Patents

Literature

427 results about "Lead sulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lead sulfide is an ionic compound of lead and sulfur, having two possible proportions: Lead sulfide, the ionic compound containing lead in the +2 oxidation state Lead sulfide, the ionic compound containing lead in the +4 oxidation state The mineral galena, a natural form of lead sulfide and a major source of lead

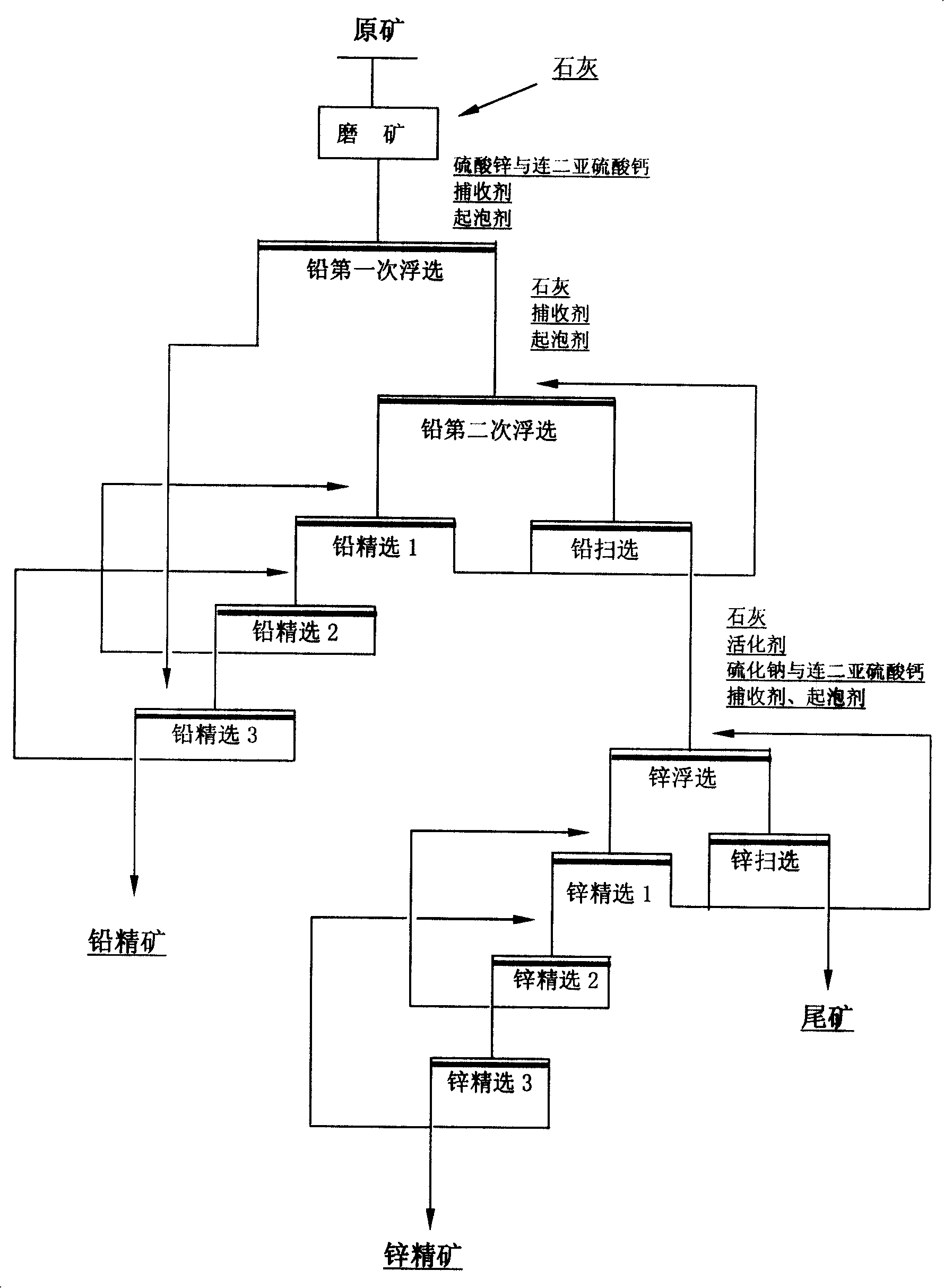

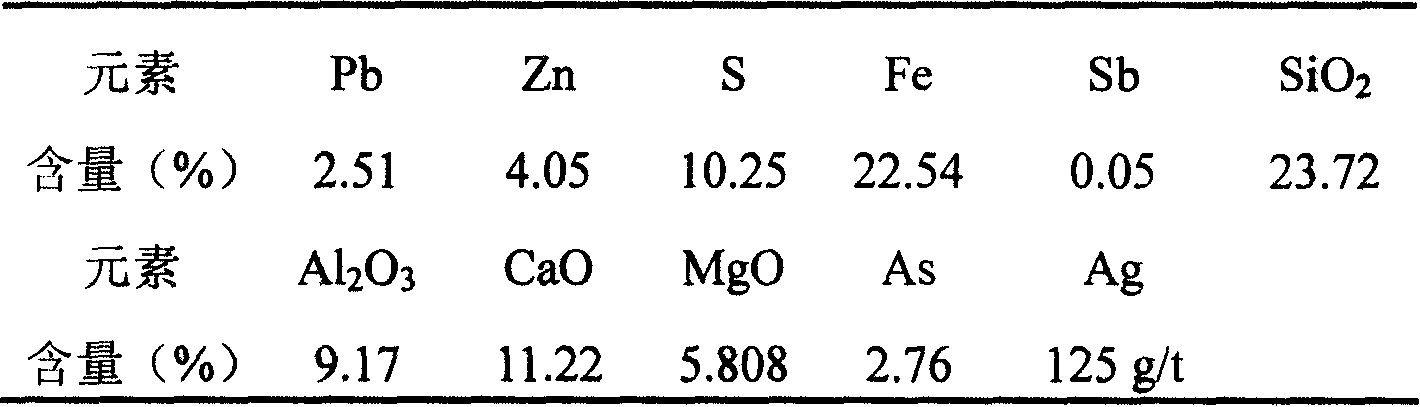

Complex plumbum, zinc, silver vulcanizing ore containing newboldite and pyrrhotite floatation method

The invention discloses a lead and zinc flotation method to ferreous blende and pyrrhotite typed complex lead zinc silver sulphide ore, mainly comprising lead ore branch flotation which controls the electrochemical conditions of the flotation and the zinc and sulfur flotation separation which controls the electrochemical conditions of the flotation. The invention has the advantages of implementing the lead-zinc sulfur separation by adopting twice branch flotation, carrying out fast flotation to the lead ore by using a novel composite catching agent to the galena and silver ore with easy floating coarse grains under the conditions of higher ore pulp potential and low pH; the normal flotation of the lead ore with difficultly floated fine grains is carried out under the conditions of lower ore pulp potential and high pH. The pH of the ore pulp is adjusted to more than 12 by lime for the gangue after the lead is floated; the iron blende is activated by bluestone; the iron blende is recovered by the catching agent with the same type of the lead sulfide floatation, thus leading the property of the lead flotation waste water to be basically consistent with that of the zinc flotation waste water and being beneficial for the circular application of floatation waste water.

Owner:CENT SOUTH UNIV

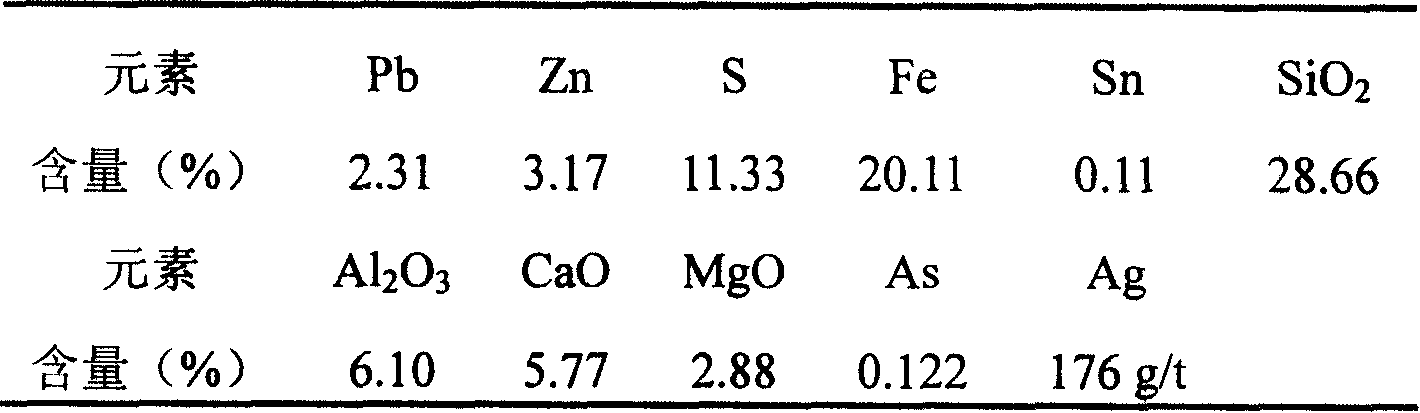

Stepped flotation of tin, lead and zinc sulfide mine

A step floatation technology for the tin-lead-zinc sulfide ore includes such steps as high-alkali high-speed floatation and separation of lead sulfide ore, high-alkali high-Ca floatation and separation of zinc sulfide ore, and floatation of zinc tailings. Its advantages are high grade and recovering rate of lead concentrate, no loss of Ag ore, and simple apparatus.

Owner:黎东明

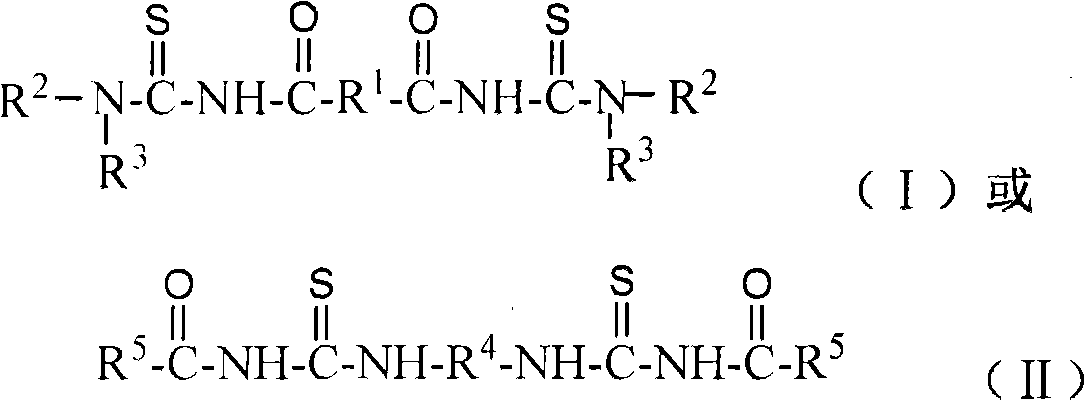

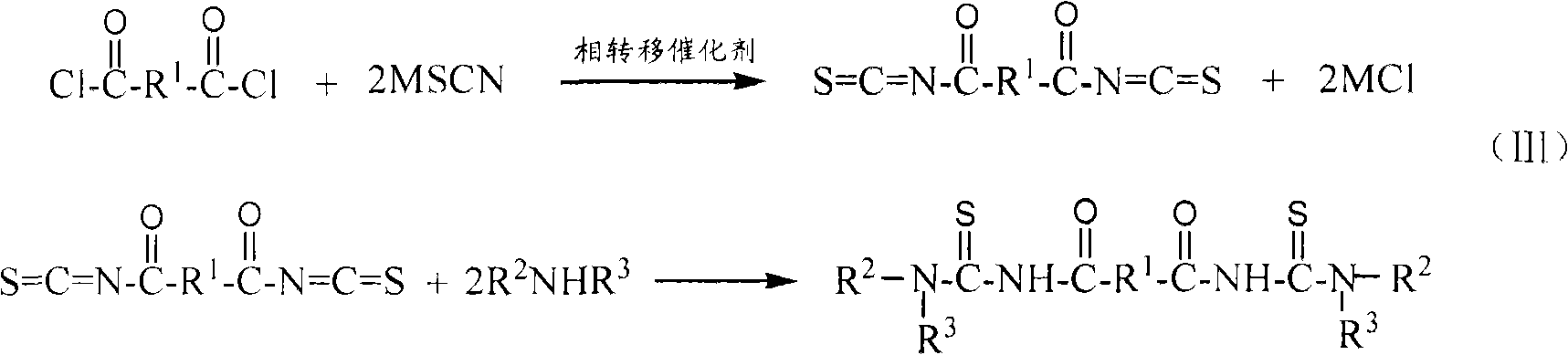

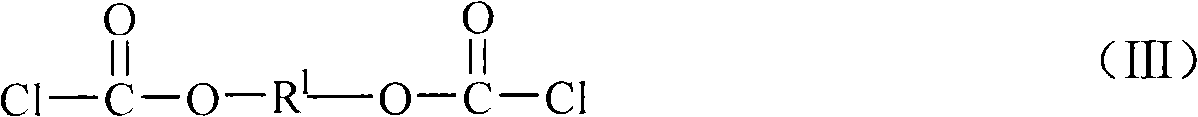

Sulphide ore floation collector and use method of diacyl bis-thiourea and preparation method thereof

InactiveCN101337206AEasy to makeEfficient flotation separationOrganic chemistryFlotationMagmaThiourea

The invention discloses the application processes and the preparation methods of a sulphide ore flotation collector as well as a diacyl bis-thiourea. The invention relates to a novel collector used for high efficiently recycling valuable sulfide minerals from metal sulphide ores; the compositions of the sulphide ore flotation collector include diacyl bis-thiourea surface active agents; the diacyl bis-thiourea compound is shown in the constitutional formula (1) or (2). The collector has strong collecting ability to copper sulphide minerals such as chalcopyrite, etc., lead sulfide minerals or zinc sulfide minerals activated by copper ions, nickel sulfide minerals as well as noble metal minerals such as gold, silver, etc., and has good selectivity to gangue sulphide minerals such as iron pyrites, pyrrhotite, etc., thereby realizing the high efficient flotation separation of the copper sulphide minerals and ferric sulfide minerals when the pH value of ore magma is below 11, reducing the used amount of lime, and improving the comprehensive recovery of copper sulphide ores.

Owner:CENT SOUTH UNIV

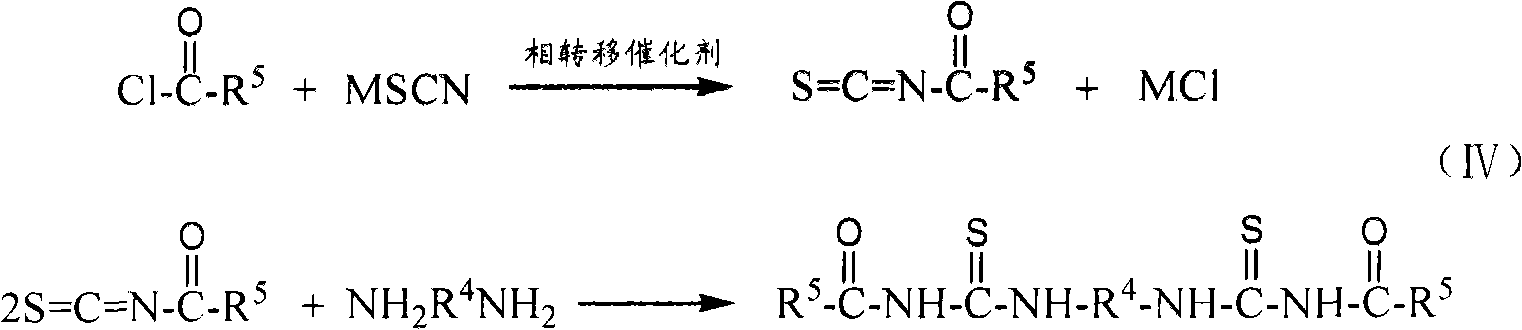

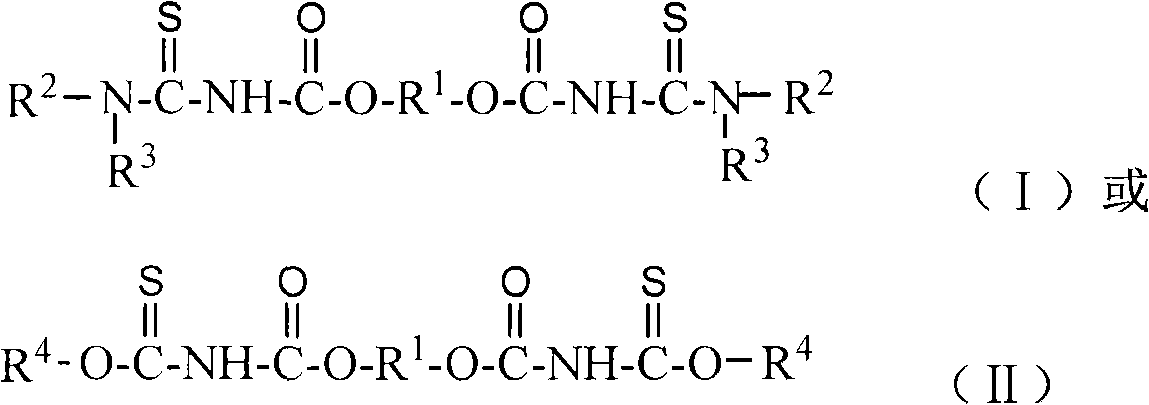

Use of diester isosulfocyanate in sulphide ore floation and preparation method thereof

InactiveCN101337205AEasy to makeStrong harvesting abilityOrganic chemistryFlotationMagmaSulfide minerals

The invention discloses a diester-based 2-thiocyanate ester derivate applied in sulphide flotation, and the preparation method thereof. Diester-based 2-thiourea (the formula one) or diester-based 2-ethionine ester (the formula two) is applied as a novel collector for high efficiently recycling valuable sulfide minerals from metal sulphide ores by floatation. The collector has wide pH range in ore magma, thereby having strong ability to collect copper sulphide minerals such as chalcopyrite, etc., lead sulfide minerals or zinc sulfide minerals activated by copper ions, nickel sulfide minerals as well as noble metal minerals such as gold, silver, etc., and having good selectivity to gangue sulphide minerals such as iron pyrites, pyrrhotite, etc.

