Patents

Literature

46results about How to "Improve the quality of selection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

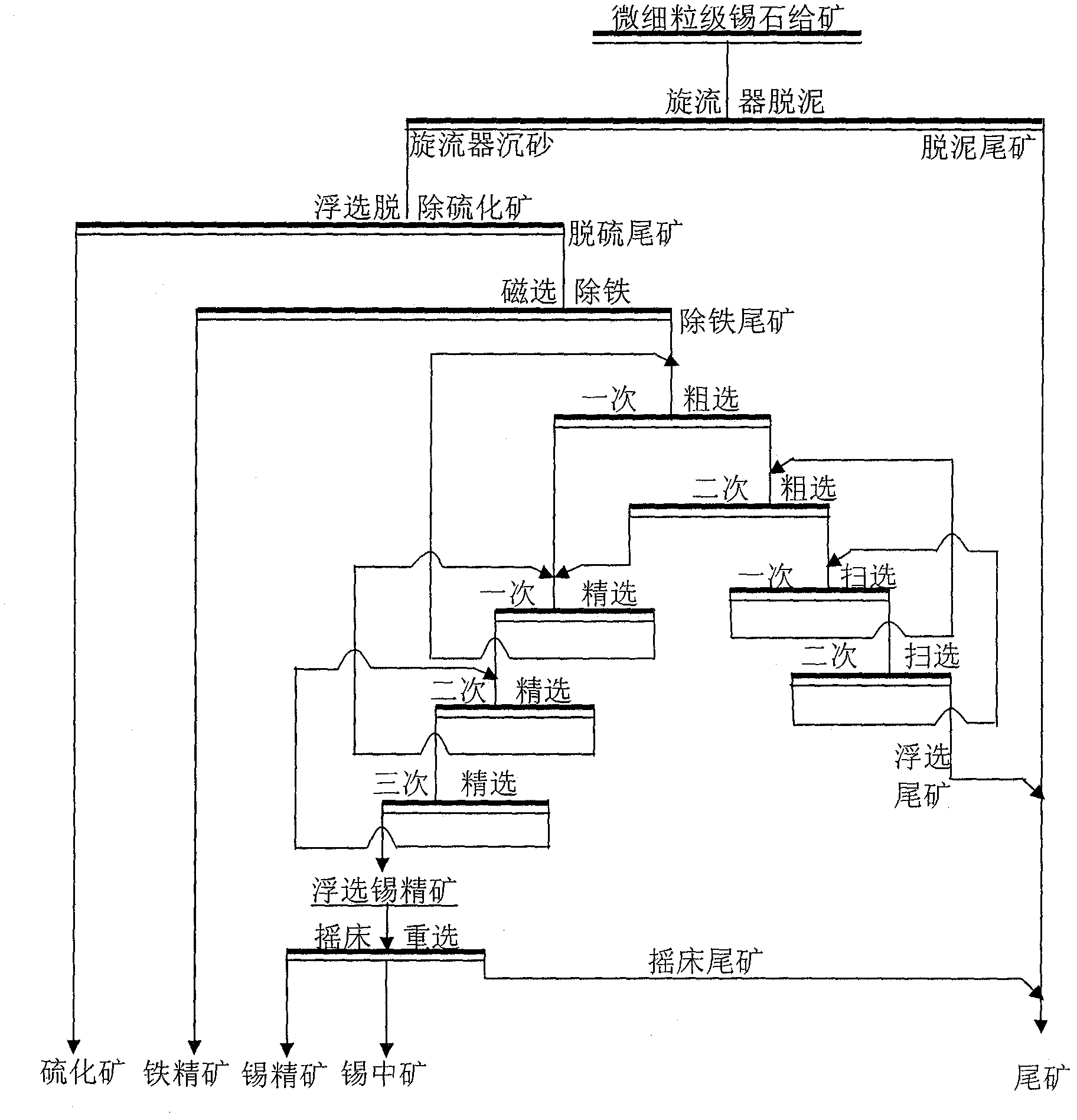

Beneficiation method for ultrafine fraction cassiterite

InactiveCN102631977AMineral processing method to solveEfficient recyclingFlotationWet separationCassiteriteMaterials science

A beneficiation method for ultrafine fraction cassiterite is characterized in that a swirler is used for desliming to obtain swirler settled sand and deslimed tailings; sulfide ores are separated from the swirler settled sand so that the sulfide ores and desulfurized tailings are obtained; iron is removed from the desulfurized tailings by means of magnetic separation to obtain iron ore concentrate and deironed tailings; flotation tin concentrate and flotation tailings are obtained after secondary roughing flotation, secondary scavenging flotation and tertiary blank concentration flotation for the deironed tailings; and a table concentrator is used for performing gravity concentration for the flotation tin concentrate to obtain tin concentrate, tin middlings and table concentration tailings. The grade of the tin concentrate is higher than 40%, the tin recovery rate of the tin concentrate is higher than 50%, the grade of the tin middlings ranges from 1% to 3%, the tin recovery rate of the tin middlings is higher than 15%, and the overall tin recovery rate of the tin concentrate and the tin middlings is higher than 65%. The beneficiation method for the ultrafine fraction cassiterite is high in recovery rate, low in production cost, high in tin grade and applicable to recovery of the ultrafine fraction cassiterite with the silt content ranging from 10% to 30%.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

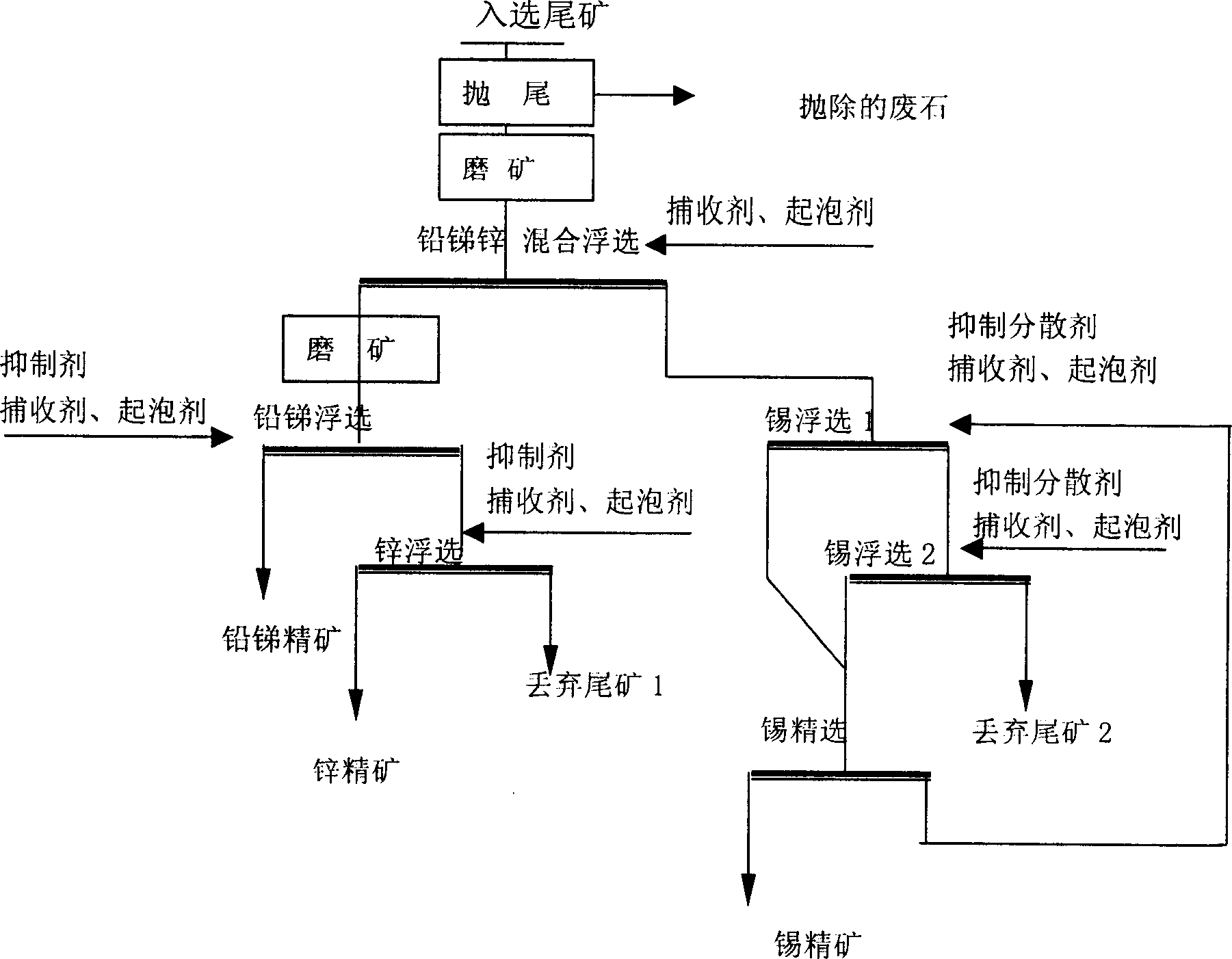

Multi-metal cassiterite sulfurizing tail concentrating method

InactiveCN1810381AImprove the quality of selectionHigh recovery rateFlotationWet separationSodium carbonateMaceral

The multi-metal cassiterite sulfurizing tail concentrating method includes: graded tail throwing with combineed screw concentrating machine and screw chute; floating of the rest tail with phenyl halogenated quaternary ammonium salt and black butyl amine as collecting agent to recover sulfurized mineral of Pb, Sb, Zn, etc and sulfurized mineral oxide of Pb, Sb, Zn, etc while leaving the cassiterite and gangue inside the trough; and recovering cassiterite with sodium carbonate and carboxymethyl polyvinyl alcohol as combined gangue dispersing and inhibiting agent and through stepped floating process. Compared with traditional method, the method has concentrating grade raised by 1-3 times, comprehensive tail loss of about 10 % and 10 % raised recovering rate of Pb, Sb, Zn, Sn, etc.

