Odorless modified asphalt waterproofing coil material and preparation method thereof

A technology for modifying asphalt and waterproofing membranes, which is applied in chemical instruments and methods, roofing using flexible materials, building insulation materials, etc., can solve the problems of unstable product quality, low tensile properties, and outdated proportioning methods, etc. Achieve the effect of realizing waste reuse, strong capture ability, and improving environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

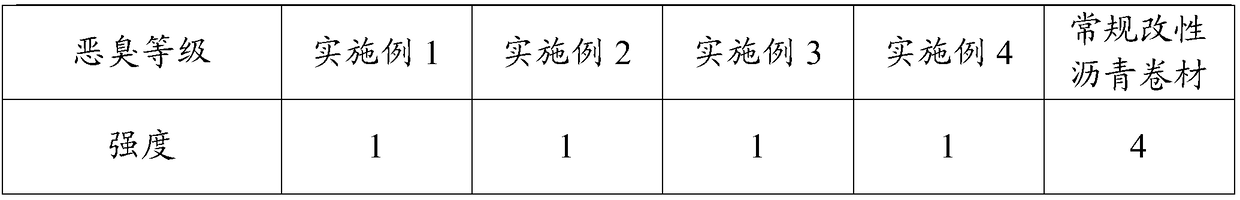

Examples

preparation example Construction

[0032] The present invention also provides a preparation method of odor-cleaning modified asphalt waterproofing membrane, the steps of which are as follows:

[0033] (1) Heat the asphalt to 170-180°C, add the measured waste rubber powder and SBS rubber, keep the heating at 190-200°C, turn on the agitator, and control the speed at 10-20rpm;

[0034] (2) After mixing evenly, after colloid mill grinding, add metered stabilizer, antioxidant, odor inhibitor and filler, stir for 30min, and prepare modified asphalt;

[0035] (3) Add the above-mentioned modified asphalt into the screw extruder, extrude the carcass through the screw extruder, and at the same time extrude the carcass, introduce the polypropylene cloth into a pair of drafting rolls from both sides at the same time, pass through Roller extrusion, the polypropylene cloth and the carcass are hot-compressed into one body, cooled and cooled, and finally a PE film is attached on the surface to form a waterproof membrane.

Embodiment 1

[0038] Weigh 35 parts of asphalt and heat it to 180°C, add 15 parts of waste rubber powder and 15 parts of SBS rubber that have been measured, keep the temperature at 200°C, turn on the agitator, and control the speed at 10rpm; after mixing evenly, grind it through a colloid mill, Add 0.5 parts of stabilizer, 0.5 parts of antioxidant, 0.5 parts of odor inhibitor and 10 parts of filler, and stir for 30 minutes to prepare modified asphalt; add the above-mentioned modified asphalt into the screw extruder, and extrude through the screw extruder Carcass, when extruded into carcass, polypropylene cloth is introduced into a pair of drafting rollers from both sides at the same time, and the polypropylene cloth and carcass are hot-compressed into one by extrusion through the rollers, cooled and cooled, and finally The surface is attached with PE film to form a waterproof membrane.

Embodiment 2

[0040] Weigh 45 parts of asphalt and heat it to 170°C, add 20 parts of waste rubber powder and 20 parts of SBS rubber that have been measured, keep the temperature at 190°C, turn on the agitator, and control the speed at 20rpm; after mixing evenly, grind it through a colloid mill, Add 2 parts of stabilizer, 1 part of antioxidant, 1 part of odor inhibitor and 20 parts of filler, and stir for 30 minutes to prepare modified asphalt; add the above-mentioned modified asphalt into the screw extruder, and extrude through the screw extruder Carcass, when extruded into carcass, polypropylene cloth is introduced into a pair of drafting rollers from both sides at the same time, and the polypropylene cloth and carcass are hot-compressed into one by extrusion through the rollers, cooled and cooled, and finally The surface is attached with PE film to form a waterproof membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com