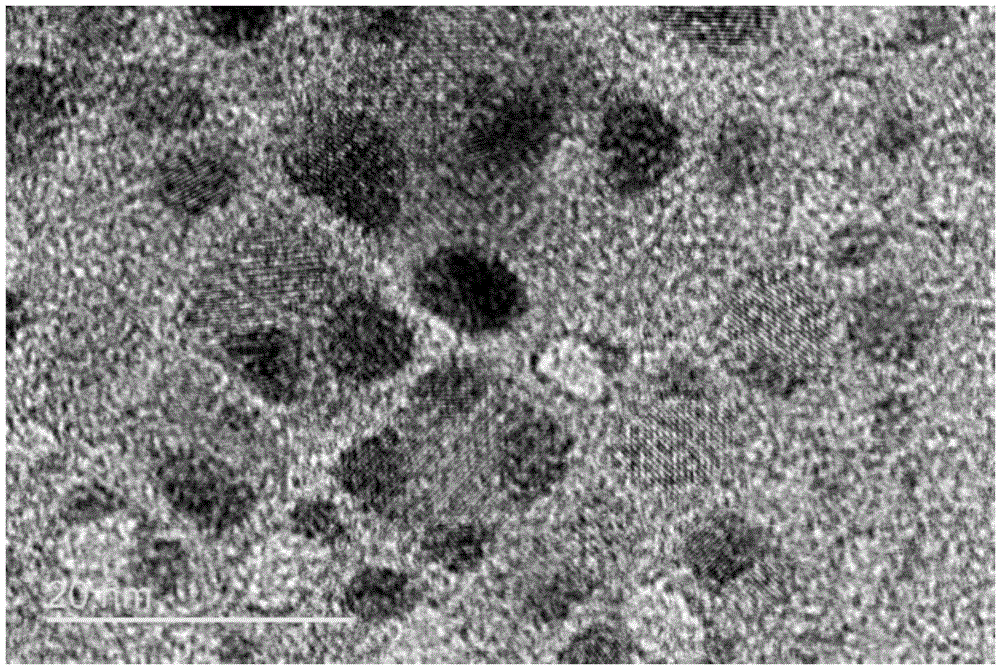

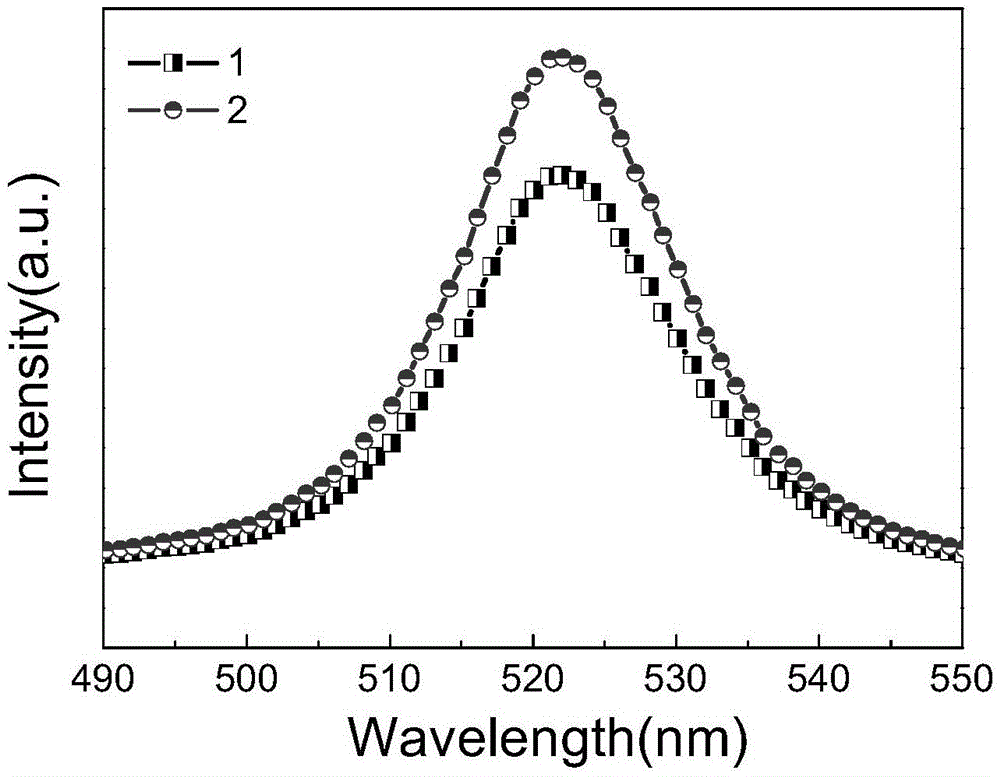

Method for synthetizing high-stability metal halide perovskite/lead sulfide heterostructure nanocrystals

A metal halide, perovskite technology, applied in chemical instruments and methods, nanotechnology, luminescent materials, etc., can solve problems such as poor stability, achieve good film formation, high luminous efficiency, and improve the effect of photocurrent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1, dissolving 6mmol of Cs(st) in 40mL of octadecene, and heating and stirring to completely dissolve it to form a cesium precursor;

[0024] Step 2, dissolve 0.5mL of DDAB-S in 2mL of toluene, stir evenly, and make sulfur precursor;

[0025] Step 3, dissolving 0.15 mmol of lead acetate in 2 mL of toluene and 1 mL of oleylamine mixture (the volume ratio of toluene and oleylamine is 2:1), stirring evenly to form a lead precursor;

[0026] Step 4, weigh 0.198g of PbBr 2 , dissolved in a mixed solution of 1.5mL oleic acid, 1mL oleylamine and 15mL octadecene, put the mixed solution in a four-necked bottle, heat and stir at 140°C, and repeatedly pump and fill with argon, and cycle 6 to 10 times , exhaust the oxygen and water in the reaction system, ensure that the reaction system is protected by an inert atmosphere, and continue to keep warm at 140°C for 10 minutes after the pumping is completed, so that the reactants are completely dissolved;

[0027] Step 5, heat up ...

Embodiment 2

[0030] Step 1, dissolving 6mmol of Cs(st) in 40mL of octadecene, and heating and stirring to completely dissolve it to form a cesium precursor;

[0031] Step 2, dissolve 1mL of DDAB-S in 2mL of toluene, stir evenly, and make sulfur precursor;

