Lithium ion battery manganese cobalt lithium oxide anode material and preparation method thereof

A battery manganese cobalt lithium, positive electrode material technology, applied in the direction of battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problems of not being able to fully mix metal ions, easily introducing impurity ions, and affecting the electrochemical performance of positive electrode materials , achieve excellent electrochemical performance, improve purity, and be easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Li 1.2 mn 0.4 co 0.4 o 2 Cathode material

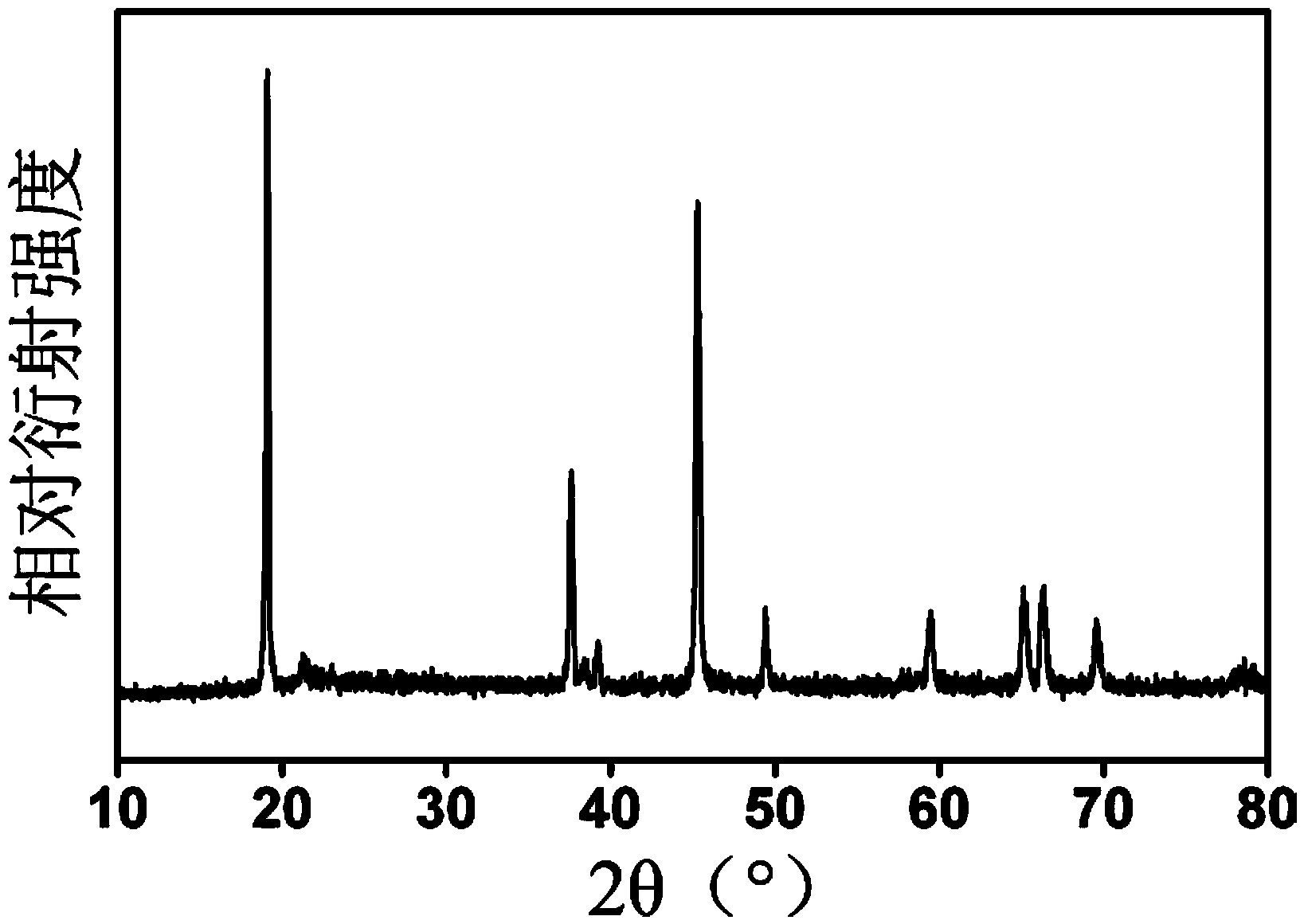

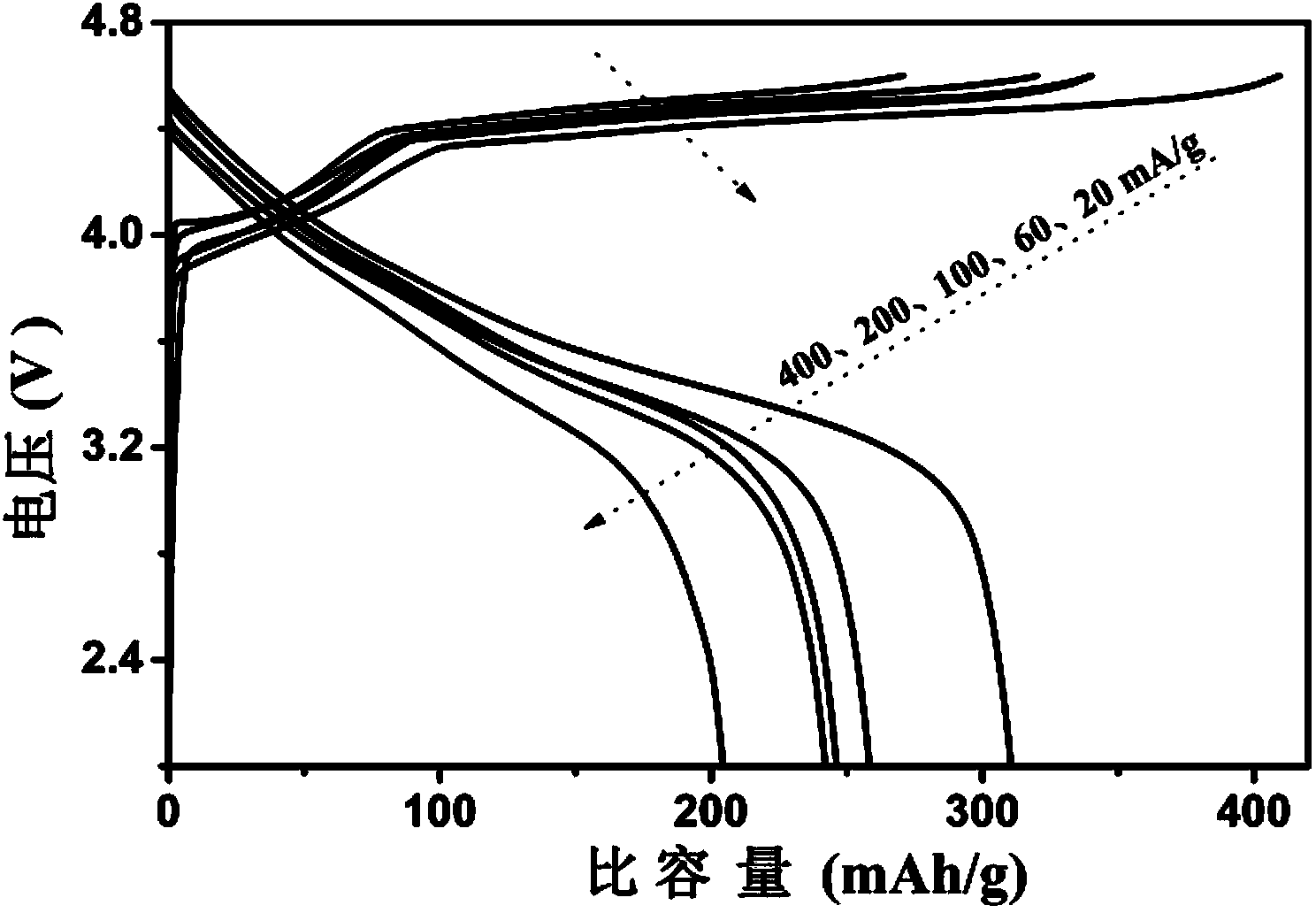

[0027] Using lithium acetate, manganese acetate, and cobalt acetate as starting materials, 2.8158 g of lithium acetate, 1.9607 g of manganese acetate, and 1.9926 g of cobalt acetate were dissolved in 100 mL of deionized water to form a clear solution; 3.6436 g of mannitol was dissolved in 100 mL of deionized water Form a mannitol aqueous solution; drop the mannitol solution into the above metal salt solution drop by drop, adjust the pH value to 2 with concentrated nitric acid, stir for 1 hour and evaporate to dryness at 80°C to obtain a xerogel; heat the xerogel After spontaneous combustion, the precursor of lithium manganese cobalt oxide is obtained; the precursor is heat treated at 900 ° C for 15 hours, and quenched at room temperature to obtain Li 1.2 mn 0.4 co 0.4 o 2 Cathode material. figure 1 Li prepared for this example 1.2 mn 0.4 co 0.4 o 2 The X-ray diffraction pattern of the positive electrode ...

Embodiment 2

[0028] Example 2: Li 1.033 mn 0.067 co 0.9 o 2 Cathode material