Owner:CENT SOUTH UNIV

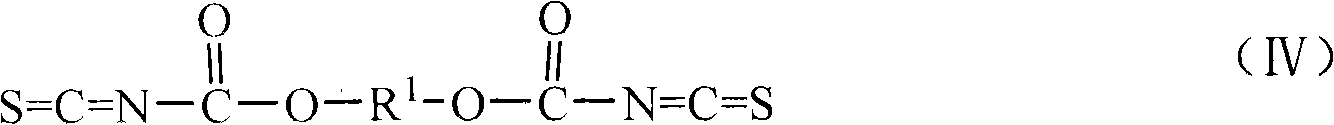

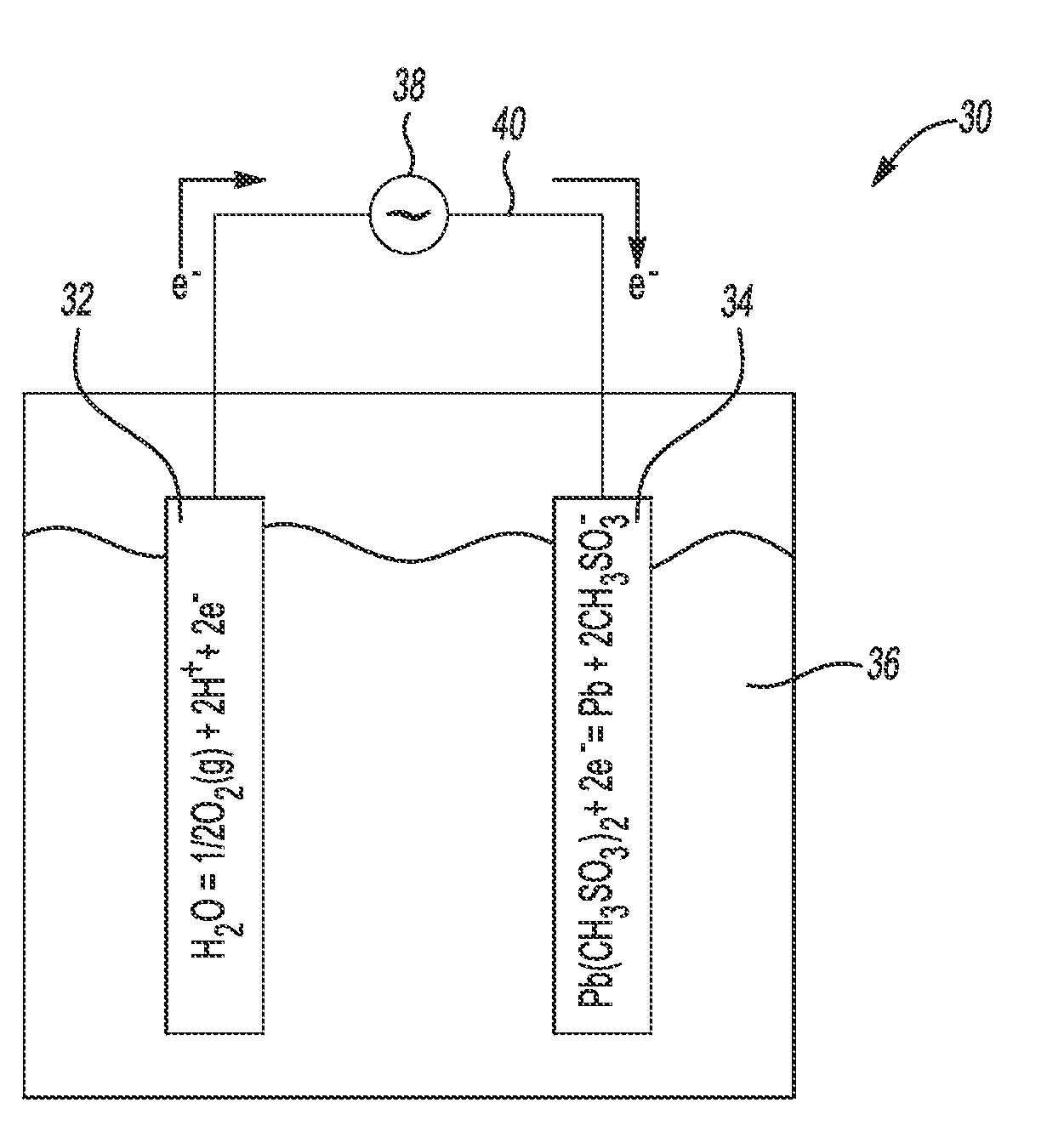

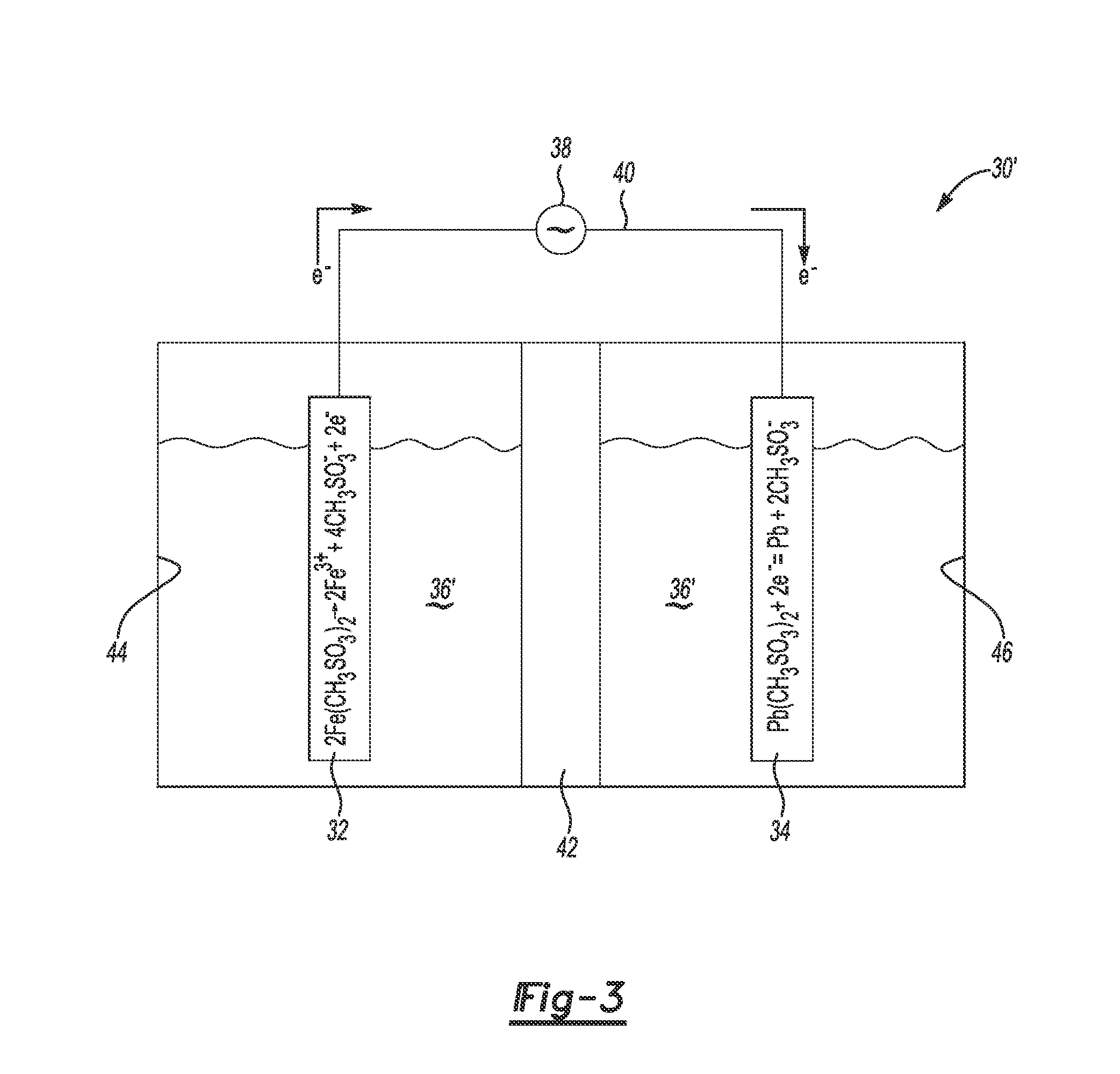

Recovering lead from a lead material including lead sulfide

In an example of a method for recovering lead from a lead material including lead sulfide, methane sulfonic acid is selected as a leaching acid for the lead material. The lead material is exposed to a solution including the methane sulfonic acid and i) ferric methane sulfonate or ii) oxygen, which leaches lead from the lead sulfide in the lead material, and generates a liquid leachate including a lead-methane sulfonate salt. The liquid leachate is purified, and lead is recovered from the purified liquid leachate using electrolysis.

Owner:THE UNIV OF BRITISH COLUMBIA

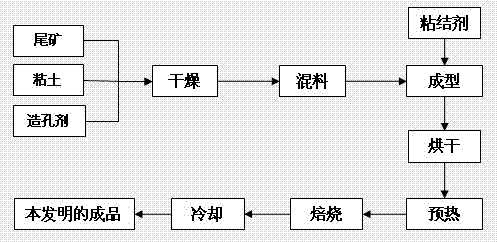

Biological ceramisite filter material made of vulcanized lead zinc ore flotation tailings, and preparation method thereof

InactiveCN103086741AImprove performance qualityLow costSolid waste disposalCeramicwareMining engineeringSulfidation

The invention relates to a biological ceramisite filter material made of vulcanized lead zinc ore flotation tailings. The material is characterized by being prepared from 80-90wt% of vulcanized lead zinc ore flotation tailings, 8-18wt% of clay, 1.5-2.5wt% of pore former and an additional bonder, wherein the pore former is sawdust, bamboo scraps or straws, the bonder is lignin calcium xanthate, sodium carbonate or sodium silicate liquid, and the solid-to-liquid ratio of materials used by the biological ceramisite filter material is (8-12):1. The preparation method comprises the following steps of: weighing based on proportion of main and auxiliary materials; drying; mixing; forming; drying; preheating; roasting; and cooling to prepare a biological ceramisite filter material product made of the vulcanized lead zinc ore flotation tailings. The preparation method is simple and convenient to implement, free from secondary pollution, practical and reliable. The biological ceramisite filter material made of the vulcanized lead zinc ore flotation tailings provided by the invention has the advantages of turning ore waste residue into wealth and greatly lowering the cost of materials, so that the biological ceramisite filter material is a high-quality water treatment agent.

Owner:HOHAI UNIV

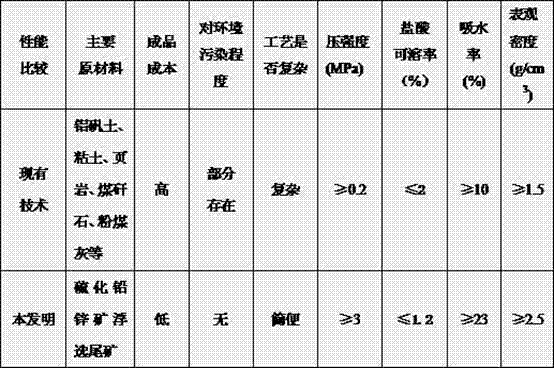

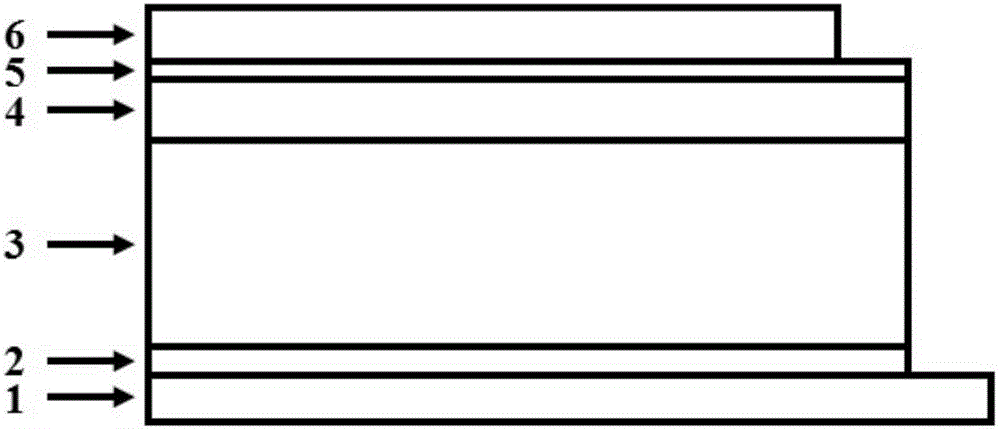

Spiro-OMeTAD/PbS composite hole transport layer based perovskite solar cell and preparation method therefor

ActiveCN106129252AImprove photoelectric conversion efficiencyImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingSolar lightEvaporation

The invention discloses a Spiro-OMeTAD / PbS composite hole transport layer based perovskite solar cell and a preparation method therefor. The perovskite solar cell comprises a transparent conductive substrate, an oxide electron transport layer, a perovskite solar light absorption layer, the Spiro-OMeTAD / PbS composite hole transport layer and a metal electrode. The perovskite thin film solar cell adopts a simple process; a lead sulfide thin film can be prepared by a large-area evaporation method; and the lead sulfide thin film can be inserted between the Spiro-OMeTAD and the metal electrode layer to be used as a buffer layer. The Spiro-OMeTAD / PbS composite hole transport layer based perovskite solar cell achieves a high photoelectric conversion efficiency which is as high as 15.11%; the lead sulfide, which is used as the buffer layer between the hole transport layer and the metal electrode, has higher hole mobility, and higher humidity stability and light and heat stability, so that the recombination of electron-hole pairs can be reduced; meanwhile, the stability of the cell can be improved; compared with other buffer layer materials, the lead sulfide can protect a device and improve the performance of the device as well; and therefore, a positive promotion effect is realized on the industrial development of the solar cell.

Owner:WUHAN UNIV

Use of coated proppant to minimize abrasive erosion in high rate fracturing operations

InactiveUS7730948B2Avoid excessive wearReduce erosionSynthetic resin layered productsCellulosic plastic layered productsHigh rateIndium

