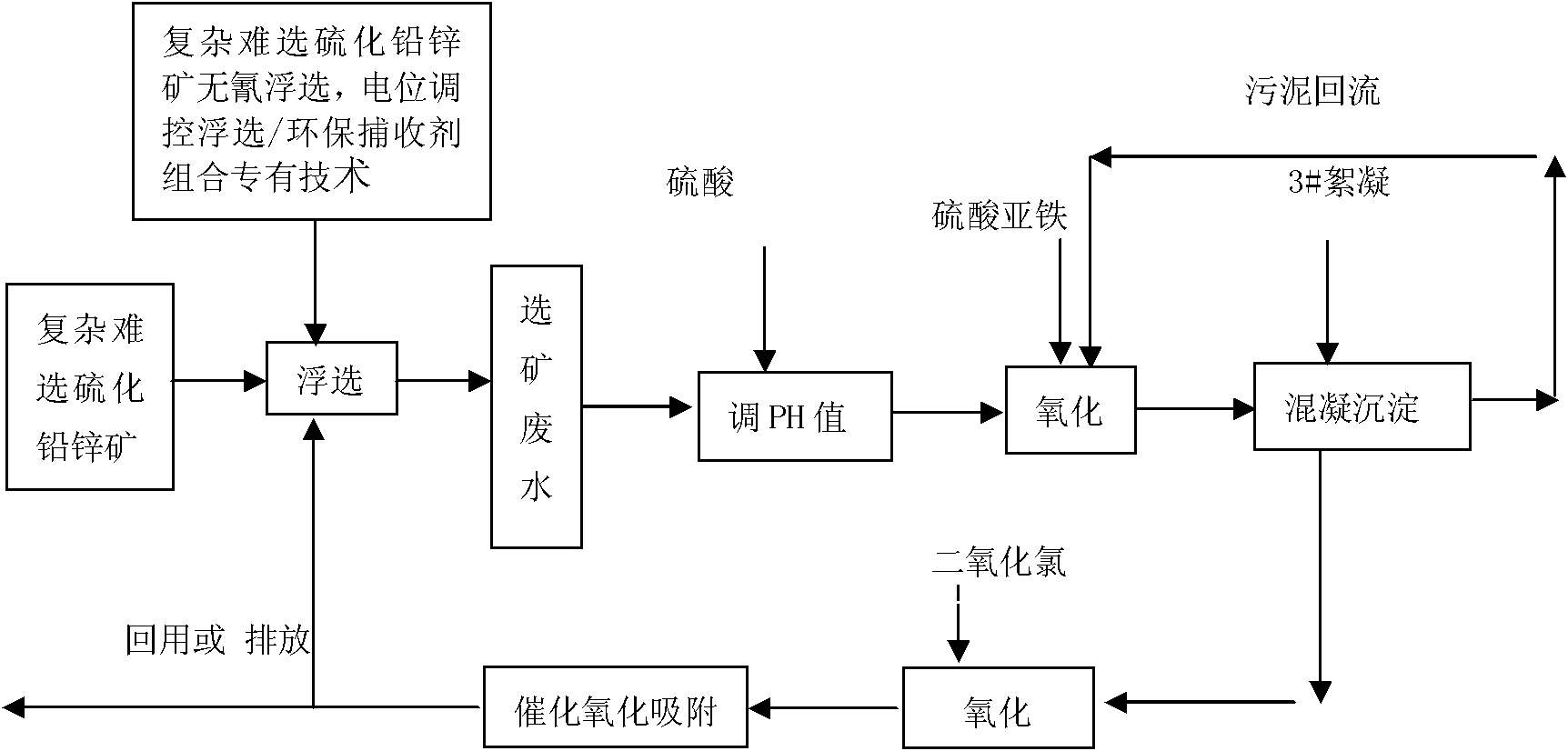

Method for treating and recycling lead-zinc sulfide ore dressing wastewater

A lead-zinc sulfide and mineral processing wastewater technology, applied in mining wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. problems, to achieve the effect of eliminating the impact and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

