Patents

Literature

86 results about "Wolframite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

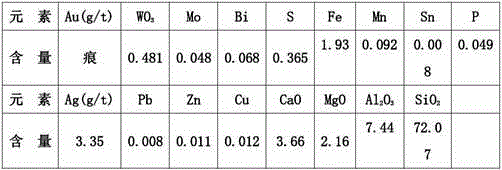

Wolframite, (Fe,Mn)WO₄, is an iron manganese tungstate mineral that is the intermediate between ferberite (Fe²⁺ rich) and hübnerite (Mn²⁺ rich). Along with scheelite, the wolframite series are the most important tungsten ore minerals. Wolframite is found in quartz veins and pegmatites associated with granitic intrusives. Associated minerals include cassiterite, scheelite, bismuth, quartz, pyrite, galena, sphalerite, and arsenopyrite.

6-aliphatic hydrocarbon amido hexyl hydroximic acid collecting agent and preparation and application methods thereof

ActiveCN103301952AImprove flotation recoveryAchieve high flotation separationFlotationReaction temperatureCarboxylic acid

A structural formula of a 6-aliphatic hydrocarbon amido hexyl hydroximic acid collecting agent is represented by a formula (I), wherein R represents C2-C18 aliphatic hydrocarbon group. The preparation method comprises the steps as follows: caprolactam and hydroxylamine hydrochloride or hydroxylamine sulphate are taken as raw materials, methylbenzene is taken as a solvent, the reaction temperature ranges from 80 DEG C to 110 DEG C, the reaction lasts for 1-4 hours, and 6-amino hexyl hydroximic acid is generated; 6-amino hexyl hydroximic acid reacts with C2-C18 fat carboxylic acid at the reaction temperature ranging from 100 DEG C to 160 DEG C for 1-4 hours to generate 6-aliphatic hydrocarbon amido hexyl hydroximic acid, and the product yield can be higher than 91%; and 6-aliphatic hydrocarbon amido hexyl hydroximic acid used in flotation of scheelite, wolframite, tombarthite ore, tin ore, bauxite, titanic iron ore or fluorite ore is taken as the collecting agent, so that the flotation recovery rate can be increased by 3%-10%.

Owner:CENT SOUTH UNIV

Pretreatment method of tungsten mineral materials

ActiveCN104232942AImprove leaching effectAchieve cycleProcess efficiency improvementPretreatment methodDiammonium carbonate

Disclosed is a pretreatment method of tungsten mineral materials. The pretreatment method of the tungsten mineral materials is characterized by including the following steps of raw material preparation and clinker sintering, the raw material preparation includes that the tungsten mineral materials (scheelite, wolframite, scheelite and wolframite mixed mineral and / or tungsten fine silt) are mixed with a certain quantity of calcic substances and mineralizer to be finely ground to obtain raw materials, and the clinker sintering includes that the prepared raw materials are calcinated under special conditions to obtain clinker. The pretreatment method of the tungsten mineral materials has the advantages that the adaptability is wide, and the method is suitable for all tungsten mineral materials, especially scheelite; (2) added calcic substances are cheap and easy to obtain; (3) the calcination temperature is low, the operation is simple, and the industrial application is easy; (4) tungsten in the obtained clinker is good in leaching performance, fully leaching can be achieved by a sodium carbonate solution or an ammonium carbonate salt solution at low temperature, especially when leaching is performed by the ammonium carbonate salt solution, the economical circulation of the solution during APT production can be achieved, and thereby, discharging of wastewater during production can be eliminated.

Owner:CENT SOUTH UNIV +1

Method for extracting tungsten from wolframite or scheelite and wolframite mixture ore through adding of high-phosphorus scheelite

The invention provides a method for tungsten from wolframite or scheelite and wolframite mixture ore through adding of high-phosphorus scheelite. In the ore grinding process of tungsten mineral raw materials (wolframite or scheelite and wolframite mixture ore), the high-phosphorus scheelite is added, fine grinding and pulp mixing are carried out, and obtained ore pulp is decomposed through phosphoric acid-sulfuric acid; after the reaction is finished, the tungsten is extracted from an obtained leaching agent, then, sulfuric acid is supplemented again, and mineral leaching is carried out again. The method has the advantages that the limitation that a sulfuric acid-phosphoric acid mixing system cannot treat the wolframite and the scheelite and wolframite mixture ore is broken through, and the wolframite and the scheelite and wolframite mixture ore is efficiently decomposed at the constant temperature and constant pressure under the system; phosphorus in the high-phosphorus scheelite can be comprehensively utilized, and meanwhile, the decomposing rate of the tungsten ore can reach more than 97 percent; the added phosphorus can generate phosphoric acid in the decomposing process, the method can be used for making up the phosphoric acid consumed in the decomposing process, energy is saved, and the leaching cost is reduced; and the whole technological process is convenient to operate, and the industrialization is easily achieved.

Owner:CENT SOUTH UNIV

Method for extracting tungsten from wolframite or scheelite and wolframite mixed ores

ActiveCN104878223AEfficient decompositionEasy to operateProcess efficiency improvementDecompositionPhosphoric acid

The invention provides a method for extracting tungsten from wolframite or scheelite and wolframite mixed ores. In the process of grinding the tungsten ores (wolframite, scheelite and wolframite mixed ores or tungsten fine silt), an alkaline calcium-containing substance is blended and fine grinding and pulp blending are performed, and then the obtained ore pulp is decomposed by use of phosphoric acid-sulfuric acid. The method has the advantages that the restriction that a sulfuric acid-phosphoric acid mixed system fails in treating the wolframite is broken through, the normal-temperature and normal-pressure efficient decomposition of the wolframite and the scheelite and wolframite mixed ores in the system is realized, and the requirements of the method on the raw material are reduced; for the wolframite, the decomposition rate can be above 98%, and for the scheelite and wolframite mixed ores, the decomposition rate can be above 97%; and the whole process is convenient to operate and prone to industrialization.

Owner:CENT SOUTH UNIV

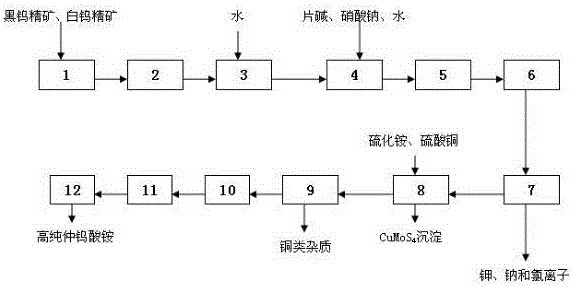

Preparation method of low-potassium low-sodium low-chloride high-purity ammonium paratungstate

A preparation method of low-potassium low-sodium low-chloride high-purity ammonium paratungstate is characterized in that wolframite concentrate and scheelite concentrate are taken as raw materials, the content of impurities in such auxiliary materials as deionized water, ammonium sulfide, copper sulfate and a strippant is controlled, and high-purity ammonium paratungstate is prepared by the procedures of ore blending and ball milling, soda boiling for decomposition, ion exchange, molybdenum removal, crystallization, drying and the like. During conversion between a prepeak solution and a high peak solution in the desorption process, the concentration of WO3 is larger than 100 g / l; during conversion between the prepeak solution and a rear section solution, the concentration of WO3 is larger than 150 g / l; the concentration of WO3 in the taken high peak solution is larger than 220 g / l, wherein K<=5 mg / l, Na<=15 mg / l and Cl<=15 g / l. The content of total impurities in high-purity ammonium paratungstate prepared by the method can be controlled within 70 ppm, which is far lower than the demand for the content (smaller than 177 ppm) of total impurities in zero grade products of the 'paratungstate' national standard (GB / T10116-2007), particularly, Na<=2 ppm, K<=3 ppm and Cl<=10 ppm.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP

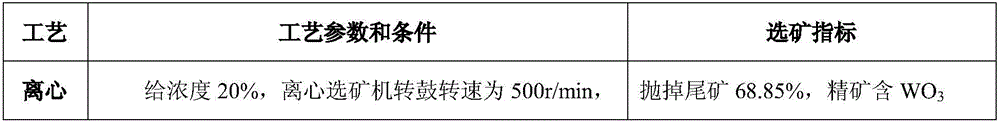

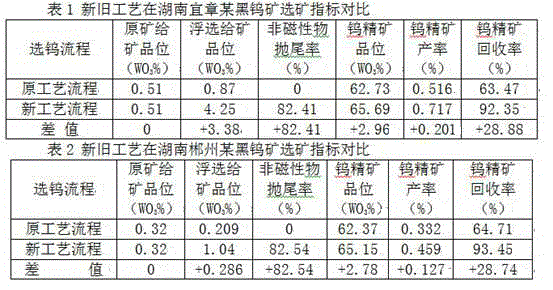

Mineral separation method for recycling wolframite from tailing

ActiveCN106669964AImprove the quality of selectionReduce the amount of oreSolid separationMechanical material recoveryGravity separationMagnetic separation

The invention discloses a mineral separation method for recycling wolframite from a tailing. The mineral separation method comprises the following steps that (1) gravity separation of a centrifugal machine is conducted for tailing discarding and preenrichment; (2) sulphide ore flotation is conducted; (3) magnetic separation is conducted and magnetic impurities are removed; (4) high-gradient magnetic separation is conducted for wolframite enrichment; (5) tabling gravity separation is conducted to obtain coarse grained wolframite; and (6) flotation is conducted to obtain fine grained wolframite. By means of centrifugation gravity separation preenrichment, the separation grade of the wolframite is improved, the ore feeding quantity and the mud content of wolframite separation are reduced, and flotation reagent dosage is saved. By means of the sulphide ore flotation and magnetic separation iron removal, the disturbance of sulphide minerals and magnetic minerals on wolframite separation is reduced. According to the mineral separation characteristics of the wolframite, the separation index of the wolframite is improved by adopting the high-gradient magnetic separation and the coarse grained and fine grained wolframite grading and separation process. Efficient recycling of the wolframite in low-grade wolframite tailing resources is achieved, and the mineral separation method is environmentally friendly, efficient and energy saving, and suitable for application and popularization.

Owner:JIANGXI UNIV OF SCI & TECH

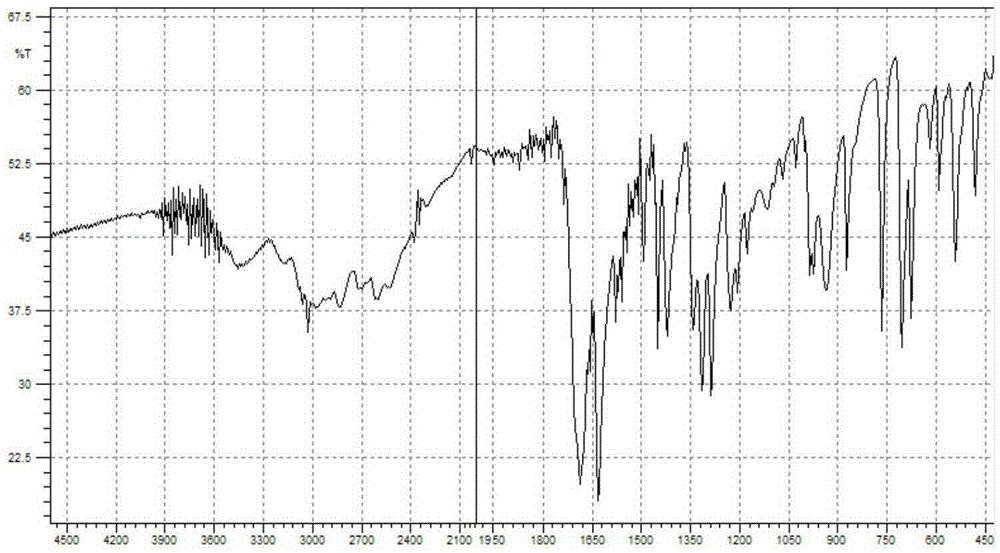

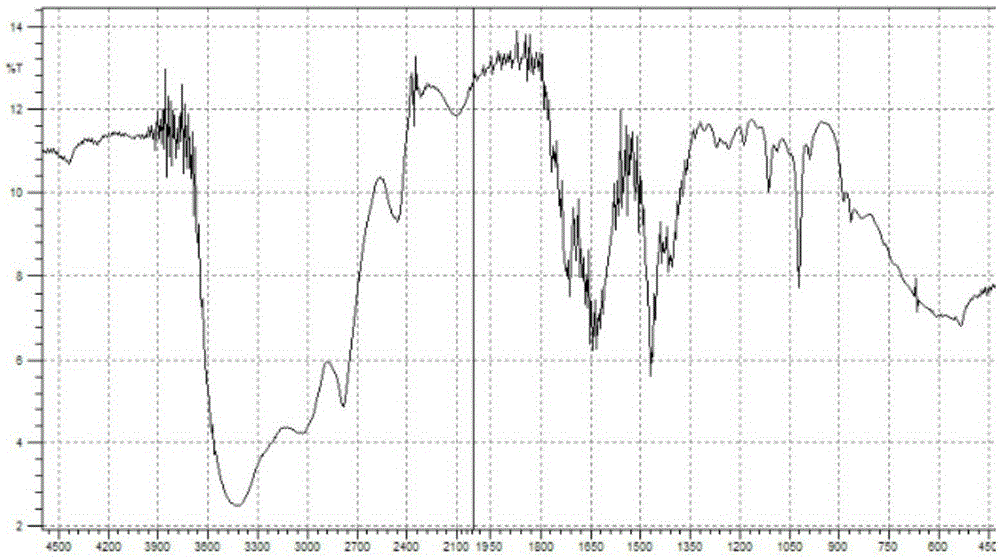

Application method of aliphatics bis-hydroximic acid compound to mineral flotation

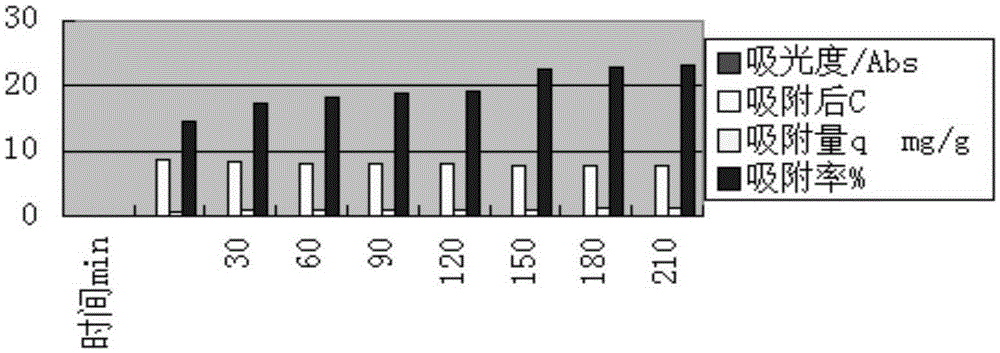

ActiveCN106423574AImprove adsorption capacityIncreased flotation recoveryFlotationMineral flotationRare earth

The invention provides an application method of an aliphatics bis-hydroximic acid compound to mineral flotation, and belongs to the technical field of mineral flotation. The aliphatics bis-hydroximic acid compound is expressed as the formula I: FORMULA; and in the formula I, R is alkylene containing 1-20 carbon atoms. The aliphatics bis-hydroximic acid compound serves as a collecting agent for flotation of scheelite, wolframite, scheelite and wolframite mixed ore, tin ore and rare earth ore, can enhance a chelating effect on metal oxidation minerals, promotes absorption of the collecting agent on the surfaces of the minerals, has such characteristics as high collecting capacity, high selectivity and low ore ton quantity, and is suitable for treating difficult-selected fine grain ore.

