Coating structure for low-temperature heat insulation container and coating method of coating structure

A technology of low-temperature heat insulation and cladding structure, which is applied in the direction of pressure vessels, fixed-capacity gas storage tanks, mechanical equipment, etc. It can solve the problems of reducing vacuum efficiency, affecting vacuum performance, and easily generating debris, so as to reduce vacuum pumping And the effect of subsequent vacuum maintenance, shortened heat insulation coating time, and simplified process engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

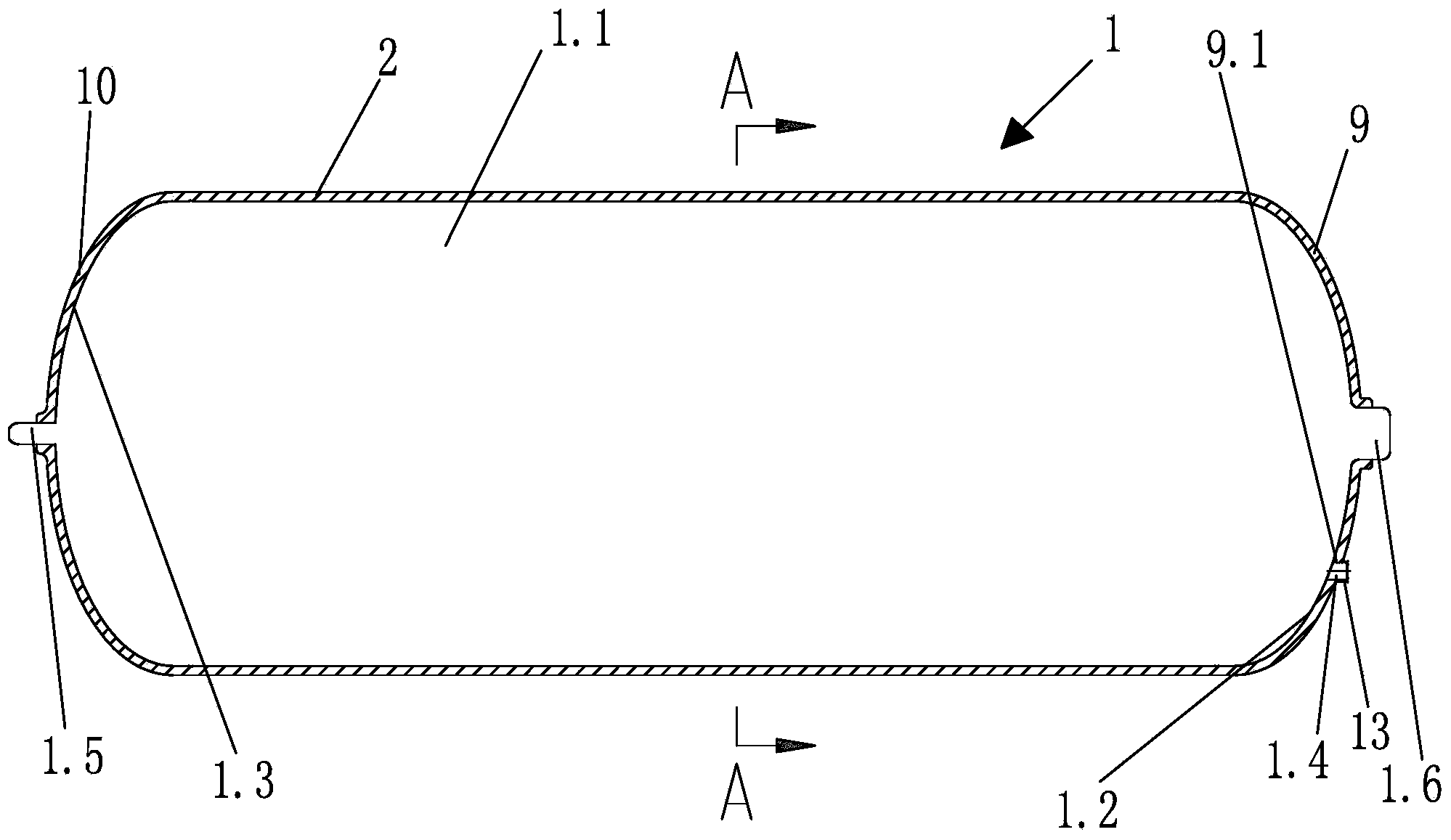

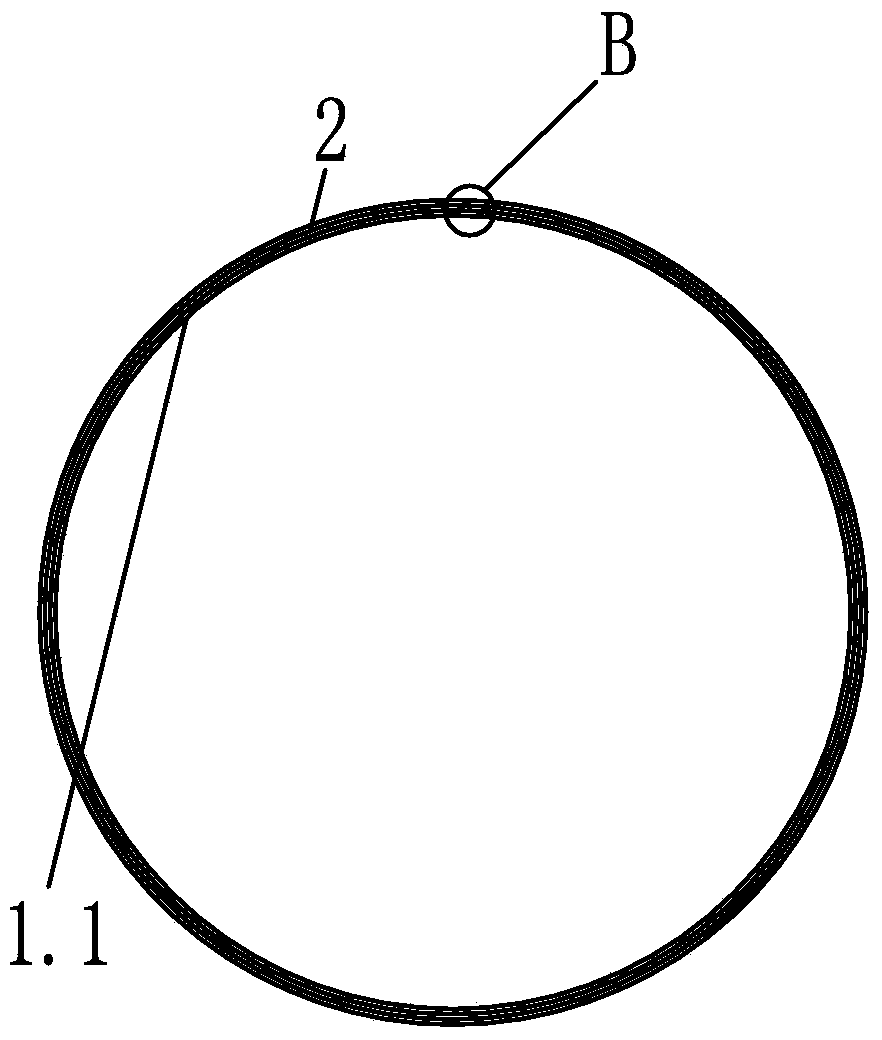

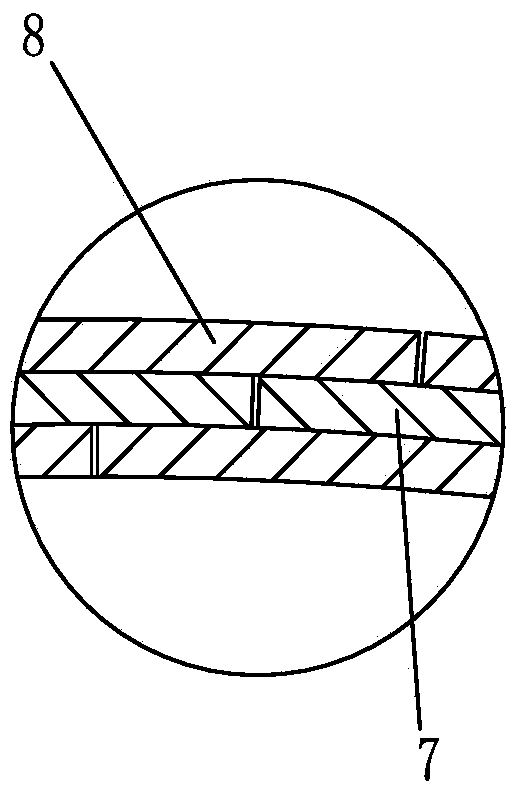

[0044] Such as Figure 1-12 The cladding structure of the low-temperature heat-insulating container shown includes an inner tank 1, the inner tank 1 has a cylindrical tank body 1.1, a spherical front head 1.2 connected to the front end of the cylindrical tank body 1.1 and connected to the rear of the cylindrical tank body 1.1 The spherical rear head 1.3 at the end, the center of the spherical front head 1.2 is provided with a front support rod 1.6, the surface of the spherical front head 1.2 is provided with a pipe joint 1.4, and the center of the spherical rear head 1.3 is provided with a rear support rod 1.5 , it also includes a thermal insulation quilt 2, a front sealing cap 3 and a rear sealing cap 4, one side of the thermal insulation quilt 2 is provided with a positive step lap edge 7, and the other side of the thermal insulation quilt 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com