Patents

Literature

64results about How to "Simplify process engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corrosion-resisting surface treatment method for stainless steel in high-corrosion environment

InactiveCN102691059AImprove electrochemical impedanceIncrease Mo element contentChromatisationElectrolytic inorganic material coatingElectrolysisMolybdate

The invention relates to a corrosion-resisting surface treatment method for stainless steel in a high-corrosion treatment. The corrosion-resisting surface treatment method is characterized by comprising a treatment link comprising a washing step, an oxidizing step, an electrolyzing step, a cleaning step and a drying step; carrying out chemical oil removal with thermokalite, and eliminating oil stains of a stainless steel part in a processing process; and carrying out total immersion oxidization passivating treatment on the stainless steel part with oxidizing solution added with molybdate, so as to generate oxide in high oxidization valence state on the surface of the stainless steel, wherein electrolyzing comprises that a metal part is taken as a cathode, the metal part is immersed into an electrolyte containing the molybdate, electrolyzing is carried out for 10 minutes at normal temperature, then washing is carried out for 3-5 times with clear water, and then the metal part is suspended and drained. Through the treatment, a protective film with the thickness of 100-700nm is generated on the surface of the stainless steel, the Cr content in the protective film reaches up to 40-50%, while the Fe content is only 10-20%, and the Mo content is doubled. The method disclosed by the invention adopts common reagents, can be completed on relatively simple equipment, consumes less time and has a simple process while the effect that the stainless steel part with excellent corrosion resistance, heat resistance and scaling resistance can be obtained is realized.