Owner:BAKER HUGHES INC

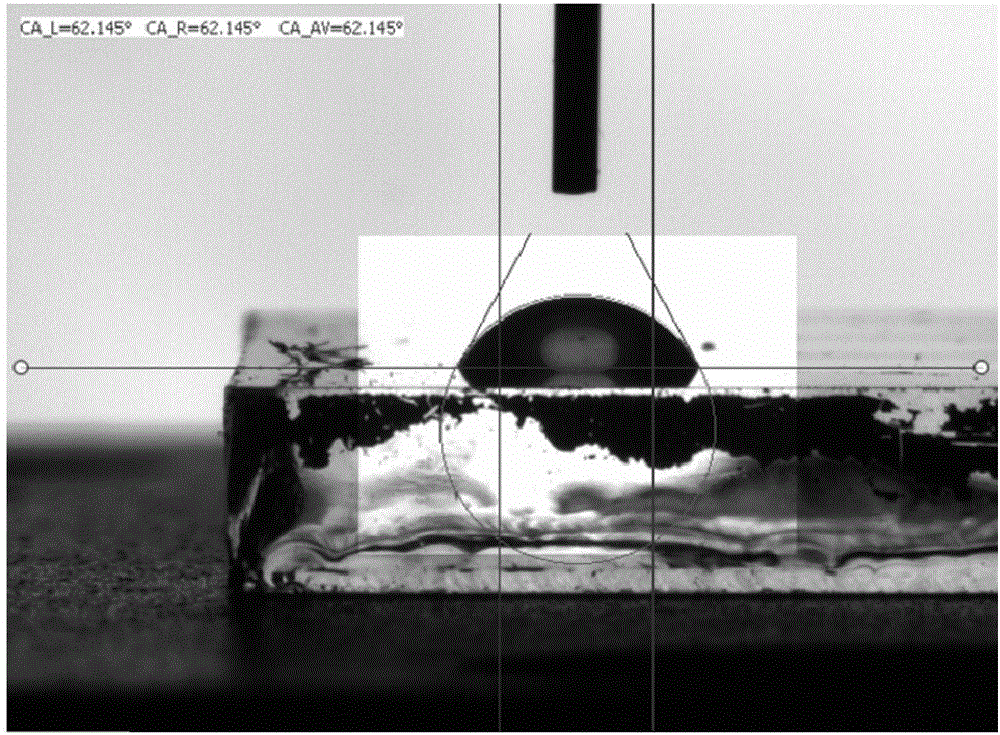

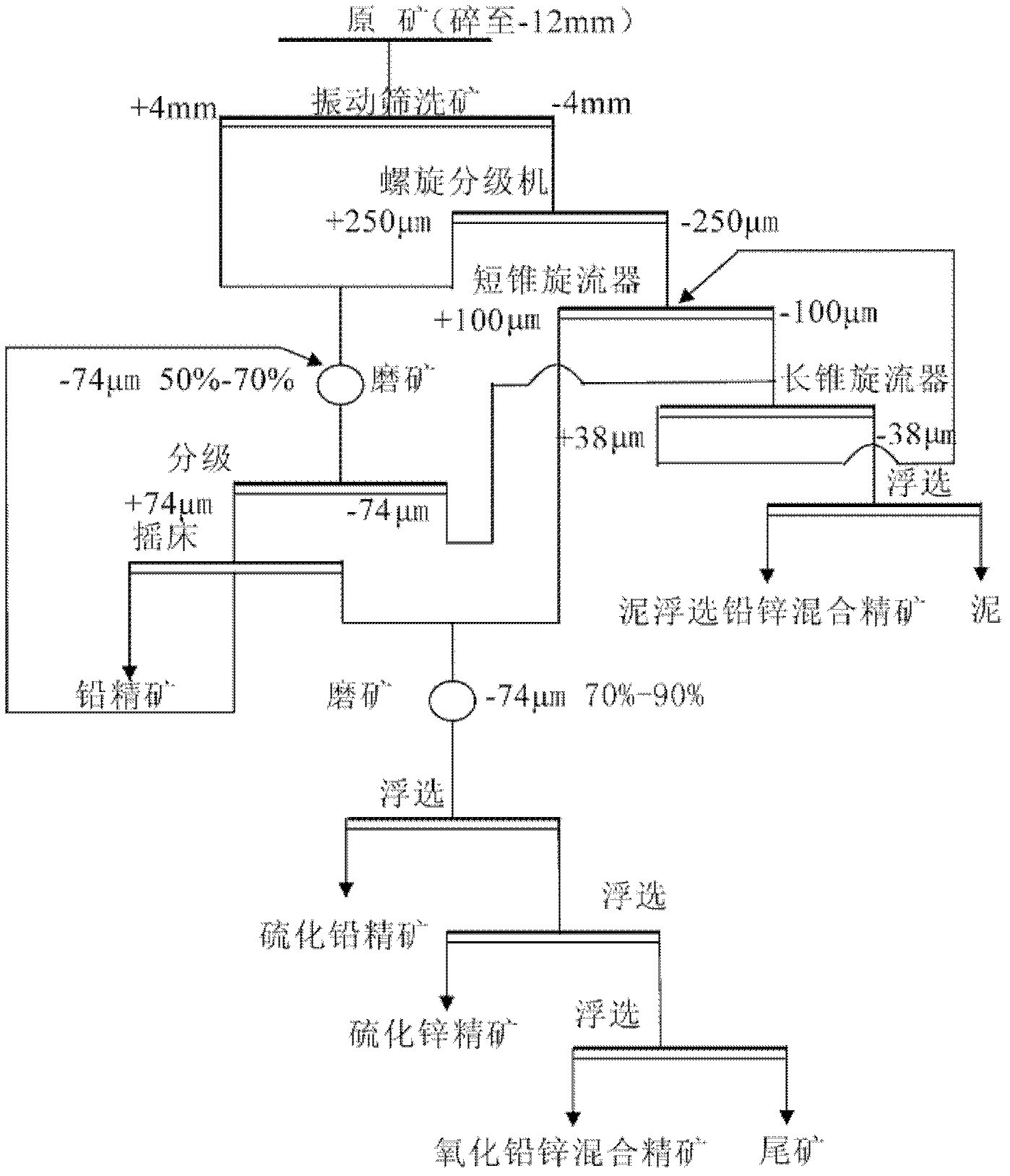

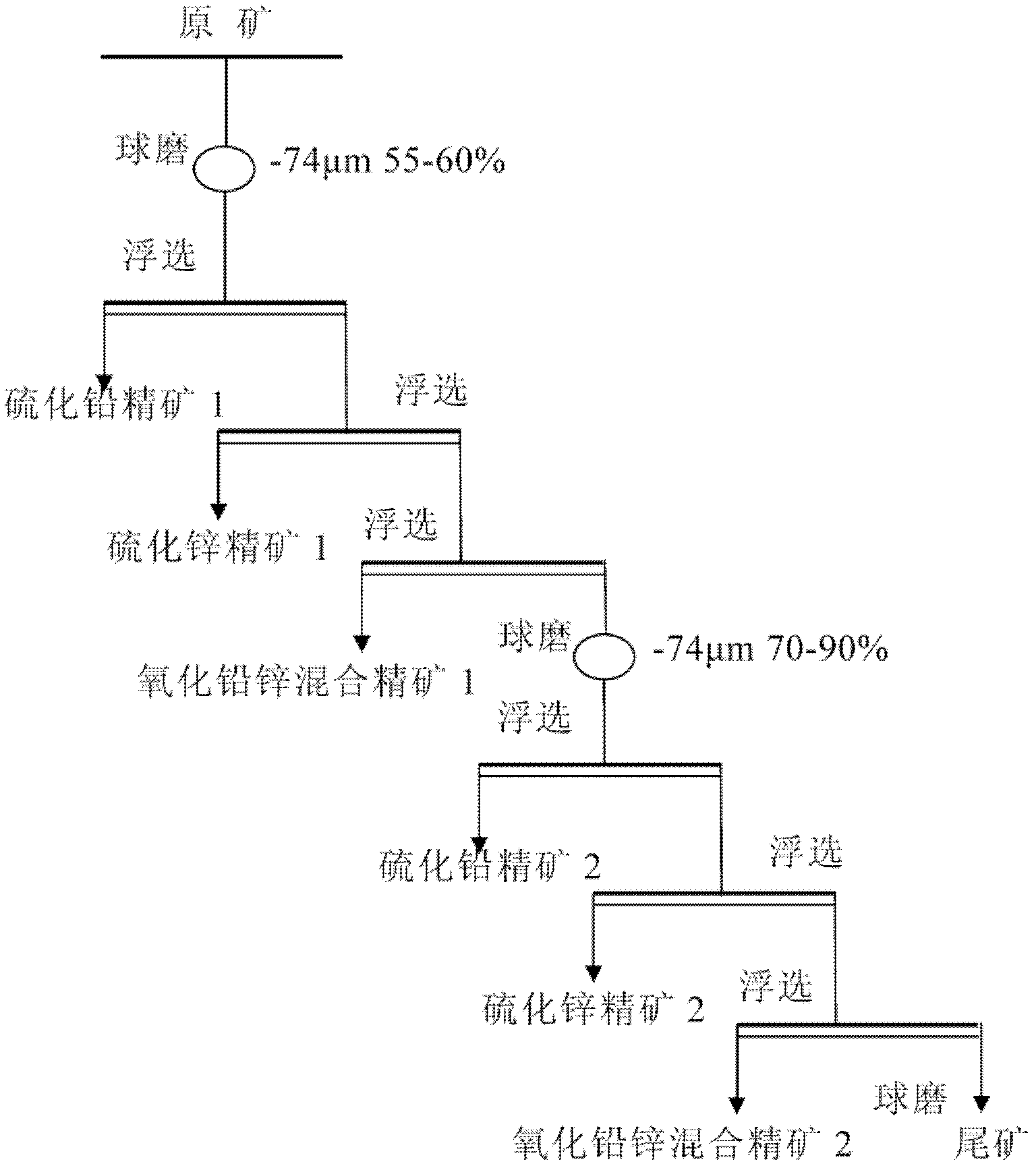

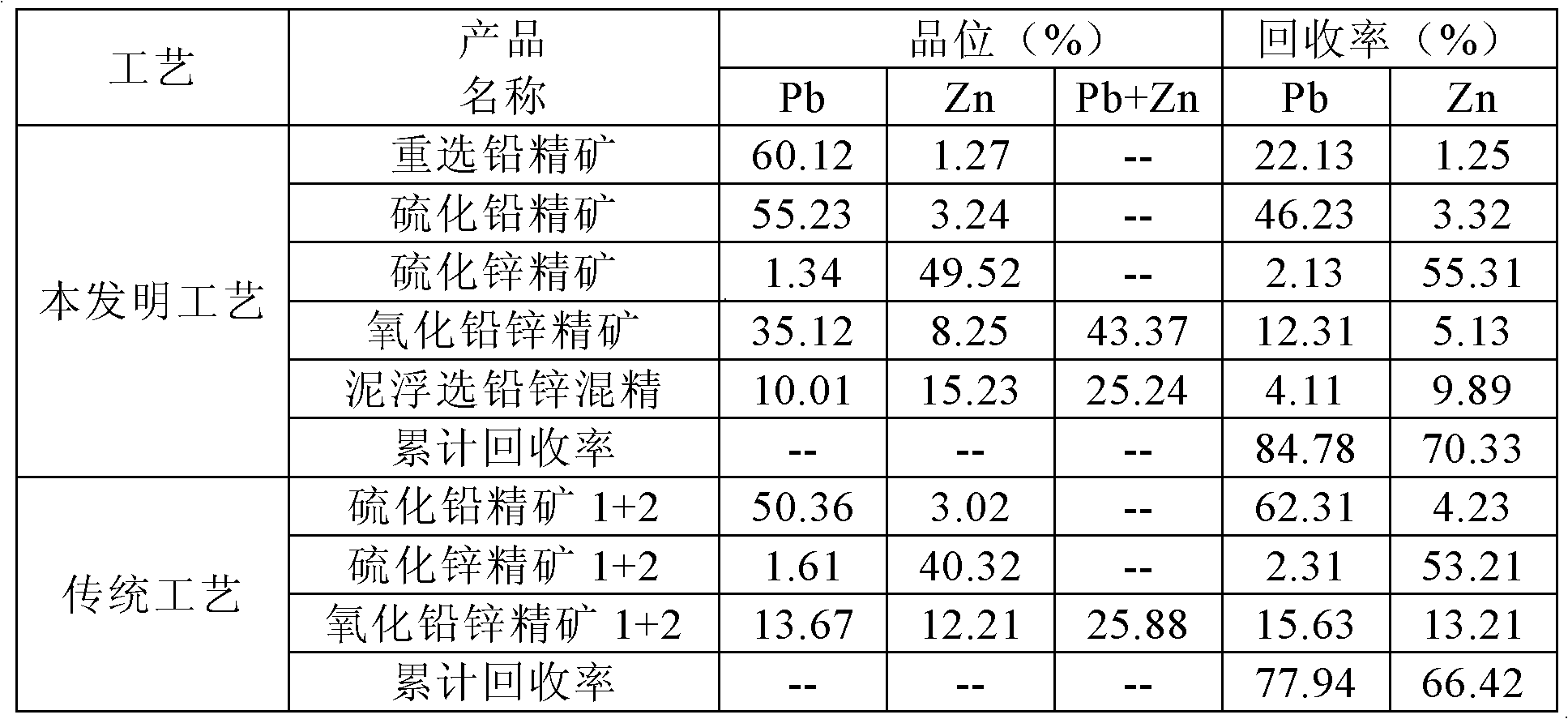

Ore dressing combination process for processing high-slime lead-zinc oxide and sulfide mixed ore

ActiveCN103182344AEasy to operateImprove technical indicatorsFlotationWet separationOxygenLead sulfide

The invention relates to an ore dressing combination process for processing a high-slime lead-zinc oxide and sulfide mixed ore. The ore dressing combination process comprises the steps as follows: crushing a raw ore and washing by a vibration sieve; carrying out primary classification on parts under the sieve and desliming fine particle fractions after primary classification through a two-stage one-closed-circuit process; combining parts over the sieve with rough particle fractions after primary classification, carrying out primary grinding, carrying out secondary classification on ground products, carrying out table-shaking gravity separation on rough particle fractions after secondary classification, and enabling fine particle fractions after secondary classification to enter a long conical cyclone for desliming; obtaining concentrate, namely lead concentrate by gravity separation, carrying out primary grinding on middlings obtained by gravity separation, combining tailings obtained by gravity separation with settled sand obtained by desliming in a short conical cyclone, carrying out ore grinding, and carrying out floatation separation to obtain lead sulfide concentrate, zinc sulfide concentrate and lead-zinc oxide bulk concentrate in sequence; and carrying out floatation separation on slime to obtain lead-zinc oxide and sulfide bulk concentrate. The ore dressing combination process is stable in operation, has very good technical indexes, and can bring very good economic benefits to enterprises.

Owner:有研资源环境技术研究院(北京)有限公司

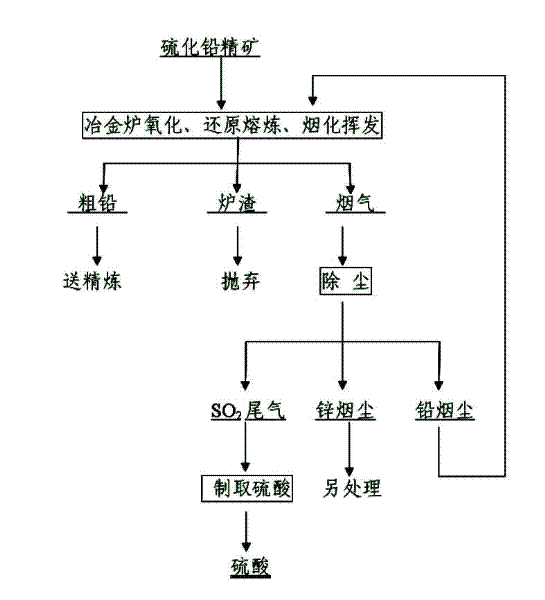

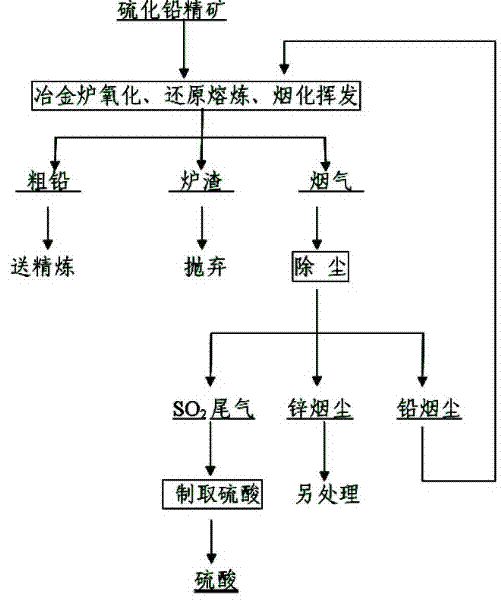

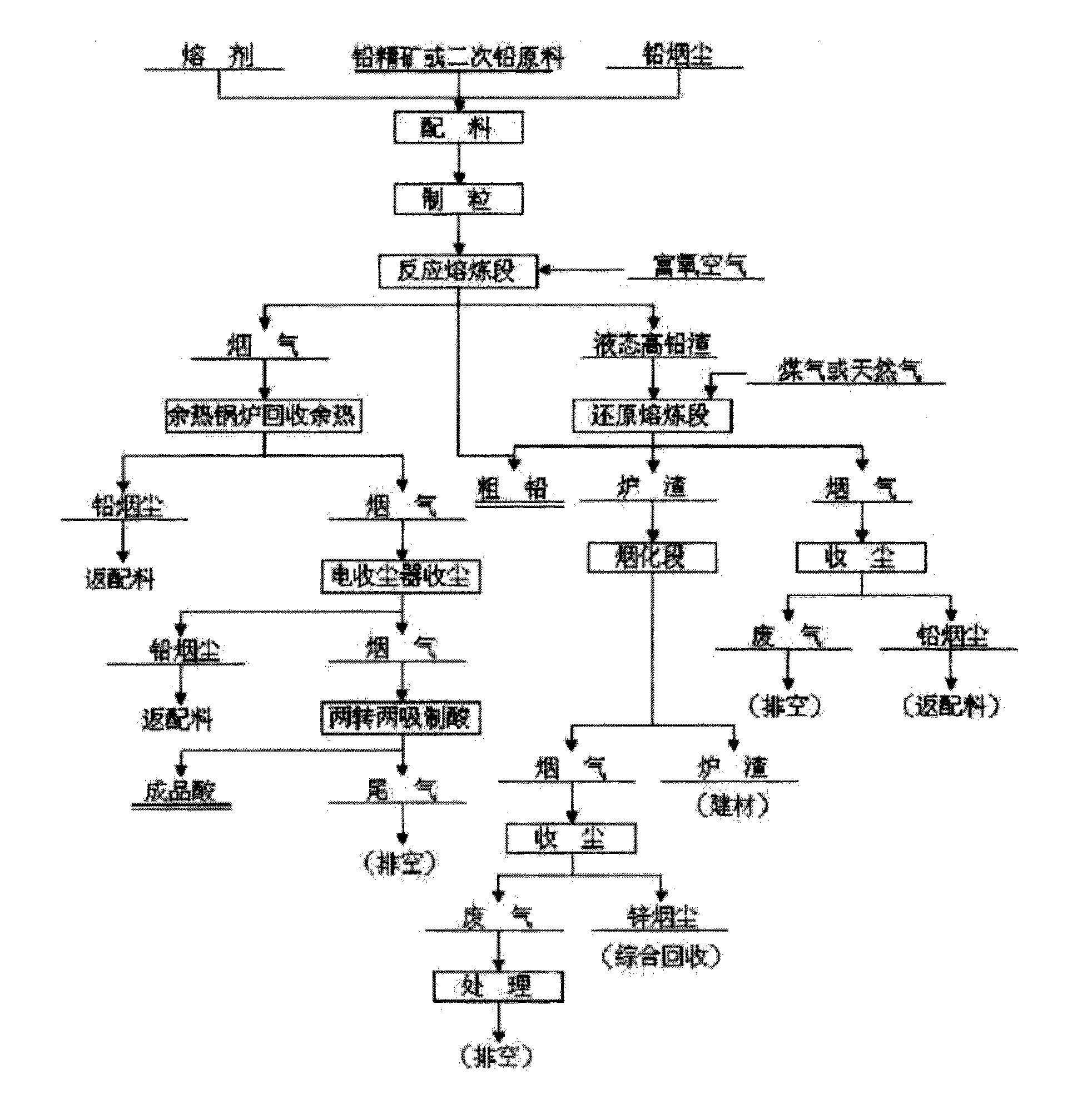

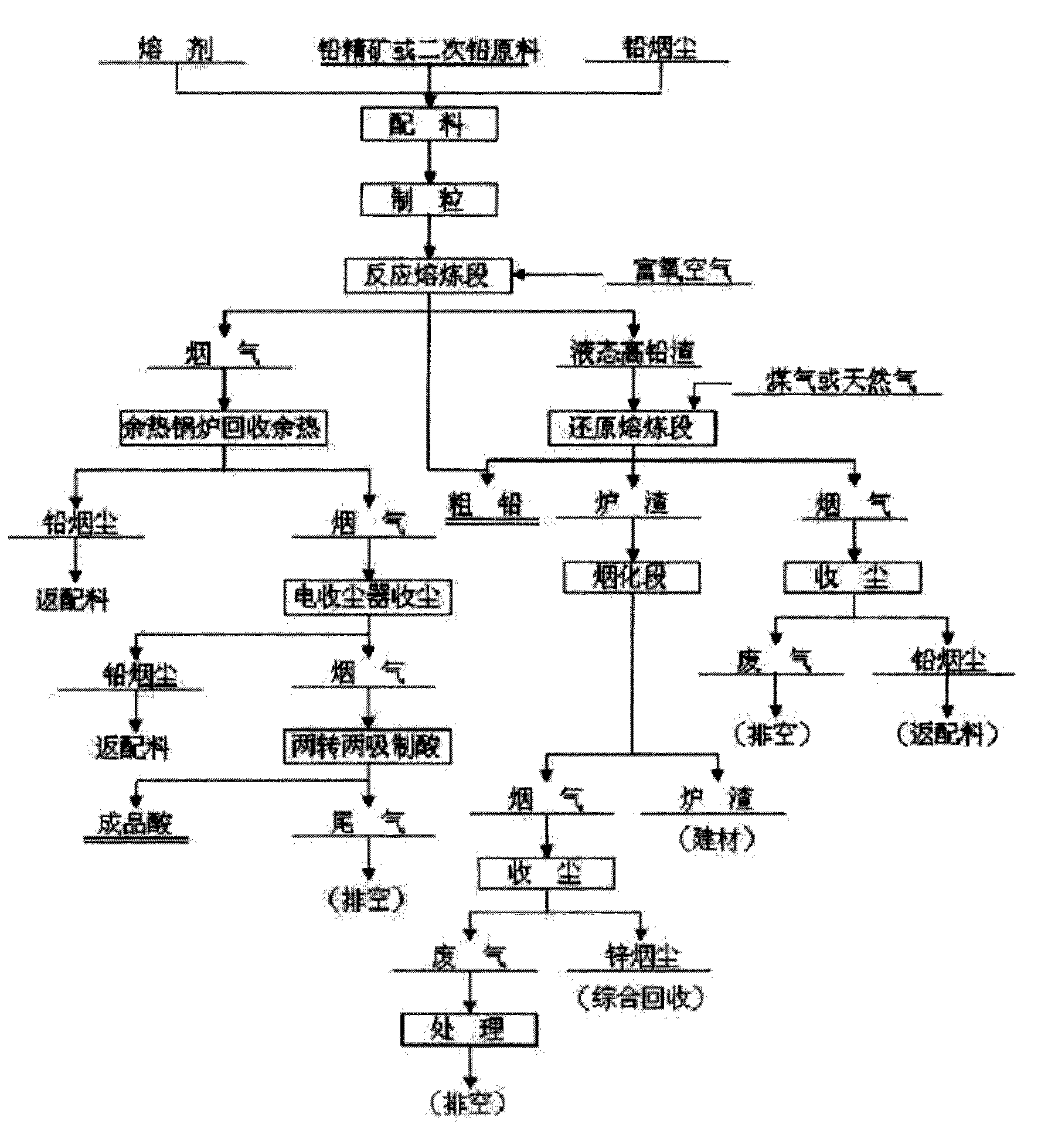

One-step oxidation smelting, reduction smelting and slag fuming and volatilization methods for lead sulfide concentrate

The invention relates to non-ferrous metal metallurgy technology, in particular to the pyrometallurgy technology of lead sulfide concentrate. The process method is to successively carry out three smelting processes of oxidation smelting, reduction smelting and fuming volatilization in the same metallurgical furnace to smelt lead sulfide concentrate, and smelt crude lead, zinc fume and discardable slag in one step. In the oxidation smelting stage, after the feed reaches the set amount, the lead oxide slag is not released, and the high-temperature liquid slag is directly used in the furnace to transfer to the reduction stage of the lead oxide slag, and the smoke generated by oxidation smelting and reduction smelting is returned to the furnace for smelting. After the reduction is completed, all the crude lead is released, and the high-temperature liquid slag remains in the furnace, and it enters the slag fuming stage, and the zinc fume dust from the slag fuming is recovered and enters the next smelting cycle. The heat of the slag in the invention is fully utilized, and the energy-saving effect is obvious. The raw material preparation of the method is simple, the reducing agent only needs ordinary anthracite, and part of the fuel that needs to be supplemented in the reducing section and the fuming section is pulverized coal, which is low in value and easy to obtain.

