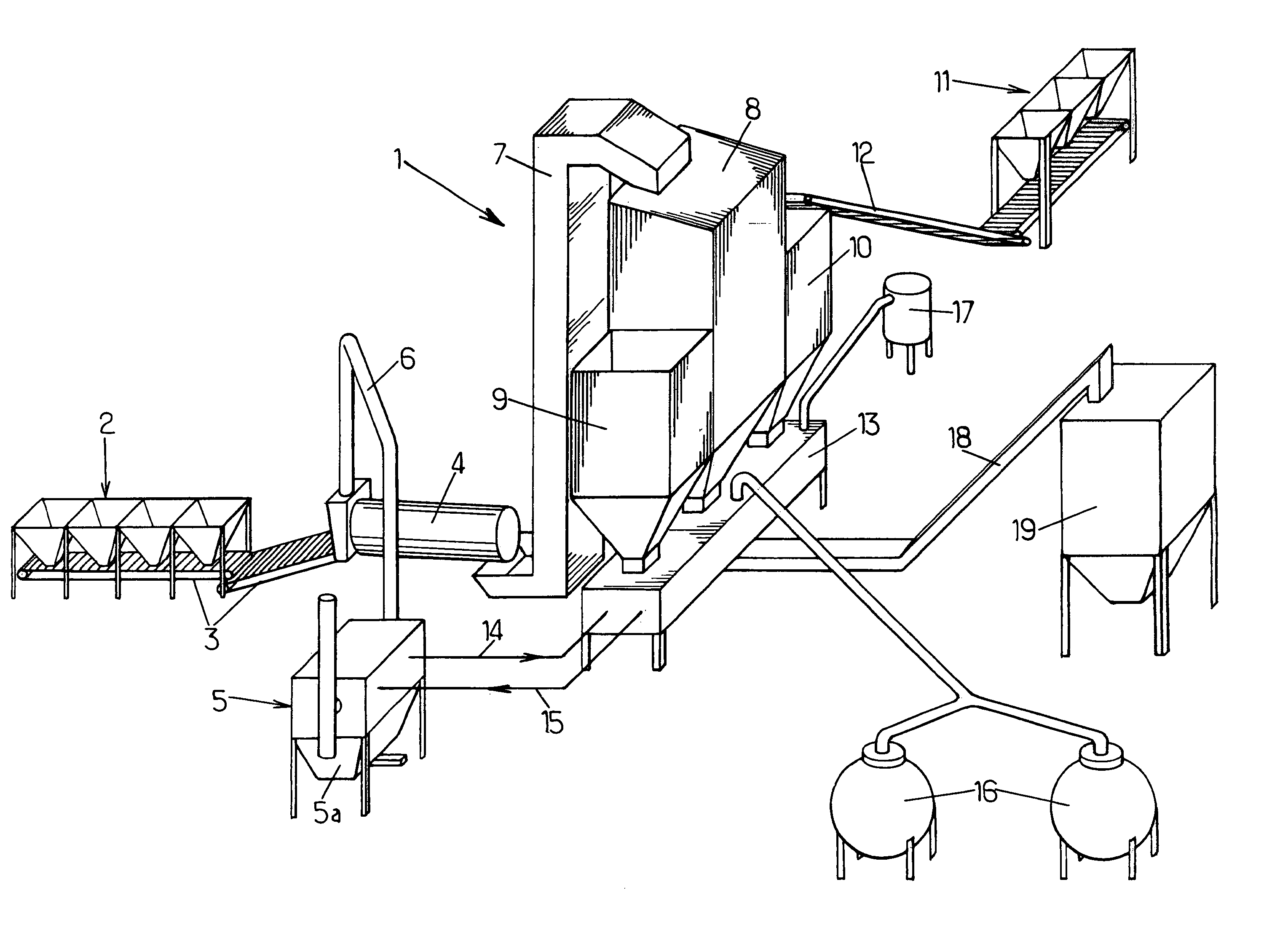

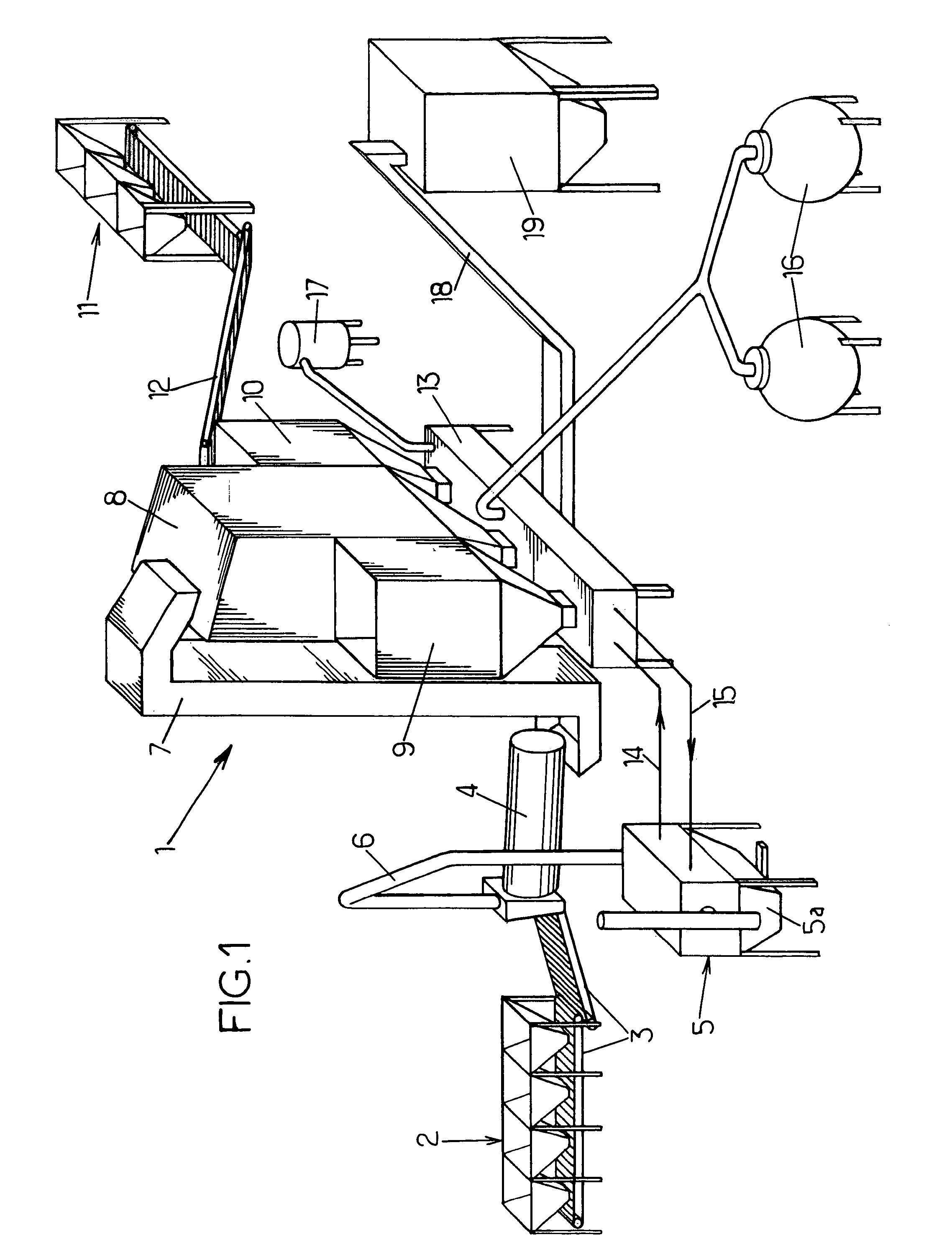

Method of manufacturing a bituminous coated aggregate mix

InactiveUS7114843B2Keep dryGenerate much dustIn situ pavingsMixing operation control apparatusConstruction aggregateMaterials science

A method of manufacturing a bituminous coated aggregate mix, said method comprising at least the following steps:(a) course aggregate are dried by heating;(b) an intermediate mix is formed by coating the course aggregate with hot bitumen; and(c) wet sand is mixed with the intermediate mix obtained in step (b).

Owner:LEA INT

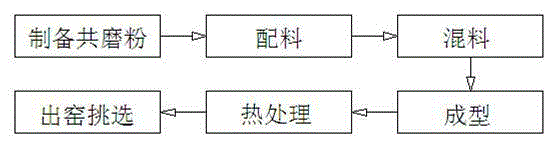

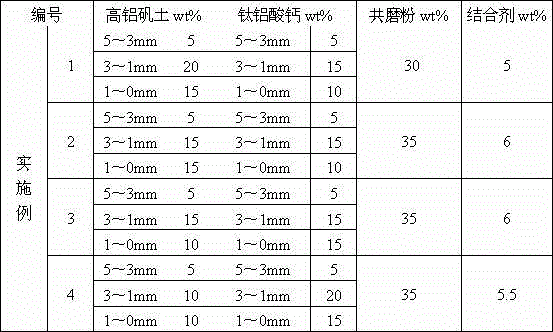

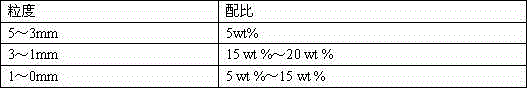

Titanium-containing calcium aluminate-high alumina bauxite modified refractory material, as well as preparation method and application thereof

ActiveCN104609872AHigh melting pointSmall coefficient of thermal expansionMelt-holding vesselsSteelmakingAluminate

The invention discloses a titanium-containing calcium aluminate-high alumina bauxite modified refractory material, as well as a preparation method and application thereof, belongs to the field of refractory materials, and adopts the technical scheme that the modified refractory material comprises 25 to 40 wt% of high alumina bauxite, 25 to 40 wt% of titanium-containing calcium aluminate, and 30 to 35 wt% of co-ground powder, and a phenolic resin binding agent which accounts for 3 to 6 wt% of the total mass of the raw materials is additionally added, wherein the co-ground powder is formed by uniformly mixing titanium-containing calcium aluminate fine powder, alpha-Al2O3 micro-powder, graphite powder, silicon carbide fine powder, graphite powder, silicon carbide fine powder, metal aluminum powder and high-temperature asphalt powder; titanium-containing calcium aluminate comprises the following ingredients by ratio: 76.21% of Al2O3, 10.6% of TiO2, 10.16% of CaO, 0.6% of Fe2O3, 1.82% of MgO, and 0.62% of SiO2. According to the invention, titanium-containing calcium aluminate being industrial slag of steelmaking is effectively recycled, so as to greatly reduce the production and manufacture cost; as titanium-containing calcium aluminate is a solid solution of calcium hexaluminate, calcium dialuminate, aluminum titanate, calcium titanate and rutile, the modified refractory material is favorable in thermal shock resistance and heat-insulating property.

Owner:MAANSHAN LIER KAIYUAN NEW MATERIAL

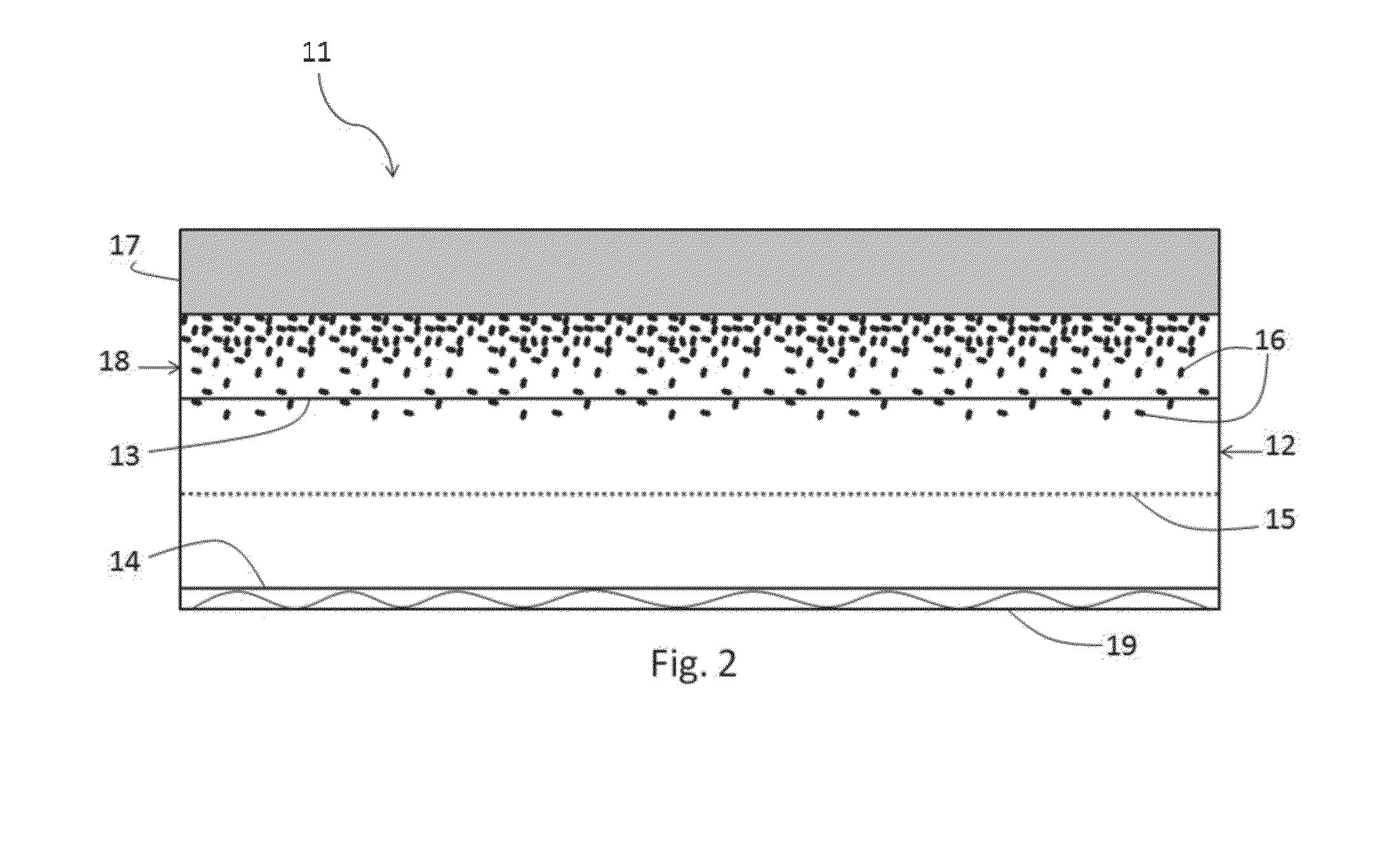

Asphaltic sheet materials including expandable graphite

ActiveUS20140013693A1Roof covering using slabs/sheetsRoof covering using flexible materialsGraphiteAsphalt