Owner:SHENZHEN CANDORTECH INC CO

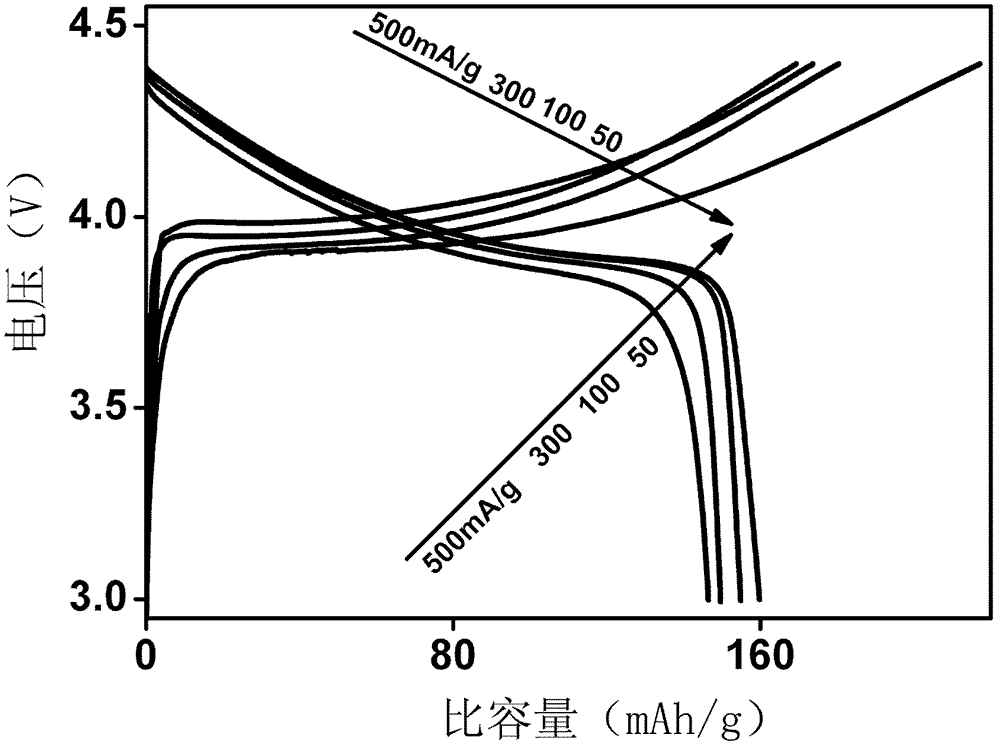

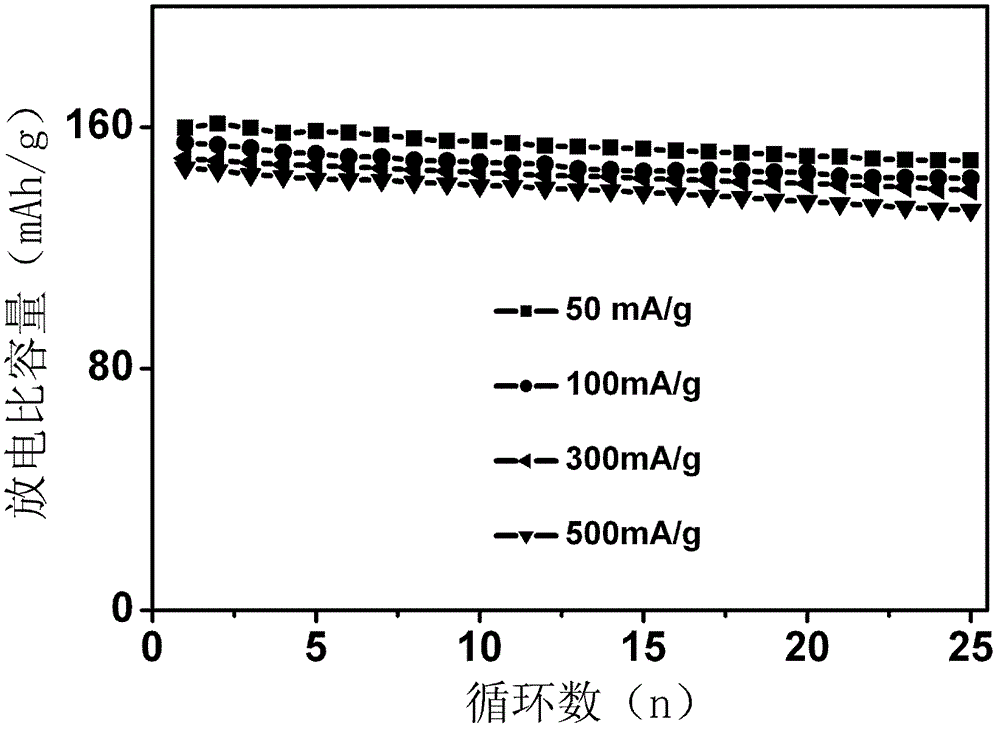

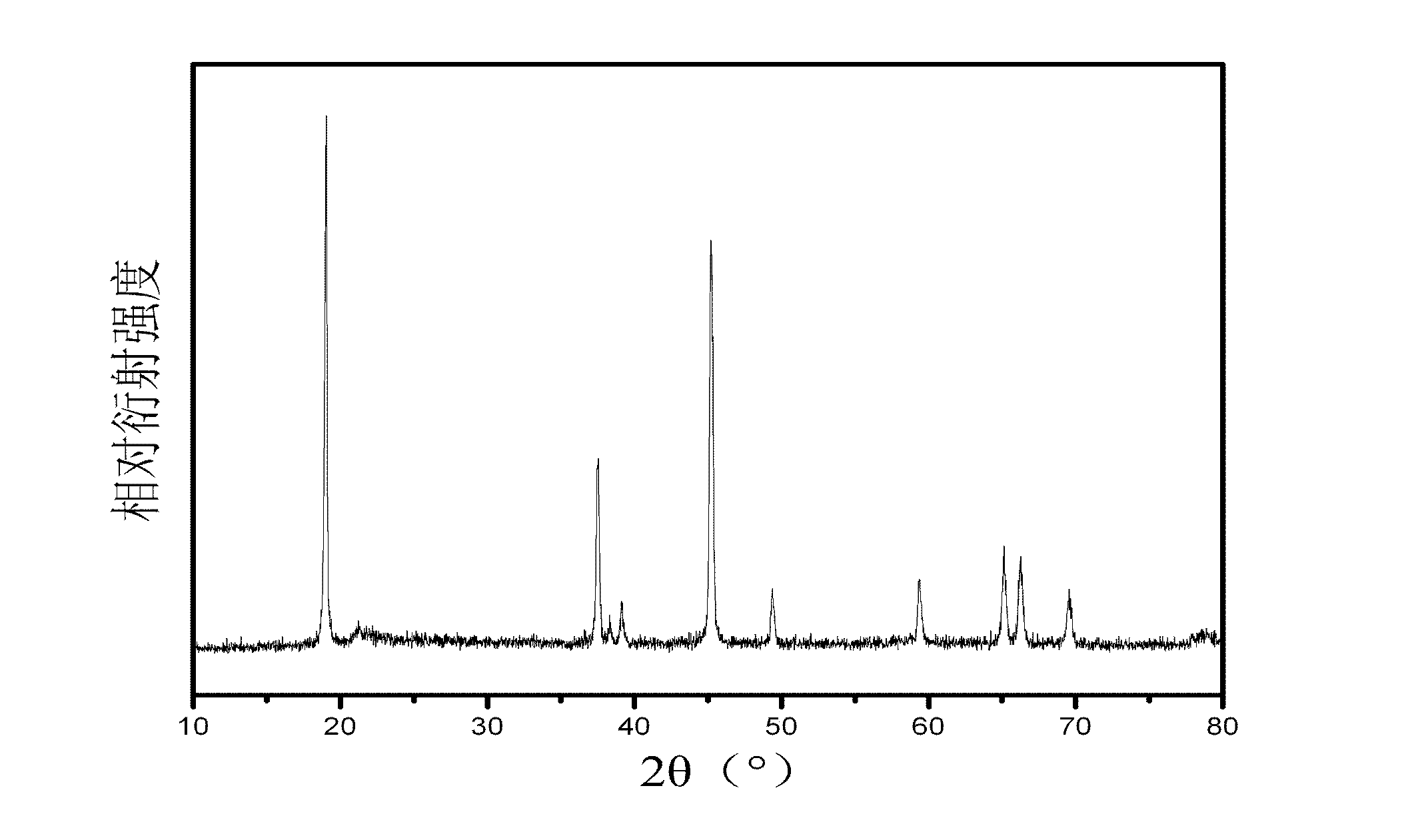

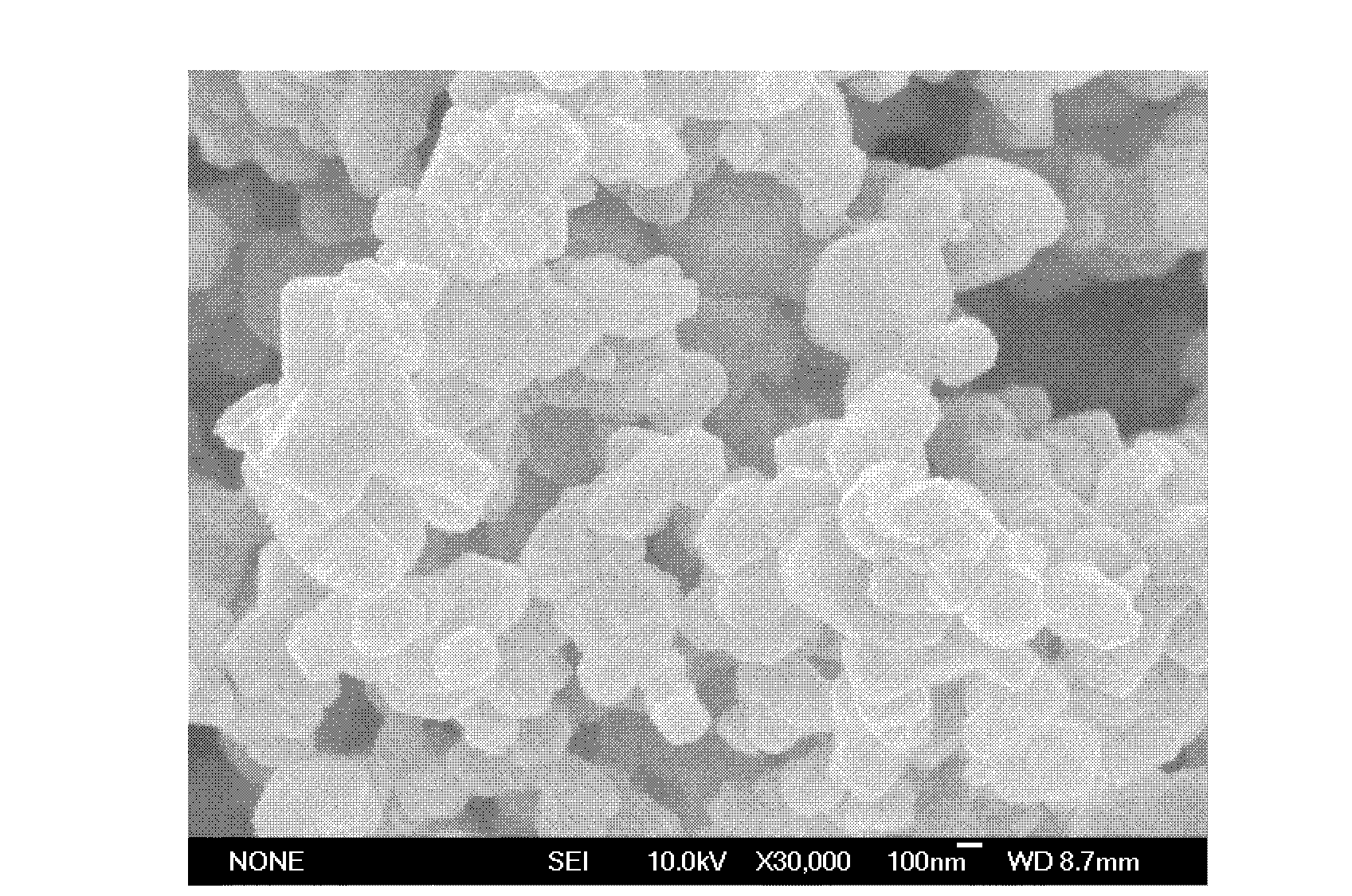

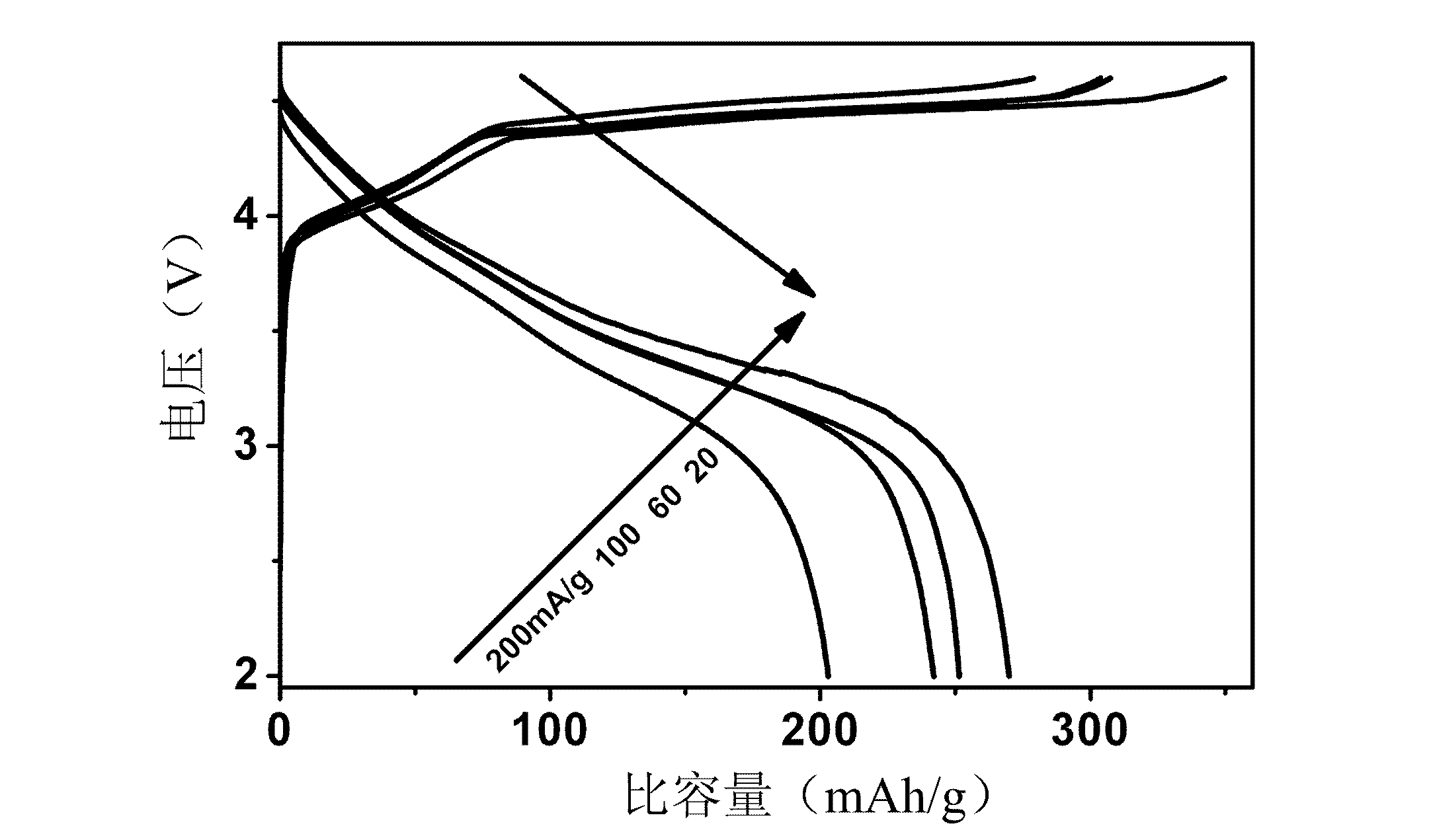

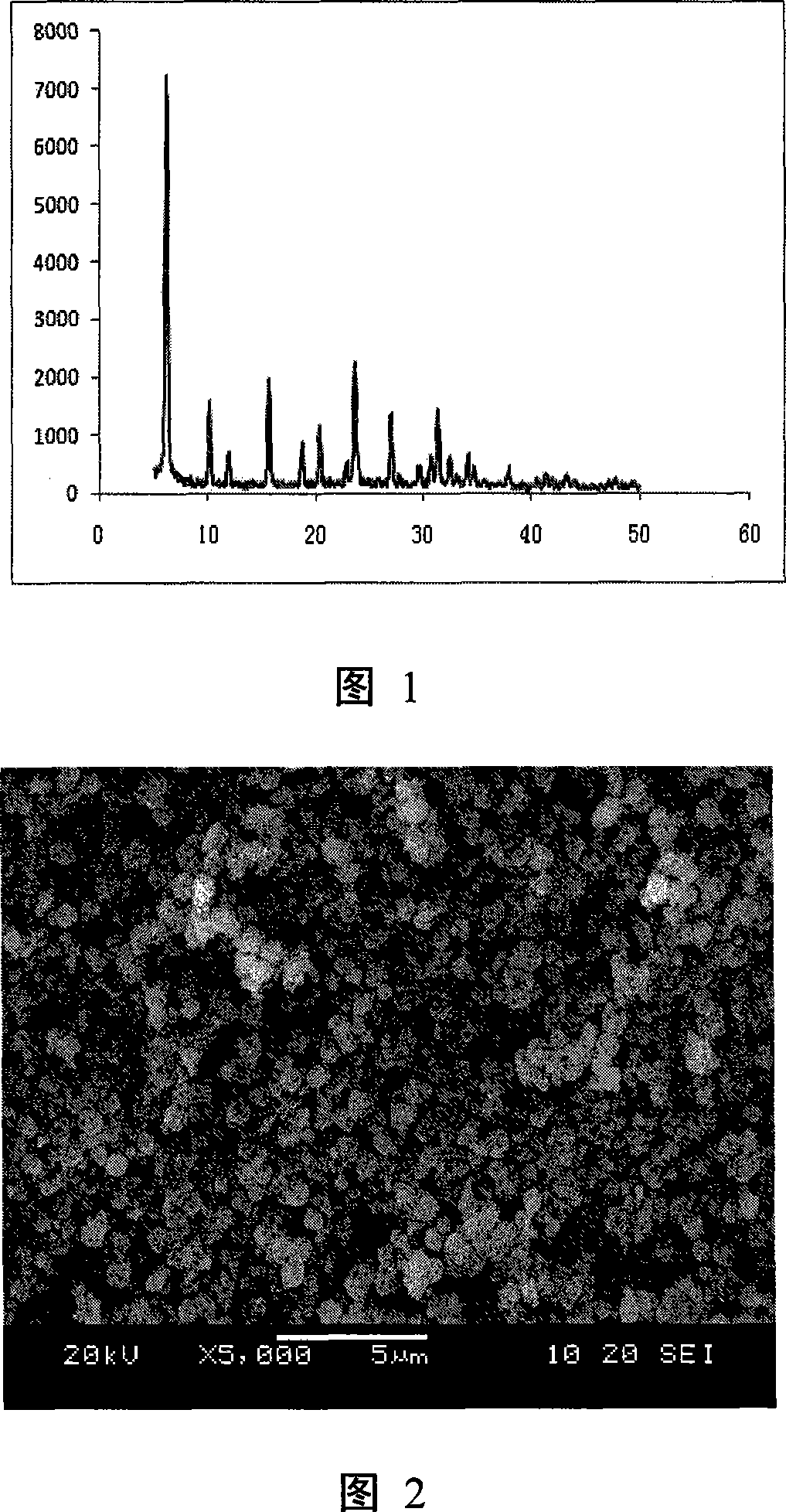

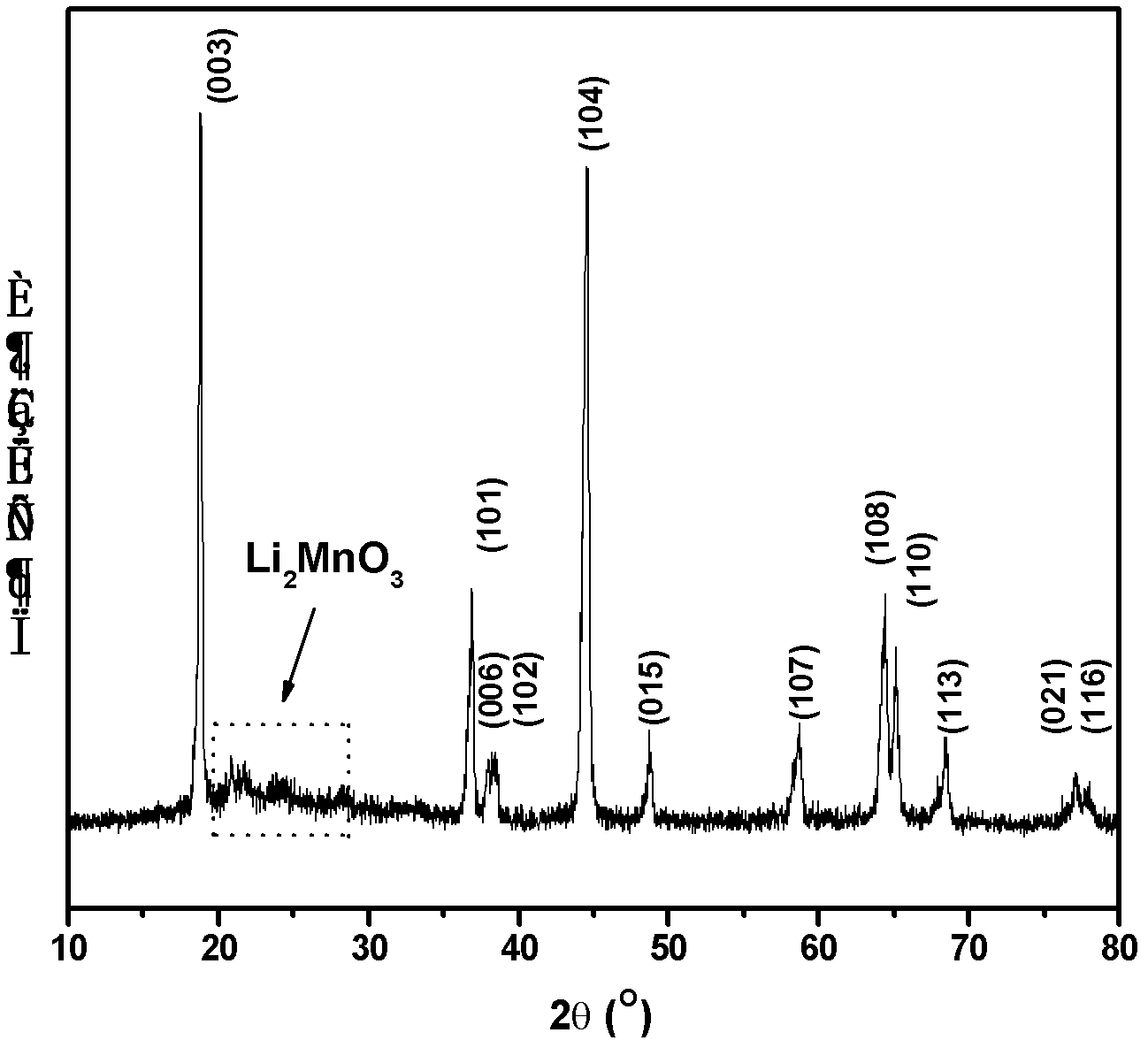

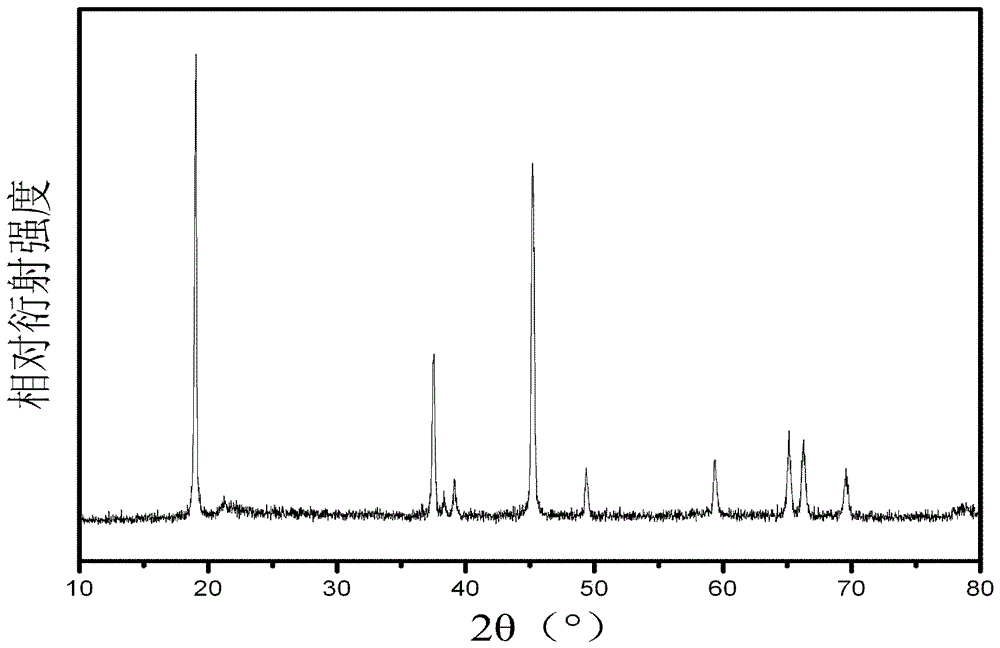

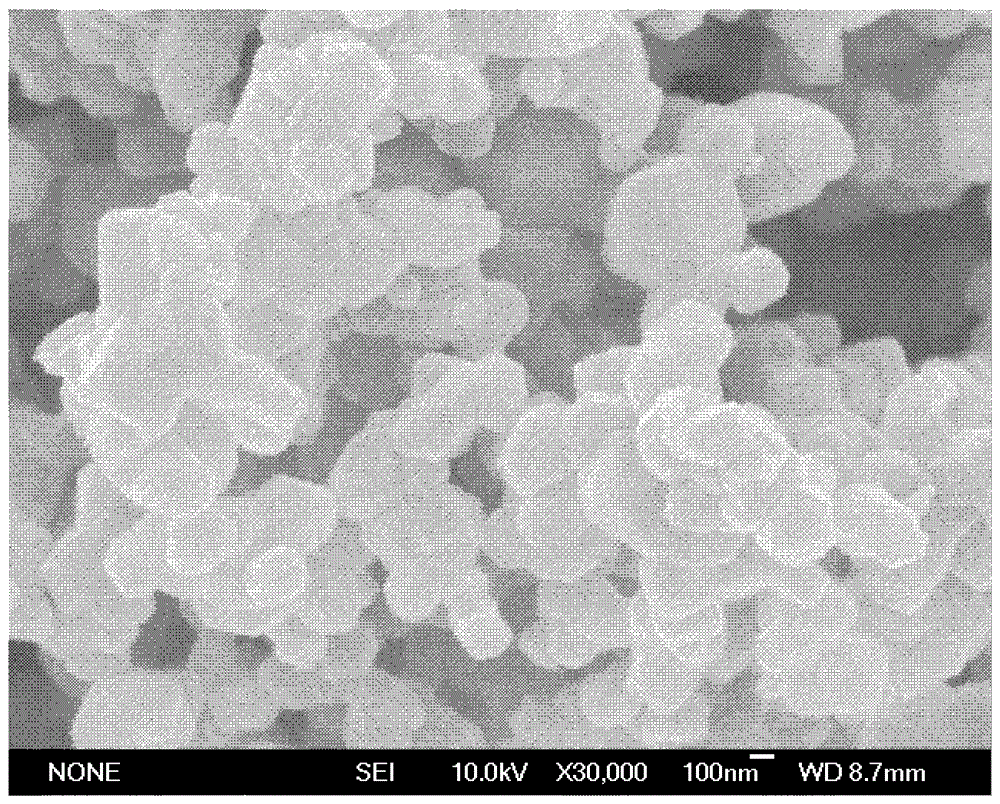

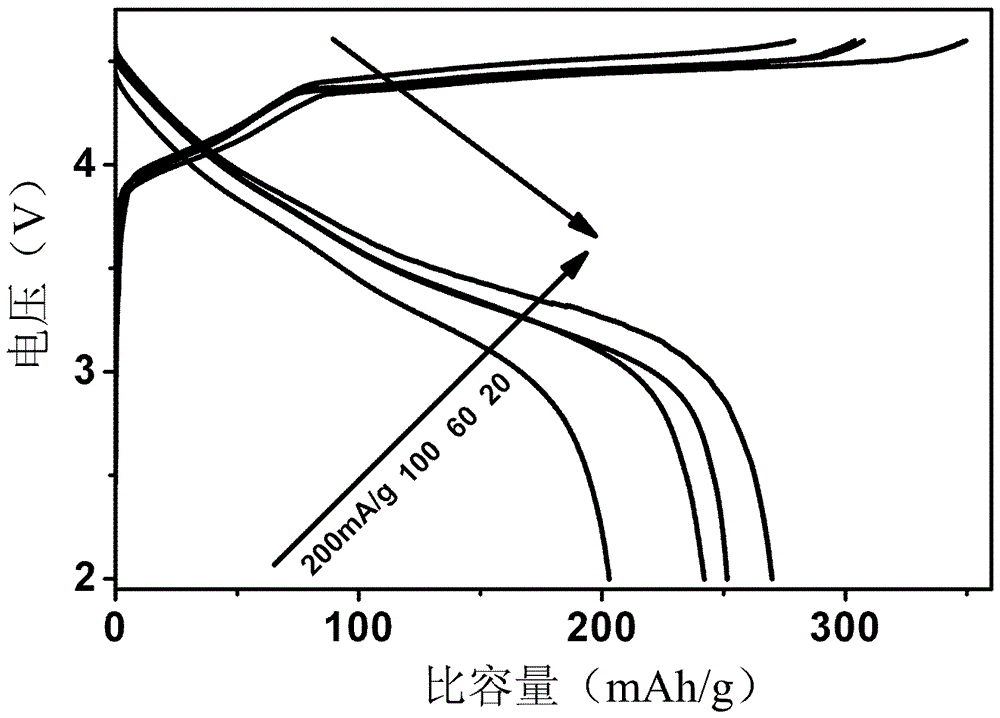

Li2MnO3 and LiCoO2 composite anode material

InactiveCN102751481AInhibition of phase transitionImprove electrochemical performanceCell electrodesHigh rateComposite oxide

The present invention discloses a Li2MnO3 and LiCoO2 composite anode material, which is a Li2MnO3 and LiCoO2 composite oxide meeting a stoichiometric ratio of xLi2MnO3.yLiCoO2, wherein x is more than or equal to 0.025 and is less than or equal to 0.15, and x plus y equals 1. The Li2MnO3 and LiCoO2 composite anode material of the present invention has characteristics of high specific capacity and high cycle life, and further has excellent performances under conditions of high rate, high temperature, low temperature, and the like.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Baicalin nano crystal suspension, nano crystal dry powder and methods for preparing baicalin nano crystal suspension and nano crystal dry powder

InactiveCN102824356AAddressing Physical Stability IssuesImprove wettabilityOrganic active ingredientsPowder deliverySolubilityFreeze-drying

The invention relates to a baicalin nano crystal suspension, a nano crystal dry powder and methods for preparing the baicalin nano crystal suspension and the nano crystal dry powder, which are used for effectively solving the problems that baicalin has bad water solubility, low oral bioavailability and common injections hardly achieve high drug-loading rate and a targeting function. A baicalin nano crystal intermediate is characterized by consisting of 1 part by weight of baicalin, 0.01-10 parts by weight of stabilizer and 0-30 parts by weight of filling protective. The baicalin nano crystal intermediate can be a nano crystal suspension and the dry power of the nano crystal suspension, which are prepared by the following steps: 1, preparing a nano primary suspension by using a dispersion method; 2, preparing the nano crystal suspension by a grain size reducing method which can be a high-pressure homogenization method or an ultrasound grinding method; and 3, preparing nano crystal dry powder by using a freeze-drying method and a spray drying method.

Owner:JIANGXI UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

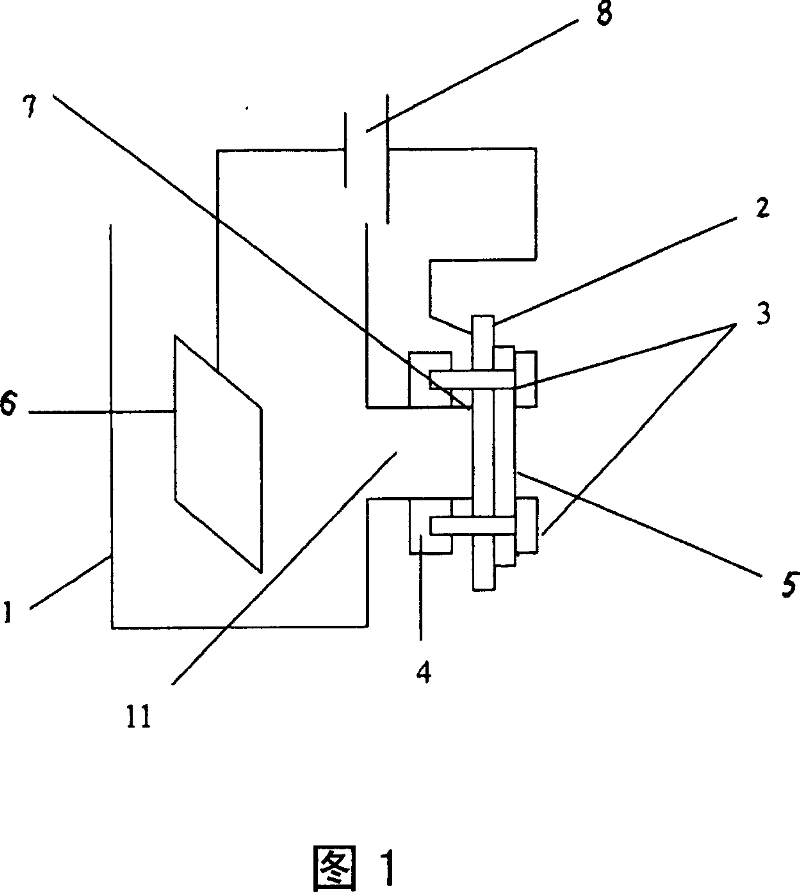

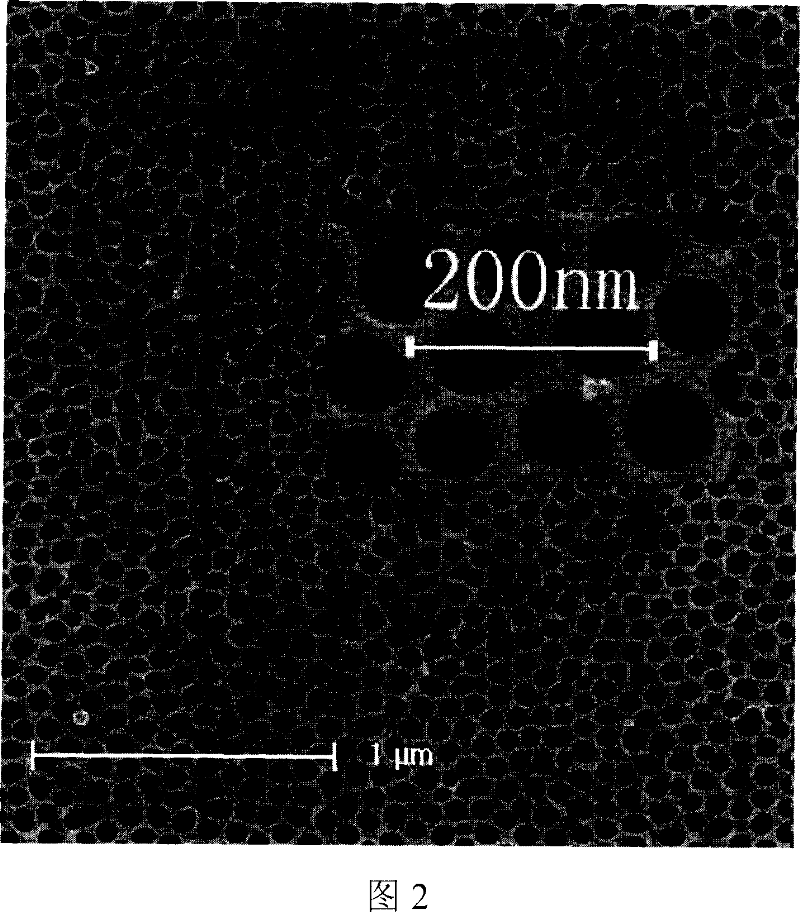

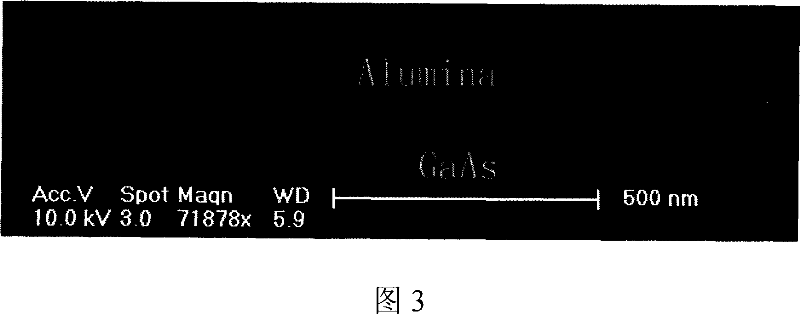

Method for preparing orderly anode alumina through-hole template by using anodic oxidation bath

InactiveCN101037783ASimplify process engineeringOvercoming pollutionAnodisationPhosphoric acidAnodic oxidation

A method for producing ordered anode alumina hole plate using anode oxidation bath, is characterized in that, includes the steps of: 1) taking out a substrate; 2) evaporating metal aluminium film on the substrate; 3) fixing the substrate with etal aluminium film in anode oxidation groove; 4) evaporating the substrate with etal aluminium film to anodize it in the electrolytic solution in anode oxidation groove; 5) placing the oxidated substrate into orthophosphoric acid solution, corroding and enlarging hole, and forming anode alumina hole plate.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

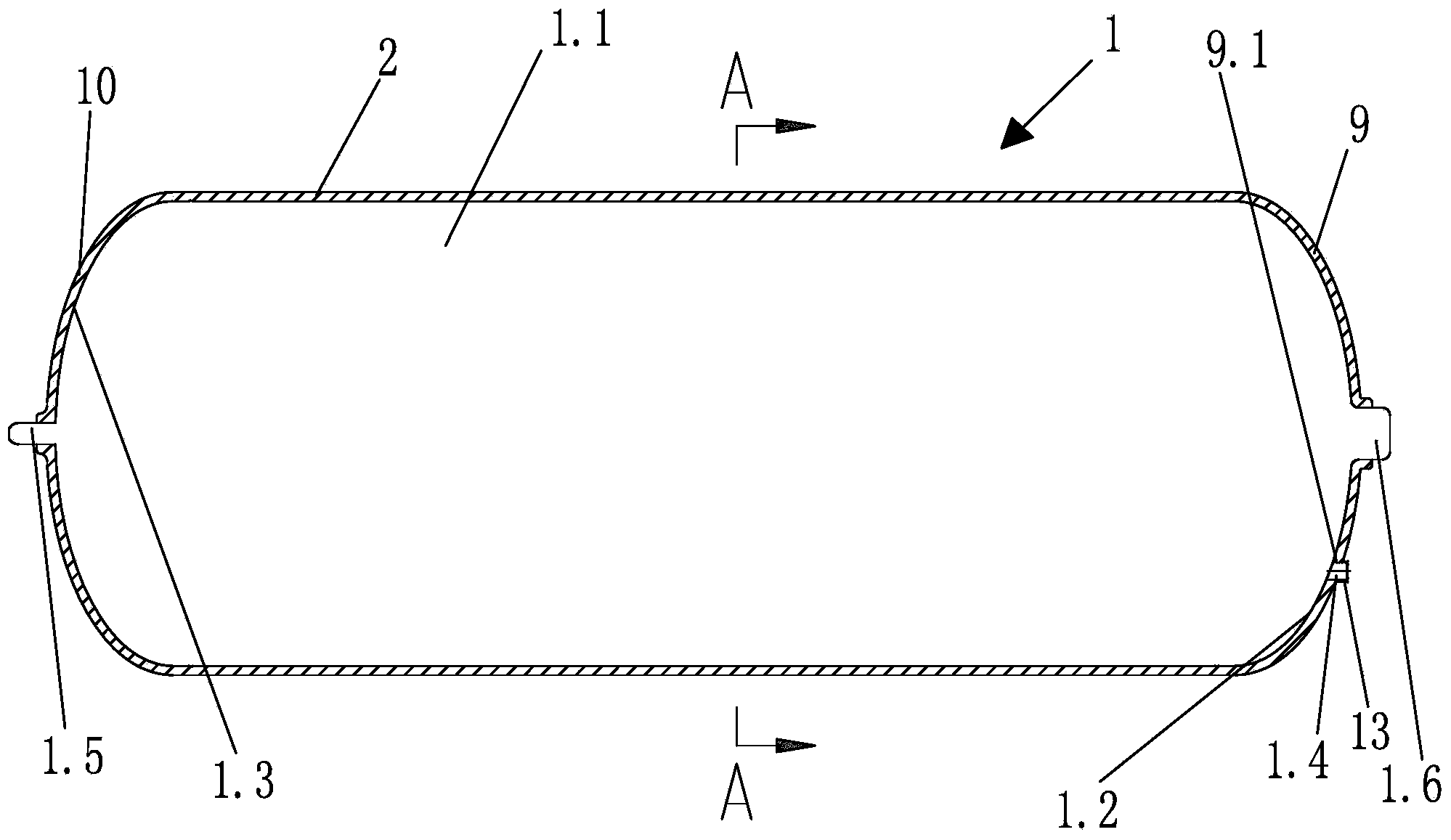

Coating structure for low-temperature heat insulation container and coating method of coating structure

The invention discloses a coating structure for a low-temperature heat insulation container. Stair-step trapezoid overlapped edges are arranged on one side of a heat insulation quilt of the coating structure, and anti-stair-step trapezoid overlapped edges are arranged on the other side of the heat insulation quilt; front trapezoid heat insulation blocks are arranged at the front end of the heat insulation quilt; a first pipe interface yield hole is formed in one trapezoid heat insulation block which corresponds to a pipe interface; back trapezoid heat insulation blocks are arranged at the back end of the heat insulation quilt; the surface of a cylindrical container is coated with the heat insulation quilt, and the forward trapezoid overlapped edges and the backward trapezoid overlapped edges are bonded; the external surface of a spherical surface front head around a front supporting rod is coated with the front trapezoid heat insulation blocks, thereby forming a front end spherical surface coating layer; the first pipe interface yield hole is sleeved with the pipe interface; the external surface of a spherical surface back head around a back supporting rod is coated with the back trapezoid heat insulation blocks, thereby forming a back end spherical surface coating layer; the external surface of the front end spherical surface coating layer is coated with a front sealing cap, and the external surface of the back end spherical surface coating layer is coated with a back sealing cap. According to the coating structure, the winding and coating efficiency of a thermal insulating material is improved, and the effect of maintaining vacuum is improved.