Owner:JIANGXI UNIV OF SCI & TECH

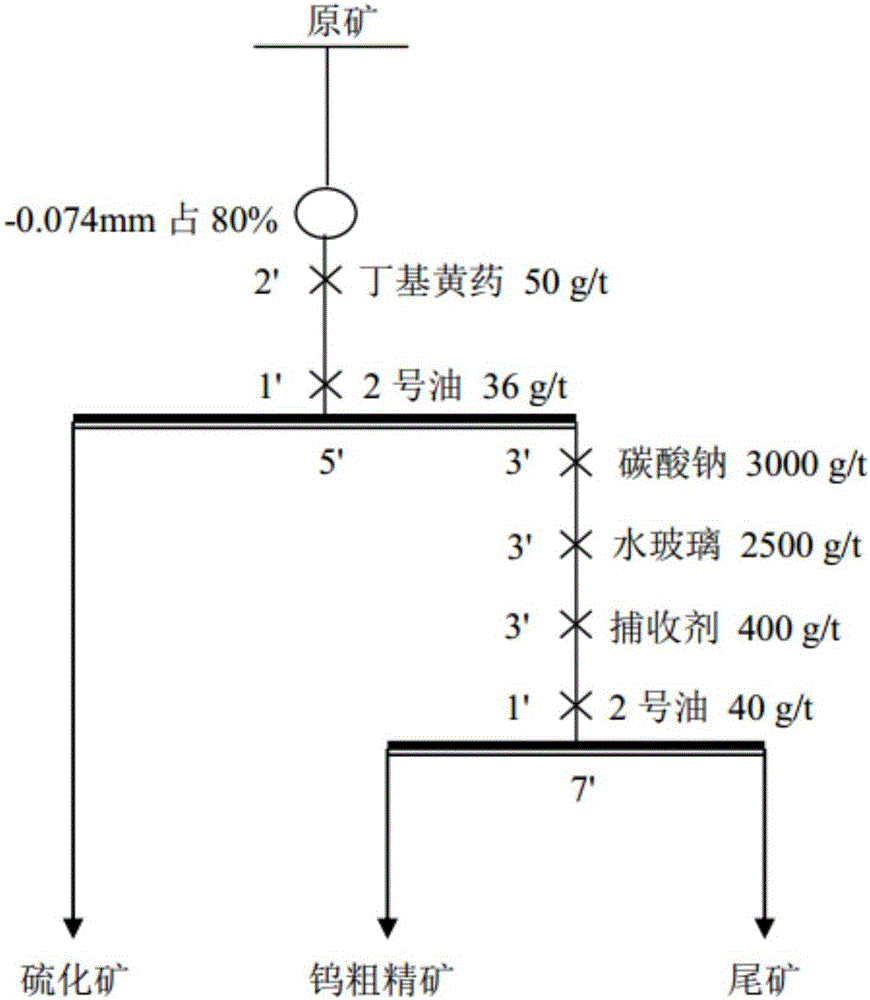

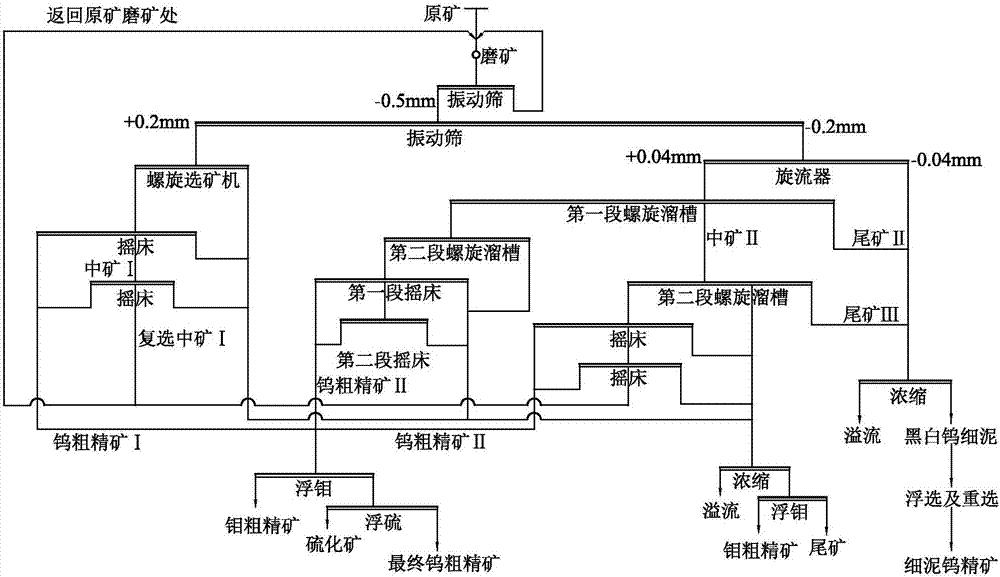

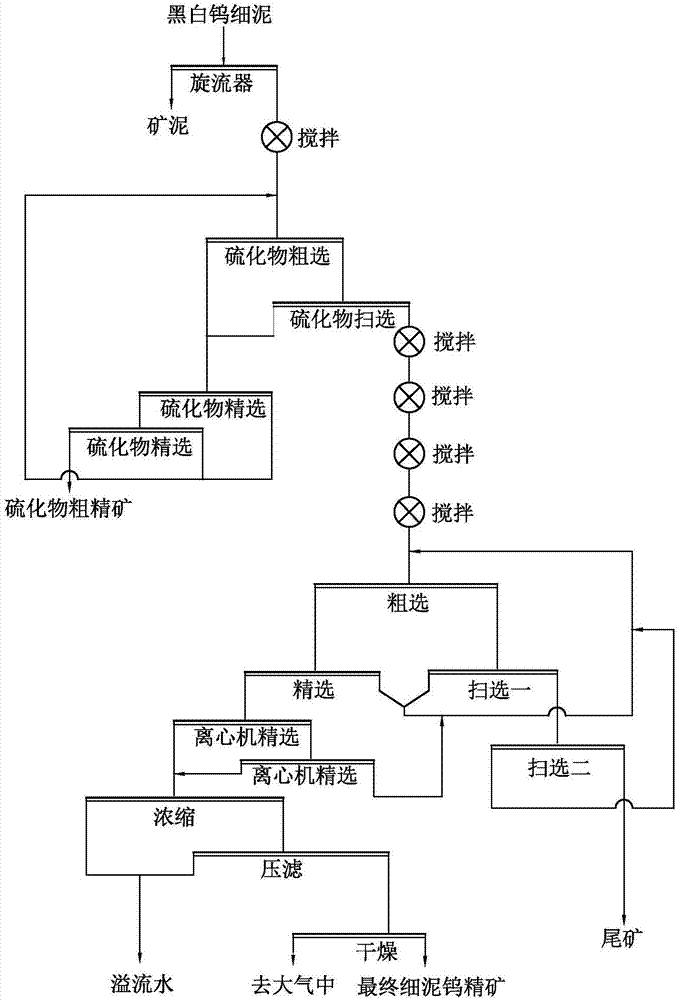

Sorting method for low-grade wolframite and scheelite

The invention discloses a sorting method for low-grade wolframite and scheelite. The sorting method for the low-grade wolframite and scheelite includes the steps that after wolframite and scheelite ore with the particle size being 0.20-0.50 mm is subjected to roughing with a spiral concentrator and concentration with table concentrators, tungsten rough concentrate I is obtained; after wolframite and scheelite ore with the particle size being 0.04-0.20 mm is subjected to roughing with spiral chutes and concentration with table concentrators, tungsten rough concentrate II is obtained; and sulfur flotation tailings are obtained by conducting sulphide ore flotation on wolframite and scheelite ore with the particle size being smaller than 0.04 mm, fine silt tungsten rough concentrate is obtained by conducting wolframite and scheelite mixing floatation on sulfur flotation tailings, a collecting agent for wolframite and scheelite mixing floatation comprises 60-120 g / t of xanthate, 400-600 g / t of a wolframite collecting agent and 30-50 g / t of a scheelite collecting agent, and fine silt tungsten concentrate is obtained by conducting concentration on the fine silt tungsten rough concentrate through a centrifugal separator. According to the sorting method, the overall recovery rate of the obtained tungsten concentrate is high, the utilization rate of mine resources is high, and production cost is low.

Owner:宁化行洛坑钨矿有限公司

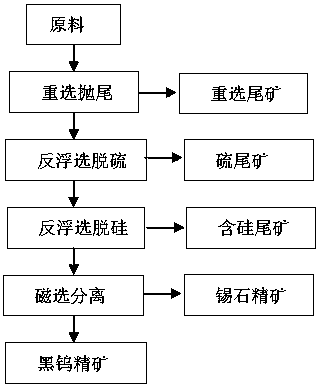

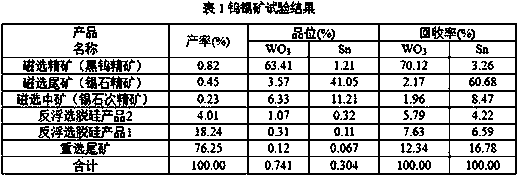

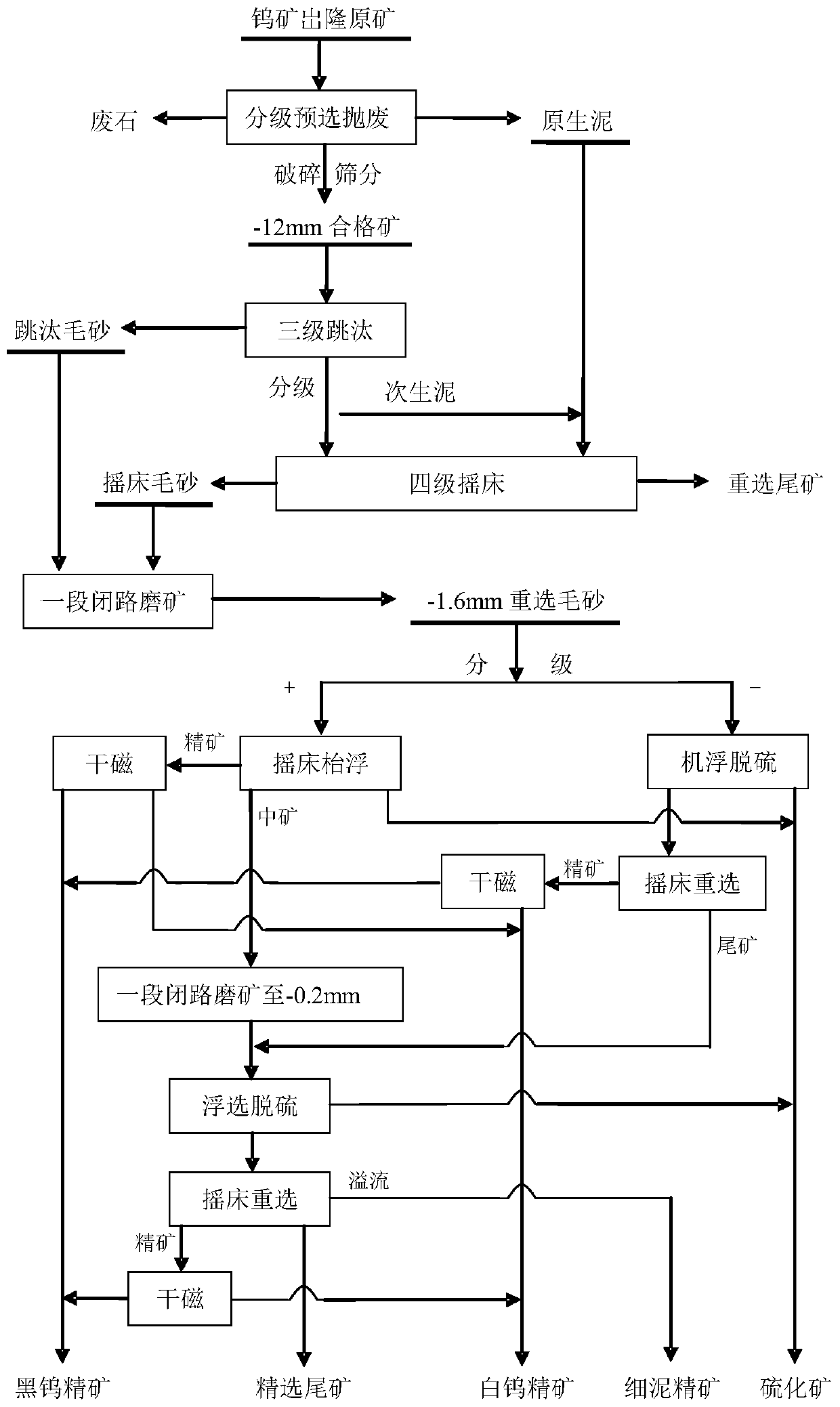

Mineral separation technique for fine-grain tungsten-tin associated minerals

InactiveCN107617508AHigh recovery rateGuaranteed concentrate gradeFlotationMagnetic separationPre selectionMagnetic separation

