Patents

Literature

83 results about "Back heads" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

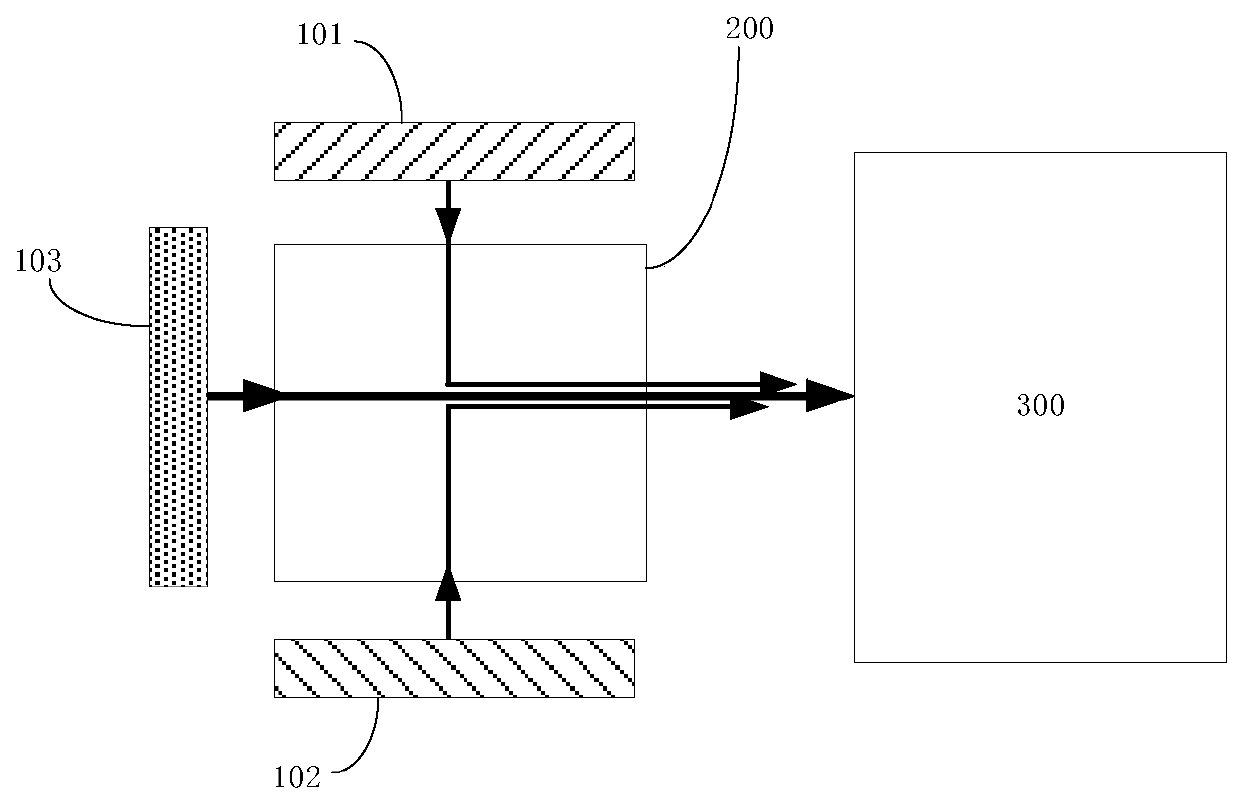

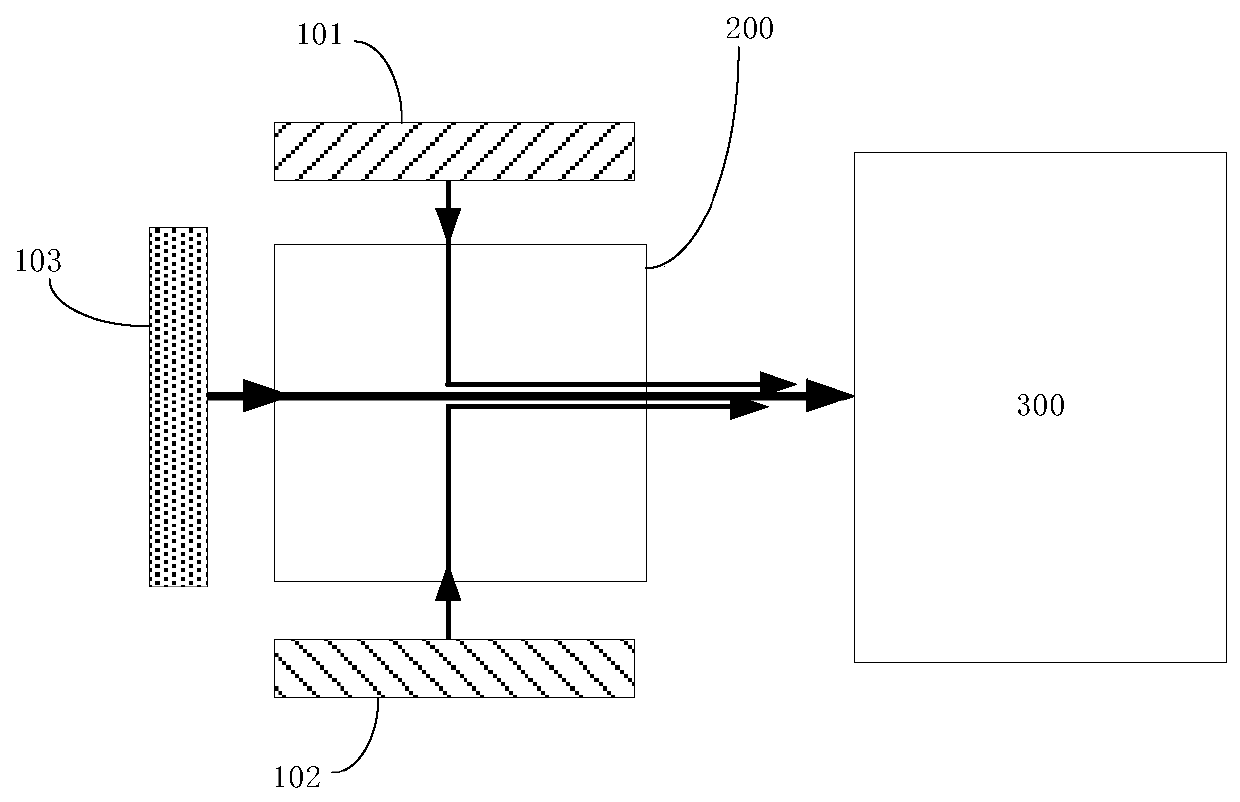

Target tracking method and system and staff behavior analyzing method and system

ActiveCN105184258AStrong angle adaptabilityImprove adaptabilityImage enhancementImage analysisPattern recognitionFace detection