Owner:黎东明

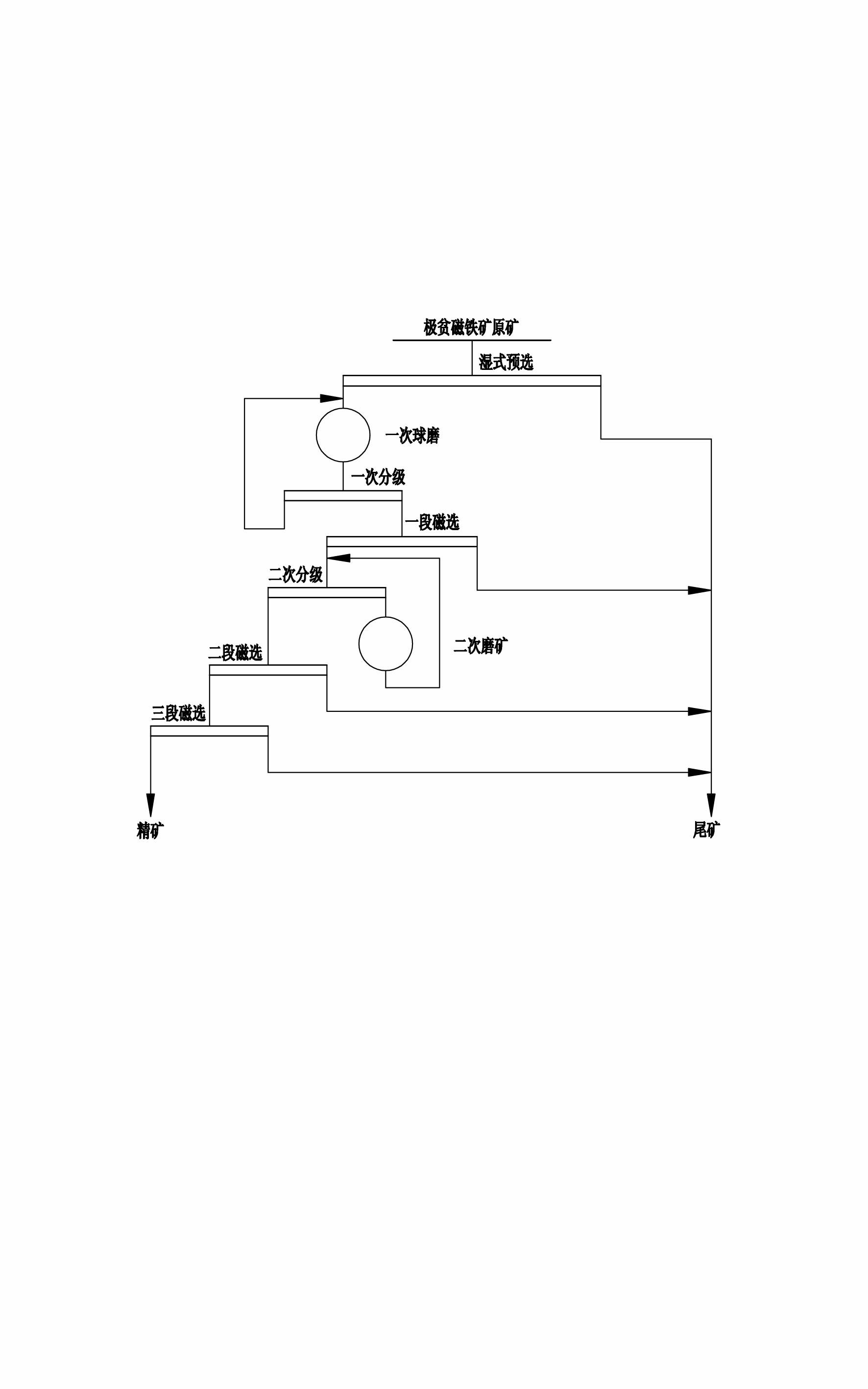

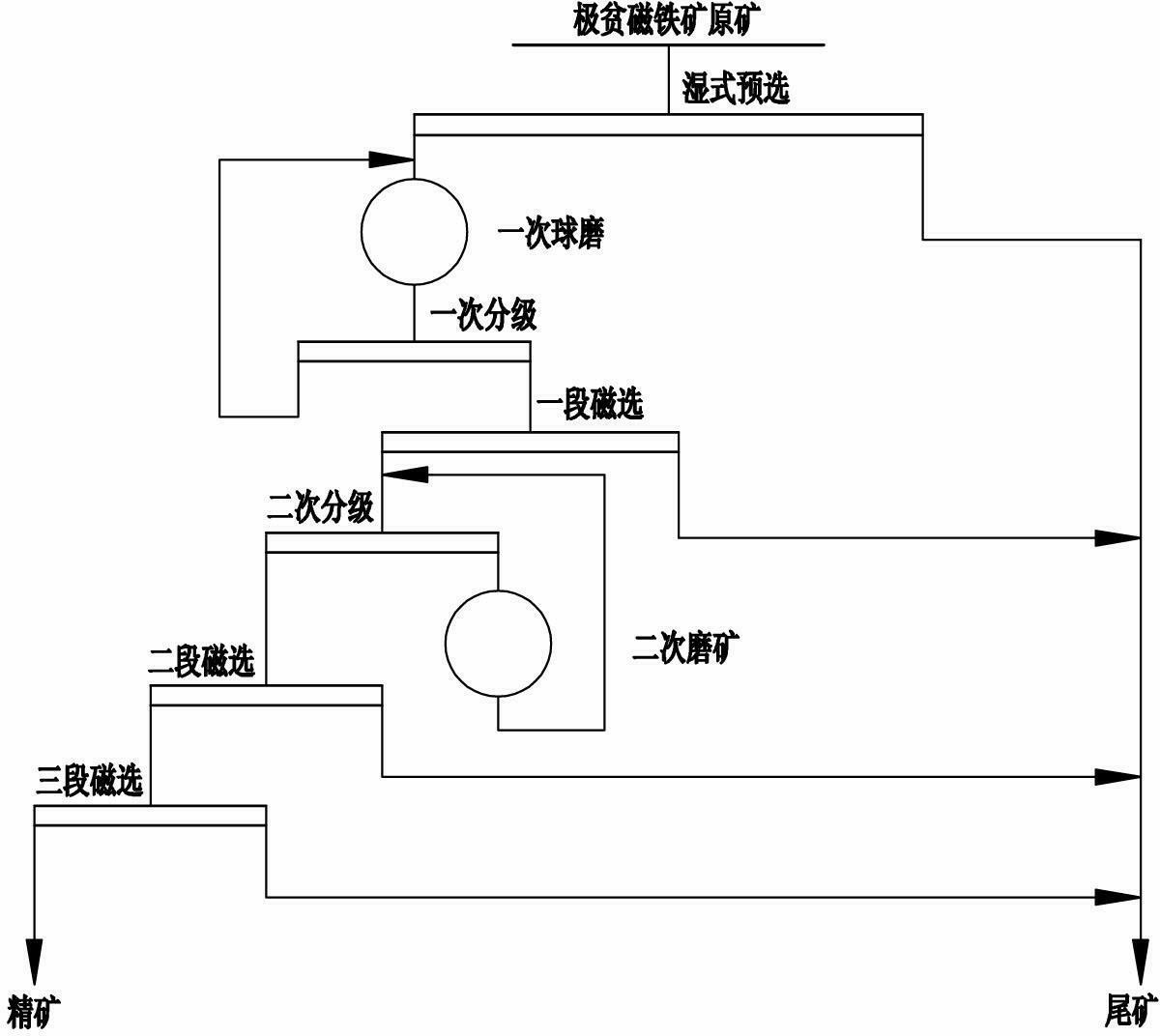

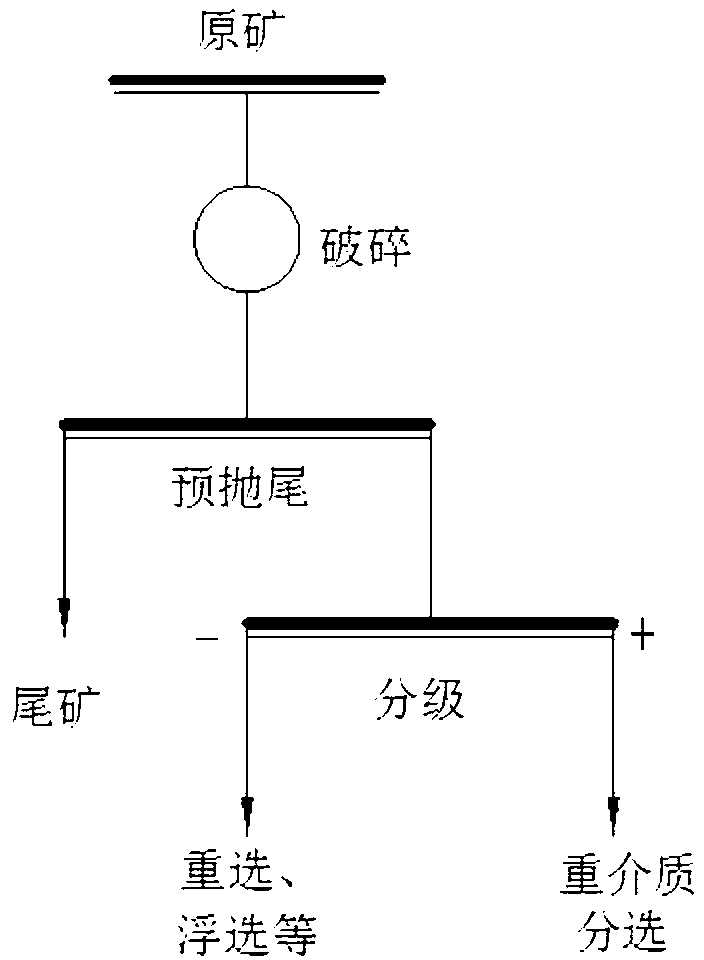

Extremely lean magnetite beneficiating process

InactiveCN102489387AReduce the cost of beneficiationEnergy savingWet separationOre concentrateBall mill

The invention relates to the technical field of ore beneficiation, and in particular relates to an extremely lean magnetite beneficiating process. The process is characterized by comprising the following steps of: 1) carrying out wet pre-beneficiation on raw ores with grain sizes being 0-5mm and concentration being 35-45%; 2) processing the concentrates obtained through wet pre-beneficiation with a primary closed-circuit milling system formed by primary ball milling and primary classifying and discarding the tailings obtained through wet pre-beneficiation; 3) carrying out first-stage magnetic separation on overflow obtained through primary classifying; 4) processing the concentrates obtained through first-stage magnetic separation with a secondary closed-circuit milling system formed by secondary ball milling and secondary classifying; 5) carrying out second-stage magnetic separation on overflow obtained through secondary classifying; 6) carrying out third-stage magnetic separation on concentrates obtained through second-stage magnetic separation; 7) taking the concentrates obtained through third-stage magnetic separation as the final concentrates with grades being 63-64%; and 8) discarding the final tailings formed by the tailings obtained through first-stage magnetic separation, second-stage magnetic separation and third-stage magnetic separation. The process has the following characteristics that: 30% of tailings are discarded by adopting the pre-beneficiation method, thus improving the beneficiation feed grade of the ores to 16-18%, reducing the quantity of the ores entering the ball mill by 30% and obviously lowering the ore beneficiation cost; and the energy is saved and the economic benefits are obvious.

Owner:鞍钢集团矿业设计研究院有限公司

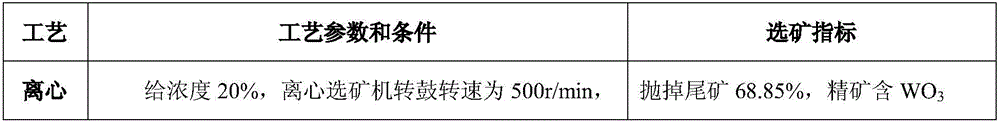

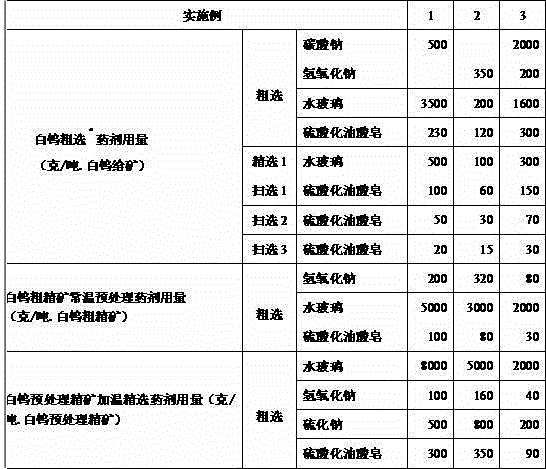

Mineral separation method for recycling wolframite from tailing

ActiveCN106669964AImprove the quality of selectionReduce the amount of oreSolid separationMechanical material recoveryGravity separationMagnetic separation

The invention discloses a mineral separation method for recycling wolframite from a tailing. The mineral separation method comprises the following steps that (1) gravity separation of a centrifugal machine is conducted for tailing discarding and preenrichment; (2) sulphide ore flotation is conducted; (3) magnetic separation is conducted and magnetic impurities are removed; (4) high-gradient magnetic separation is conducted for wolframite enrichment; (5) tabling gravity separation is conducted to obtain coarse grained wolframite; and (6) flotation is conducted to obtain fine grained wolframite. By means of centrifugation gravity separation preenrichment, the separation grade of the wolframite is improved, the ore feeding quantity and the mud content of wolframite separation are reduced, and flotation reagent dosage is saved. By means of the sulphide ore flotation and magnetic separation iron removal, the disturbance of sulphide minerals and magnetic minerals on wolframite separation is reduced. According to the mineral separation characteristics of the wolframite, the separation index of the wolframite is improved by adopting the high-gradient magnetic separation and the coarse grained and fine grained wolframite grading and separation process. Efficient recycling of the wolframite in low-grade wolframite tailing resources is achieved, and the mineral separation method is environmentally friendly, efficient and energy saving, and suitable for application and popularization.

Owner:JIANGXI UNIV OF SCI & TECH

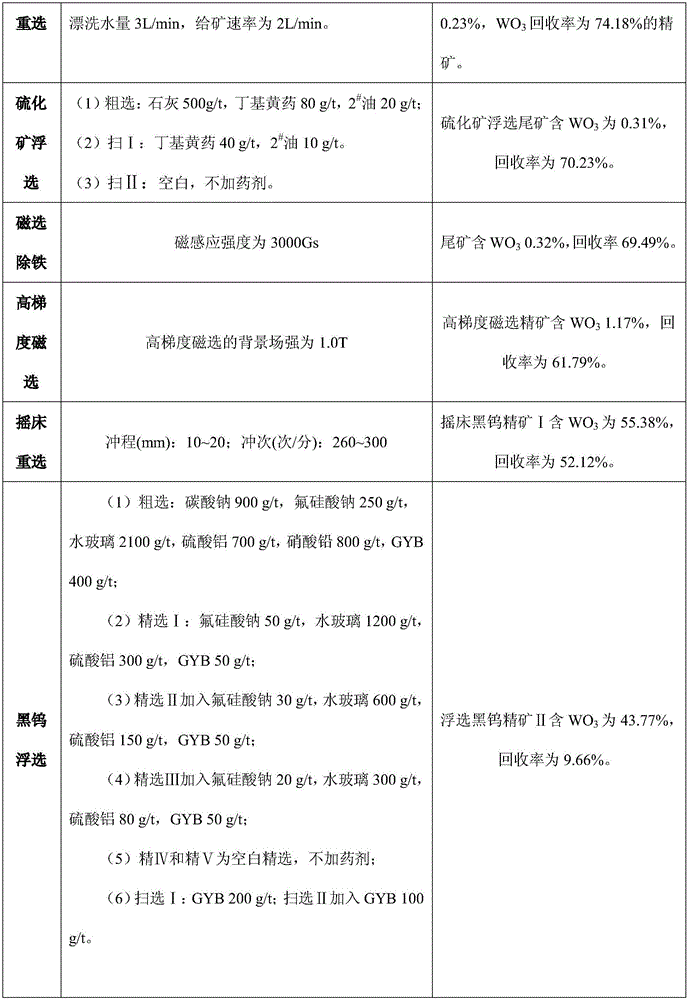

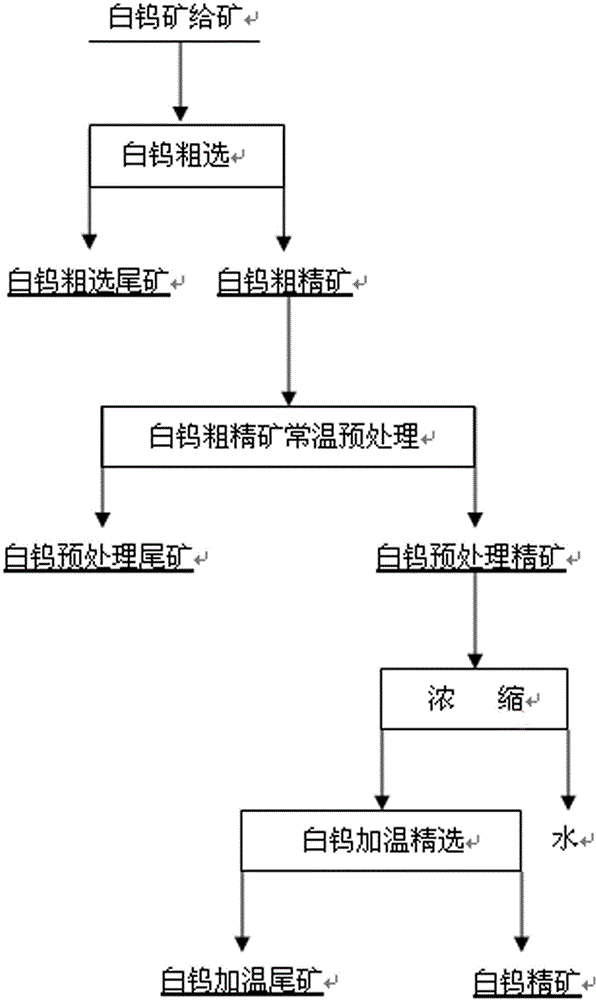

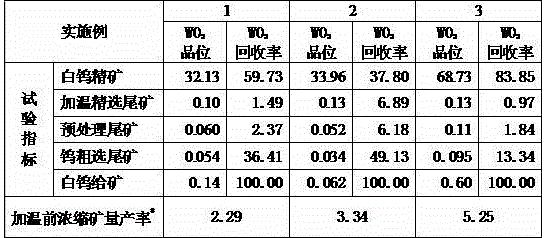

Scheelite beneficiation method

Disclosed is a scheelite beneficiation method. The scheelite beneficiation method is characterized by sequentially including the following steps of scheelite rough concentration, scheelite rough concentrate normal temperature pretreatment and scheelite pretreatment concentrate heating concentration. As for scheelite rough concentration, according to scheelite ore feeding, one time of rough concentration, two to three times of fine concentrations and two to three times of scavenging are performed to obtain scheelite rough concentrate and scheelite rougher tailings; as for scheelite rough concentrate normal temperature pretreatment, according to scheelite rough concentrate, one time of rough concentration, two to three times of fine concentrations and two to three times of scavenging are performed to obtain scheelite pretreated concentrate and shceelite preheated tailings; as for scheelite pretreatment concentrate heating concentration, scheelite pretreated concentrate is concentrated to 60%-70% in concentration; heating is performed to reach 80 DEG C to 95 DEG C, and according to scheelite pretreated concentrate, one time of rough concentration, two to three times of fine concentrations and two to three times of scavenging are performed to obtain scheelite concentrate and scheelite heated tailings. According to the scheelite beneficiation method, concentrated and heated ore quantities can be reduced, good indicators in beneficiation of scheelite concentrate can be achieved, and the scheelite beneficiation method is applicable to flotation of scheelite in which the WO3 content is 0.06%-0.85%, the CaCO3 content is larger than or equal to 10% and CaF2 content is larger than or equal to 5%.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