The invention discloses a mineral separation technique for fine-grain tungsten-tin associated minerals. The mineral separation technique includes the following specific steps that (1) secondary slurrygenerated by quartz vein type tungsten-tin associated minerals or tailings generated by floatation of sulphide ore of polymetallic ore are crushed; (2) enrichment via gravity concentration is carriedout, specifically, tailings are discarded via gravity concentration, and the gangue tailing discarding amount is 60%-85%; (3) silicone is removed through reverse floatation, specifically, regulatorsinclude a sodium carbonate solution and a starch solution, and collecting agents include one or more of an ether amine solution, a lauryl amine solution and an octadecylamine solution; and (4) tungsten-tin minerals are separated through magnetic separation, specifically, concentrate obtained after magnetic separation is wolframite, and tailings obtained after magnetic separation are tinstone concentrate. For fine-grain tungsten-tin minerals, the technique that gravity-concentration tailing discarding is adopted for pre-selection, sulfur and silicon are removed through reverse floatation, and wolframite and tinstone are separated through magnetic separation is utilized, on the premise of guaranteeing the concentrate grade, the recovery rates for wolframite and tinstone are increased, and the mineral separation technique is mainly applied to comprehensive recovery of tungsten and tin in tungsten-tin associated minerals and nonferrous-metal associated tungsten-tin minerals.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Mineral flotation collecting agent for oxidized ores

The invention provides a collecting agent for collecting minerals of oxidized ores such as ilmenite and a preparation method thereof, and belongs to the technical field of mineral flotation collectingagents. The mineral flotation collecting agent for the oxidized ores such as ilmenite is used after ammonium dibutyl dithiophosphate, ethylenediaminetetraacetic acid salt, maleate, sodium oleate andthe like are mixed; and the mineral flotation collecting agent has the characteristics of good water solubility, good dispersion and high selective adsorption ability to objective minerals, and is mainly used for flotation separation of valuable minerals in the oxidized ores such as the ilmenite, scheelite and wolframite. The preparation method of the mineral flotation collecting agent for the oxidized ores is simple in process, operation is easy to control, the prepared collecting agent has the advantages of high selectivity, good dispersion, low agent dosage and high mineral separation comprehensive efficiency, and quite important significance for promoting mineral separation of the minerals such as the oxidized ores is achieved.

Owner:河南天鸿新材料科技有限公司

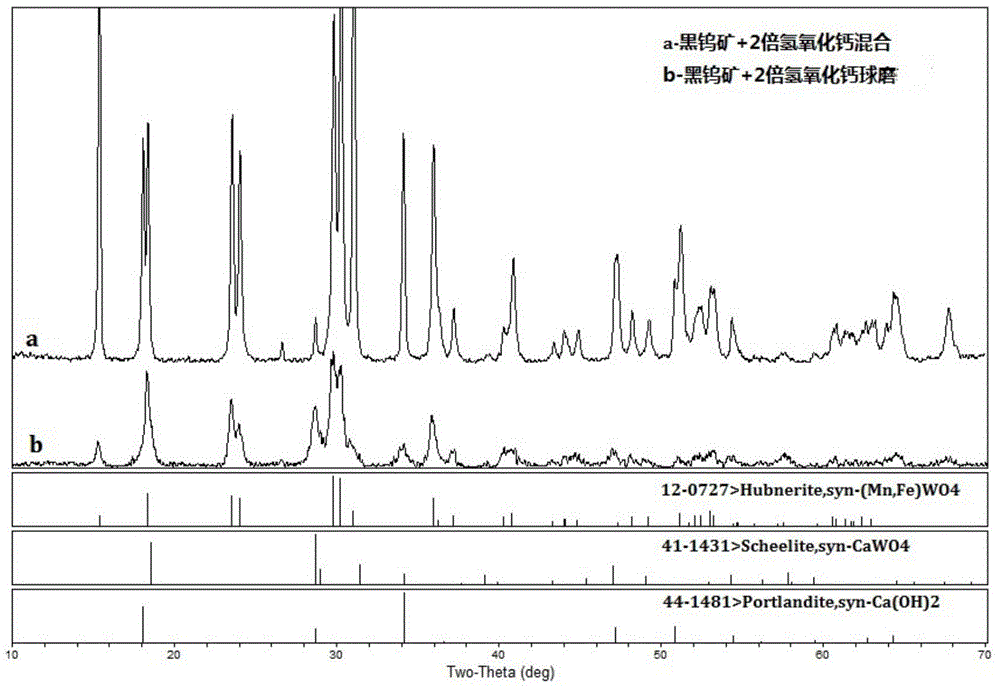

Method for transforming wolframite into scheelite

InactiveCN102649995AEfficient transformationAchieve emissionsProcess efficiency improvementSmelting processWastewater

The invention relates to a method for transforming wolframite into scheelite. The method comprises the steps as follows: mixing the wolframite with a calcium salt, and calcining to obtain a scheelite-containing calcined product. The method for transforming the wolframite into the scheelite provided by the embodiment of the invention can transform the wolframite into the scheelite with high efficiency, is jointed with the closed smelting and wastewater zero discharge smelting processes for the scheelite so as to realize the closed smelting and wastewater zero discharge of the wolframite; and the production cost can be reduced while the economic benefit is improved.

Owner:CHONGYI ZHANGYUAN TUNGSTEN

Method for efficiently leaching wolfram from wolfram-containing mixed material

The invention discloses a method for efficiently leaching wolfram from a wolfram-containing mixed material. The method aims to solve the technical problems that the properties of existing wolfram-containing materials are complicated, and various complicated processes are needed for separation. The method includes the specific steps that any one or two or more materials among wolframite and scheelite mixed wolfram ore, wolframite, wolfram slag and a dead catalyst are obtained and mixed uniformly, any one or two or more materials among sodium carbonate, sodium chloride and sodium hydroxide are added, and uniform stirring is performed; a mixed material is roasted, the roasting temperature and roasting time are controlled, the roasting air-rich atmosphere is guaranteed, and stirring is continuously performed in the roasting process; a roasted material is directly subjected to wet grinding and water leaching while the material is hot, stirring is performed through rotary vanes in the wet grinding process, and leached liquid is obtained; and the obtained leached liquid is filtered, filtered slag is washed with hot water, and then a wolfram-containing solution is obtained. Through the method, the effect that the wolfram is efficiently leached from various wolfram-containing materials is achieved.

Owner:XINYANG HUARUI MOLYBRENUM NEW MATERIALS CO LTD

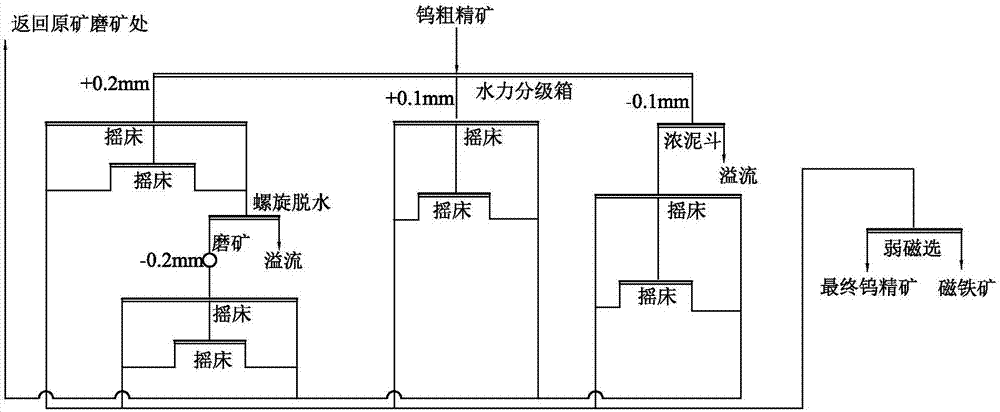

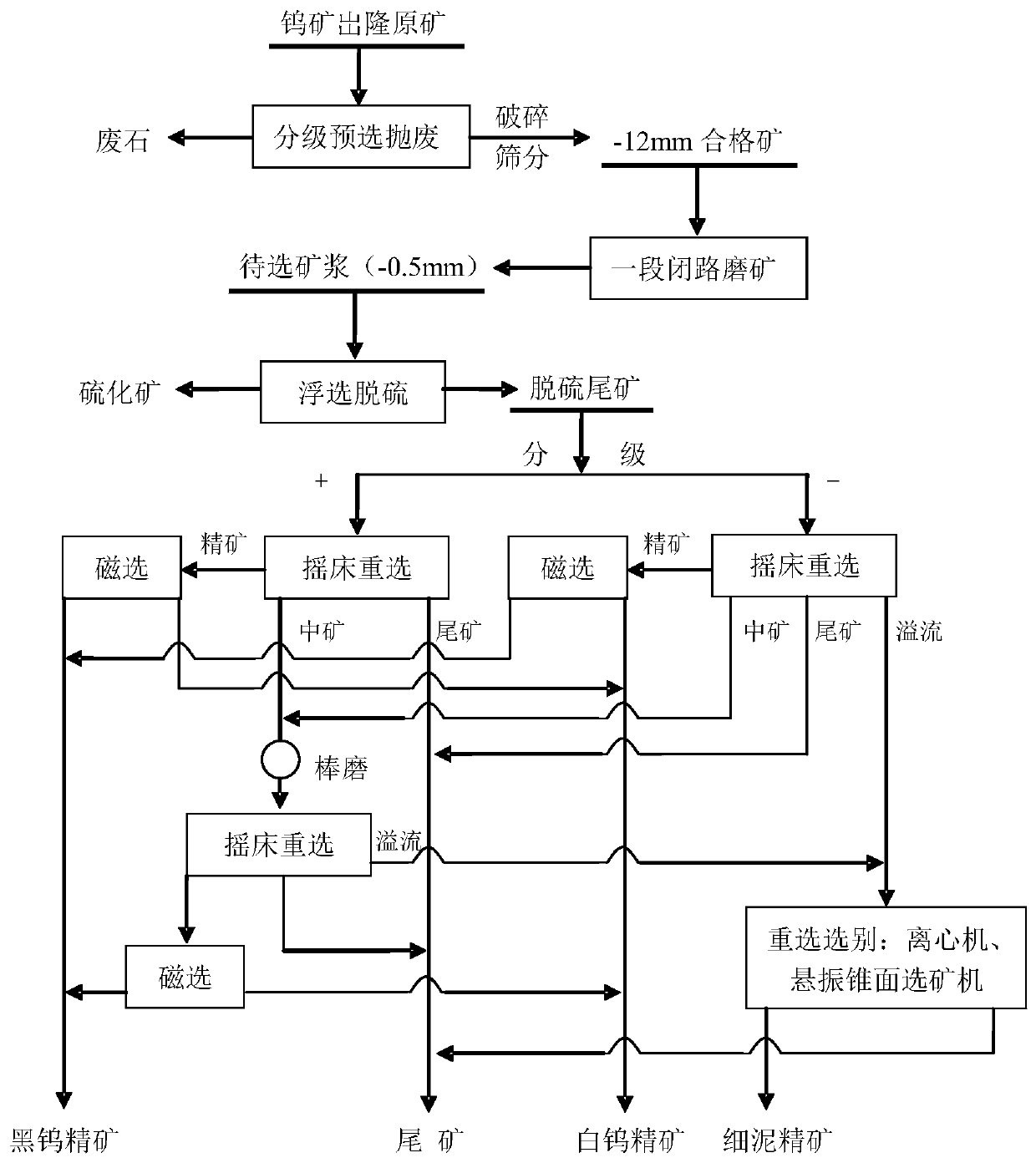

Tungsten ore sorting method

ActiveCN111229449AEfficient recyclingSimple process structureWet separationGravity separationMagnetic separation

The invention provides a tungsten ore sorting method and belongs to the technical field of ore dressing. According to the tungsten ore sorting method, tungsten ore drawing raw ore is pre-selected anddiscarded to obtain qualified ore containing primary mud; one-stage closed-circuit grinding is performed on the qualified ore to obtain ore pulp to be sorted; flotation desulfurization is performed onthe ore pulp to be sorted, and obtained desulfurized tailing ore pulp is graded to obtain coarse ore pulp and fine ore pulp; a gravity separation and magnetic separation combined process of a shakingtable is adopted on the coarse ore pulp and the fine ore pulp to obtain wolframite concentrate, scheelite concentrate, shaking table middlings, shaking table overflow and discardable shaking table tailings; and after the shaking table middlings are subjected to roll milling, wolframite concentrate, scheelite concentrate, shaking table overflow and discardable shaking table tailings are obtained through the gravity separation and magnetic separation combined process of the shaking table; and after all the shaking table overflows are combined and then reselected, fine mud concentrate and discardable tailings are obtained. The method provided by the invention not only can realize effective recovery of tungsten resources, but also has the characteristics of simple flow structure, low production cost, ecological environment friendliness and the like.