Owner:YUNNAN TIN GROUP HLDG

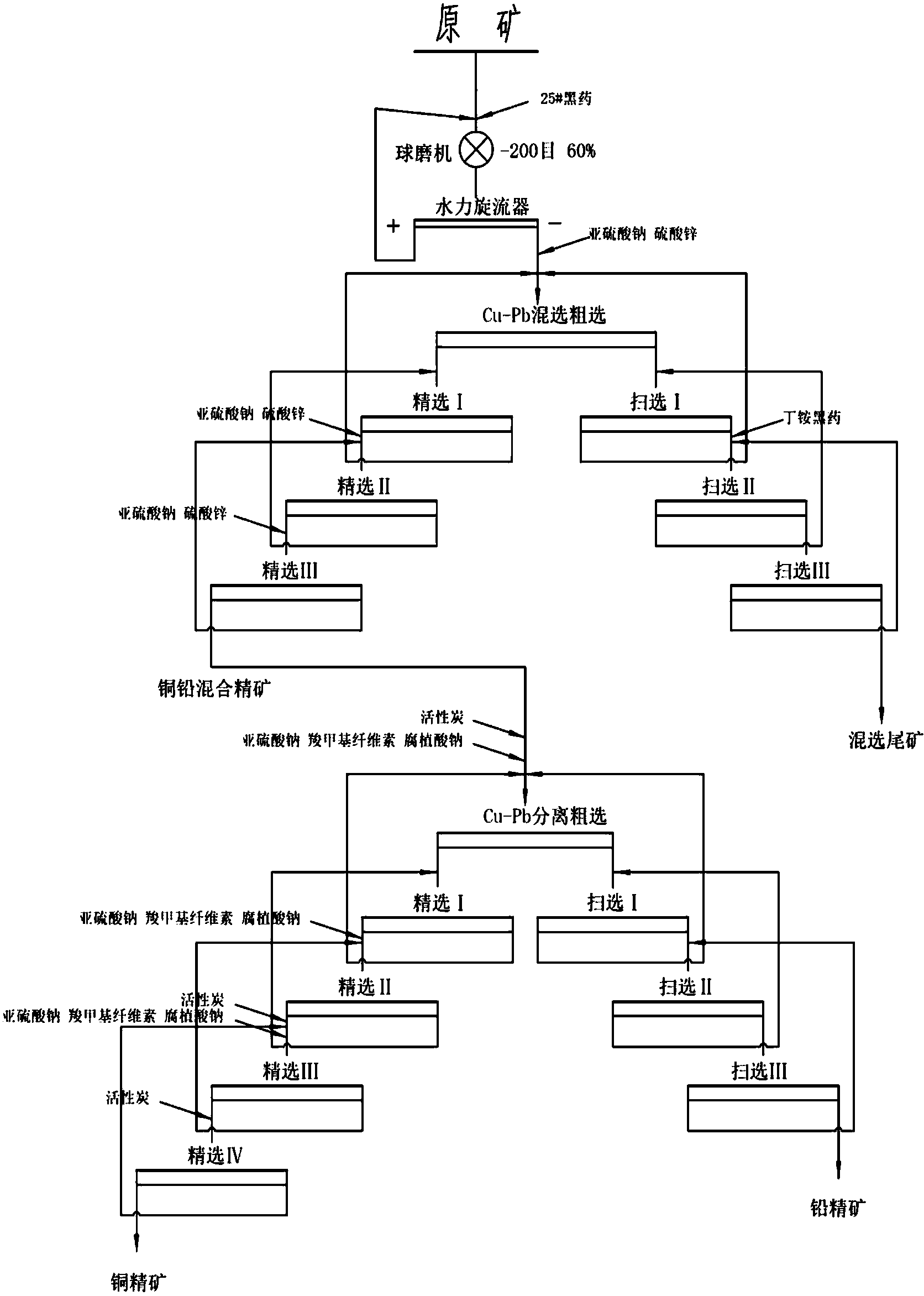

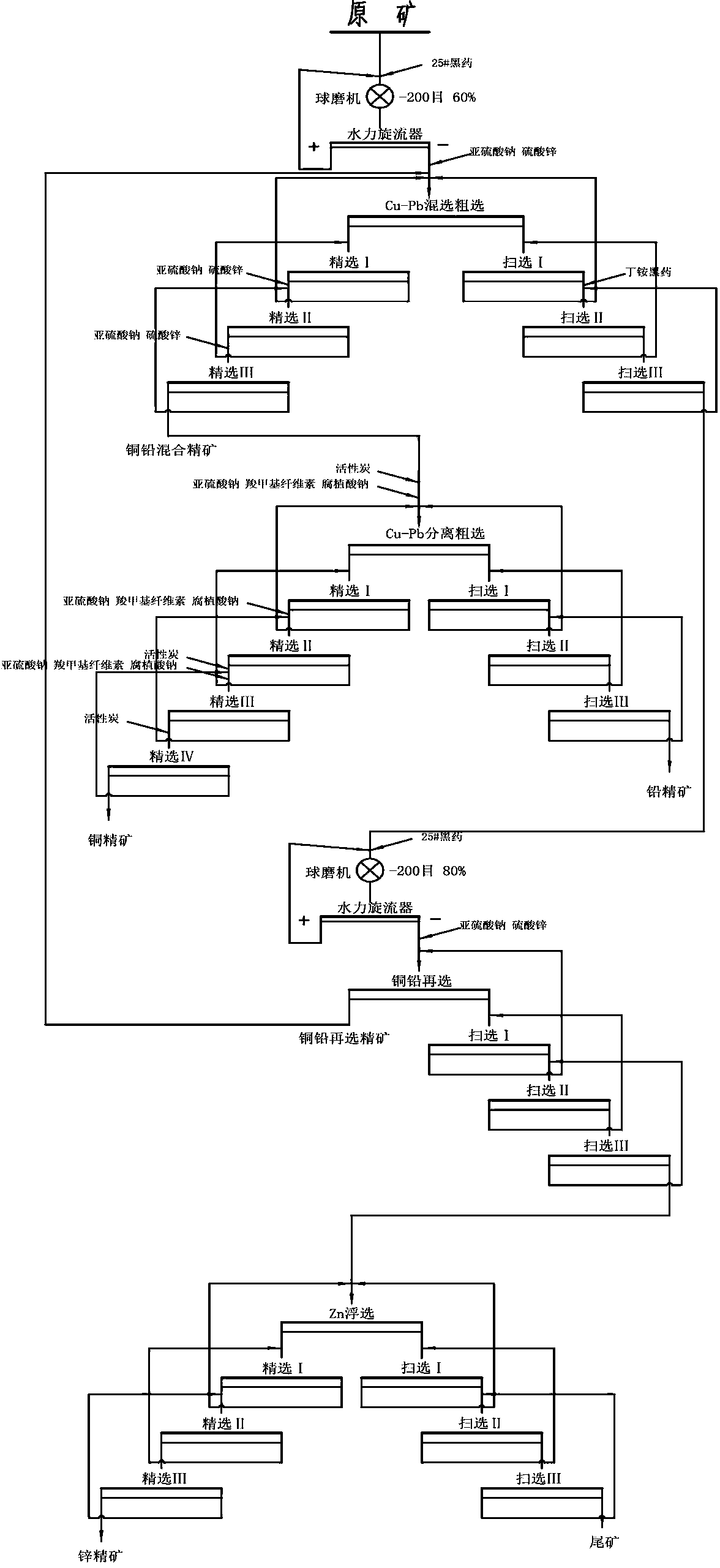

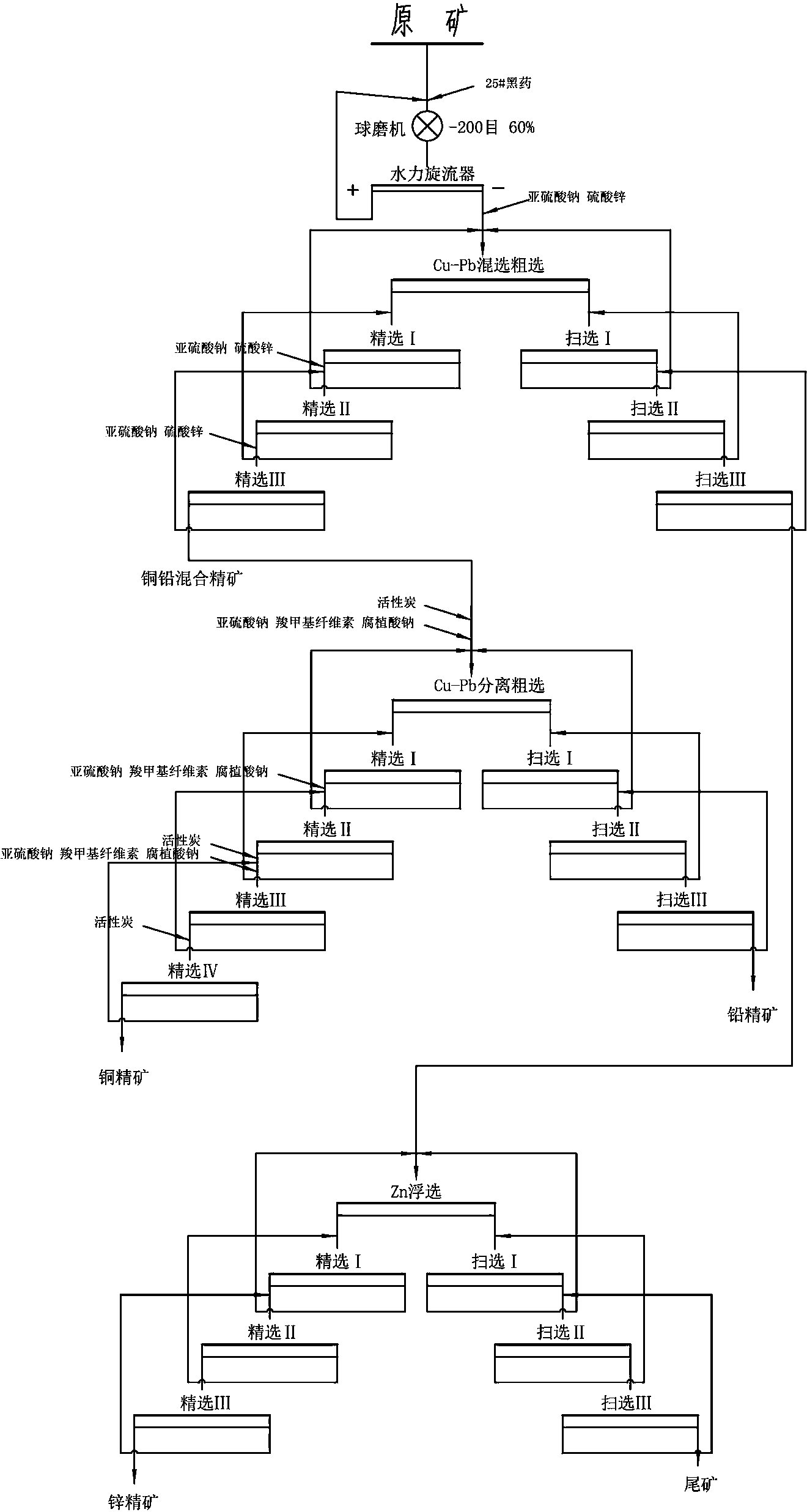

Copper and lead separating cyanide-chrome-free beneficiation method for low-grade multi-metal sulfide ore

The invention discloses a copper and lead separating cyanide-chrome-free beneficiation method for low-grade multi-metal sulfide ore. The beneficiation method is performed according to the following steps that (1) raw ore after ore grinding and grading enters the step of copper and lead bulk flotation to obtain copper and lead bulk concentrate and bulk flotation tailings, beneficiation reagents including 25# black powder and tetrabutyl ammonium black powder are adopted as collecting agents for copper and lead ore, and sodium sulfite and zinc sulfate are adopted as inhibitors of zinc ore; (2) copper and lead separating flotation is performed on the copper and lead bulk concentrate to obtain qualified copper concentrate and lead concentrate, in the copper and lead separating flotation process, activated carbon is adopted for reagent removal, and an inhibitor combined by sodium sulfite, sodium carboxymethyl cellulose and sodium humate serves as the inhibitor of lead sulfide ore. The beneficiation method has the following advantages of being low in price and production and application cost, it is unnecessary to perform special treatment on ore pulp, the process is easy to control, and technological and economic indexes are stable. The great defect that a dichromate titration method, a cyanide method and a less-cyanide-chrome technology can cause pollution to the environment is overcome, and the usage amount of beneficiation new water is greatly reduced.

Owner:XINBARHU YOU BANNER RONG DA MINING LLC

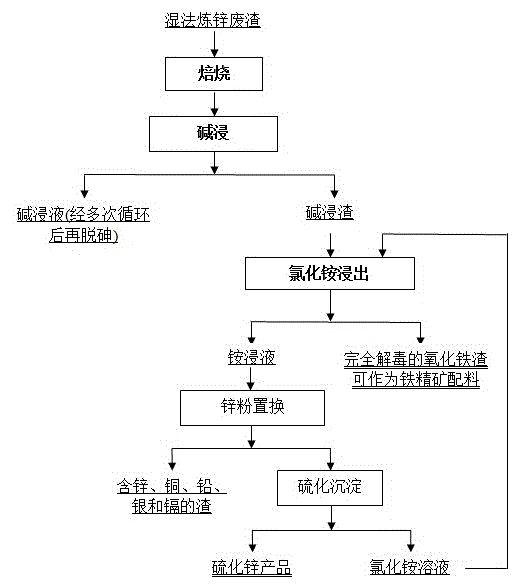

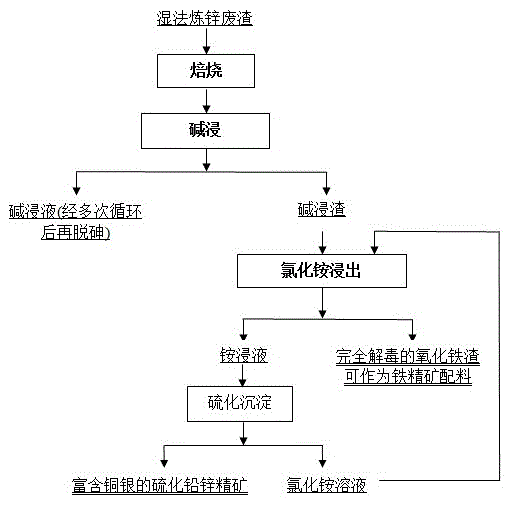

Method for treating zinc hydrometallurgy waste residue by using alkali ammonium sulfur coupling method

The present invention discloses a method for treating zinc hydrometallurgy waste residue by using an alkali ammonium sulfur coupling method, relates to a method for comprehensive utilization of lead silver residue and iron alum residue in zinc hydrometallurgy waste residue by using a alkali ammonium sulfur coupling clean metallurgical method, and belongs to the field of metallurgical hazardous solid reside treatment, wherein the method can further be used to treat other complex waste containing lead and zinc. According to the method, a medium temperature calcination method is performed on zinc hydrometallurgy residue; then an alkali leaching treatment is performed; then the leached alkali residue is leached with ammonium chloride; the resulting alkali leaching liquid is replaced by zinc powder to obtain residues containing zinc, copper, lead, silver and cadmium, and a solution; the solution is subjected to precipitation by using a sulfide to obtain a zinc sulfide product and an ammonium chloride solution; or after the ammonium chloride is leached, the resulting leaching liquid is directly treated by using a precipitating agent, and then is filtered to obtain a lead-zinc sulfide concentrate containing copper and silver and an ammonium chloride solution. With the method of the present invention, valuable metal resources in zinc hydrometallurgy residue can be subjected to effective comprehensive recovery, harmlessness and resource of the final residue are achieved, and good environmental benefits and economic benefits can be achieved.

