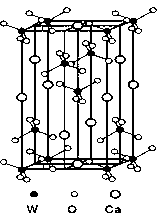

Low-medium low-loss LTCC (Low Temperature Co-Fired Ceramic) microwave ceramic material and preparation method thereof

A technology of microwave ceramics and low loss, applied in the field of electronic ceramic materials and its manufacturing, can solve the problems of reducing ceramic microwave performance, ceramic cracking, etc., and achieve the effects of improving process compatibility and yield, convenient operation, and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

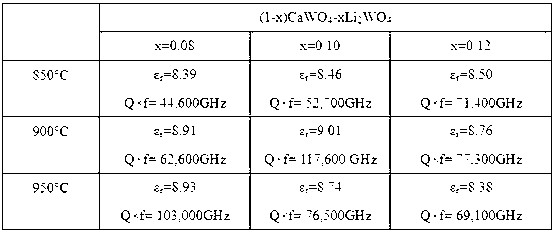

Examples

Embodiment Construction

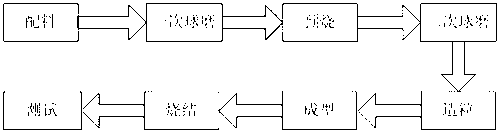

[0027] The following description is a specific embodiment of the LTCC microwave ceramic material of the present invention. Such as figure 2 Shown, the concrete preparation method of this material is as follows:

[0028] Step 1: Using CaCO 3 , WO 3 , Li 2 CO 3 As the initial raw material, according to 0.9 CaWO 4 -0.1 Li 2 WO 4 The molar ratio of each element in the formula molecular formula is converted into CaCO 3 , WO 3 and Li 2 CO 3 The mass percentage of the mass percentage is accurately weighed, ball milled in a planetary ball mill for 12 hours at a time, and the ball milled material is placed in an oven and dried at 100°C.

[0029] Step 2: Pass the dried material obtained in Step 1 through a 40-mesh sieve, put it into a crucible for compaction, and pre-burn it at a heating rate of 2 °C / min to 900 °C, keep it for 2 hours, and cool it with the furnace to obtain a pre-fired material for use .

[0030] Step 3: Roughly grind the bulk calcined material obtained in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com