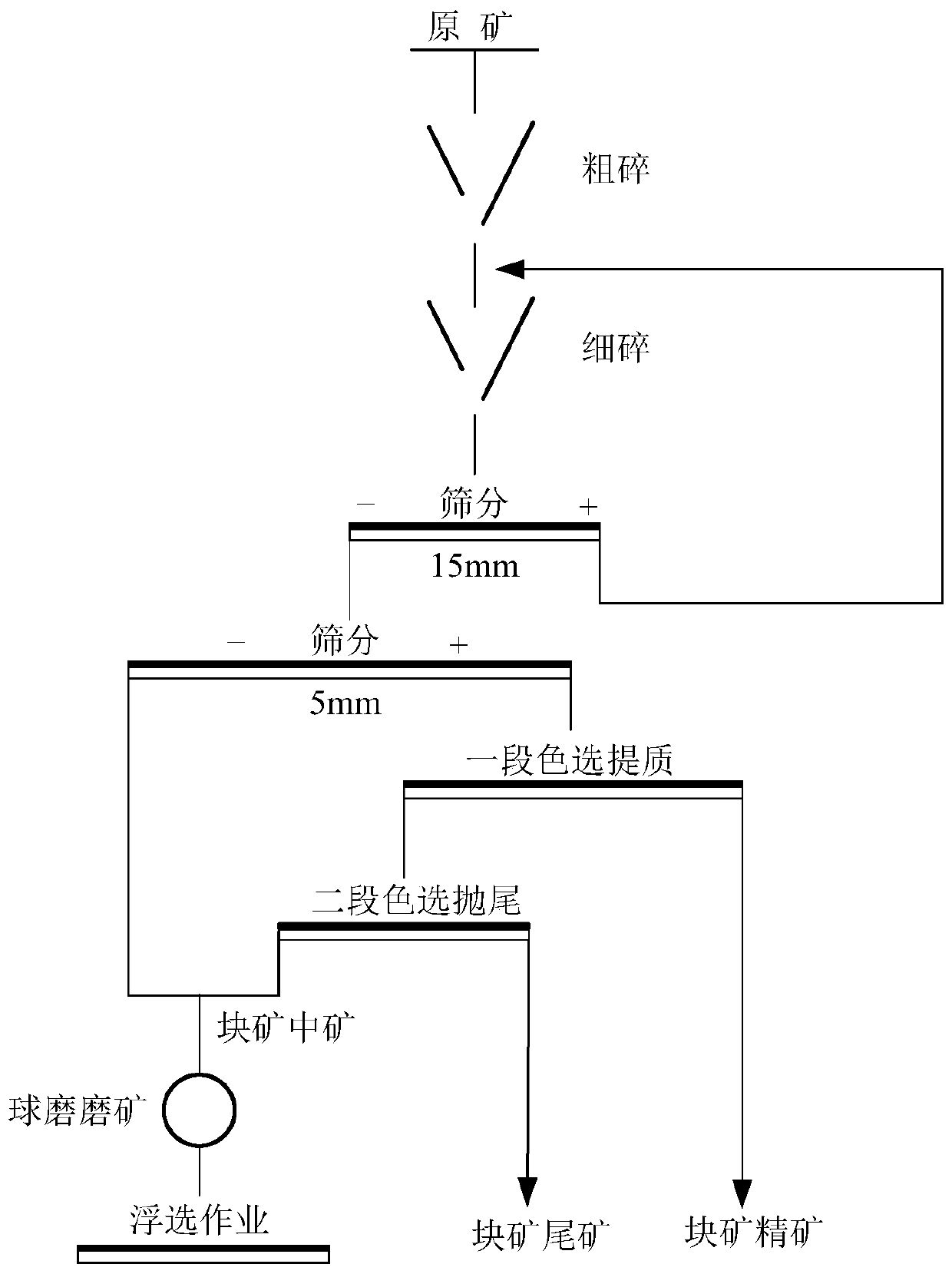

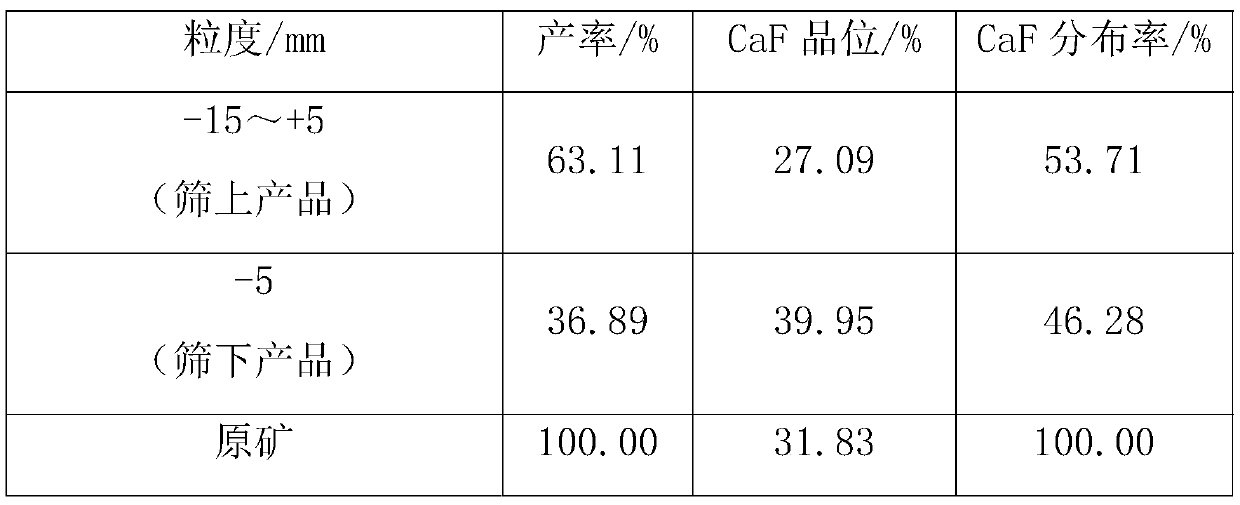

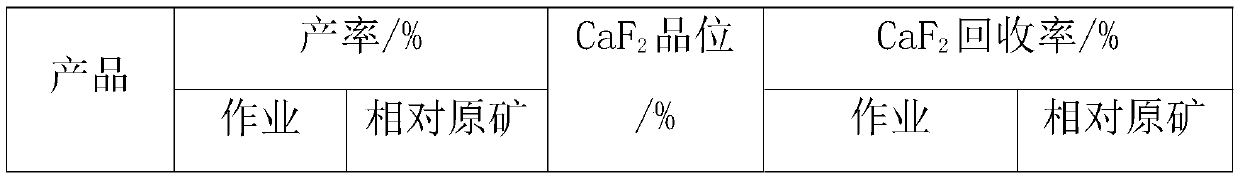

Fluorite lean ore color sorting upgrading-tailing pre-sorting method

The invention provides a fluorite lean ore color sorting upgrading-tailing pre-sorting method. The method comprises the following steps that (1) fluorite lean ore is crushed through two sections of closed circuits, and crushed products are -15 mm; (2) the crushed products are screened to obtain oversize products and undersize products, wherein the size of sieve pores is 5 mm, and the oversize products enter a first section color sorter for fluorite upgrading and sorting to obtain lump ore concentrates; (3) tailings sorted through the first section of color sorter enter into a second-section color sorter for tailing discarding sorting to obtain lump ore tailings and lump ore middlings; and (4) the undersize products in the step (2) and the lump ore middlings in the step (3) are mixed and ground, and then flotation is conducted. According to the method, the raw ore amount entering a ball mill is greatly reduced by pre-upgrading and sorting and pre-tailings-discarding of a large quantityof hard minerals, so that the beneficiation feed grade is improved, over-crushing of the hard minerals to the fluorite in the ore grinding process is reduced, so that the production cost is reduced, and the sorting quality is improved.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Mineral floatation colleting agent and manufacturing method thereof

InactiveCN105750091AGuarantee beneficiation effectImprove the quality of selectionFlotationPhenyl EthersPolythylene glycol

The invention discloses a mineral floatation colleting agent, and especially discloses a mineral floatation colleting agent and a manufacturing method thereof, and belongs to the technical field of floatation colleting agents. The raw materials comprise the following components in the following parts by weight: 0.30-0.70 parts of oleic acid, 0.20-0.40 parts of oxidized paraffinum sodium salt, 0.02-0.08 parts of emulgator, 0.10-0.20 parts of C7-9 hydroximic acid, 0.05-0.10 parts of polyethylene glycol octylphenol ether, and 0.05-0.12 parts of citric acid. The colleting agent is manufactured by the following method: heating the oleic acid and the oxidized paraffinum sodium salt, and adding an alkali liquor, mixing, saponifying, and adding the emulgator and mixing uniformly, and finally adding the C7-9 hydroximic acid, the polyethylene glycol octylphenol ether, and the citric acid, and mixing uniformly to form the colleting agent. The colleting agent is advantaged by environmental-friendly and low cost while effectively ensuring mineral separation effect of ilmenite floatation collection. After coordination of each component, concentration grade of the ilmenite can be effectively improved, and use amount of sulfuric acid in the floatation is effectively reduced.

Owner:LESHAN SHUNCHEN TECH

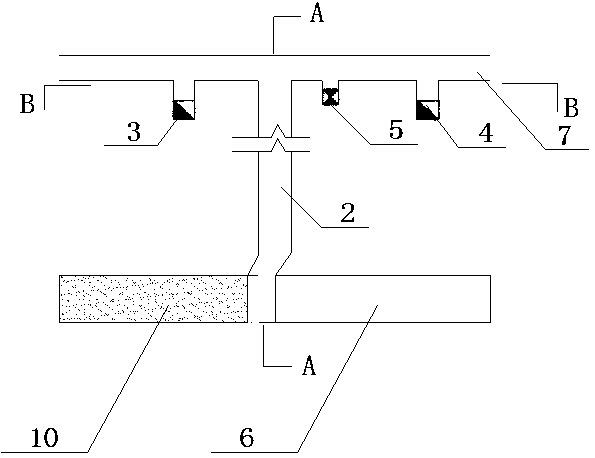

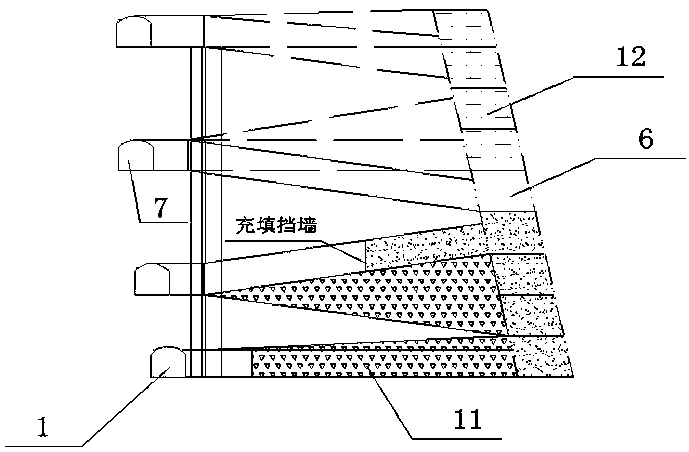

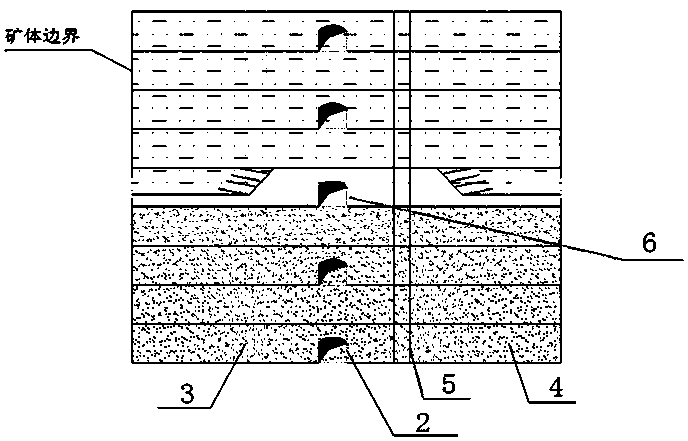

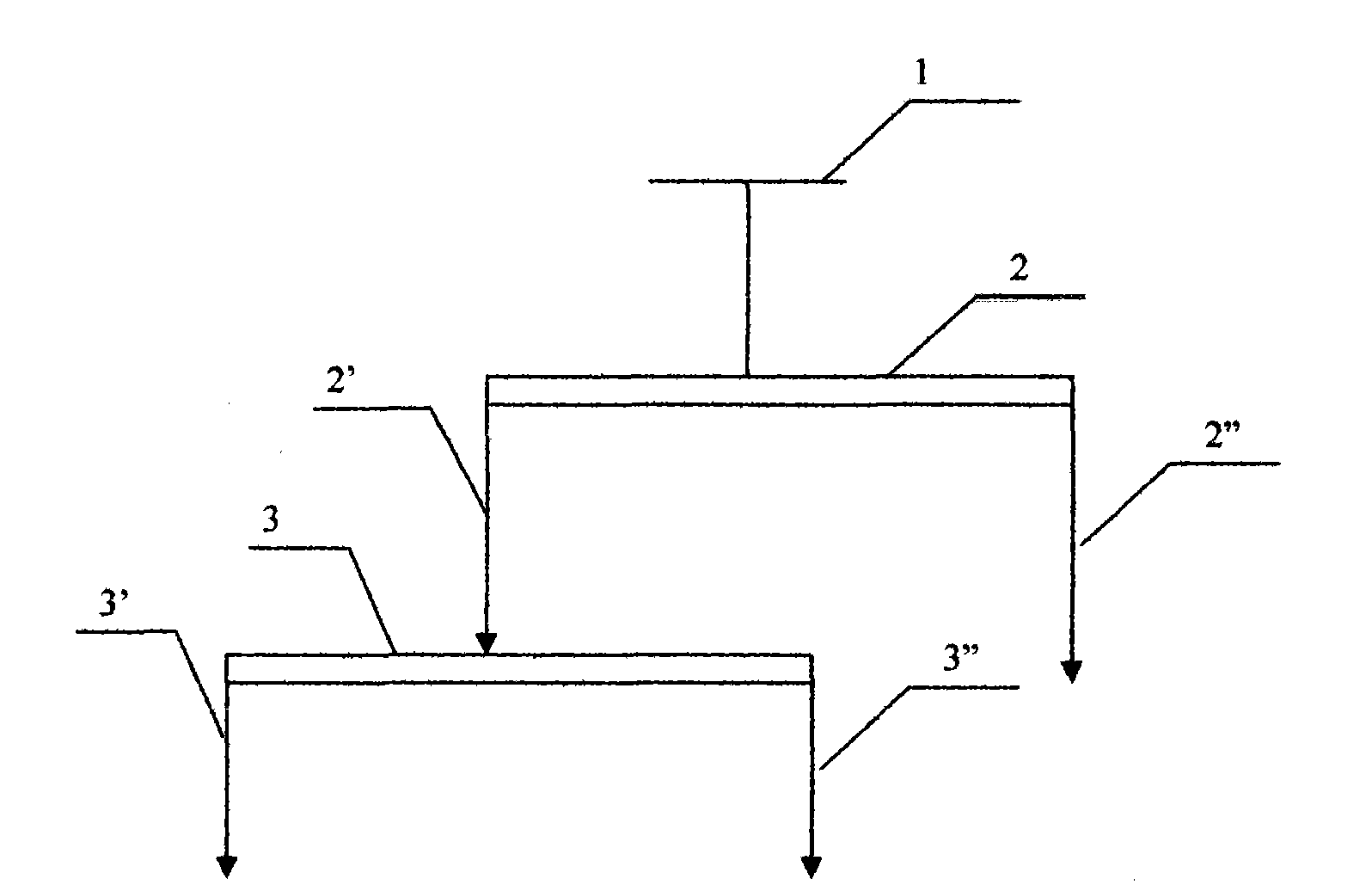

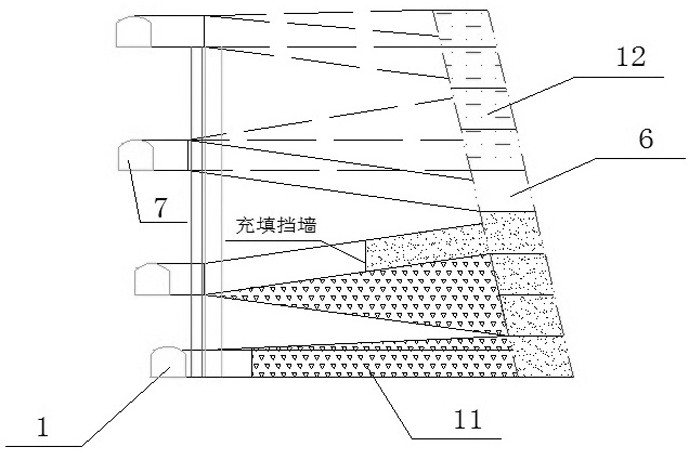

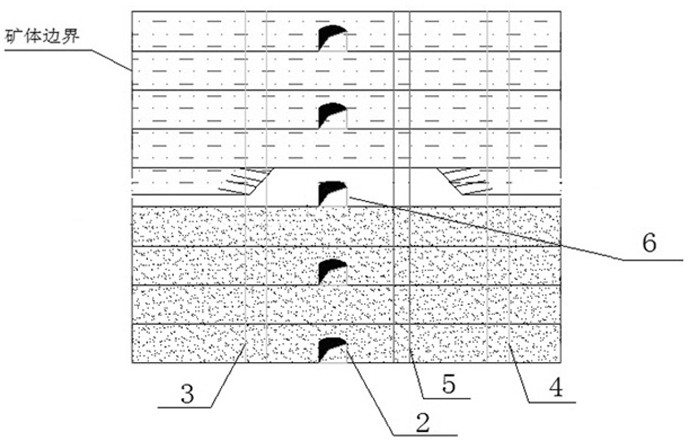

Continuous mining method suitable for high-middle section

ActiveCN110905517AHigh strengthImprove recovery efficiencyUnderground miningSurface miningMining engineeringMechanical engineering

