Fine product dry type separation iron fine powder technology

A technology for iron powder and fine crushing, which is applied in solid separation, wet separation, grain processing, etc., can solve the problems of large fluctuation of product quality, heavy equipment maintenance workload, and high production cost, so as to improve mineral processing efficiency and reduce investment. And the effect of maintaining and improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further clarified below in conjunction with specific drawings and embodiments.

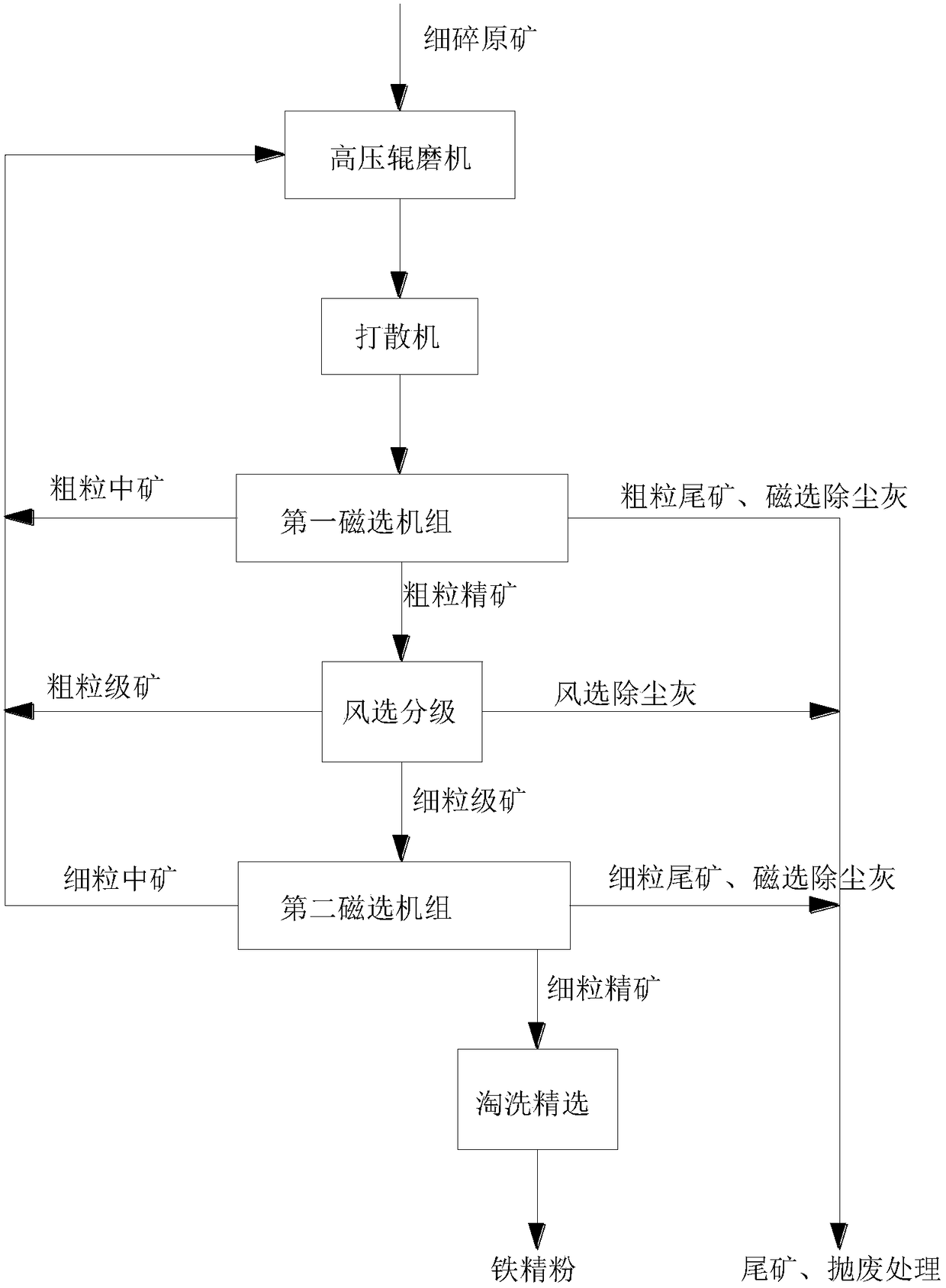

[0021] combined with figure 1 As shown, the present invention provides a kind of finely crushed product dry sorting iron fine powder process, specifically comprising:

[0022] (1) Extrude the finely crushed raw ore into a material cake through a high-pressure roller mill, then break up the material cake and put it into a magnetic separation unit for magnetic separation to obtain coarse tailings, coarse medium ore and coarse concentrate, of which The coarse tailings are discarded, the coarse medium ore is returned to the high-pressure roller mill for roller grinding again, and the coarse concentrate enters the next process;

[0023] (2) The coarse-grained concentrate obtained in step (1) obtains coarse-grained ore and fine-grained ore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com