Owner:湖北三江航天江北机械工程有限公司

Cathode material of manganese, cobalt and lithium oxidate for lithium ion battery and preparation method of cathode material

ActiveCN102583583AWide variety of sourcesEasy to controlCell electrodesCobalt oxides/hydroxidesAluminium-ion batteryManganese

The invention discloses a cathode material of manganese, cobalt and lithium oxidate for a lithium ion battery and a preparation method of the cathode material. The chemical formula of the cathode material is as follow: Li(3+x) / 3Mn2x / 1-xO2, wherein x is larger than or equal to 0.1 and is less than or equal to 0.9. The cathode material has excellent electrochemistry performances of high specific capacity, applicability of high temperature and low temperature, and the like. The preparation method is characterized by simplicity in operation, low manufacturing cost, short synthesis period, high repeatability and the like; no foreign ion is introduced, so that the purity of the product is greatly improved; lithium ions and transitional metal ions settle together, so that all the ions are mixed more uniformly; and the method can be extensively applied to synthesis of cathode material of oxidate for the lithium ion battery.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

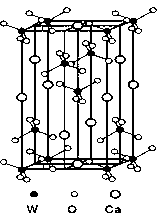

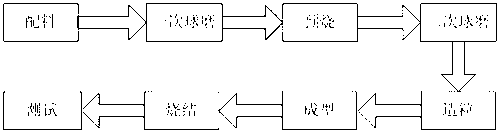

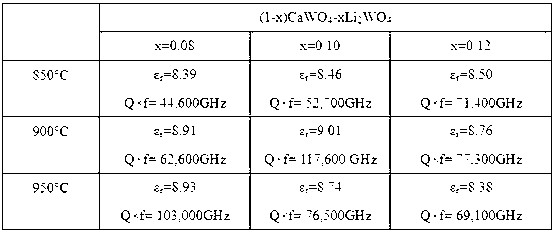

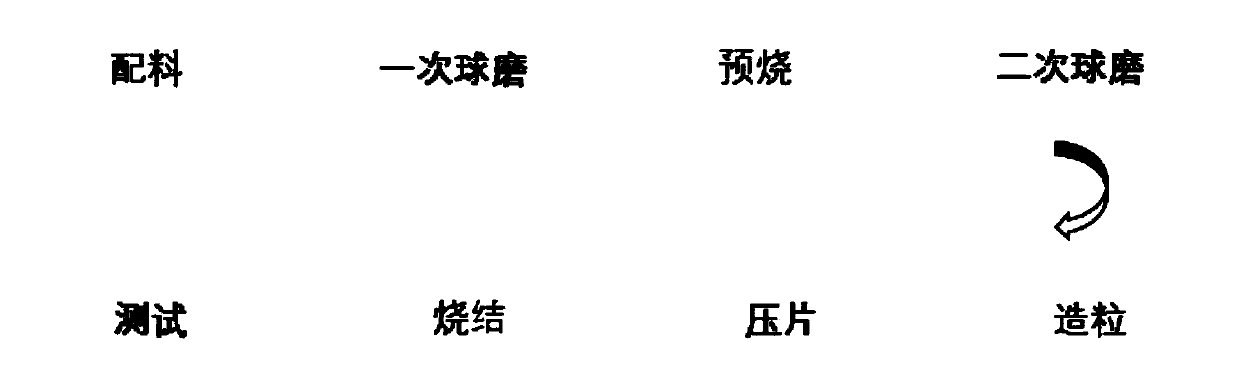

Low-medium low-loss LTCC (Low Temperature Co-Fired Ceramic) microwave ceramic material and preparation method thereof

ActiveCN103121842ALow dielectric lossAvoid the problem of easy cracks in welding processMicrowaveComposite ceramic

The invention discloses a low-medium low-loss LTCC (Low Temperature Co-Fired Ceramic) microwave ceramic material and a preparation method thereof. The material is composite ceramic containing double phases, wherein the principal crystalline phase is tetragonal-phase scheelite CaWO4; the auxiliary phase is a trigonal crystal system phenacite structure Li2WO4 with the molecular formula of (1-x) CaWo4-xLi2WO4. The preparation method of the low-medium low-loss LTCC microwave ceramic material comprises the following steps of: with CaCO3, WO3 and Li2CO3 as initial materials, calculating the mass percentages of CaCO3, WO3 and Li2CO3 according to the molar ratio of each element in the molecular formula (1-x)CaWo4-xLi2WO4; weighing the materials, preliminarily ball-milling the materials, drying the materials, pre-sintering, secondarily ball-milling the materials; and obtaining the low-medium low-loss microwave ceramic material by carrying out a series of processes including drying, pelletizing, forming, sintering and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

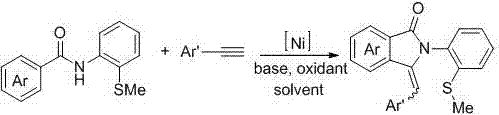

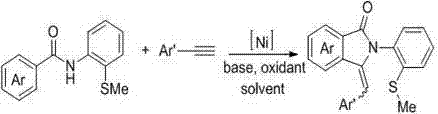

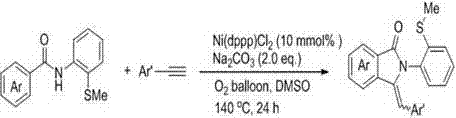

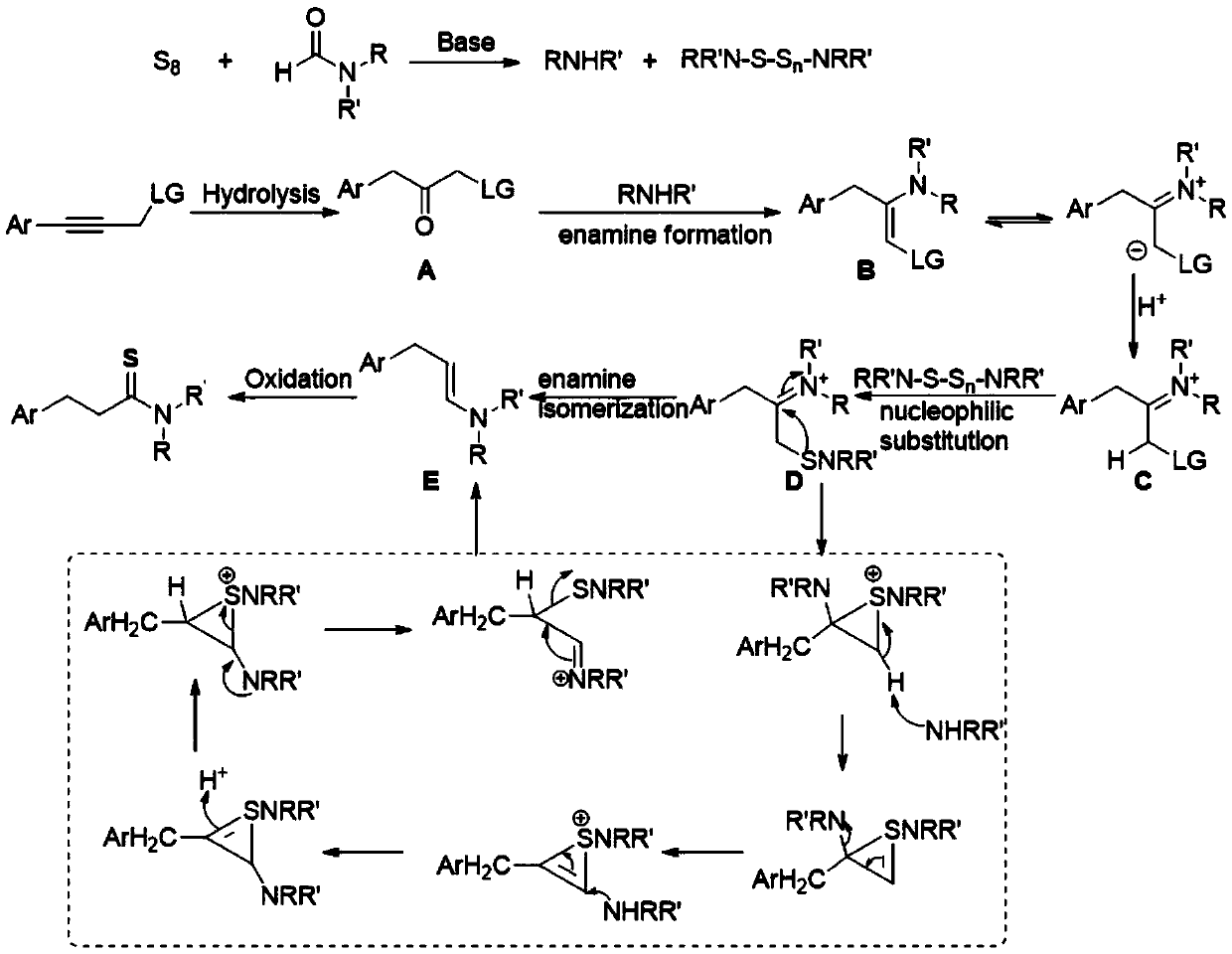

Preparation method of sulfur-containing 3-arylmethylene isoindolinone derivative

The invention relates to a preparation method of a sulfur-containing 3-arylmethylene isoindolinone derivative. The method comprises the following steps: taking N-(8-quinolyl)Ar amide and aryl terminal alkyne A' as substrates, adding a catalyst, alkali and an oxidizing agent in the substrates, and in a reaction solvent, stirring the materials for a reaction for 24 h at the temperature of 140 DEG C; wherein Ar is one of phenyl, 4-methyl phenyl, 4-methoxyphenyl, 4-fluorophenyl, 4-chlorophenyl, 3-chlorophenyl, 4-bromophenyl, 4-nitro phenyl, 4-biphenyl, and 2-thienyl; and Ar' is one of 4-methyl phenyl, 4-methoxyphenyl, 4-fluorophenyl, 4-chlorophenyl, 4-bromophenyl, 4-nitro phenyl, and 4-benzotrifluoride; and obtaining a target product after the reaction is completed. The preparation method has the advantages of simple process and novel product structure, a special apparatus or a mode is not required, and the method has the advantages of simple operation, easy acquisition of the product and good yield.

Owner:WENZHOU UNIVERSITY

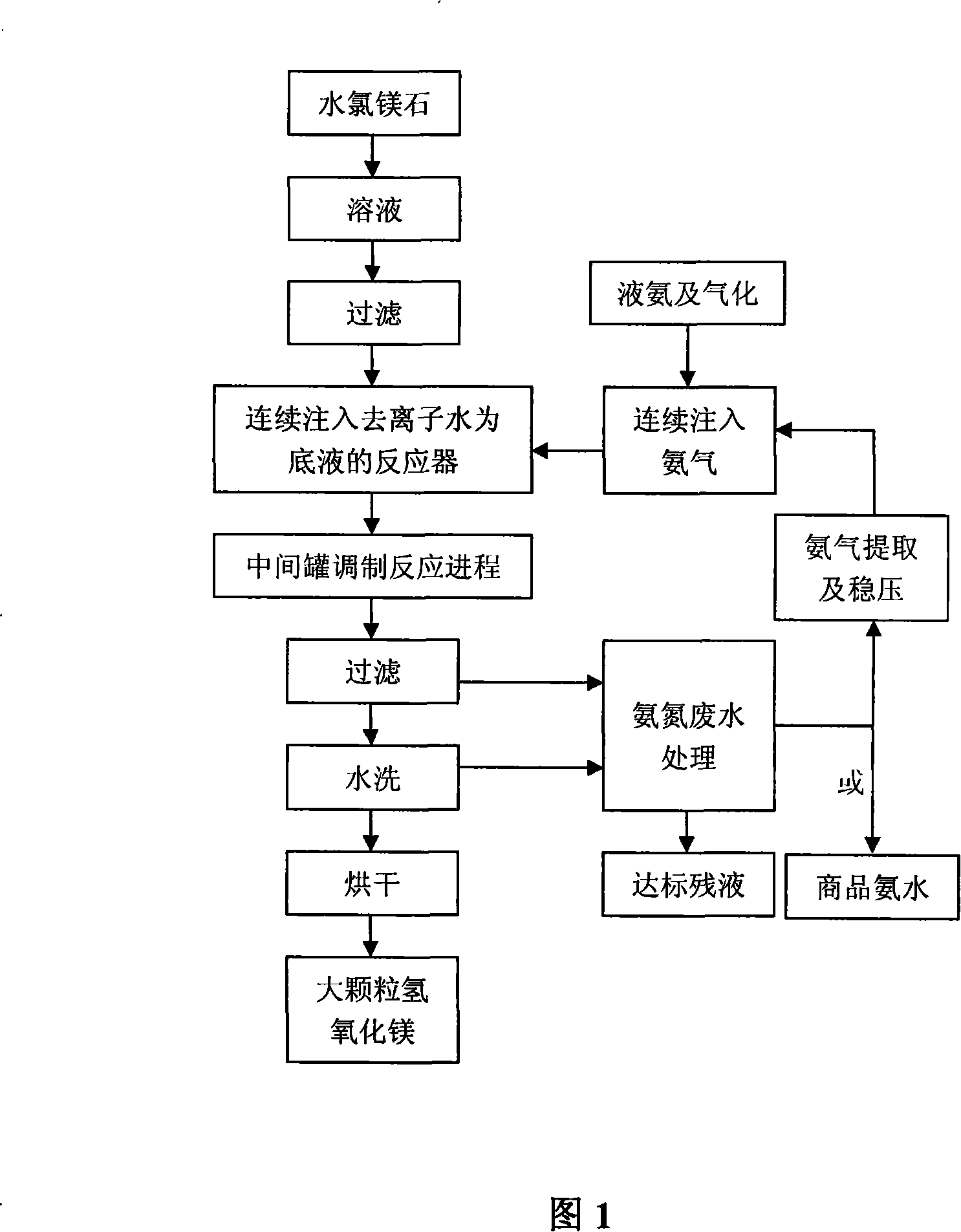

Continuous preparation method of high-purity magnesium hydroxide

The invention provides a method for continuously preparing highly pure magnesium hydroxide which relates to a method for continuously producing highly pure magnesium hydroxide with bischofite as raw material and ammonia as precipitant. The method is characterized in that: a treated bischofite is prepared into a solution with the concentration of 0.5 mol / L-4 mol / L, the bischofite solution and ammonia gas are added continuously after the reaction begins and the chemical reaction for depositing the magnesium hydroxide is carried out continuously. Characteristics of the reaction vessel utilization ratio, the productive capacity of unit volume, technical reliability and stability and so on of the method are greatly improved compared with intermittent reaction technology. The base liquid does not need to be replaced or heated repeatedly, thus energy-saving effect is distinct and labor productivity is high. The method can be used for obtaining magnesium hydroxide with the granularity of 10 microns-100 microns and the purity of 99 percent-99.999 percent. The ammonia nitrogen treatment of the tail solution adopts a commercial method that meets environmental protection requirement. The product produced by the invention has large granule size, high purity, more specifications, low cost, high equipment utilization rate and low one-time investment and has no pollution to the environment.

Owner:DALIAN MARITIME UNIVERSITY +1

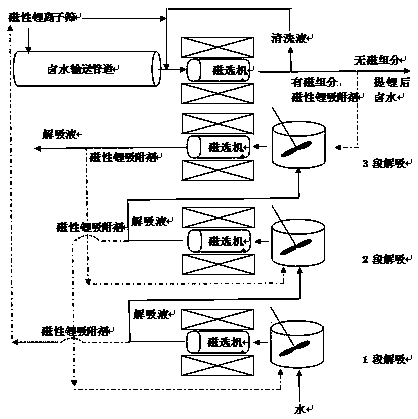

Method for extracting lithium from brine by magnetic powder aluminum lithium adsorbent

InactiveCN108083301AReduce lossesImprove adsorption capacityOther chemical processesLithium compoundsLithiumHigh concentration

The invention discloses a method for extracting lithium from brine by a magnetic powder aluminum lithium adsorbent. The method includes the steps: (1) mixing the magnetic powder aluminum lithium adsorbent with the brine to be treated; (2) controlling uniform mixing preset time of the magnetic powder aluminum lithium adsorbent and the brine; (3) feeding mixture of the magnetic powder aluminum lithium adsorbent and the brine into a magnetic separator for solid-liquid separation; (4) rapidly replacing intra-field adhered brine for the magnetic powder aluminum lithium adsorbent by cleaning liquidin a magnetic separator; (5) mixing washed and magnesium-removed magnetic powder aluminum lithium adsorbent with desorption solution to perform cascade desorption. The magnetic powder aluminum lithiumadsorbent can be desorbed and is good in environmental protection property and less in adsorbent loss, lithium loss in the adsorbent is reduced by controlling cleaning time, and high-concentration enrichment of lithium in the desorption solution is realized.

Owner:江苏旌凯中科超导高技术有限公司

Method for quick synthesis of NaY molecular screen

InactiveCN101112996AEasy to prepareSynthetic cycle is shortFaujasite aluminosilicate zeoliteCrystallizationChemistry

The invention discloses a fast synthetic method of NaY zeolite. The method comprises the steps: firstly, silica source, aluminum source, alkali and water is mixed and stirred according to a proportion of 5-20Na2O:1.0Al2O3:10-30SiO2:200-600H2O then is aged, crystallized and post-process so as to get the NaY zeolite. Compared with the traditional synthetic process of NaY, the method does not need preparation directing agent, therefore, the crystallization time is greatly shortened and the shortest time to synthesize NaY zeolite is 20h.

Owner:NANJING UNIV OF TECH

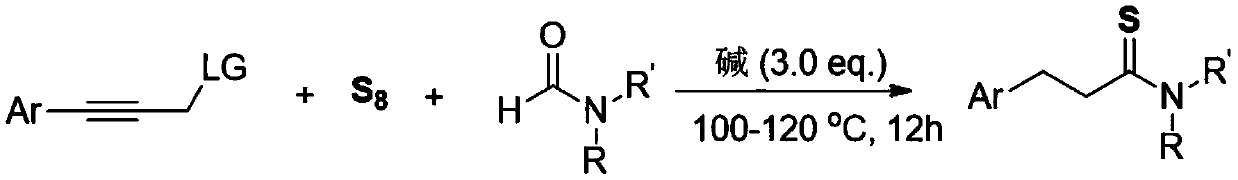

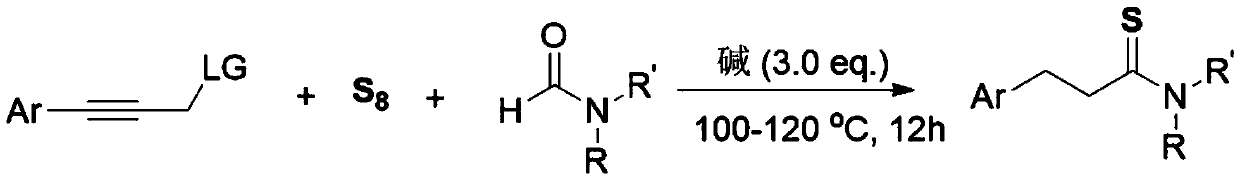

Method for synthesizing 3-aryl thiopropionamide derivative

The invention relates to a method for synthesizing a 3-aryl thiopropionamide derivative. The method comprises the following step: by taking an aryl allylene derivative as a substrate, an alkali as a promoter and elemental sulfur as a sulfur source, performing a stirring reaction for 12 hours in a formamide solvent at 100-120 DEG C. The method adopts the elemental sulfur which is odorless, easy toobtain and low in price as the sulfur source, and has the advantages of being simple and easy in raw material obtaining, simple in reaction operation, mild in condition, wide in substrate universality, high in yield and good in functional group compatibility.

