Medium low-loss LTCC microwave dielectric ceramic material and preparation method thereof

A technology of microwave dielectric ceramics and ceramic materials, applied in sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve problems such as the difference in temperature coefficient of resonance frequency, achieve the effect of improving Qf value and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

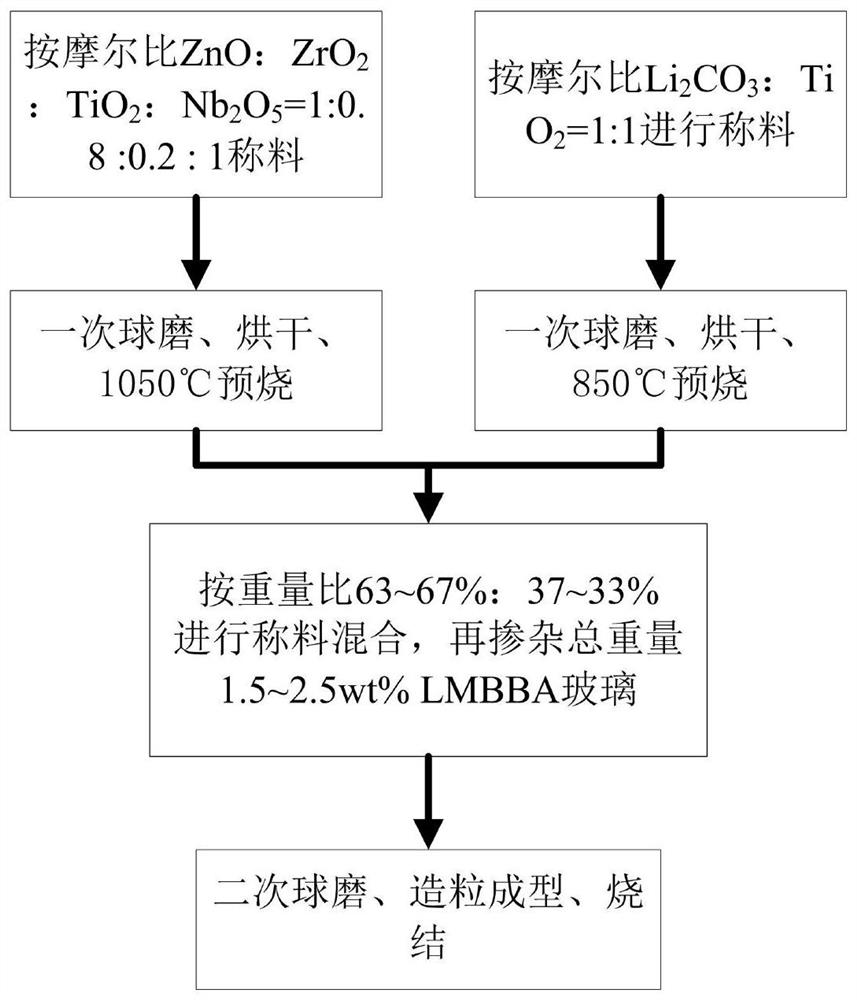

Method used

Image

Examples

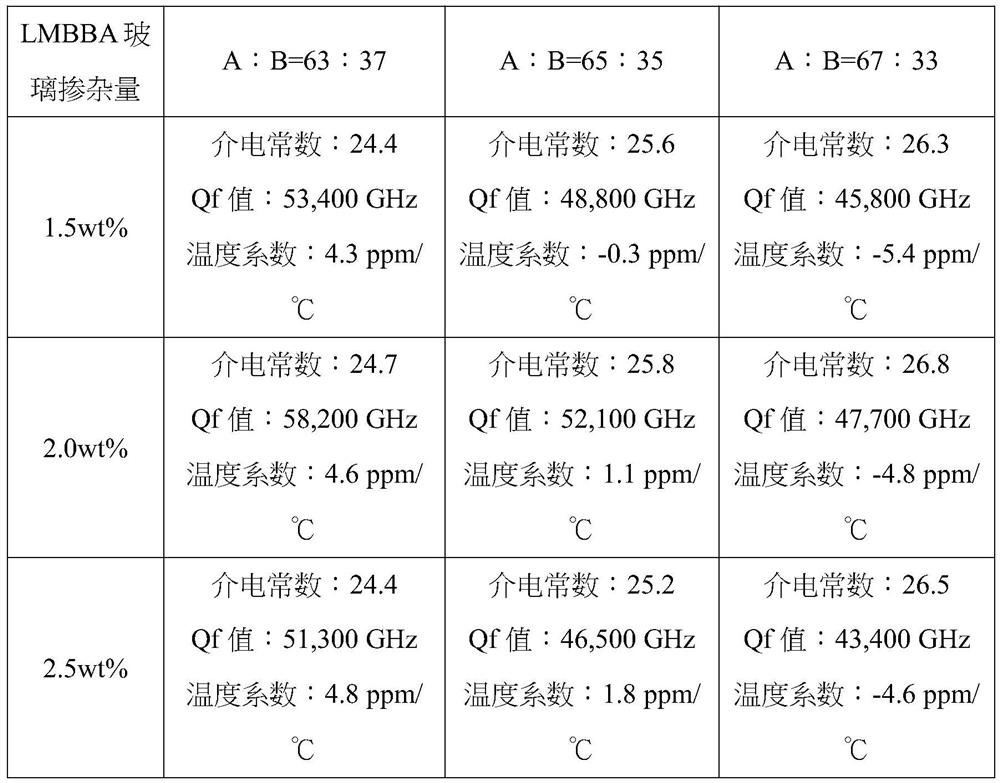

Embodiment 1-9

[0023] The intermediate low-loss LTCC microwave dielectric ceramic material provided by the present embodiment 1-9 includes a two-phase mixed ceramic material, wherein the main crystal phase is ZnZr of a monoclinic wolframite structure (1-x) Ti x Nb 2 o 8 , x=0.1~0.2, the auxiliary phase is Li with monoclinic structure 2 TiO 3 , ZnZr (1-x) Ti x Nb 2 o 8 Pre-fired material and Li 2 TiO 3 The pre-fired material is mixed according to the weight percentage of 63-67wt%: 37-33wt%, and then mixed with 1.5-2.5wt% LMBBA glass accounting for the two-phase mixed ceramic material as a flux for sintering, and the sintering temperature is 900°C; the composition of the LMBBA glass is Li 2 CO 3 -MgO-Bi 2 o 3 -B 2 o 3 -Al 2 o 3 .

[0024] in,

[0025] The ZnZr (1-x) Ti x Nb 2 o 8 The calcined material included oxides in the following molar ratios:

[0026] ZnO: ZrO 2 : TiO 2 : Nb 2 o 5 =1:0.8:0.2:1.

[0027] The Li 2 TiO 3 The calcined material comprises raw mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com