[0029]Using lithium acetate, manganese acetate, and cobalt acetate as starting materials, 2.4239 g of lithium acetate, 0.3284 g of manganese acetate, and 4.4834 g of cobalt acetate were dissolved in 100 mL of deionized water to form a clear solution; 3.6436 g of mannitol was dissolved in 100 mL of deionized water Form a mannitol aqueous solution; drop the mannitol solution into the above metal salt solution drop by drop, adjust the pH value to 2 with concentrated nitric acid, stir for 1 hour and evaporate to dryness at 80°C to obtain a xerogel; heat the xerogel After spontaneous combustion, the precursor of lithium manganese cobalt oxide is obtained; the precursor is heat treated at 900 ° C for 15 hours, and quenched at room temperature to obtain Li 1.033 mn 0.067 co 0.9 o 2 Cathode material. The XRD test results of powder materials show that the synthesized powder has a layered rock-salt structure (R3m)...

Embodiment 3

[0030] Example 3: Li 1.1 mn 0.2 co 0.7 o 2 Cathode material

[0031] Using lithium acetate, manganese acetate, and cobalt acetate as starting materials, 2.5811 g of lithium acetate, 0.9804 g of manganese acetate, and 3.4871 g of cobalt acetate were dissolved in 100 mL of deionized water to form a clear solution; 3.6436 g of mannitol was dissolved in 100 mL of deionized water Form a mannitol aqueous solution; drop the mannitol solution into the above metal salt solution drop by drop, adjust the pH value to 2 with concentrated nitric acid, stir for 1 hour and evaporate to dryness at 80°C to obtain a xerogel; heat the xerogel After spontaneous combustion, the precursor of lithium manganese cobalt oxide is obtained; the precursor is heat treated at 900 ° C for 15 hours, and quenched at room temperature to obtain Li 1.1 mn 0.2 co 0.7 o 2 Cathode material. The XRD test results of powder materials show that the synthesized powder has a layered rock-salt structure (R3m). The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com