Owner:HOLCIM

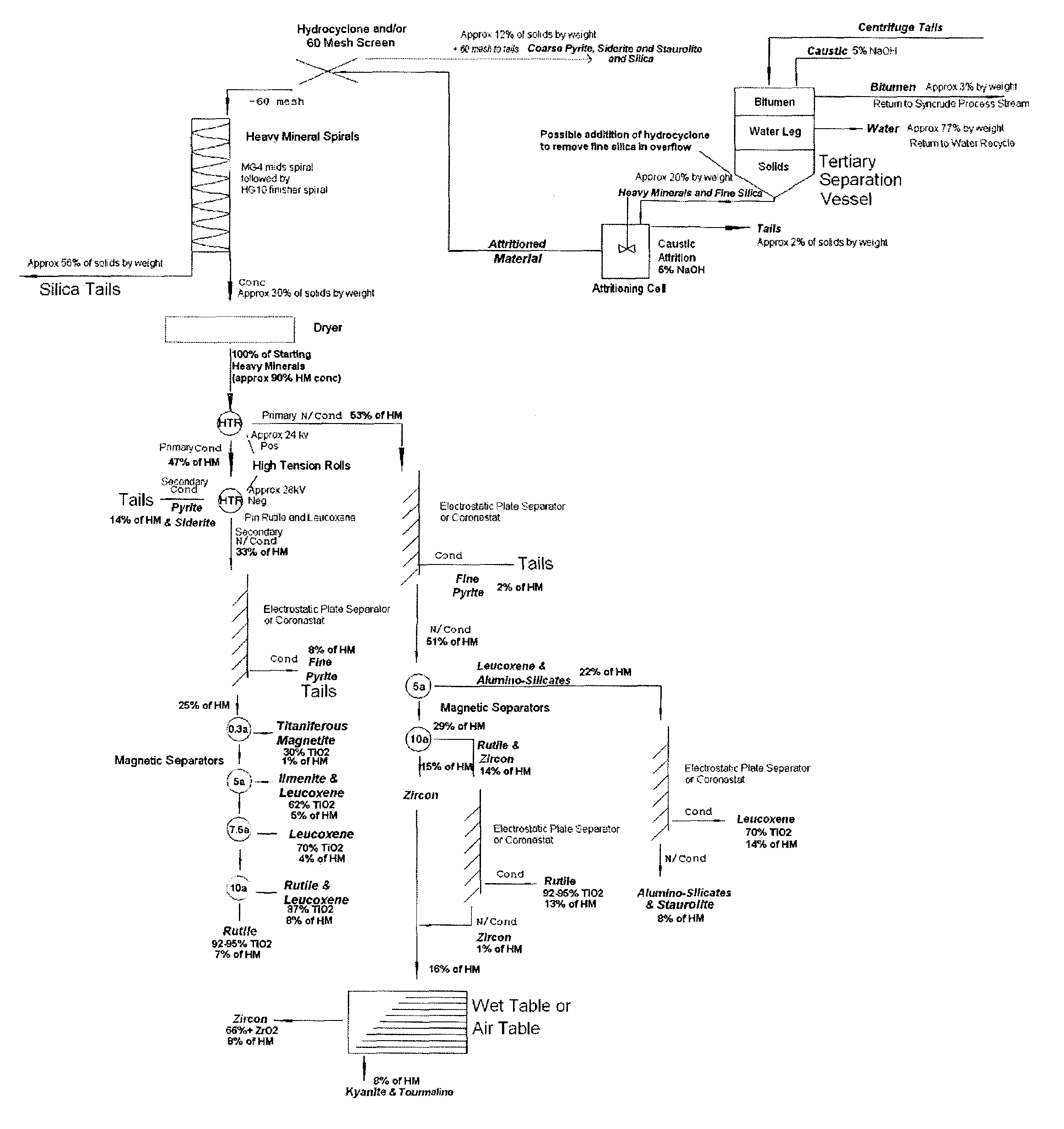

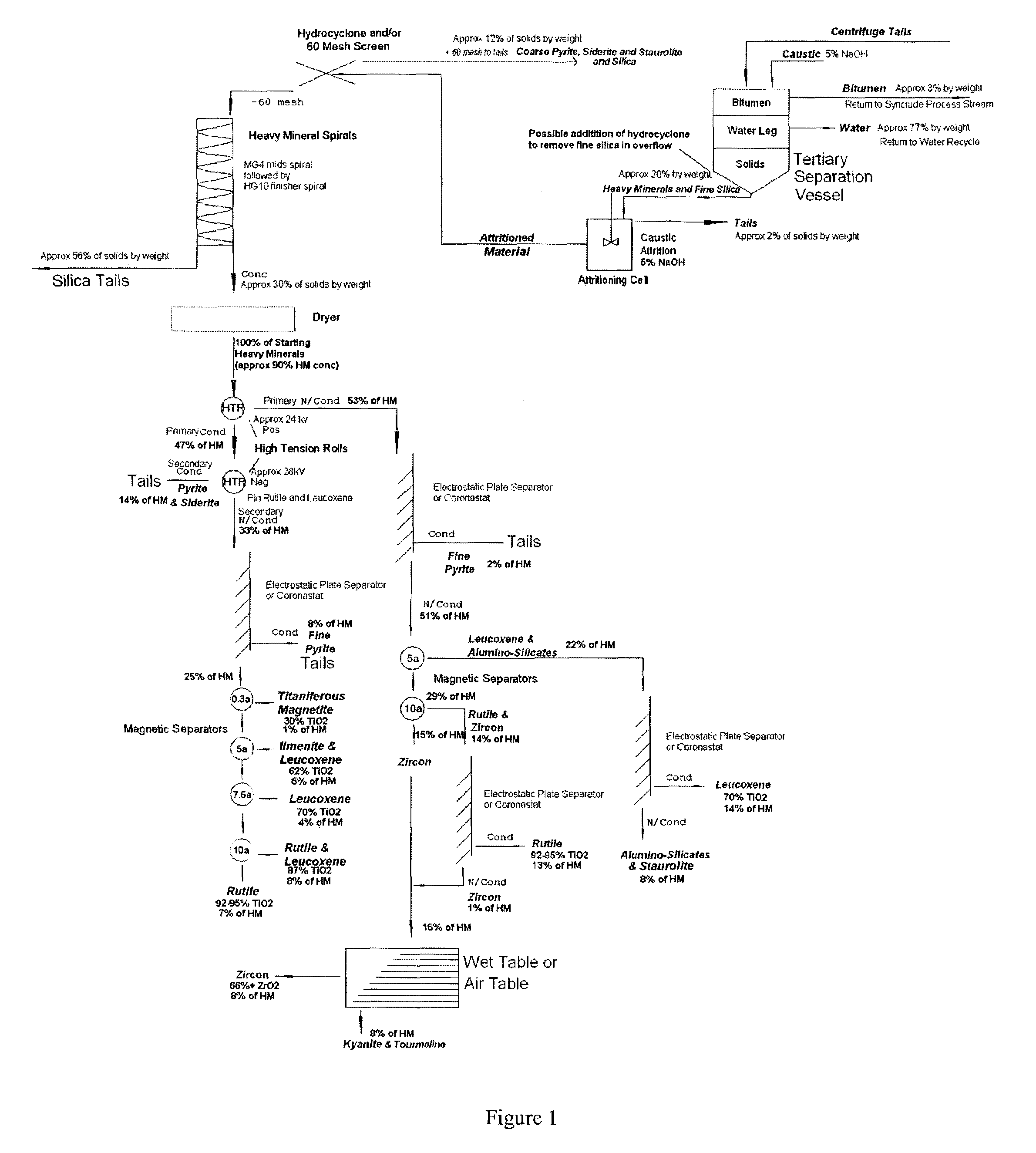

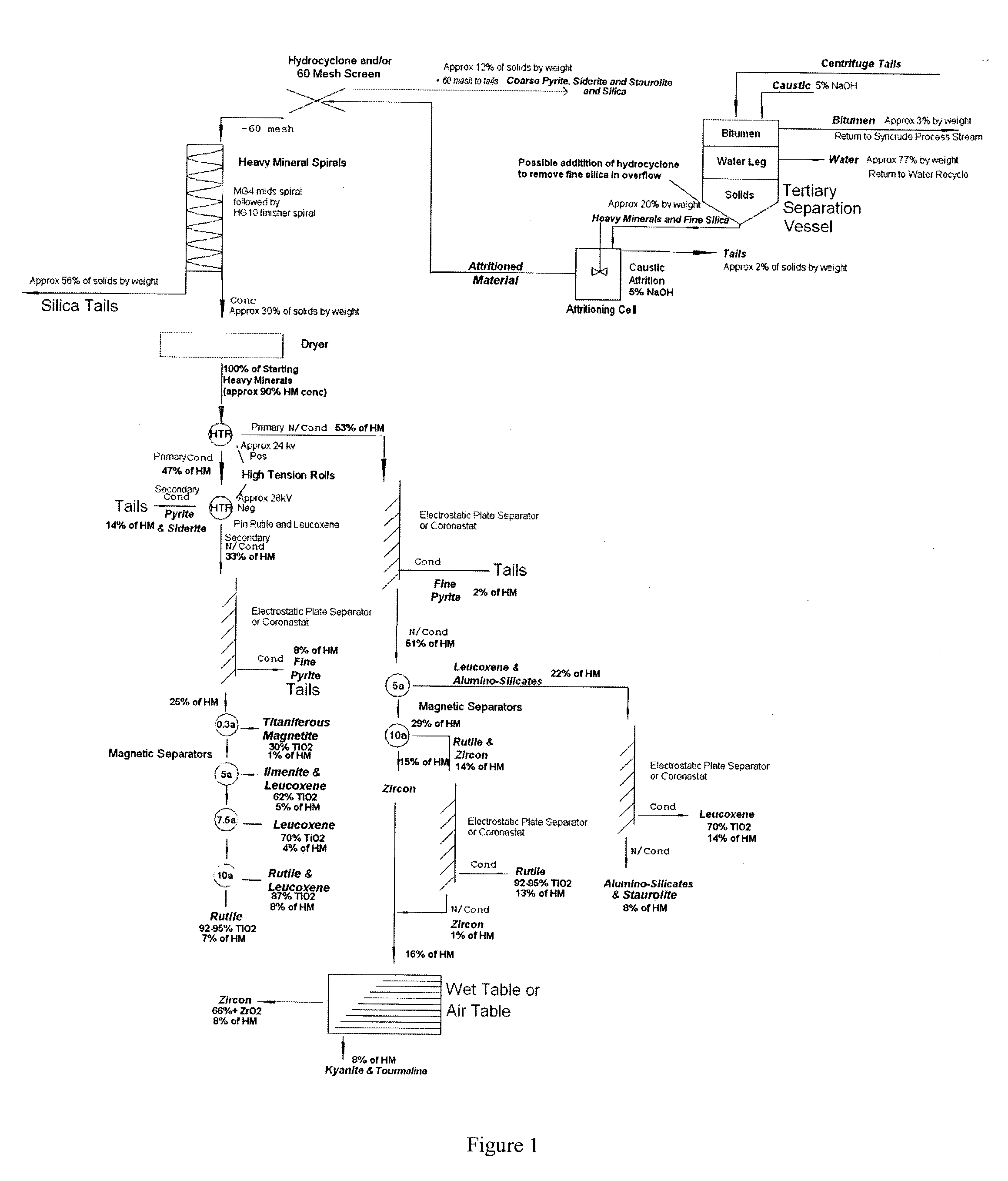

Recovery of heavy minerals from a tar sand

A process for recovering heavy minerals (e.g., titanium minerals such as TiO2) from a feedstock comprising tar sands or a tar sands-derived solids fraction. The feedstock comprises bitumen and heavy minerals. The process comprises the steps of: (i) contacting the solids fraction with water at a temperature of at least about 100° F. to cause production a bituminous phase and a heavy minerals phase; and (ii) separating the heavy minerals phase from the bituminous phase. Optionally, these steps may be preceded by one or more steps used to produce a tar-sands derived solids fraction from a tar sands feedstock.