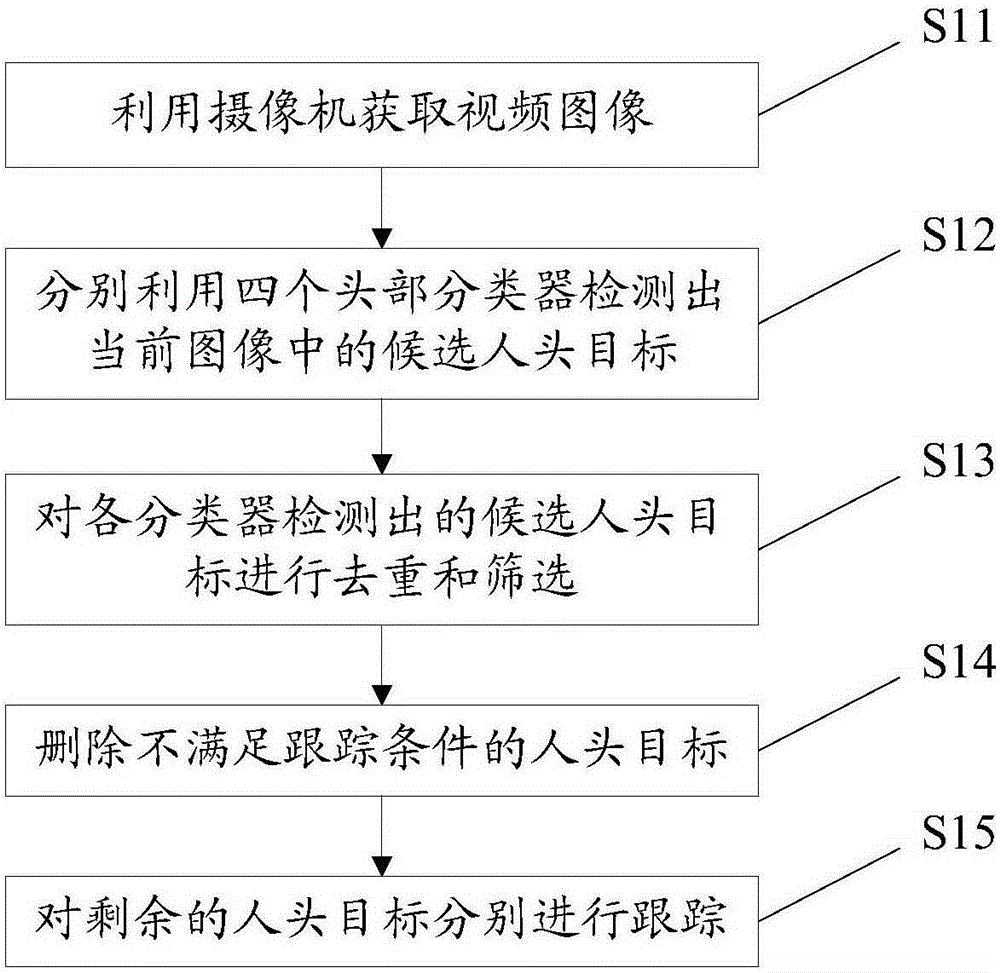

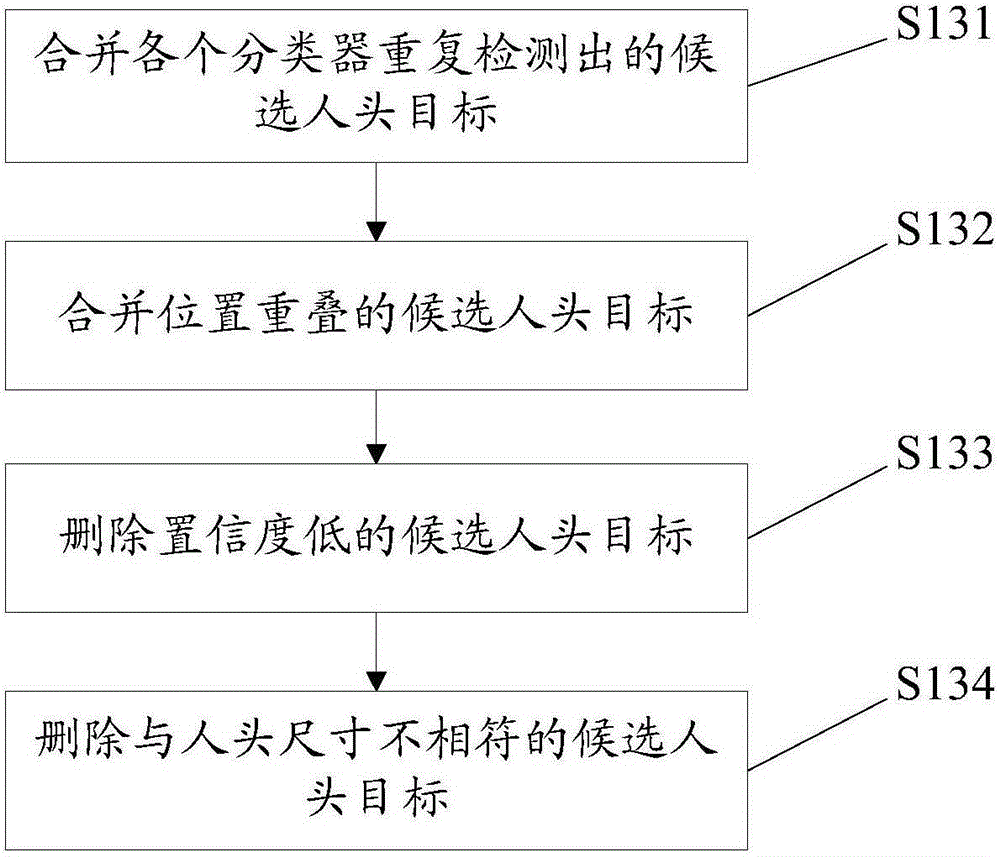

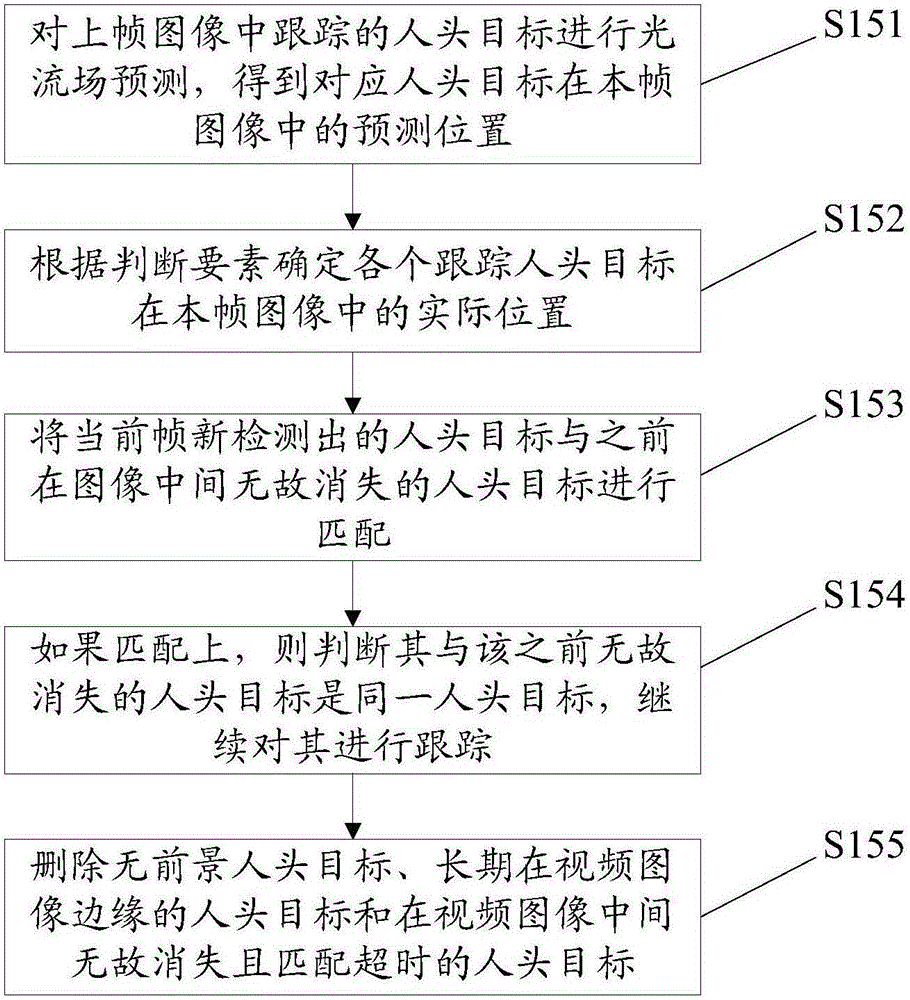

The invention provides a target tracking method and system and a staff behavior analyzing method and system. The target tracking method comprises the steps that a camera is used to acquire a video image; a front head classifier, a back head classifier, a left head classifier and a right head classifier are respectively used to detect candidate head targets in the current image; deduplication and screening are carried out on the candidate head targets detected by the classifiers; head targets which does not meet a tracking condition are deleted; and the remaining head targets are respectively tracked. The technical problems of false positives, false negatives, difficulty tracking and high camera erection requirement, which are caused by easily being blocked, difficulty target classification and the like, of a staff detection and tracking method based on face detection, head and shoulder detection or whole body detection are solved. According to the invention, accurate staff track tracking can be carried out based on the head targets; the problem of target restating can be reduced; and staff behavior analyzing can be carried out based on tracking results.

