A pretreatment method for high-calcium and high-magnesium fine-grained scheelite

A scheelite, high-magnesium technology, applied in solid separation, mechanical material recovery, recycling technology and other directions, can solve the problems of waste of rare metal resources, large loss of scheelite, low recovery rate, etc. dosage, improving beneficiation efficiency and reducing the amount of ore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

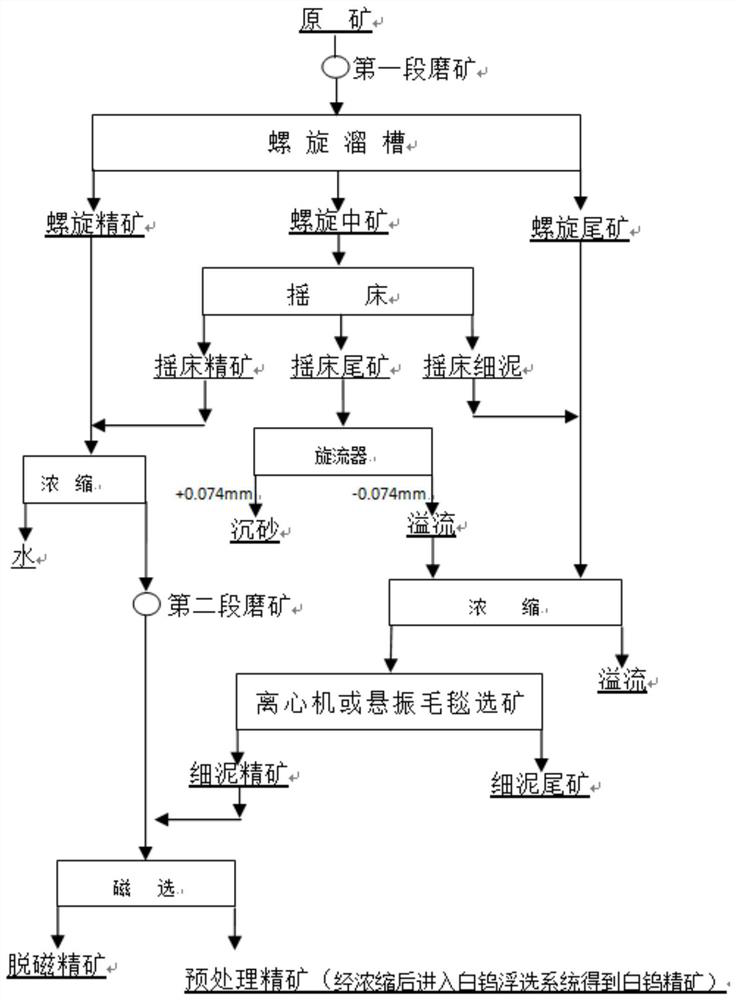

[0029] Pretreatment of scheelite ore, the composition of scheelite ore is: 0.155% WO 3 , 30% CaCO 3 , 15% MgO, refer to figure 1 , preprocess as follows:

[0030] The first stage of grinding: Add 100 g / ton of sodium hexametaphosphate to the raw scheelite ore (that is, add 100 grams of sodium hexametaphosphate per ton of scheelite ore), and prepare sodium hexametaphosphate into an aqueous solution For adding, the mass percent concentration of the sodium hexametaphosphate aqueous solution is 1%. Then the slurry is adjusted to a mass concentration of 62.5%, and the ore is ground to a scheelite monomer dissociation degree of 70%.

[0031] The first gravity separation and classification: adjust the pulp concentration after grinding to 23.5% of the mass concentration, carry out gravity separation and classification in the spiral chute, and obtain spiral concentrate, spiral medium ore and spiral tailings; the spiral concentrate has a high content of scheelite, and the spiral Tailin...

Embodiment 2

[0039] Pretreatment of scheelite ore, the composition of scheelite ore is: 0.447% WO 3 , 35% CaCO 3 , 28% MgO, refer to figure 1 , preprocess as follows:

[0040] The first stage of grinding: Add 800 g / ton of sodium hexametaphosphate to raw scheelite ore (that is, add 800 grams of sodium hexametaphosphate per ton of scheelite ore), and add sodium hexametaphosphate into an aqueous solution. The mass percent concentration of the sodium phosphate aqueous solution is 0.5%. Then the slurry is adjusted to a mass concentration of 67.5%, and the ore is ground to a scheelite monomer dissociation degree of 78%.

[0041] The first gravity separation and classification: adjust the pulp concentration after grinding to a mass concentration of 28.5%, carry out spiral chute gravity separation and classification to obtain spiral concentrate, spiral medium ore and spiral tailings; spiral concentrate has high scheelite content, spiral Tailings are mainly gangue minerals.

[0042] The second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com