Method for processing food processing wastewater by adopting facultative membrane bioreactor and facultative membrane bioreactor

A membrane bioreactor, food processing wastewater technology, applied in aerobic and anaerobic process treatment, food industry wastewater treatment and other directions, can solve the problems of high energy consumption, unsatisfactory ammonia nitrogen removal effect, high operating cost, and achieve treatment efficiency High, simplified water treatment process engineering, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

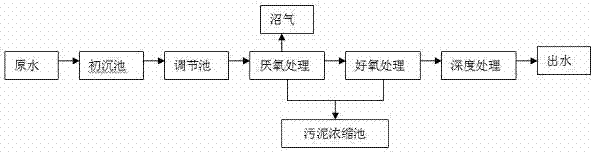

[0033] In this embodiment, the method of the present invention for treating food processing wastewater using a facultative membrane bioreactor is used to treat pastry food processing wastewater. The processing scale is 50t / d, and the main process flow is: food processing wastewater→pretreatment→ Adjusting tank → facultative membrane bioreactor → effluent.

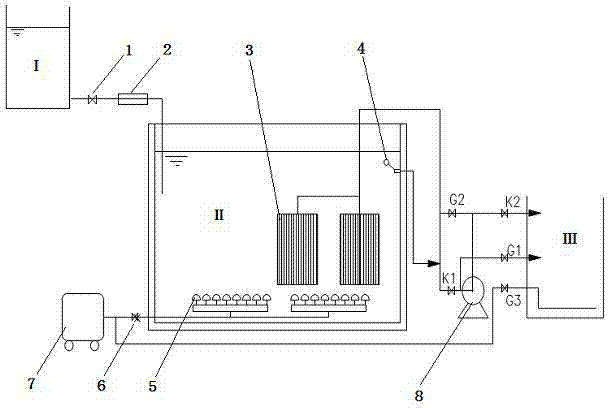

[0034] see Figure 2 ~ Figure 4 , this embodiment adopts a facultative membrane bioreactor, including biochemical reaction tank II and the membrane module 3 installed therein and the aeration head device 5, the aeration head device 5 is arranged under the membrane module 3, and the high The preliminarily treated wastewater from the tank I is transported to the biochemical reaction tank II through the water pipe with the water inlet valve 1 and the flow meter 2, and the air pump 7 is set outside the biochemical reaction tank II, and the air pump 7 passes through the water tank with the air valve 6 The air pipeline of the ai...

Embodiment 2

[0045] This embodiment is basically the same as Embodiment 1, especially in that:

[0046] In this embodiment, the method for treating food processing wastewater using a facultative membrane bioreactor comprises the following steps:

[0047] a. same as embodiment one;

[0048] b. same as embodiment one;

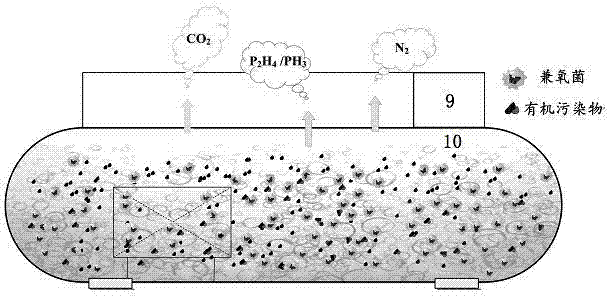

[0049] c. In the reaction zone 10 in the biochemical reaction tank II, a bacterial phase form in which facultative bacteria are the main form, and aerobic and facultative bacteria coexist, forming a facultative membrane biological reaction purification system;

[0050] d is the same as in Example 1.

[0051] In this embodiment, facultative bacteria are the main form, and aerobic and facultative bacteria coexist to form a facultative membrane biological reaction purification system, which can more effectively biochemically treat sewage and improve sewage treatment efficiency.

Embodiment 3

[0053] This embodiment is basically the same as the previous embodiment, and the special features are:

[0054] In this example, see Figure 5 , water is transported between the biochemical reaction tank II and the clear water tank III through a mixed parallel pipeline system formed by the first water outlet pipeline and the second water outlet pipeline, after the treatment in the biochemical reaction tank II The clean water enters the clean water tank III through the pre-first control valve G1 and the rear first control valve K1 set on the first outlet pipeline in turn, and the clean water treated in the biochemical reaction tank II is returned to the tank in turn. It can enter the clear water pool III through the second outlet pipeline with a pre-installed second control valve G2 and a rear-installed second control valve K2 at one time, the first outlet pipeline and the second outlet pipeline There is also a connecting pipe between them, so that the clean water can enter th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com