Method for quick synthesis of NaY molecular screen

A synthesis method and technology of molecular sieves, applied in the direction of octahedral crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of complicated synthesis process and time waste of NaY molecular sieve, and achieve short synthesis period and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

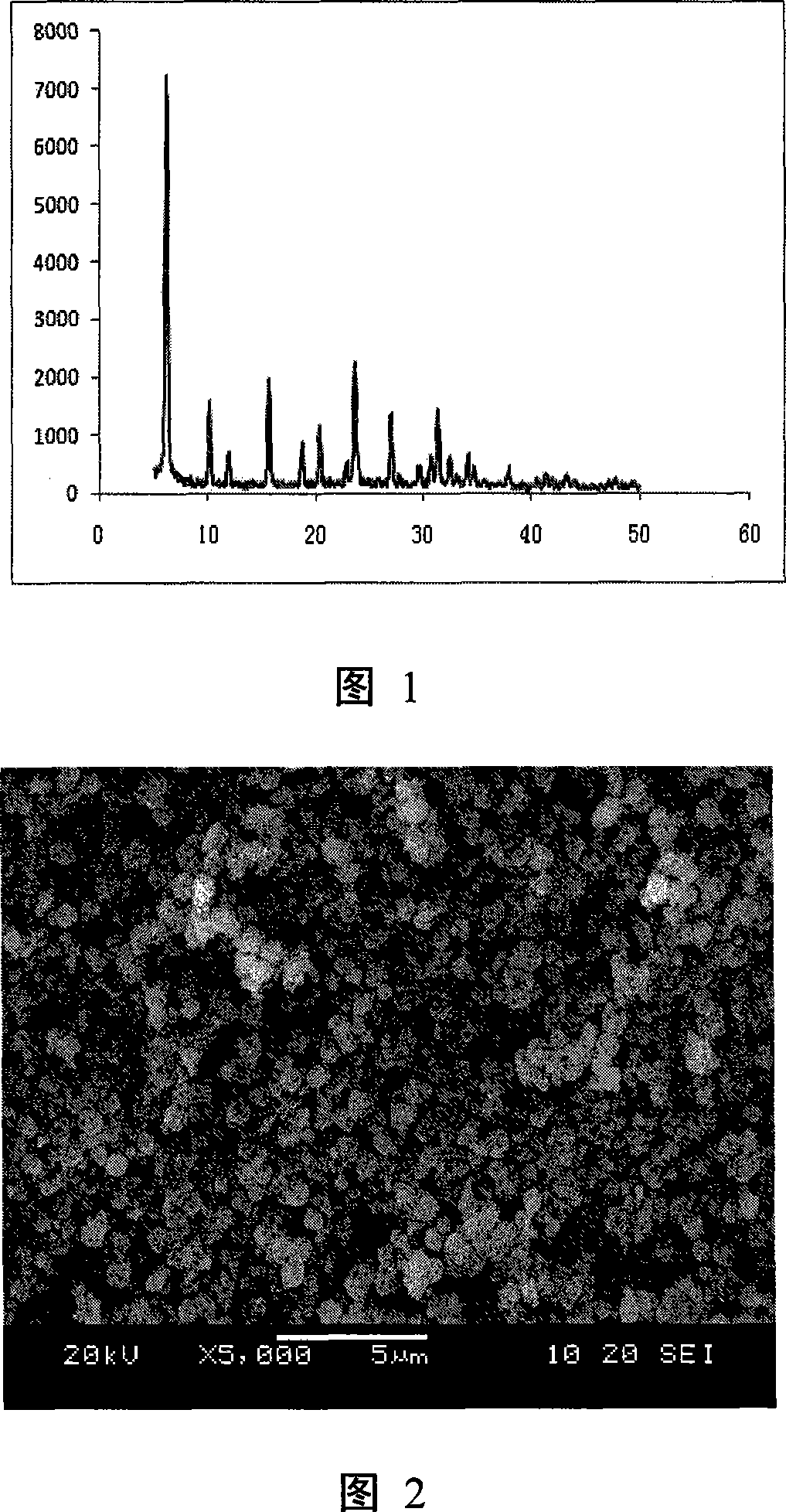

[0019] During the preparation of the mixture, pay attention to the order of adding various substances, mix 8.0g NaOH and 15g water, add 30g silica sol, 6.7g Al 2 (SO 4 ) 3 ·6H 2 O, add water 15g, make the final molar ratio of mixture be 10Na 2 O:Al 2 o 3 : 15SiO 2 : 300H 2 O. After uniformly stirring at 10°C for 4 hours, put it into a high-pressure reactor, age at room temperature for 12 hours, and finally put it in a 100°C oven for crystallization for 12 hours. After washing and drying, it becomes the original powder of NaY molecular sieve. See accompanying drawing 1 for its XRD diagram, and refer to accompanying drawing 2 for its SEM diagram, and refer to Table 1 for its silicon-aluminum ratio and crystallinity.

Embodiment 2

[0021] Mix 8.0g NaOH and 15g water, add 30g silica sol, 3.4g Al during stirring 2 (SO 4 ) 3 ·6H 2 O, add water 15g, make the final molar ratio of mixture be 20Na 2 O:Al 2 o 3 : 30SiO 2 : 600H 2 O. After stirring evenly at 20°C for 2 hours, put it into a high-pressure reactor, age at room temperature for 14 hours, and finally put it in an oven at 120°C for crystallization for 16 hours. After washing and drying, it becomes the original powder of NaY molecular sieve. The silicon-aluminum ratio and crystallinity are shown in Table 1.

Embodiment 3

[0023] Mix 8.0g NaOH and 15g water, add 30g silica sol, 10.1g Al 2 (SO 4 ) 3 ·6H 2 O, add water 15g, make the final molar ratio of mixture be 6.7Na 2 O:Al 2 o 3 : 10SiO 2 : 200H 2 O. After uniform stirring at 40°C for 6 hours, put it into a high-pressure reactor, age at room temperature for 20 hours, and finally put it in an oven at 100°C for 24 hours of crystallization. After washing and drying, it is the original NaY molecular sieve powder. and crystallinity are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com