[0032] Step 3, dissolving 0.15 mmol of lead acetate in a mixture of 2 mL of toluene and 1 mL of oleylamine (the volume ratio of toluene and oleylamine is 1:2), stirring evenly, and forming a lead precursor;

[0033] Step 4, weigh 0.198g of PbBr 2 , dissolved in a mixed solution of 1.5mL oleic acid, 1mL oleylamine and 15mL octadecene, put the mixed solution in a four-necked bottle, heat and stir at 80°C, and repeatedly pump and fill with argon, and cycle 6 to 10 times , Exhaust the oxygen and water in the reaction system to ensure that the reaction system is protected by an inert atmosphere. After the pumping is completed, continue to keep warm at 80°C for 10 minutes to completely dissolve the reactants;

[0034] Step 5, heat up the mi...

Embodiment 3

[0036] Step 1, dissolving 6mmol of Cs(st) in 40mL of octadecene, and heating and stirring to completely dissolve it to form a cesium precursor;

[0037] Step 2, dissolve 1mL of DDAB-S in 2mL of toluene, stir evenly, and make sulfur precursor;

[0038] Step 3, dissolving 0.3 mmol of lead acetate in a mixture of 2 mL of toluene and 1 mL of oleylamine (the volume ratio of toluene and oleylamine is 1:2), stirring evenly, and forming a lead precursor;

[0039] Step 4, weigh 0.198g of PbBr 2 , dissolved in a mixed solution of 1.5mL oleic acid, 1mL oleylamine and 15mL octadecene, put the mixed solution in a four-necked bottle, heat and stir at 80°C, and repeatedly pump and fill with argon, and cycle 6 to 10 times , Exhaust the oxygen and water in the reaction system to ensure that the reaction system is protected by an inert atmosphere. After the pumping is completed, continue to keep warm at 80°C for 10 minutes to completely dissolve the reactants;

[0040]Step 5, heat up the mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com