Owner:KUNMING UNIV OF SCI & TECH

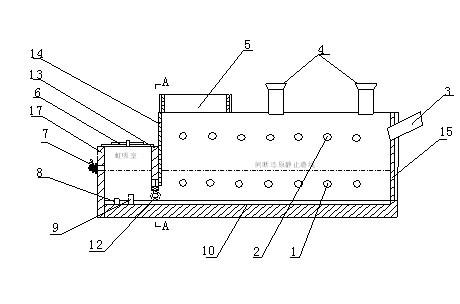

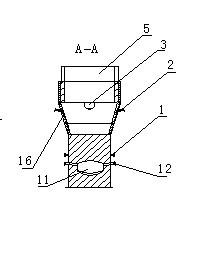

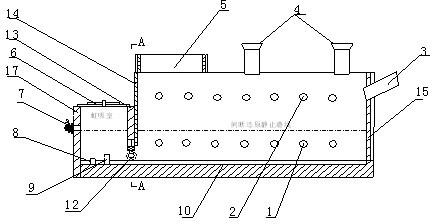

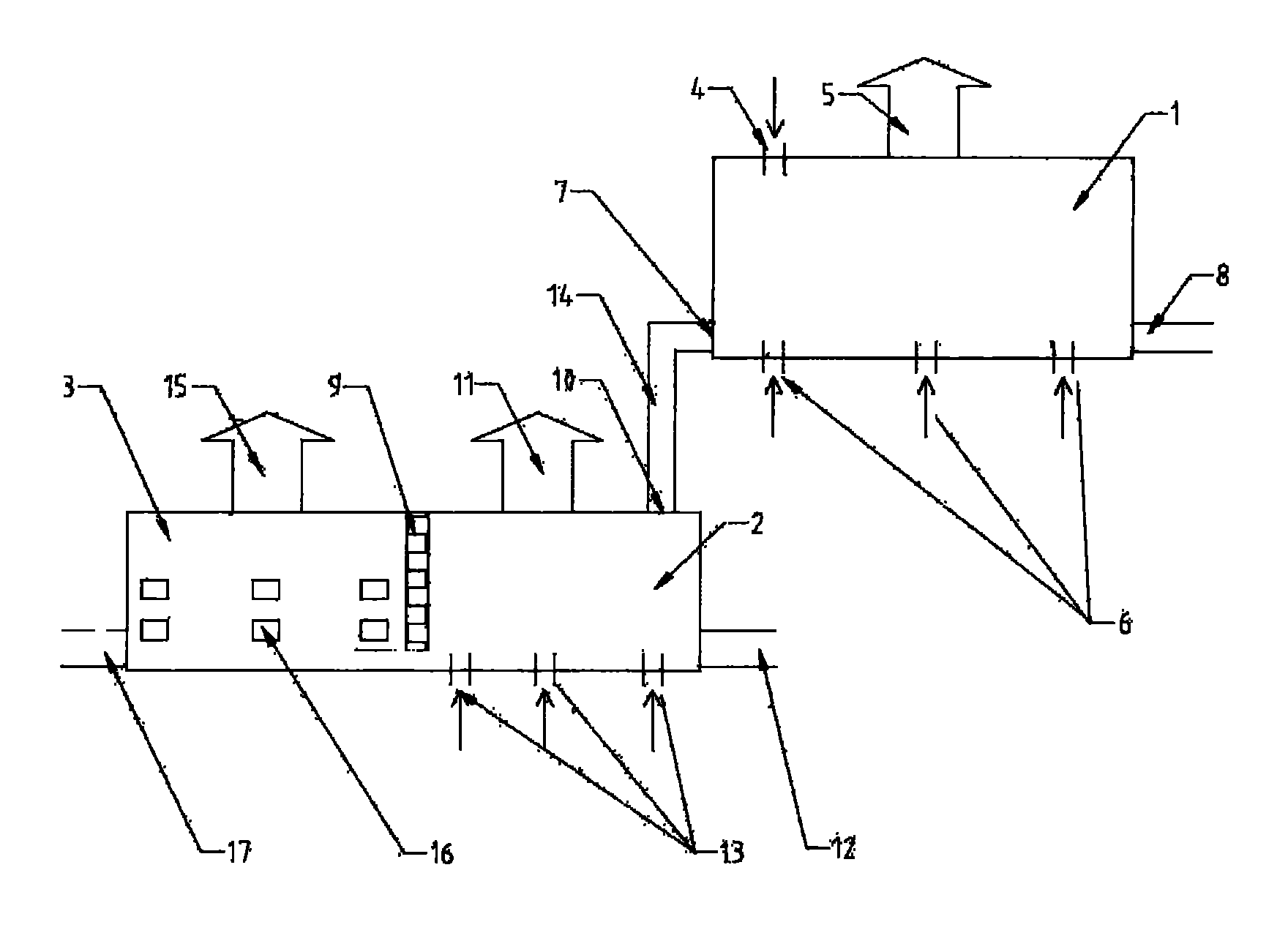

Smelting method and device for molten oxidized lead slag

InactiveCN102618729AReduce the amount of smokeImprove energy savingFurnace typesProcess efficiency improvementFlue gasSlag

The invention discloses a smelting method and device for molten oxidized lead slag. The smelting method comprises the following steps of: enabling high-lead slag melt obtained by oxidization and smelting of a lead sulfide concentrate melting pool to flow into a rectangular reduction furnace through a chute, spraying oxygen-enriched air into molten high-lead slag melt through air openings at two side walls of the rectangular reduction furnace, and adding coal granules or coke granules from a feeding port arranged at the top of the reduction furnace; under strong stirring of the oxygen-enrichedair, fully mixing the coal granules or the coke granules with the high-lead slag for reaction, realizing the cyclic operation of feeding, reduction, deslagging and refeeding of molten high-lead slag in the reduction furnace of the melting pool, heating and stirring a stagnant slag layer in the melting pool by a temperature rising port arranged at the side wall of the reduction furnace at a certain time interval, and after reduction, producing crude lead, flue gas, fume and reduced slag. The smelting method and device have the advantages that the flue-gas amount is less, and the energy-saving effect is obvious; and the amount of lead in the reduced slag is reduced and the recovery rate of the lead in the reduction process is high.

Owner:CENT SOUTH UNIV

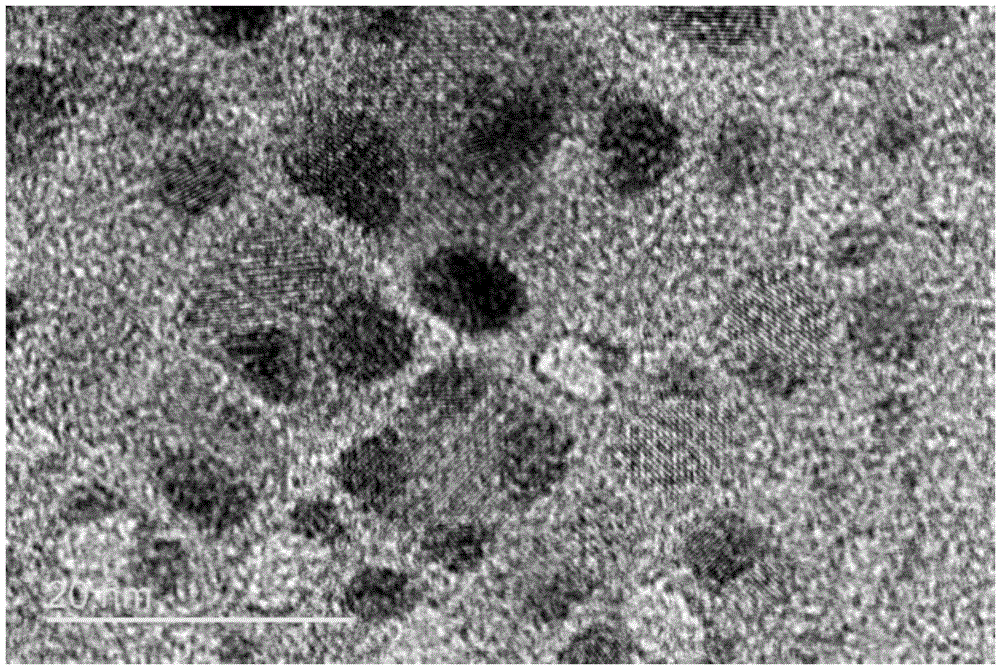

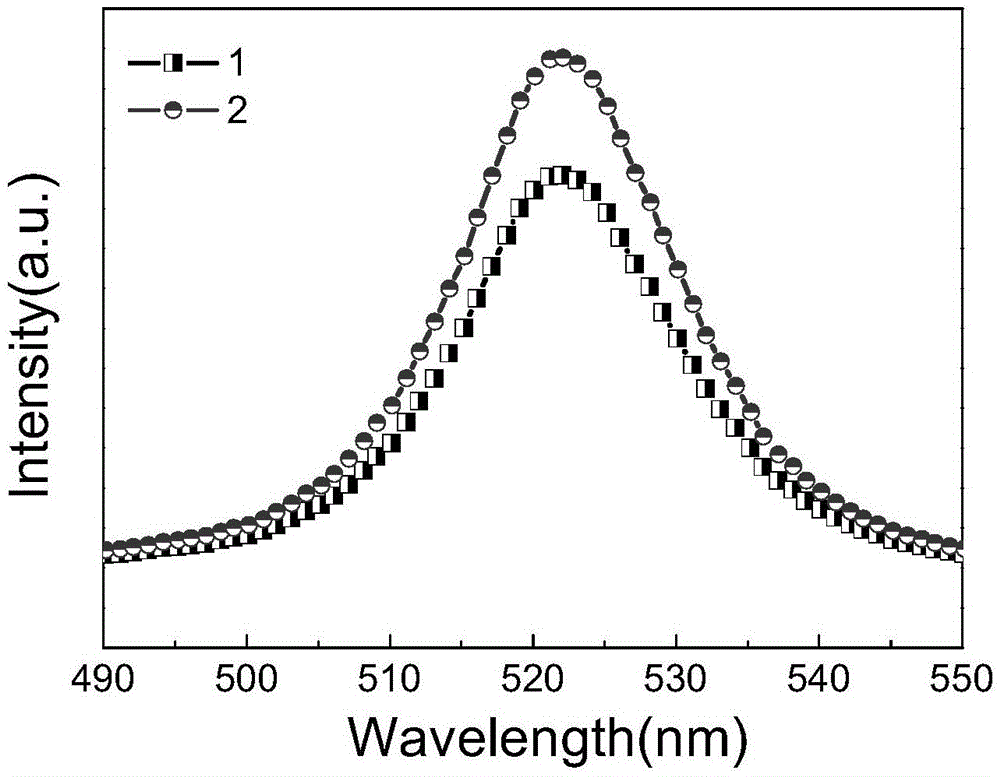

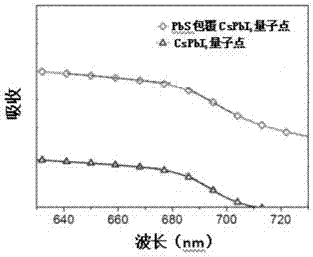

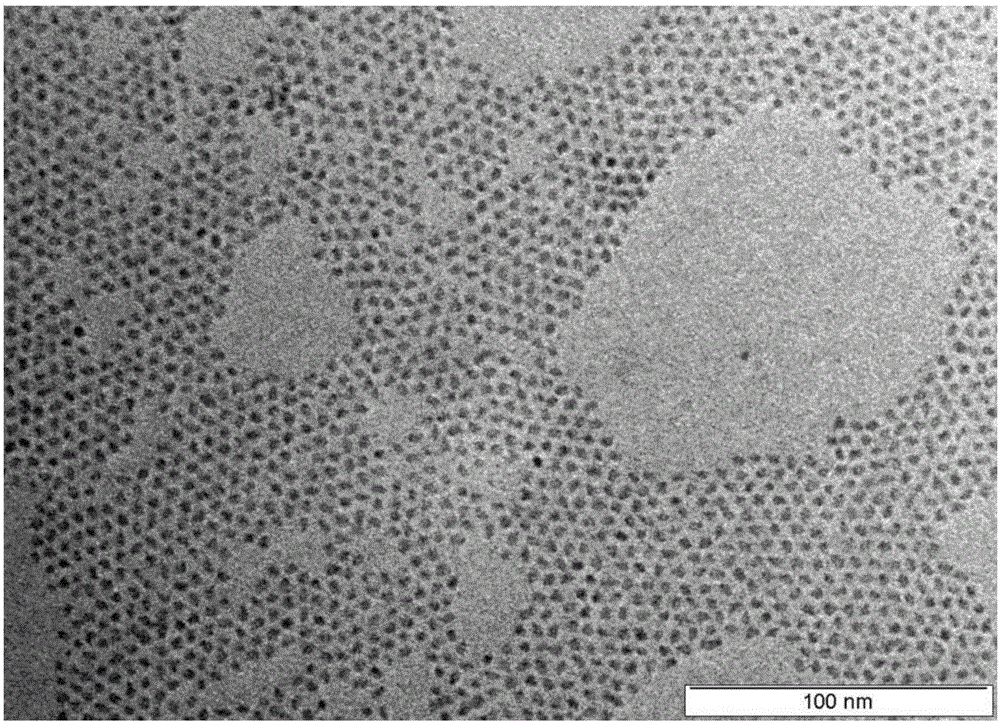

Method for synthetizing high-stability metal halide perovskite/lead sulfide heterostructure nanocrystals

ActiveCN105602560AImprove stabilityImprove efficiencyNanotechnologyLuminescent compositionsSynthesis methodsSolvent

The invention discloses a method for synthetizing high-stability metal halide perovskite / lead sulfide heterostructure nanocrystals. The method comprises the following steps: firstly mixing lead halide with reactive solvent oleic acid, organic amine with long alkyl chains and octadecene in the presence of an inert gas so as to completely dissolve lead halide; then heating a mixed solution to 160-200 DEG C, rapidly injecting a caesium precursor, and reacting to generate CsPbX3; cooling to room temperature, then sequentially injecting a sulphur precursor and a lead precursor, and stirring for reaction, thereby finally obtaining the CsPbX3 / PbS heterostructure nanocrystals. The synthetized CsPbX3 / PbS heterostructure nanocrystals are uniform in appearance; the synthesis method is simple; due to epitaxial growth of lead sulfide, the perovskite performance stability is improved, and the CsPbX3 / PbS heterostructure nanocrystals are enhanced in light-emitting efficiency and are beneficial to later-stage photoelectric device assembly.

Owner:NANJING UNIV OF SCI & TECH

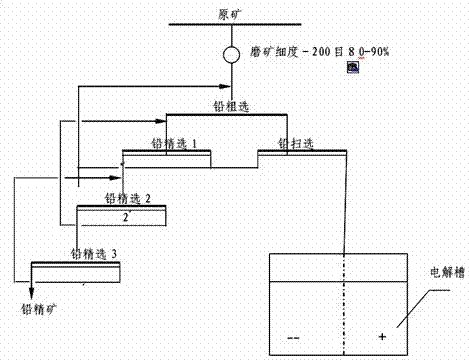

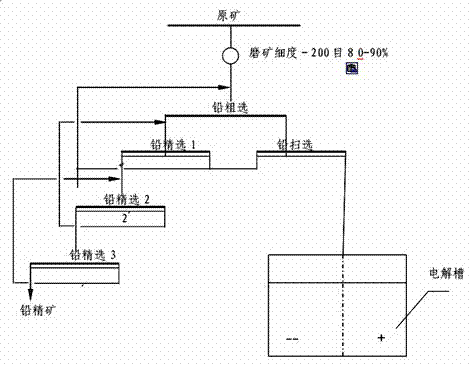

Flotation method for lead and zinc sulfide ores

The invention discloses a flotation method for lead and zinc sulfide ores. The method comprises the following steps of: crushing the lead and zinc sulfide ores through a crushing process in three sections of closed route; grinding the ores through two sections of closed route, wherein powder with the ore grinding granularity of -200 meshes is up to 80 to 90 percent; after grinding the ores, adding a catching agent, an inhibitor, a foaming agent and a pH regulator to perform differential flotation on lead, wherein lead concentrate is obtained by performing rough concentration for one time, scavenging for one time and fine concentration for three times on the ores; and putting the tailings obtained after lead scavenging into an electrolyte tank to perform flotation on zinc through an electrolytic method to obtain zinc concentrate. Because the electrolytic method is adopted to separate minerals in the method, the using amount of medicinal agents is reduced, the cost is reduced, the pollution to environment is reduced, and the extraction rate is increased.