Owner:TITANIUM CORP

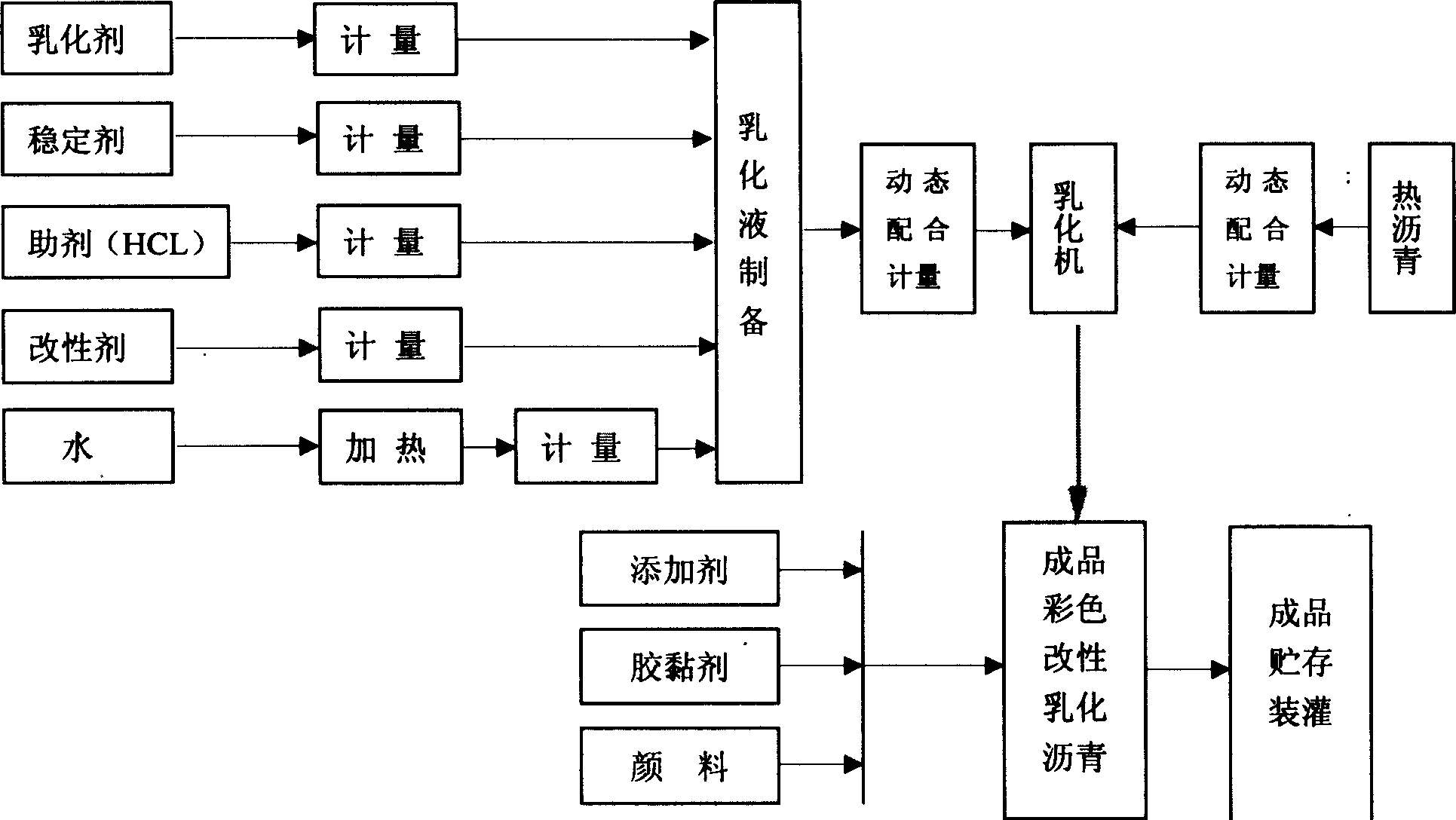

Coloured modified emulsified asphalt

InactiveCN1760280AAvoid pollutionImprove warning effectIn situ pavingsBuilding insulationsOrganic acidAsphalt

Owner:杨毅男

Coloured cementing material for paving road surface and its preparation method

InactiveCN1478955ASimple preparation processSave energyIn situ pavingsEpoxy resin adhesivesEpoxyDiluent

A color cementing material for paving is prepared from epoxy resin, diluent, toughening agent, inorganic pigment and solidifying agent through stirring. Its advantages are ordinary-temp application, high adhesion and resistance to high temp, low temp and abrasion, and long service life.

