Stepped flotation of tin, lead and zinc sulfide mine

A step-by-step flotation and sulfide ore technology, applied in flotation, solid separation and other directions, can solve the problems of high zinc content, low lead and silver recovery rate, environmental pollution, etc., to avoid losses and ensure the effect of grade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] 1. A cassiterite lead-zinc sulfide ore in Yunnan. The main metal minerals of the ore are galena, sphalerite, cassiterite, pyrite, and pyrrhotite. The main gangue minerals are quartz, feldspar, calcite and so on. The results of the multi-element analysis of the raw ore are shown in Table 1.

[0028] Table 1 Multi-element analysis of raw ore

[0029] Element Pb Zn S Fe Sn SiO 2

[0030] Content, % 3.38 5.27 14.50 18.98 0.30 26.81

[0031] Element Al 2 o 3 CaO MgO As Ag

[0032] Content, % 4.13 6.14 2.35 0.094 158g / t

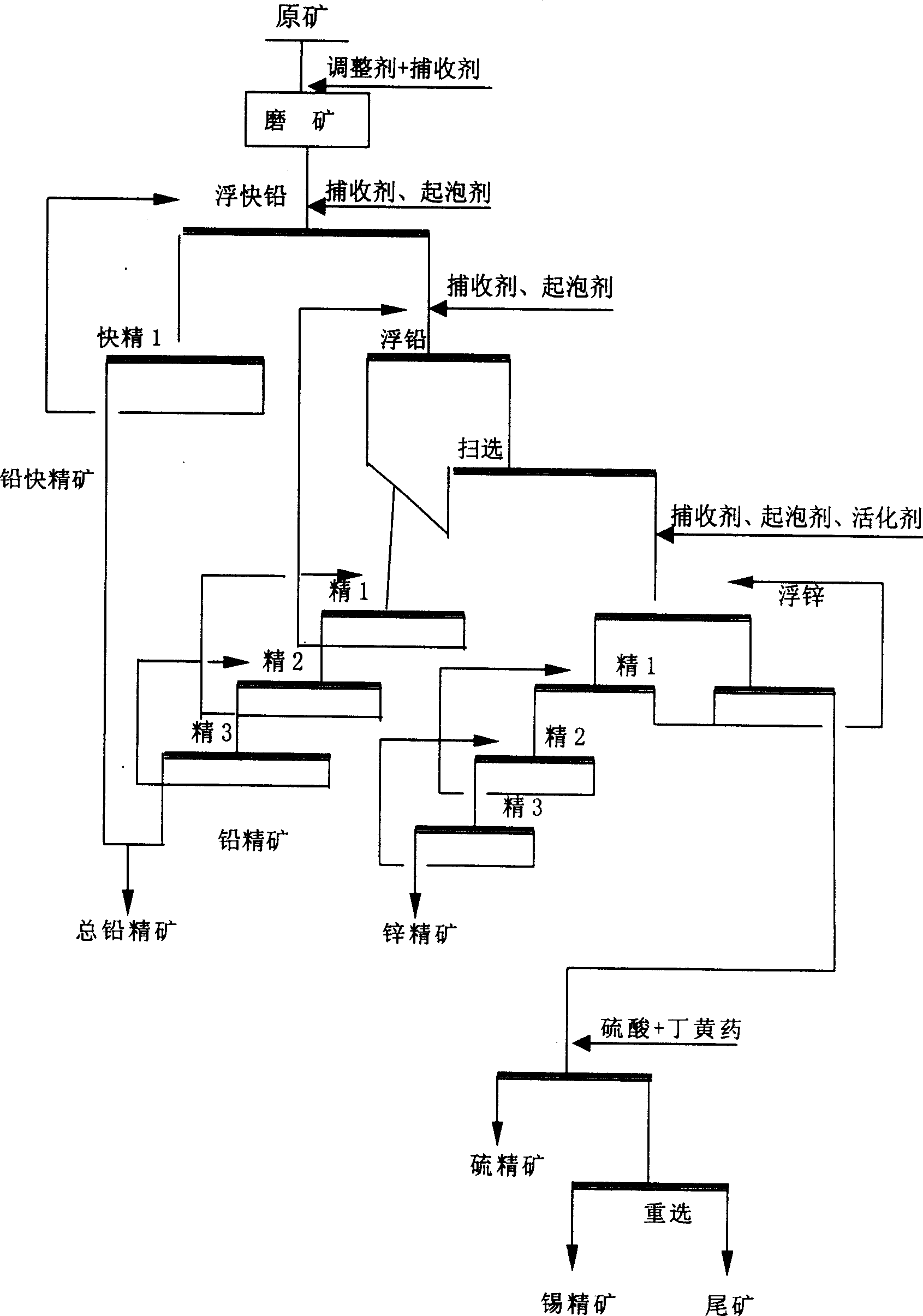

[0033] use as figure 1 The process flow is shown, and the specific process parameters are;

[0034] ① Potential regulators are calcium hydroxide 2000g / t, ethionazine 30g / t, butyl xanthate 60g / t;

[0035] Lead quick selection: ethyl sulfur nitrogen 30g / t, 2 # Oil 30g / t; floating lead: ethyl disulfide 50g / t, 2 # Oil 20g / t;

[0036] ②Zinc flotation: activator copper sulfate 300g / t, butyl xanthate 120g / t, 2 # Oil 40g / t, sodium sulfite 500...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com