Owner:KUNMING UNIV OF SCI & TECH

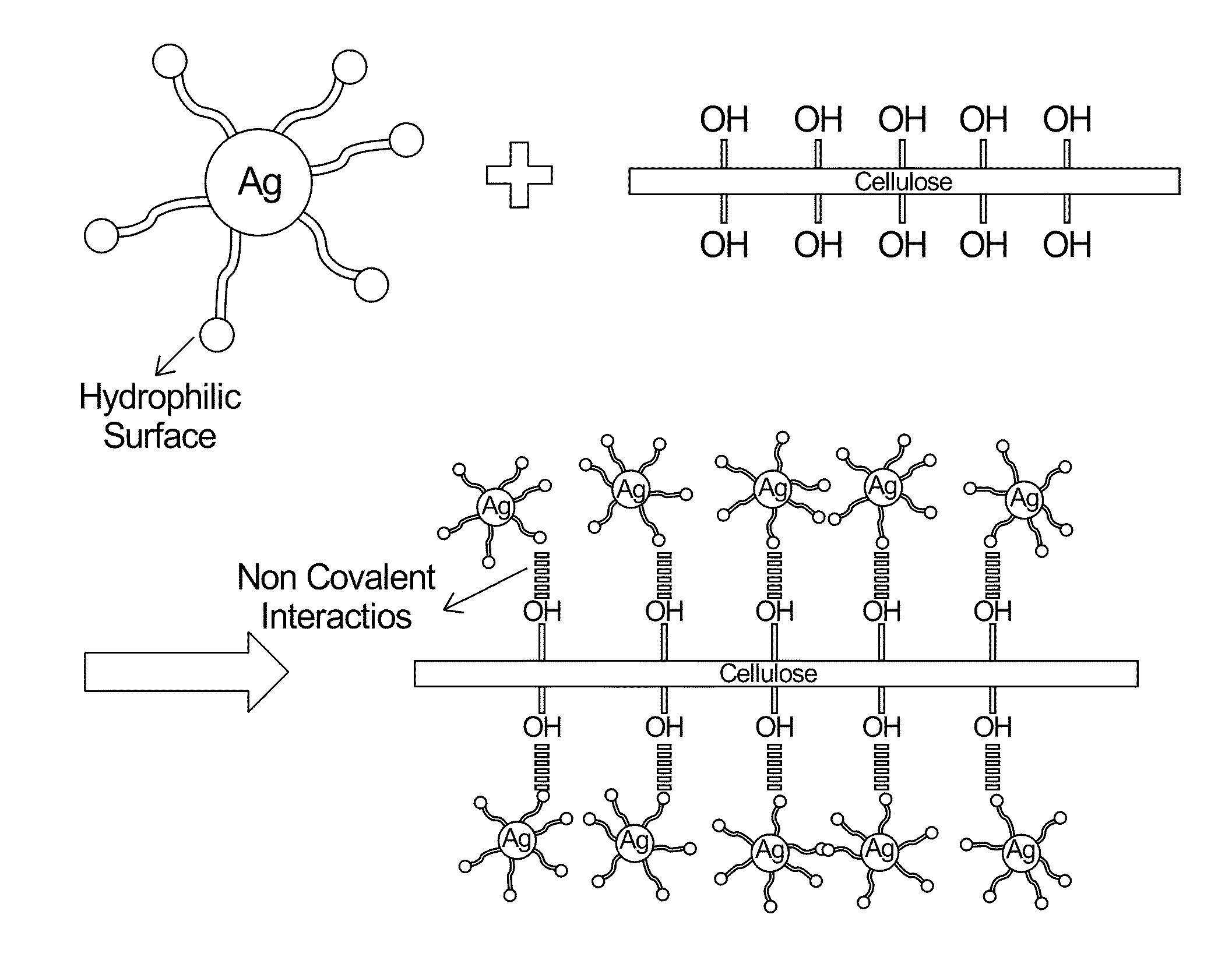

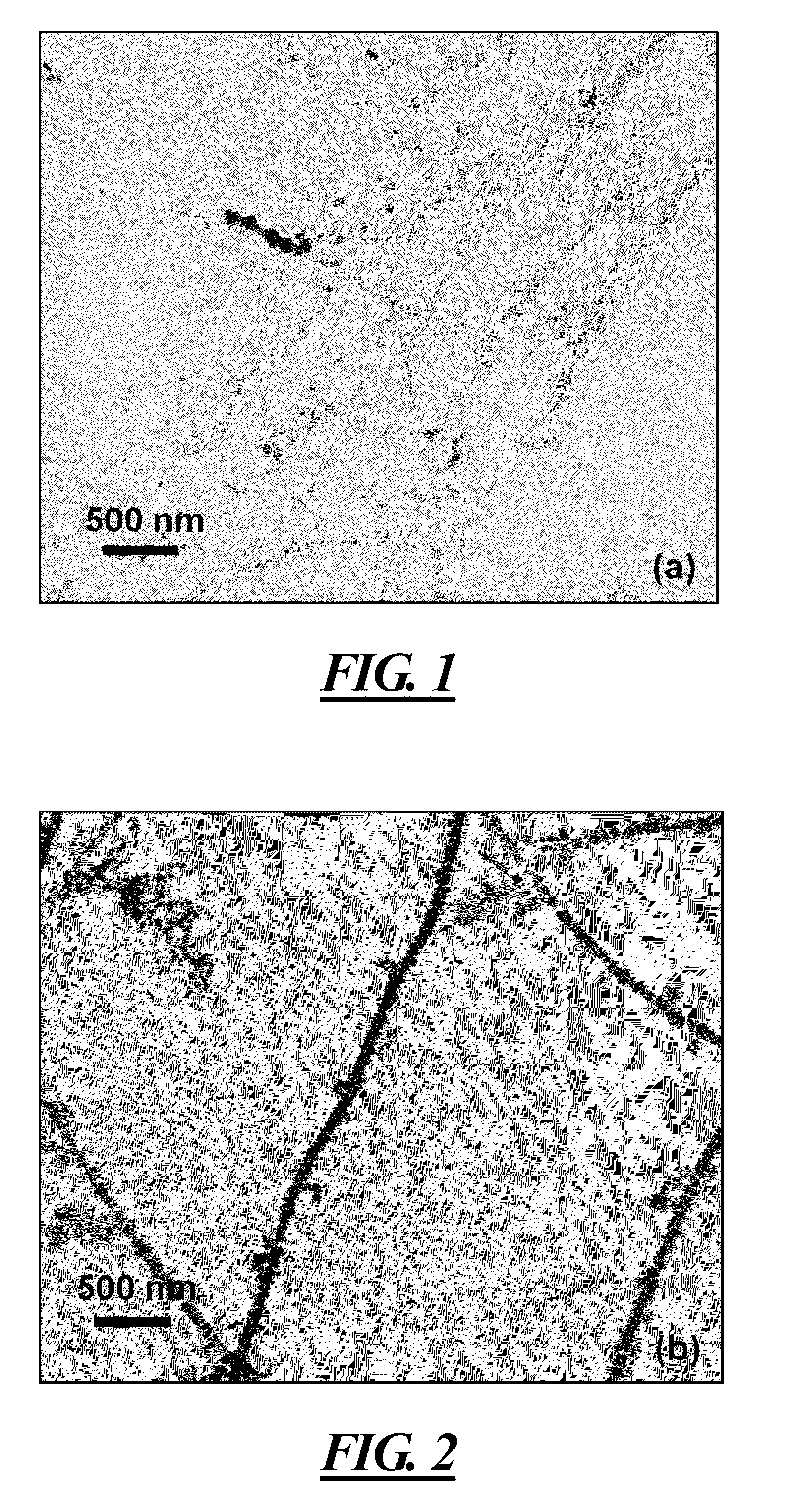

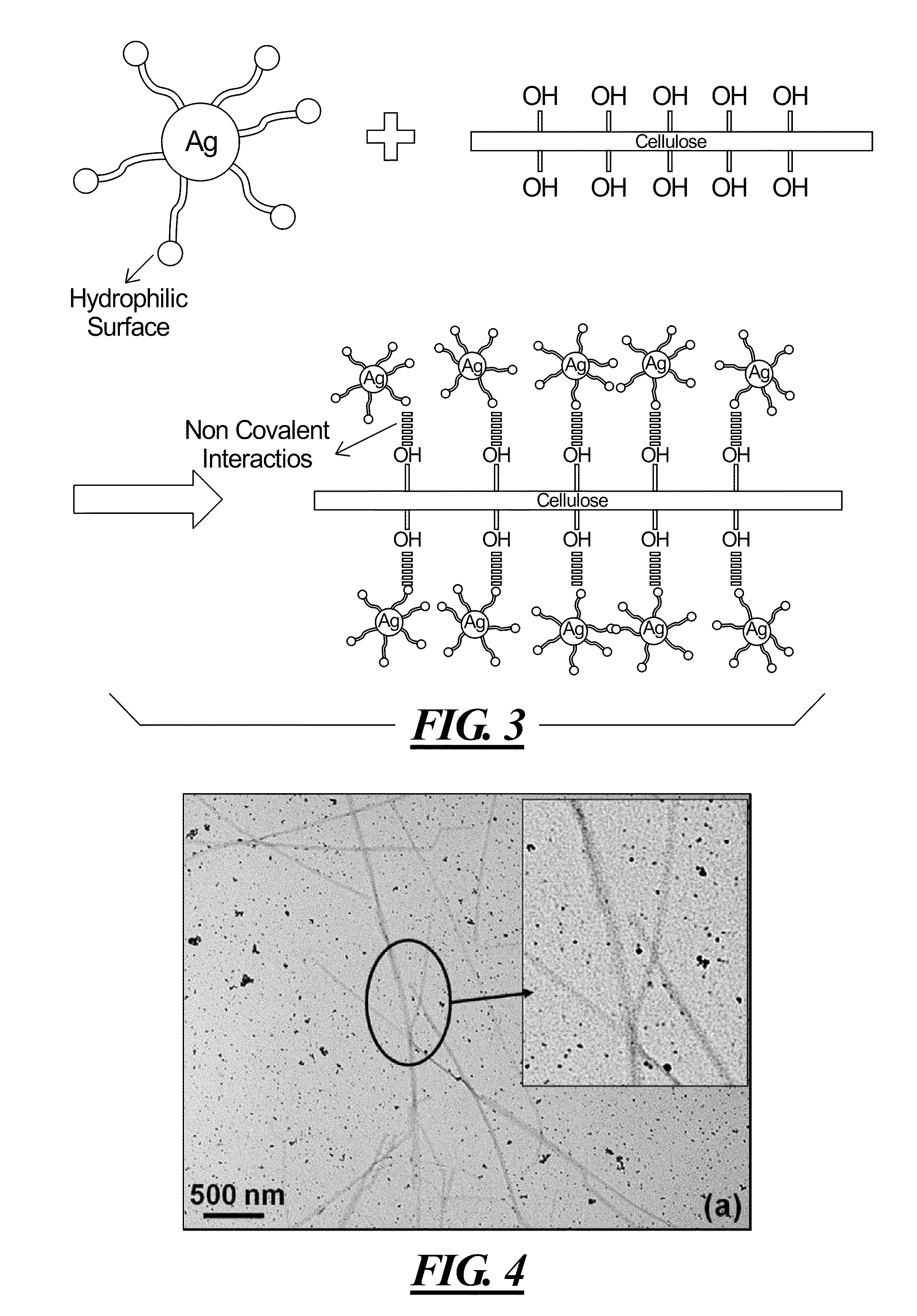

Surfactant-Assisted Inorganic Nanoparticle Deposition on a Cellulose Nanocrystals

Natural biopolymers in the form of cellulose nanocrystals (CNC) are shown to have the required characteristics to serve as chemically reactive biotemplates for metallic and semiconductor nanomaterial synthesis. Silver (Ag), gold (Au), copper (Cu) and platinum (Pt), cadmium sulfide (CdS), zinc sulfide (ZnS) and lead sulfide (PbS) nanoparticles, nanoparticle chains and nanowires may be synthesized on CNCs by exposing metallic precursor salts to a cationic surfactant, cetyltrimethylammonium bromide (CTAB), and a reducing agent. The nanoparticle density and particle size may be controlled by varying the concentration of CTAB, pH of the salt solution, as well as the reduction time or reaction time between the reducing agent and the metal precursor.

Owner:US SEC AGRI +1

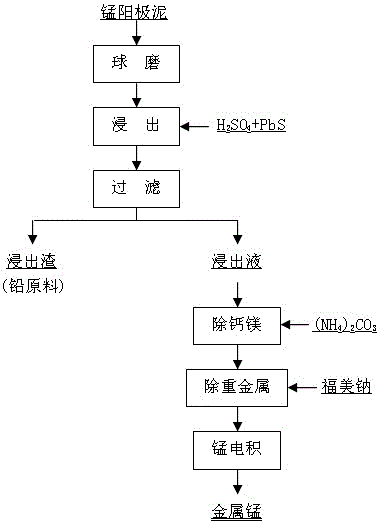

Method for comprehensively recycling manganese, lead, silver and selenium from manganese anode slime

ActiveCN106544511AWide variety of sourcesLow costPhotography auxillary processesProcess efficiency improvementLead smeltingElectrolysis

The invention provides a method for comprehensively recycling manganese, lead, silver and selenium from manganese anode slime. The method comprises the steps that firstly, the manganese anode slime, lead sulfide concentrate and ball milling liquid are mixed and subjected to wet-type ball milling; secondly, leaching of valuable metals such as manganese and selenium is conducted, leachate is reserved, and leached residues serve as lead smelting raw materials for recycling lead and silver; thirdly, a calcium-magnesium removing agent is added for impurity removing; and fourthly, a neutralizer, namely, ammonium hydroxide, and ammonium sulfate are added, a cleaning agent, namely, sodium dimethyl dithiocarbamate is dropwise added, and after stewing is conducted, activated carbon is added for adsorption, filter pressing is conducted, an electrolyzing additive is dropwise added into filtrate, and electrolytic manganese metal is prepared through electrolyzation. The method is small in investment, simple in technology, low in cost and capable of effectively increasing the comprehensive recovery rate.

Owner:ZHUZHOU SMELTER GRP

Method for preparing polyferric chloride flocculant by using steel wire rope sludge and waste salt

ActiveCN105271436AExcellent purificationReduce turbidityIron halidesWater/sewage treatment by flocculation/precipitationSludgeSulfide

The invention discloses a method for preparing a polyferric chloride flocculant by using steel wire rope sludge and waste salt. According to the method, the steel wire rope pickling sludge is dissolved in waste hydrochloric acid, lead ions in the dissolved solution are removed with a sulfide precipitation method, and the polyferric chloride flocculant is obtained; produced hydrogen sulfide gas meets the national odor pollutant emission standard after being subjected to falling-film absorption, packed tower absorption and activated carbon adsorption treatment, and meanwhile, whole-process sulfur element recycling is realized; cement is added to sludge residues for curing, and heavy metals are cured and stabilized. With the adoption of the method, the recovery rate of iron in the sludge is higher than 90%, the produced polyferric chloride flocculant has excellent performance in purification of domestic sewage, and produced lead sulfide meets the industrial purity requirement and can be used as an industrial raw material. With the adoption of the method, harmless disposal and resource utilization of the steel wire rope pickling sludge and the waste hydrochloric acid are realized simultaneously.

Owner:刘阳生

Continuous lead smelting clean production process

InactiveCN102031393APrevent escapeImprove recycling ratesProcess efficiency improvementLead smeltingLiquid state

The invention discloses a continuous lead smelting clean production process. The process comprises the following steps of: proportioning materials such as lead sulfide concentrate or a secondary lead raw material, a flux, lead dust and the like as required; performing a mixed granulation process; feeding a reaction smelting section of the entire equipment; smelting by an oxygen enriched bottom blowing method; directly feeding liquid-state high-lead slag into a reduction smelting section to perform reduction smelting so as to produce coarse lead; and directly feeding the reduced liquid-stage slag into a fuming section to perform fuming treatment so as to comprehensively recover valuable metals from the liquid-stage slag. Therefore, continuous clean production is realized in the true sense.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

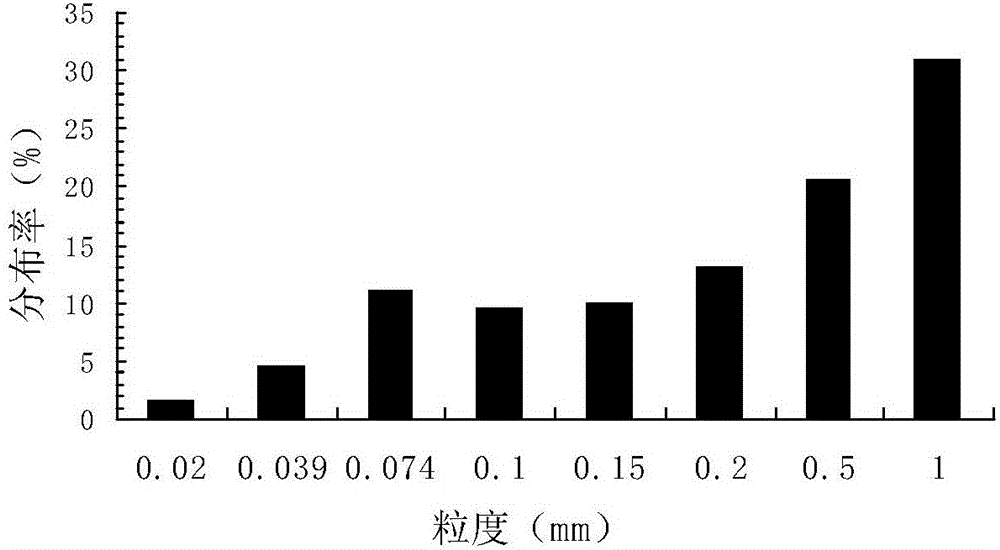

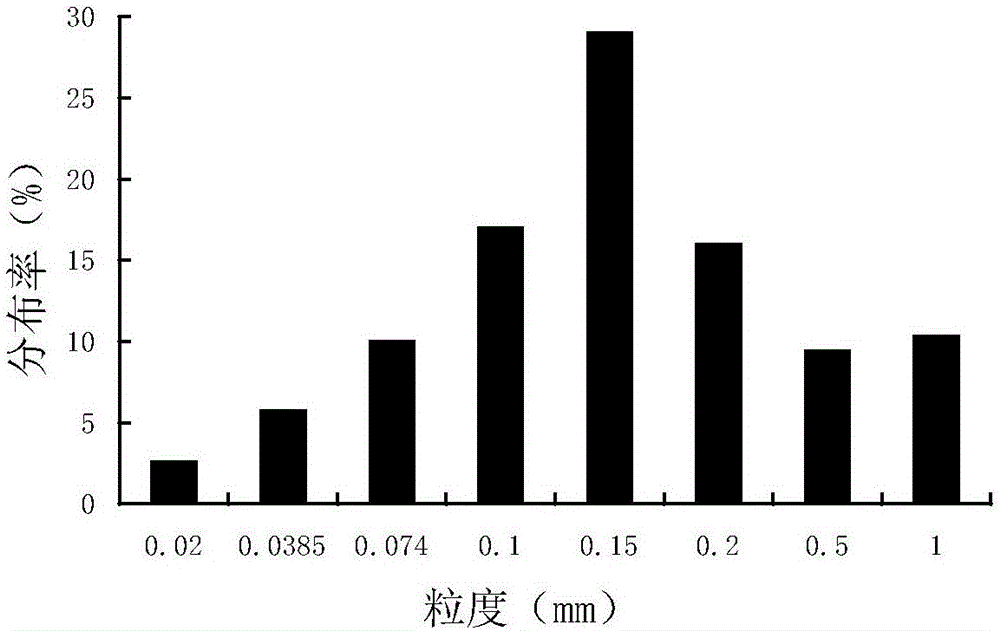

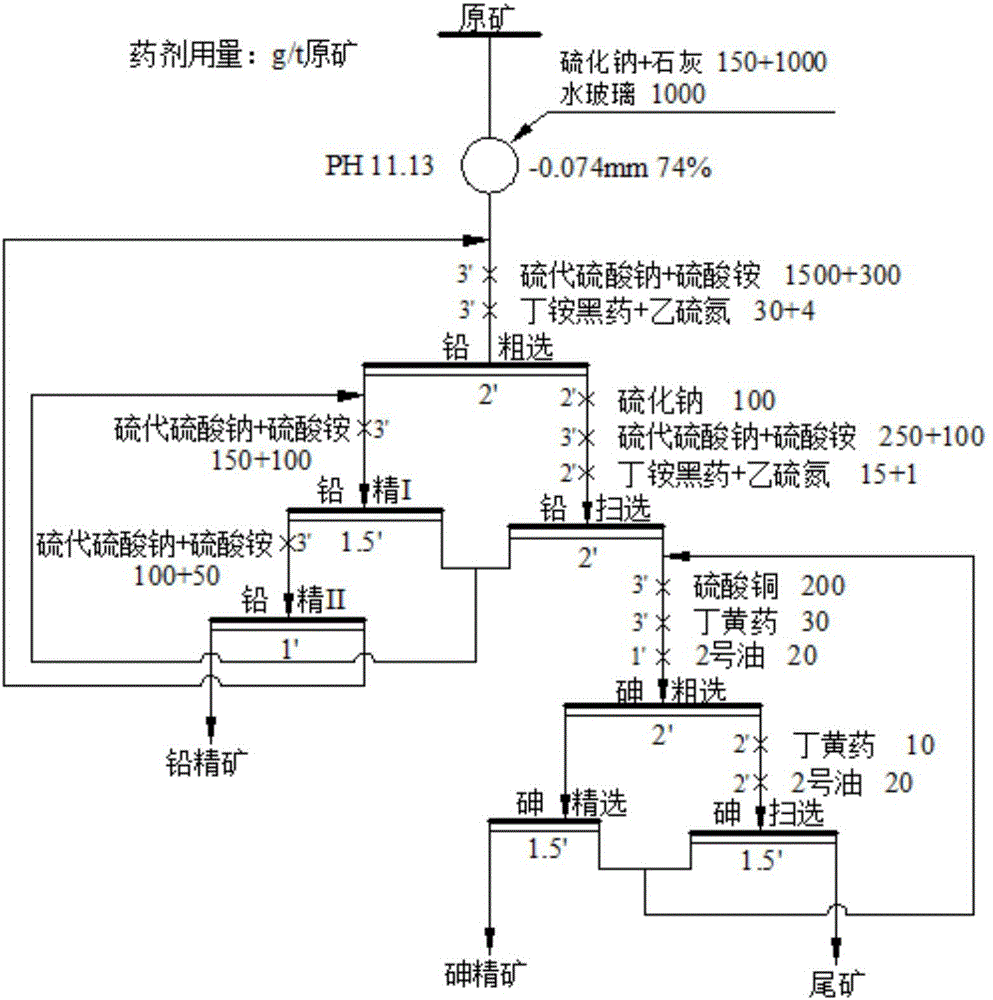

Beneficiation method for arsenic-containing lead sulfide ore

Provided is a beneficiation method for arsenic-containing lead sulfide ore. The method comprises the steps that 1, raw ore is ground; 2, ore powder obtained through grinding is subjected to flotation, one time of roughing, two times of scavenging and two times of concentration, so that lead concentrate is obtained; and 3, tailings obtained through scavenging are subjected to flotation grading including one time of roughing, one time of scavenging and one time of concentration, so that arsenic concentrate is obtained. Through the process grading, the lead grade of the lead concentrate is 66.30%, the lead recovery rate is 85.04%, the arsenic grade of the arsenic concentrate is 8.48%, and the arsenic recovery rate is 79.84%.