Owner:CHONGQING POFUN TRAFFIC TECH

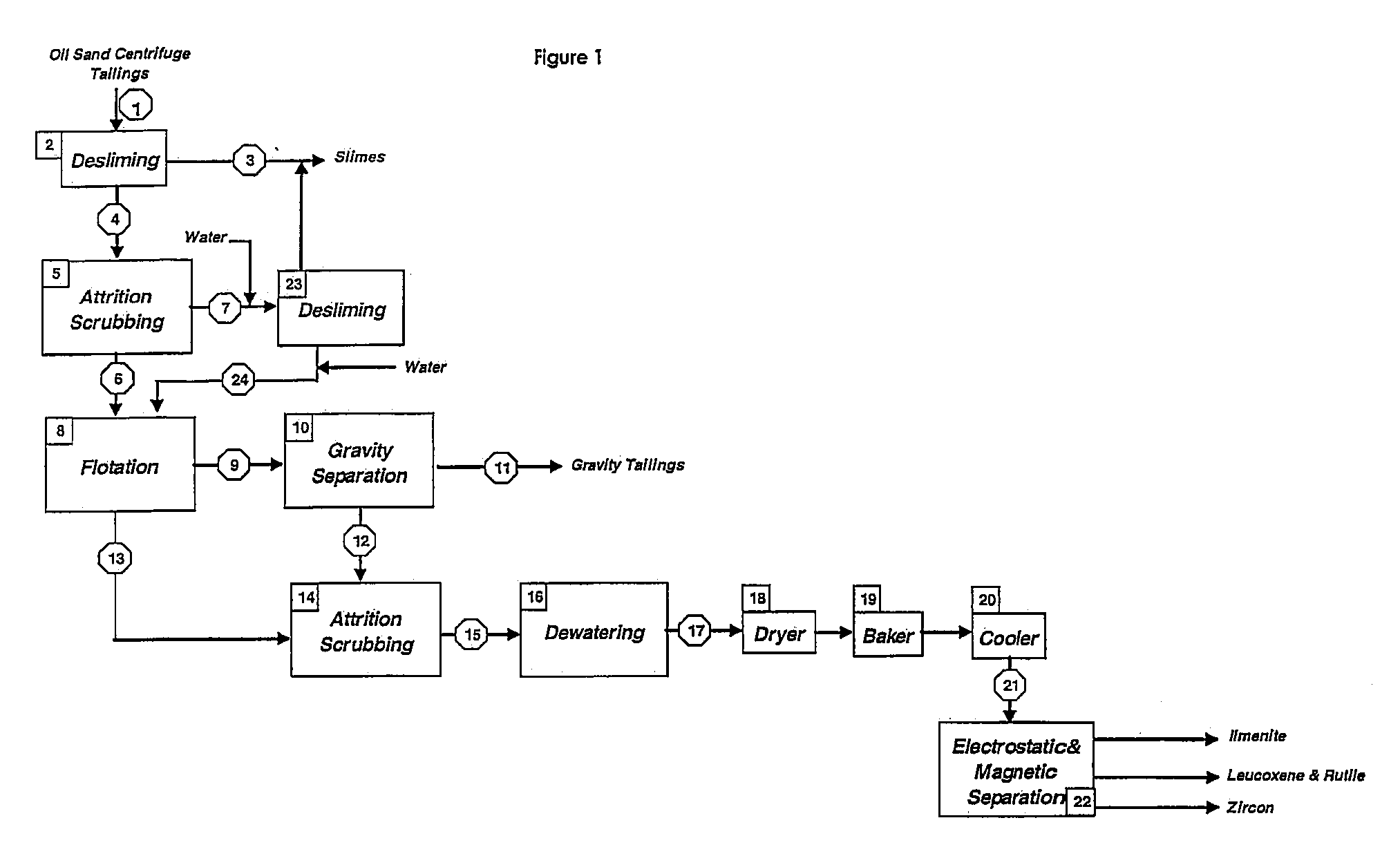

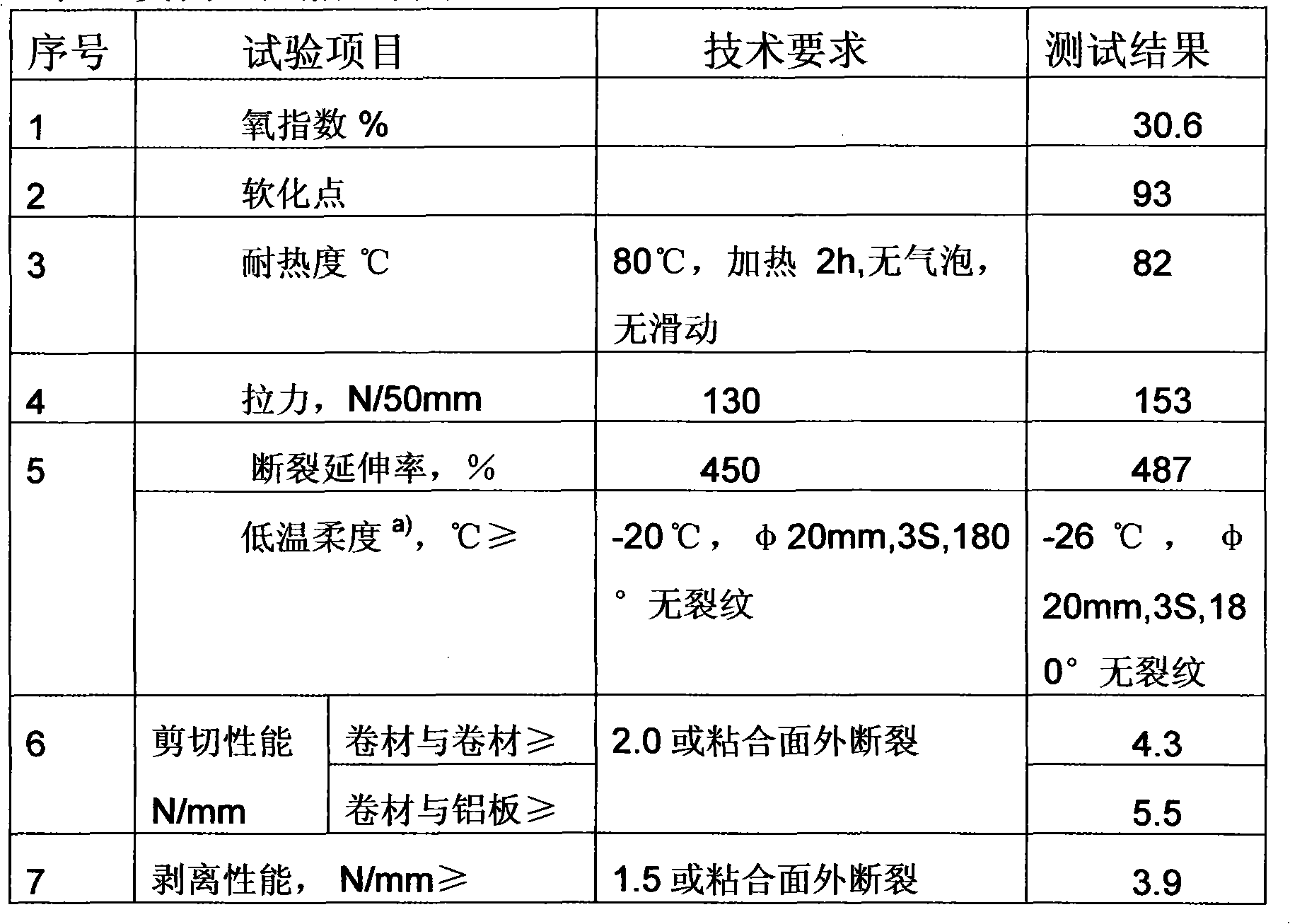

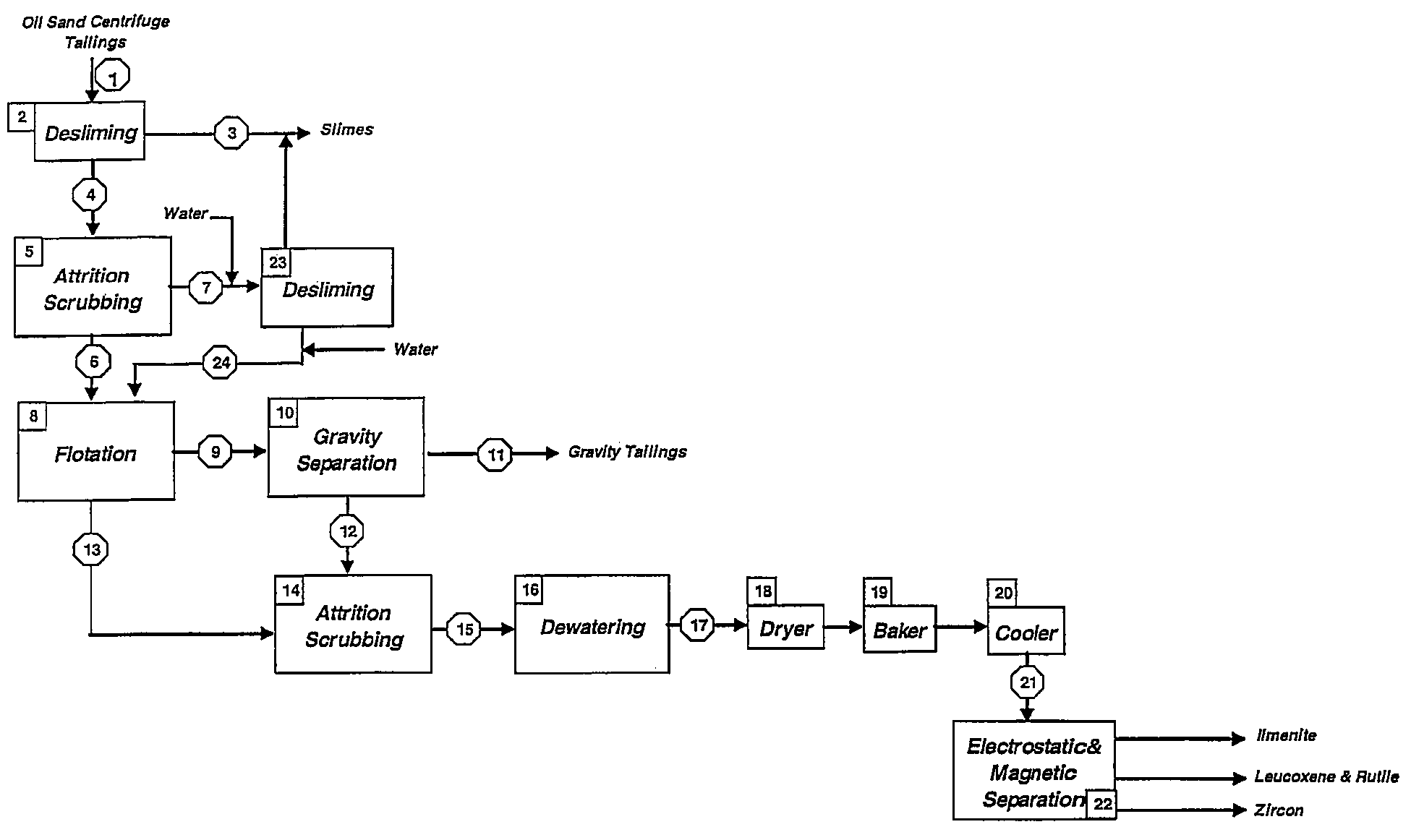

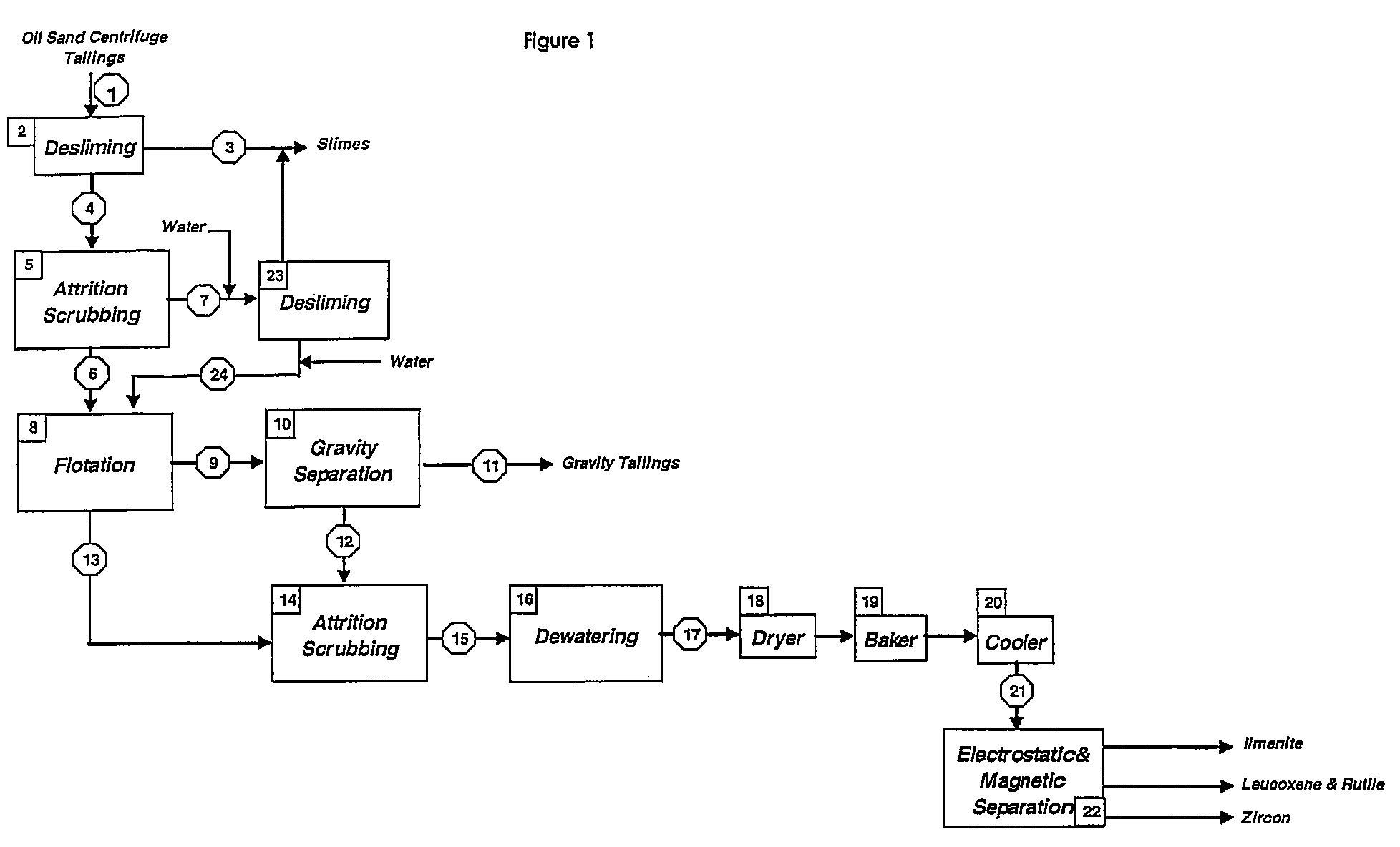

Process for recovering heavy minerals from oil sand tailings

ActiveUS20070272596A1Quality improvementExpansion quantityWater/sewage treatment by centrifugal separationCentrifugal force sediment separationSilicon dioxideMaceral

A process is provided for recovering heavy minerals from aqueous oil sand tailings, the oil sand tailings having heavy minerals, other coarse solids such as silica, fines, residual bitumen and water, including desliming the oil sand tailings in a desliming means by removing a portion of free fines and residual bitumen from the oil sand tailings; attritioning the oil sand tailings in an attritioner to remove adhered fines and residual bitumen from the heavy minerals and other coarse solids; and subjecting the deslimed and attritioned tailings to separation in a separation means to separate the heavy minerals from the other coarse solids present in the deslimed and attritioned tailings and produce a concentrated heavy minerals fraction.

Owner:TITANIUM CORP

Asphalt-mastic-broken stone mixture using steel slag as coarse aggregate and its application

An asphalt-mastic-broken stone mixture used for pavement of highway and street is prepared from steel slags, machined sand, powdered ore, lignofibres as stabilizer and asphalt as cementing agent through proportional mixing. Its advantages are high mechanical performance long service life and reducing environmental pollution.

Owner:北京国道通公路设计研究院股份有限公司

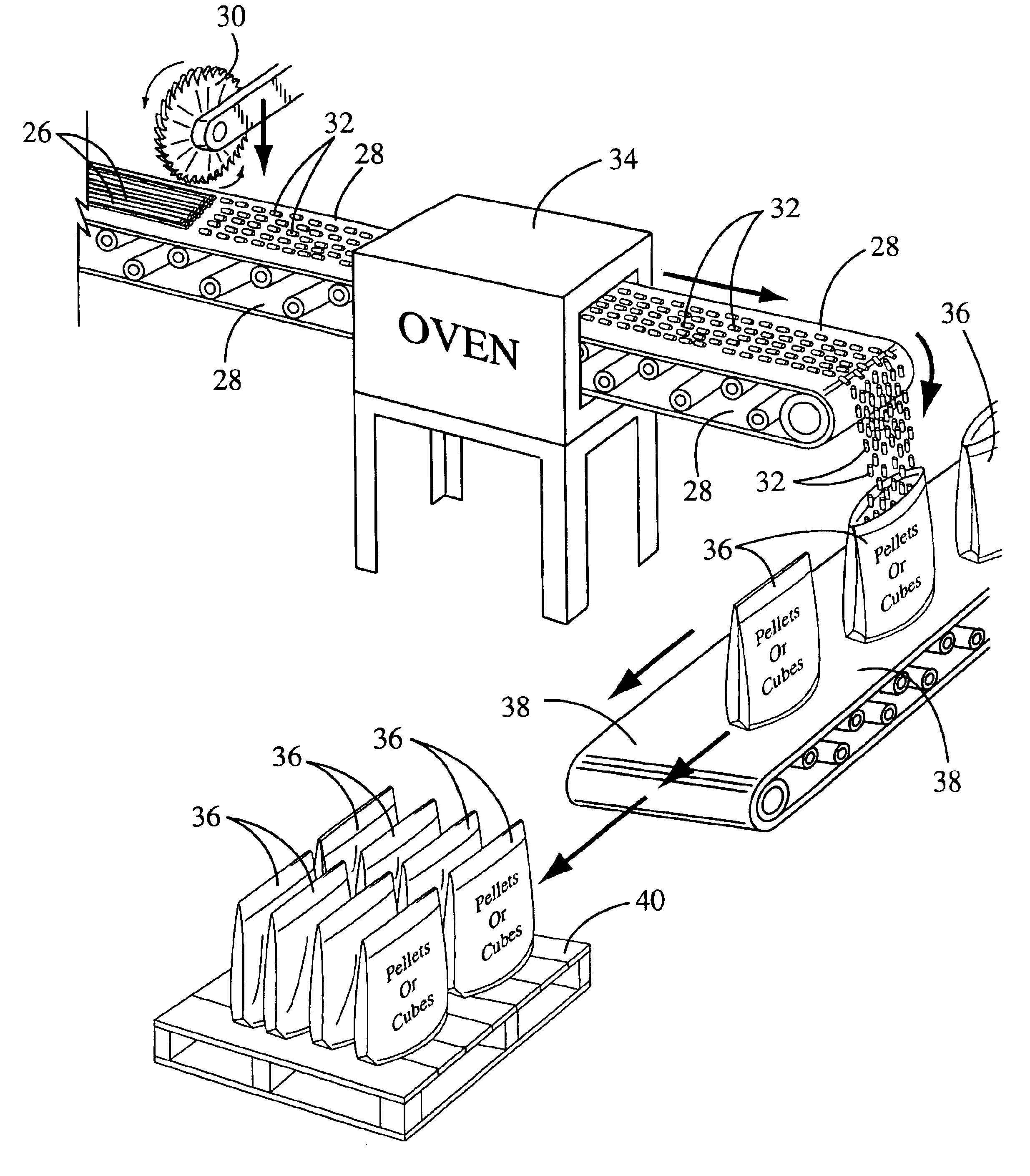

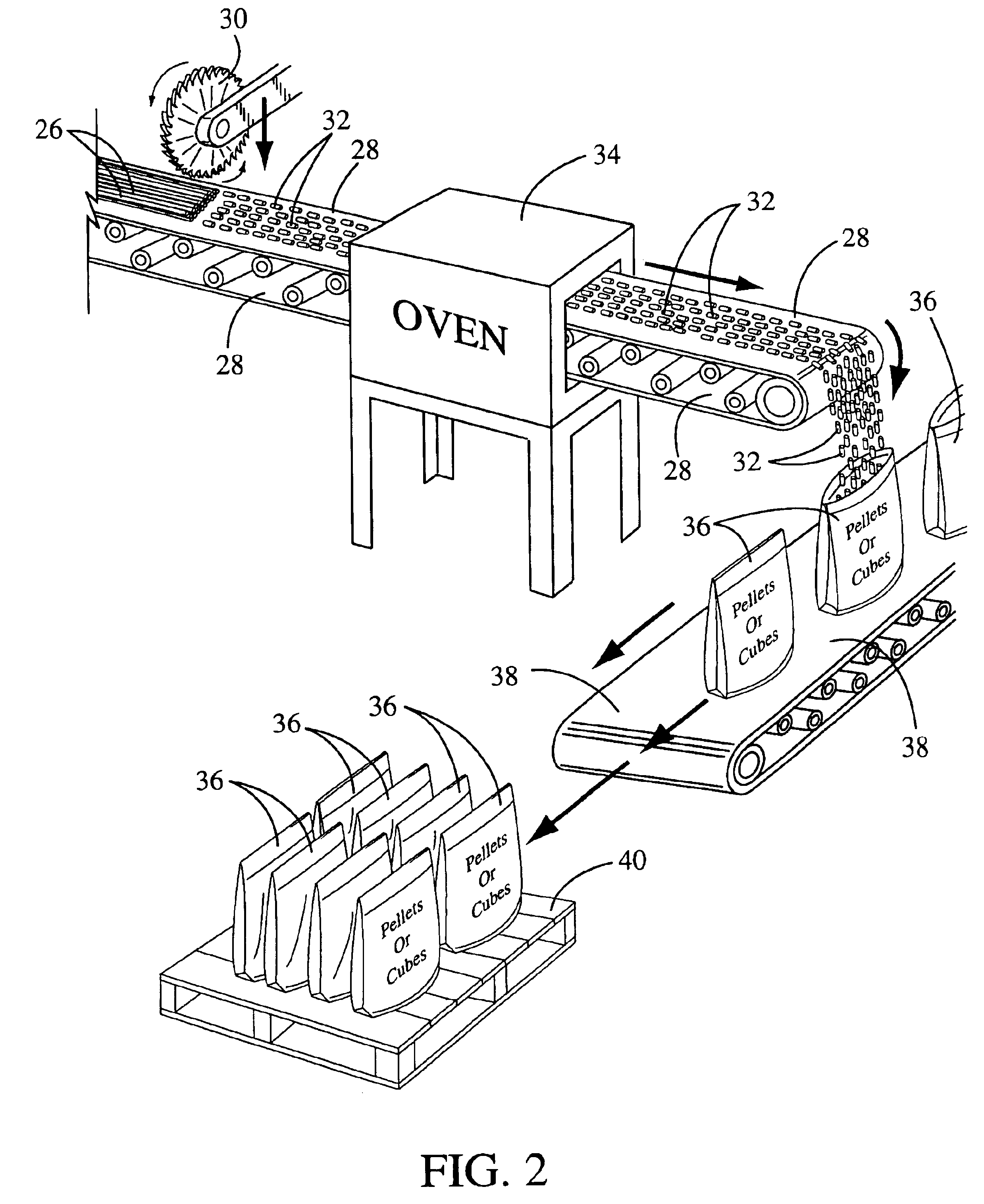

Method of making coconut coir pitch cat litter from powder created from crushed coconut husks

A method of making pellets of coconut coir pith used as cat litter. The coconut coir pith is nontoxic, lightweight and creates very little dust when compared to other cat litter products. Also, the coir pith pore structure absorbs all of the cat urine and doesn't release any of the typical cat urine smell to the atmosphere. In the method of making cat litter pellets from powdered coir pith, the first step includes crushing coconut husks and mixing the residual powdered coconut coir pith with water. The coir pith and water mixture is then compressed through a die having a plurality of ⅛th inch diameter holes therein for creating spaghetti like strings of coir pith. The strings of coir pith are then cut to a length of ½ inches or less. The pellets are heated in an oven for removing moisture and hardening them. The harden pellets are then packaged for shipment to customers.

