Ilmenite floatation collecting agent, and preparation method and application thereof

A collector and ilmenite technology, applied in flotation, solid separation, etc., can solve the problems of weak pertinence of ilmenite collectors, the need to add additional foaming agents, general selective dispersion, etc., to achieve Excellent flotation effect, outstanding environmental benefits, good foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take 40g of high-grade fatty hydroxamic acid, 20g of triethylenetetramine hexamethylene phosphonic acid, 450g of cotton oil, 300g of mixed fatty acid (lauric acid and palmitic acid), 100g of NaOH and 607g of water, add them to the autoclave at 140-180℃ After reacting for 2-5 hours, a brown-black paste is obtained. The solid content is calculated by weighing, and water is added to make a 2% solid content solution.

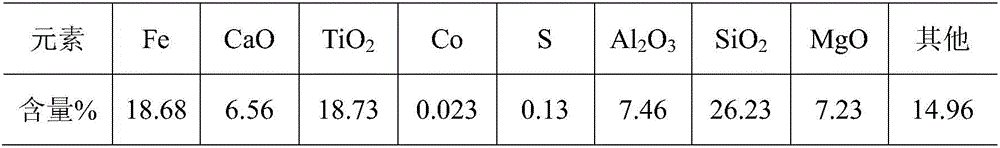

[0025] Taking a certain ilmenite in Panzhihua as the mineral sample, its chemical composition is:

[0026]

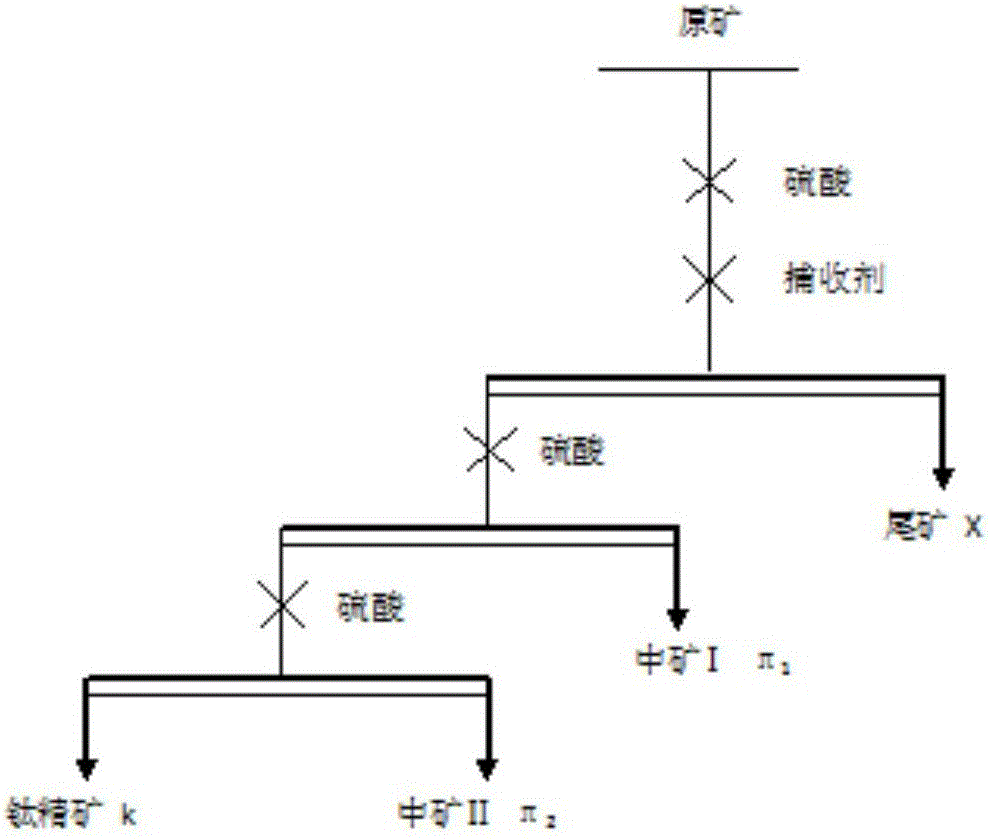

[0027] Use the collector prepared in this example to perform one coarse and two fine flotation on the ore sample. The flotation process is as follows: figure 1 As shown, the specific process is as follows:

[0028] (1) Pretreatment of ore: Take the tailings slurry after floating sulfur, filter and dry, separate samples after wet mixing, and the grinding fineness is less than -200 mesh accounting for 82%.

[0029] (2) Flotation enrichment: add 166g of raw ore ...

Embodiment 2

[0034] Take 20g of high-grade fatty hydroxamic acid, 30g of triethylenetetramine hexamethylene phosphonic acid, 300g of cotton oil, 500g of mixed fatty acids (lauric acid and palmitic acid), 150g of NaOH and 667g of water, add them to the autoclave at 140-180℃ After reacting for 2-5 hours, a brown-black paste is obtained. The solid content is calculated by weighing, and water is added to make a 2% solid content solution.

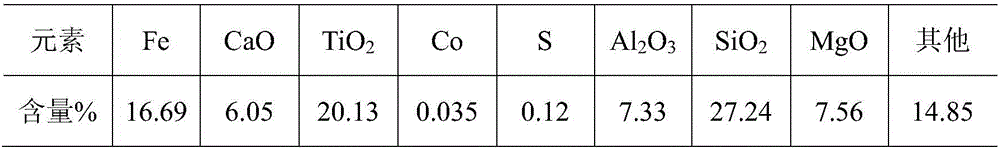

[0035] Taking a certain ilmenite in Chengde as the mineral sample, its chemical composition is:

[0036]

[0037] Use the collector prepared in this example to perform one coarse and two fine flotation on the ore sample. The specific process is as follows:

[0038] (1) Pre-treatment of ore: Take the tailings slurry after floating sulfur, filter and dry, and separate samples after wet mixing. The grinding fineness is less than -200 mesh, accounting for 88.2%.

[0039] (2) Flotation enrichment: Add 166g of raw ore to the flotation tank, then add a certain amount of ta...

Embodiment 3

[0044] Take 50g higher fatty hydroxamic acid, 50g triethylenetetraamine hexamethylene phosphonic acid, 200g cotton oil angle, 400g mixed fatty acid (lauric acid and stearic acid), 200g KOH and 600g water, add them to the autoclave at 140-180 React at ℃ for 2-5 hours to obtain a brown-black paste, weigh it to calculate its solid content, and add water to make a solution with a solid content of 2%.

[0045] Taking a certain ilmenite ore in Guangdong as the mineral sample, its chemical composition is:

[0046]

[0047] Use the collector prepared in this example to perform one coarse and two fine flotation on the ore sample. The specific process is as follows:

[0048] (1) Pre-treatment of ore: Take the tailings slurry after floating sulfur, filter and dry, and separate samples after wet mixing. The grinding fineness is less than -200 mesh, accounting for 90.3%.

[0049] (2) Flotation enrichment: add 166g of raw ore to the flotation tank, then add a certain amount of tap water to adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com