Owner:GANZHOU NONFERROUS METALLURGICAL RES INST

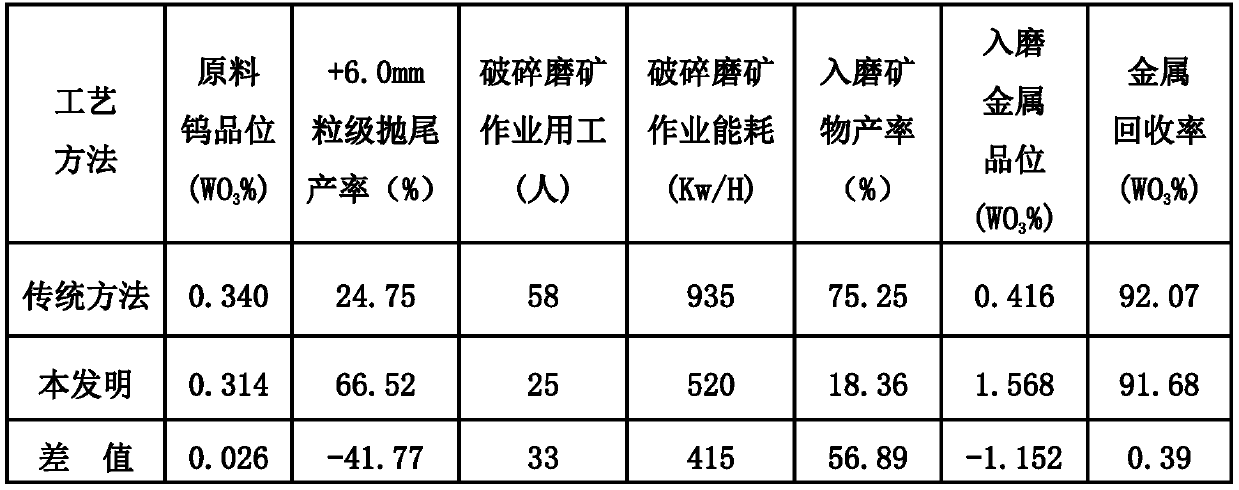

Wolframite tailing discarding and refining beneficiation method

ActiveCN109894268AReduce energy consumptionReduce the burden onMagnetic separationWet separationX-rayHigh pressure

The invention discloses a wolframite tailing discarding and refining beneficiation method. The method aims to solve the technical problems that an existing wolframite beneficiation method is high in manpower cost and low in labor operation efficiency. The method comprises the steps that single-stage crushing grading operation is adopted to meet the fraction requirement of subsequent-stage tailingdiscarding operation; then an X-ray intelligent concentrating machine is adopted to perform sorting operation, metallic minerals and non-metallic minerals are separated, and large-yield direct tailingdiscarding of 6-50mm large-fraction minerals is realized; next, a high-pressure roller mill is adopted to make the granularity of broken minerals below 6.0mm; and then a coarse-particle ultrahigh-field-intensity vertical-ring high-gradient magnetic separator is used to perform one-roughening-one-sweeping sorting operation, and by use of super-strong magnetic force of the ultrahigh-field-intensityvertical-ring high-gradient magnetic separator, weakly-magnetic wolframite is effectively recovered, and meanwhile direct tailing discarding of coarse-particle minerals is further realized. Through the method, the large-fraction minerals can be subject to direct tailing discarding, the burden on subsequent operation can be greatly relieved, therefore, the beneficiation cost of wolframite is substantially lowered, and low-energy-consumption high-efficiency recovery of wolframite is realized.

Owner:赣州金环磁选科技装备股份有限公司

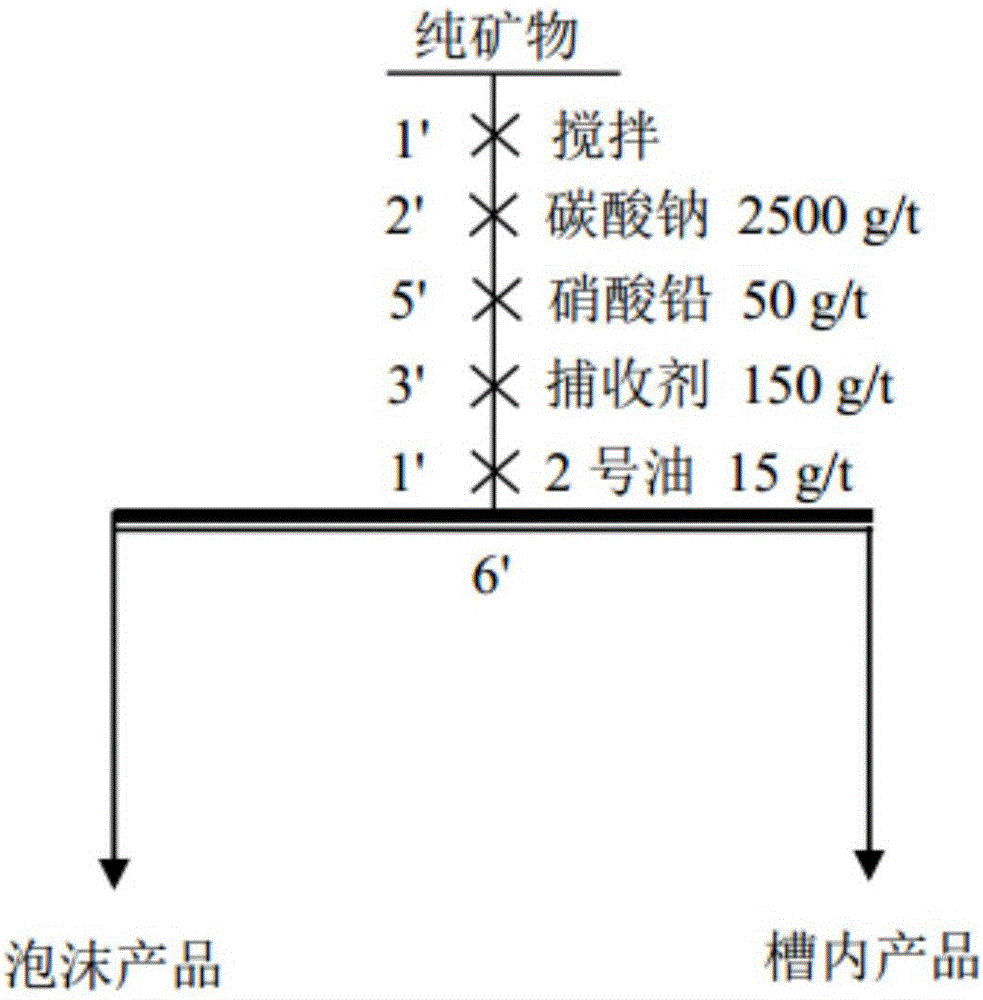

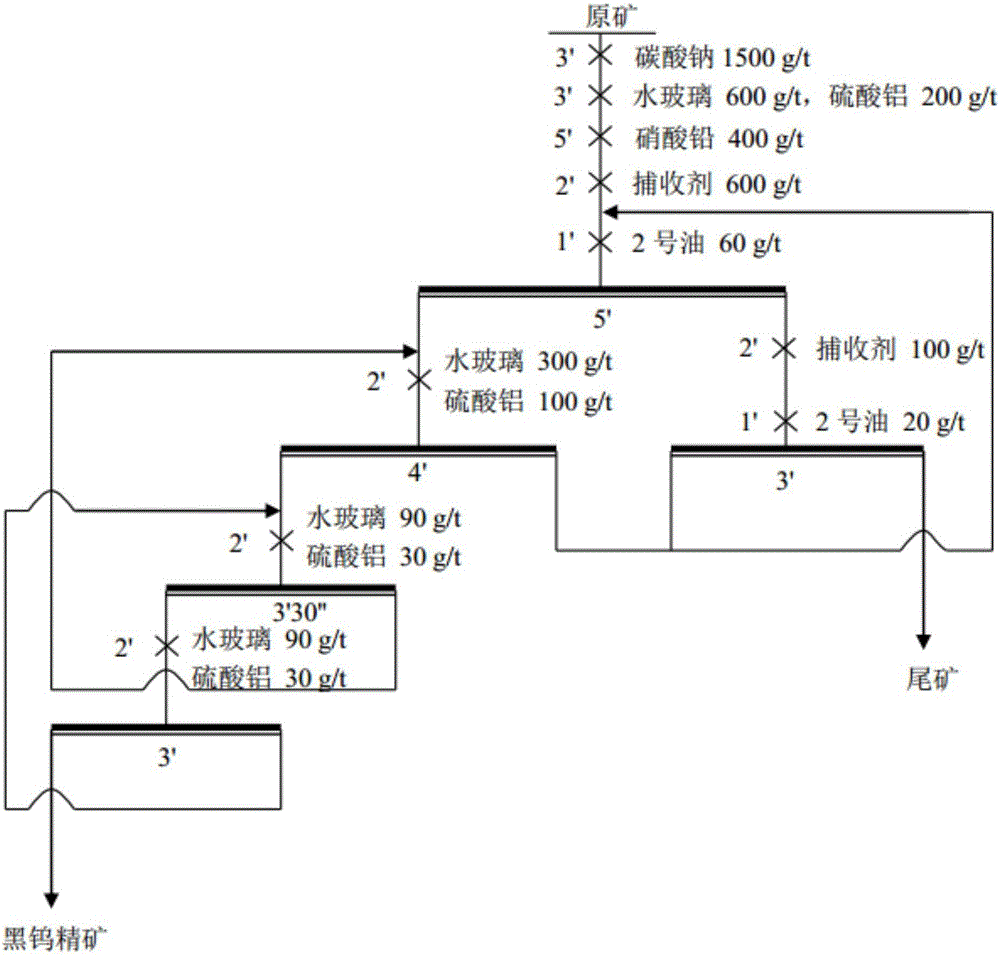

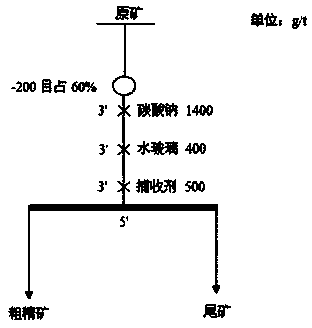

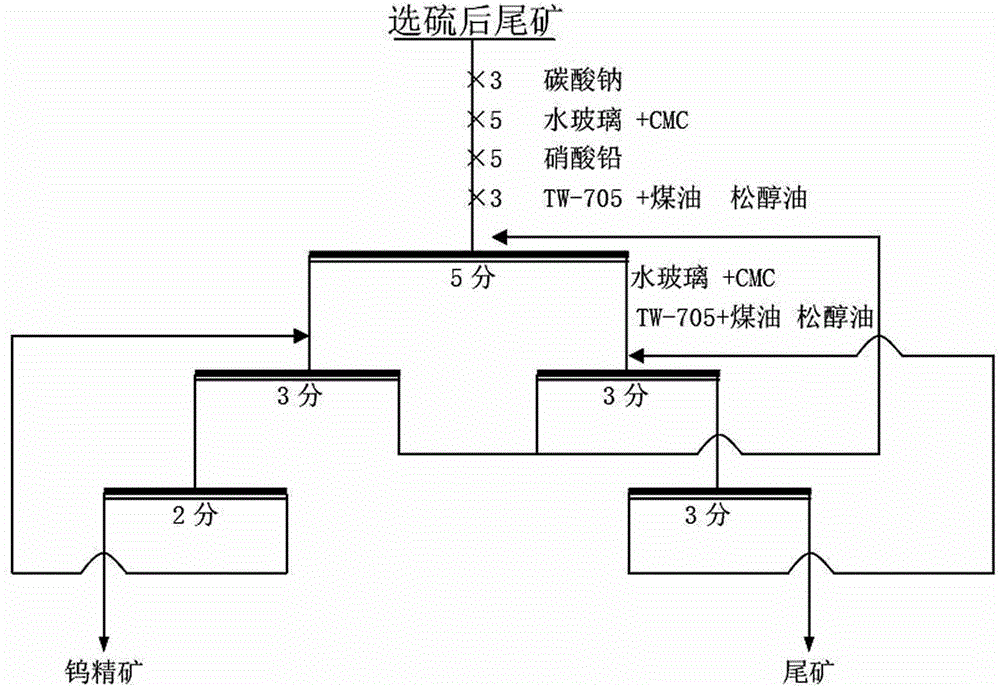

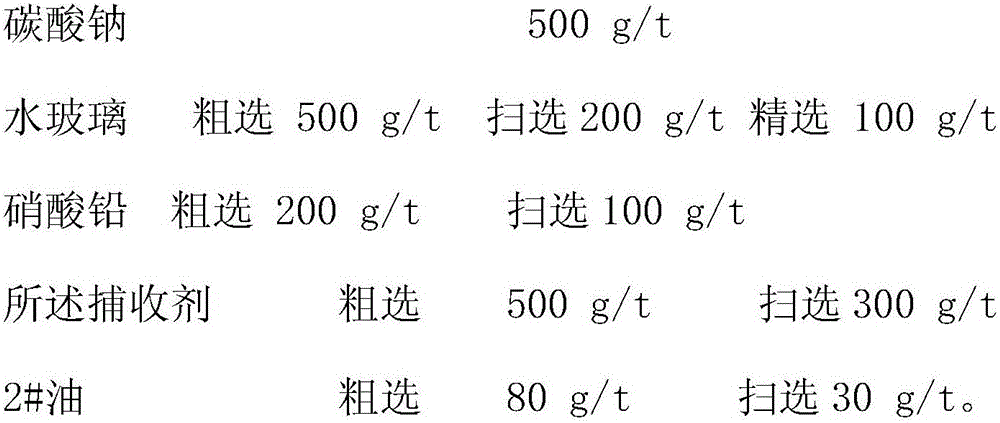

Flotation reagent system for fine wolframite in gravity concentration tailings

A flotation reagent system for fine wolframite in gravity concentration tailings is characterized in that 1, a gravity concentration tailing sample is put into a stirring tank, the concentration of ore pulp is controlled, sodium carbonate is added, the pH value of the ore pulp is controlled, and the mixture is stirred; 2, a gangue inhibitor and a fine silt dispersant are added and stirred; 3, a lead nitrate activator for the wolframite is added and stirred; 4, TW-705 serving as a collecting agent, kerosene serving as an auxiliary collecting agent and terpenic oil serving as a foaming agent are added and stirred; 5, the process flow path of carrying out rough concentration once, concentration twice and scavenging twice is adopted in tungsten flotation, the time for rough concentration is 5 min, the time for first-time scavenging and the time for second-time scavenging are 3 min, sodium silicate, a TW-705 and kerosene mixed collecting agent and terpenic oil are added in first-time scavenging, and the time for first-time concentration and the time for second-time concentration are 3 min and 2 min respectively. Tungsten concentrate is obtained through sorting. The tungsten grade of the fine wolframite in the gravity concentration tailings is improved, the tungsten recovery rate of the fine wolframite in the gravity concentration tailings is increased, and fine-fraction tungsten resources can be efficiently recovered.