Owner:SUZHOU KEDA TECH +2

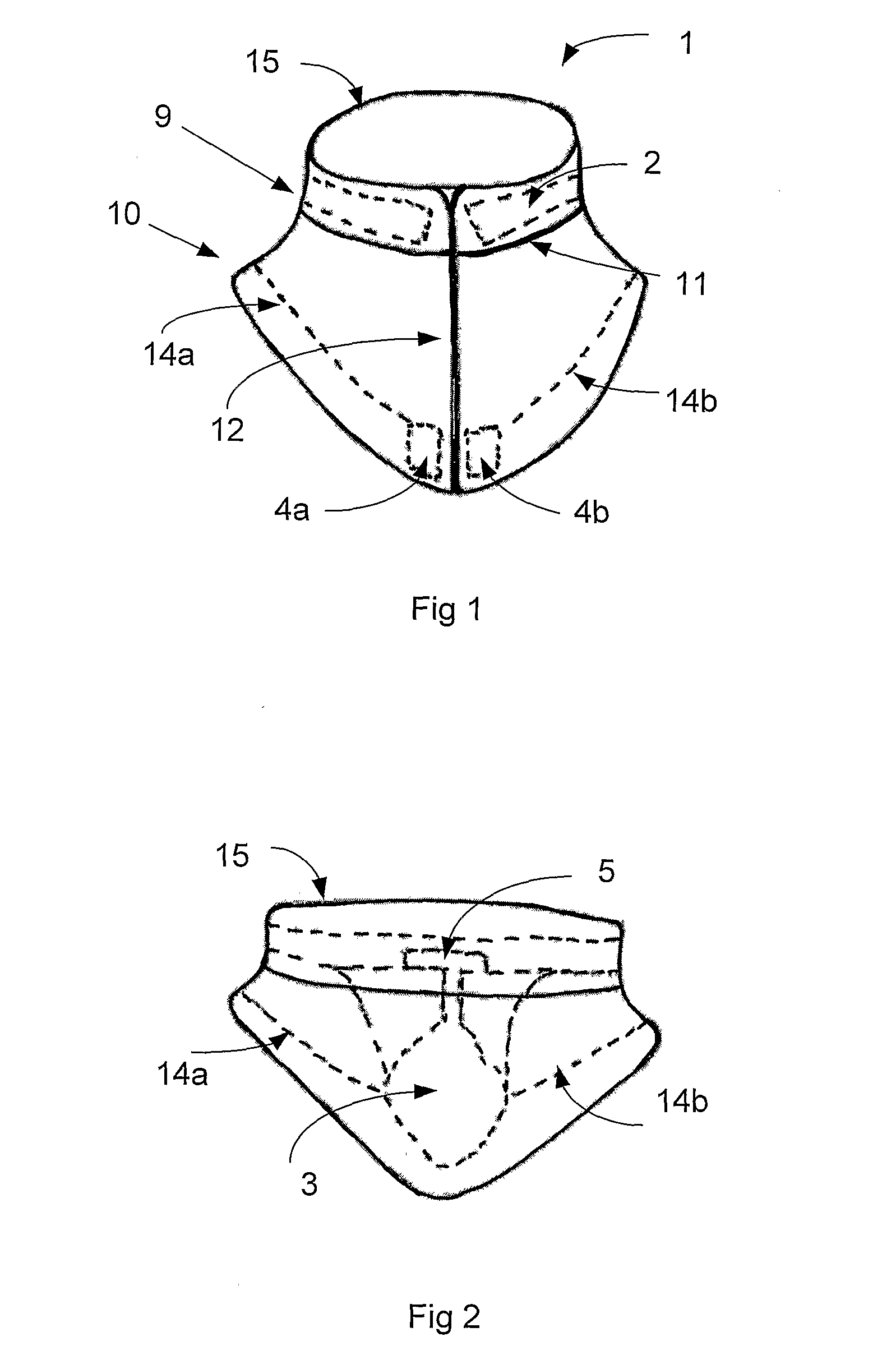

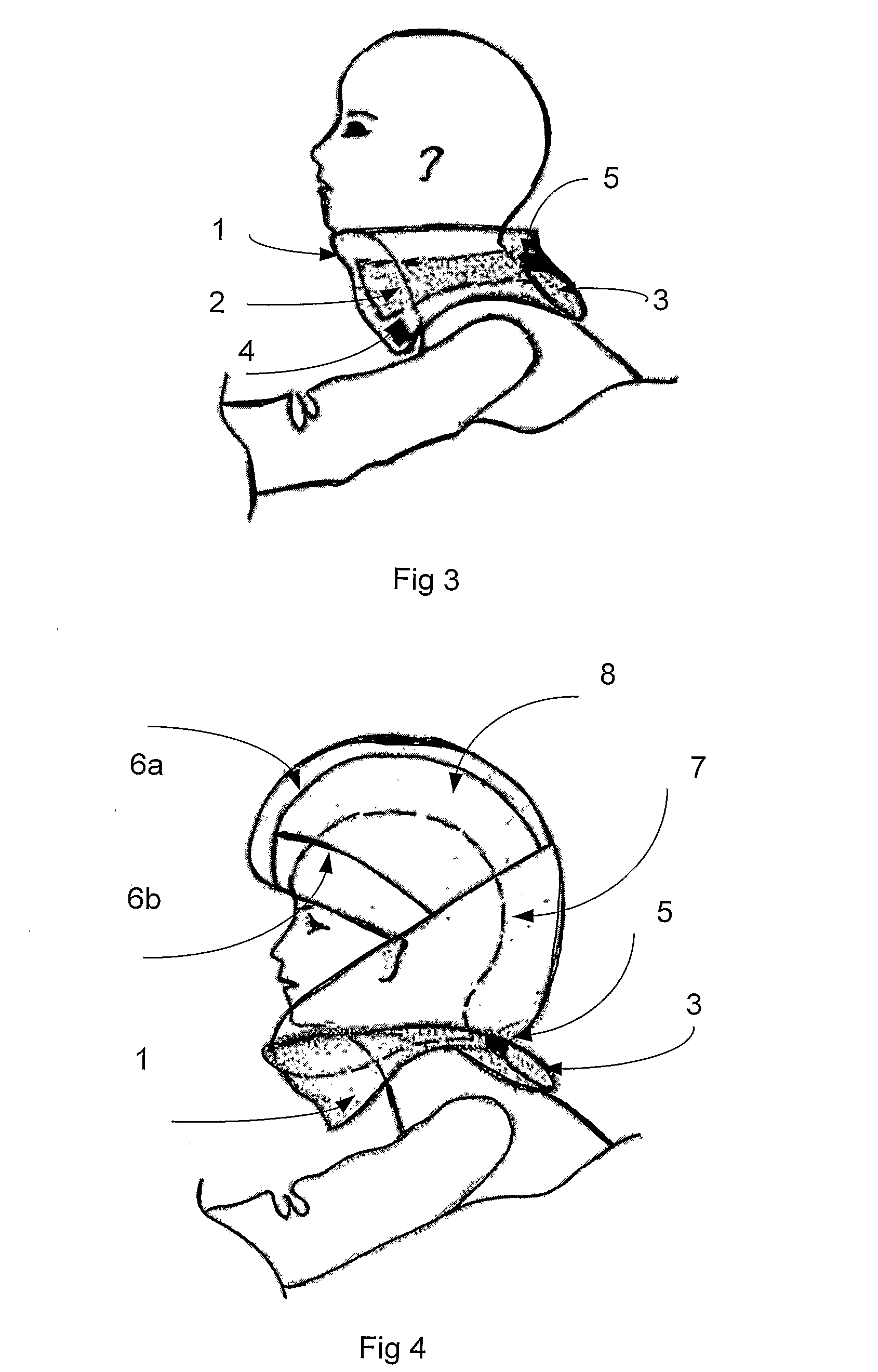

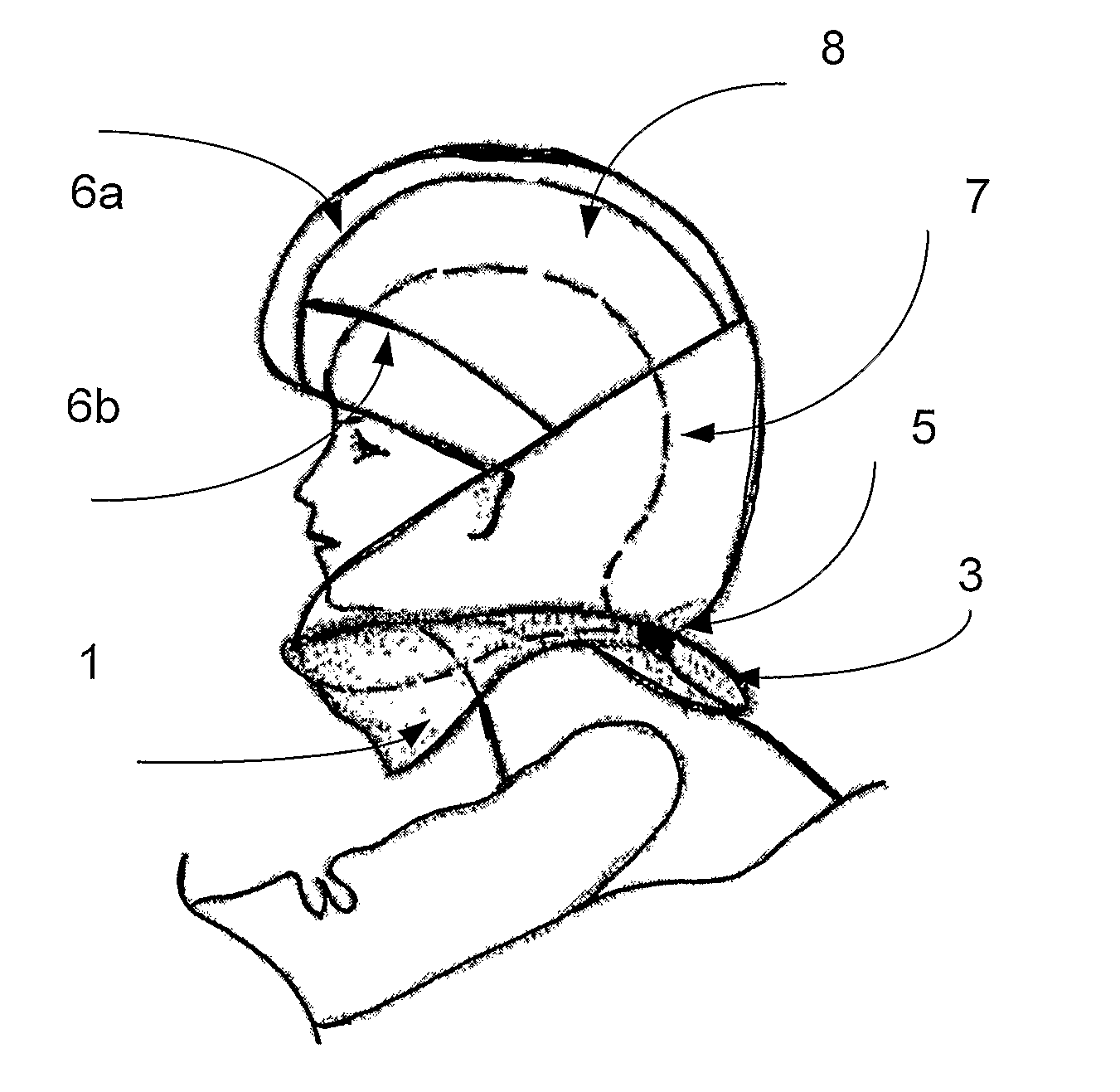