Owner:SILVA TILAK

Vegetable-based products of the siccative type for recycling and rejuvenating reclaimed asphalt pavements in situ or in a dedicated plant

InactiveUS20120315088A1Easy to crackImproves rutting resistanceIn situ pavingsPaving detailsNatural sourceEmulsion

A method for recycling or renovating old pavements, wherein a rejuvenating binder is used including at least one compound based on fatty substances of natural origin including hydrocarbon fatty chains, these fatty substances of natural origin having undergone at least one chemical functionalization reaction through which at least one oxygenated functional group has been introduced. The rejuvenating binders and rejuvenating binder emulsions especially suitable to the method, and asphalt mixes based on regenerated reclaimed asphalt pavement are also disclosed.

Owner:COLAS LTD

Steel slag permeable asphalt mixture

The invention relates to a steel slag permeable asphalt mixture. The steel slag permeable asphalt mixture is obtained through blending aggregates, a fiber stabilizing agent and asphalt, the weights of the fiber stabilizing agent and asphalt are 0.2-0.4% and 4-5% of the weight of the aggregates respectively, the aggregates are composed of coarse aggregates, fine aggregates and a filler, the coarse aggregates are steel slag or a mixture comprising the steel slag and limestone and have granularities composed of 19-13.2mm, 13.2-9.5mm and 9.5-4.75mm, the fine aggregates are limestone and have a granularity of 4.75-0mm, and the aggregates concretely comprise 15-17wt% of a coarse aggregate having a granularity of 19-13.2mm, 26-29wt% of a coarse aggregate having a granularity of 13.2-9.5, 43-45wt% of a coarse aggregate having a granularity of 9.5-4.75mm, 11-13wt% of a fine aggregate having a granularity of 4.75-0mm, and 2-4wt% of the filler. The permeable asphalt mixture prepared through the use of the steel slag to partially or completely substitute the aggregates and the addition of the fiber stabilizing agent and the asphalt has a porosity satisfying requirements, and has a high Marshall stability, a small drainage loss and a small Starkenburg flying rate.

Owner:宝武环科武汉金属资源有限责任公司

Rock asphalt composite modifier and its preparation method and use

The invention discloses a rock asphalt compound modifier and a preparation method and use of the rock asphalt compound modifier. The rock asphalt compound modifier is composed of rock asphalt and polymer, wherein, the amount of the rock asphalt is 10 percent to 90 percent and the amount of the polymer is 10 percent to 90 percent in weight percentage. The preparation method is that the rock asphalt and the polymer are mixed together by a twin screw extruder in proportion, and then are granulated by a cold bracing and granulating equipment. The use of the rock asphalt compound modifier is that the rock asphalt compound modifier is put into an asphalt mixture mixing plant to be mixed with hot mineral aggregation for 5 to 20 seconds, and then basic asphalt is sprayed in to be mixed with the hot mineral aggregation for 20 to 60 seconds, at last the compound modified asphalt mixture is prepared. The rock asphalt compound modifier is in granular shape and has the advantages of accurate adding measurement, fine dispersion, uniform mixing and convenient construction. The compound modified asphalt mixture is suitable for paving the roads in high grade with further improved performance.