Owner:WENZHOU UNIVERSITY

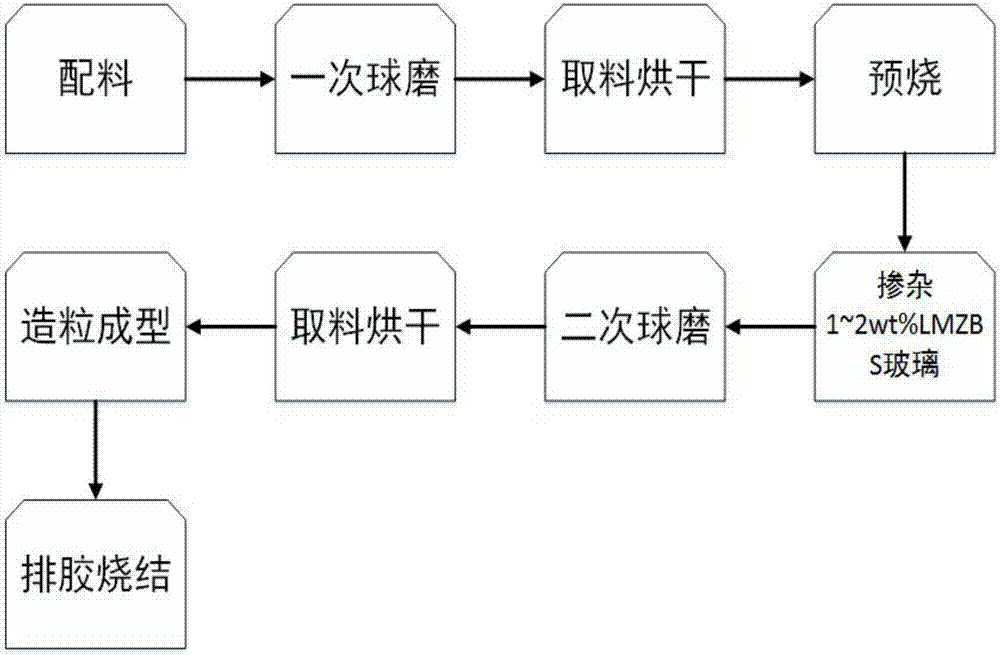

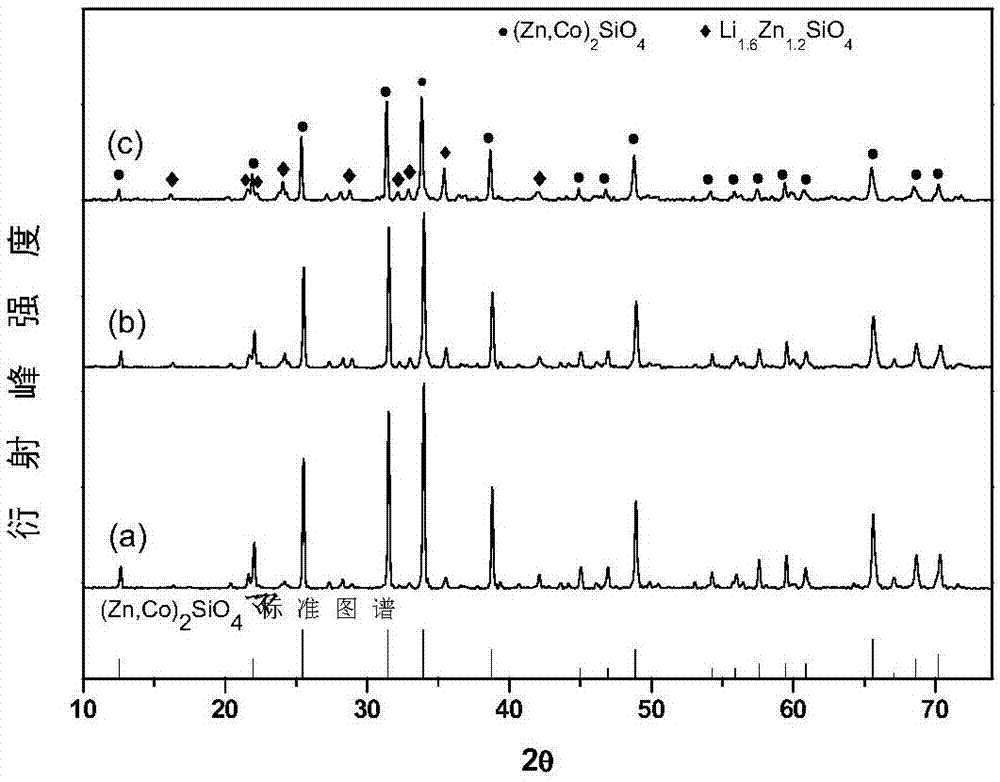

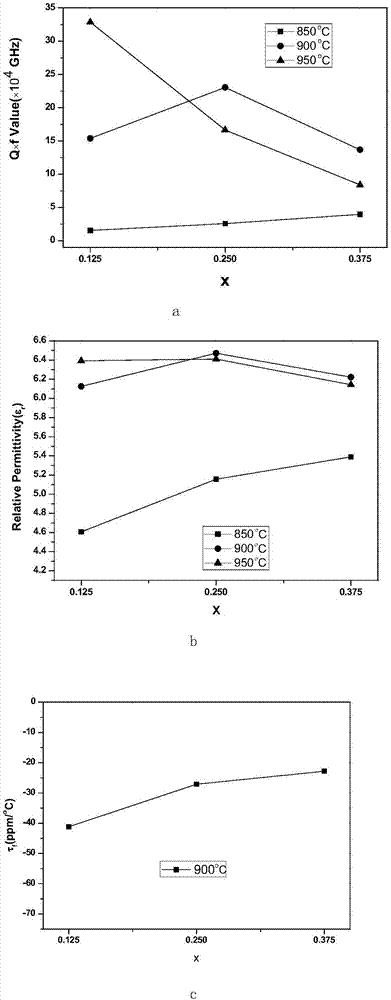

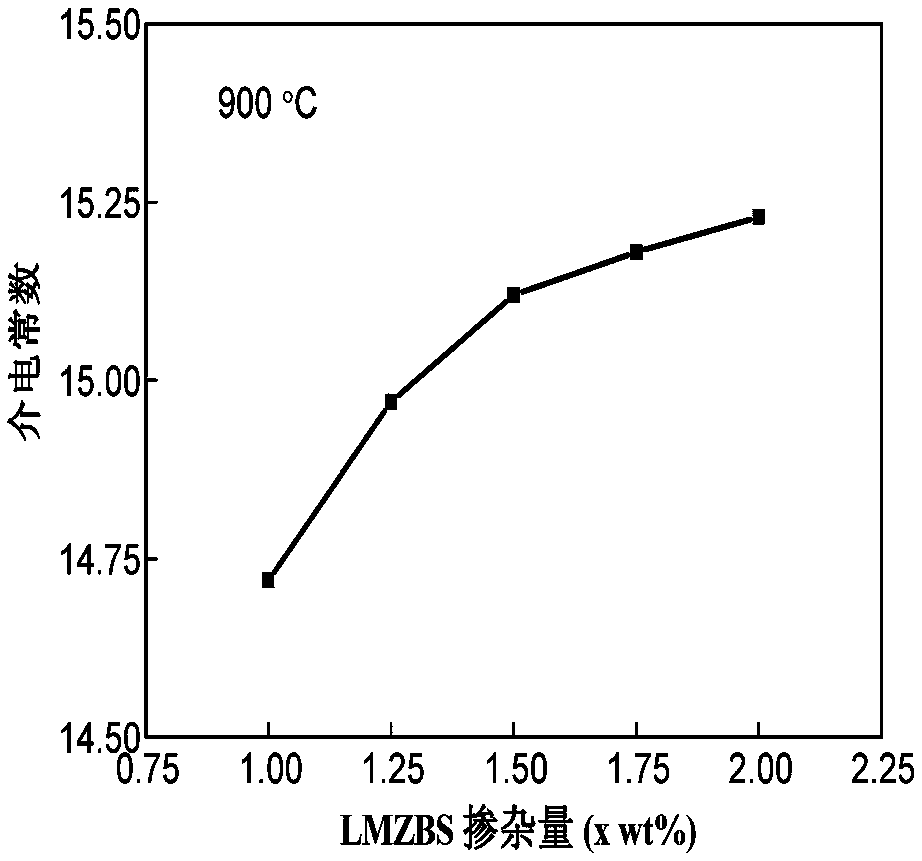

Composite system LTCC material, and preparation method thereof

The invention belongs to the field of electronic ceramic material and manufacturing of electronic ceramic material, and more specifically relates to a composite system LTCC material, and a preparation method thereof. The general chemical formula of the composite system LTCC material is Li<2x>(Zn<0.96>Co<0.05>)<2-x>SiO<4-y>LMZBS (0.125<=x<=0.375, and y ranges from 1 to 2wt%); the principal crystalline phase is (Zn,Co)<2>SiO<4> with a rhombohedron structure; the secondary crystalline phase is Li<1.6>Zn<1.2>SiO<4> with an orthorhombic system structure; the composite system LTCC material is prepared via low temperature sintering at 900 to 950 DEG C; the dielectric constant epsilon<r> ranges from 6.1 to 6.5; the Q*f value is higher than 130000GHz, and the highest Q*f value is 230602GHz; the temperature coefficient of resonance frequency tau<f> ranges from -41 to -22ppm / DEG C. The raw materials are cheap; the preparation method is simple; operation is convenient; production cost is low; and the composite system LTCC material is capable of reducing the loss of microwave devices or modules as a LTCC microwave medium or device.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

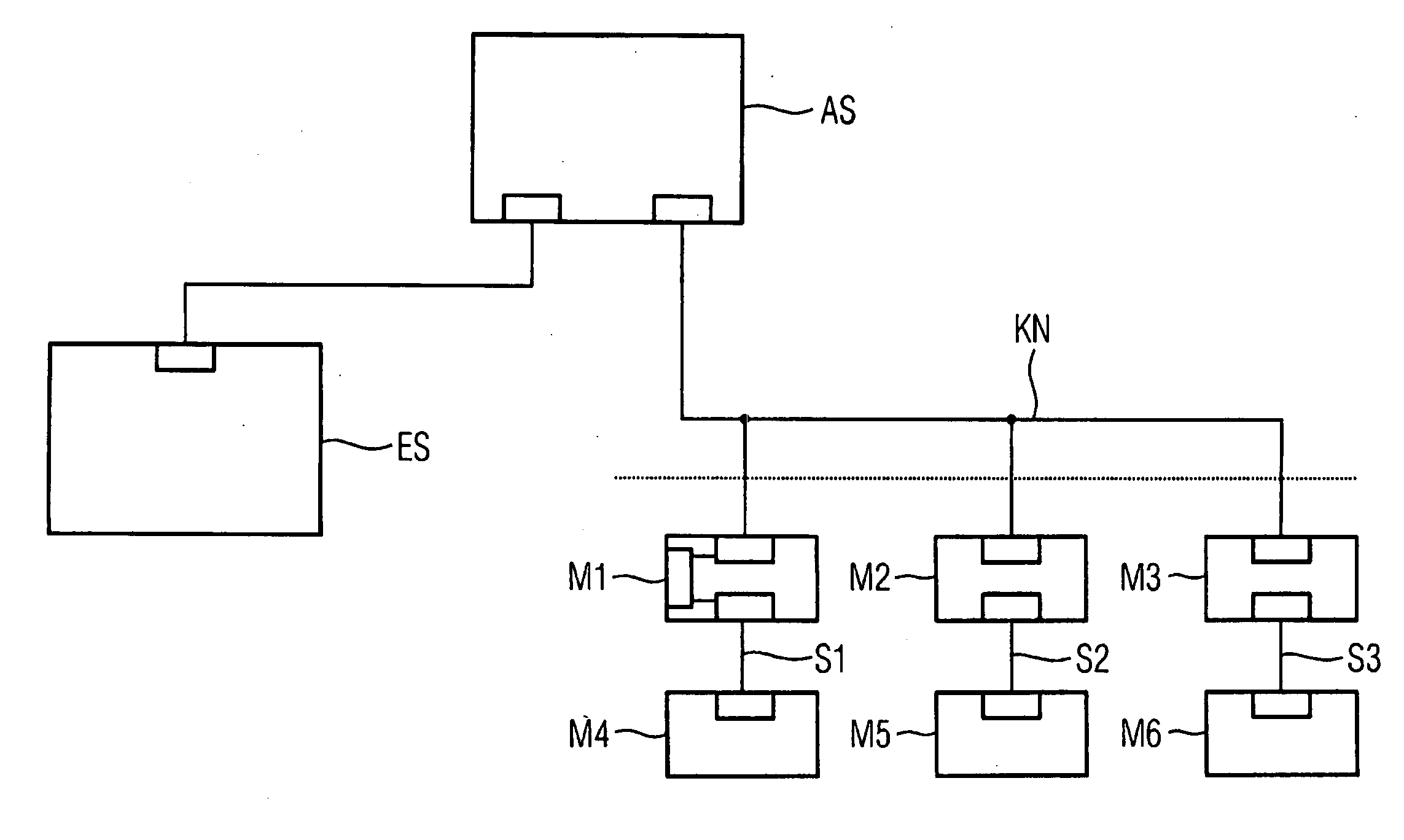

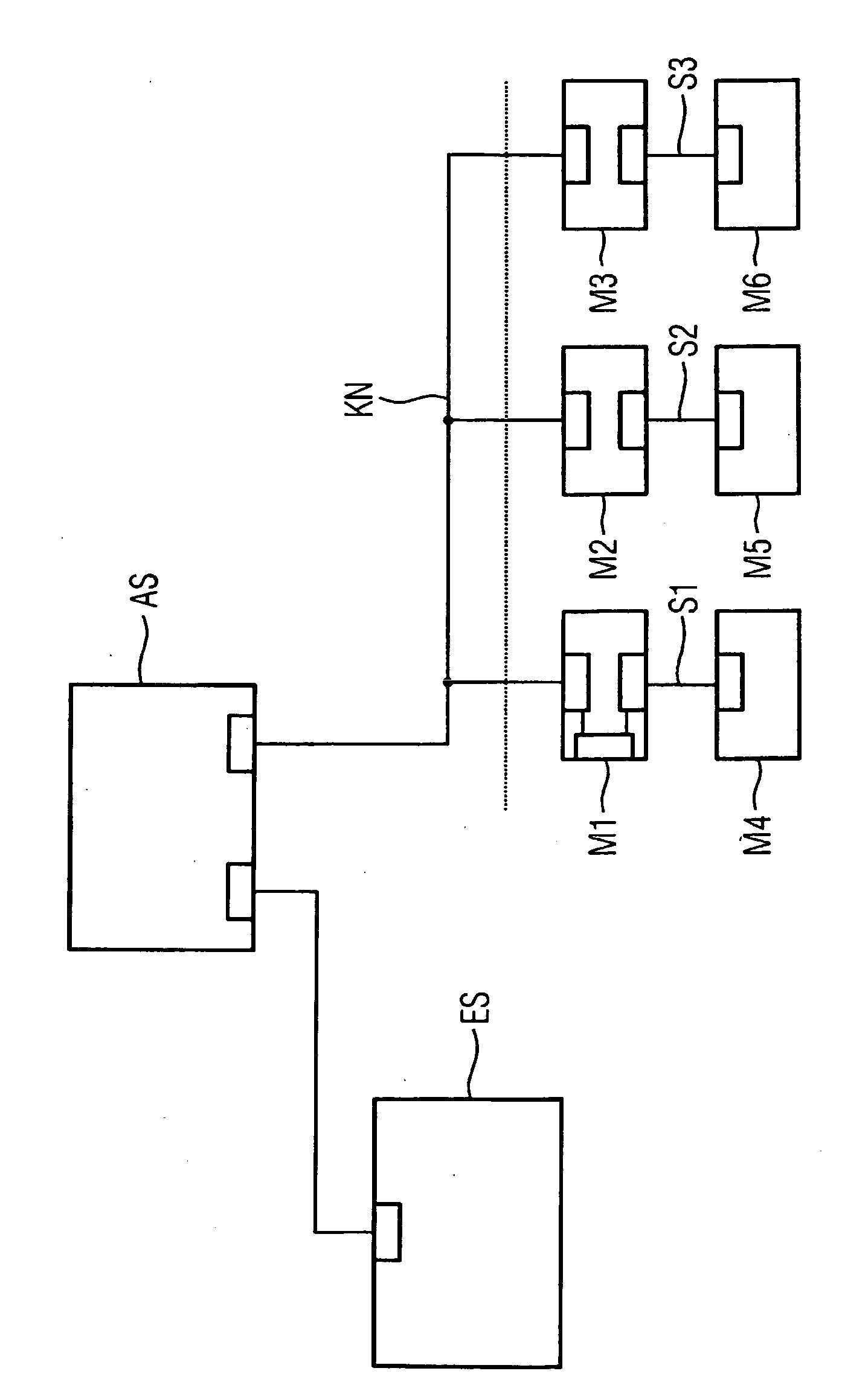

Modular machine and corresponding method for dynamically configuring the topology of said machine

InactiveUS20070198752A1Simplify process engineeringEasy to reconfigureComputer controlSimulator controlModularityEmbedded system

In one aspect, a method for dynamic configuration of a modular machine, whose modules are interconnected and connected to a control unit via a communications network is provided in order to facilitate the modification of a machine configuration in automated systems. According to the method, during the operation of the machine, one of the communications partners determines the communications partners in the communications network. The communications partner then generates a suitable communications configuration and activates said configuration. This permits the communications configuration or design to be automatically executed, even during the operation of the machine.

Owner:SIEMENS AG

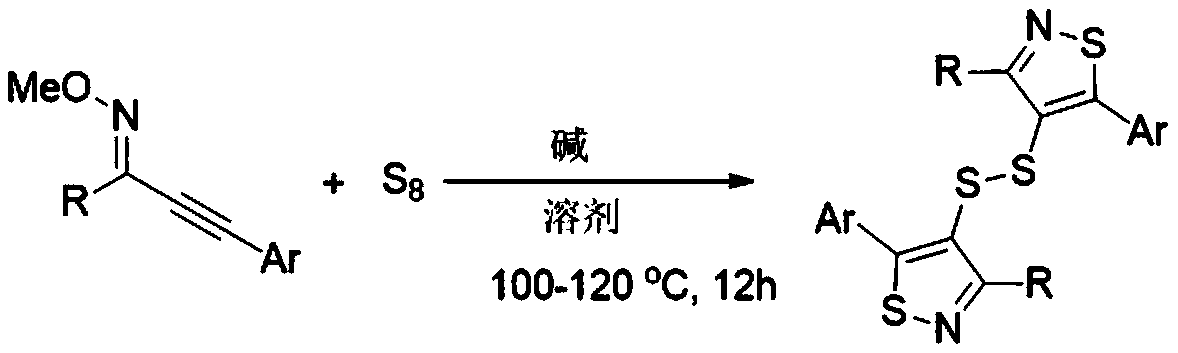

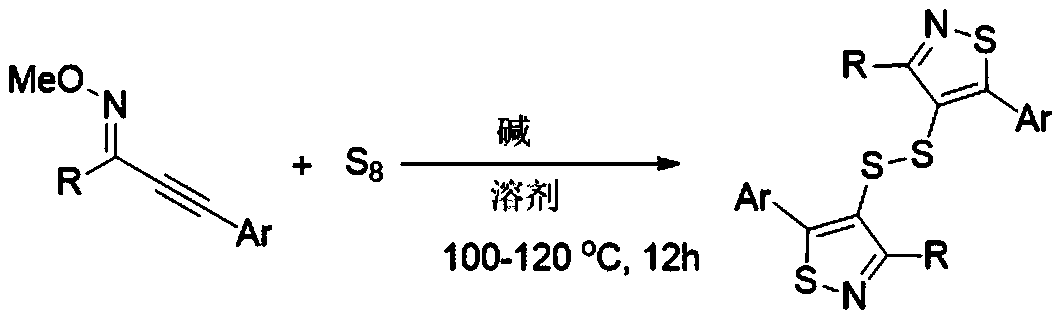

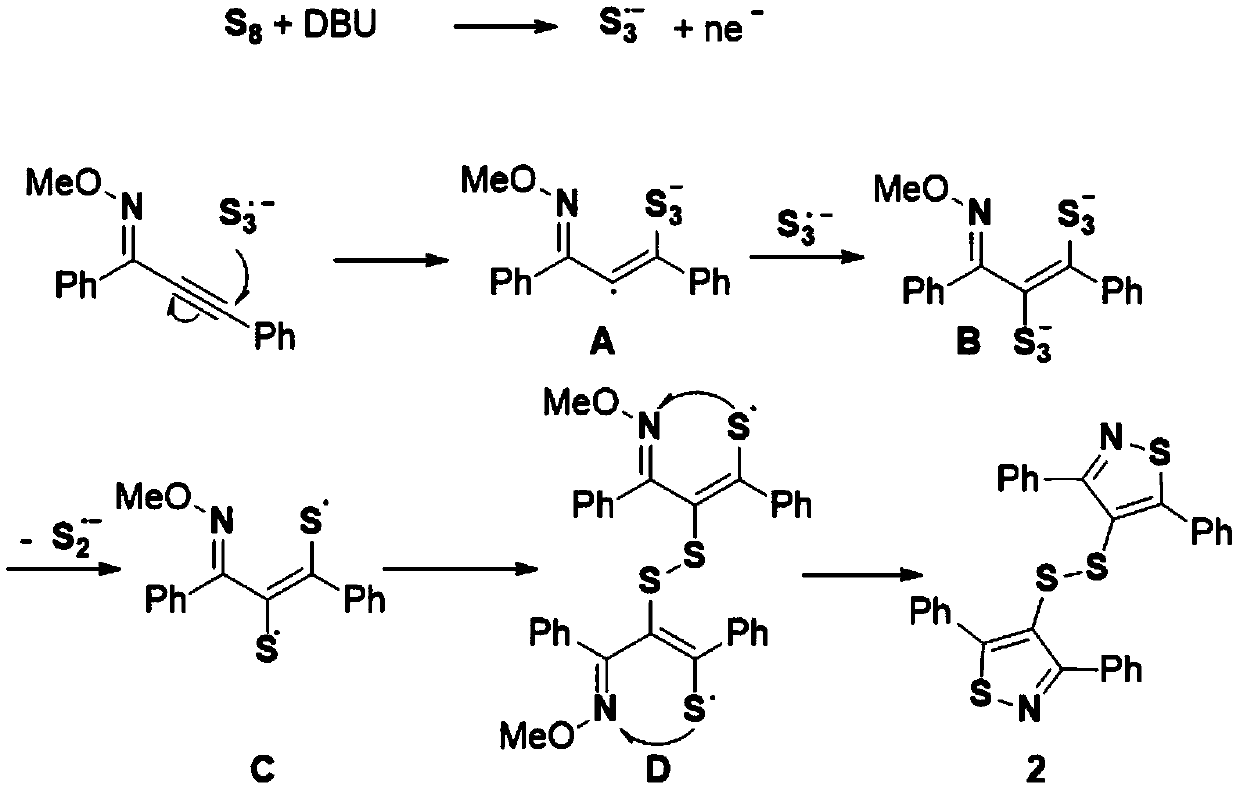

Synthesis method of bithiazole-4-yl disulfide derivative

ActiveCN111233783ASimple processSimple and fast operationOrganic chemistryThiazoleCombinatorial chemistry

The invention relates to a synthetic method of a bithiazole-4-yl disulfide derivative. The synthesis method comprises the following steps: taking alkynyl oxime ether as a substrate, taking elemental sulfur as a sulfur source, taking 1,8-diazabicycloundec-7-ene as alkali and NMP-H2O (5:1, V:V) as a solvent, and carrying out a reaction at 100-120 DEG C under stirring for 12 hours. Odorless, easily available and cheap elemental sulfur is used as a sulfur source, and the method has the advantages of simple and easily available raw materials, simple operation, relatively mild conditions, wide substrate universality, high yield and good functional group compatibility.