The invention provides a continuous mining method suitable for a high-middle section. The method comprises the steps of S1, a stope preparation project and S2, a back production project. The stope preparation project comprises the steps that S101, a high-middle section stope is divided into a plurality of layered stopes; S102, an out-of-vein roadway is tunneled along the trend on the lower plate of the ore body, and then a sectional flat roadway and a stope connected roadway are tunneled, wherein the central line of the stope connected roadway is perpendicular to the central line of the corresponding layered stope; S103, a filling return air service raise is arranged and communicates with the out-of-vein roadway, the sectional flat roadway and the stope connected roadway; a waste stone chute and an ore chute are respectively arranged; and S104, a bottom pillar is not left in the high-middle section stope, a bottom-pulling roadway is directly tunneled at the upper part of a bottom plate, the bottom-pulling roadway is expanded to the boundary of a mine room by taking the bottom-pulling roadway as a free surface, a bottom-pulling space is formed, top-lifting mining is performed upwards, and mined ore is transported away. In the back production project, the stope with relatively stable rock conditions adopts an upward horizontal layering filling mining method, and the stope with relatively broken rock condition adopts an upward horizontal drift filling mining method. The method can effectively improve the back production strength and the ore drawing efficiency of the thin ore body.

Owner:山东金洲矿业集团有限公司

Comprehensive recovery production method with gold concentrate flotation and cyanide flotation

Owner:SHANDONG GOLD MINING LAIZHOU CO LTD REFINERY

Pre-sieving technology added before flotation operation

The invention relates to a prescreening process added before floatation operation. The prescreening process is characterized in that the process comprises: adding the prescreening process during thickness classification operation before floatation; condensing floatation fed ore through a large condensation well; carrying out purification treatment of condensation overfall; feeding condensation underset into a sieve to carry out screen separation; feeding minus mesh into floatation operation to carry out floatation; taking plus sieve and floatation operation tailings as floatation tailings; and taking floatation operation ore concentrate as floatation ore concentrate. A vibration sieve (with the sieve mesh ranging from 0.1 to 0.2 mm) is installed before floatation feeding to carry out screen separation of floatation fed ore; minus mesh is fed into a floatation operation feeding box to carry out floatation, while plus sieve and floatation operation tailings are combined as operation tailings; moreover, material overflowed during thickness classification operation before floatation is turned into floatation operation feeding material through magnetic separation operation. The prescreening process can eliminate coarse granule during floatation operation, thereby increasing floatation milling grade and treatment capacity of floatation operation and reducing the consumption of floatation reagent.

Owner:ANSTEEL GRP MINING CO LTD

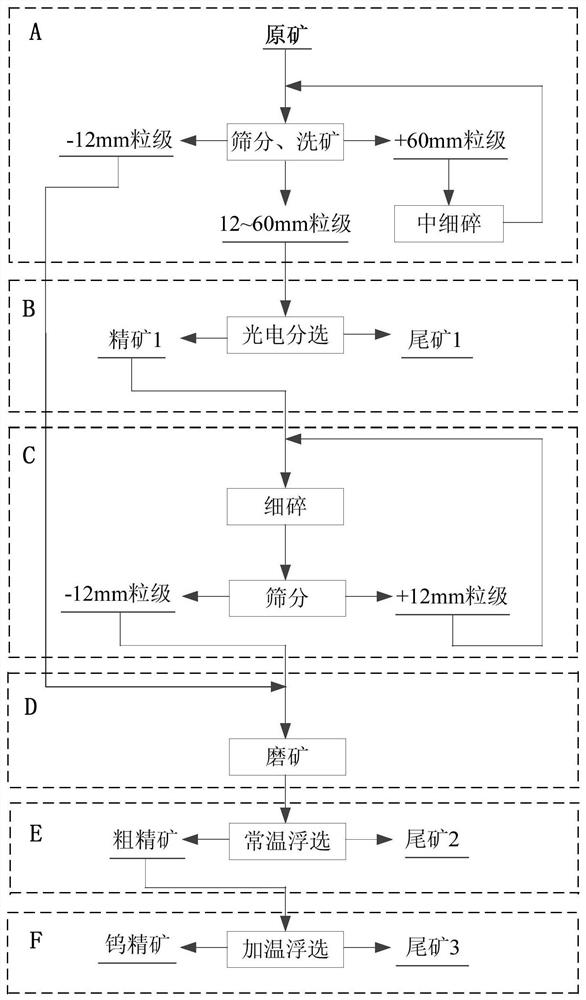

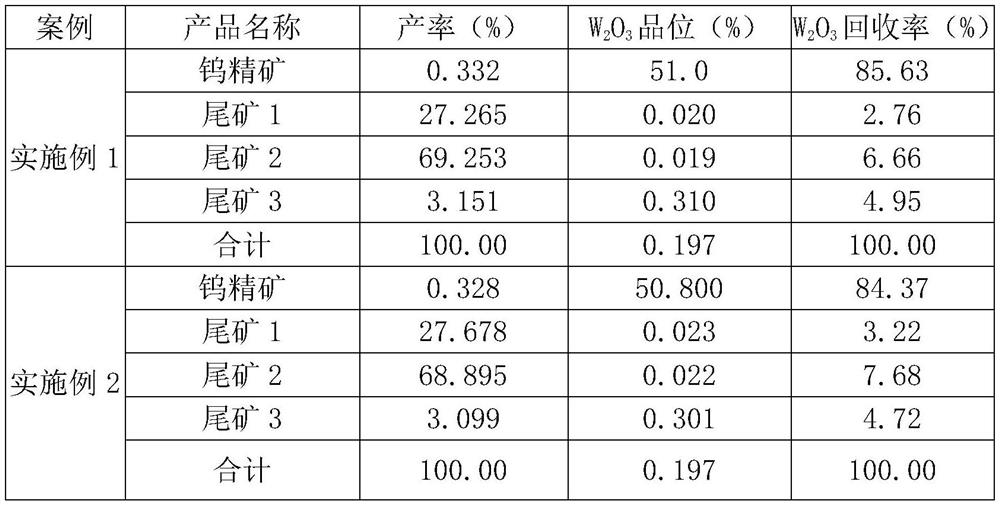

Beneficiation method of low-grade tungsten ore

InactiveCN111841871AImprove the quality of selectionEfficient use ofWet separationOre concentrateMineralogy

The invention relates to a beneficiation method of low-grade tungsten ore. A combined technology including crushing and screening, photoelectric sorting, fine screening, ore grinding and dual-temperature flotation is utilized. Qualified tungsten concentrate is obtained through three-stage tailings throwing, low-grade tungsten ore resources are utilized, tungsten can be efficiently recycled, the recovery rate of the tungsten ore W2O3 reaches 85% or above, the grading cost can also be reduced, and the comprehensive utilization rate of the resources is improved. The method has the advantages of being simple and feasible, high in operability and environmentally friendly and having important reference significance for utilization of other mineral low-grade ore, and is suitable for the mining and metallurgy industry to use.

Owner:ZIJIN MINING GROUP

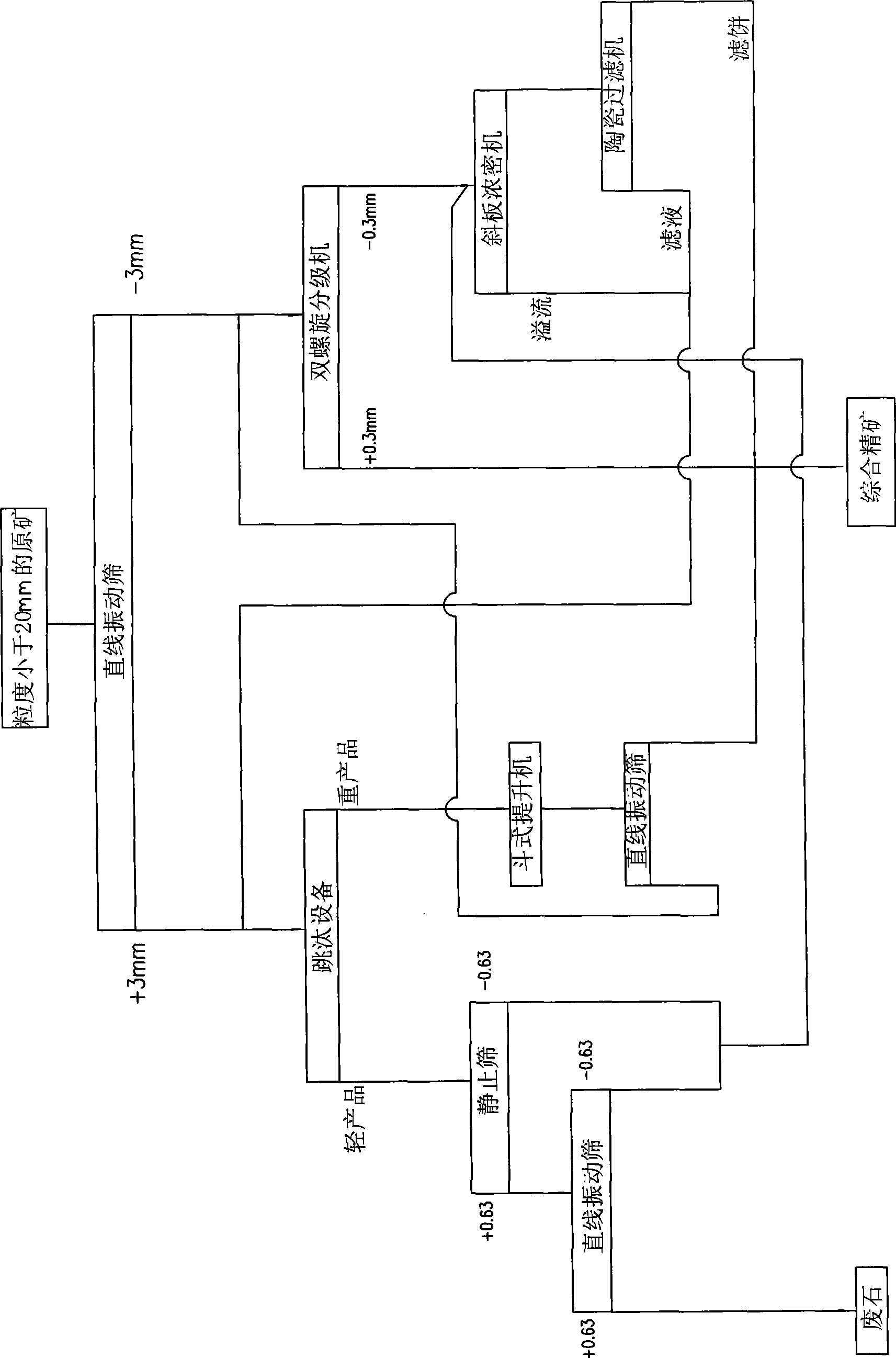

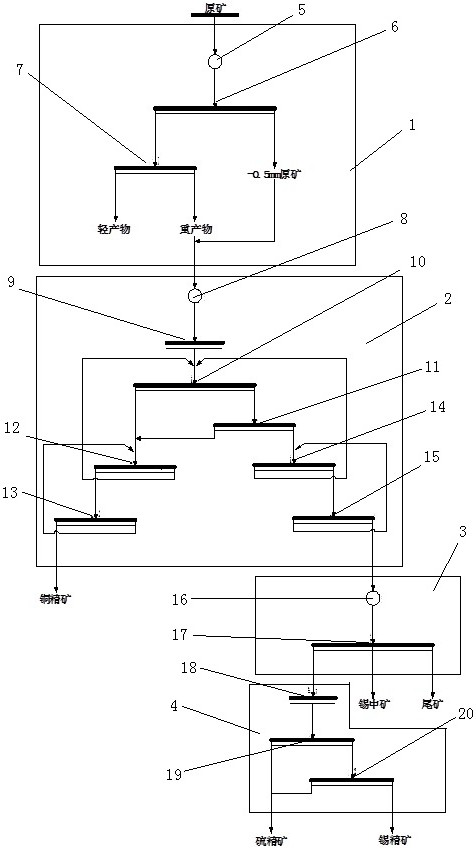

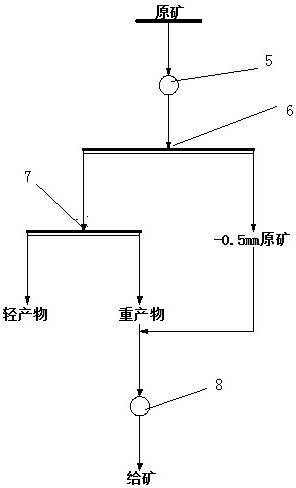

Coarse-size separation technique

The invention discloses a rough particle separation process comprising the following steps: (1) after the particle size of a pulverized greenore achieves 20mm, pulverized ores are processed by the operation of wet prescreening to separate fine particle products which are smaller than or are equal to 3 mm and 3-20mm rough particle products, and the fine particle products which are smaller than or are equal to 3 mm are dehydrated to be directly led into the next step of ore benefication; (2) the 3-20mm rough particle products are led into jigging equipment; according to the composition and the distribution of the ores, light products, i.e. waste rocks, and heavy products are separated by the jigging equipment, and the heavy products are discharged from the bottom of the jigging equipment; and (3) the heavy products discharged from the bottom of the jigging equipment are dehydrated by dehydration plant and then are led into the next step of ore benefication. The invention adopts a BATAC wind pulse jigger as the jigging equipment. The rough particle separation process can greatly improve the selection level of the ores, and has the advantages of simple technological procedure, easy engineering, environmental protection and energy saving.