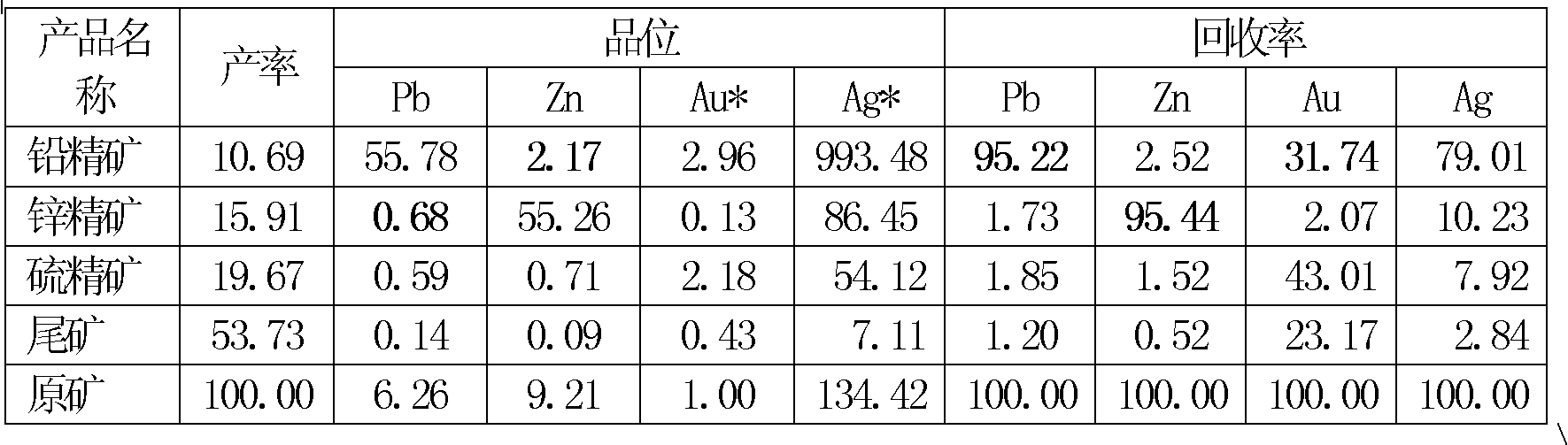

[0036] Example 1: For the treatment of mineral processing wastewater produced by the lead-zinc sulfide mine of Hunan Baoshan Nonferrous Metals Mining Co., Ltd. using potential-regulated flotation and environmental protection collector combined application technology, the water quality components of the wastewater are shown in Table 1, and 10% sulfuric acid is first used to adjust the wastewater PH value to PH=10.24, then add a certain concentration of ferrous sulfate and flocculant polyacrylamide, stir, let stand for 60 minutes and then take samples for analysis, when the dosage of ferrous sulfate is 50-200mg / l, add flocculant When the amount is 1.0mg / l, the concentration of heavy metal ions, CODcr, and petroleum in the treated water have all reached a lower level, and the water quality is relatively clear. The treatment results are shown in Table 2.

[0037] Table 1 Mineral processing wastewater composition table Unit: mg / l

[0038] project

pH

COD

Petro ...

Embodiment 2

[0041] Embodiment 2: For the beneficiation wastewater produced by Hunan Baoshan Nonferrous Metal Mining Co., Ltd. lead-zinc sulfide ore, adjust the pH value to PH=9.5, add a certain concentration of ferrous sulfate and flocculant, stir, and take it after standing for 60 minutes For the clear liquid, add chlorine dioxide to the treated water, sample and analyze after 60 minutes of oxidation, when the dosage of ferrous sulfate is 100mg / l, when the dosage of 3# flocculant (polyacrylamide) is 1.0mg / l , when the dosage of chlorine dioxide is 10-20mg / l, the concentration of heavy metal ions, phenol, CODcr, etc. in the treated water will reach a lower level, and the water quality will be relatively clear, which can reach the relevant national sewage comprehensive discharge standards. The treatment results are shown in the table 3.

[0042] Table 3 Oxidation treatment results after flocculation treatment of mineral processing wastewater Unit: mg / l

[0043] Chlorine dioxide (...