Owner:WENZHOU UNIVERSITY

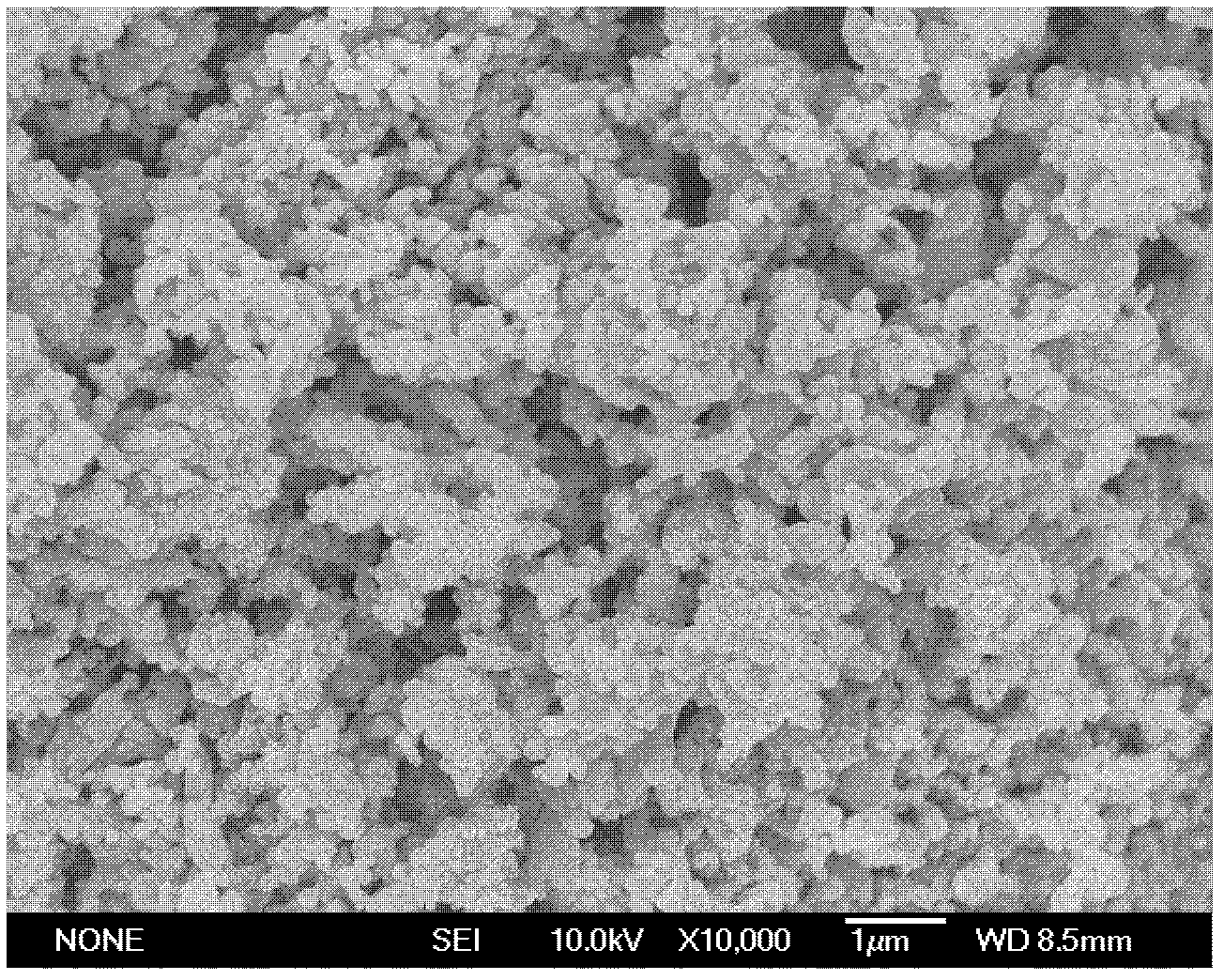

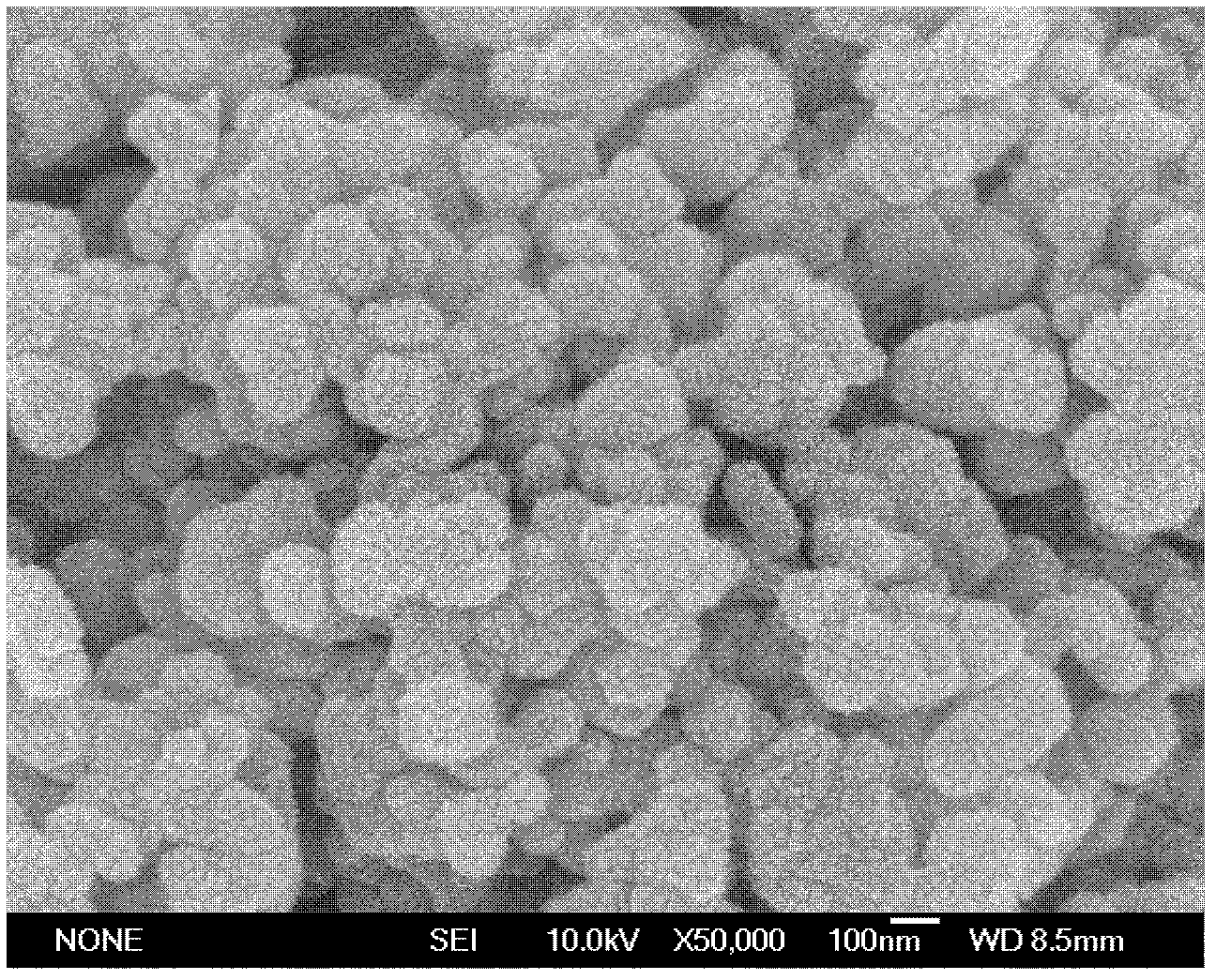

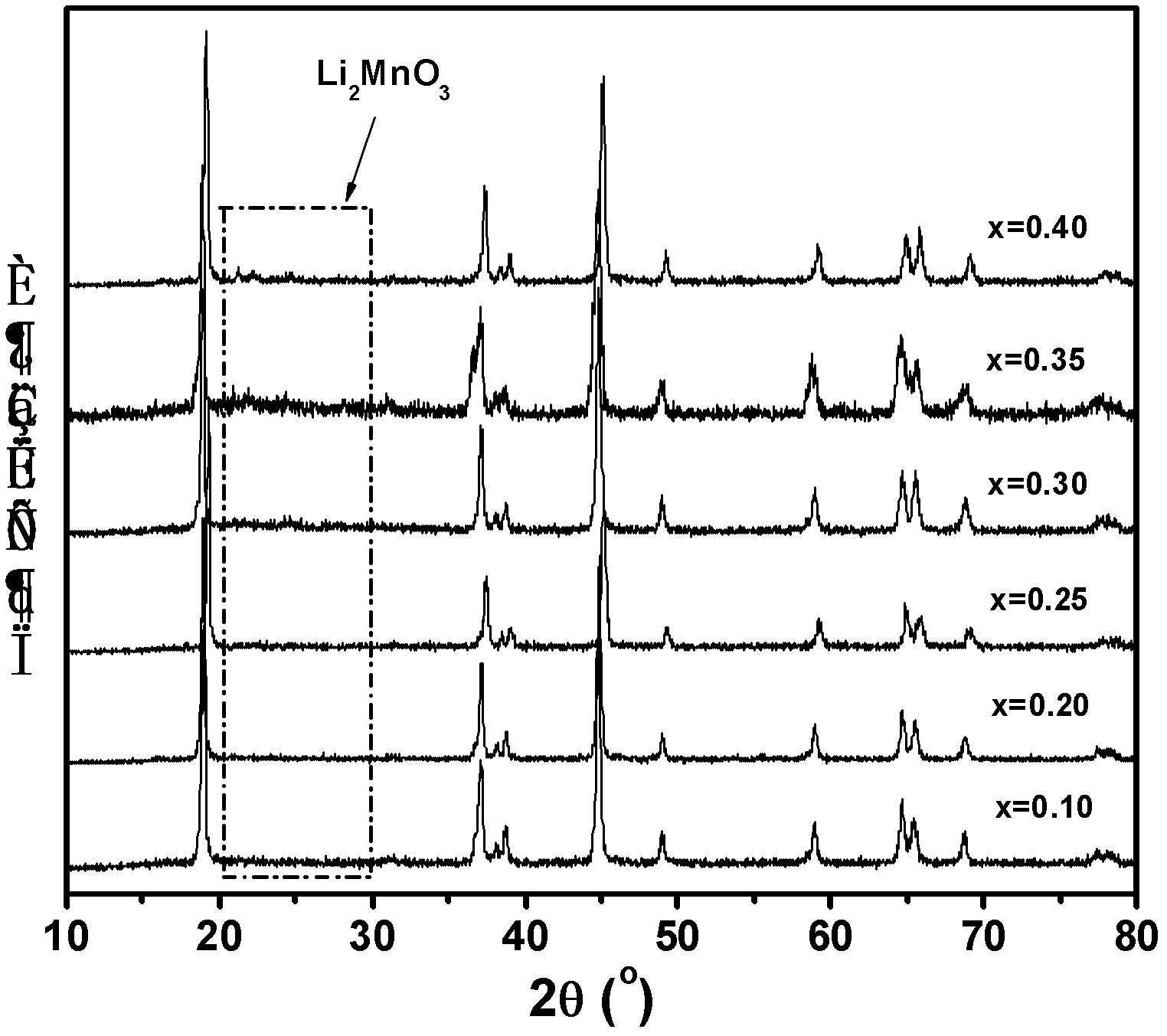

High capacity solid solution composite positive electrode material preparation method

InactiveCN103022466AWide variety of sourcesGood reproducibilityCell electrodesSolid reactionRoom temperature

The present invention relates to a high capacity solid solution composite positive electrode material preparation method, wherein a metal salt and a hydroxide are subjected to a solid phase reaction at a room temperature to obtain a nano-scale precursor, and then the metal salt in the precursor is adopted as a flux in the subsequent heat treatment process, such that the precursor is subjected to complete contact mixing and diffusion in the flux so as to achieve a rapid reaction purpose, and the solid solution composite positive electrode material xLi2MnO3.(1-x)LiMn0.5Ni0.5O2 is finally prepared, wherein x is 0.1-1.0. According to the present invention, lithium ion battery production products produced by using the solid solution composite positive electrode materials have stable electrochemistry performance, stable cycle performance and good reproducibility; and the preparation method has advantages of easy operation, practical process, good safety, low cost, high product material purity, excellent electrochemical performance and the like.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

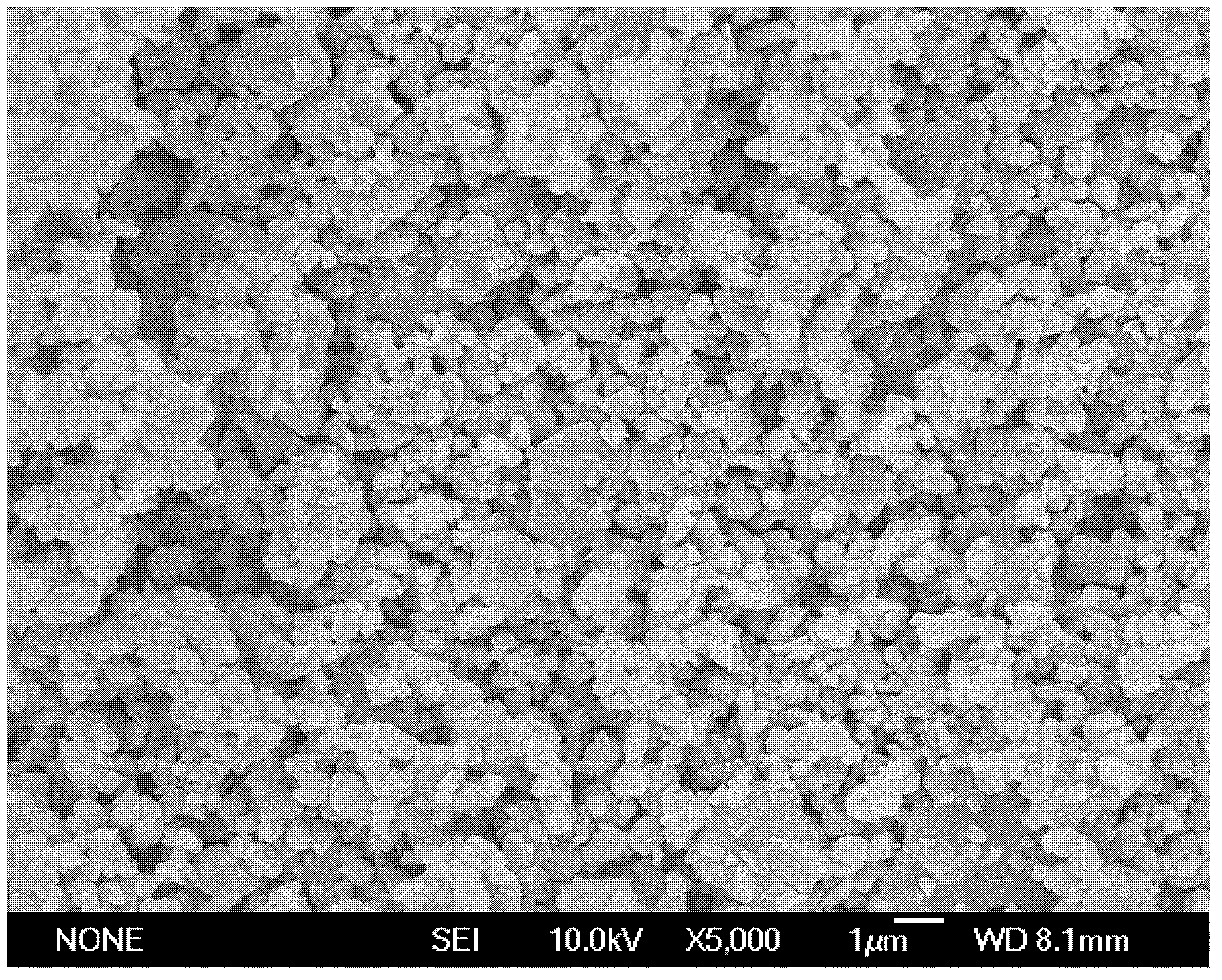

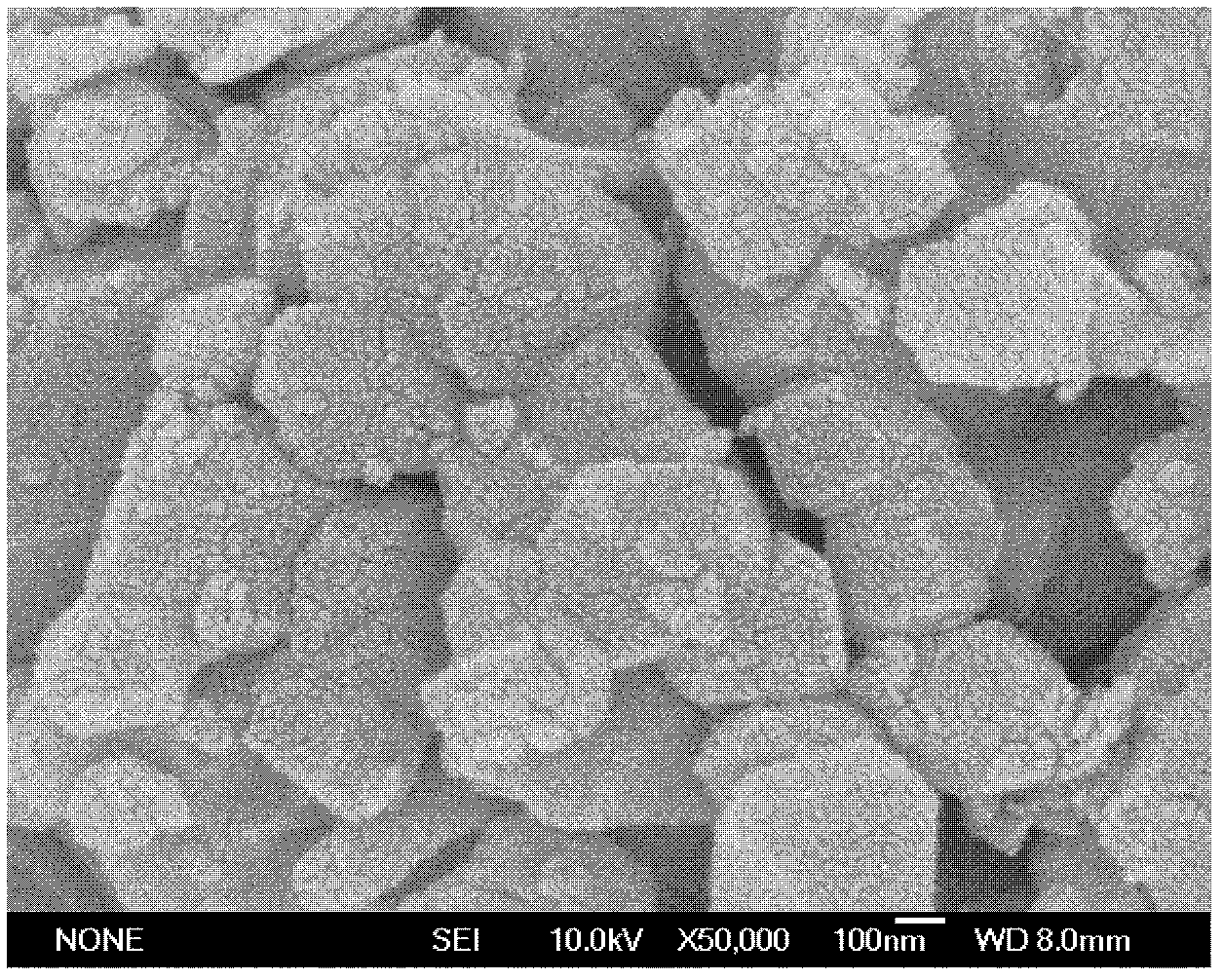

Layered lithium-rich manganese-nickel-cobalt oxide positive electrode material preparation method

