Smashing and classifying technology for molybdenite

A molybdenite and process technology, which is applied in the field of molybdenite grinding and classification technology, can solve the problems of high production cost of grinding and classification, low content of ore easy to select, and influence on the recovery rate of molybdenum, so as to reduce the number of spare parts. Consumption, reduce maintenance intensity, improve the effect of molybdenum recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

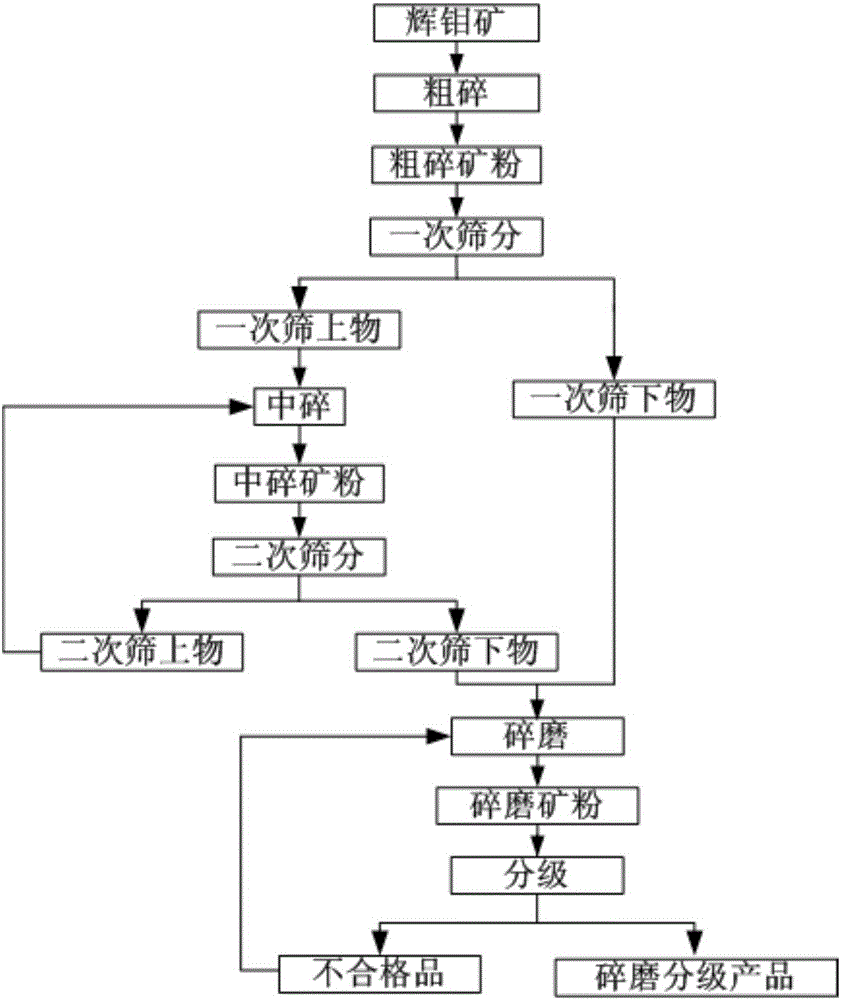

[0022] combine figure 1 , the crushing and grading process of molybdenite in the present embodiment comprises the following steps:

[0023] Step 1. The molybdenite is roughly crushed by a gyratory crusher with a width of 160 mm at the ore discharge port to obtain a coarse crushed ore powder, and then the coarse crushed ore powder is screened once with a sieve with an aperture of 50 mm to obtain a primary oversize and primary undersize;

[0024] Step 2: Use a cone crusher with a width of 30 mm to carry out secondary crushing on the primary sieve material described in step 1 to obtain medium crushed ore powder, and then use a screen with an aperture of 50 mm to process the medium crushed ore powder Secondary sieving to obtain secondary oversize and secondary undersize; return the secondary oversize to the cone crusher for secondary crushing;

[0025] Step 3. Mix the primary undersize described in step 1 and the secondary undersize described in step 2, and then add it to the hi...

Embodiment 2

[0029] combine figure 1 , the crushing and grading process of molybdenite in the present embodiment comprises the following steps:

[0030] Step 1. The molybdenite is roughly crushed by a gyratory crusher with a width of 160 mm at the ore discharge port to obtain a coarse crushed ore powder, and then the coarse crushed ore powder is screened once with a sieve with an aperture of 50 mm to obtain a primary oversize and primary undersize;

[0031] Step 2: Use a cone crusher with a width of 35 mm to carry out secondary crushing treatment on the primary sieve material described in step 1 to obtain medium crushed ore powder, and then use a screen with an aperture of 50 mm to process the medium crushed ore powder Secondary sieving to obtain secondary oversize and secondary undersize; return the secondary oversize to the cone crusher for secondary crushing;

[0032] Step 3. Mix the primary undersize described in step 1 and the secondary undersize described in step 2, and then add it...

Embodiment 3

[0036] combine figure 1 , the crushing and grading process of molybdenite in the present embodiment comprises the following steps:

[0037] Step 1. The molybdenite is roughly crushed by a gyratory crusher with a width of 160 mm at the ore discharge port to obtain a coarse crushed ore powder, and then the coarse crushed ore powder is screened once with a sieve with an aperture of 50 mm to obtain a primary oversize and primary undersize;

[0038] Step 2: Use a cone crusher with a width of 32 mm to carry out secondary crushing on the primary sieve material described in step 1 to obtain medium crushed ore powder, and then use a screen with an aperture of 50 mm to process the medium crushed ore powder Secondary sieving to obtain secondary oversize and secondary undersize; return the secondary oversize to the cone crusher for secondary crushing;

[0039]Step 3. Mix the primary undersize described in step 1 and the secondary undersize described in step 2, and then add it to the hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com