Owner:青海省地质矿产测试应用中心

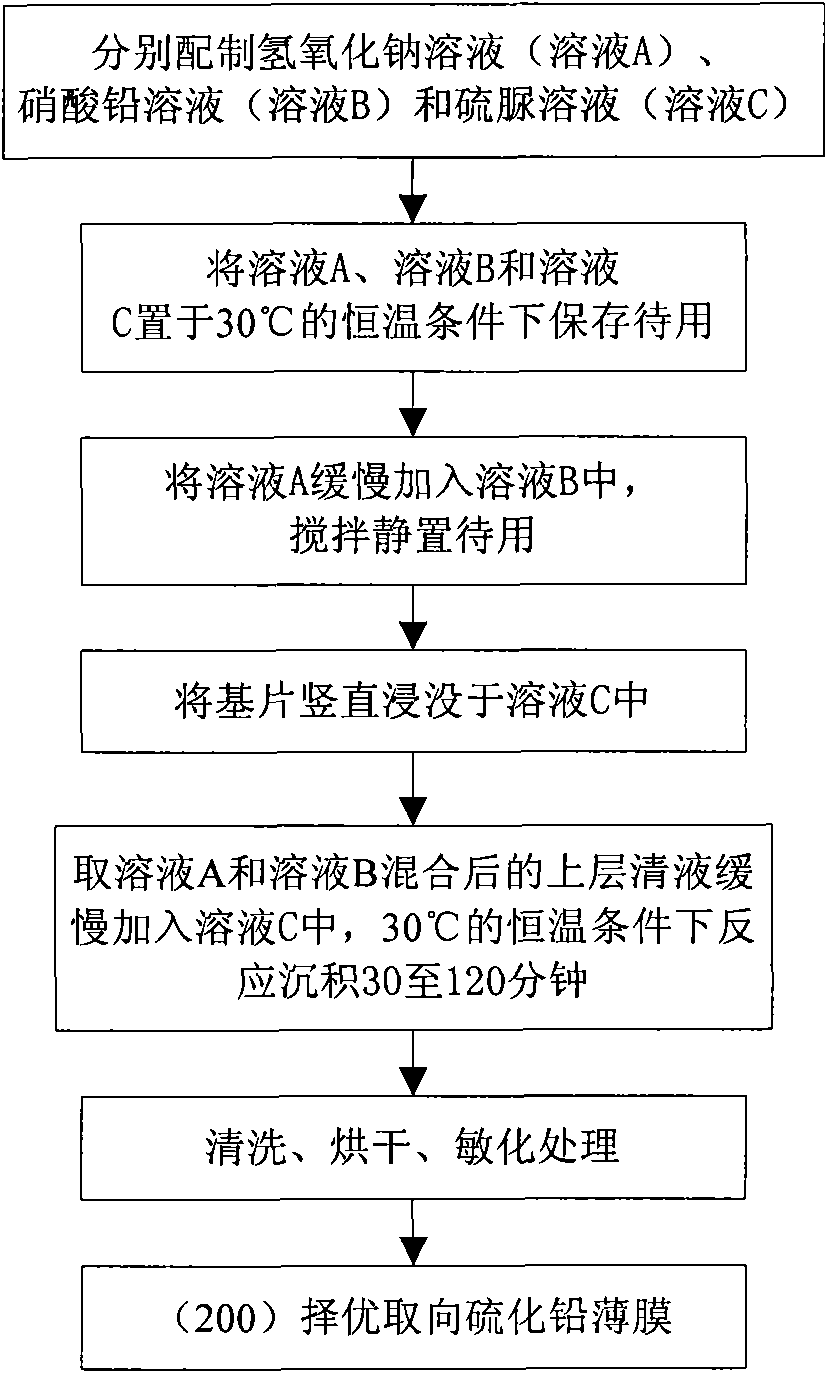

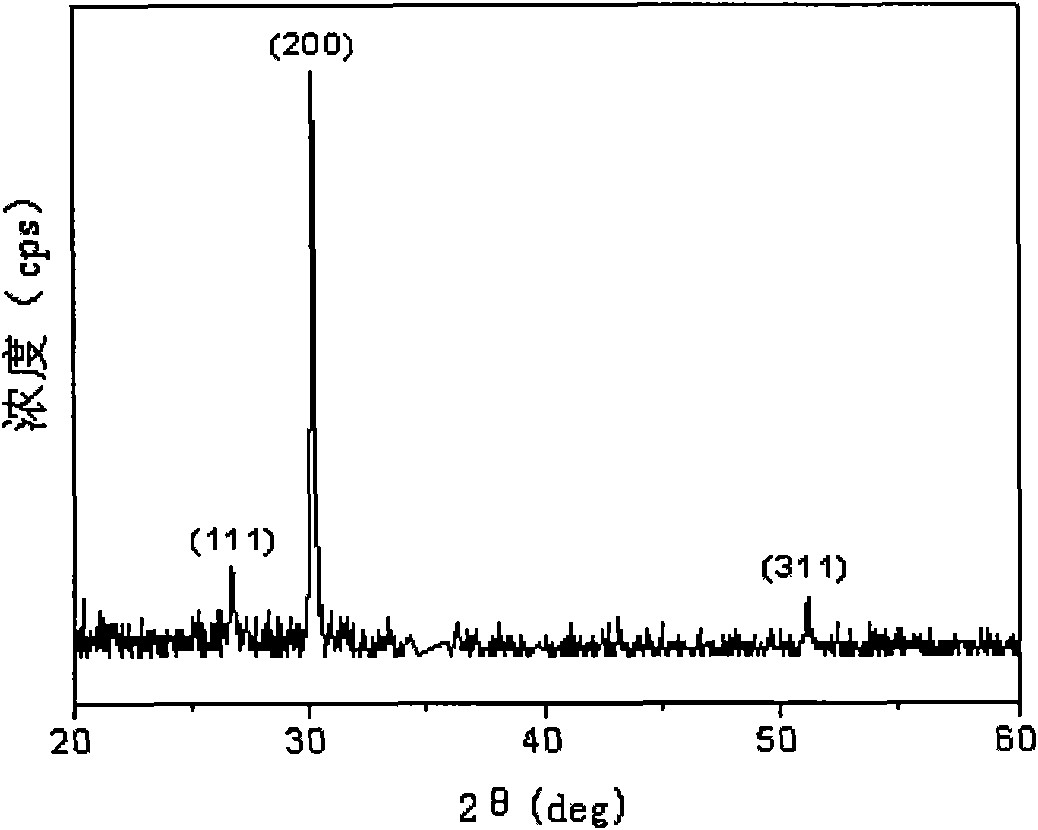

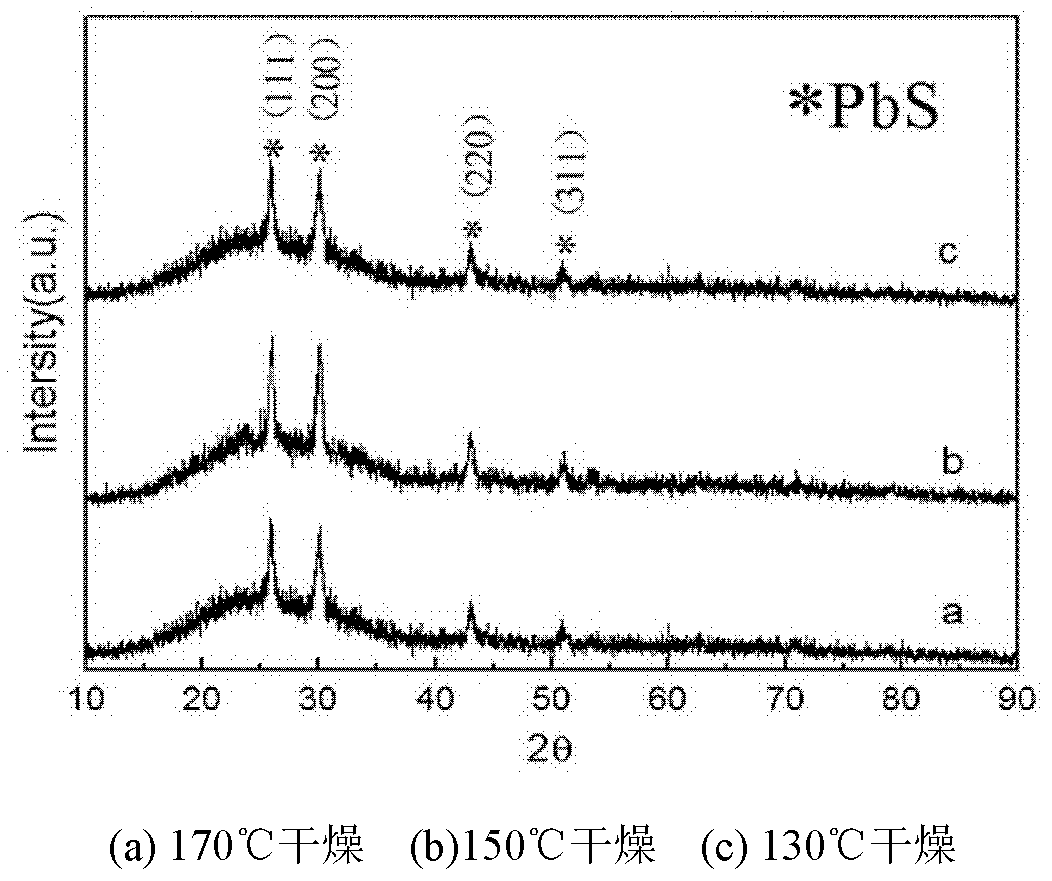

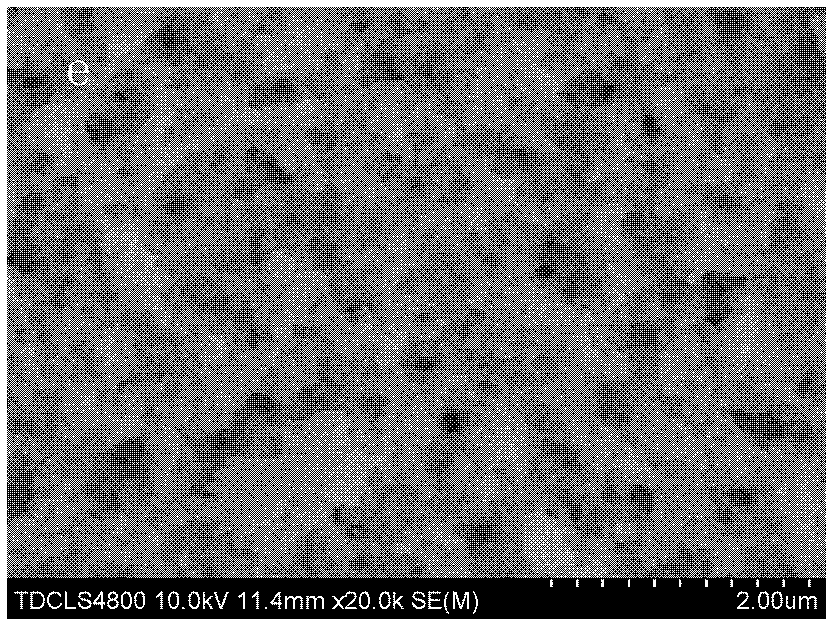

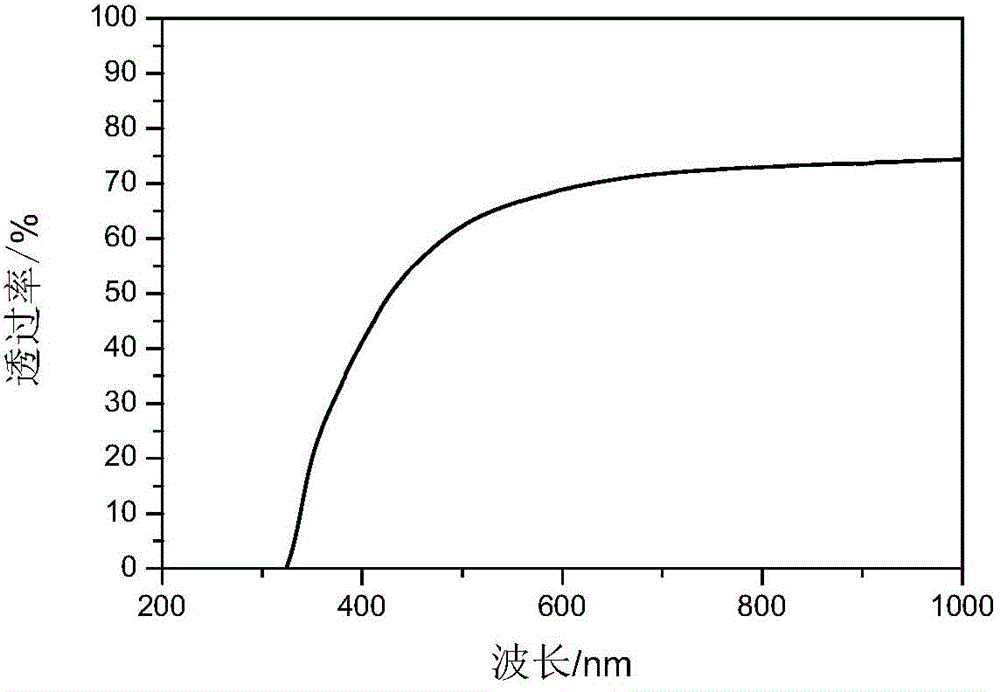

Method for preparing lead sulfide thin films with (200) preferred orientation

InactiveCN101792930AImprove uniformityImprove featuresPolycrystalline material growthFrom normal temperature solutionsPhotovoltaic detectorsLead sulfide

The invention provides a method for preparing lead sulfide thin films with (200) preferred orientation, which belongs to the technical field of electronic materials and relates to semiconductor optoelectronic thin films and infrared photoelectric detectors, in particular to a method for preparing the lead sulfide thin films with (200) preferred orientation of near-infrared photoelectric detectors by using chemical bath deposition. In the invention, the bicontinuous cubic phase lead sulfide thin films with (200) preferred orientation are obtained by using the chemical bath deposition, designing a preparation flow of solution of a reaction precursor, strictly controlling the initial nucleating process of the thin films and performing a subsequent high-temperature sensitizing process. The lead sulfide thin films prepared by the method have high uniformity and a light sensitive characteristic and can be used in the near-infrared photoelectric detectors. The invention has the advantages that: the whole preparation technical process is simple and easy to control; and the preparation device is simple and low in cost.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

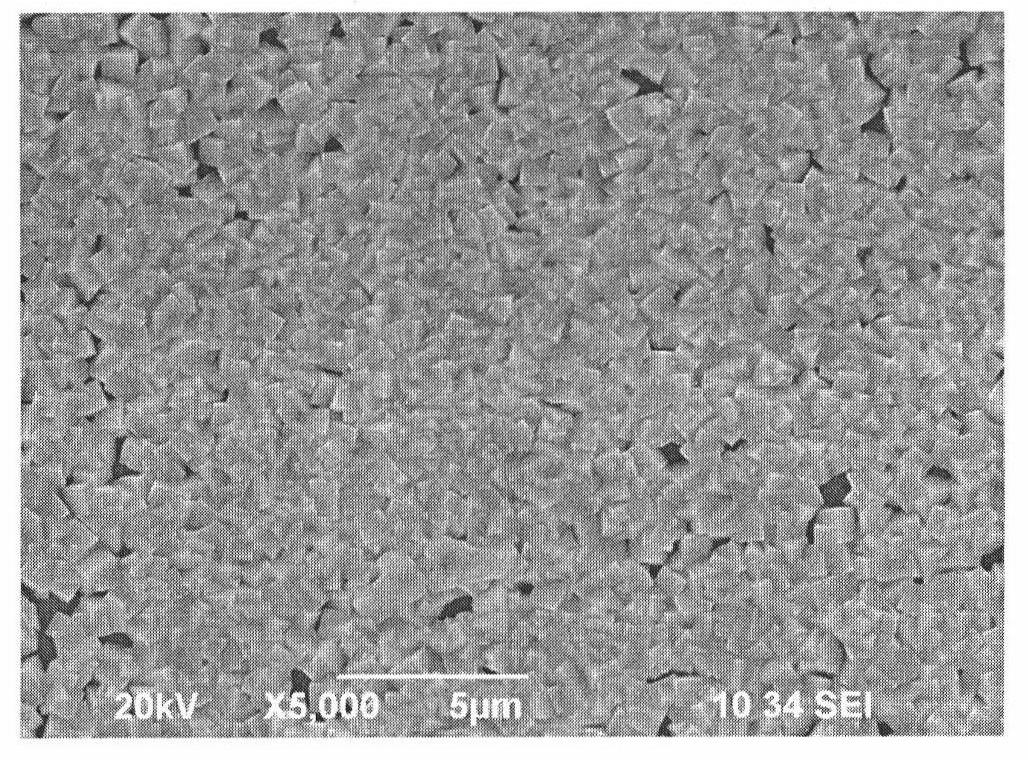

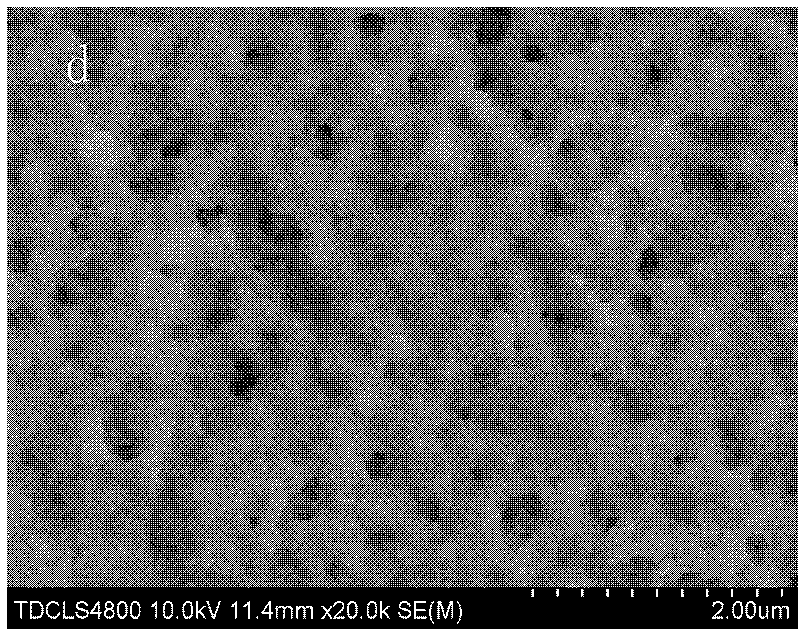

Method for synthesizing lead sulfide (PbS) film through chemical in-situ reaction of solution

The invention discloses a method for synthesizing a lead sulfide (PbS) film through the chemical in-situ reaction of a solution. The method comprises the steps of: (1) preparing a precursor solution; (2) preparing the PbS film through carrying out an in-situ reaction: vertically immerging a deposition substrate, of which a lead precursor film is attached to the surface, into a sulfur source anionic precursor solution for carrying out an in-situ chemical reaction, after 10 seconds, pulling the deposition substrate out of the reaction solution at a uniform speed, washing the deposition substrate by using deionized water, then, placing the deposition substrate in a drying box so as to form a PbS reaction deposition layer; and (3) carrying out heat treatment. The invention provides a novel in-situ chemical synthesizing method for the PbS film with high efficiency, convenience, little pollution and low cost, low-toxicity chemical raw materials, such as inorganic salt which serves as a precursor, alcohol ether and alcohol amine which serve as solvents, and the like, are adopted, and the PbS film is synthesized at a lower temperature, so that method for synthesizing the PbS film through the chemical in-situ reaction of the solution has the advantages of good evenness in solution deposition reaction, high degree of crystallizing, and easiness for controlling the thickness of the film.