The present invention relates to a layered lithium-rich manganese-nickel-cobalt oxide positive electrode material preparation method, which comprises: uniformly mixing a certain molar ratio of metal salts of lithium, manganese, nickel and cobalt, and a hydroxide, carrying out a solid phase reaction at a room temperature to obtain a nano-scale lithium-manganese-nickel hydroxide and a metal salt mixing precursor, adopting the metal salt in the precursor as a flux, heating at a high temperature, melting, and adopting the melting material as a reaction medium, such that the precursor is subjected to complete contact mixing and diffusion in the flux so as to achieve a rapid reaction purpose, and the layered lithium-rich manganese-nickel-cobalt oxide positive electrode material xLi2MnO3.(1-x)LiMO2 is prepared, wherein M is Mn1-(y+z)NiyCoz, x is 0.1-1.0, y is 0.1-0.5, and z is 0.1-0.5. Compared to the gas protection coprecipitation method, the sol-gel method and other methods commonly used for preparing the layered lithium-rich manganese-nickel-cobalt oxide positive electrode material, the method of the present invention has advantages of easy operation, practical process, good safety, low cost, high material purity, excellent electrochemistry performance, and the like.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

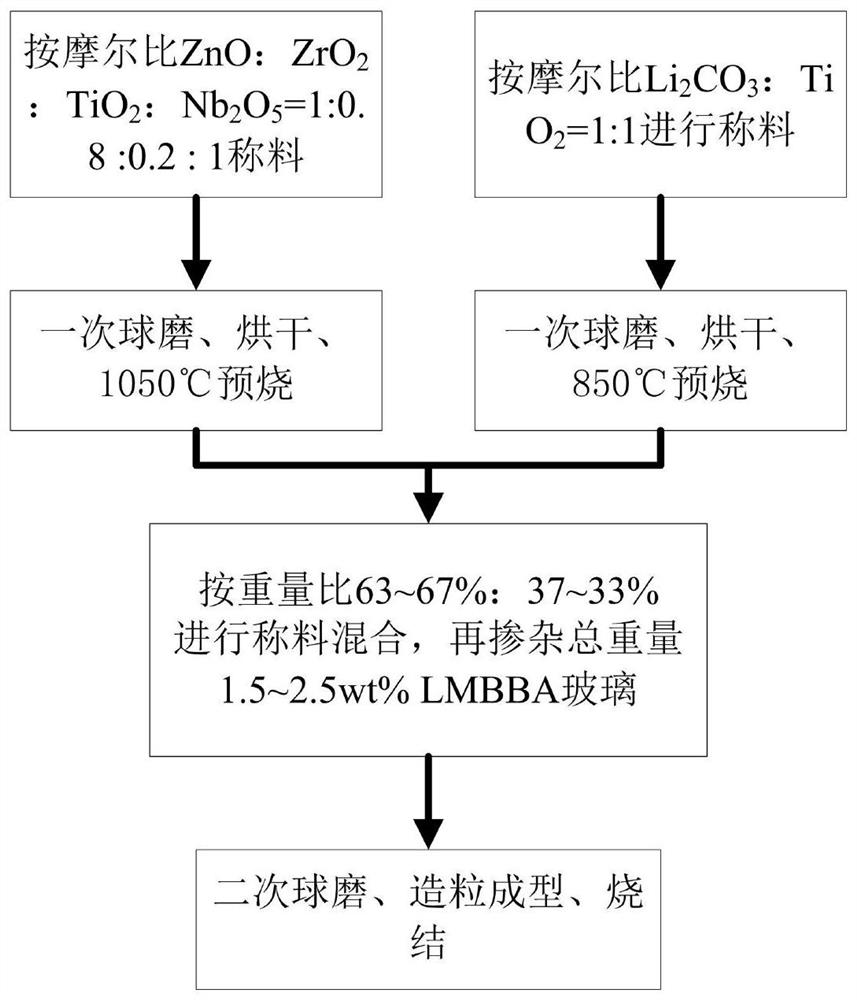

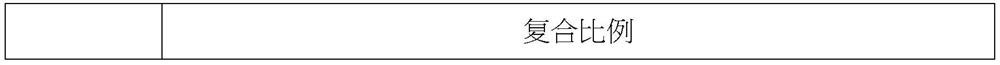

Medium low-loss LTCC microwave dielectric ceramic material and preparation method thereof

ActiveCN112125668AHigh dielectric constantNo reactionChemical industryDielectric lossDielectric ceramics

The invention provides a medium low-loss LTCC microwave dielectric ceramic material and a preparation method thereof.The LTCC microwave dielectric ceramic material comprises a two-phase mixed ceramicmaterial, the main crystalline phase is ZnZr(1-x)TixNb2O8 of a monoclinic wolframite structure, x is 0.1-0.2, the auxiliary phase is Li2TiO3 of a monoclinic system structure, a ZnZr(1-x)TixNb2O8 pre-sintered material and a Li2TiO3 pre-sintered material are mixed according to a the weight percentage ratio of (63-67 wt%): (37-33 wt%), and then LMBBA glass accounting for 1.5-2.5 wt% of the two-phasemixed ceramic material is doped as a cosolvent and is sintered at 900 DEG C; and the component of the LMBBA glass is Li2CO3-MgO-Bi2O3-B2O3-Al2O3. The LTCC microwave dielectric ceramic material disclosed by the invention not only has a relatively high dielectric constant and very low microwave dielectric loss, but also has a temperature coefficient close to zero, and has a very high application value in LTCC radio frequency microwave devices.

Owner:YANCHUANG PHOTOELECTRIC TECH GANZHOU

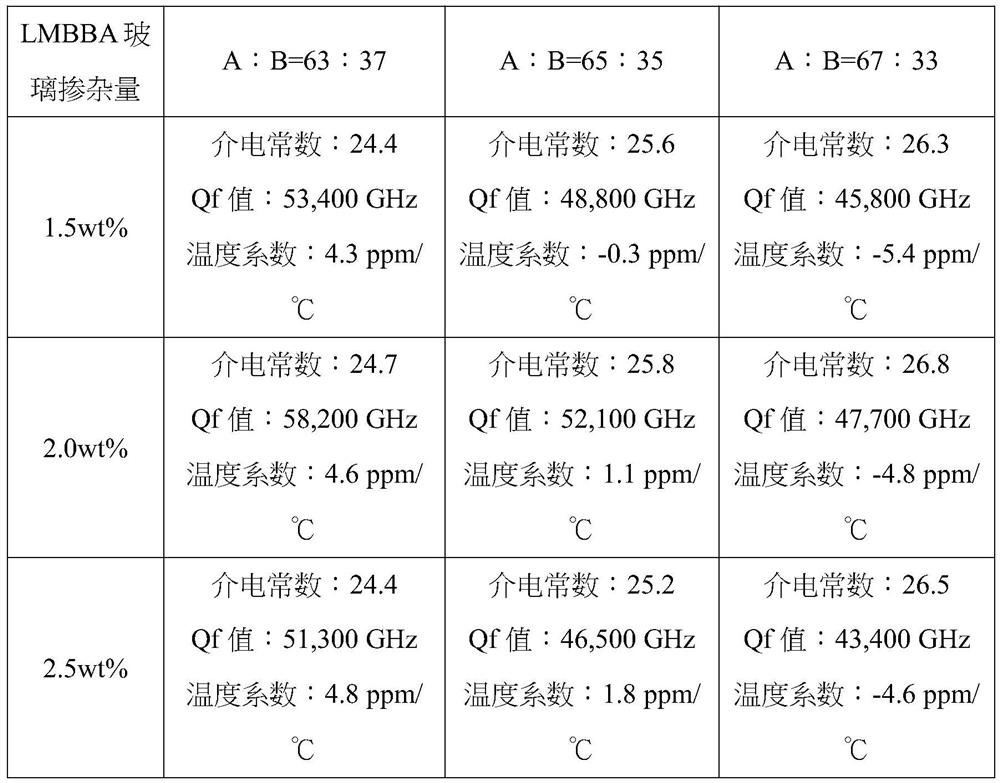

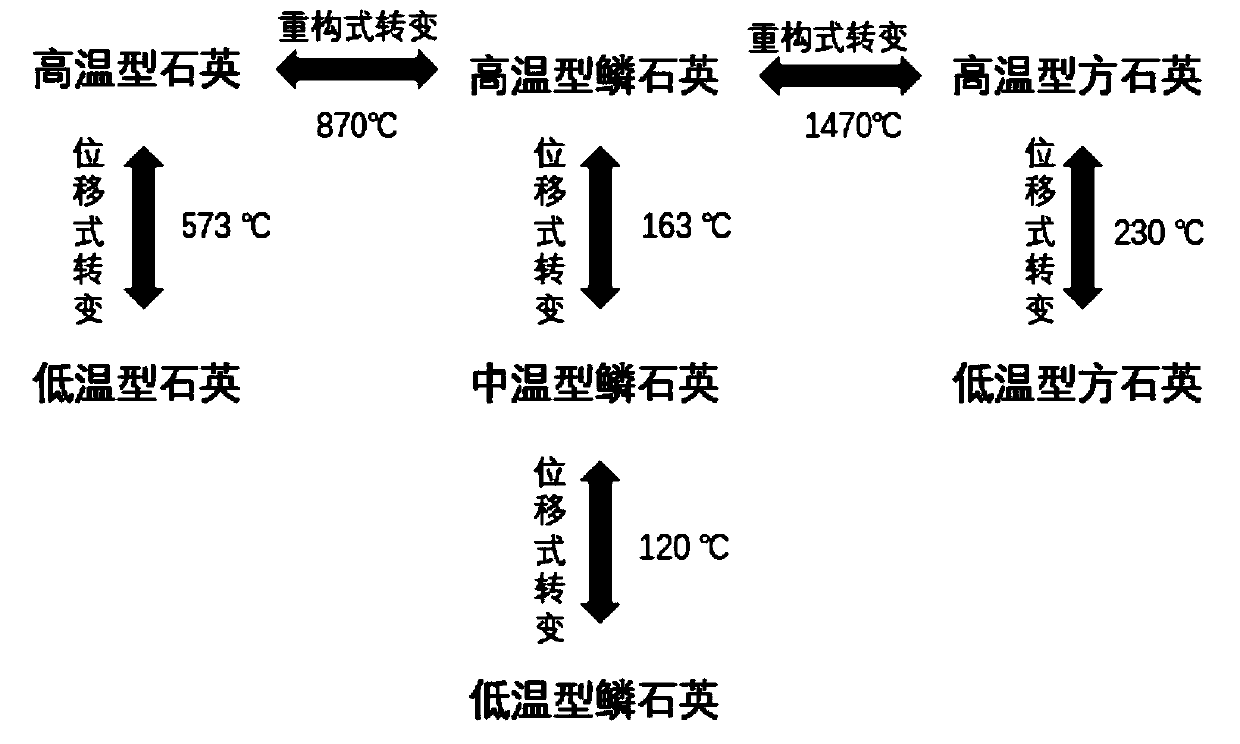

Ultra-low dielectric LTCC microwave ceramic material and preparation method thereof

InactiveCN110903078APromote growthEasy to implement transmissionMicrowave substrateComposite ceramic

The invention belongs to the field of electronic ceramic materials and manufacturing thereof, and relates to an ultra-low dielectric LTCC microwave ceramic material and a preparation method thereof. The ultra-low dielectric LTCC microwave ceramic material provided by the invention is a SiO2-Li2TiO3 composite ceramic taking SiO2 as a main crystal phase, wherein the sintering temperature is 850-900DEG C; the dielectric constant epsilon r is 4.5-5.1; the quality factor Q * f value ranges from 18500 GHz to 26000 GHz; the resonance frequency temperature coefficient tau f ranges from -4.5 ppm / DEG Cto 5 ppm / DEG C; the molecular formula is xSiO2-(1-x)Li2TiO3-yLBSCA(Li2O-B2O3-SiO2-CaO-Al2O3)glass, x is more than or equal to 0.9 and less than or equal to 0.95 molar ratio, y is more than or equal to 4wt% and less than or equal to 8wt% by mass, and the ultra-low dielectric LTCC microwave ceramic material is prepared by a solid phase method. The ultra-low dielectric LTCC microwave ceramic material is simple in manufacturing process, can be produced in batches, and can be widely applied to LTCC microwave substrates, laminated microwave devices and modules when being used as an LTCC microwave dielectric substrate or device material; the low dielectric constant corresponds to the short signal delay time, and the signal transmission speed can be improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

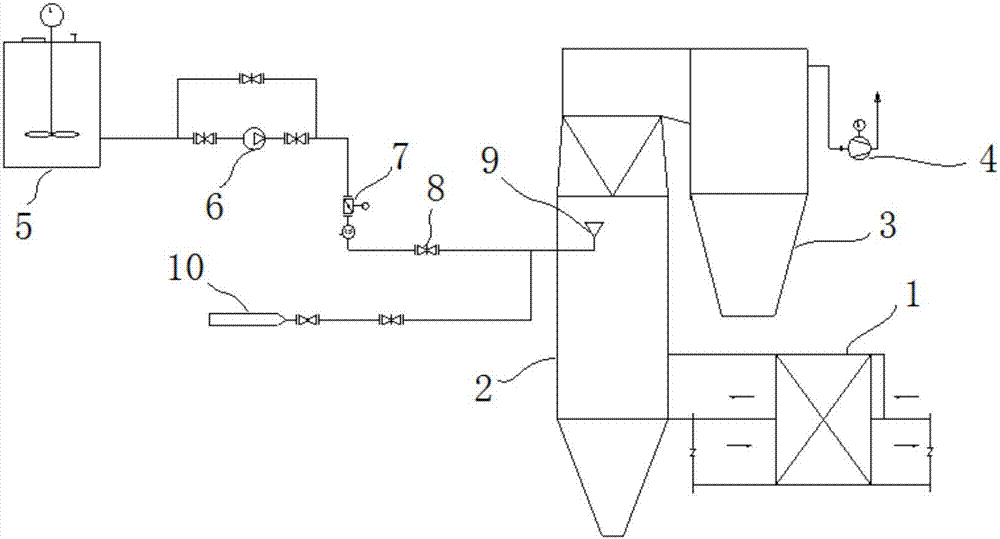

Desulfurization wastewater treatment method

InactiveCN106986401AAchieve pollutionNo corrosion problemsGeneral water supply conservationWaste water treatment from gaseous effluentsGas phasePhase change

The invention discloses a desulfurization wastewater treatment method, and belongs to the field of desulfurization wastewater treatment. A hot air unit introduces hot air into a phase change generator; meanwhile, a wastewater system conveys desulfurization wastewater to an atomizer in the phase change generator for atomization, hot wind formed by the desulfurization wastewater and the hot air is changed into a gas phase from a liquid phase through mass and heat exchange and the gas phase is discharged from an outlet of the phase change generator along with the hot wind; a solid formed by impurity crystal in the desulfurization wastewater enters the hot air unit at a solid outlet of the phase change generator under the action of gravity. According to the desulfurization wastewater treatment method, hot air in the phase change generator and atomized desulfurization wastewater drops are subjected to mass and heat exchange, and the desulfurization wastewater drops are evaporated and crystallized and then subjected to gas-solid separation. The problems that an original desulfurization balance is broken and equipment corrosion is caused in the desulfurization wastewater treatment process in a flue are solved, so that zero pollution and zero emission of the desulfurization wastewater are achieved.

Owner:张玉君

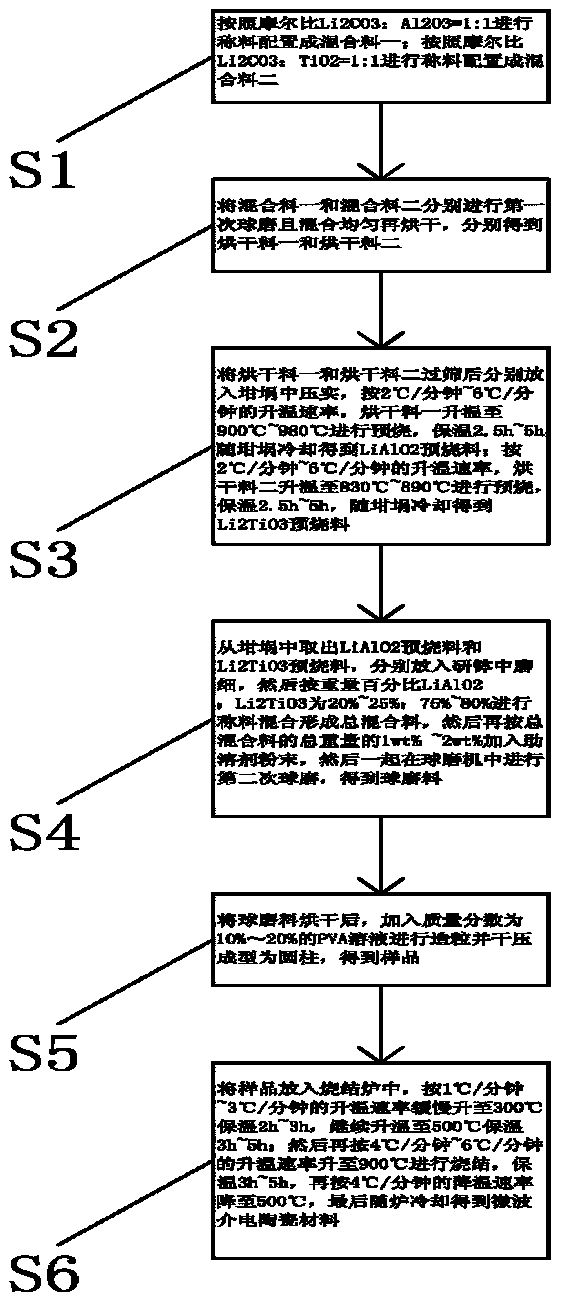

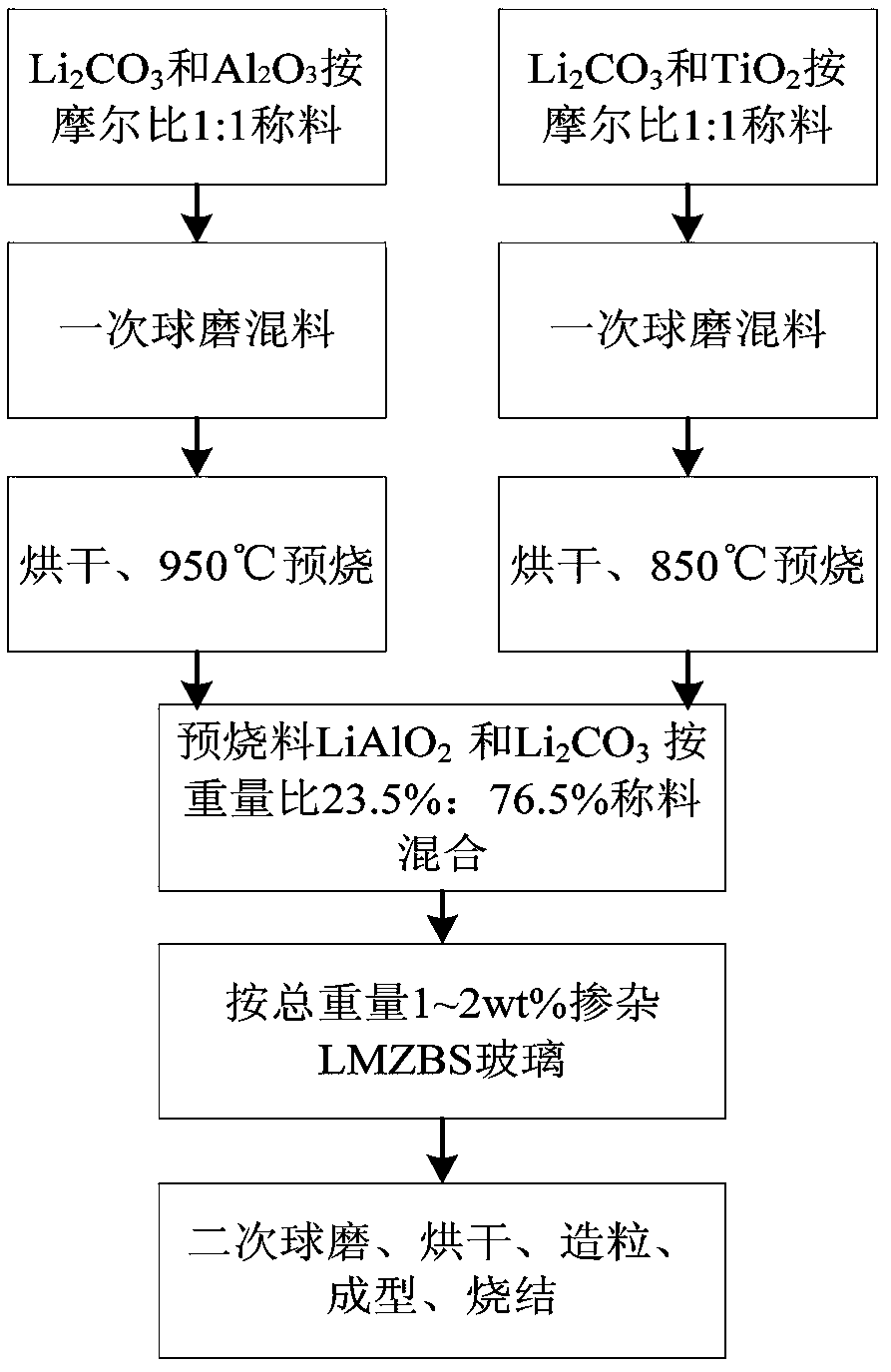

High-performance microwave dielectric ceramic material and preparation method thereof

The invention relates to the technical field of electronic ceramics, in particular to a high-performance microwave dielectric ceramic material and a preparation method thereof. The material is a composite material prepared from a main crystalline phase and an auxiliary crystalline phase, wherein the main crystalline phase is LiAlO2 and the auxiliary crystalline phase is Li2TiO3. The high-performance microwave dielectric ceramic material with characteristics of quite low loss and near-zero temperature coefficient is obtained by compositing LiAlO2 and Li2TiO3; production raw materials are cheap,the technological process is simple, operation is convenient, and cost is reduced; the dielectric ceramic material has the advantages of low loss and small temperature coefficient.

