High-performance microwave dielectric ceramic material and preparation method thereof

A high-performance technology of microwave dielectric ceramics, applied in the field of electronic ceramics, can solve the problems of Q×f (decrease of microwave dielectric loss, influence of material loss performance, difficult low-temperature sintering, etc., to achieve low loss, small temperature coefficient, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

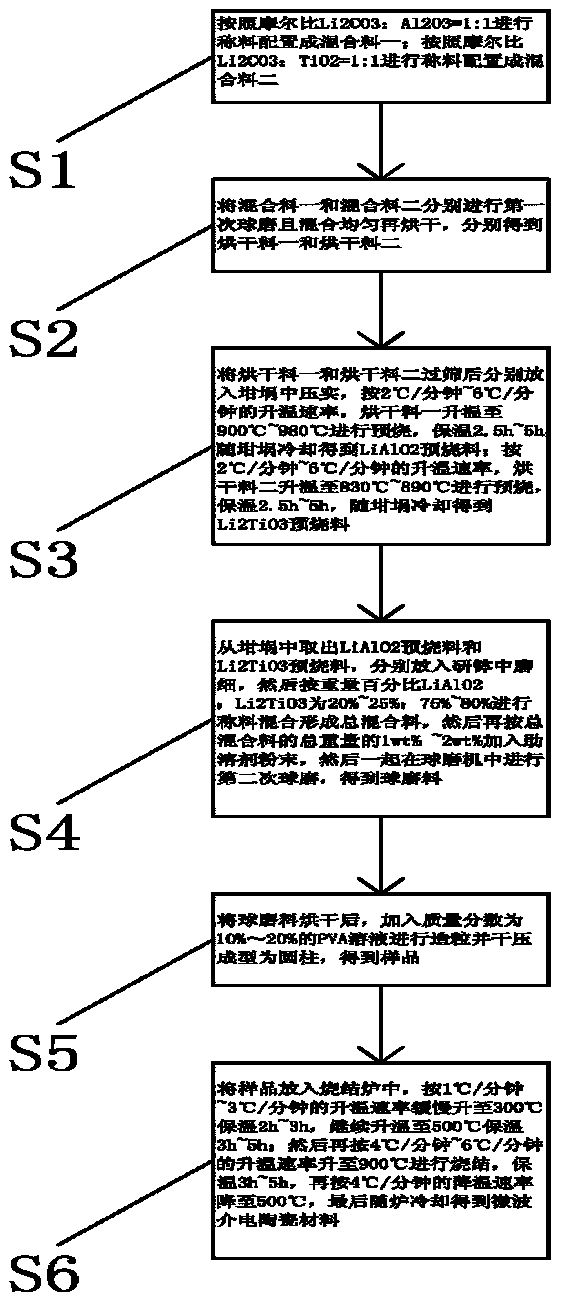

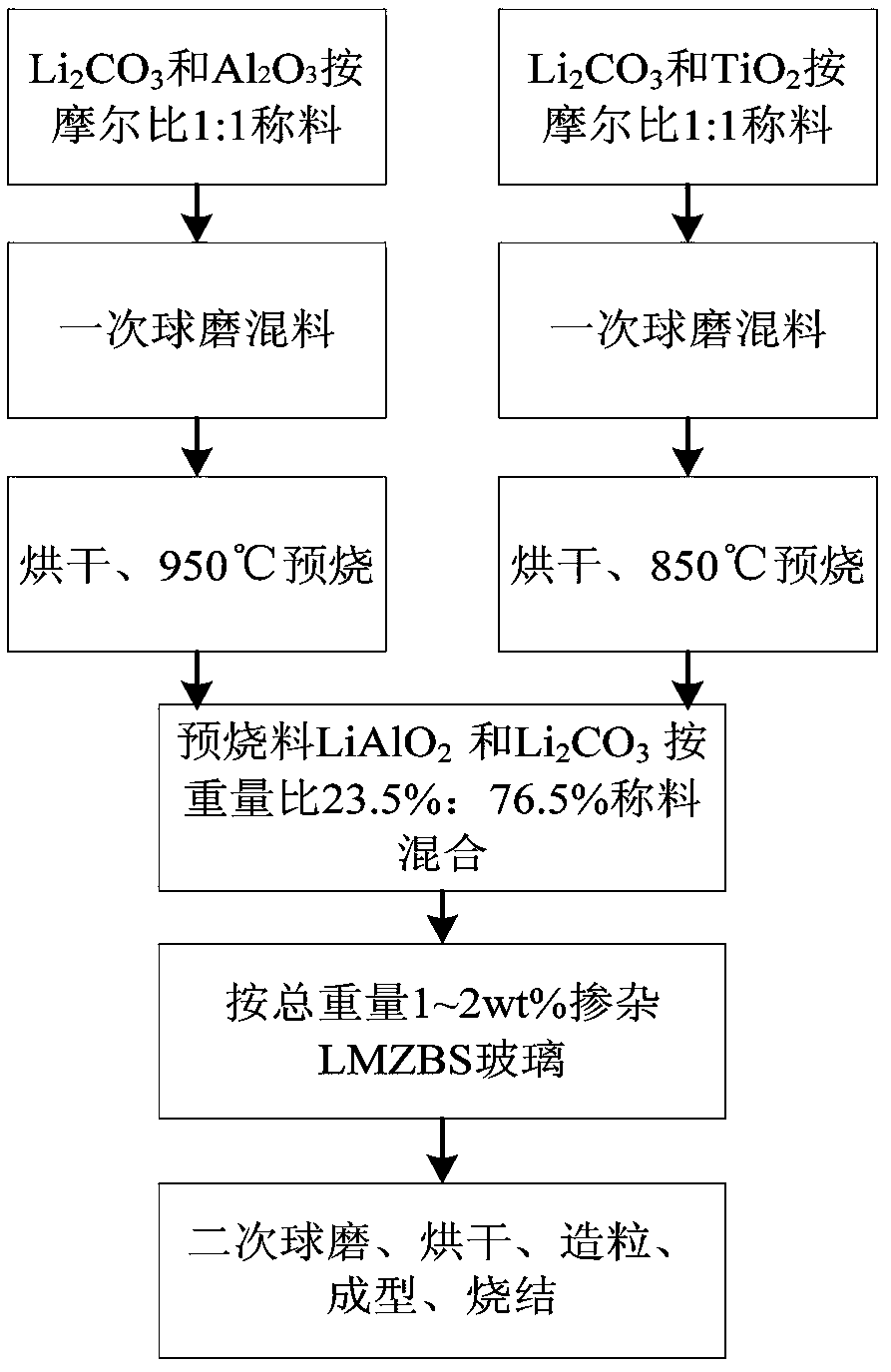

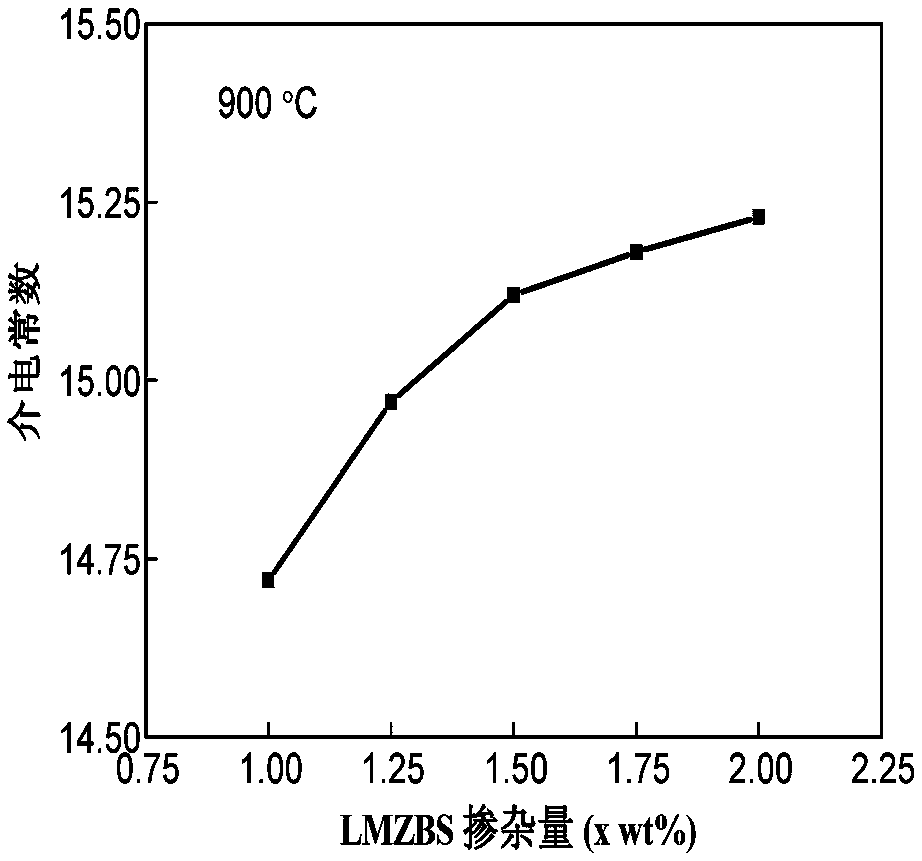

Method used

Image

Examples

Embodiment 1

[0036] The first embodiment is a composite material composed of a main crystal phase and an auxiliary crystal phase, and the main crystal phase is LiAlO 2 , the auxiliary phase is Li 2 TiO 3 , by weight percent LiAlO 2 : Li 2 TiO 3 23.5%: 76.5%.

Embodiment 2

[0038] The second embodiment is a composite material composed of a main crystalline phase and an auxiliary crystalline phase, and the main crystalline phase is LiAlO 2 , the auxiliary phase is Li 2 TiO 3 , by weight percent LiAlO 2 : Li 2 TiO 3 23%: 77%.

Embodiment 3

[0040] The third embodiment is a composite material composed of a main crystalline phase and an auxiliary crystalline phase, and the main crystalline phase is LiAlO 2 , the auxiliary phase is Li 2 TiO 3 , by weight percent LiAlO 2 : Li 2 TiO 3 21%: 79%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com