Preparation method of wolframite collecting agent

A technology of wolframite and collector, applied in the field of preparation of wolframite collector, can solve the problems of high loss rate, weak selectivity of flotation reagents, and no better recovery method found, and achieves the use of pharmaceuticals. The effect of low amount, good selectivity and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] An example of the preparation method of wolframite collector of the present invention, comprises the following steps:

[0018] First, oleic acid and sodium methanesulfonate were stirred and mixed at room temperature for 1 hour at a mass ratio of 1:1 to obtain solution 1, and then ethylenediamine was slowly added to solution 1 at a mass ratio of 1:3. Stirring and reacting at ℃ for 2.5 hours to prepare solution 2, and finally neutralizing with 10% sodium hydroxide, the obtained brownish-yellow translucent thick substance is the wolframite collector.

Embodiment 2

[0020] Another example of the preparation method of wolframite collector of the present invention, comprises the following steps:

[0021] First, oleic acid and sodium methanesulfonate were stirred and mixed at room temperature for 1 hour at a mass ratio of 2:3 to obtain solution 1, and then ethylenediamine was slowly added to solution 1 at a mass ratio of 2:7, at a temperature of 90°C The solution 2 was prepared by stirring and reacting under the conditions for 3 hours, and finally neutralized with 15% sodium hydroxide, and the obtained brownish-yellow translucent thick substance was the wolframite collector.

Embodiment 3

[0023] This embodiment is an application example of the wolframite collector in flotation wolframite.

[0024] 1. Mineral raw materials:

[0025] The tungsten content in the ore used is 0.37%, the silicon dioxide content is 13.54%, and the iron content is 15.75%. Phase analysis shows that tungsten mainly exists in the form of wolframite, and there is a small amount of scheelite; the gangue minerals are mainly silicon It exists in the form of acid salt, and some magnetite and goethite.

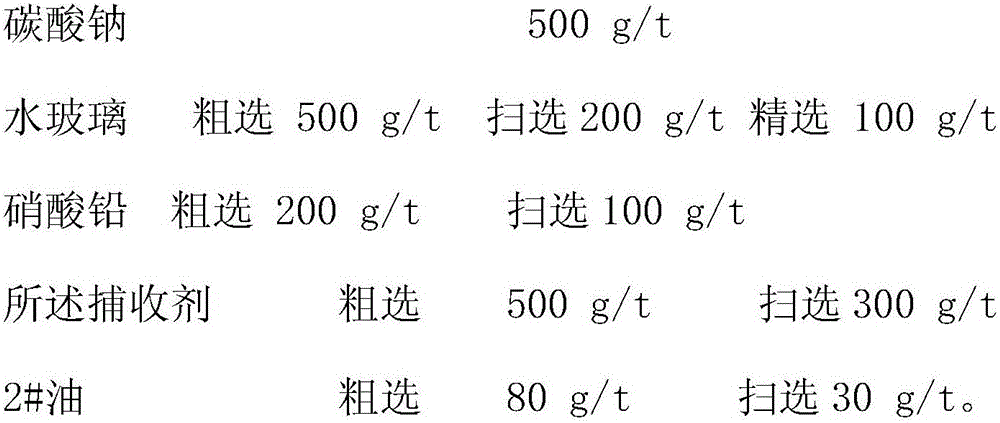

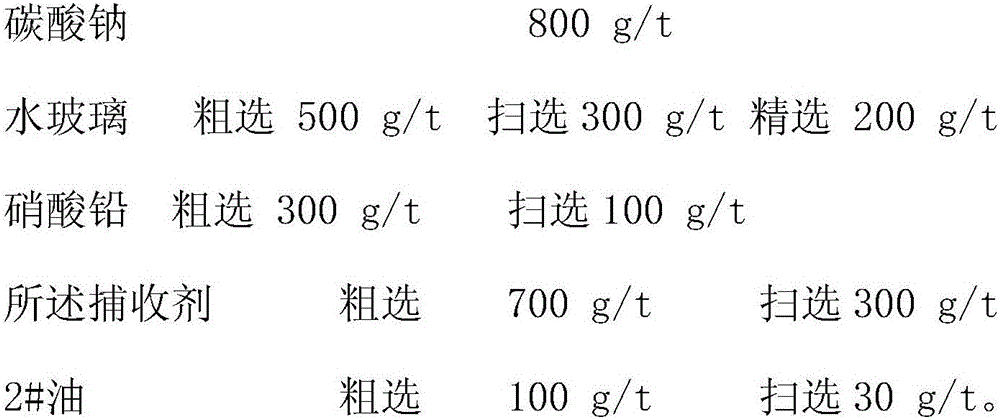

[0026] 2. Flotation agents and operating conditions:

[0027]

[0028] During the flotation process, after the ore is ground until the mineral monomers are dissociated, sodium carbonate and water glass are added to disperse and suppress the gangue minerals, then lead nitrate is added to activate wolframite, and finally the collector is added to the wolframite Collect tungsten concentrate products. The test results show that wolframite can be effectively recovered by adopting the above pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com