Owner:TIANJIN UNIV

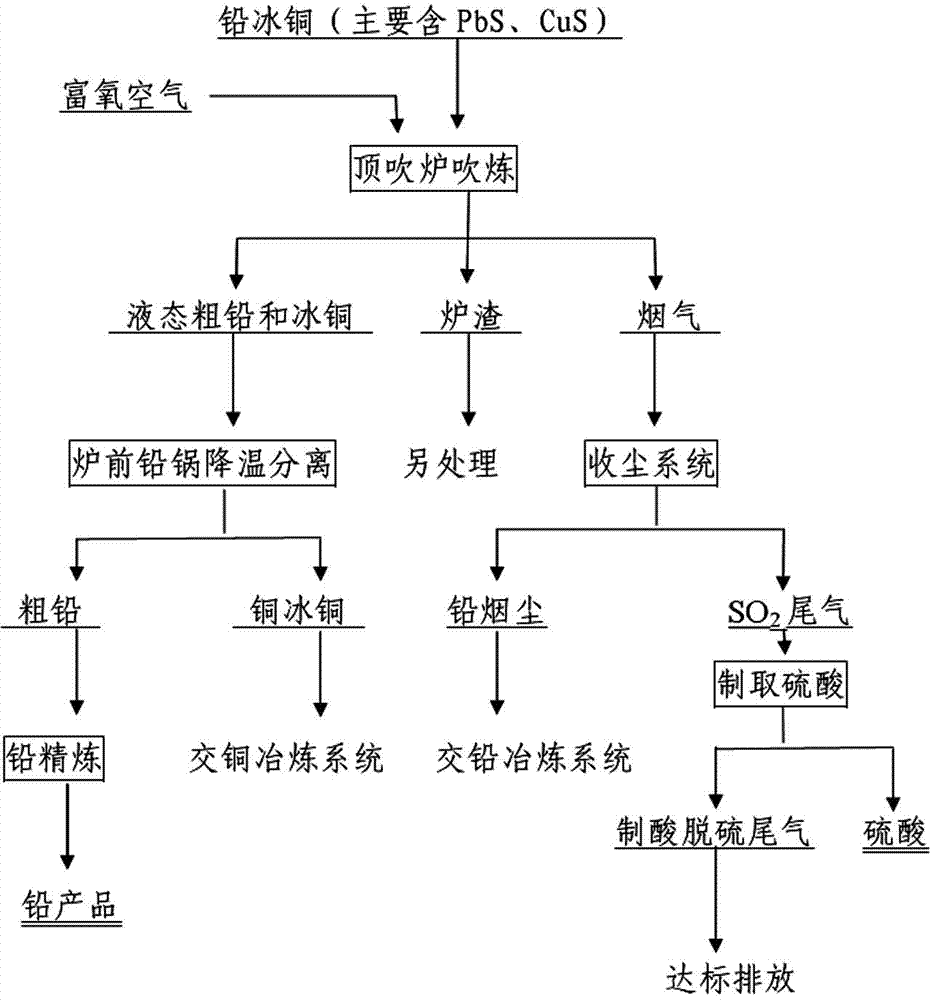

Oxygen-rich blowing technology for producing coarse lead and matte from lead matte in top-blowing furnace

InactiveCN103937990AImprove smelting recovery rateReduce operating costsRotary drum furnacesCrucible furnacesRefining (metallurgy)Nonferrous metal

The invention specifically relates to an oxygen-rich blowing technology for producing coarse lead and matte from lead matte in a top-blowing furnace, and belongs to the technical filed of nonferrous metal metallurgy. The technology comprises the following steps: leaving a FeO-SiO2-CaO three-element primary molten pool in a top-blowing furnace, continuously adding lead matte into the furnace, controlling the blowing temperature, spraying quantitative oxygen gas from a spray gun to carry out continuous oxidation blowing by adding, wherein the amount of the oxygen gas is calculated so as to completely covert the sulfur of the lead sulfide in the lead matte to SO2; stopping adding lead matte and oxygen-rich air after the top blowing is over, directly adding a reducing agent to carry out reduction smelting on liquid lead slag; wherein during the blowing process and the lead slag reduction smelting process, a mixture of molten coarse lead and copper sulfide is discharged out, cooling and settling the mixture in a lead boiler in front of the furnace, fishing out the copper sulfide in a solid matte form, and transporting the liquid coarse lead to a lead refining system. The technology has the advantages of high production efficiency, high lead and copper recovery rate, low cost, reduced discharge, and environment-friendliness.

Owner:YUNNAN TIN

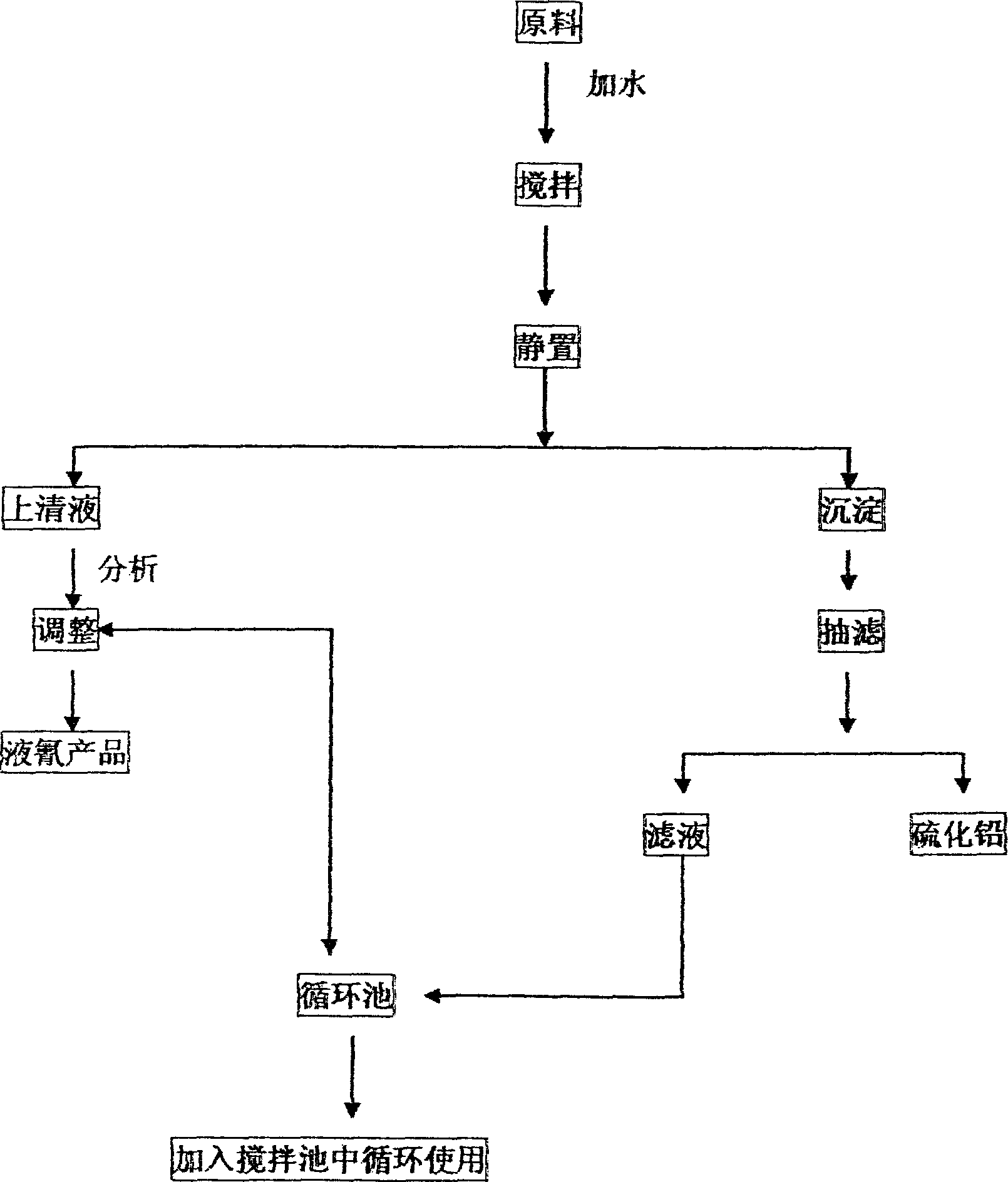

Process of preparing sodium cyanide and lead sulfide for gold ore sorting from waste sodium cyaide desulfurizing dreg

InactiveCN1673082AComplete resourceThe production process is simple and effectiveAlkali metal cyanidesLead sulfidesSodium cyanideLead sulfide

The waste sodium cyanide desulfurizing dreg containing various components with different physical and chemical properties, especially different dissolubility in water, is separated and extracted with water as medium to obtain liquid cyanide product with dissolved sodium cyanide and waste dreg, which is dried as the lead ore product. The said production process is simple and effective, and has no waste produced, no pollution, low cost, high yield and complete utilization of resource.

Owner:安庆盖娅环保科技有限公司

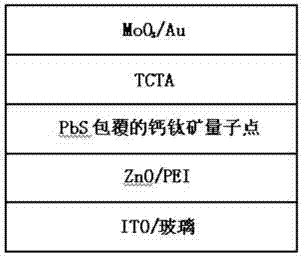

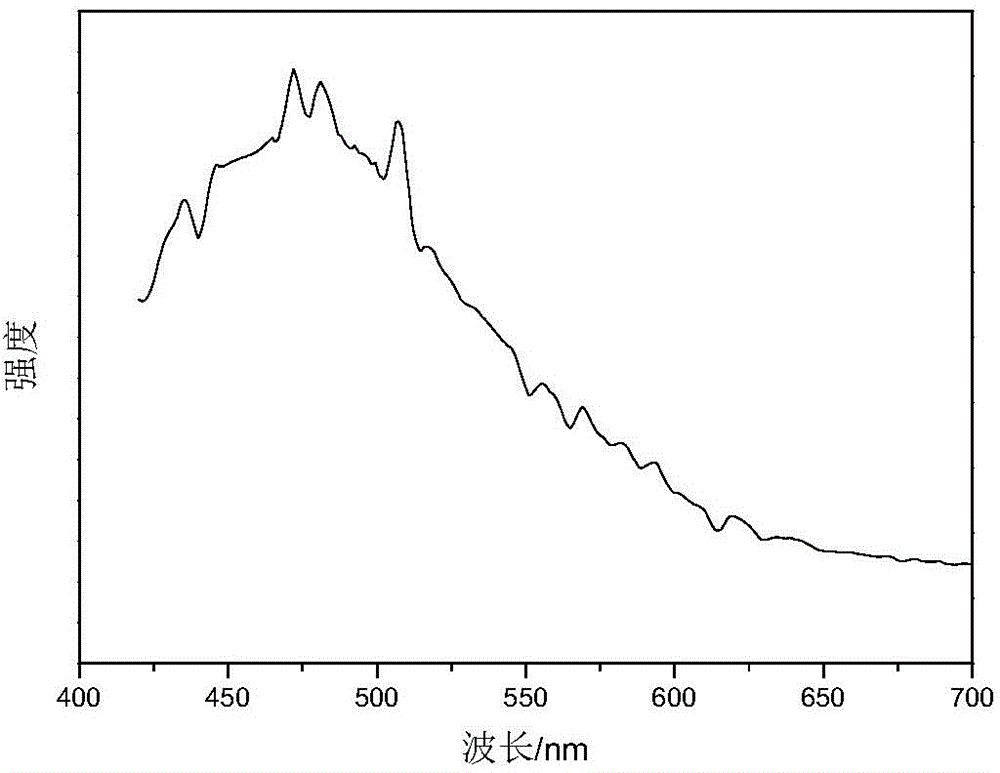

Lead sulfide-coated perovskite quantum dots-based electroluminescent LED and preparation method

InactiveCN107978688AReduce surface defectsImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingHole transport layerAniline

The invention relates to a lead sulfide-coated perovskite quantum dots-based electroluminescent LED and a preparation method. The electroluminescent LED comprises ITO glass as a bottom electrode, n-type ZnO / polyethyleneimine as an electron transport layer (ETL) and a hole blocking layer (HBL), PbS-coated perovskite quantum dots as a light-emitting layer, a p-type 4,4',4''-tris(carbazol-9-yl) aniline film as a hole transport layer (HTL) and an electron blocking layer (EBL), and MoO3 / Au as a top electrode. The preparation method comprises the steps of firstly preparing a cesium oleic acid solution; preparing the PbS-coated CsPbI3 quantum dots, the electron transport layer, the hole blocking layer, the light-emitting layer, the hole transport layer and the electron blocking layer; and obtaining the PbS-coated perovskite quantum dots-based electroluminescent LED. By adopting the PbS-coated perovskite quantum dots, the photoelectric property of the perovskite quantum dots is improved, the stability of the quantum dots is ensured and good semiconductor performance of the quantum dots is kept at the same time, and the efficient and stable electroluminescent LED is prepared from the quantum dots as the light-emitting layer.

Owner:JILIN UNIV

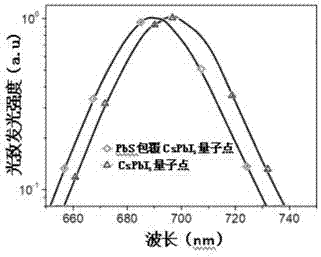

Cyanide-free and chromium-free copper lead flotation separation method

The invention provides a cyanide-free and chromium-free copper lead flotation separation method which is characterized in that copper lead bulk flotation is realized by adopting a combined collector of ethyl thio carbamate +Z-200 which has better selectivity and collecting force according to raw ore properties of and process mineralogy characteristics of copper lead sulphide ore; bulk flotation concentrate is subjected to thickening, regrinding and thickening deep dereagent, and sodium sulphide and activated carbon are added in the regrinding process to strengthening the dereagent effect; in the copper lead separation process, sodium sulphite, zinc sulfate and carboxymethylcellulose combined inhibitor are adopted to restrict lead and float copper; The process is mainly implemented through three process links including raw ore copper lead bulk flotation, multi-mean strengthening dereagent, bulk concentrate copper lead separation; the method adopts the technological process of copper lead bulk flotation-multi-mean strengthening dereagent-cyanide-free and chromium-free copper lead separation and has an obvious effect in treatment of complex copper lead sulfide ore and similar ore; the copper grade of obtained copper concentrate is greater than 32%, the copper recovery rate is greater than 65%, the lead grade of lead concentrate is greater than 49%, and the lead recovery rate is greater than 88%.

Owner:ZIJIN MINING GROUP

Novel friction material for brake pad

InactiveCN103045162AStable coefficient of frictionReduce wear rateOther chemical processesFriction liningCarbon fibersIron powder

The invention discloses a novel friction material for a brake pad, which is prepared from the following raw material in parts by weight: 20-40 parts of aramid fiber, 10-30 parts of carbon fibers, 1-5 parts of red copper powder, 5-10 parts of aluminum powder, 1-5 parts of expanded iron powder, 1-5 parts of lead sulfide, 5-10 parts of calcined coke and 5-10 parts of artificial graphite. The novel friction material for the brake pad disclosed by the invention has the advantages of stable friction coefficient, low abrasion rate and good strength, and has the advantages of better impact-resisting strength, low product density, low hardness, low braking noises, no damages to braking antithesis and the like; and the service life is greatly prolonged.

Owner:殷国忠

Repair and maintenance type charging method of lead-acid storage battery

InactiveCN105098269AShorten charging timeShorten repair timeSecondary cells charging/dischargingCapacitancePolarization phenomenon

The invention discloses a repair and maintenance type charging method of a lead-acid storage battery. The method comprises the following steps: a continuous and repeated constant-current restricted-voltage output process comprising constant current output, pause, discharging, pause, sweep frequency pulse output, pause, discharging and pause, a standing and stable process and a constant-voltage restricted-current complementary charging process. With adoption of the method disclosed by the invention, in the battery repair and charging process, lead sulfide crystals existing on a battery plate before repair can be broken and dissolved, three polarization phenomena including ohmic polarization, concentration polarization and electrochemical polarization and generated during charging or repair can be eliminated, formation of new lead sulfide crystals on the battery plate can be restrained, generation of high temperature of the lead-acid storage battery can be effectively prevented in repair and charging, time of repair or charging can be reduced, and the service life of the lead-acid storage battery can be prolonged; therefore, the maximum repair efficiency and the maximum capacitance of the lead-acid storage battery can be reached.

Owner:王惠民

Preparation method of monodisperse PbS quantum dot

The invention belongs to the technical field of preparation of compound semiconductor nanomaterials and particularly relates to a preparation method of a monodisperse PbS quantum dot. The method comprises steps as follows: S1, a halide of lead and oleylamine are mixed, heated to 80-190 DEG C and fully stirred to form a lead precursor, and then the lead precursor is cooled to 20-35 DEG C; S2, thioacetamide and oleylamine are fully stirred at 20-35 DEG C to form a sulfur precursor; S3, the lead precursor and the sulfur precursor are mixed in the molar ratio of Pb and S being (2-5):1, heated to 60-90 DEG C and subjected to heat preservation for a certain period; S4, the solution after heat preservation in S3 is cooled to 20-35 DEG C, and oleic acid is added to remove the residual lead precursor; S5, the PbS quantum dot is obtained after separation and purification. The prepared PbS quantum dot has the characteristics of high crystallinity, size uniformity, oleic acid and halogen mixed passivation, efficient luminescence, high stability and the like.

Owner:深圳市联宝威科技有限公司

Preparation method of EVA/lead sulfide quantum dot composite packaging adhesive film material with light converting function

ActiveCN104927688AWith light turning functionWith transparencyNon-macromolecular adhesive additivesFilm/foil adhesivesCross-linkPlasticizer

The invention discloses a preparation method of an EVA / lead sulfide quantum dot composite packaging adhesive film material with a light converting function. The material is formed by compounding lead sulfide quantum dots and an EVA packaging adhesive film, wherein the lead sulfide quantum dots are lead sulfide nano-particles of which the sizes are 1 to 20 nm. The preparation method comprises the following steps: conducting surface treatment on the lead sulfide quantum dots under an ultrasonic condition; carrying out melt compounding between the treated lead sulfide quantum dots, and EVA, a cross-linking agent, an ultraviolet stabilizer, an anti-oxygen, a plasticizer and the like to prepare the EVA / lead sulfide quantum dot composite packaging adhesive film material with the light converting function. The material prepared according to the method can absorb ultraviolet light and emit visible light, so as to improve the ultraviolet light utilization ratio of a solar cell module, and further improve efficiency; moreover, the material prepared according to the method is longer in service life than a rare earth light converting material.

Owner:无锡市钱氏功能塑胶有限公司 +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com