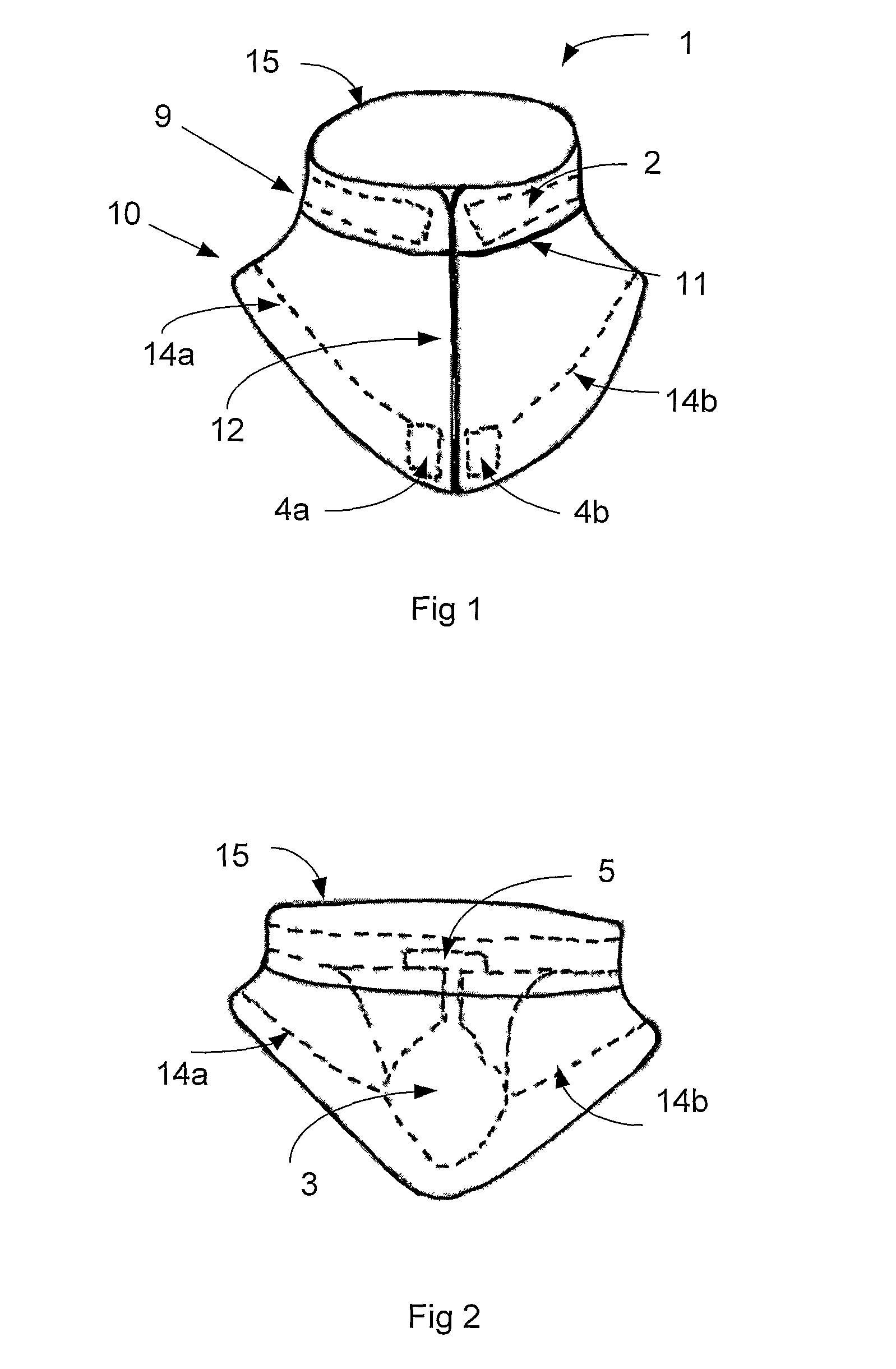

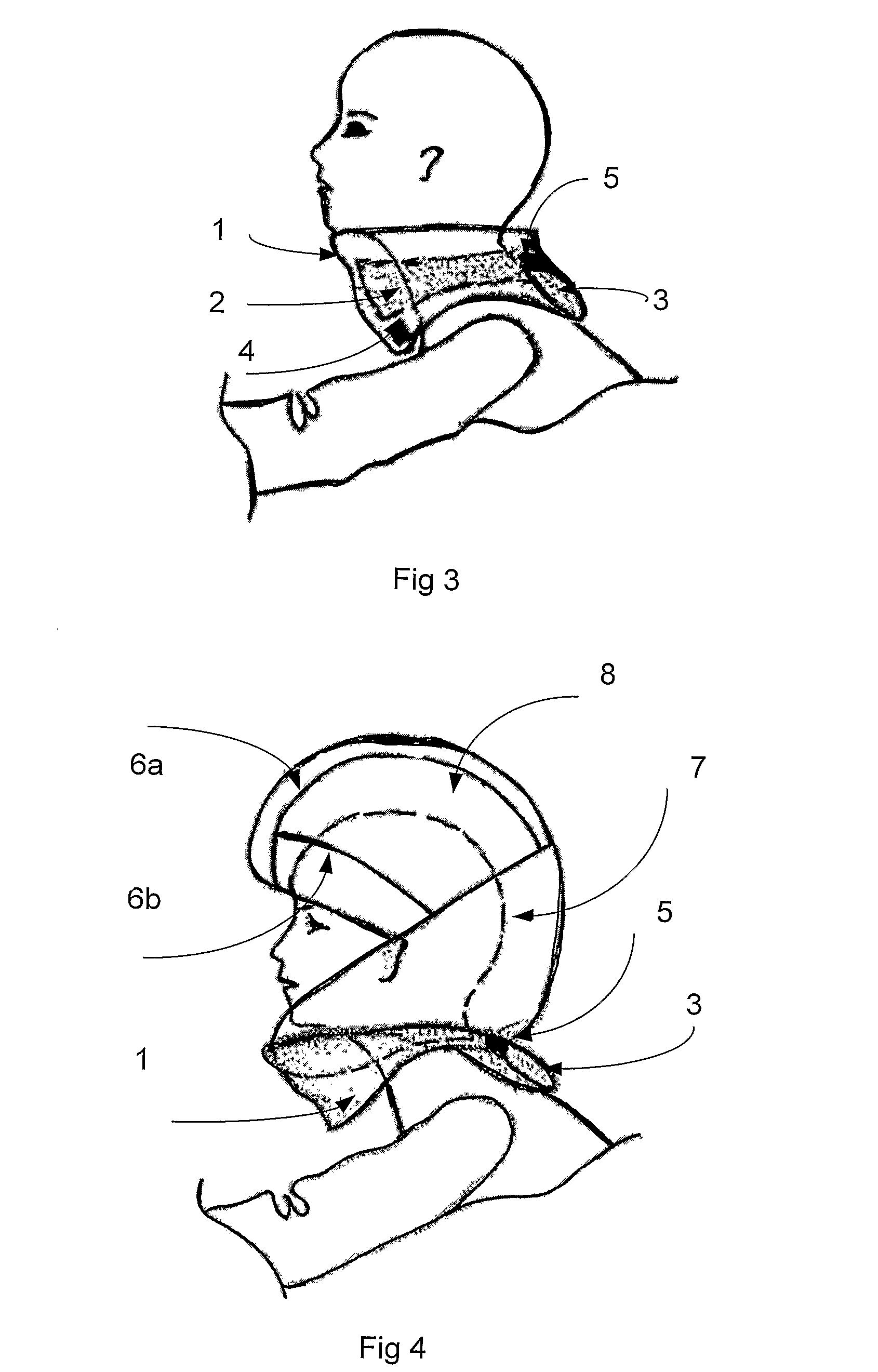

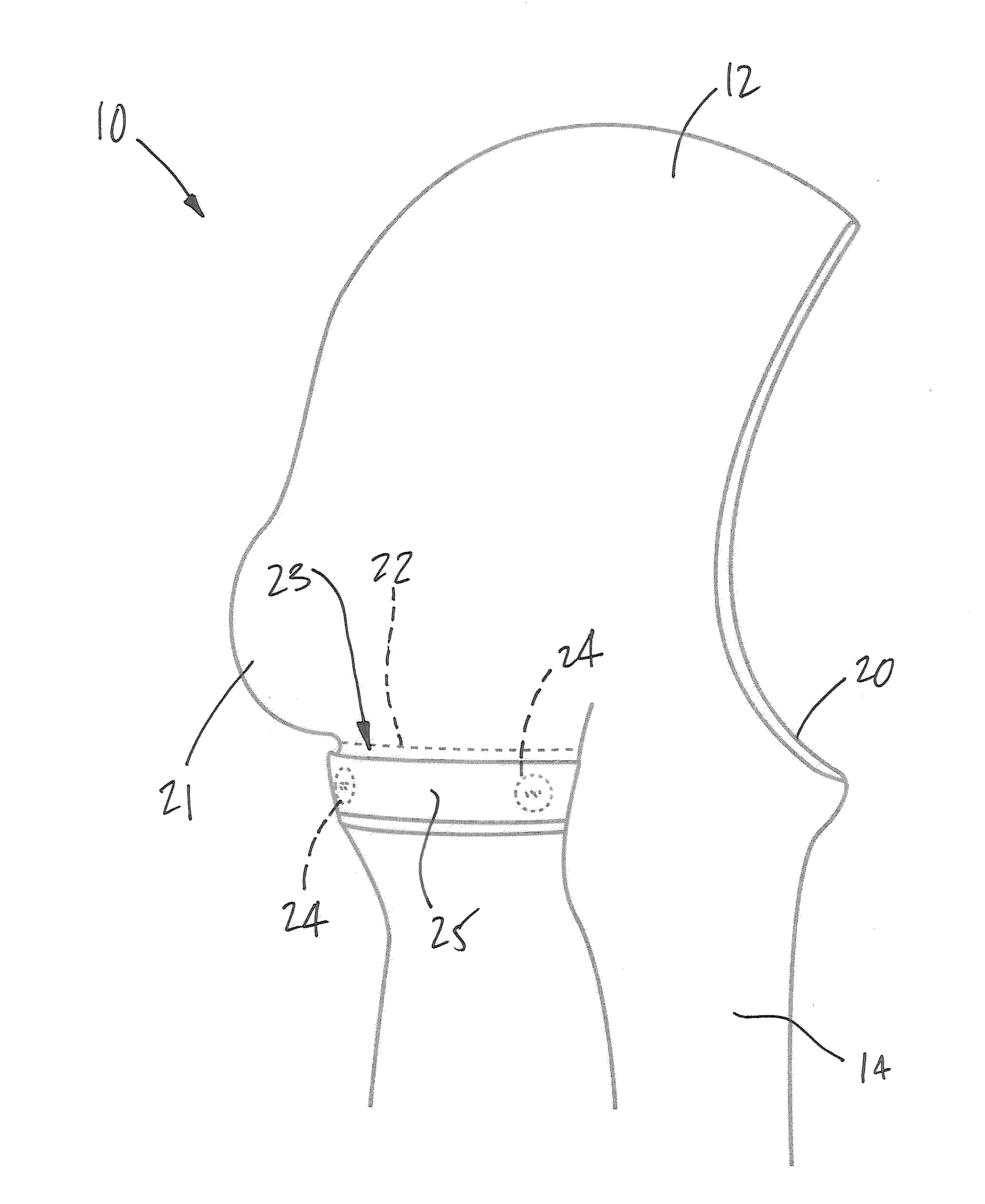