Owner:交通部公路科学研究院 +1

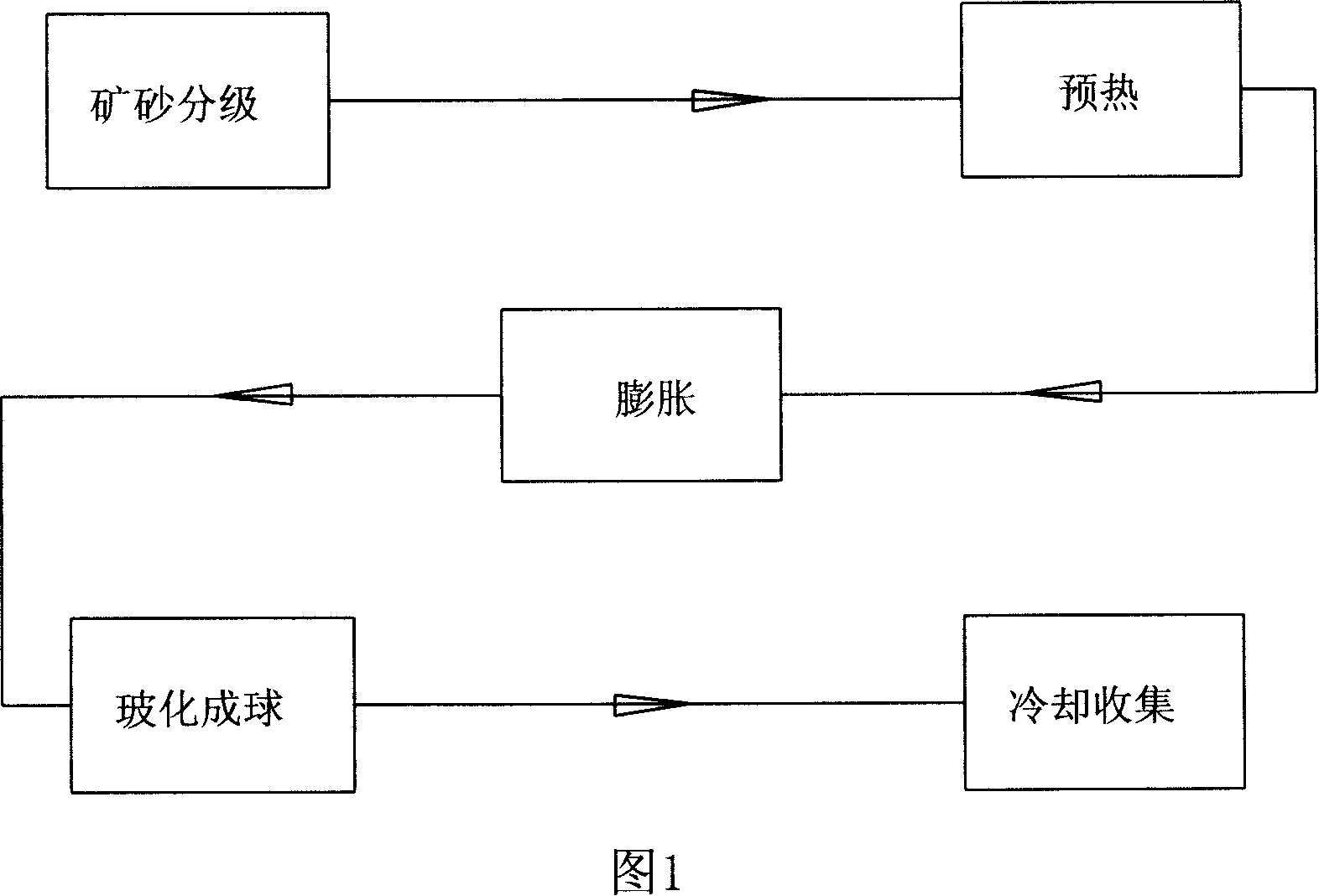

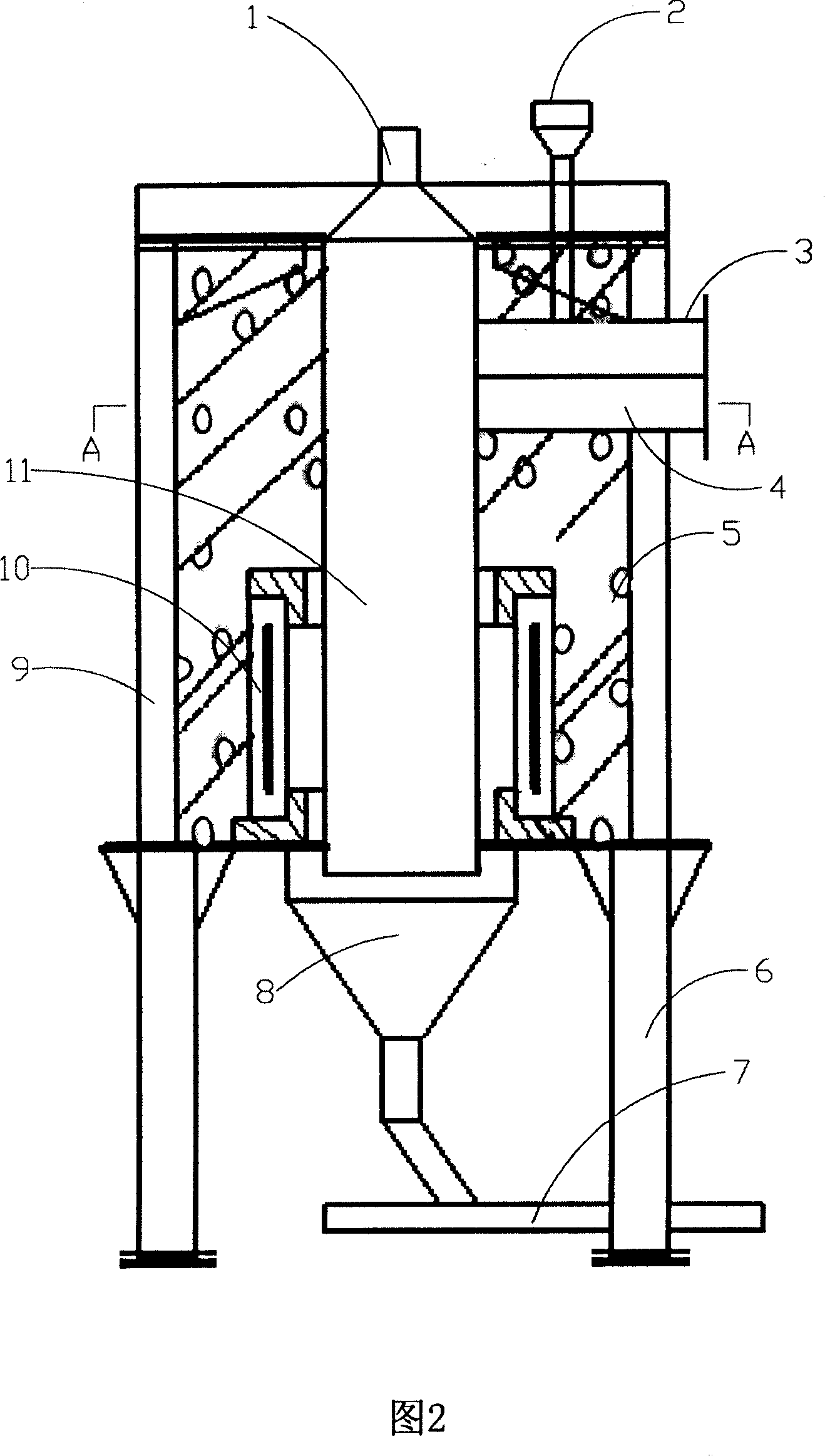

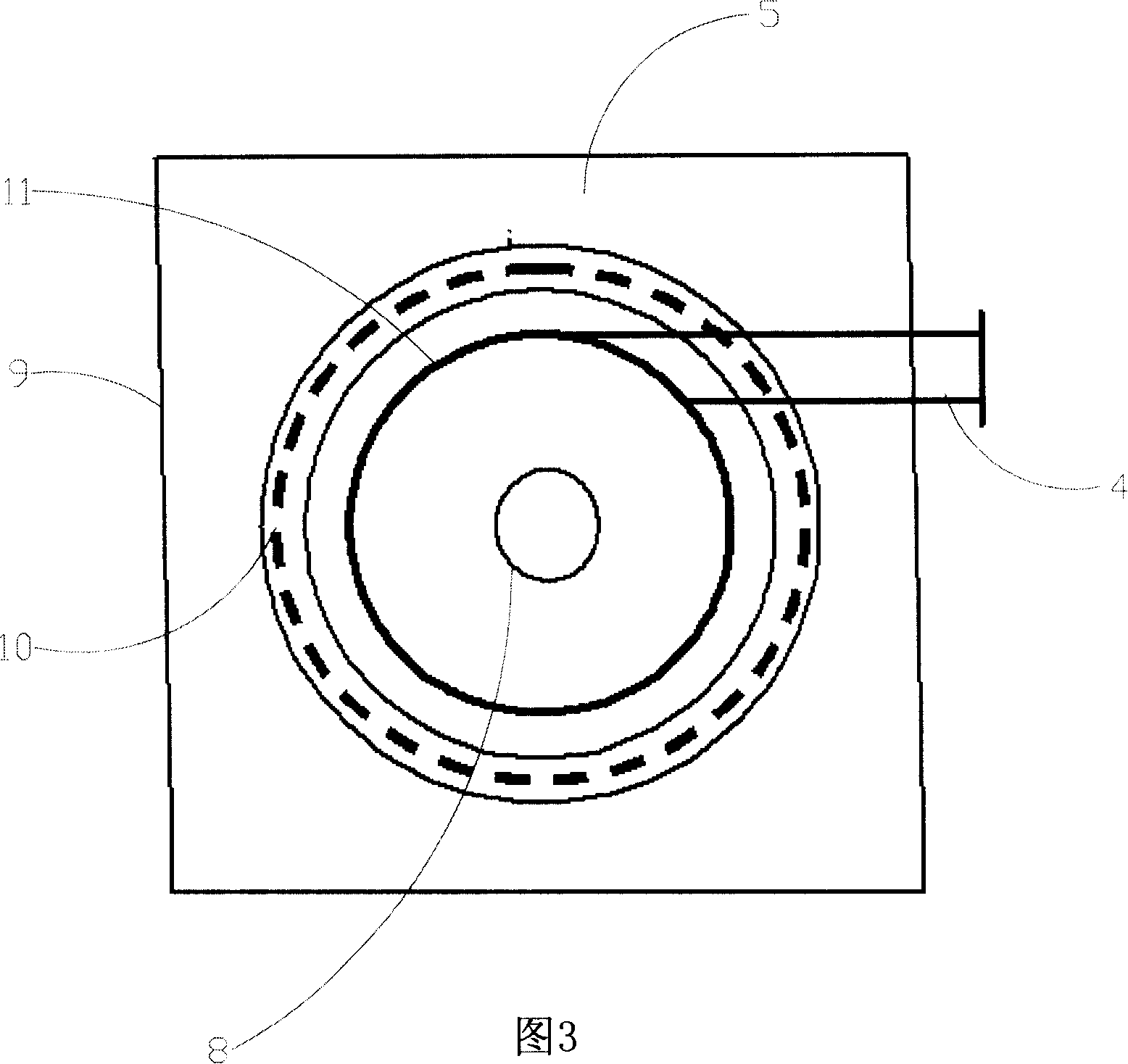

Process for making dilation vitrified microbead and rotary floating dilation vitrification furnace

The present invention relates to one kind of expanded and vitrified bead and its making process and rotary floating expanding and vitrifying furnace. The rotary floating expanding and vitrifying furnace includes one casing, one furnace body and one pedestal, as well as one sand bin, one sand preheating gas burning pipe, and one or several expanding gas burning pipes. The expanded and vitrified bead is made with vitreous pitchstone, and through preheating, expanding, vitrifying and cooling. The furnace has compact structure, small size and low power consumption; the making process is reliable; and the expanded and vitrified bead has grain size greater than 2 mm and excellent heat insulating effect.

Owner:北京华伟佳科技有限公司

Construction method for rubber grain asphalt concrete pavement

InactiveCN101153478AImprove deformation abilityGood flexibilityIn situ pavingsSnowpackWear resistant

A method for constructing rubber particles asphalt concrete road surfaces relates to a method for constructing asphalt concrete road surfaces, aiming to resolve the problems that: the asphalt concrete road surfaces have weak wear-resistant, and the attachment coefficient and the adhesive force are reduced and vehicles have the problem of braking stability when the road surfaces are covered by snow and ice. The construction method comprises the following steps that: compositions by weigh percentage of the following materials are adopted: 76.5 to 91.5 percent of mineral aggregate, 2.5 to 7.5 percent of asphalt, 4 to 10 percent of mineral powder and 2 to 6 percent of rubber particles; the mineral aggregate is heated up to 190 to 200 DEG C, the rubber particles are added into the mineral aggregate with mixing about 20 to 25 seconds, the asphalt heated up in advance and the mineral powder are added into the rubber particles and the mineral aggregate with mixing lasting for 70 to 80 seconds, and then the road surfaces are subject to the pavement, the first stage initial pressure, the first and the second stage re-pressure and the second stage final pressure. The invention can increase the deformation capabilities of the road surfaces effectively, improve the bond state between the road surfaces and snow, and the invention can improve the attachment coefficient, increase the adhesive force, and improve the braking and turning operation stability of vehicles when the road surfaces are cover by snow and ice.

Owner:HARBIN INST OF TECH

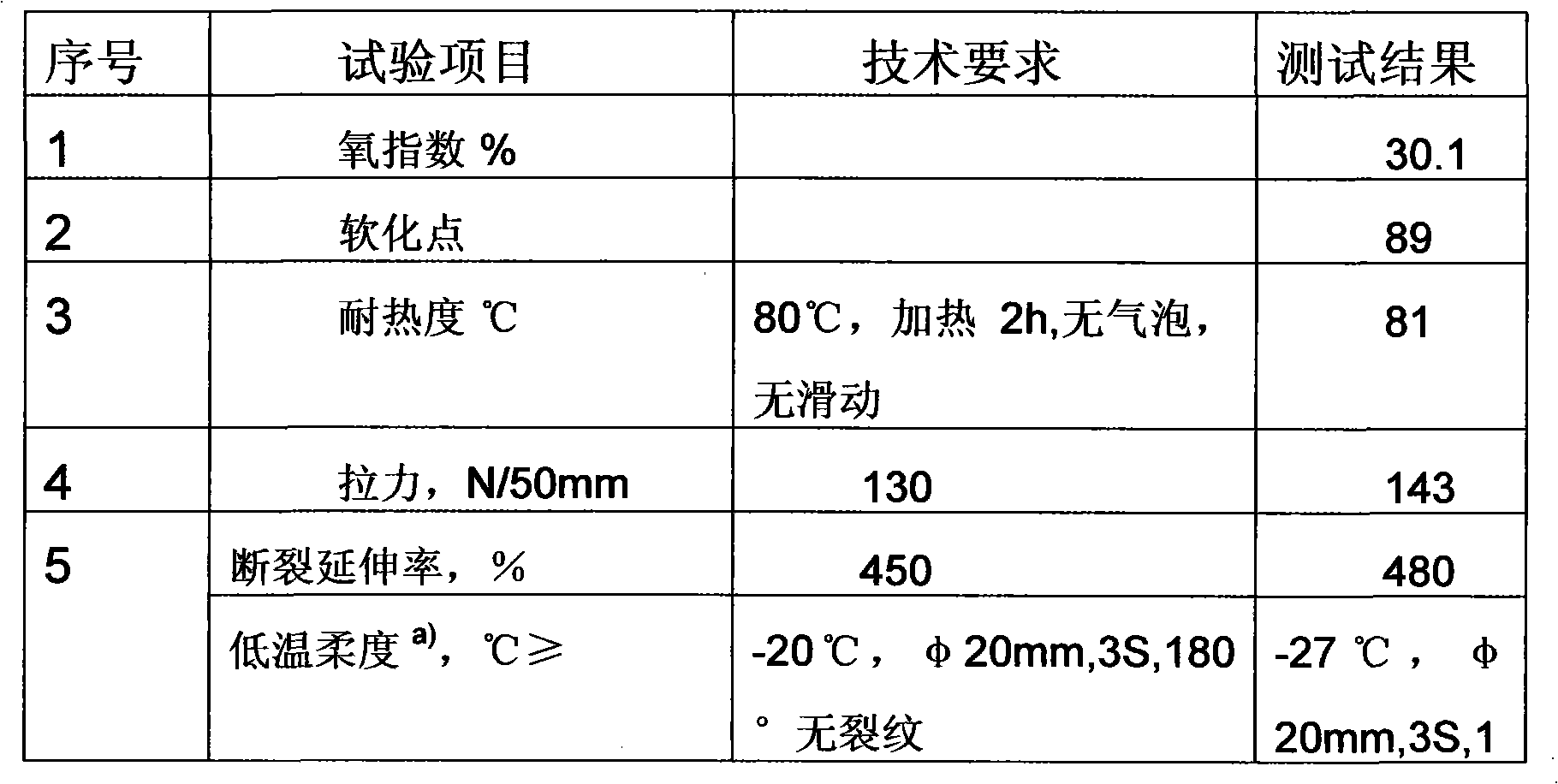

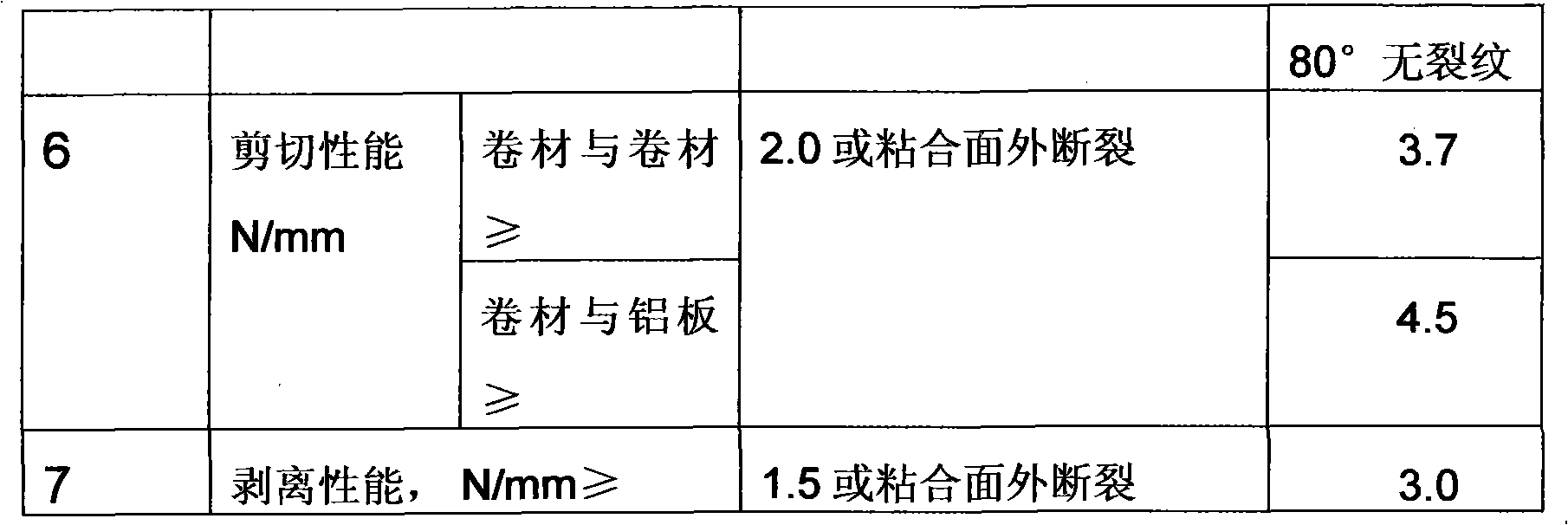

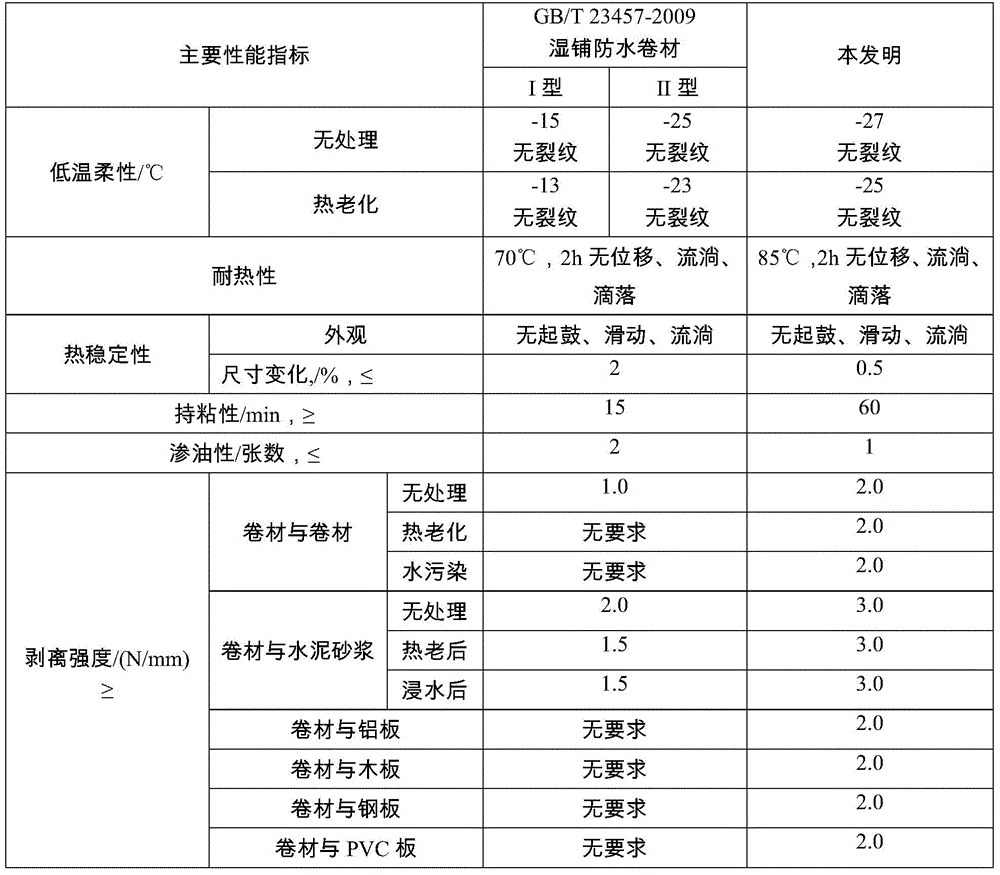

Flame-retardant self-adhesive coiled material

InactiveCN101818549AImprove flame retardant performanceEnvironmental protection is goodRoof covering using flexible materialsGlass/slag layered productsGlass fiberPolymer modified

The invention discloses a flame-retardant self-adhesive coiled material, which has a three-layer composite structure and is characterized in that the middle layer is a glass fiber felt and both the upper and lower surfaces of the glass fiber felt are polymer modified asphalt layers into which a flame retardant and an adhesion promoter are added. The invention provides a formula and a process for preparing the flame-retardant self-adhesive polymer modified asphalt water-proof coiled material. The flame-retardant self-adhesive polymer modified asphalt is prepared by mixing the flame retardant, the adhesion promoter, polymer, asphalt and the like. The invention further provides a method for preparing the coiled material.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Process for recovering heavy minerals from oil sand tailings

ActiveUS7695612B2Quality improvementExpansion quantityWater/sewage treatment by centrifugal separationCentrifugal force sediment separationSilicon dioxideMaceral

A process is provided for recovering heavy minerals from aqueous oil sand tailings, the oil sand tailings having heavy minerals, other coarse solids such as silica, fines, residual bitumen and water, including desliming the oil sand tailings in a desliming means by removing a portion of free fines and residual bitumen from the oil sand tailings; attritioning the oil sand tailings in an attritioner to remove adhered fines and residual bitumen from the heavy minerals and other coarse solids; and subjecting the deslimed and attritioned tailings to separation in a separation means to separate the heavy minerals from the other coarse solids present in the deslimed and attritioned tailings and produce a concentrated heavy minerals fraction.