Owner:江西国创产业园发展有限公司 +1

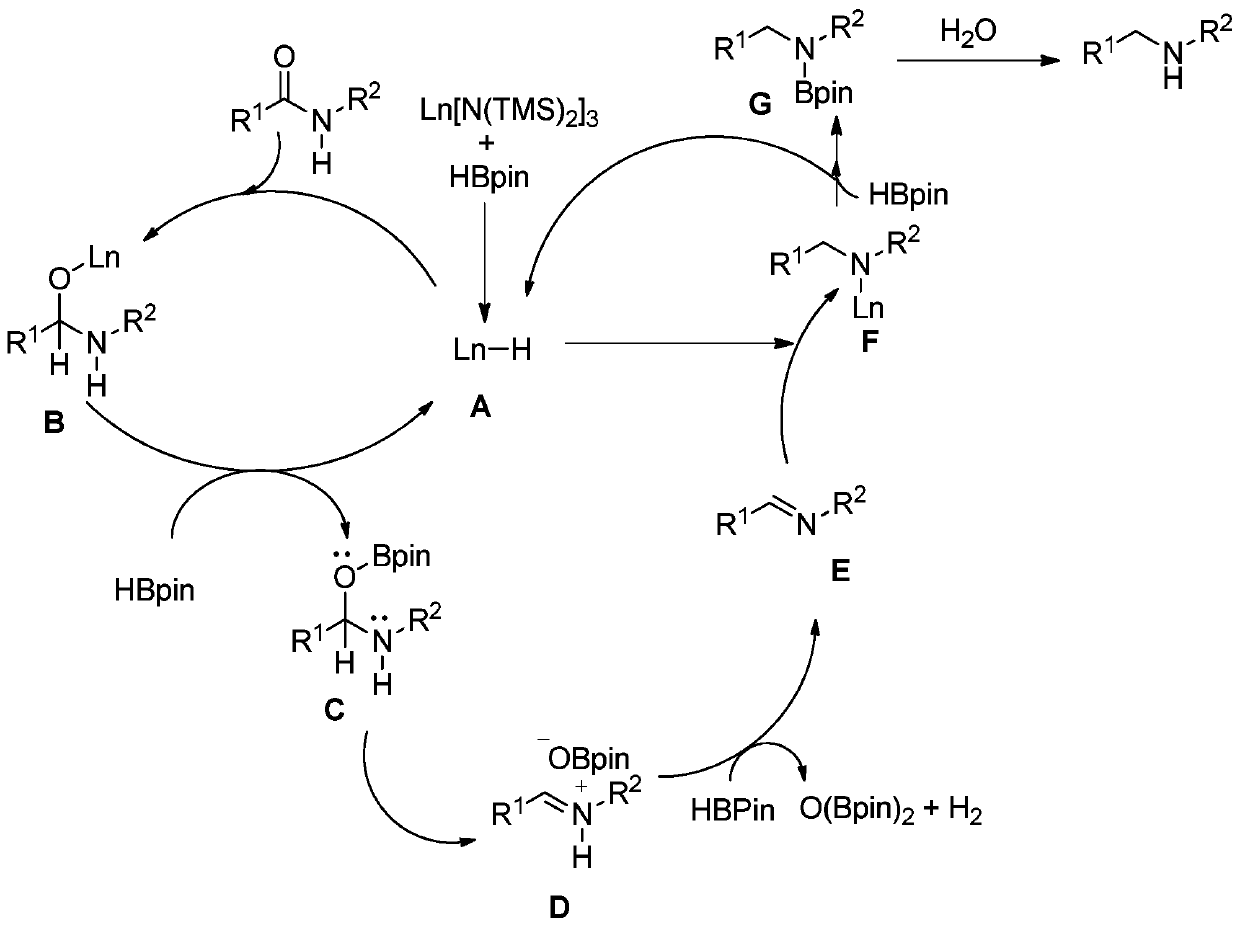

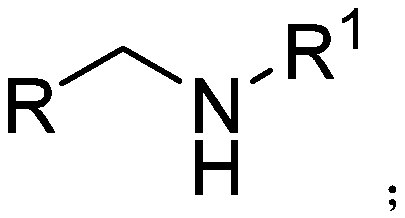

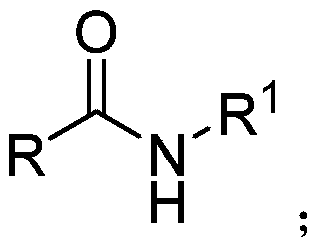

Secondary amine derivative synthesized through rare earth catalysis, and preparation method thereof

ActiveCN110818576AEasy to getWide variety of sourcesAmino preparation from aminesOrganic compound preparationPtru catalystReaction temperature

The invention discloses a secondary amine derivative synthesized through rare earth catalysis, and a preparation method thereof. According to the preparation method, the secondary amine derivative isprepared by carrying out a reaction on reactants of secondary amide and pinacol borane; a rare earth catalyst bis(trimethylsilyl) amino yttrium is added; the reaction temperature is 100-140 DEG C, andthe reaction time is 20-25 h; the whole reaction is carried out under a normal pressure, and the reaction conditions are mild, easy to achieve and safe; the method is simple and convenient to operateand high in reaction selectivity, can directly synthesize the target product without intermediate product separation, can obtain the target product only through a reaction under a normal pressure, issimple in reaction process, has the yield of 90% at most, substantially simplifies the process engineering, reduces the energy consumption, and has high yield; the reaction raw materials are stable and easy to store; a series of secondary amine derivatives can be prepared; and the method has high substrate universality so as to provide the good guarantee for development of related substances related to secondary amine derivatives, and is suitable for large-scale application and popularization.

Owner:WENZHOU UNIVERSITY

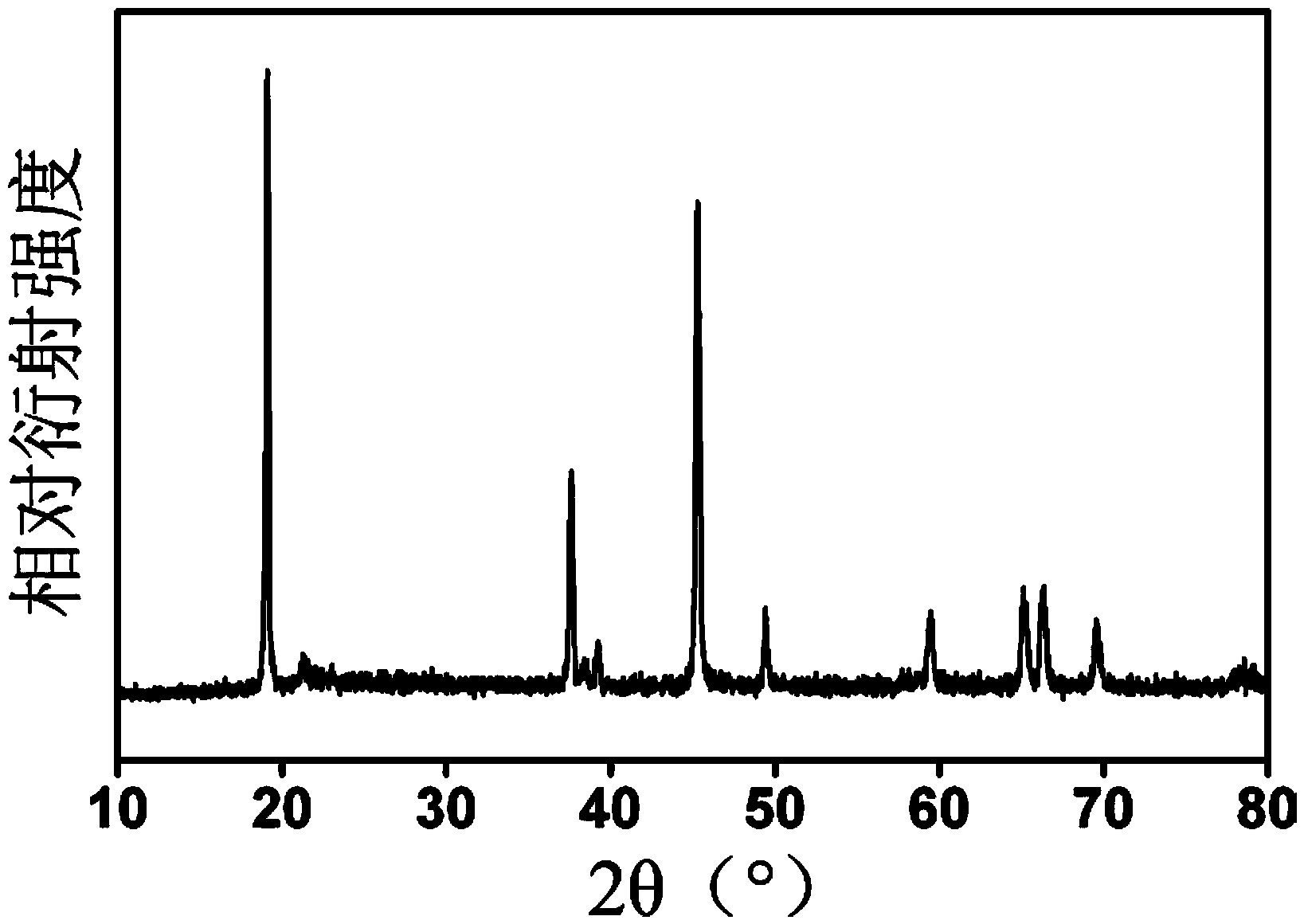

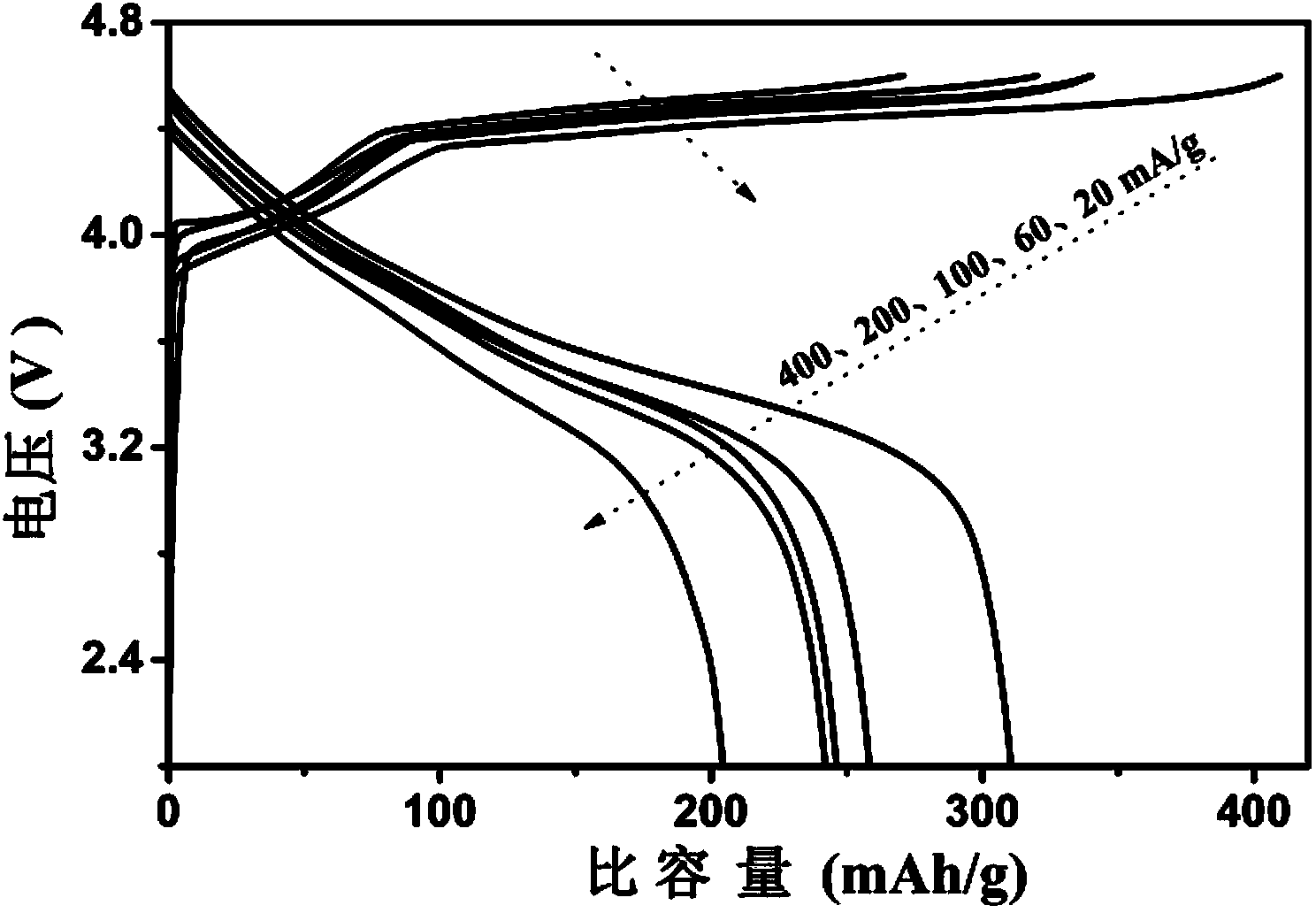

A kind of lithium ion battery manganese cobalt lithium oxide cathode material and preparation method thereof

ActiveCN102583583BWide variety of sourcesEasy to controlCell electrodesCobalt oxides/hydroxidesLithium oxideManganese

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

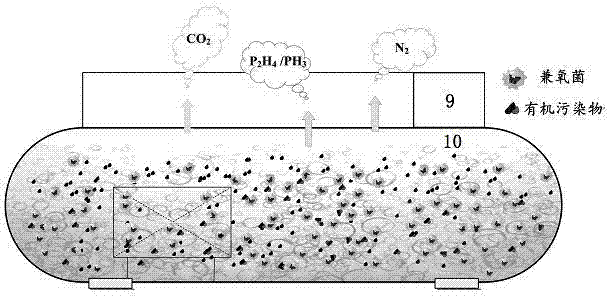

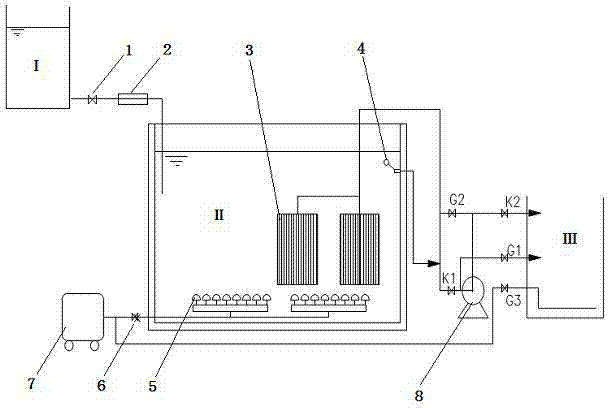

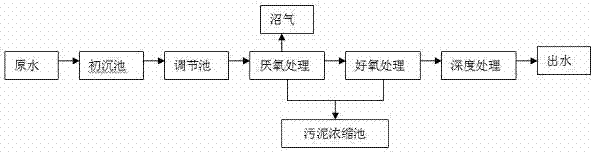

Method for processing food processing wastewater by adopting facultative membrane bioreactor and facultative membrane bioreactor

InactiveCN103864211ASolve difficult problemsNear zero emissionsTreatment with aerobic and anaerobic processesWaste water treatment from food industryFood processingWater treatment

The invention discloses a method for processing food processing wastewater by adopting a facultative membrane bioreactor. By adopting the method, pretreatment is carried out on the food processing wastewater to remove coarse impurities and suspended solids in the wastewater, and then the wastewater enters a regulating reservoir to adjust the water quality and quantity; the wastewater enters the facultative membrane bioreactor to carry out biological treatment, and the wastewater continuously and alternatively passes through an aerobic zone, a facultative region and an anaerobic zone inside the reaction region in the facultative membrane bioreactor, so that he anaerobic ammonia oxidation denitrification is achieved when biodegradation and transformation are carried out on pollutants; the processed clean water is reused or discharged. The invention also provides the facultative membrane bioreactor. By adopting the method and the facultative membrane bioreactor, the water treatment process engineering is simplified, the equipment is more compact and concentrated, small in floor area, high in biochemical treatment efficiency of organic sewage, and small in yield of residual organic sludge, not only can the effluent be discharged up to the emission standard, but also near zero emission of the residual organic sludge can be achieved, and synchronous reuse of sewage treatment can be achieved.