Owner:SHENYANG RES INST OF NONFERROUS METALS

Method for extracting tungsten by pressurization decomposition on wolframite or black and white tungsten mixed ore through hydrochloric acid-phosphoric acid

ActiveCN108642307AEasy to produceReduce manufacturing costProcess efficiency improvementDecompositionPhosphoric acid

The invention relates to a method for extracting tungsten by pressurization decomposition on wolframite or black and white tungsten mixed ore through hydrochloric acid-phosphoric acid. The method is mainly characterized in that a reaction system is pressurized in the process of extracting tungsten from wolframite or the black and white tungsten mixed ore with mix acid of phosphoric acid and hydrochloric acid, so that the temperature of the reaction system is higher than 100 DEG C. According to the method, by pressurizing, calcium-containing compounds do not need to be added to conduct conversion on the black tungsten in the extracting process of the tungsten, that is, the tungsten can be directly extracted from wolframite or the black and white tungsten mixed ore, so that the production process is simplified, and the production cost is reduced.

Owner:CENT SOUTH UNIV

Method for effectively improving mineral processing efficiency of wolframite

ActiveCN104096627ARaise the gradeImprove work efficiencyGrain treatmentsMagnetic separatorProcess engineering

The invention discloses a method for effectively improving the mineral processing efficiency of wolframite. The method comprises the following steps: after raw ores of the wolframite are crushed, the wolframine and impurities are fully separated through the flow of multistage grinding-size grading-strong magnetic separation; and the wolframite is enriched in quantity by a high gradient magnetic separator before being floated, so that the separation of the wolframite and the impurities is realized, tailings of the wolframite is discarded in quantity before the wolframite is floated, and efficiency of the technological process is further improved. The method has the following main characteristics that (1) the flow of multistage grinding and size grading creates conditions for the strong magnetic enrichment and the tailing discarding operation; (2) the mineral processing process is improved, and the flotation feeding index is enhanced; (3) the flotation reagent dosage and the production cost are reduced, and the efficiency of the whole technological process is improved; and (4) the full dissociation and the beforehand tailing discarding of minerals are realized through the novel process, so that the flotation flow is simplified, the efficiency of the whole technological process and the wolframite mineral processing index are enhanced, and the comprehensive utilization ratio of resources is improved.

Owner:赣州金环磁选科技装备股份有限公司

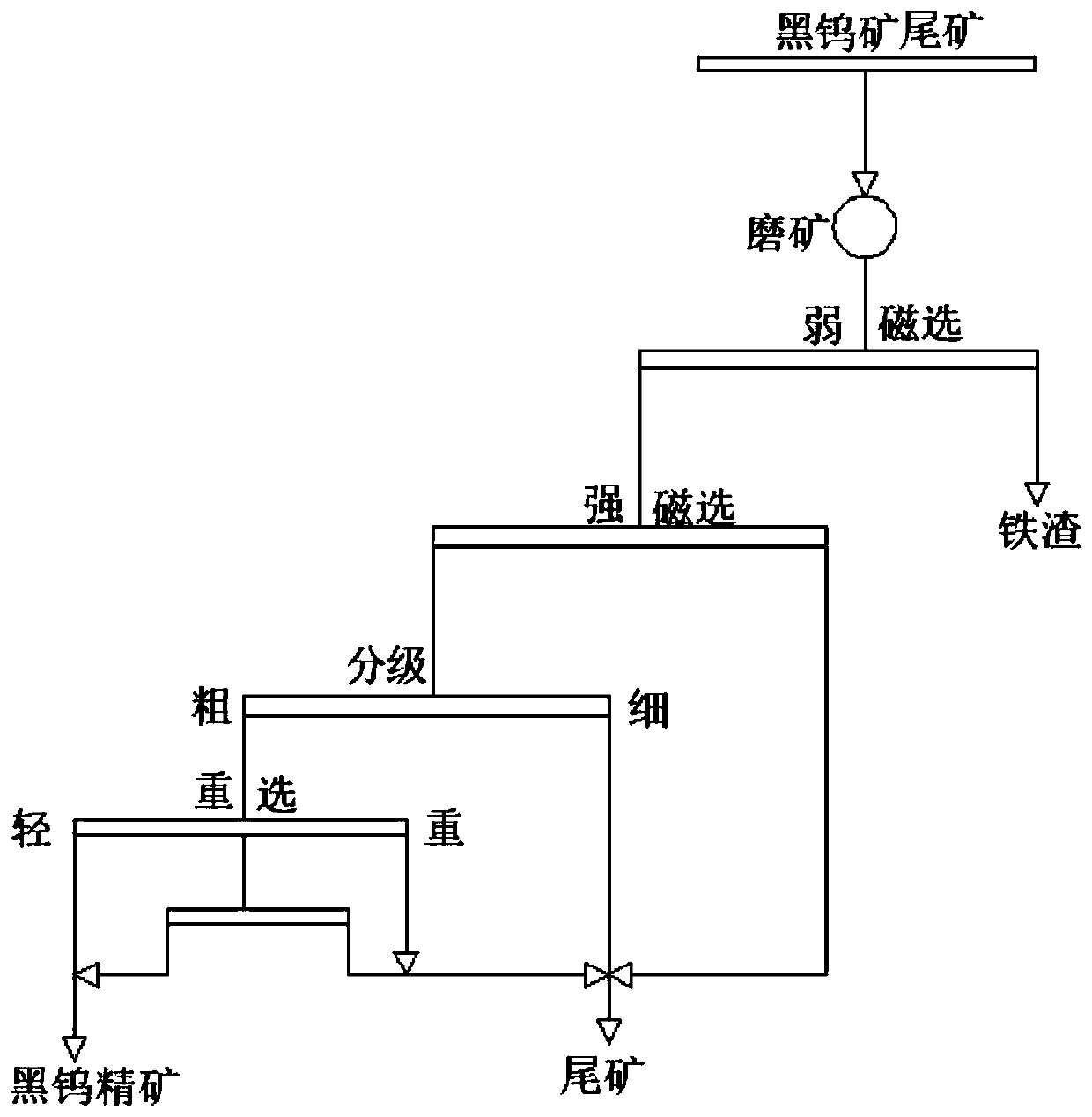

Beneficiation method for recovering wolframite from tailings

InactiveCN110813517AImprove qualityAvoid pollutionMagnetic separationWet separationEngineeringChemical agent

The invention relates to a beneficiation method for recovering wolframite from tailings, and belongs to the technical field of beneficiation recovery. The beneficiation method for recovering wolframite from tailings comprises the steps: (1) grinding wolframite tailings until the -0.075mm content is 70-90%; (2) performing magnetic separation on the materials obtained in the step (1) under the magnetic field intensity of 0.1-0.2T to obtain weak magnetic concentrate and weak magnetic tailings; (3) performing magnetic separation on the weak magnetic tailings obtained in the step (2) under the magnetic field intensity of 0.8-1.4T to obtain strong magnetic concentrate and non-magnetic tailings; (4) classifying the strong magnetic concentrate obtained in the step (3) into two grades of +0.051-0.075 mm, and -0.051-0.075 mm, and taking the coarse fraction therein; and (5) carrying out gravity separation on the materials obtained in the step (4), firstly carrying out roughing separation to obtain roughed concentrate, roughed middlings and roughed tailings, carrying out scavenging separation, wherein the feeding raw materials are the roughed middlings to obtain scavenged concentrate and scavenged tailings, and combining the roughed concentrate with the scavenged concentrate to obtain gravity separation wolframite concentrate. According to the beneficiation method for recovering wolframitefrom tailings, a flotation process which can be adopted in conventional wolframite beneficiation recovery is avoided, any chemical agent does not need to be added, and secondary pollution to the environment is avoided.