Owner:CINF ENG CO LTD

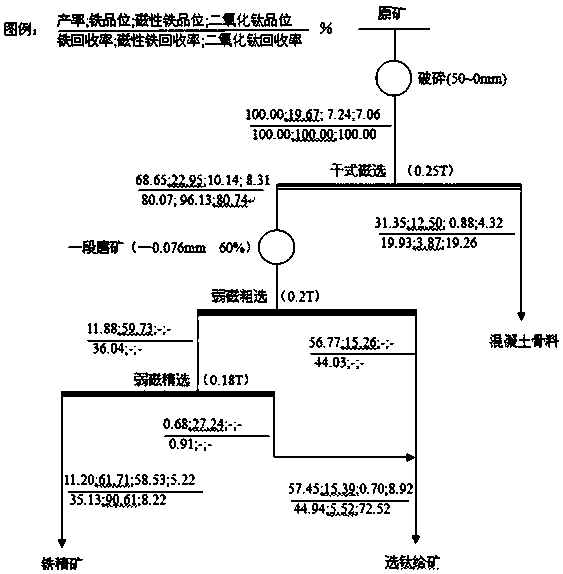

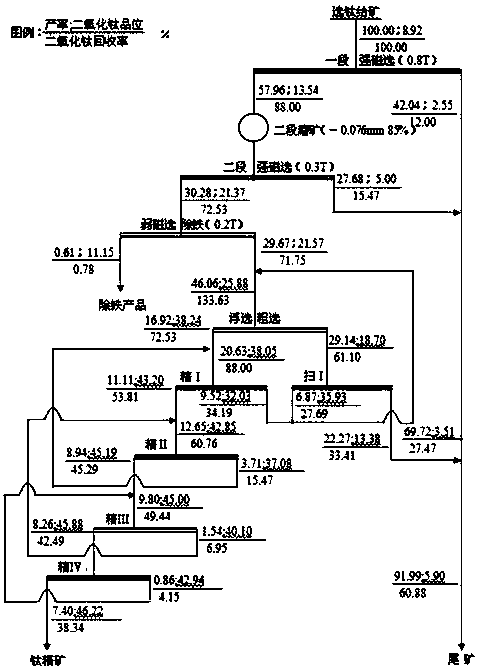

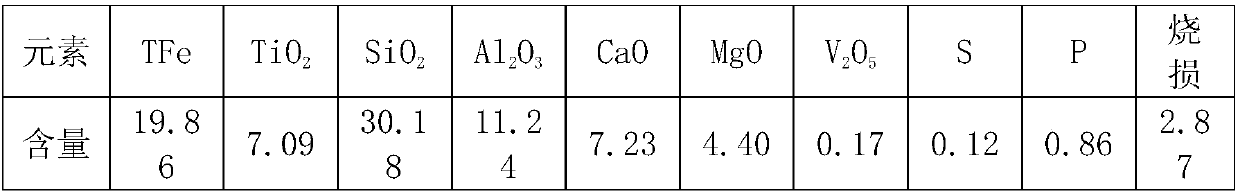

Method for sorting low-grade titaniferous magnetite

ActiveCN107649278AReduce follow-up job processingImprove the quality of selectionHigh gradient magnetic separatorsFlotationBeneficiationLow graded

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

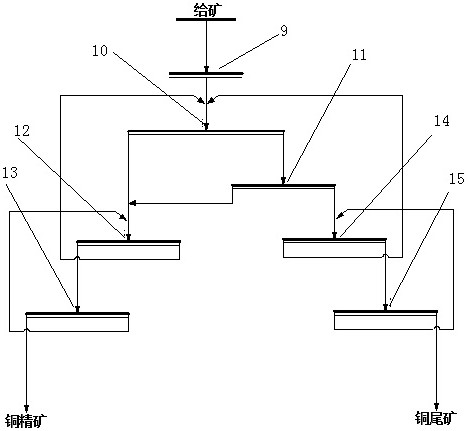

Copper-tin ore separation process

ActiveCN114308368AImprove the quality of selectionReduce storage capacityProcess efficiency improvementWet separationCassiteriteCopper

The invention relates to the technical field of copper-tin ore beneficiation, in particular to a copper-tin ore separation process which is characterized by comprising the following separation steps: (1) dense medium separation: crushing raw ore of copper-tin ore, and sequentially removing light-specific-gravity minerals with the specific gravity lower than that of copper minerals and tin minerals in the ores; (2) copper recovery: carrying out copper flotation on the ore pulp subjected to ore grinding treatment to obtain copper concentrate and copper tailings; (3) tin recovery: regrinding the copper tailings, feeding the copper tailings into a table concentrator, and separating to obtain tin rough concentrate, tin middlings and tailings; and (4) tin rough concentrate desulfurization: carrying out desulfurization flotation on the obtained tin rough concentrate, and separating to obtain tin concentrate and sulfur concentrate. The method has the advantages that the selected grade is high, the concentrate index is ensured, the production cost is reduced, the economic benefit is improved and the like.

Owner:CENT SOUTH UNIV +1

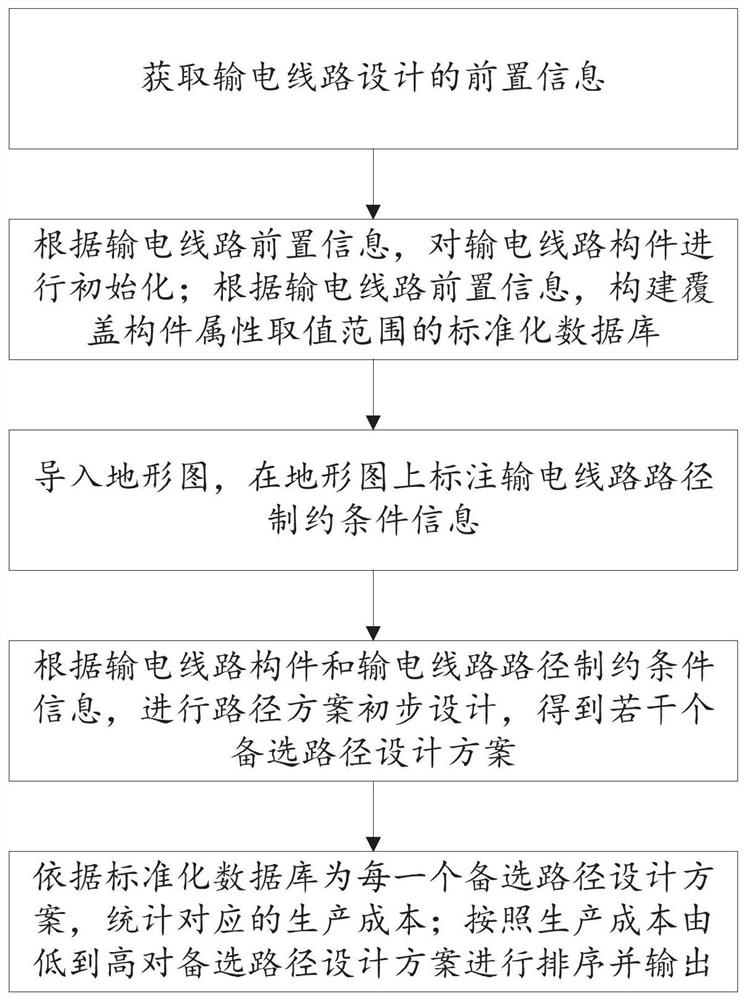

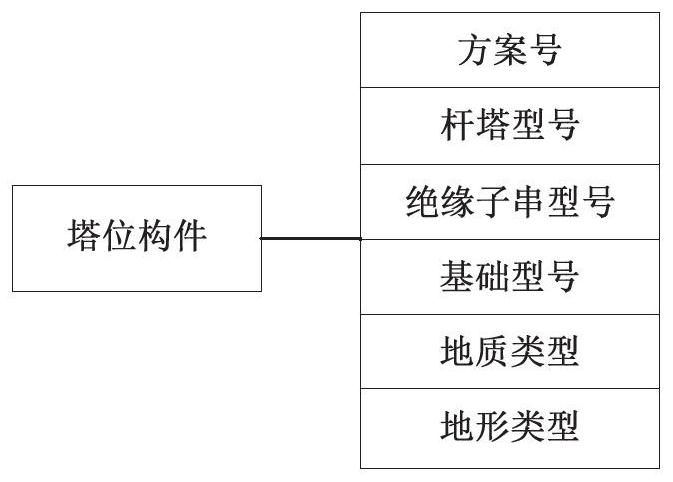

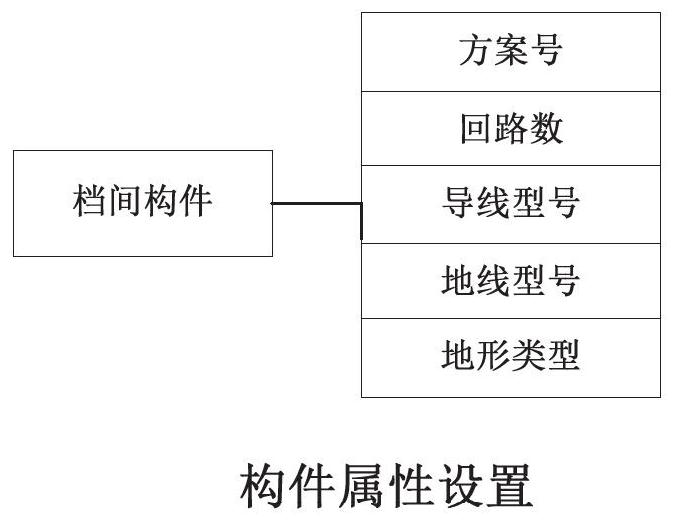

Power transmission line path selection method and system

PendingCN111611664AImprove the level of parallel collaborative designReduce handoverGeometric CADConstraint-based CADTopographic mapComputer science

The invention discloses a power transmission line path selection method and system. The method comprises the following steps: acquiring preposition information of power transmission line design; initializing a power transmission line component according to the power transmission line preposition information; constructing a standardized database covering a component attribute value range accordingto the power transmission line preposition information; importing a topographic map, and marking power transmission line path constraint condition information on the topographic map; according to thepower transmission line component and the power transmission line path constraint condition information, carrying out path scheme preliminary design to obtain a plurality of alternative path design schemes; designing a scheme for each alternative path according to a standardized database, and counting the corresponding production cost; and sorting and outputting the alternative path design schemesaccording to the production cost from low to high.

Owner:SHANDONG ELECTRIC POWER ENG CONSULTING INST CORP

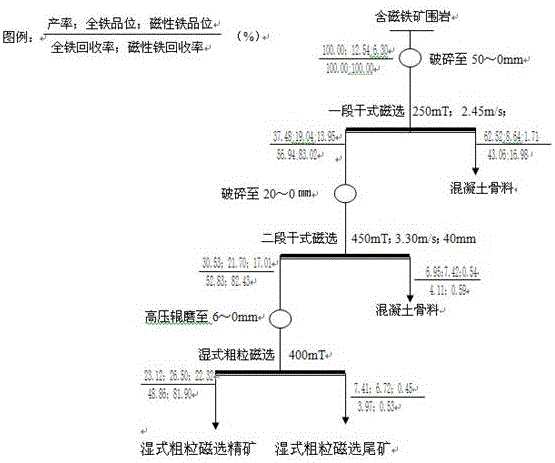

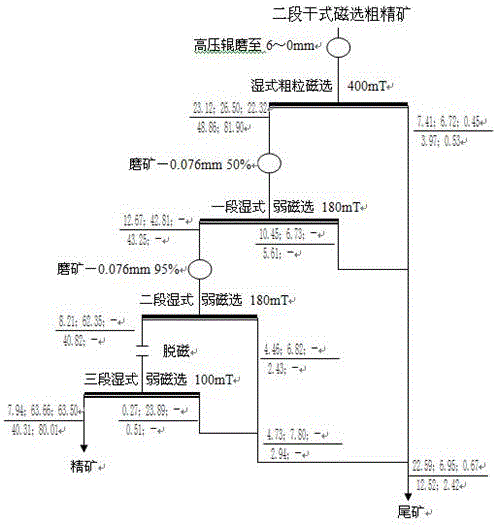

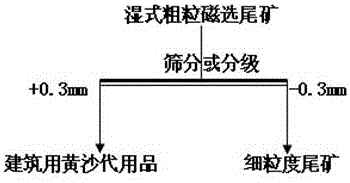

A method for comprehensive utilization of surrounding rock containing magnetite

ActiveCN104722396BEmission reductionReduce follow-up job processingMagnetic separationMagnetiteHigh pressure

Owner:MASTEEL GRP MINING CO LTD +2

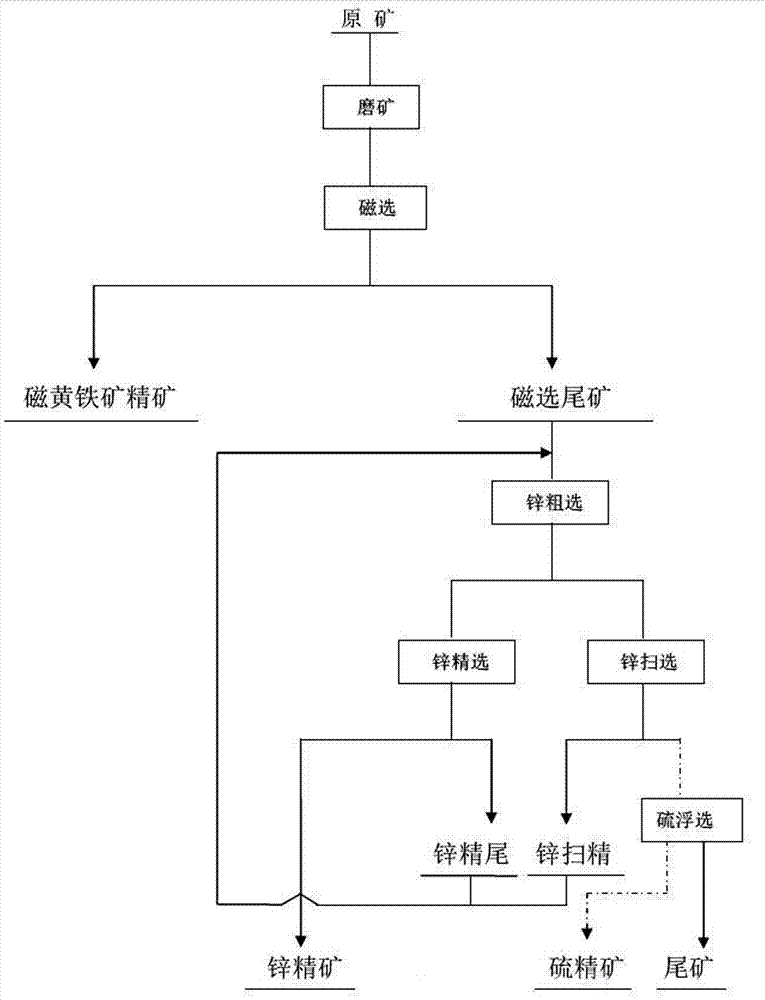

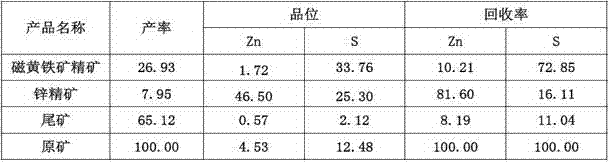

Zinc-sulfur separation and beneficiation method of pyrrhotite-rich zinc sulfide ore

