Ultra-low dielectric LTCC microwave ceramic material and preparation method thereof

A microwave ceramic and ultra-low dielectric technology, which is applied in the field of ultra-low dielectric LTCC microwave ceramic materials and their preparation, can solve the problem of not having both low dielectric constant and the like, and achieves reduction of grain boundaries and defects, elimination of pores, and dielectric constant. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Described below is the specific embodiment of LTCC microwave ceramic material of the present invention, and the prescription molecular formula of this ultra-low dielectric LTCC microwave ceramic material is 0.95SiO 2 -0.05Li 2 TiO 3 -y LBSCA, where y takes the value of 5wt%, SiO 2 Nano-SiO with an average particle size of less than 100nm 2 .

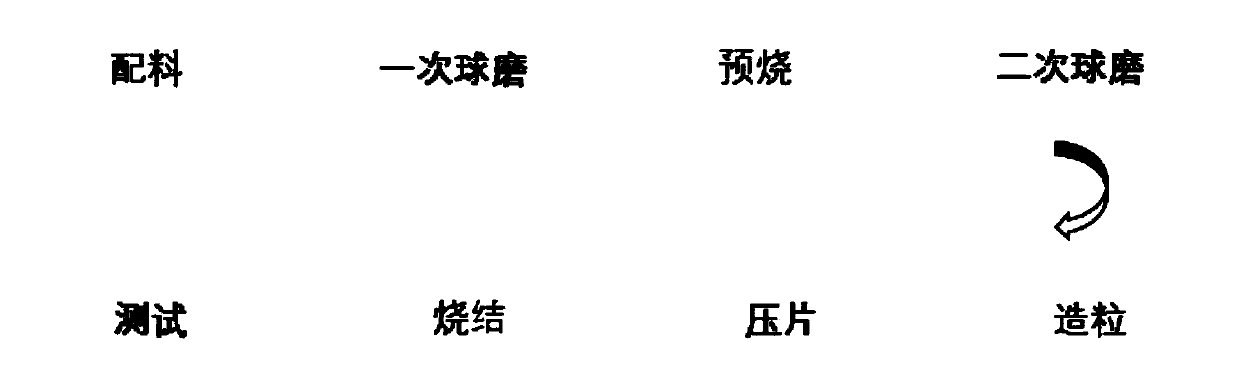

[0027] Its preparation process is as follows image 3 Shown, concrete preparation method comprises the following steps:

[0028] Step 1, with Li 2 CO 3 、TiO 2 As the initial raw material, according to the molar ratio Li 2 CO 3 :TiO 2 = 1:1 convert the corresponding mass to weigh the material, and then perform a ball mill in a planetary ball mill for 12 hours. After ball milling, the material is placed in an oven and dried at 100 ° C. The molecular structure formed is Li 2 TiO 3 .

[0029] Step 2. Pass the dried material obtained in step 1 through a 40-mesh sieve, put it into a crucible for compaction, and heat it up t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com