Owner:CHANGCHUN GOLD RES INST

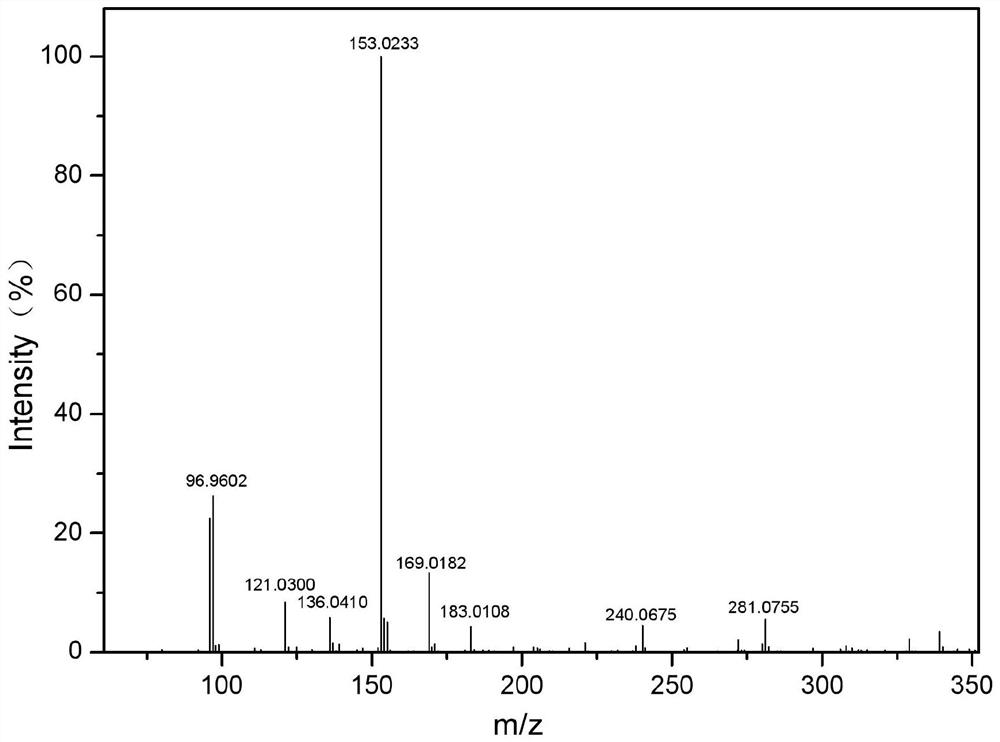

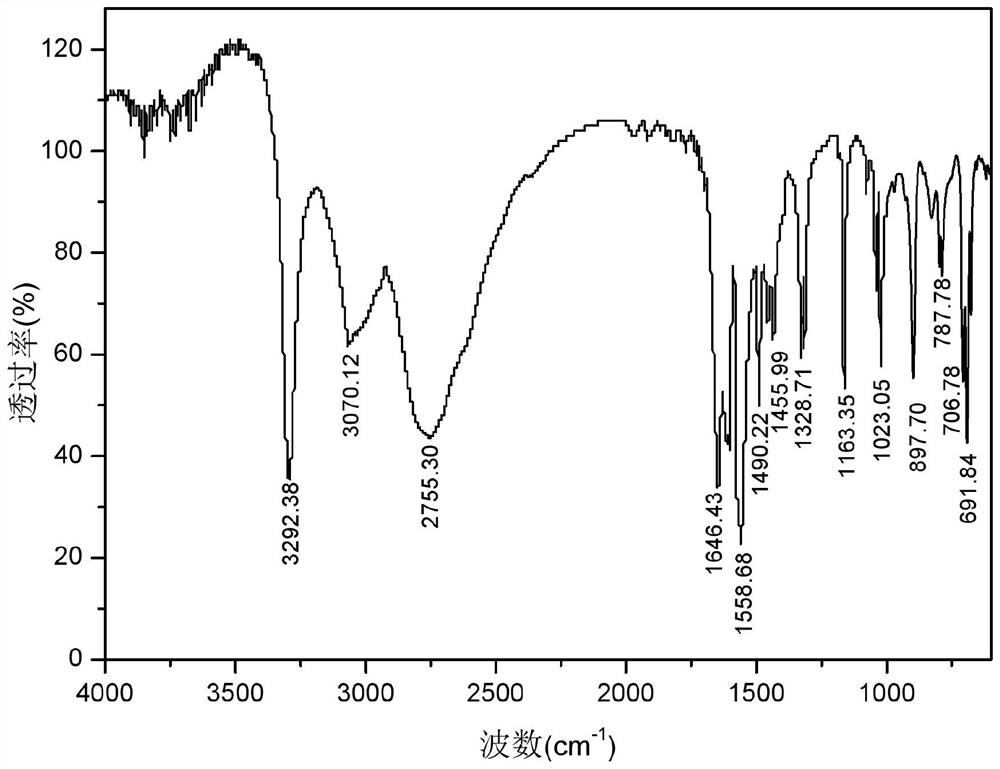

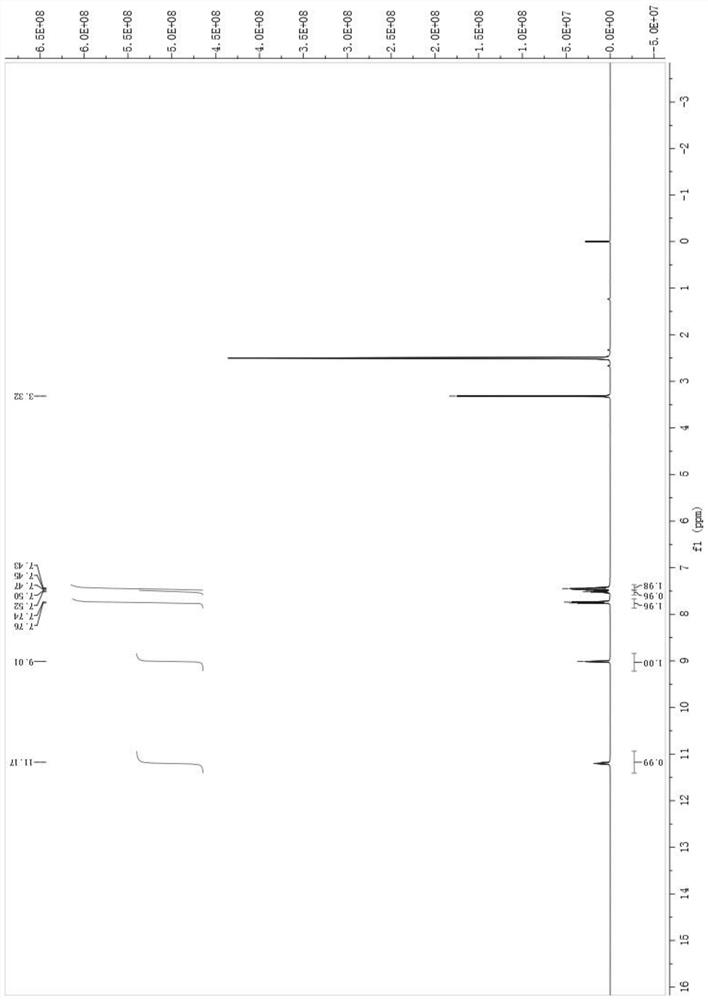

Heavy-metal macromolecule capture agent and preparation method and application thereof

InactiveCN105413662AImprove adsorption capacityStrong adsorptionOther chemical processesWater/sewage treatment by sorptionHydroxamic acidRed mud

The invention discloses a heavy-metal macromolecule capture agent and a preparation method and application thereof. The heavy-metal macromolecule capture agent is polyvinyl alcohol modified by phthalahydroxamic acid; the polyvinyl alcohol modified by the phthalahydroxamic acid is modified hydroxamic acid type macromolecule polymer, the polyvinyl alcohol and heavy-metal ions can be quickly chelated into stable chelate, high adsorption capacity to the heavy-metal ions is achieved, the heavy-metal macromolecule capture agent can be used for treatment of heavy-metal pollution, and compared with a common traditional metal ion capture agent, the heavy-metal macromolecule capture agent can adsorb fine particles in sewage more effectively, has selective adsorption capacity and has quite good application prospect on the aspect of heavy metal ion sediment and separation; besides, the heavy-metal macromolecule capture agent can be further used for ore floatation, and high capture capacity is achieved for oxides of oxidized ores such as cassiterite, wolframite, cerusite and chrysocolla; besides, the heavy-metal macromolecule capture agent can be further widely applied to the fields of oilfield drilling, separation of red mud produced by aluminium oxide and the like.

Owner:CHONGQING TECH & BUSINESS UNIV

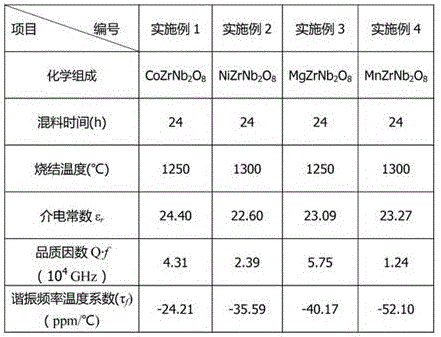

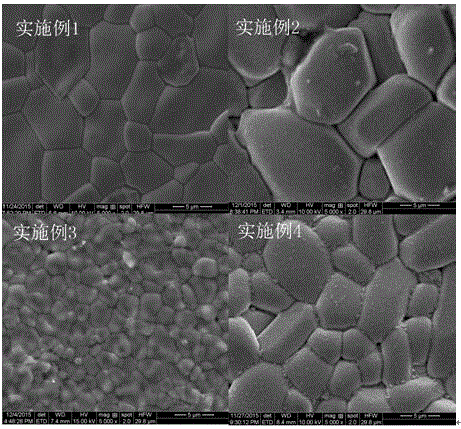

Method for preparing low-loss wolframite-structure microwave dielectric ceramic by means of reaction sintering technology

The invention discloses a method for preparing low-loss wolframite-structure microwave dielectric ceramic by means of a reaction sintering technology.The chemical composition expression of the ceramic is AZrNb2O8, wherein A represents Mg, Co, Ni and Mn.When the ceramic is prepared, the raw materials such as ZrO2, MgO, CoO, NiO, MnO and Nb2O5 are blended according to the chemical formula, the technologies of material mixing, drying, sieving, granulating, compression molding and the like are conducted, sintering is conducted at 1,250 DEG C-1,300 DEG C by means of the reaction sintering technology, and the AZrNb2O8 ceramic is obtained.According to the method for preparing the low-loss wolframite-structure microwave dielectric ceramic by means of the reaction sintering technology, the technological processes of presintering and secondary material mixing are omitted, the preparation time is greatly reduced, the preparation cost is reduced, the reaction sintering process technology is simple, the obtained ceramic is excellent in microwave dielectric property, the process is environmentally friendly, and the ceramic has a great application value in industry.

Owner:UNIV OF JINAN

Method for pressurizing decomposing high-tin tungsten ore with mixed acid of phosphoric acid and sulfuric acid

ActiveCN108642308AEasy to produceReduce manufacturing costProcess efficiency improvementSlagPhosphoric acid

The invention relates to a method for pressurizing decomposing a high-tin tungsten ore with mixed acid of phosphoric acid and sulfuric acid. According to the method, the improvements comprise the following that a reaction system is pressurized and the temperature of the reaction system is 110-250 DEG C in the process of extracting tungsten from a high-tin wolframite ore or high-tin black and whitetungsten mixed ore with the mixed acid of phosphoric acid and sulfuric acid, and tin concentrate can be obtained directly or through the ore dressing process from decomposed slag with the tungsten being already extracted. According to the method, by pressurizing, calcium-containing compounds do not need to be added to conduct conversion on the wolframite in the extracting process of the tungsten,the tungsten can be directly extracted from wolframite or the black and white tungsten mixed ore, meanwhile, the tin concentrate is obtained, so that the production process is simplified, and the production cost is reduced.

Owner:CENT SOUTH UNIV

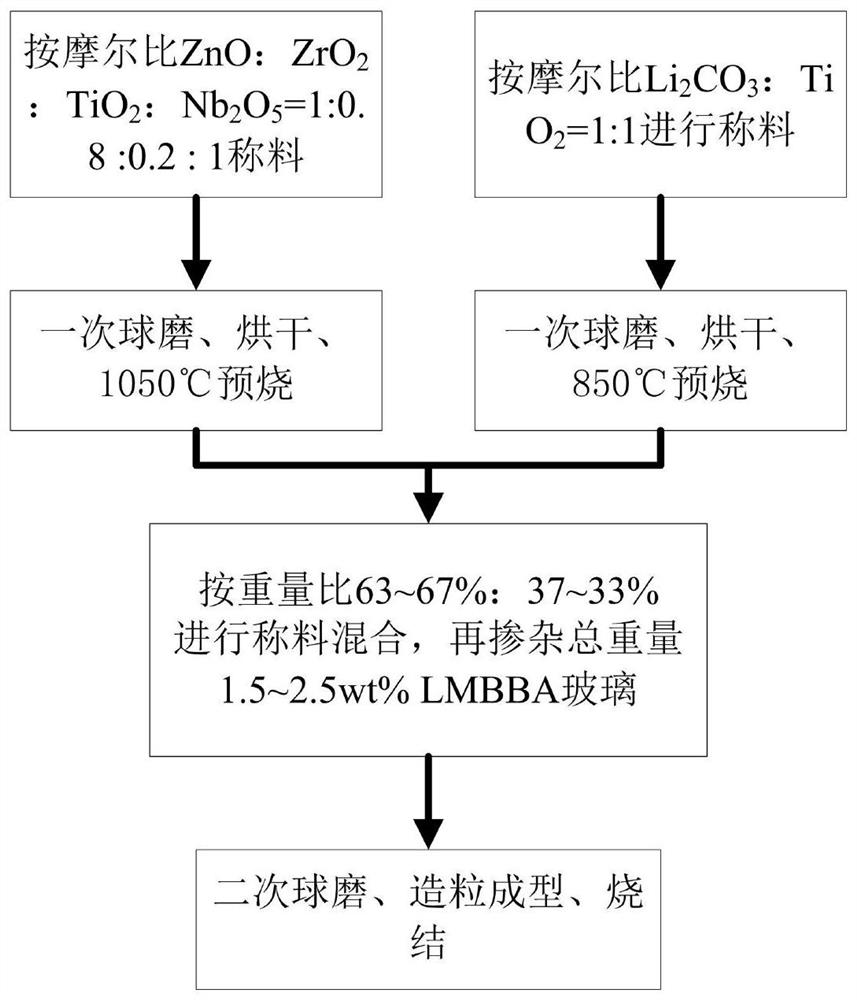

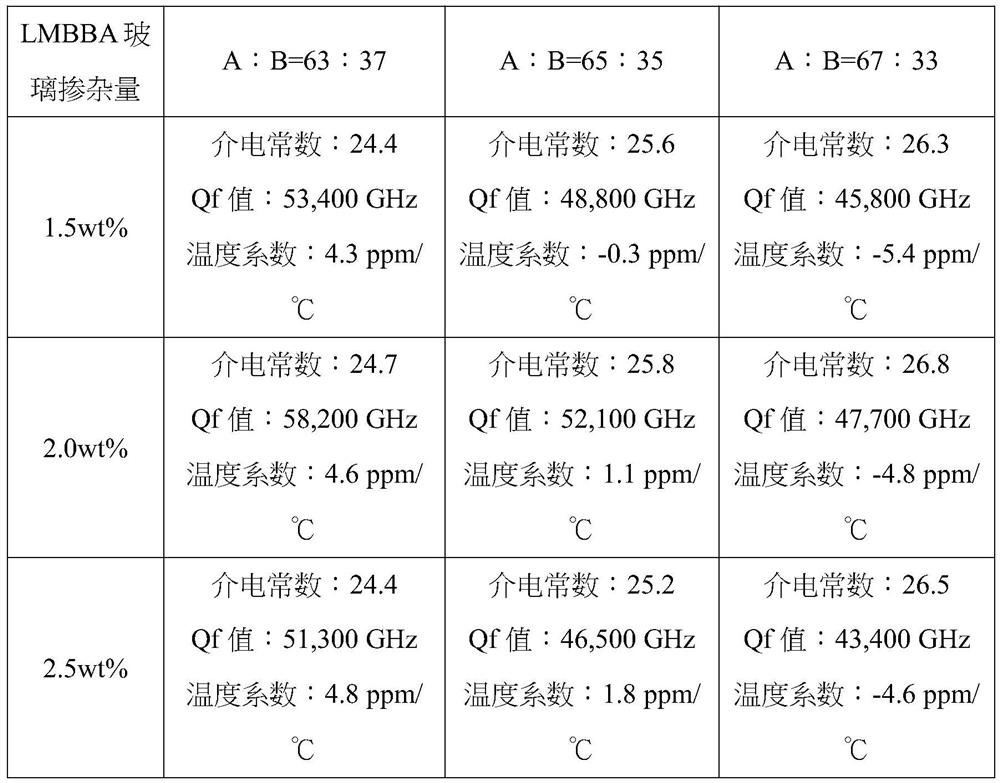

Medium low-loss LTCC microwave dielectric ceramic material and preparation method thereof

ActiveCN112125668AHigh dielectric constantNo reactionChemical industryDielectric lossDielectric ceramics

The invention provides a medium low-loss LTCC microwave dielectric ceramic material and a preparation method thereof.The LTCC microwave dielectric ceramic material comprises a two-phase mixed ceramicmaterial, the main crystalline phase is ZnZr(1-x)TixNb2O8 of a monoclinic wolframite structure, x is 0.1-0.2, the auxiliary phase is Li2TiO3 of a monoclinic system structure, a ZnZr(1-x)TixNb2O8 pre-sintered material and a Li2TiO3 pre-sintered material are mixed according to a the weight percentage ratio of (63-67 wt%): (37-33 wt%), and then LMBBA glass accounting for 1.5-2.5 wt% of the two-phasemixed ceramic material is doped as a cosolvent and is sintered at 900 DEG C; and the component of the LMBBA glass is Li2CO3-MgO-Bi2O3-B2O3-Al2O3. The LTCC microwave dielectric ceramic material disclosed by the invention not only has a relatively high dielectric constant and very low microwave dielectric loss, but also has a temperature coefficient close to zero, and has a very high application value in LTCC radio frequency microwave devices.