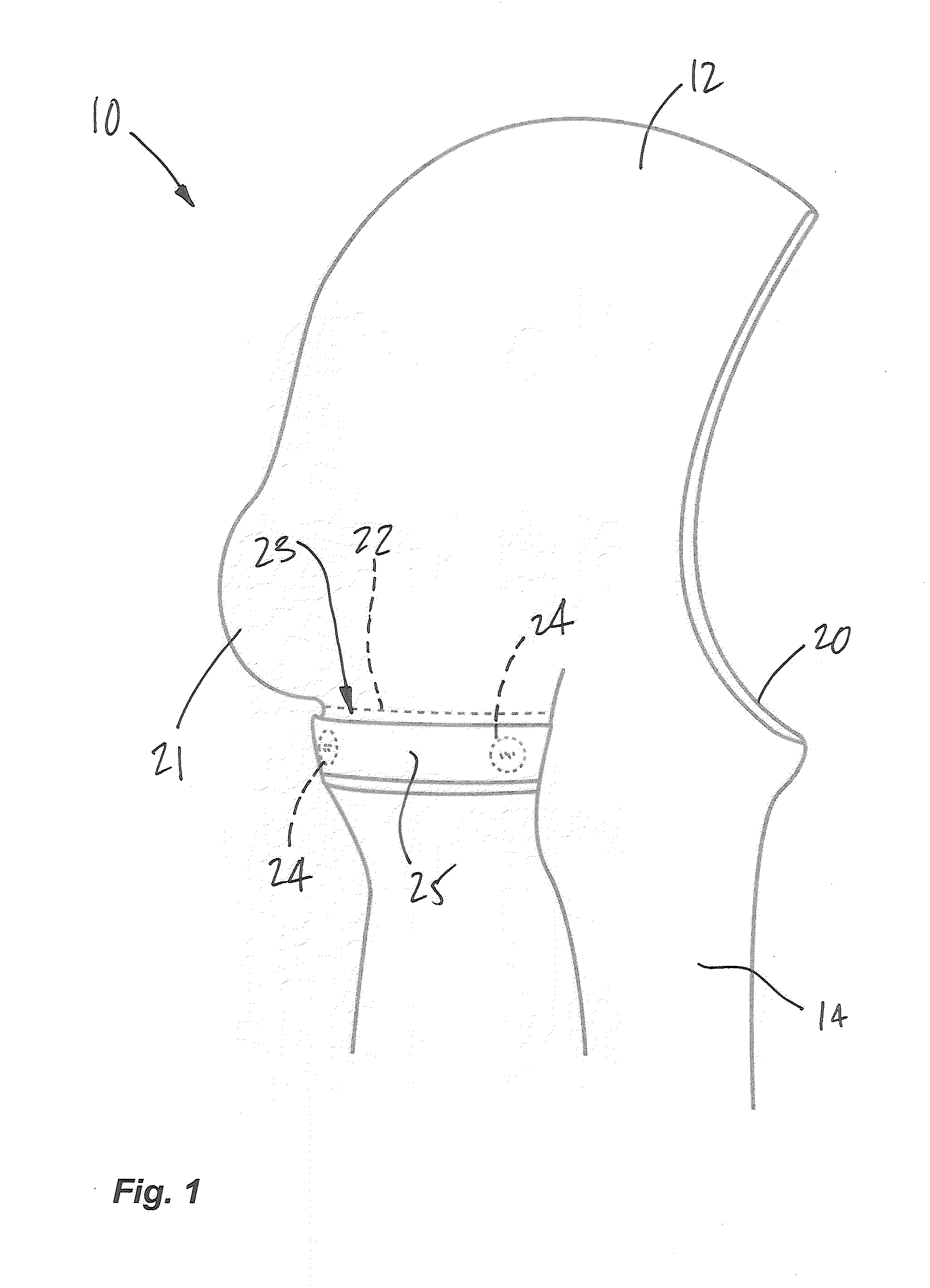

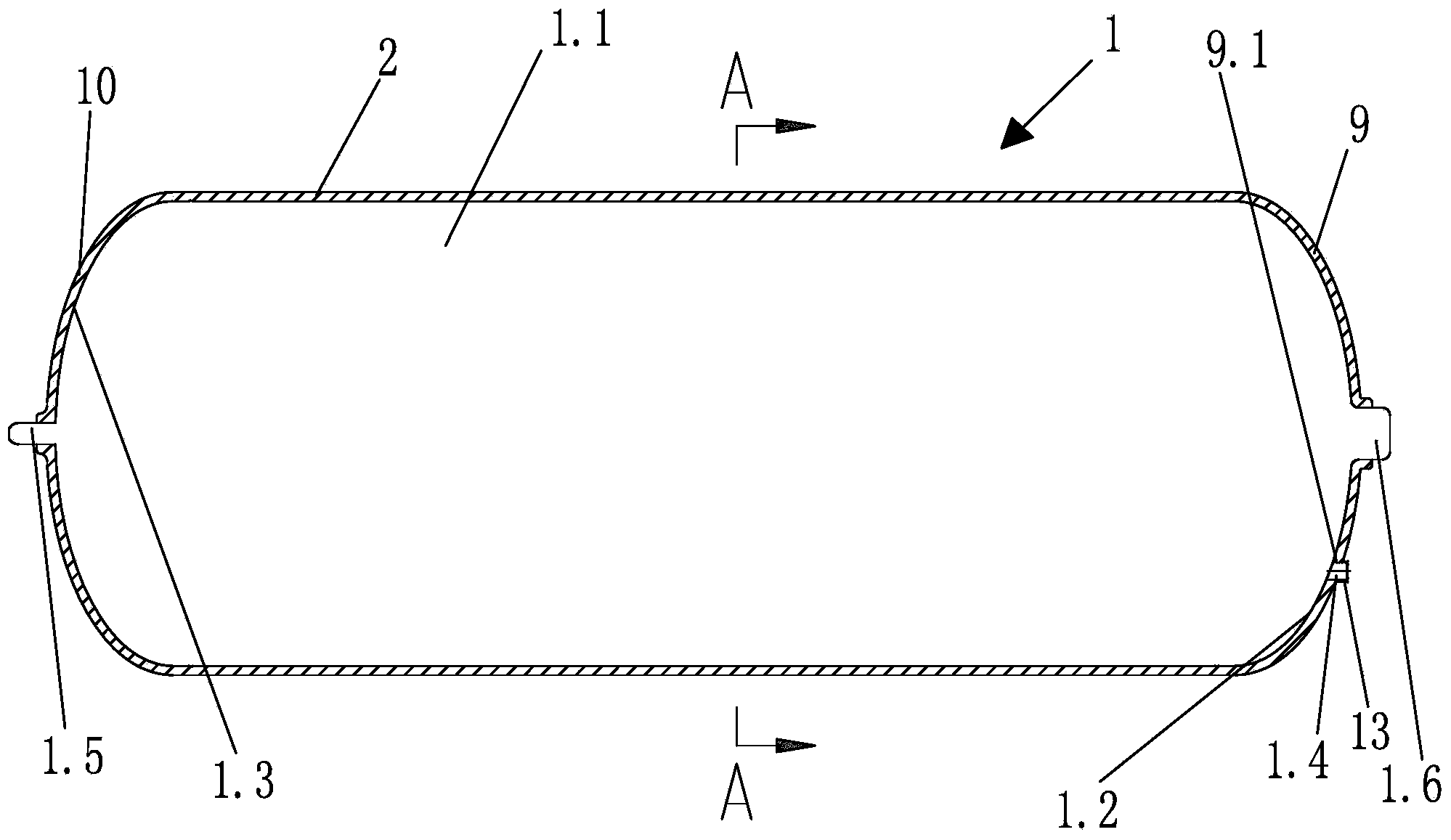

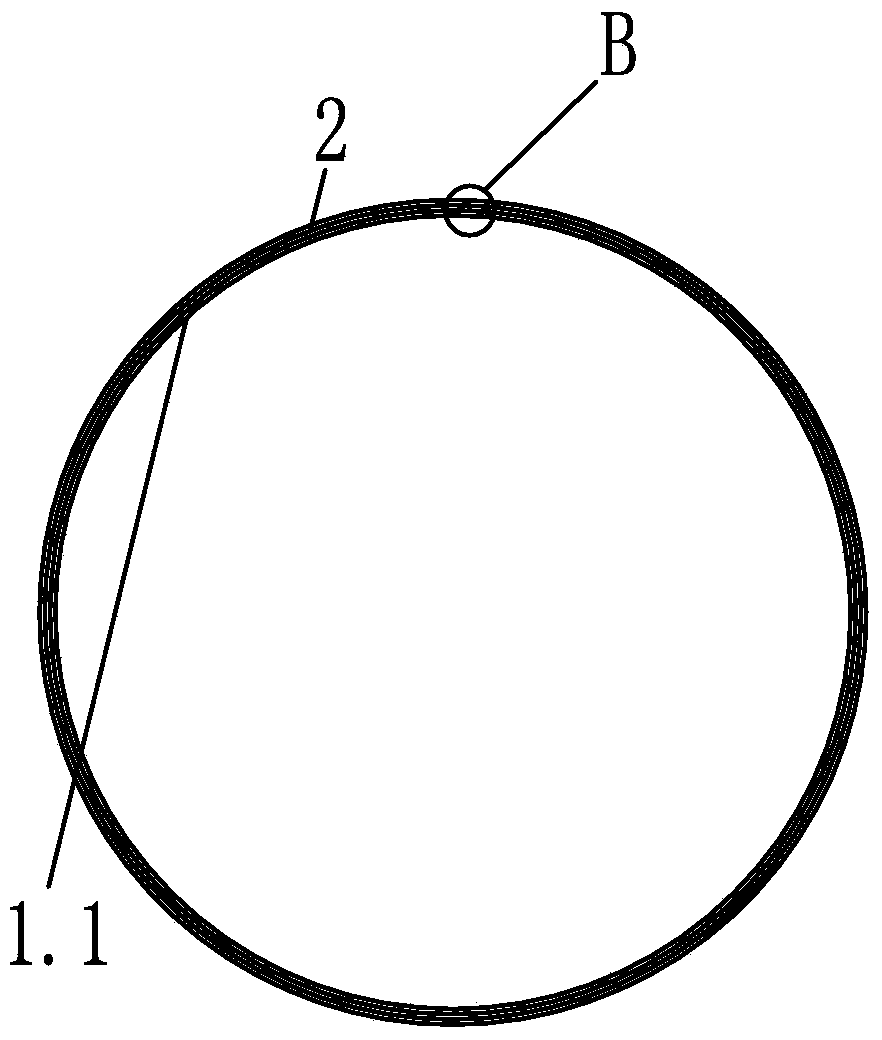

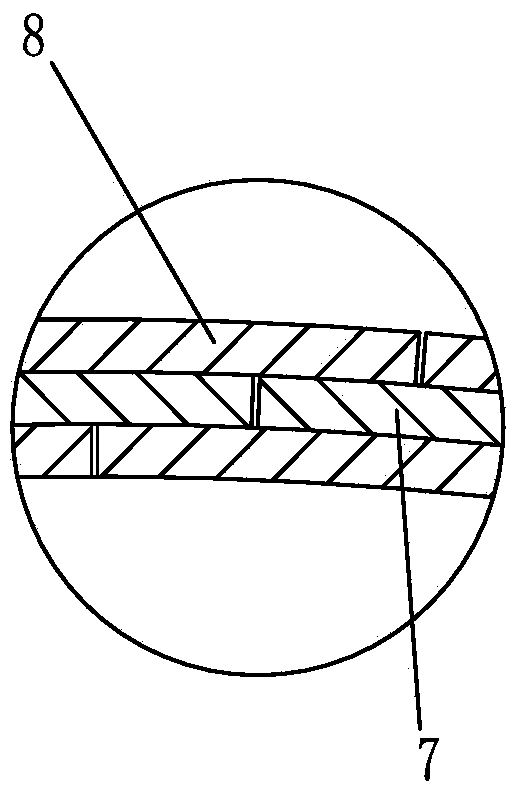