Owner:SHANGHAI UNIV

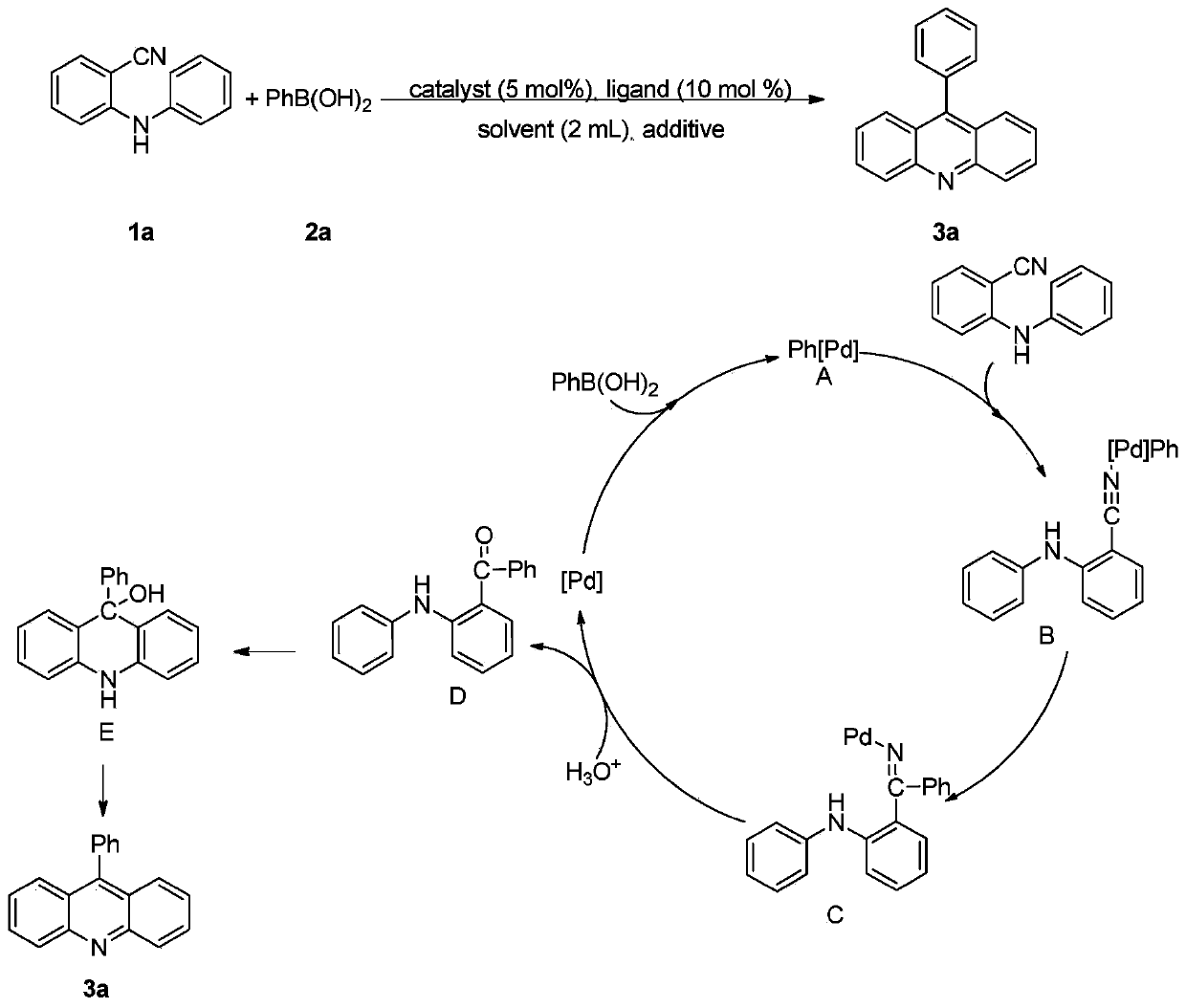

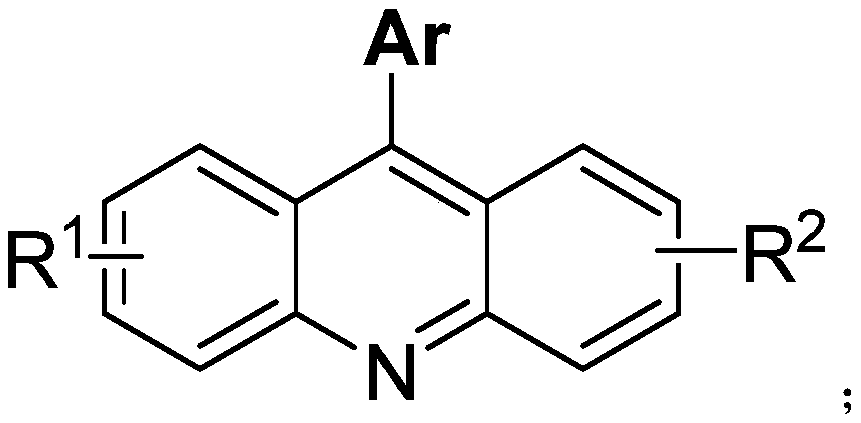

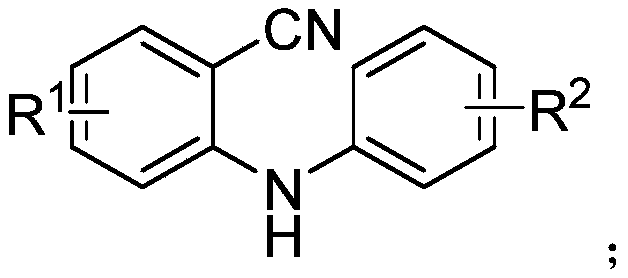

Dibenzo[c,e]azepine derivative and preparation method thereof

ActiveCN110590666AReduce consumptionProtect healthOrganic chemistryN dimethylformamideReaction temperature

The invention discloses a dibenzo[c,e]azepine derivative and a preparation method thereof. The derivative is prepared by using [1,1'-biphenyl]-2,2'-dinitrile and an aryl boronic acid as reactants; thereagents are easy to prepare, have relatively wide sources, relatively low cost, and relatively low toxicity, and is not easy to affect human health. The reaction is performed in a solvent, and the solvent is any one of toluene, xylene, methanol, tetrahydrofuran, N,N-dimethylformamide, and N,N-dimethylacetamide. When the reaction is carried out, a palladium catalyst and an acid promoter are added, wherein the palladium catalyst is any one of palladium trifluoroacetate, tetrakis(triphenylphosphine) palladium, diacetylacetone palladium, bis(dibenzylideneacetone) palladium, and tris(dibenzylideneacetone) dipalladium. A reaction temperature is 100-120 DEG C, a reaction time is 20-30 h, and reaction conditions are mild, easy to reach, and safe. The method can directly synthesize a target product without separating intermediate products, and the yield can be up to 95%.

Owner:WENZHOU UNIVERSITY

Arylacridine derivatives synthesized under palladium catalysis and preparation method thereof

The invention discloses arylacridine derivatives synthesized under palladium catalysis and a preparation method thereof. The arylacridine derivatives are prepared through a reaction with 2-(arylamino)benzonitrile derivatives and aryl boric acid as reactants. According to the invention, the reactants are wide in source; preparation is easy; the arylacridine derivative is low in cost and toxicity and difficultly affects human health; the reaction is carried out in a solvent which is water; during the reaction, a palladium catalyst, an additive and a ligand are also added into the solvent, wherein the palladium catalyst is any one selected from the group consisting of palladium chloride, palladium acetate, palladium trifluoroacetate and palladium acetylacetonate, and the additive is methanesulfonic acid; a reaction temperature is 90-110 DEG C, and reaction time is 20-25 h; and the whole reaction is carried out in air, the reaction conditions are very mild, easy to realize and safe, and the health of experimenters is guaranteed. The highest yield of the method can reach 94%; a series of the arylacridine derivatives can be prepared; and the method has high substrate universality and isworthy of popularization.

Owner:WENZHOU UNIVERSITY

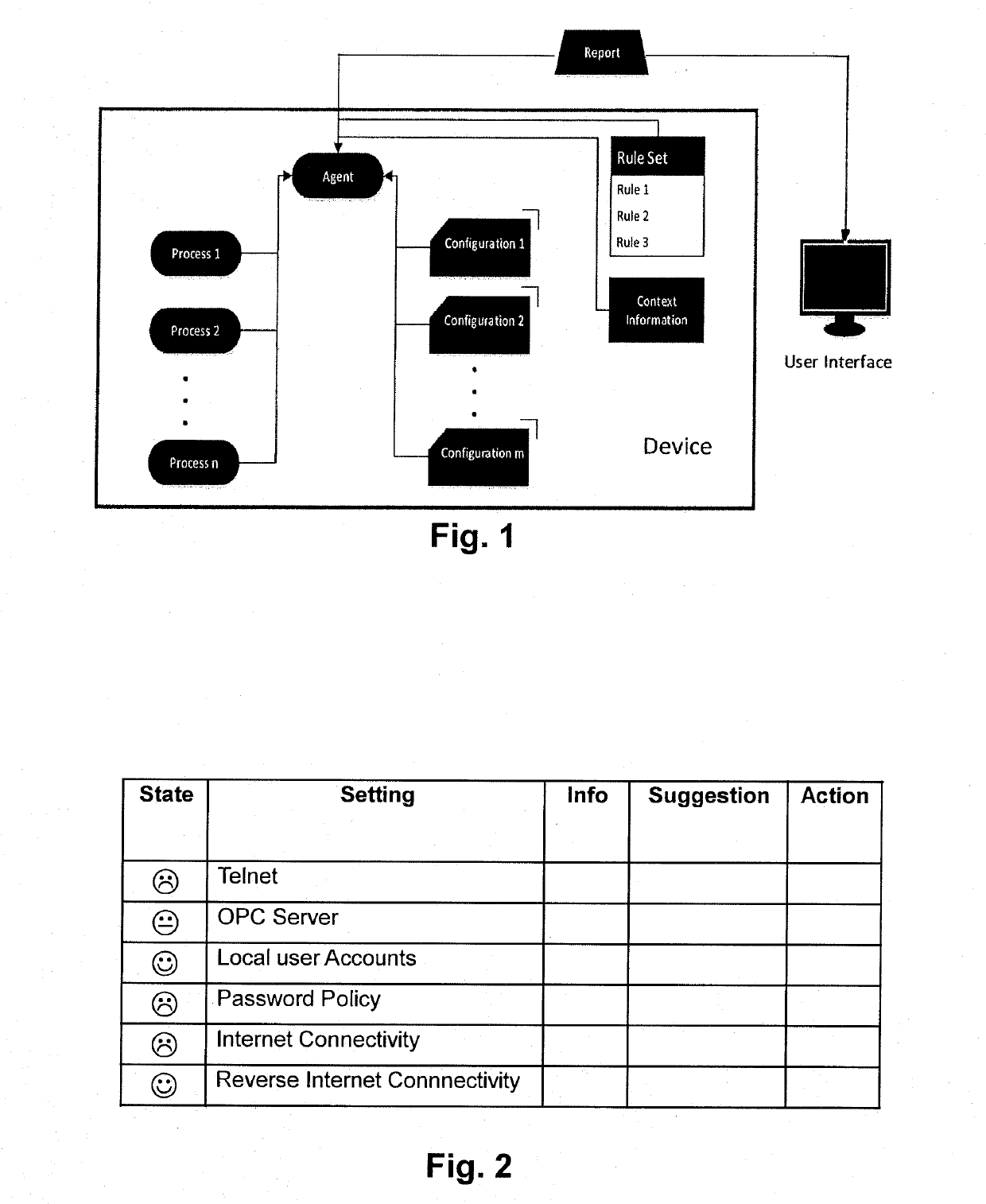

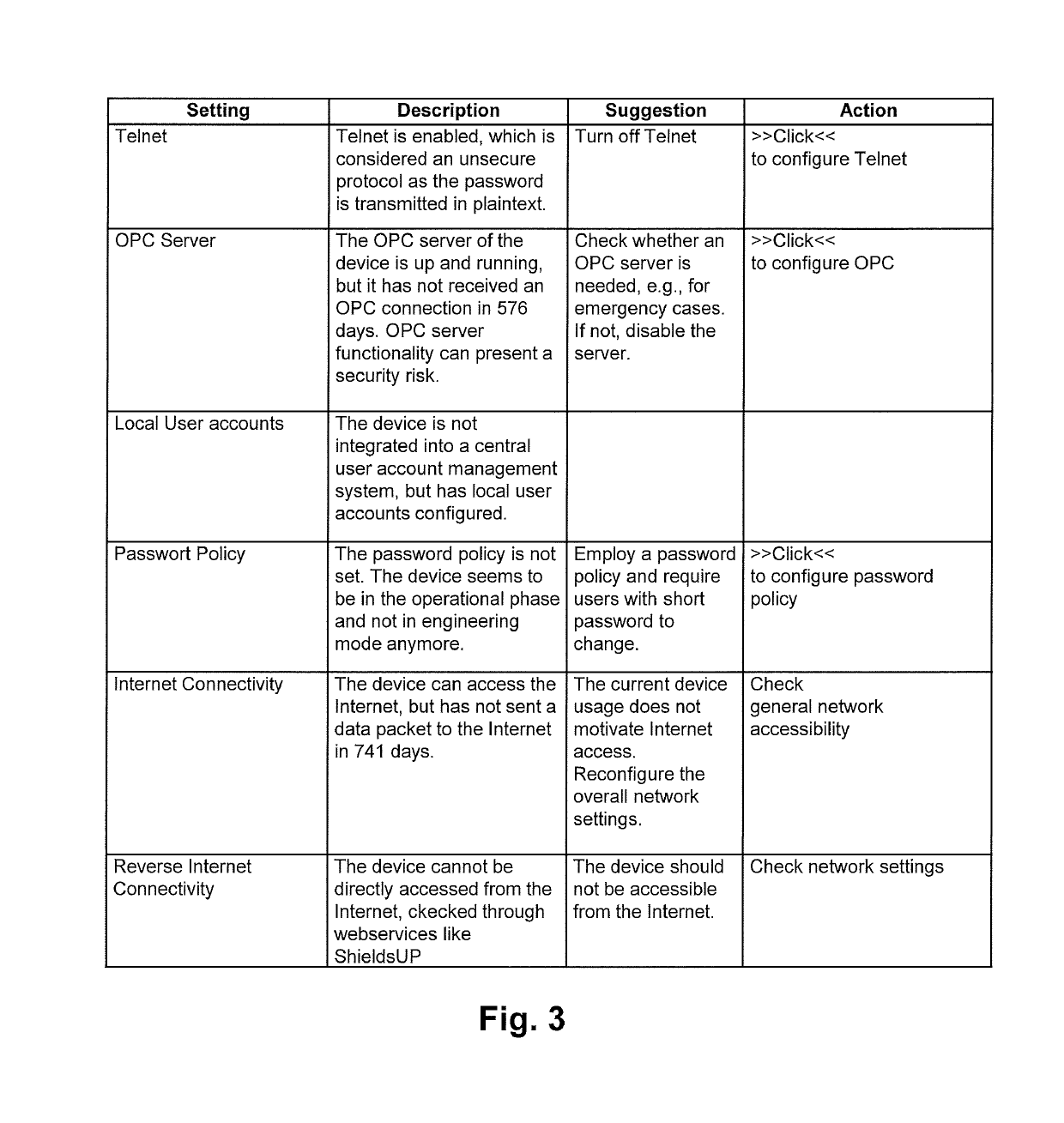

Context-aware security self-assessment

ActiveUS20190130113A1Simplify process engineeringReduce operating expensesComputer controlInternal/peripheral component protectionControl systemComputer science

The present invention generally relates to a context-aware security self-assessment method or module that determines the context in which the device is used and based on this, assesses the devices security settings. The context may refer to the system environment, the applications the device is used for, and / or the current life-cycle stage of the device, without being limited to said contexts. The method of the present invention preferably prioritizes and rates the security relevant findings and presents them in combination with mitigation options through a web interface, a configuration tool, or through notifications in the control system.

Owner:HITACHI ENERGY SWITZERLAND AG

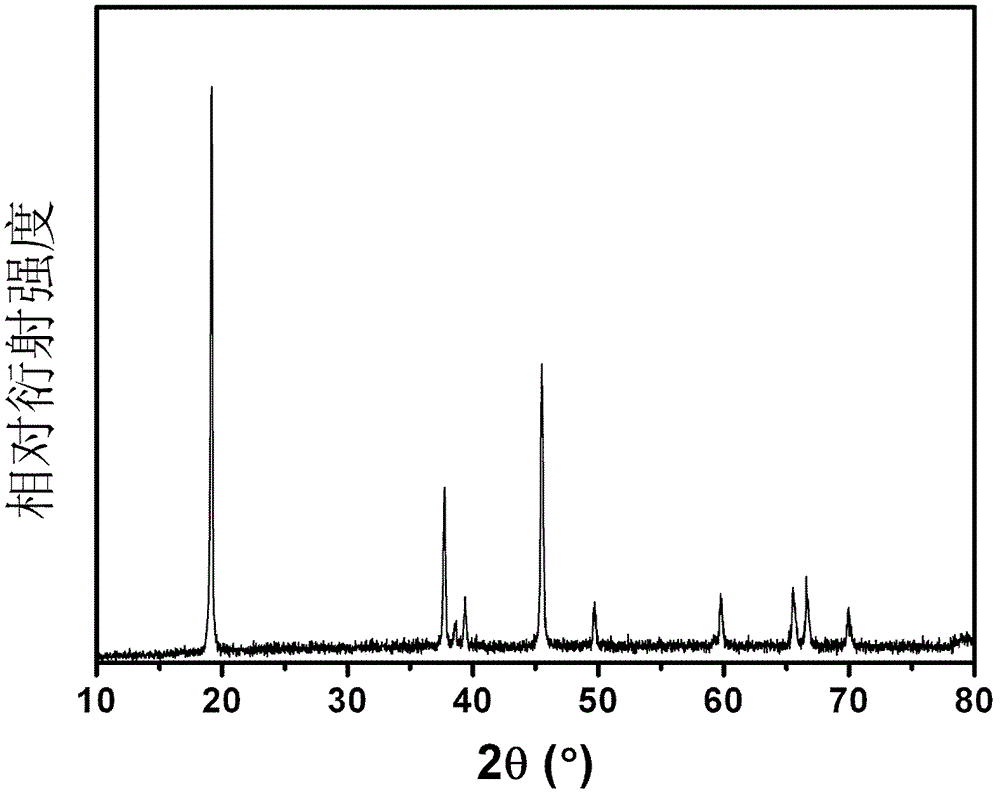

Lithium ion battery manganese cobalt lithium oxide anode material and preparation method thereof

InactiveCN103715411AWide variety of sourcesSimplify process engineeringCell electrodesSecondary cellsLithium oxideManganese

The invention discloses a lithium ion battery manganese cobalt lithium oxide anode material and a preparation method thereof. The chemical formula of the anode material is Li(3+x) / 3Mn2x / 3Col-xO2, wherein the x is greater than or equal to 0.1 and is less than or equal to 0.9. The lithium ion battery manganese cobalt lithium oxide anode material disclosed by the invention is prepared by adopting a sol-gel burning method. The preparation method disclosed by the invention has the advantages that the operation is simple, the production cost is low, the synthesis period is short, the repeatability is high and the like, the impurity ions are not introduced, the product purity is greatly improved, and lithium ions and transition metal ions are uniformly mixed under the assistance of mannitol; the method is widely applied in the synthesis of the lithium ion battery oxide anode material.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

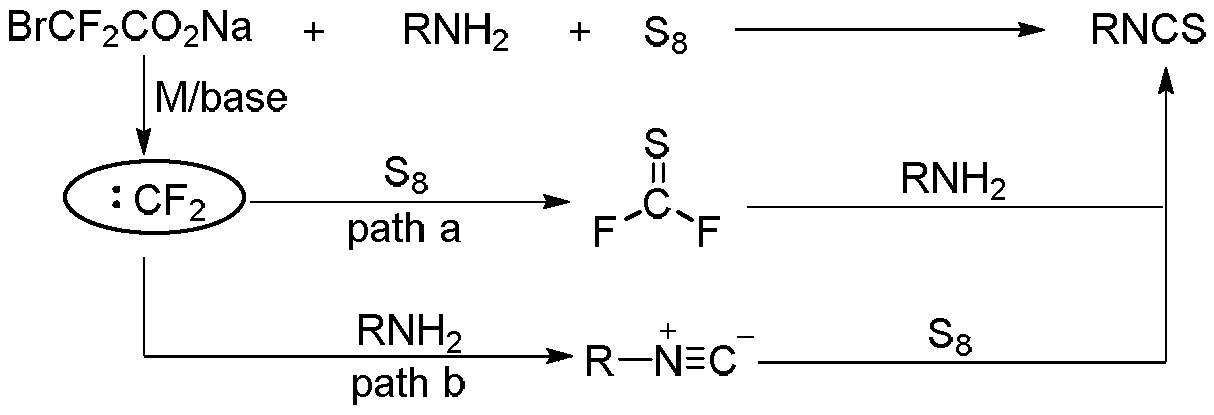

Isothiocyanate synthesized by three components and preparation method of isothiocyanate

InactiveCN109608295AEmission reductionProtect healthFunctional group formation/introductionSodium bicarbonateReaction temperature

The invention discloses isothiocyanate and a preparation method thereof. The method comprises the steps that primary amine, sodium difluorobromoacetate and elemental sulfur are taken as reactants forreaction; the reaction is carried out under the action of a copper catalyst, wherein the copper catalyst is any one of cuprous chloride, copper bromide, cuprous iodide, copper chloride and copper trifluoromethanesulfonate; an alkali is also added, wherein the alkali is any one of sodium bicarbonate, potassium carbonate, cesium carbonate, potassium phosphate, DABCO and sodium tert-butoxide; the whole reaction is carried out in a solvent, wherein the solvent is acetonitrile or dimethyl sulfoxide, the reaction temperature is 80-120 DEG C, and the reaction time is 10-14 hours. The method can directly synthesize the target product, does not need to separate intermediate products and only needs stirring and heating reaction under normal pressure to obtain the target product, and the yield can beup to 87%; a waste solution is fewer during the reaction, and the method protects the environment and ensures the health of an operator; in addition, a series of isothiocyanate derivatives can be prepared, and the method has a stronger substrate universality.

Owner:WENZHOU UNIVERSITY

Method for preparing palmatine by producing salting-out waste liquid by means of palmatine

The invention discloses a method for preparing palmatine by producing salting-out waste liquid by means of the palmatine. The method comprises the steps that alkali for producing the salting-out wasteliquid with the palmatine is subjected to pH adjustment and then filtered, filtrate enriches alkaloid through a resin column, impurities are eluted with purified water, the alkaloid is eluted with anethanol solution, eluent is concentrated and dried to obtain an alkaloid mixture containing jateorhizine, palmatine and columbamine, the alkaloid mixture is dissolved and then subjected to iodomethane methylation, the alkaloid is re-enriched through the resin column, hydrochloric acid is used for adjusting the pH, and then a crude palmatine product is obtained; the crude palmatine product is subjected to recrystallization with ethyl alcohol, filtered and dried, and the palmatine is obtained. Accordingly, the palmatine production waste liquid is reused, the content of the obtained palmatine islarger than 98%, the resource utilization rate is increased, the production cost is lowered, and the method for preparing the palmatine is simple, easy to implement and suitable for industrial production.

Owner:云南海沣药业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Dibenzo[c,e]azepine derivative and preparation method thereof Dibenzo[c,e]azepine derivative and preparation method thereof](https://images-eureka.patsnap.com/patent_img/1ee0426e-2e2d-4ecf-86b3-30e7ee69aa73/FDA0002211633130000012.png)

![Dibenzo[c,e]azepine derivative and preparation method thereof Dibenzo[c,e]azepine derivative and preparation method thereof](https://images-eureka.patsnap.com/patent_img/1ee0426e-2e2d-4ecf-86b3-30e7ee69aa73/FDA0002211633130000013.png)

![Dibenzo[c,e]azepine derivative and preparation method thereof Dibenzo[c,e]azepine derivative and preparation method thereof](https://images-eureka.patsnap.com/patent_img/1ee0426e-2e2d-4ecf-86b3-30e7ee69aa73/FDA0002211633130000014.png)