Owner:TITANIUM CORP

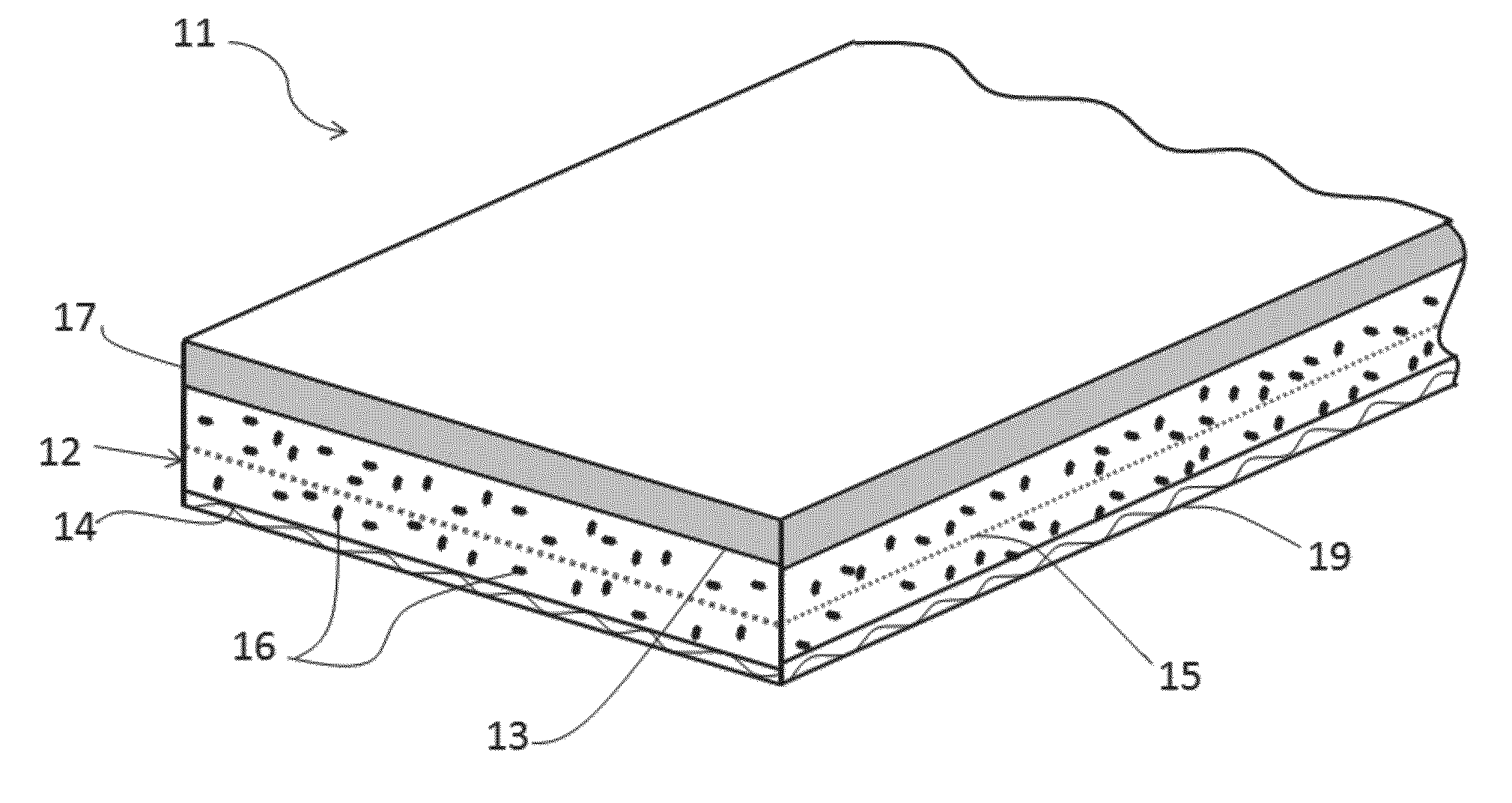

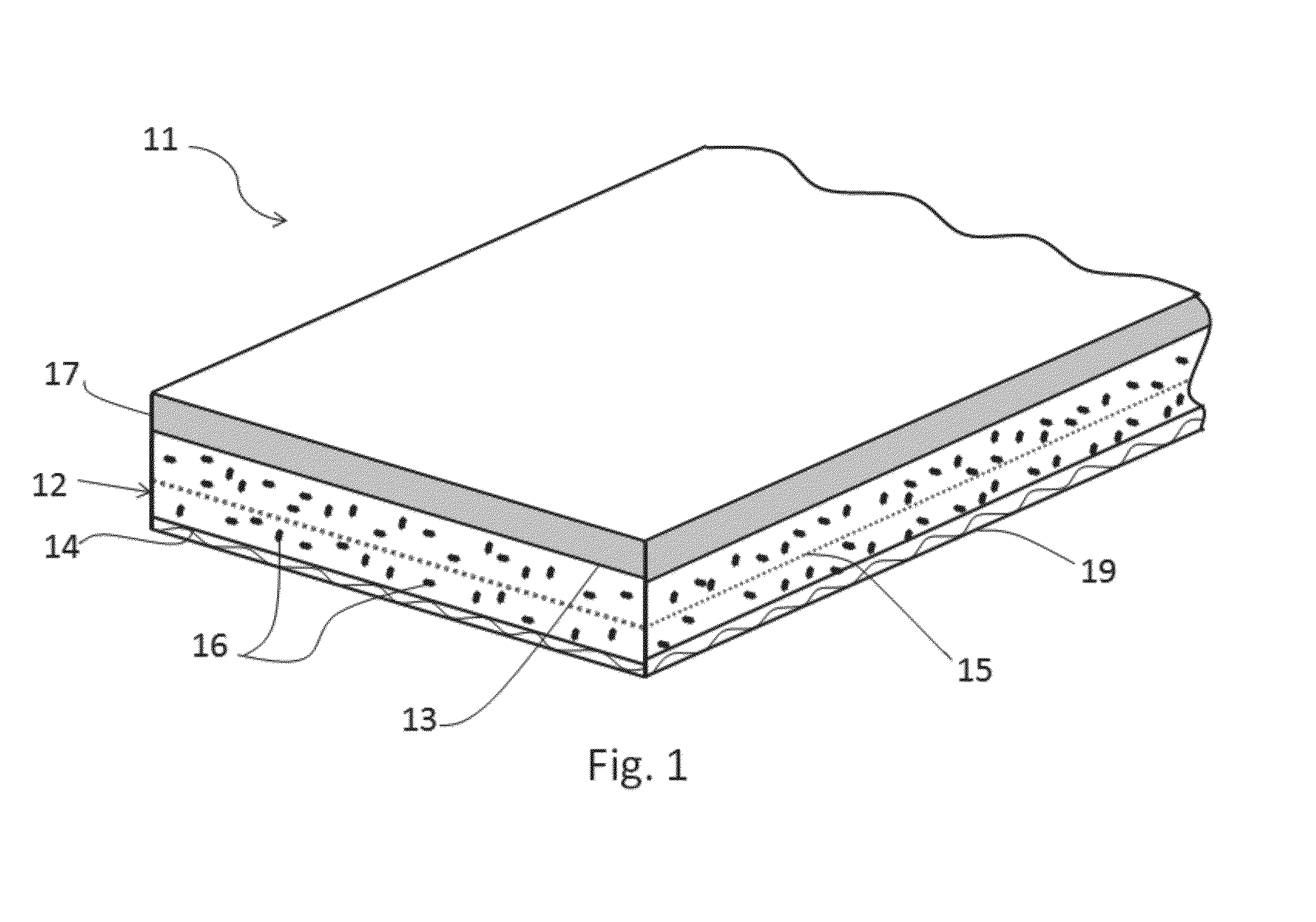

Use of thermoplastic polyurethanes in rubber modified bitumen roofing membranes

ActiveUS20100297902A1Improves UV resistanceGood resistance to oxidationIn situ pavingsAntifouling/underwater paintsPliabilityThermoplastic polyurethane

A roofing membrane that includes a blend of thermoplastic polyurethane and petroleum liquid so as to improve the UV stability of the blend without adversely affecting the flexibility of the dried and / or cured blend.

Owner:GARLAND INDS

Polymer modification asphalt cement for open-Graded pavement and its preparation method

ActiveCN1765996AHigh viscosityImprove viscosity and toughnessIn situ pavingsBuilding insulationsPolymer sciencePolymer modified

The invention discloses a polymer modified asphalt cementing material for open-graded pavement, which comprises asphalt, thermoplastic elastomer and rubber polymer. The preparation method comprises: on condition of high-speed shear, dispersing the polymer and crosslinking agent in alphalt to store for 2~24h at high temperature. This product has characters as following: 40~801 / 10mm penetration at 25Deg, 70~110Deg softening point, 80000~3000000Paíñs viscosity at 60Deg, tenacity more than 25Níñm, toughness more than 20Níñm, difference of softening points in resolution testing less than 2.5Deg.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing lightweight aggregate and inorganic insulation using product thereon as main insulation source

The invention relates to a preparation method of lightweight aggregate and an inorganic heat insulation material which takes the product thereof as a main heat insulation source. The lightweight aggregate is prepared by two surface treatments after the sudden cooling after the high-temperature melting by pitchstone and the introduction of gasification materials, the water absorption is low and the adhesion is good. The inorganic heat insulation material takes the obtained lightweight aggregate with the excellent performances as the main heat insulation sources and takes cement as an adhesive material, lightweight powder, expansion agent, acrylic short fiber, re-dispersible emulsion powder, cellulose and calcium formate are further added to adjust the mechanical and the construction performances of the heat insulation material. The prepared inorganic heat insulation material has excellent heat insulation, fire resistance, durability, long service life, environmental protection, energy conservation, material economy and better social and economic values.