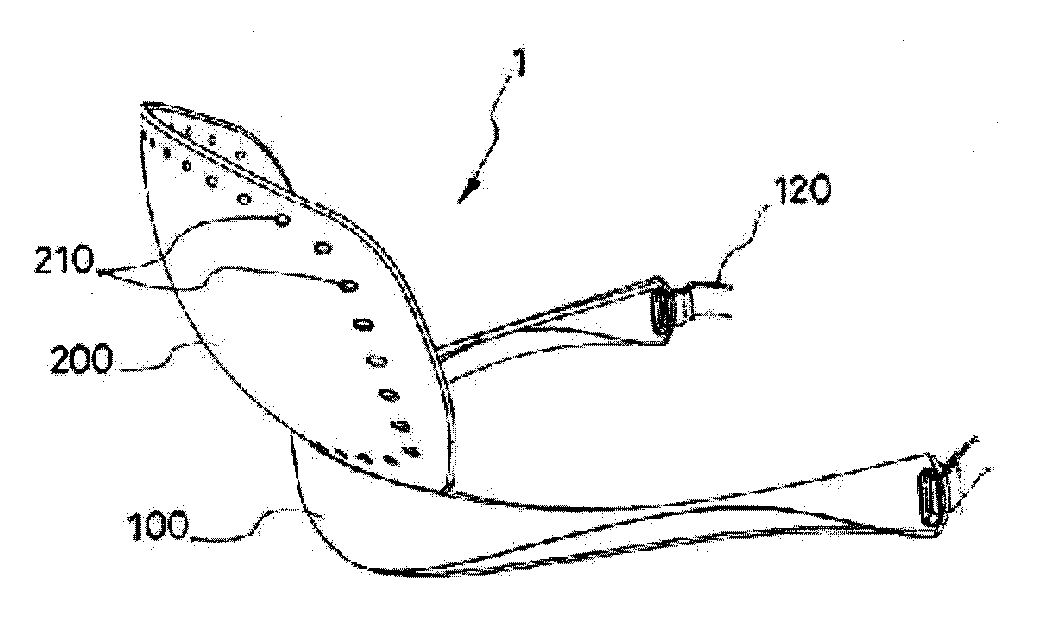

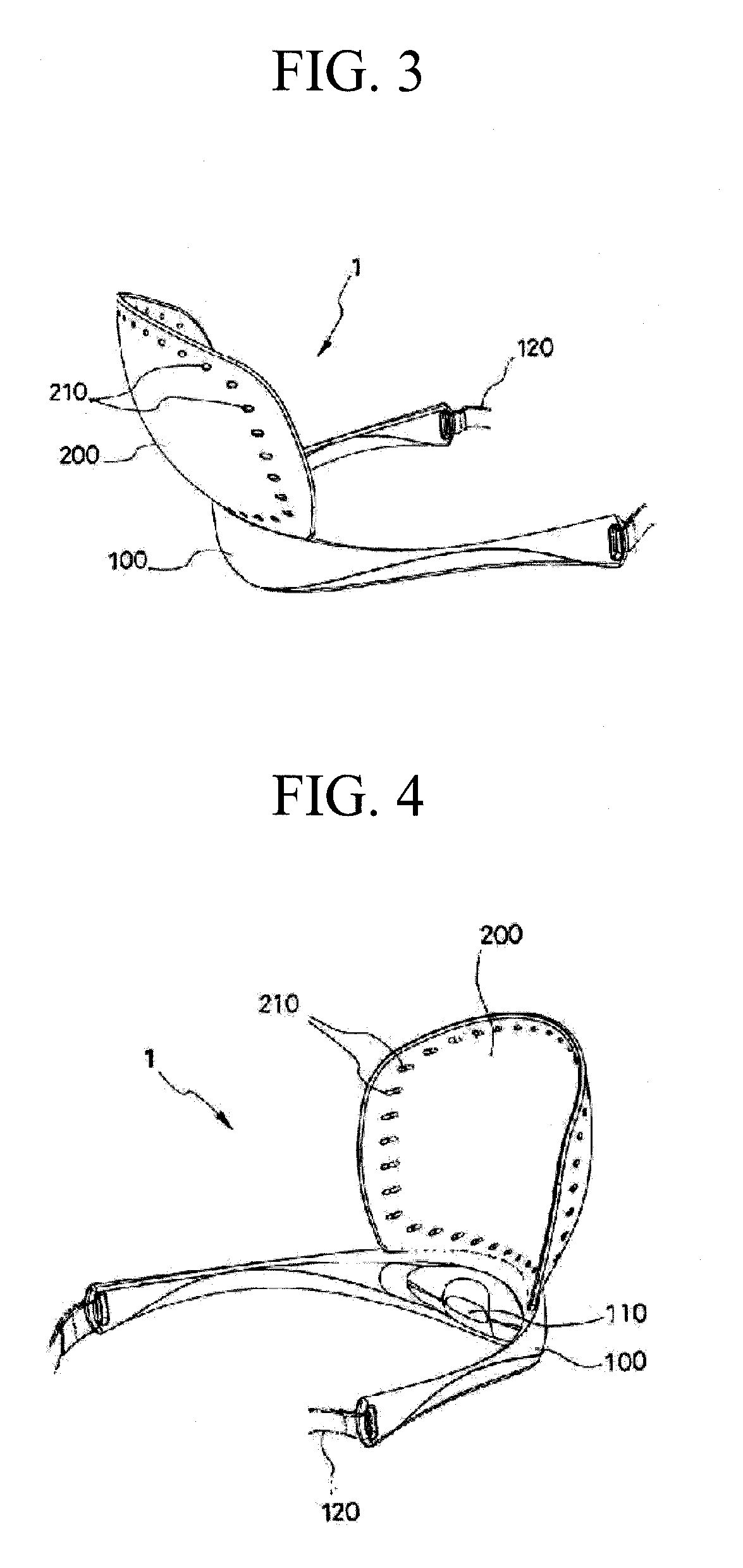

System and Method for Protecting a Bodypart

ActiveUS20080282453A1Mitigate, alleviate or eliminate one or more of the above-identified deficienciesEye treatmentHatsEngineeringAbnormal movements