Embodiment 3

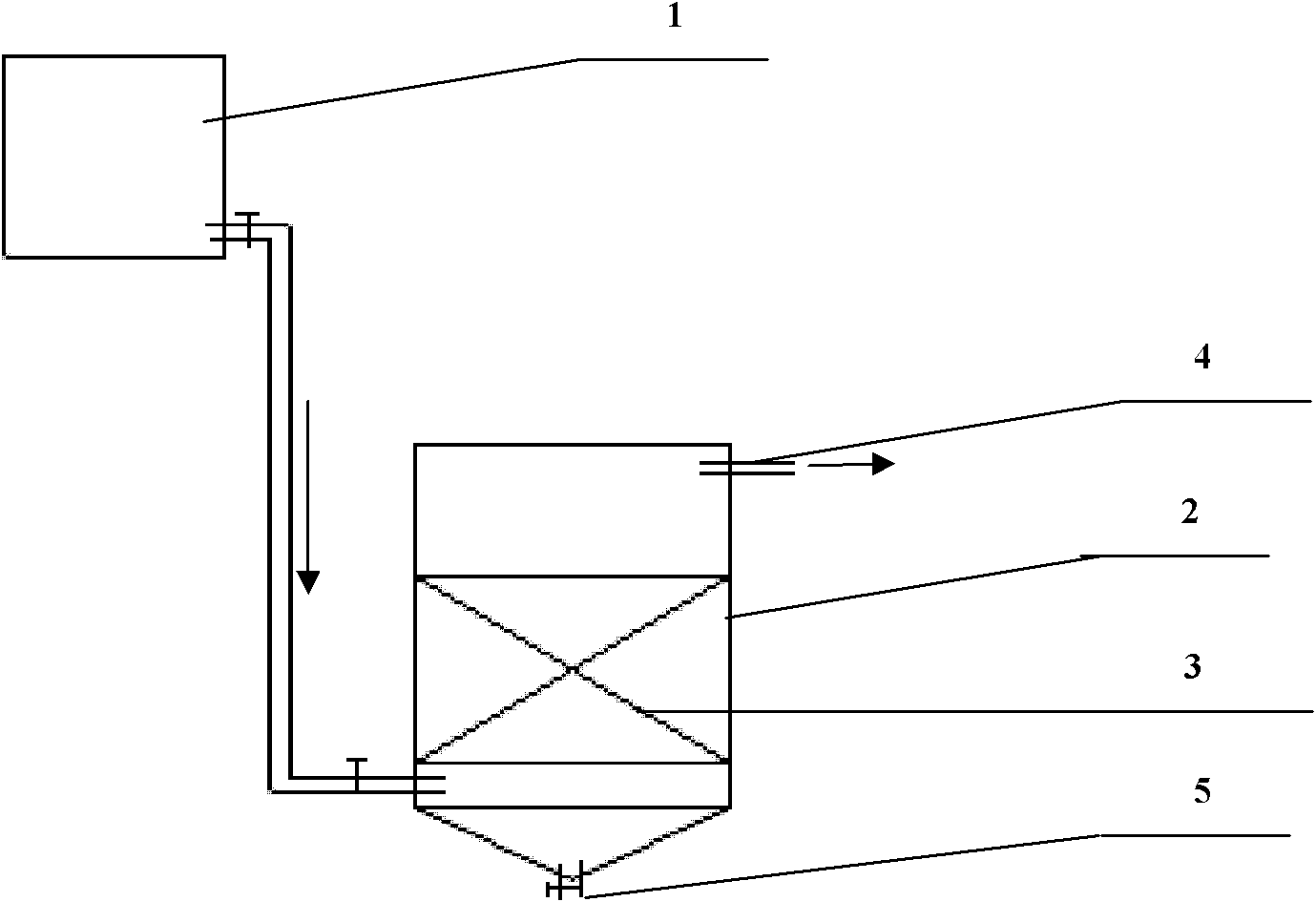

[0044] Example 3: Add a certain concentration of ferrous sulfate and flocculant (polyacrylamide) to the ore dressing wastewater whose pH value is adjusted to 9.5, stir, take the supernatant after standing for 60 minutes, and add carbon dioxide to the treated water Chlorine 20mg / l, after oxidizing for 30 minutes, treat with the reaction bed that uses activated carbon as the medium, the activated carbon bed device (see figure 2 ) device size: φ18×20cm; activated carbon filling height: 16cm, when the dosage of ferrous sulfate is 100mg / l, the dosage of 3# flocculant is 1.0mg / l, chlorine dioxide is 20mg / l, the adsorption device When the residence time is 30min; the phenol, petroleum and CODcr in the treated water are all at a lower level, and the water quality is relatively clear. The analysis results of the treated water are shown in Table 4.

[0045] Table 3 Catalytic oxidation adsorption treatment results after flocculation oxidation treatment of mineral processing wastewater U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com