Method for preparing orderly anode alumina through-hole template by using anodic oxidation bath

A technology of anodized aluminum and anodic oxidation, which is applied in the direction of anodic oxidation, can solve the complex process, affect the preparation of nanostructures on the substrate, pollution and other problems, and achieve the effect of simple process engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

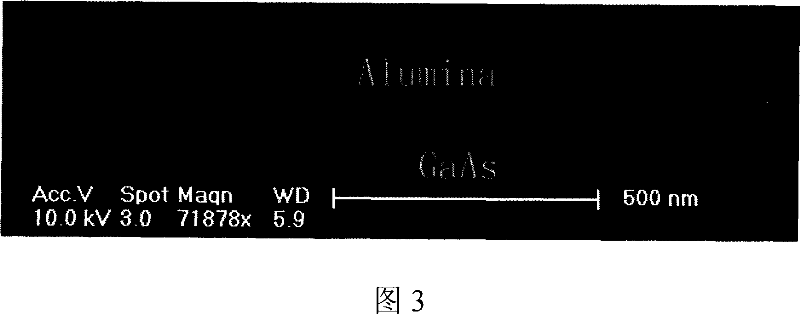

[0048] 1. The core idea of the present invention is to vapor-deposit aluminum on a semi-insulating GaAs substrate for in-situ anodic oxidation, and adopt a three-step anodic oxidation method to obtain uniform and orderly oxidation on the GaAs substrate by improving the flatness of the surface. Aluminum formwork.

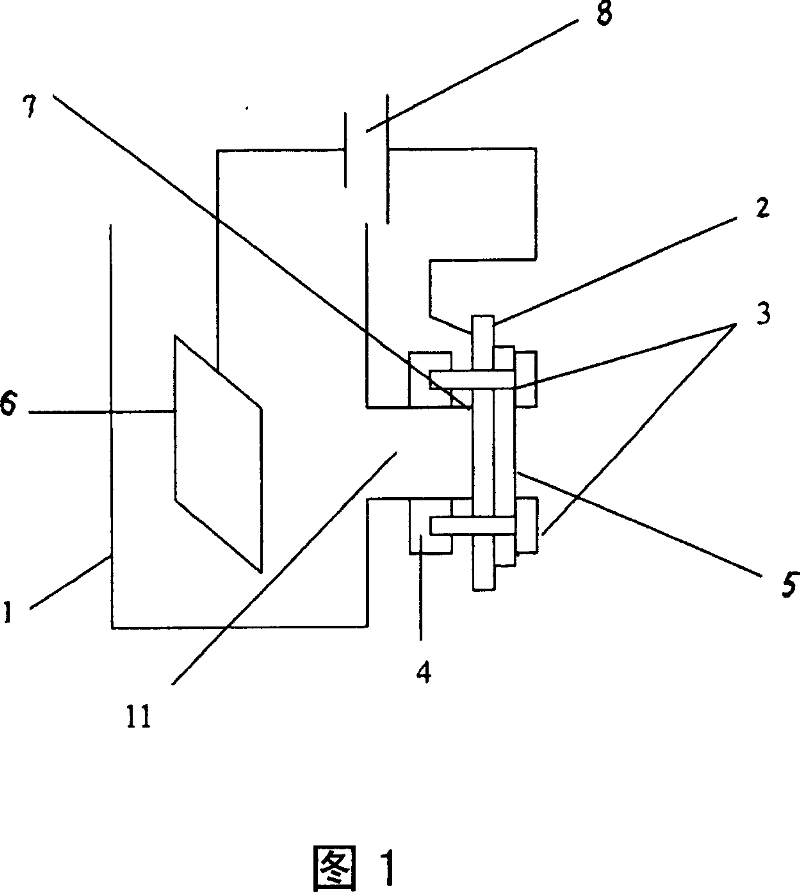

[0049] 2. Fig. 1 is a structural representation of an anodic oxidation bath of the present invention; it is a device for in-situ anodic oxidation on a semi-insulating GaAs substrate;

[0050]Design of in-situ anodic aluminum oxidation device for semi-insulating GaAs substrates: the anodizing device is used for in-situ anodizing on semi-insulating GaAs substrates to form ordered through-hole templates, and a glass electrolytic cell 1 is designed. There is a round hole 11 on the side wall of the electrolytic cell 1; a fixed ring 4, which is fixed on the outer side wall of the round hole 11 on the electrolytic cell 1; a movable ring 5, which is fixed with a screw 3 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com