Owner:SHENYANG RES INST OF NONFERROUS METALS

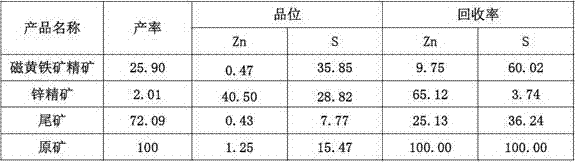

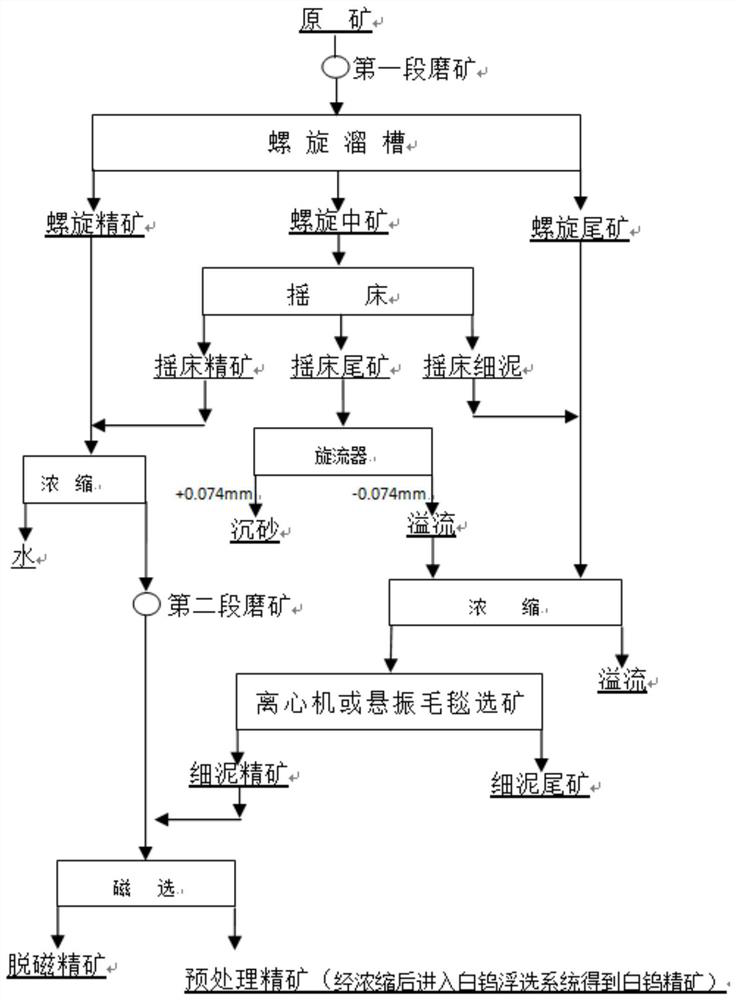

Pretreatment method for high-calcium and high-magnesium fine-grained disseminated scheelite

ActiveCN111715399AImprove beneficiation efficiencyReduce the effect of flotationSolid separationMechanical material recoveryPretreatment methodMining engineering

The invention belongs to the technical field of mineral treatment, and particularly discloses a method for pretreating high-calcium and high-magnesium fine-grained disseminated scheelite. The method comprises the steps: raw scheelite is subjected to two times of gravity-separation classification after being subjected to primary grinding, primary concentrating and secondary concentrating are combined for secondary grinding, and then magnetic-separation treatment is conducted; secondary tailings are de-slimed to obtain a spillover flow, the spillover flow, fine slime and primary tailings are enriched, and fine slime concentrate is obtained; the fine slime concentrate enters into magnetic-separation treatment; and ore pulp of secondary grinding and the fine slime concentrate are combined to be subjected to magnetic-separation treatment, and pretreated concentrate is obtained. According to the pretreatment method, the technical problem that the high-calcium and high-magnesium slime is agglomerated, and consequently the fine-grained disseminated scheelite is difficult to recover is solved, most gangue minerals and slime are abandoned through pretreatment, the amount of ore entering intosubsequent scheelite flotation is decreased, the beneficiation feed grade of WO3 in the flotation ore is increased, and the using quantity of a reagent during subsequent flotation is greatly decreased.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

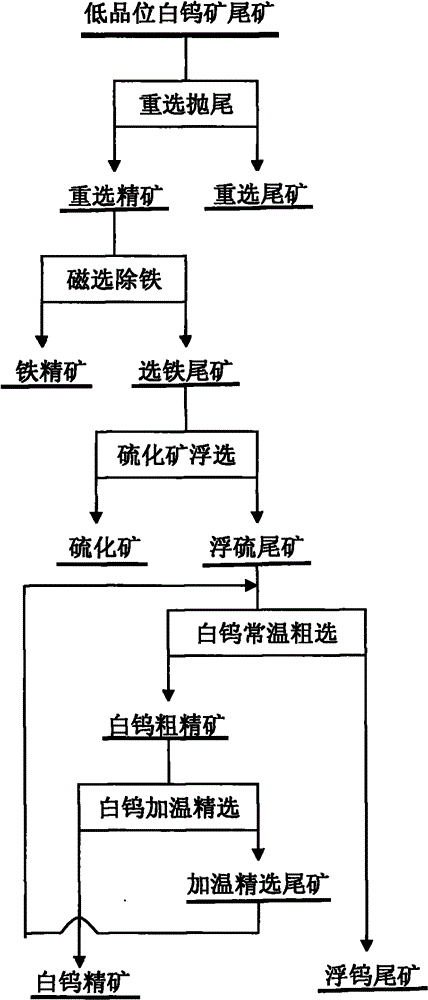

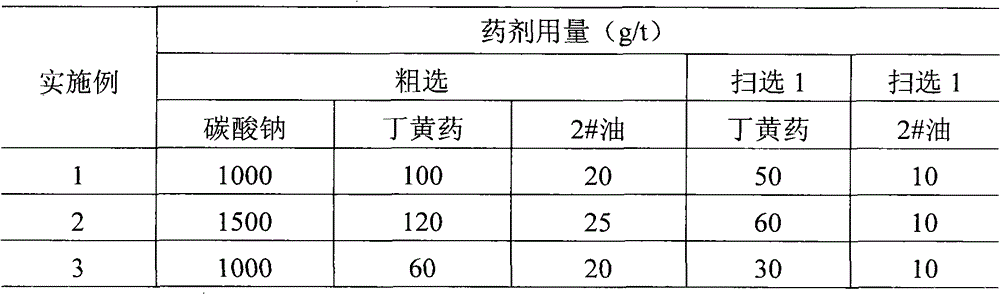

Ore dressing method of low-grade scheelite

InactiveCN101869876BImprove sorting indexImprove the quality of selectionFlotationMining engineeringSulfidation

The invention relates to an ore dressing method of a low-grade scheelite, which is characterized by comprising the following steps: 1. tailing discard by gravity concentration; 2. iron removal by magnetic separation; 3. sulfide ore flotation; 4. normal-temperature rougher flotation of scheelite; and 5. heating concentration of the scheelite. The invention provides a lower-cost ore dressing method for dressing scheelite concentrates from the tailings of the low-grade scheelite. The invention has the characteristics that the comprehensive recovery cost is saved, the beneficiation feed grade of the scheelite is improved, the flotation feed ore quantity is reduced, the dosage of a flotation reagent is reduced, the used ore dressing reagent is more friendly to the environment, and secondary pollution can not be caused. The method of the invention is applicable for low-grade scheelite resources with 0.03 to 0.15 percent of WO3.

Owner:广东省资源综合利用研究所

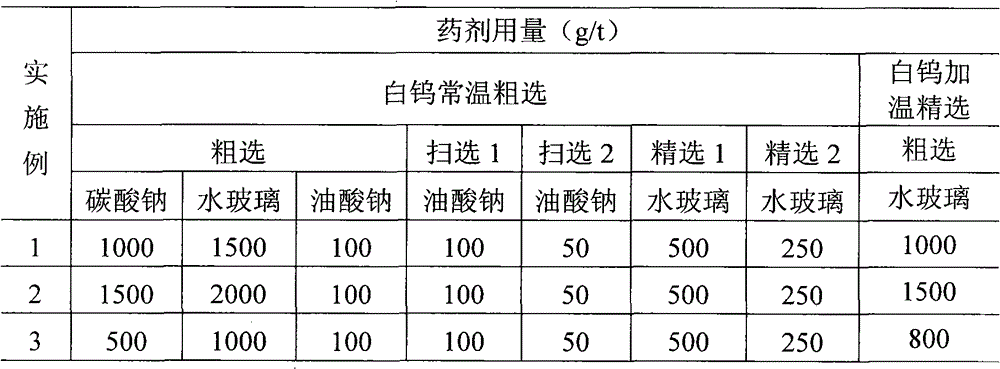

Dry pre-concentration process for weakly magnetic iron ore by size grading

The invention relates to a dry pre-concentration process for weakly magnetic iron ore by size grading. The process mainly includes the following process steps that the granularity of weakly magnetic iron ore ranges from 0 to 80 mm after the weakly magnetic iron ore is crushed, and the crushed weakly magnetic iron ore is graded in different particle size ranges of 0 to 15 mm, 15 mm to 30 mm, 30 mm to 50 mm, 50 mm to 80 mm and the like through a mechanical vibration screen; the ore with the particle size of 0 to 15 mm is graded in different particle size ranges of 0 to 3 mm, 3 mm to 10 mm, 10 mm to 15 mm and the like through a multi-roller granularity classification device or a fine screen; and the iron ore in different particle size ranges is subjected to separation of ore and surrounding rock through a dry type high-intensity magnetic separation machine, a jigger and composite dry type gravity concentration equipment. Dry type pre-concentration of the weakly magnetic iron ore is achieved, and the technical problem that the weakly magnetic iron ore cannot be subjected to pre-concentration or pre-concentration cost is high is solved; and conditions are created for reducing following ore dressing procedure cost and improving ore feed grades, the domestic weakly magnetic iron ore development and utilization cost is further reduced, and the competitive power of iron and steel enterprises is improved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

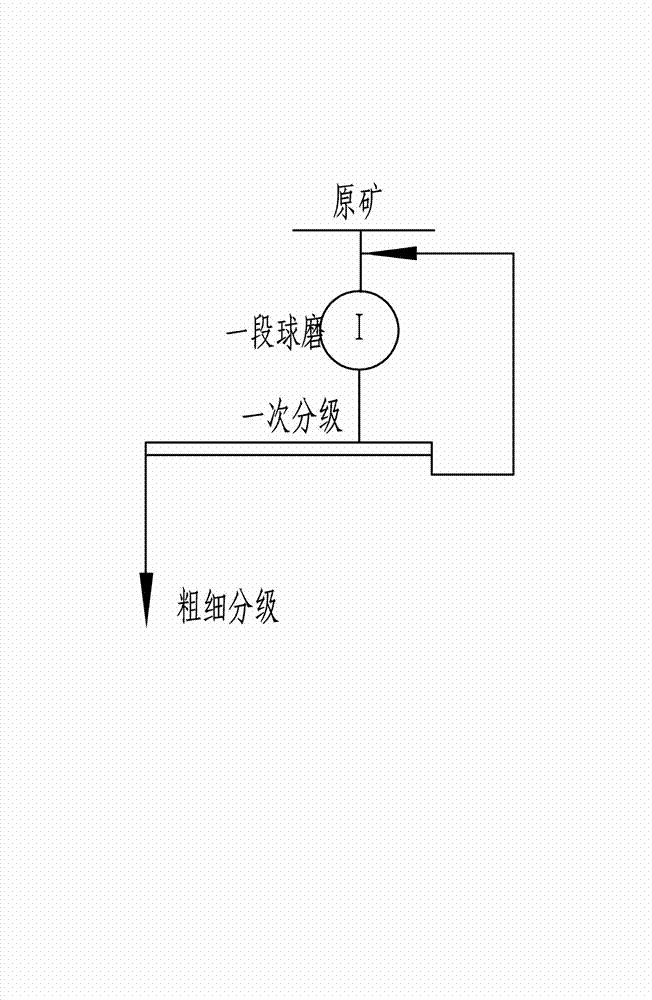

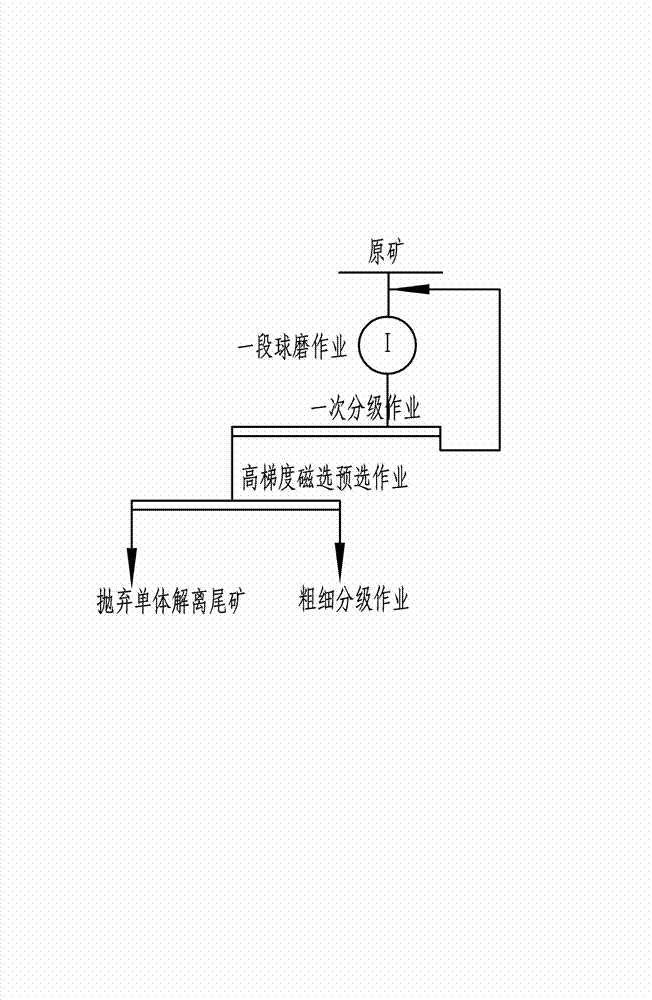

Preselecting technology for extremely hungry hematite one-step classifying overflows through high gradient magnetic separator

InactiveCN102814233AImprove the quality of selectionOptimize sorting statusMagnetic separationSeparation technologyMagnetic separator

The invention belongs to the field of mineral separation technologies, and particularly relates to a preselecting technology for extremely hungry hematite one-step classifying overflows through a high gradient magnetic separator. The preselecting technology comprises the steps of processing raw ores-grinding the ores at a first section-classifying by one step-classifying based on the thickness; and the preselecting technology is characterized in that a) charging overflows of a whirlcone under the one-step classifying work to the high gradient magnetic separator to be processed, and returning sunken sand in the one-step classifying work to the one-step ore grinding work, so as to form a closed ore grinding section; b) charging concentrate processed by the high gradient magnetic separator into a thickness classifying work; and removing tailings which are subject to monomer separation under the high gradient magnetic separator. According to the preselecting technology provided by the invention, the high gradient magnetic separator is adopted to efficiently preselect low-level ores at a level of 10 to 20%, so that the level of the raw ores entering the thickness classifying work can be raised from 10-20% to 30-35%, and 40% of useless mines are removed, and therefore, the purpose of preselecting is achieved. The preselecting technology has a wide application prospect on hungry hematite and magnetite which have small crystallization granule size.