Owner:北京北科华电科技股份有限公司

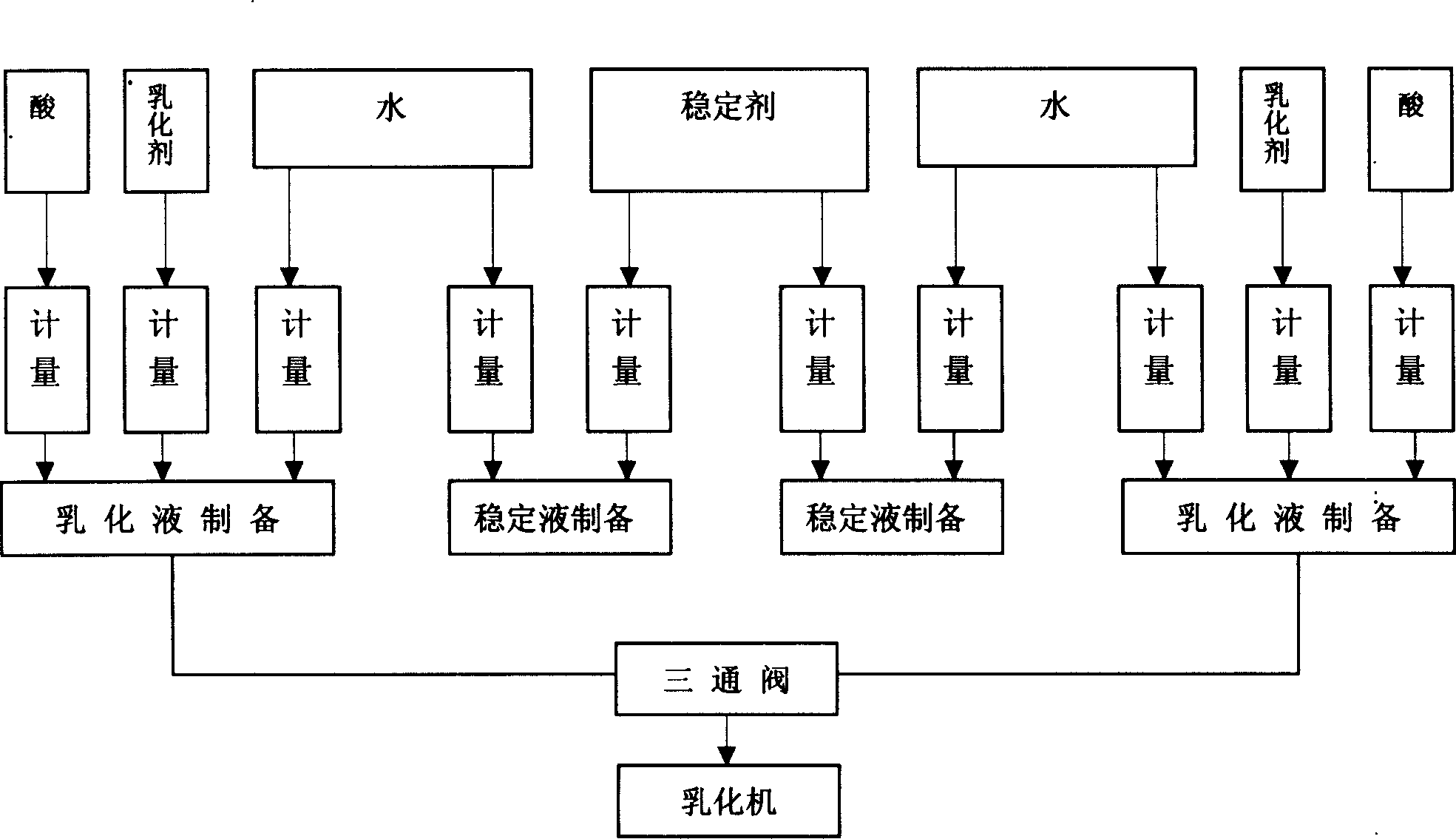

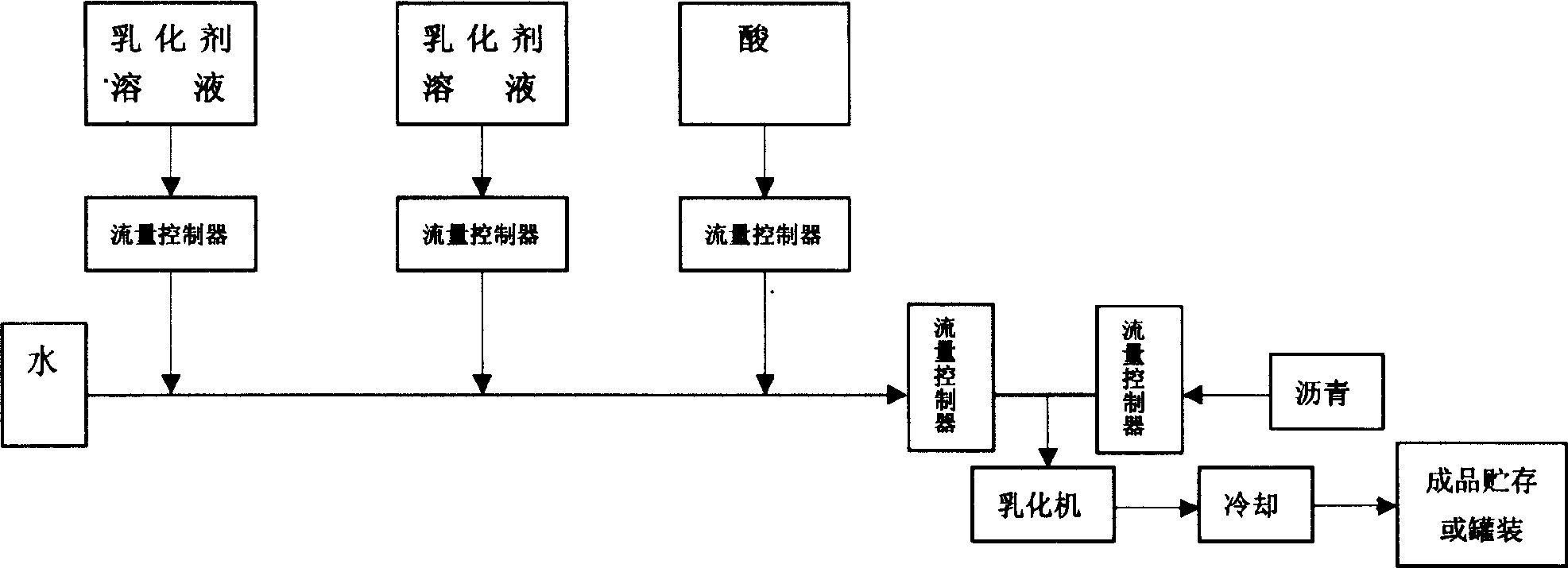

Emulsified SBS (styrene-butadiene-styrene) modified asphalt and preparation method of emulsified SBS modified asphalt

The invention discloses an emulsified SBS (styrene-butadiene-styrene) modified asphalt and a preparation method of the emulsified SBS modified asphalt; the emulsified SBS modified asphalt comprises 55-60 percent of matrix asphalt, 2.5-4 percent of SBS, 0.1-0.5 percent of SBS modified asphalt stabilizer SWD, 1-3 percent of asphalt cationic emulsifier, 40-45 percent of water, calcium chloride equivalent to 0.3-0.8 percent of water quality, thickening agent equivalent to 0.1-0.5 percent of water quality and acid for adjusting the pH value to be from 2 to 4, wherein SBS has a linear structure, the block ratio is 20 / 80-28 / 72, and the molecular weight is 100,000-160,000. The emulsified SBS modified asphalt evaporated residue has good high-temperature performance, the softening point can reach more than 72 DEG C, and the ductility can reach more than 30cm, thereby being the emulsified modified asphalt with high performance and widely applied to the building and maintenance of high-level roads.

Owner:CHINA PETROCHEMICAL CORP

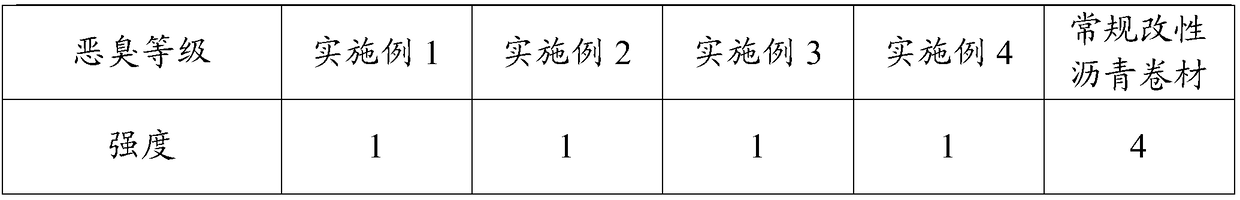

Odorless modified asphalt waterproofing coil material and preparation method thereof

InactiveCN108382039AAchieve reuseSuppress generationRoof covering using flexible materialsSynthetic resin layered productsBituminous waterproofingAntioxidant

The invention provides an odorless modified asphalt waterproofing coil material, which comprises modified asphalt, a polypropylene fiber cloth and a PE film, wherein the modified asphalt comprises, byweight, 35-45 parts of asphalt, 15-25 parts of waste rubber powder, 15-30 parts of an SBS rubber, 0.5-2 parts of a stabilizer, 0.5-1 part of an antioxidant, 0.5-1 part of an odor inhibitor, and 10-20parts of a filler. According to the present invention, the waterproofing coil material is produced by using the waste rubber powder, and the generation and volatilization of H2S, SO2, NOx and other asphalt flue gas during asphalt production and construction is reduced by using the action of the odor inhibitor, such that the significant odor elimination effect is achieved, the performance of the asphalt is not obviously changed, and the environmental protection and the health of personnel can be easily achieved. The invention further provides a preparation method of the odorless modified asphalt waterproofing coil material.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

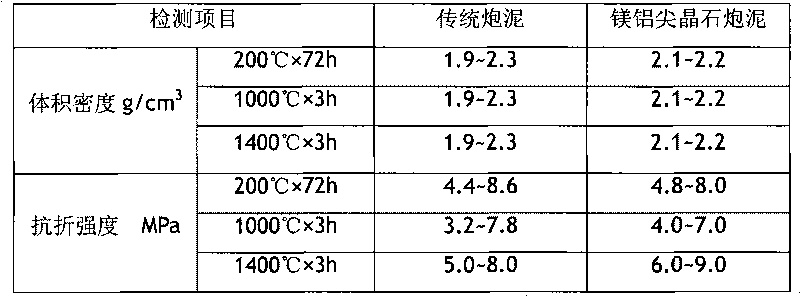

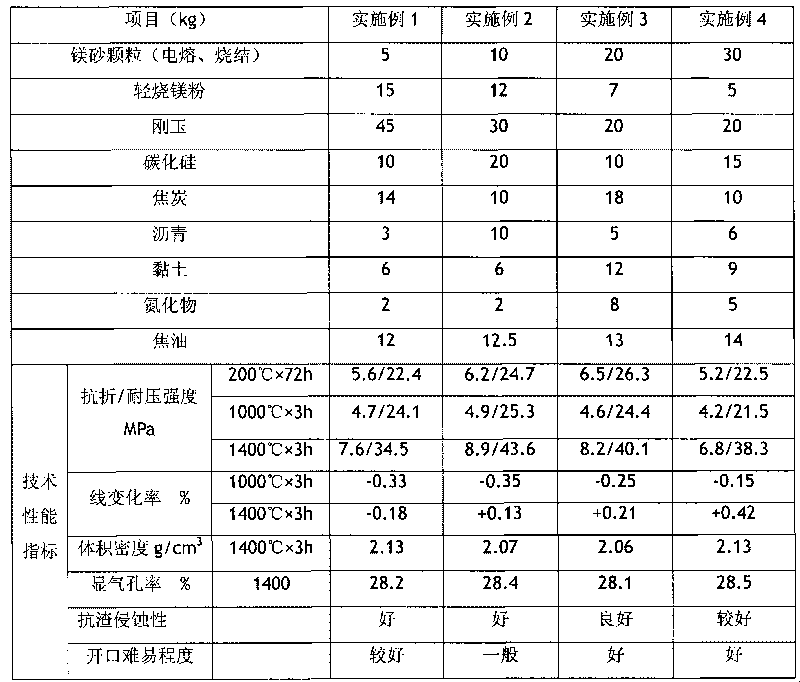

Magnesia-alumina spinel stemming

The invention provides a magnesia-alumina spinel stemming with micro expansibility, good slag corrosion resistance and abrasion resistance for a blast furnace casting port, which belongs to the field of metallurgical fireproof material. The stemming comprises the following raw materials in part by mass: 5 to 30 parts of magnesia particles, 5 to 15 parts of light-burnt magnesia powder, 20 to 45 parts of corundum, 10 to 20 parts of silicon carbide, 10 to 18 parts of coke, 3 to 10 parts of asphalt, 6 to 12 parts of clay, 12 to 24 parts of tar, and 2 to 8 parts of nitride. The magnesia-alumina spinel stemming has the advantages that: a magnesium material adopts the compound addition of the magnesia particles and the light-burnt magnesia powder, and the spinel generated by reaction and the preserved magnesium material are fireproof materials with excellent performance; the proportional relation of the magnesia, the light-burnt magnesia powder and the corundum is optimized based on the addition of the light-burnt magnesia powder so that the linear variation of the stemming after high-temperature calcination has micro-expansion, and the service performance of the stemming is improved; and simultaneously, the reduction of the consumption of tar is helpful for improving the environment and reducing the production cost of the stemming.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Recovery of heavy minerals from a tar sand

A process for recovering heavy minerals (e.g., titanium minerals such as TiO2) from a feedstock comprising tar sands or a tar sands-derived solids fraction. The feedstock comprises bitumen and heavy minerals. The process comprises the steps of: (i) contacting the solids fraction with water at a temperature of at least about 100° F. to cause production a bituminous phase and a heavy minerals phase; and (ii) separating the heavy minerals phase from the bituminous phase. Optionally, these steps may be preceded by one or more steps used to produce a tar-sands derived solids fraction from a tar sands feedstock.

Owner:TITANIUM CORP

Method of preparing zeolite/active carbon type composite material

InactiveCN101234333AHigh mechanical strengthLow costOther chemical processesAlkali metal oxides/hydroxidesSorbentMaterials science

The invention relates to a preparation method of activated carbon / zeolite complex materials, belonging to the field of preparing inorganic materials and absorbents. The invention is characterized in that the method takes coal gangue and asphalt powders as raw materials to prepare the zeolite / activated carbon complex materials. The method comprises the followings steps: fully mixing the ground coal gangue and asphalt powders, molding by adding water and activating the carbon in the carbon dioxide atmosphere after drying and carbonizing; dynamic crystallizing the activated coal gangue in NaOH water solution and activating after washing and drying, thus obtaining the zeolite / activated carbon complex materials. The activated carbon / zeolite complex materials prepared by the method have double surface properties and porous structures of both zeolite and activated carbon with adjustable proportion; the complex materials are high in mechanical intensity, easy in preparation method, low in cost, thus having important values in comprehensive utilization of coal gangues and development of novel absorption materials.

Owner:TAIYUAN UNIV OF TECH

Modified asphalt, method for preparing modified asphalt and nanometer reaction adhesive waterproof roll

ActiveCN105647206AImprove high temperature resistanceHigh surface energyBuilding insulationsBituminous layered productsSilicon dioxidePetroleum

The invention discloses modified asphalt, a method for preparing the modified asphalt and a nanometer reaction adhesive waterproof roll. The modified asphalt comprises petroleum asphalt and nano particles, wherein the nano particles include nano-silica and nanosized zeolite, and the weight ratio of nano particles to petroleum asphalt is (36-44):100. By adding nano-silica and nanosized zeolite to petroleum asphalt, the high temperature resistance of petroleum asphalt is improved.

Owner:广东省盛世恒辉工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com