Owner:YANCHUANG PHOTOELECTRIC TECH GANZHOU

Method for carrying out pressurization and reverse-flow decomposition on wolframite with mixed acid of phosphoric acid and sulfuric acid

The invention relates to a method for carrying out pressurization and reverse-flow decomposition on wolframite with mixed acid of phosphoric acid and sulfuric acid. According to the method, the main improvements are that a reaction system is pressurized and the temperature is controlled to be higher than 100 DEG C in the process of extracting tungsten from wolframite powder with the mixed acid ofphosphoric acid and sulfuric acid, and a reverse-flow decomposition method is adopted in the operation process. According to the method, by pressurizing, calcium-containing compounds do not need to beadded to conduct conversion on the wolframite in the extracting process of the tungsten, the tungsten can be directly extracted from the high-tin wolframite or a high-tin black and white tungsten mixed ore, so that the production process is simplified, and the production cost is reduced; and through the process of reverse-flow decomposition, the mixed acid can be recycled, and the production costis further reduced.

Owner:CENT SOUTH UNIV

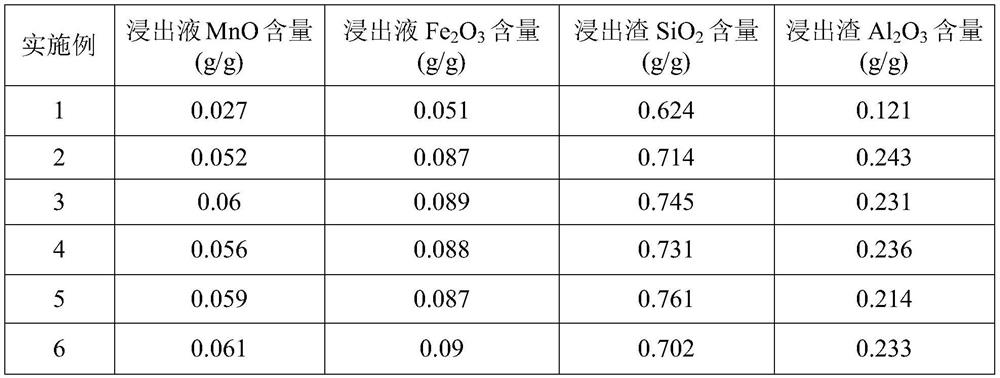

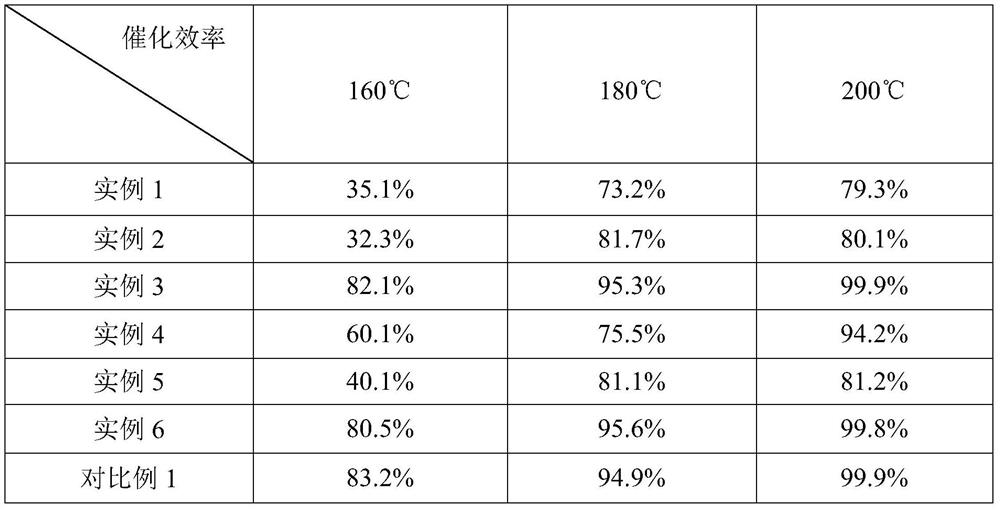

Preparation method of low-temperature SCR denitration catalyst based on wolframite smelting slag

ActiveCN112264034AImprove denitrification effectRealize high value-added resource utilizationHeterogenous catalyst chemical elementsDispersed particle separationPtru catalystSlag

The invention discloses a preparation method of a low-temperature SCR denitration catalyst based on wolframite smelting slag, relates to the field of environment-friendly catalytic materials, and aimsat solving the problems that the existing SCR denitration catalyst is high in production cost, the tungsten concentrate and tungsten slag treatment process is complex, the treatment cost is high, andhigh-added-value resource utilization of the wolframite smelting slag cannot be realized. The method has the advantages that the SCR denitration catalyst is prepared by taking the waste wolframite smelting slag as the raw material, and based on the efficient denitration performance of manganese oxide and ferric oxide and the characteristic that the wolframite smelting slag is rich in manganese oxide and ferric oxide, the wolframite smelting slag is treated, and then the titanium dioxide carrier is added, the preparation and the synthesis of the denitration catalyst are realized, and high-added-value resource utilization of hazardous wastes is realized. Meanwhile, the prepared SCR denitration catalyst is good in catalytic performance, the removal rate of nitric oxide can reach 95 percent or above, and the denitration performance is excellent.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

Flotation composite collecting agent as well as preparation method and application thereof

ActiveCN112246441AAtom utilization is highEasy to operateFlotationPreparation by oxygen reductionHydroxylamineHydroxamic acid

The invention belongs to the technical field of mineral flotation, and particularly relates to a flotation composite collecting agent and a preparation method and an application thereof. The preparation method comprises the following steps: taking peroxide and hydroxylamine salt as raw materials to prepare a composite collecting agent containing a hydroxamic acid compound and alcohol; the preparation method is wide in raw material source and simple in technological operation, the prepared flotation composite collecting agent has high collecting capacity and selectivity on ilmenite, scheelite,wolframite, cassiterite and other ores, and good flotation indexes are obtained in a flotation test.

Owner:CENT SOUTH UNIV

Method for recovering fine-grained wolframite by applying superconducting magnetic separation

InactiveCN111346741AAchieve pre-enrichmentPromote enrichmentHigh gradient magnetic separationCentrifugesResource recoveryMagnetic separator

The invention discloses a method for recovering fine-grained wolframite by applying superconducting magnetic separation. The method aims to solve the technical problems that in the prior art, the recovery rate of the fine-grained wolframite is low through traditional shaking table reselection, so that great economic loss and resource waste are formed, a large amount of reagents are needed in flotation, and environmental pollution is prone to being caused. The method comprises the following steps that ores containing the fine-grained wolframite are used as raw materials, firstly, the raw materials are subjected to centrifugal reselection, minerals with small specific gravity in the raw materials are removed, the fine-grained wolframite is pre-enriched, and reselected concentrates are obtained; and then superconducting magnetic separation is carried out on the reselected concentrates by using a superconducting magnetic separator, so that fine-grained wolframite concentrates are obtained.According to the method, the process of gravity separation-superconducting magnetic separation is used in a breakthrough mode, so that the sorting precision and efficiency are greatly improved, meanwhile, any reagent does not need to be added, the process is energy-saving and environment-friendly, the resource recycling rate is high, and the high-efficiency recycling of the wolframite resources is realized.

Owner:JIANGXI UNIV OF SCI & TECH +1

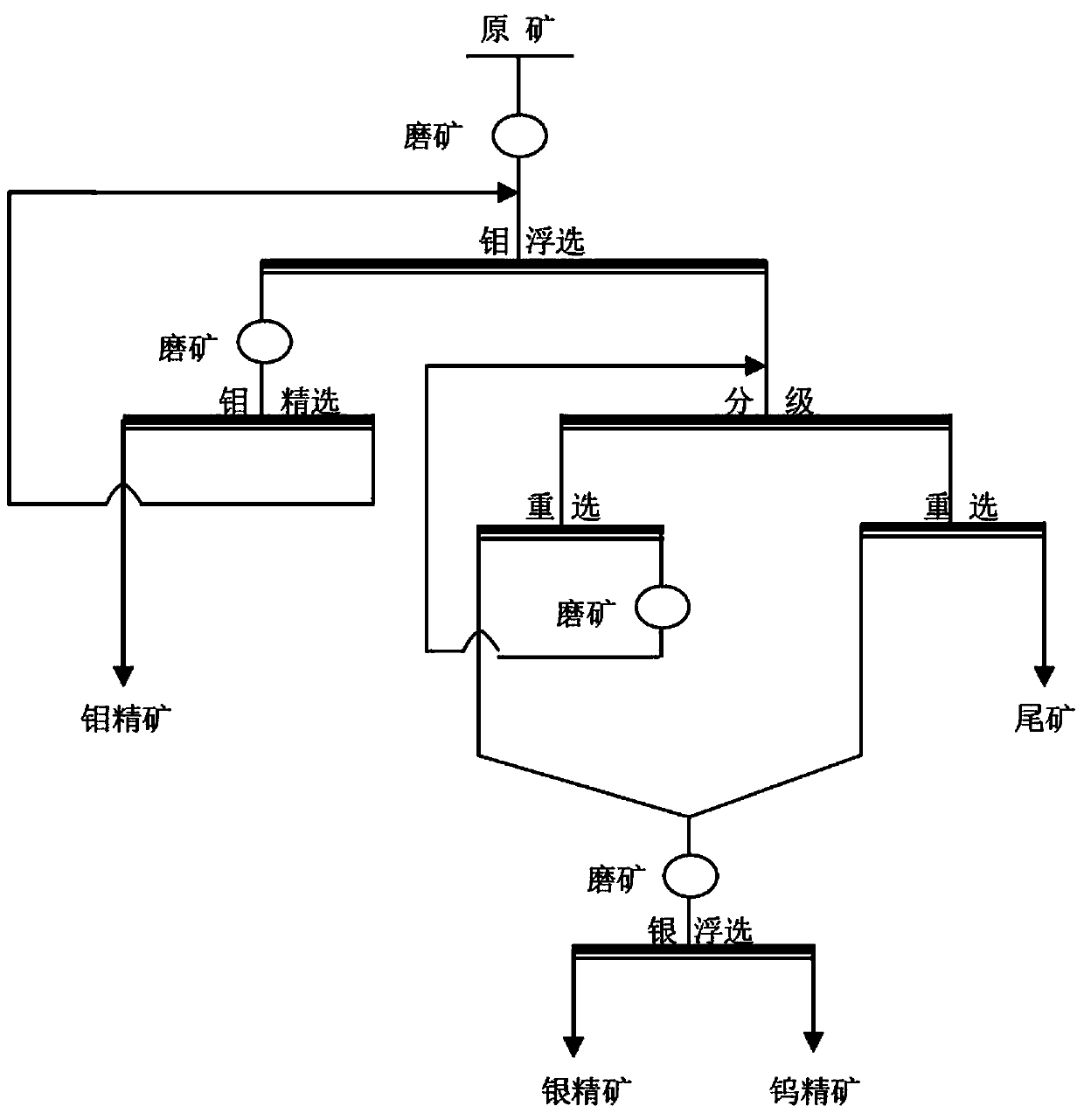

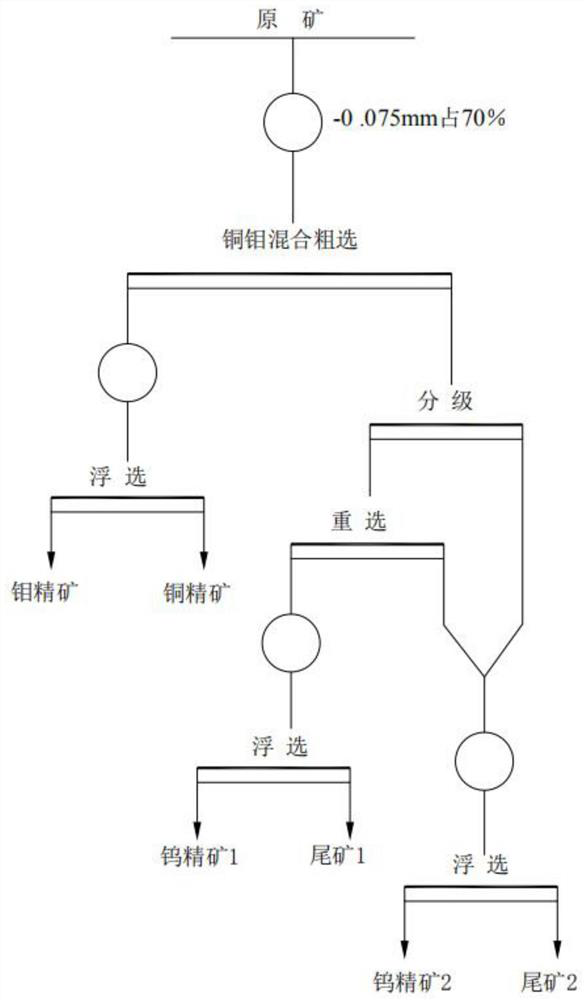

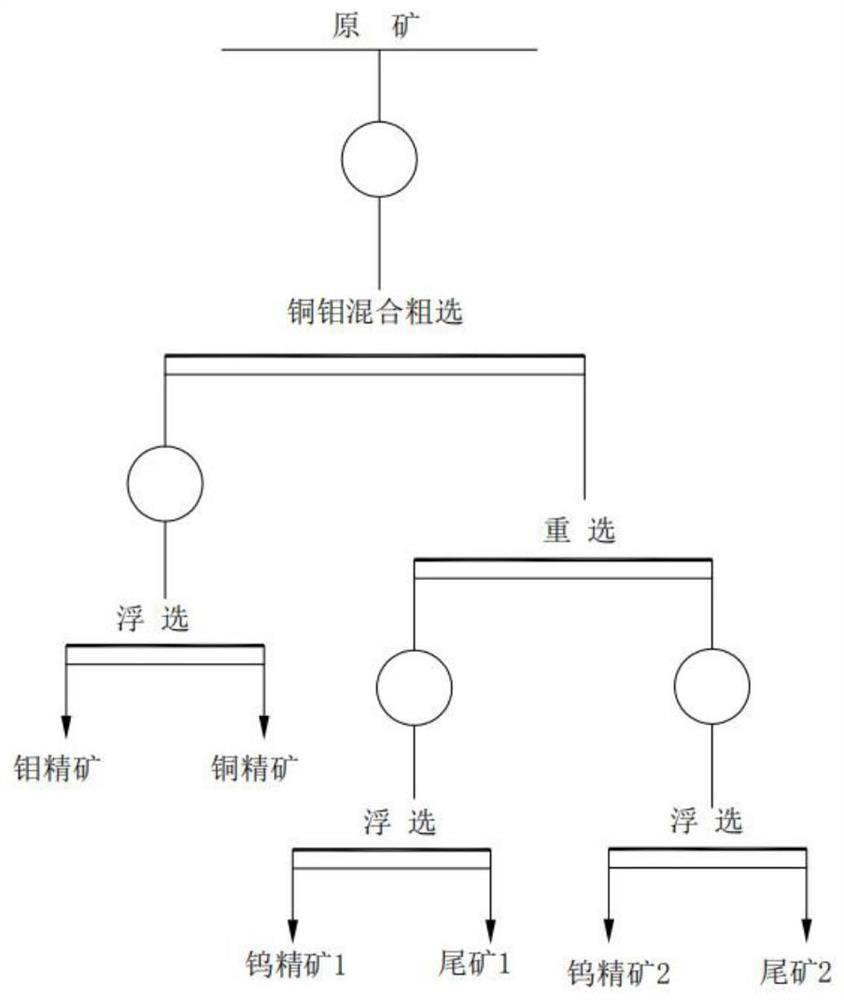

Tungsten-molybdenum-silver multi-metal ore beneficiation process

InactiveCN110918249AAvoid and prevent overgrindingGuaranteed RecoverySolid separationMaterials scienceTailings