Owner:ANSTEEL GRP MINING CO LTD

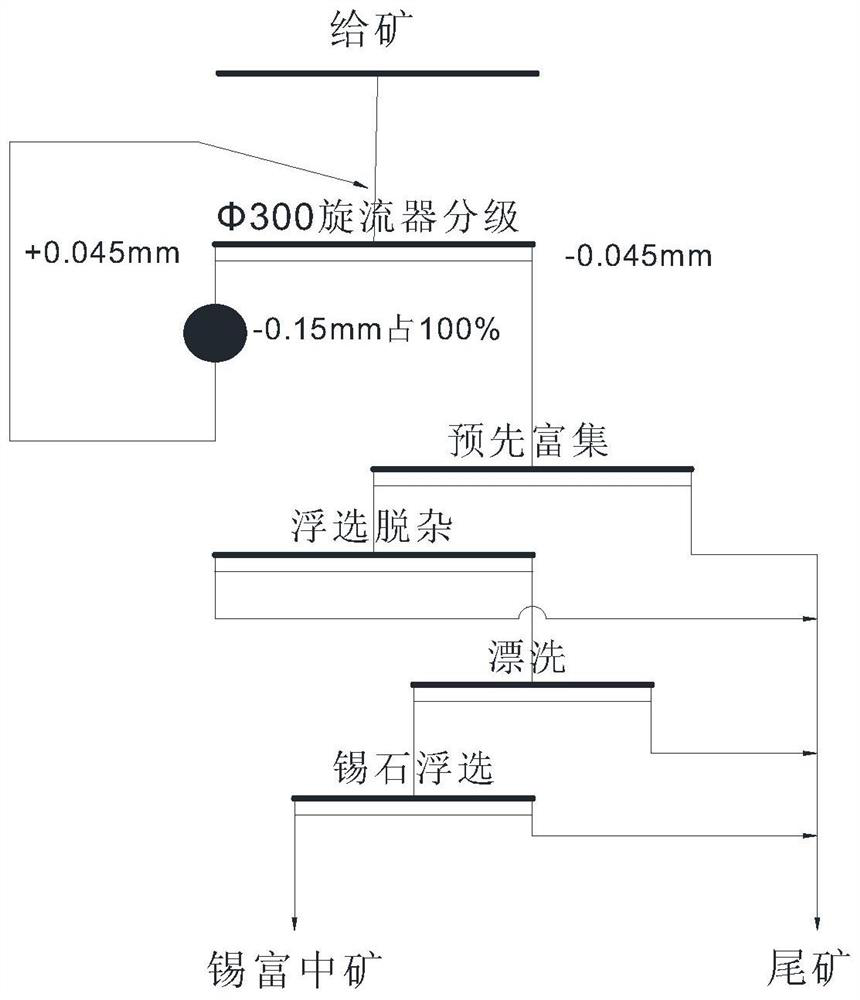

Method for recovering tin metal from low-grade tin old tailings

The invention relates to a method for recovering tin metal from low-grade tin old tailings. The method comprises the following steps: grading the tin old tailings pulped by using a cyclone; after grading, grinding + 0.045 mm size fraction minerals till 0.015 mm size fraction minerals account for 100%; combining the graded 0.045 mm product with the ground 0.015 mm product and carrying out pre-enrichment; carrying out flotation on the enriched concentrate for impurity removal; adding water to rinse after removing calcium-containing impurities, removing reagents, and concentrating; and finally, carrying out tinstone flotation to obtain a product rich in middlings, the tin grade of which is greater than 5%. The method is simple in technological process, good in beneficiation index, low in operation cost and easy to implement industrially, and has good application and popularization prospects.

Owner:云南锡业研究院有限公司

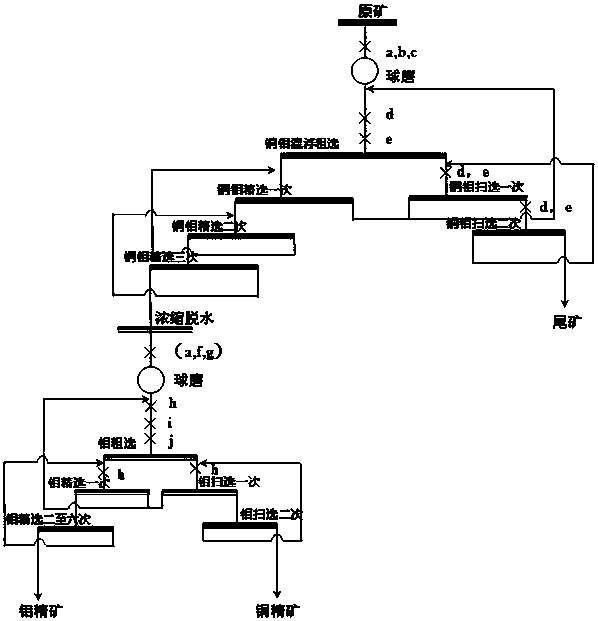

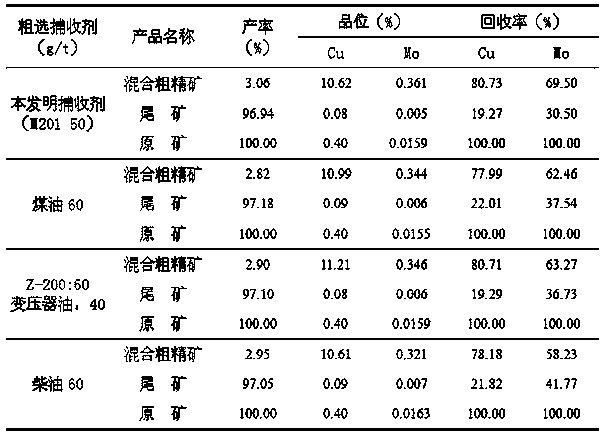

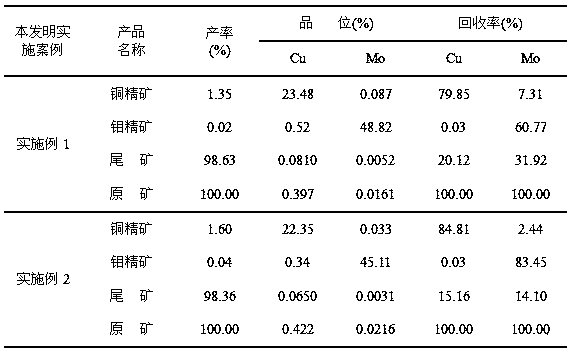

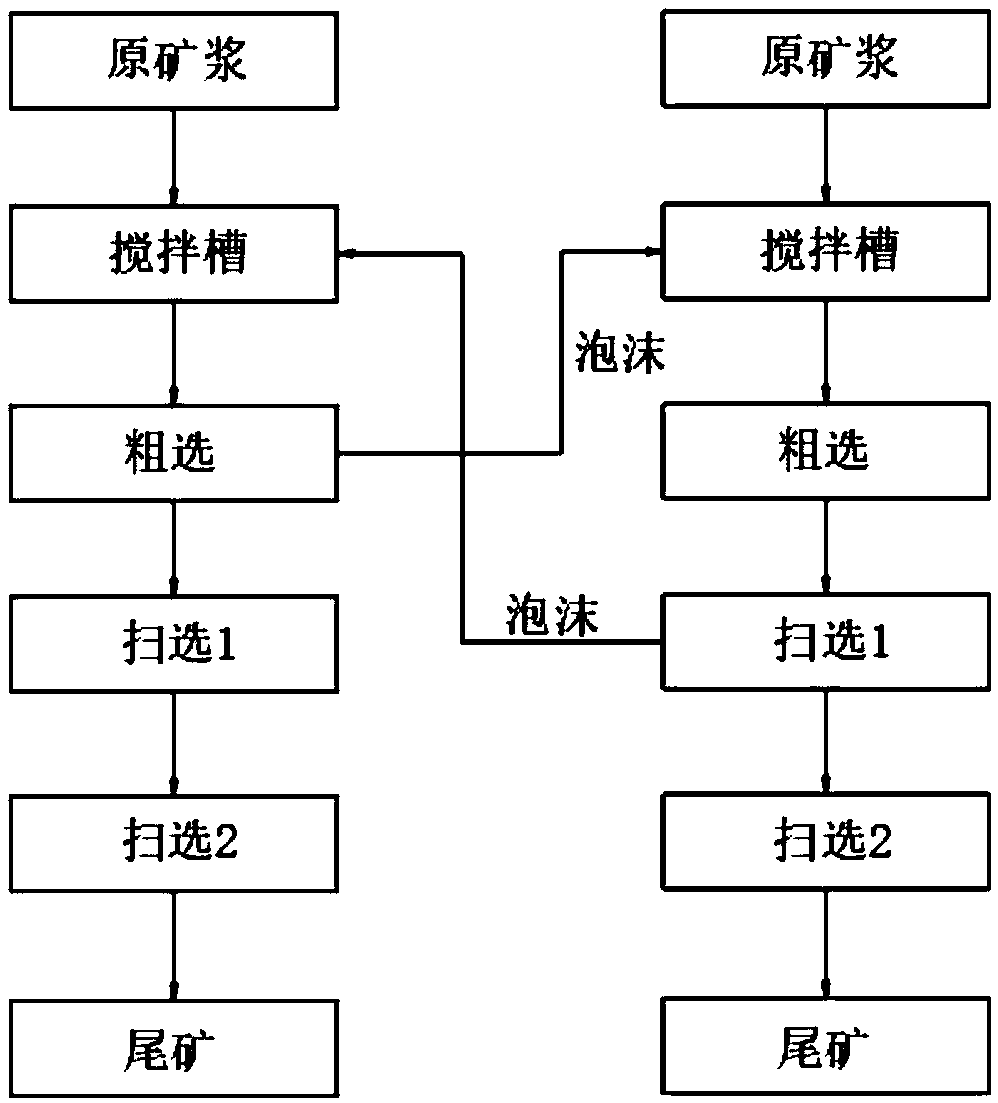

A kind of beneficiation method of molybdenum-containing low-grade mixed copper ore

ActiveCN105435953BImprove the quality of selectionIncrease ion concentrationFlotationWet separationMineral SourcesLower grade

The invention discloses a beneficiation method for low-grade mixed copper ore containing molybdenum. According to the properties and characteristics of the low-grade mixed copper ore containing molybdenum, the copper and molybdenum bulk floatation and re-separation principle technological process is adopted, and high-efficiency concentration of minerals is achieved by using a combination of butyl xanthate and a high-efficiency collector M201 during copper and molybdenum bulk floatation operation; high-efficiency reagent removal of bulk concentrates is achieved through a concentration dewatering and fine grinding method during copper and molybdenum separation operation so that the impact of a large number of reagents existing in copper-lead bulk concentrates on copper and molybdenum separation can be reduced; and moreover, copper minerals are suppressed by means of suppressant F-6, so that separation of copper and molybdenum is effectively realized, and the copper content and molybdenum content of the concentrates are effectively reduced. Meanwhile, in order to stabilize the floatation indexes, the floatation process is optimized for site production, namely, branching and streaming floatation; accordingly, the purpose of comprehensive recovery and utilization of mineral resources is achieved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

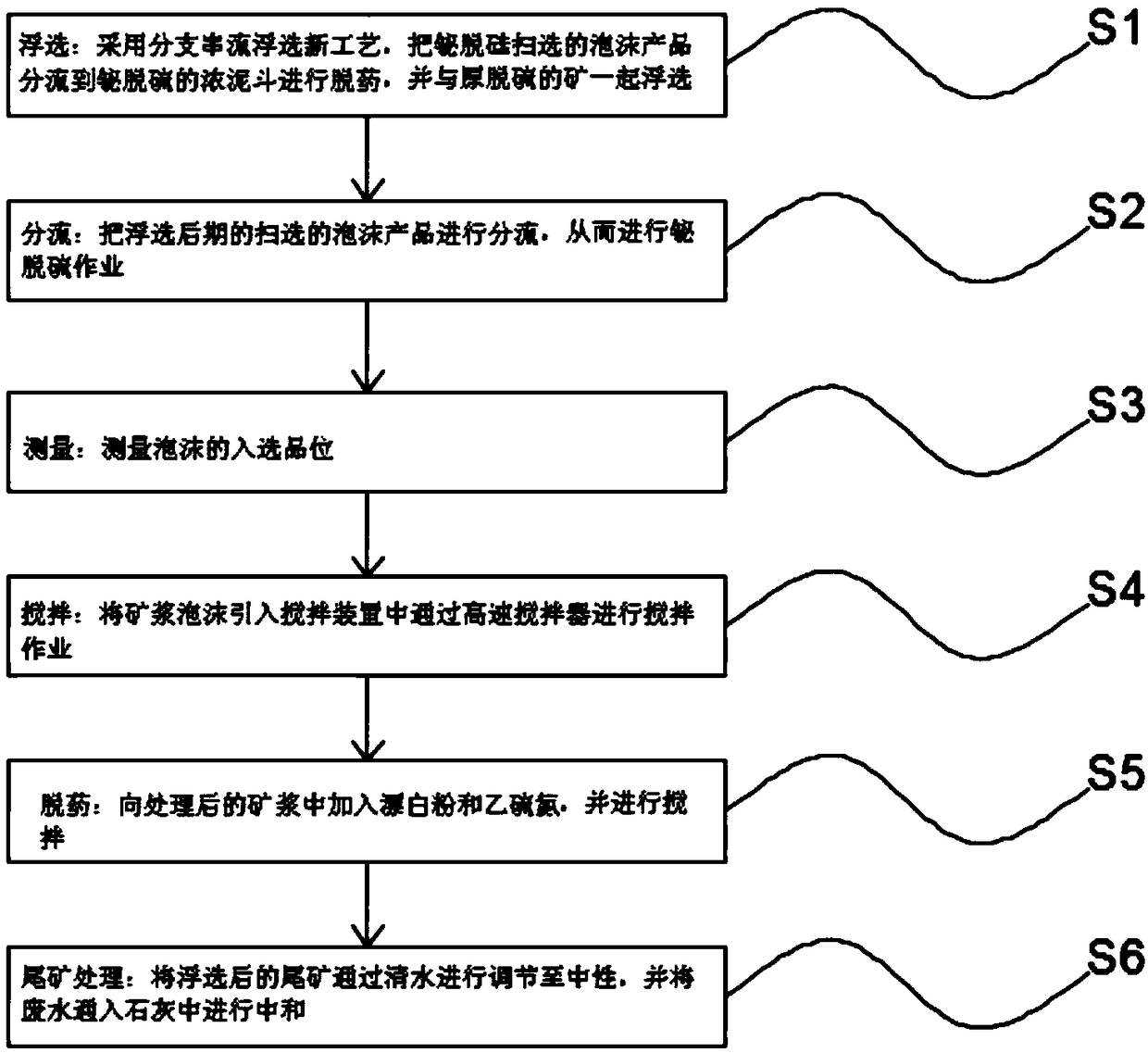

Mineral separation method for replacing sodium cyanide during bismuth concentration

The invention discloses a mineral separation method for replacing sodium cyanide during bismuth concentration. The method comprises the following steps of 1, flotation, wherein a branch series flow flotation novel technology is adopted, a foam product obtained after bismuth silicon removal scavenging and original desulfurated mine are subjected to flotation together; S2, flow division, wherein foams obtained after scavenging at the later period of flotation are subjected to flow division; S3, measurement, wherein the selected grades of the foams obtained after flow division are measured; S4, stirring, wherein pulp foams are introduced into a stirring device for performing stirring work through a high speed stirrer; S5, reagent removal, wherein bleaching powder and ethyl thio carbamate areadded into the treated pulp; S6, tailing treatment, wherein tailings obtained after flotation is adjusted through clean water to be neutral, and wastewater is introduced into lime for performing neutralizing. The method is scientific, reasonable and safe and convenient to use; bleaching powder and ethyl thio carbamate are added into the reagent removal process, sodium cyanide replied on in siliconremoval work in bismuth concentration work is replaced, flotation reagent consumption is lowered, a separation index is increased, and potential safety hazards caused by sodium cyanide leakage are reduced.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL

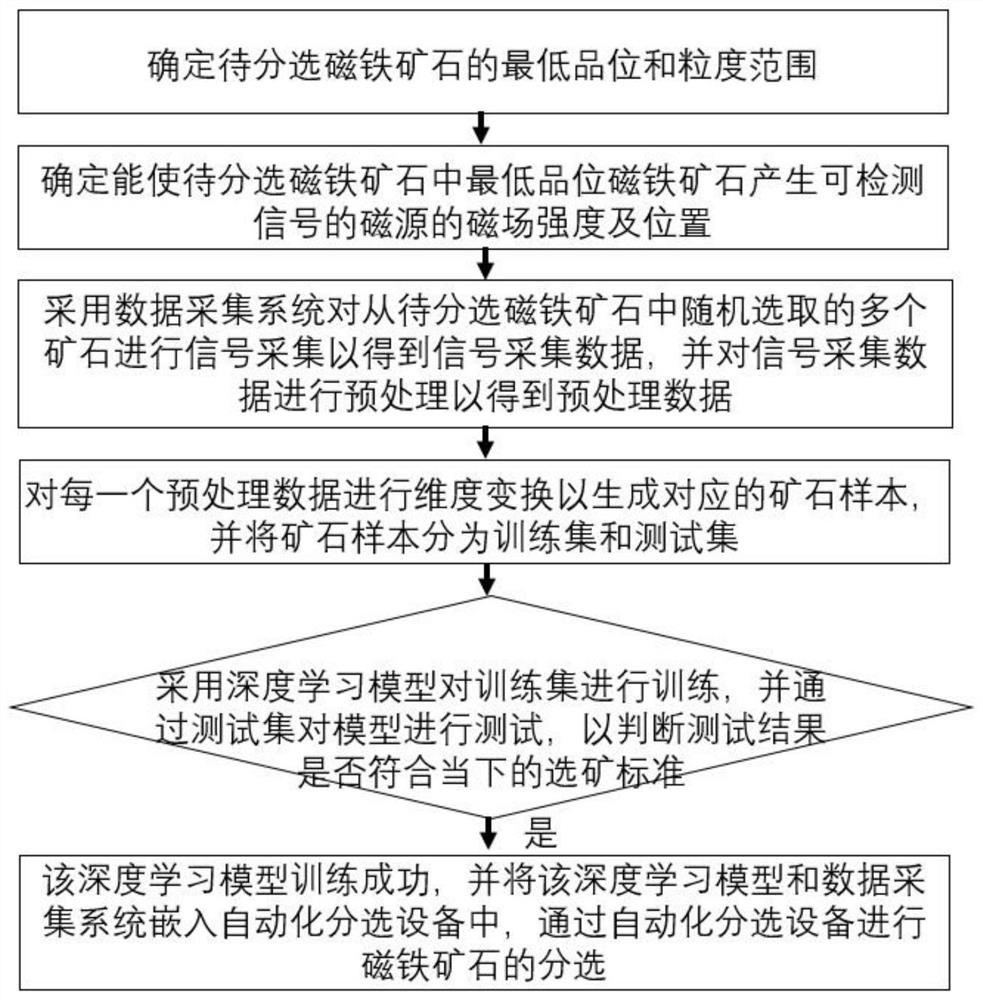

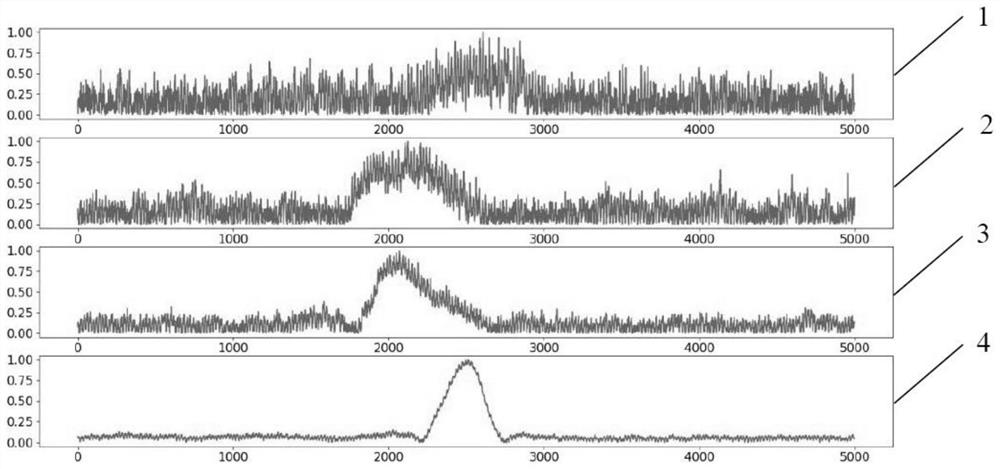

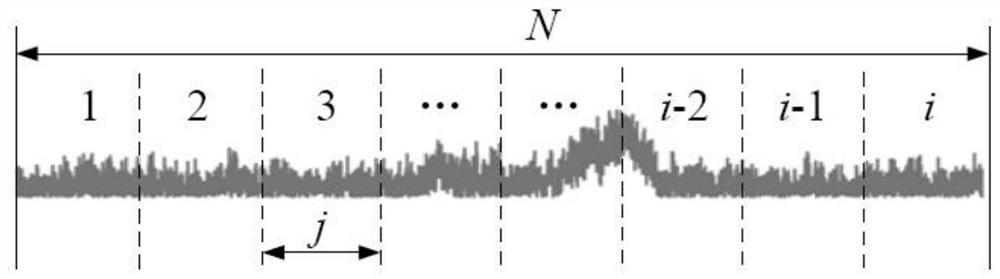

Intelligent magnetic iron ore separating method and device

ActiveCN112916432AImprove ore utilizationReduce the cost of beneficiationProcess efficiency improvementSortingMagnetic field magnitudeBeneficiation

The invention discloses an intelligent magnetic iron ore separating method and device. The method comprises the following steps that the lowest grade and the particle size range of to-be-separated magnetic iron ore are confirmed; the magnetic field intensity and position of a magnetic source capable of making the lowest-grade magnetic iron ore in the to-be-separated magnetic iron ore generate a detectable signal are determined; signal acquisition is conducted on the ore randomly selected from the to-be-separated magnetite ore to obtain signal acquisition data, and the signal acquisition data are preprocessed to obtain preprocessed data; dimension transformation is conducted on the preprocessed data to generate corresponding ore samples, and the ore samples are divided into a training set and a test set; the training set is trained, and a model is tested through the test set to judge whether the test result meets the current mineral separation standard or not; and if yes, the deep learning model is trained successfully, and the deep learning model and a data acquisition system are embedded into an automatic separation device to conduct magnetic iron ore separation. The selected grade of the to-be-separated magnetite ore is expanded, and the ore utilization rate is increased.

Owner:JIANGXI UNIV OF SCI & TECH

Method for enriching valuable metal minerals in tailings

The invention relates to a method for refining valuable metal minerals in tailings. The method comprises the following operating steps: with an aqueous solution of sodium hexametaphosphate as a dispersant, dispersing the tailings, grading fine granules of the tailings according to the size of granularity, carrying out gravity separation on the graded tailings, and refining valuable metals obtained after gravity separation. According to the method disclosed by the invention, the tailings are processed by adopting simple process flows, the tailing resources are sufficiently utilized, multiple valuable metal minerals in the tailings are enriched, and thus the beneficiation feed grade of the flows is improved and relatively high concentrate grade and recycling rate can be obtained; meanwhile, the flow processing capability is also improved and the equipment load is alleviated. According to the method, fewer dispersant is used, the process flows are simple and easy to operate, the energy consumption is reduced, and thus the processing cost of the tailings is reduced and the economic benefit for site selection is increased.

Owner:广西华锡集团股份有限公司 +1

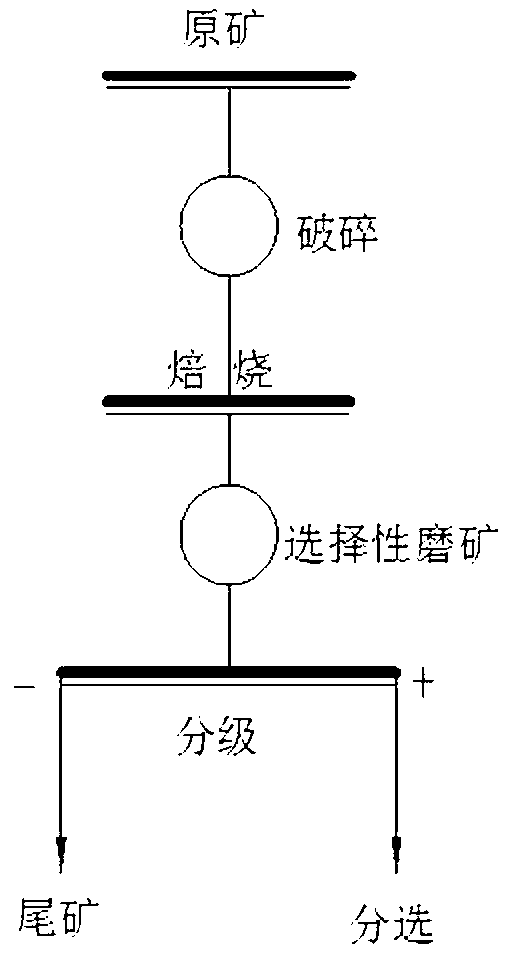

Tailing pre-discarding method for andalusite ore separation

InactiveCN102794223AHigh removal rateImprove the quality of selectionSolid separationWater resourcesRoom temperature

The invention provides a tailing pre-discarding method for andalusite ore separation. The tailing pre-discarding method comprises the following steps: 1) andalusite crude ores are crushed until the particle sizes are not more than 20 mm; 2) the crushed raw materials are burned in a high-temperature furnace at the burning temperature of 700-900 DEG for 10-20 minutes, and then the crushed materials are cooled to room temperature in a cooling bed; and 3) the cooled materials are subjected to dry process selective ore grinding, ore grinding products are subjected to dry process grading so as to remove tailing discarding materials, and the residual materials enters into the sequent ore separation work to carry out separation and purification. According to the invention, some gangue minerals are removed by tailing discarding before separation, so that water resources are saved, the sequent separation efficiency is improved, and the ore separation cost is reduced.

Owner:WUHAN UNIV OF TECH

A pretreatment method for high-calcium and high-magnesium fine-grained scheelite

ActiveCN111715399BImprove beneficiation efficiencyReduce the effect of flotationSolid separationMechanical material recoveryHigh magnesiumPretreatment method

The invention belongs to the technical field of mineral processing, and specifically discloses a method for pretreating high-calcium and high-magnesium fine-grained scheelite. In this method, the raw ore of scheelite is ground for the first stage and then subjected to two gravity separation classifications, the primary concentrate and the secondary concentrate are combined for the second stage grinding, and then magnetic separation treatment; the secondary tailings are deslimed to obtain overflow, Enrich the overflow, fine mud and primary tailings to obtain fine mud concentrate; the fine mud concentrate enters magnetic separation treatment; the second stage grinding slurry and fine mud concentrate are combined for magnetic separation treatment to obtain pretreatment concentrate. The pretreatment method of the present invention overcomes the technical problem that fine-grained scheelite is difficult to recycle due to the agglomeration of high-calcium and high-magnesium scheelite, and discards most of the vein minerals and scheelite through pretreatment, reducing the amount of scheelite that enters the subsequent process. The amount of ore in flotation increases the WO in flotation ore 3 The selected grade greatly reduces the amount of chemicals used in subsequent flotation.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

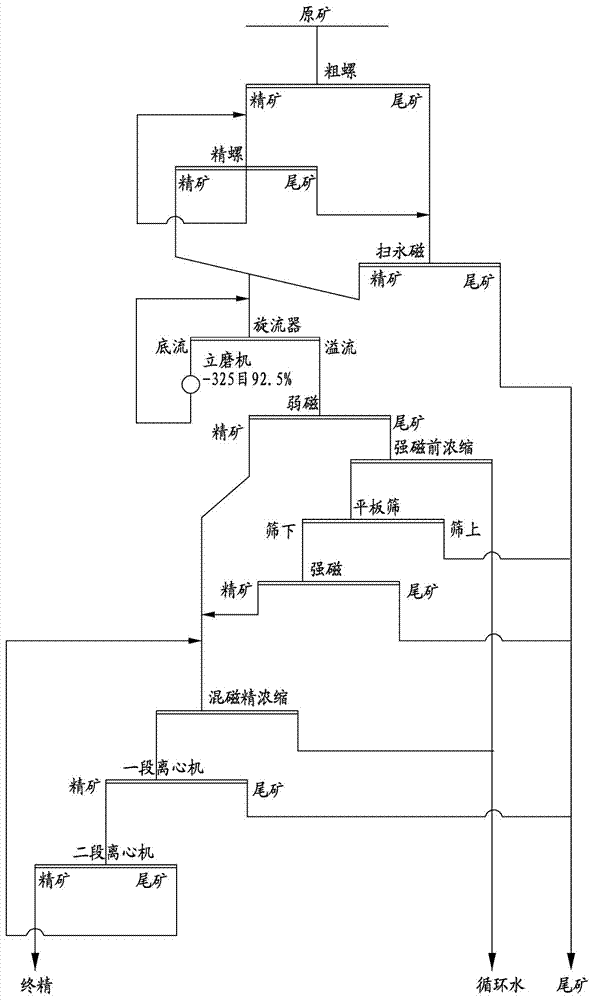

Magnetic gravity pre-selection, coarse concentrate regrinding and hematite tailings recovery process

ActiveCN104888939BImprove the quality of selectionReduce processingMagnetic separationWet separationMaterials scienceMagnet

The invention relates to a recovery process of magnetic gravity pre-selection, coarse concentrate regrinding and hematite tailings recovery, which adopts "coarse-fine spiral chute, permanent magnet-grinding classification-strong magnetic, centrifuge process" for separation , when the grinding particle size is ‑325 mesh 92.5%, the separation indicators obtained are: feed grade 12.63%, concentrate grade 67.95%, concentrate yield 4.00%, recovery rate 21.52%, tailings grade 10.33%. The tailings are discharged to the tailings pond by gravity in the early stage, and then pumped to the tailings pond in the later stage. The overflow water of each thickener is returned to the tailings recovery plant for recycling.

Owner:ANSTEEL GRP MINING CO LTD

A Continuous Mining Method Applicable to High and Middle Sections

ActiveCN110905517BHigh strengthImprove recovery efficiencyUnderground miningSurface miningMining engineeringPetroleum engineering

The present invention proposes a continuous mining method suitable for the high and middle section, including S1, mining standard engineering, including S101, dividing the stope at the high and middle section into several layered stopes; S102, excavating the roadway outside the vein along the direction of the footwall of the ore body , and then excavate the sub-level entry and the stope entry, the center line of the stope entry is perpendicular to the center line of the corresponding layered stope; , the stope roadway is connected; a waste rock chute and an ore chute are respectively arranged; S104, no bottom column is left in the stope at the high and middle section, and the bottom roadway is directly excavated on the upper part of the floor, and the free surface is expanded to the boundary of the mine, Form the bottom-drawing space, then lift the top upwards for mining, and transport the mined ore away; S2, mining engineering: the stope with relatively stable rock conditions adopts the upward horizontal layered filling mining method; the stope with relatively broken ore-rock conditions Upward horizontal approach filling mining method is adopted. The above method can effectively improve the mining strength and mining efficiency of the thin ore body.

Owner:山东金洲矿业集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com