The invention provides a tungsten-molybdenum-silver multi-metal ore beneficiation process. The beneficiation process comprises the steps that (1) tungsten-molybdenum-silver multi-metal ores are crushed, grinded and floated to prepare molybdenum rough concentrates; (2) the molybdenum rough concentrates are grinded and selected to obtain molybdenum concentrates; (3) molybdenum floatation tailings are classified and reselected to obtain tungsten-silver mixed concentrates; (4) the tungsten-silver mixed concentrates are grinded; and (5) silver is floated to prepare silver concentrates and tungstenconcentrates. The beneficiation process can prevent excessive grinding and excessive crushing of molybdenite and wolframite to gradually achieve the monomer dissociation to obtain the qualified molybdenum concentrates and tungsten concentrates under the precondition of guaranteeing the recovery rate; the floatation separation is performed after preparation of the tungsten-silver mixed concentratesthrough reselection, so that the ore flotation quantity is reduced, and the use level of flotation medicaments is reduced; and valuable elements of tungsten, molybdenum and silver in the ores can befully recovered to improve the comprehensive utilization rate of resources.

Owner:SHENYANG RES INST OF NONFERROUS METALS

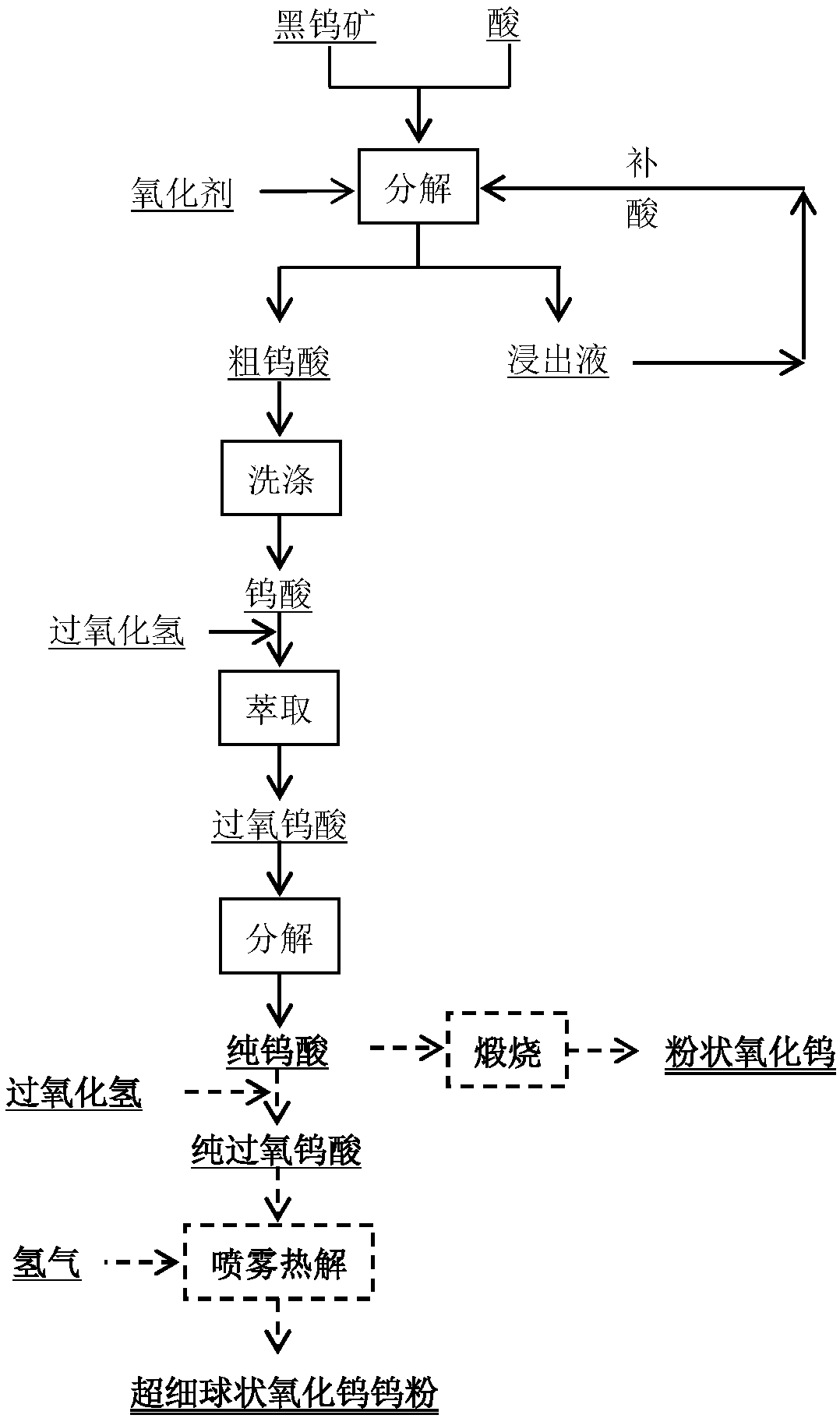

Method for extracting tungsten by acid decomposition of wolframite

ActiveCN108677037AReduce break down costReduce environmental costsTungsten compounds preparationTungsten oxides/hydroxidesDecompositionCalcination

The invention relates to a method for extracting tungsten by acid decomposition of wolframite. The method comprises the following steps: (1) a leaching reaction; (2) filtering and washing; (3) hydrogen peroxide extraction-tungsten decomposition extraction; (4) multi-time hydrogen peroxide dissolving-decomposition for purifying tungstic acid; (5) preparation of tungsten trioxide by calcination of pure tungstic acid; and (6) preparation of tungsten oxide and tungsten powder by spray pyrolysis of a peroxotungstic acid solution. A small amount of nitric acid or hydrochloric acid and a large amountof cheap and easily available sulfuric acid are actually consumed in the decomposition process of the method, so the decomposition cost of tungsten ores is greatly reduced; hydrogen peroxide is usedas an extractant for tungstic acid, so ammonia nitrogen wastewater is not generated, an ammonia nitrogen wastewater generating technology used in tungsten smelting for many years is abolished, and the environmental protection cost is greatly reduced; and the method allows various tungsten end products (tungsten oxide and tungsten powder) of tungsten to be directly produced, so the added values oftungsten smelting enterprises are increased.

Owner:CENT SOUTH UNIV

Preparation method of wolframite collecting agent

The invention discloses a preparation method of a wolframite collecting agent. The preparation method comprises the following steps of firstly, stirring and mixing oleic acid and sodium methanesulfonate for one hour at the normal temperature according to the mass ratio of (1-2): (1-3), so that a solution 1 is obtained; then, slowly adding ethylenediamine to the solution 1 according to the mass ratio of (1-2): (3-7), and stirring the mixture and making the mixture react for 2.5-3 hours at the temperature of 85-90 DEG C, so that a solution 2 is obtained; and finally, adding sodium hydroxide with the mass percentage concentration ranging from 10% to 15% for neutralization, so that claybank semitransparent thick matter is obtained, wherein the claybank semitransparent thick matter is the wolframite collecting agent.

Owner:JIANGXI UNIV OF SCI & TECH

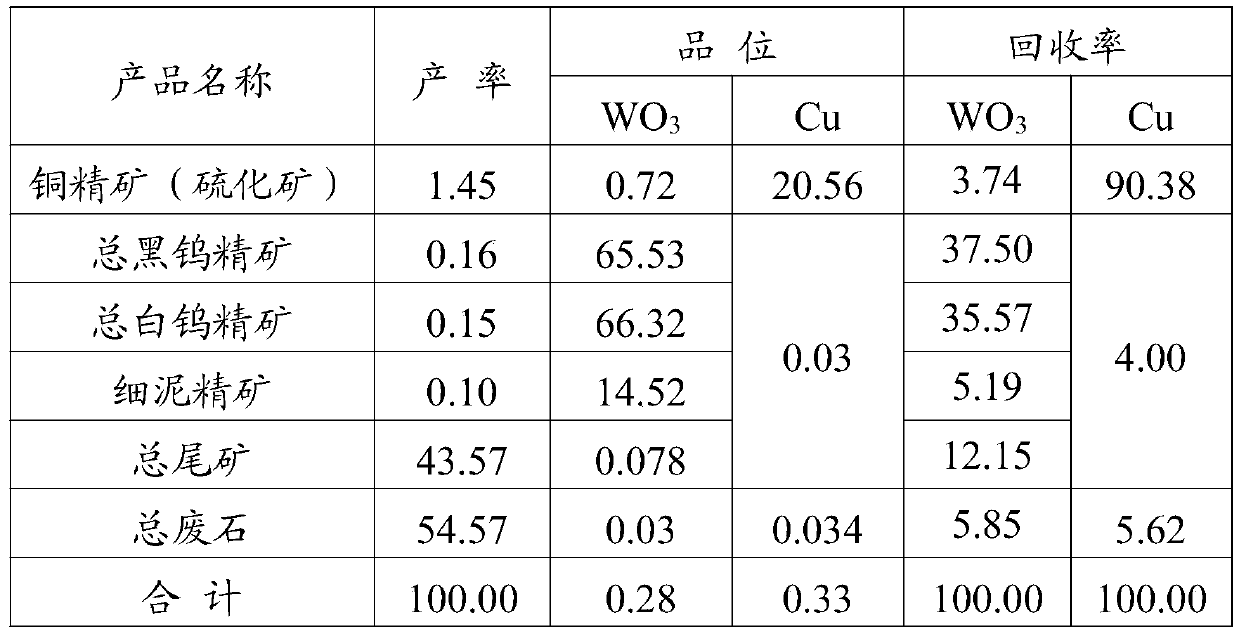

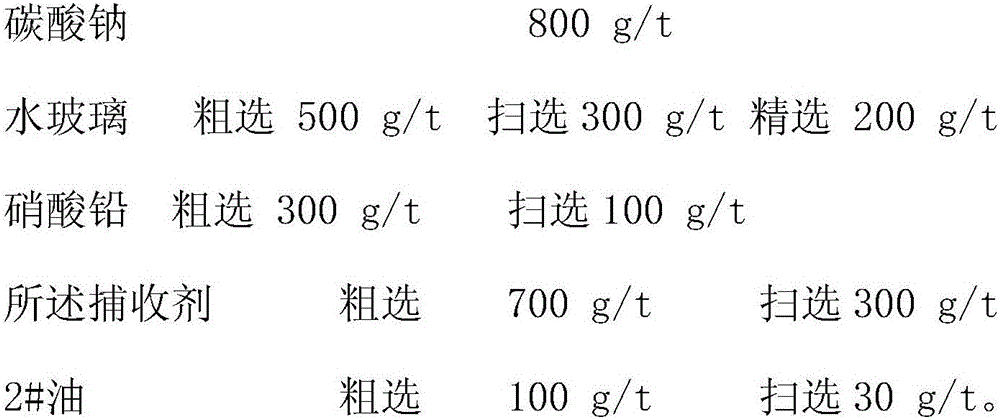

Comprehensive recovery and beneficiation process for wolframite and scheelite and associated valuable metals of wolframite and scheelite

The invention discloses a comprehensive recovery and beneficiation process for wolframite and scheelite and associated valuable metals of wolframite and scheelite. The comprehensive recovery and beneficiation process comprises the following steps: tungsten-molybdenum-copper polymetallic ore is crushed, ground and floated to obtain copper-molybdenum mixed rough concentrate and copper-molybdenum flotation tailings; the copper-molybdenum mixed rough concentrate is subjected to ore grinding and molybdenum floating and copper inhibiting separation, and molybdenum concentrate and copper concentrate are obtained; the copper-molybdenum flotation tailings are graded, and oversize products and undersize products are obtained; the oversize product is subjected to gravity separation, and gravity separation rough concentrate and gravity separation tailings are obtained; the reselected rough concentrate is subjected to ore grinding and flotation, and tungsten concentrate 1 is obtained; and the undersize products and the gravity separation tailings are subjected to ore grinding and flotation, and tungsten concentrate 2 is obtained. According to the beneficiation process, over-crushing of the ore can be effectively avoided, monomer dissociation is gradually achieved, and qualified tungsten concentrate, molybdenum concentrate and copper concentrate are obtained on the premise that the recovery rate is guaranteed, so that valuable elements in the ore are fully recovered, and the comprehensive utilization rate of resources is increased.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com