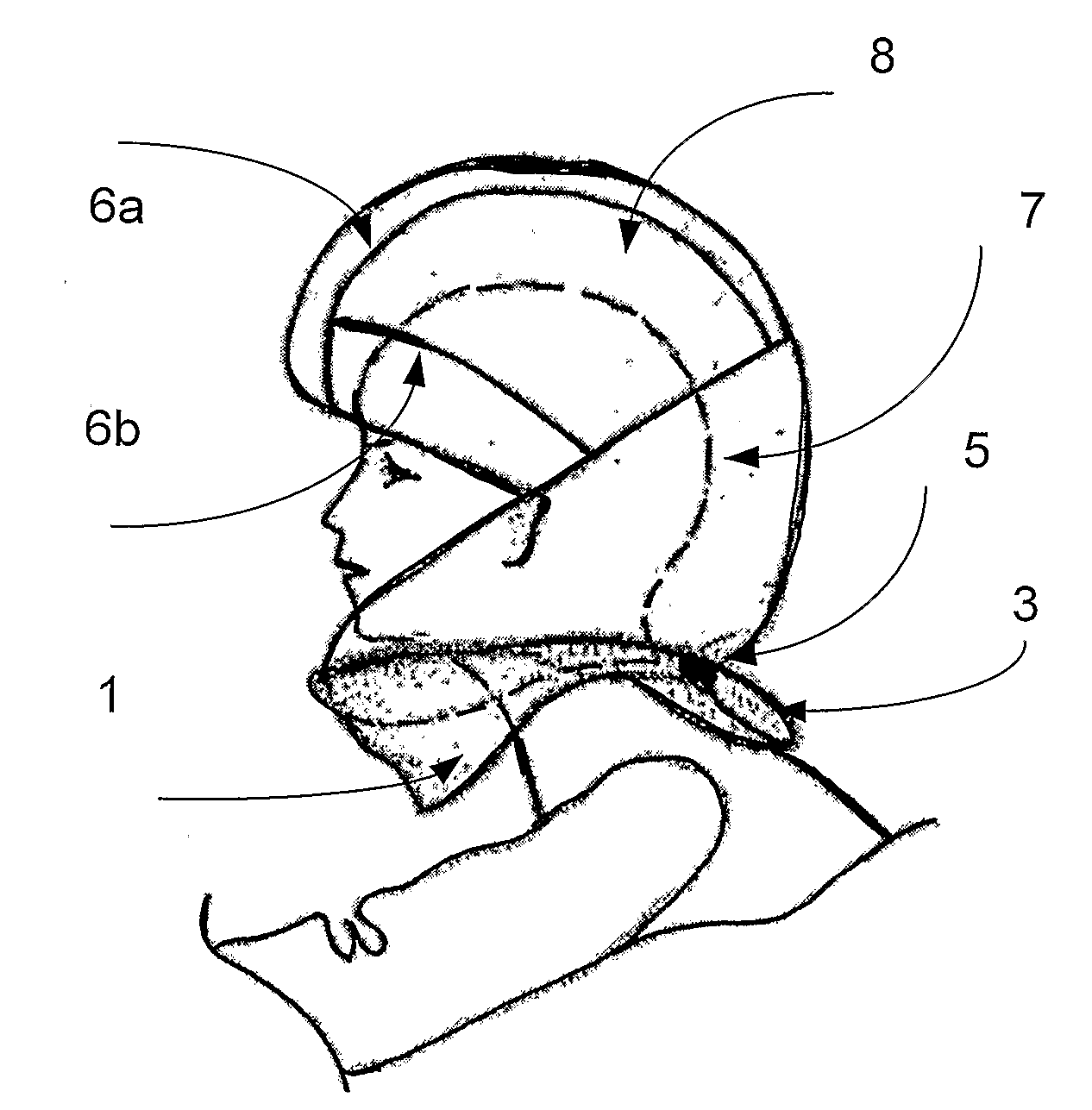

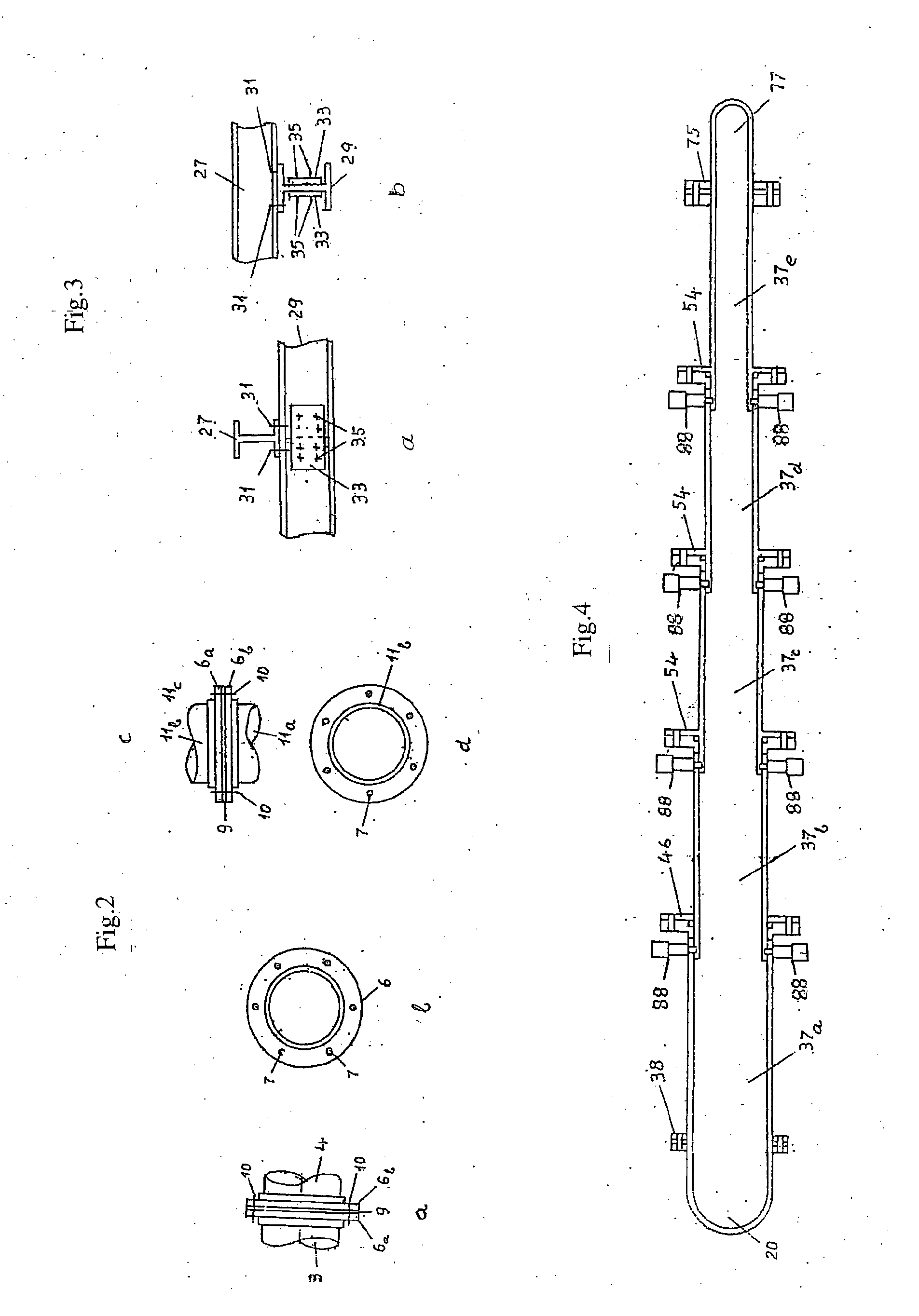

A system and a method for protecting the head of a user in case of an abnormal movement, such as a fall or a collision. The system comprises an apparel (1), an airbag (2), an inflator (3), and a trigger. The airbag includes a first part (7) for surrounding the neck and back head portion of the user after inflation, and a second part (8) for forming a hood surrounding the skull of the user after inflation. The first part (7) and second part (8) are folded and arranged in the apparel (1) before inflation. The apparel is arranged around the neck of the user, like for example a collar or a scarf.

Owner:HOEVDING SVERIGE AB

System and method for protecting a bodypart

ActiveUS8402568B2Mitigate, alleviate or eliminate one or more of the above-identified deficienciesEye treatmentHatsEngineeringAirbag

A system and a method for protecting the head of a user in case of an abnormal movement, such as a fall or a collision. The system comprises an apparel (1), an airbag (2), an inflator (3), and a trigger. The airbag includes a first part (7) for surrounding the neck and back head portion of the user after inflation, and a second part (8) for forming a hood surrounding the skull of the user after inflation. The first part (7) and second part (8) are folded and arranged in the apparel (1) before inflation. The apparel is arranged around the neck of the user, like for example a collar or a scarf.

Owner:HOEVDING SVERIGE AB

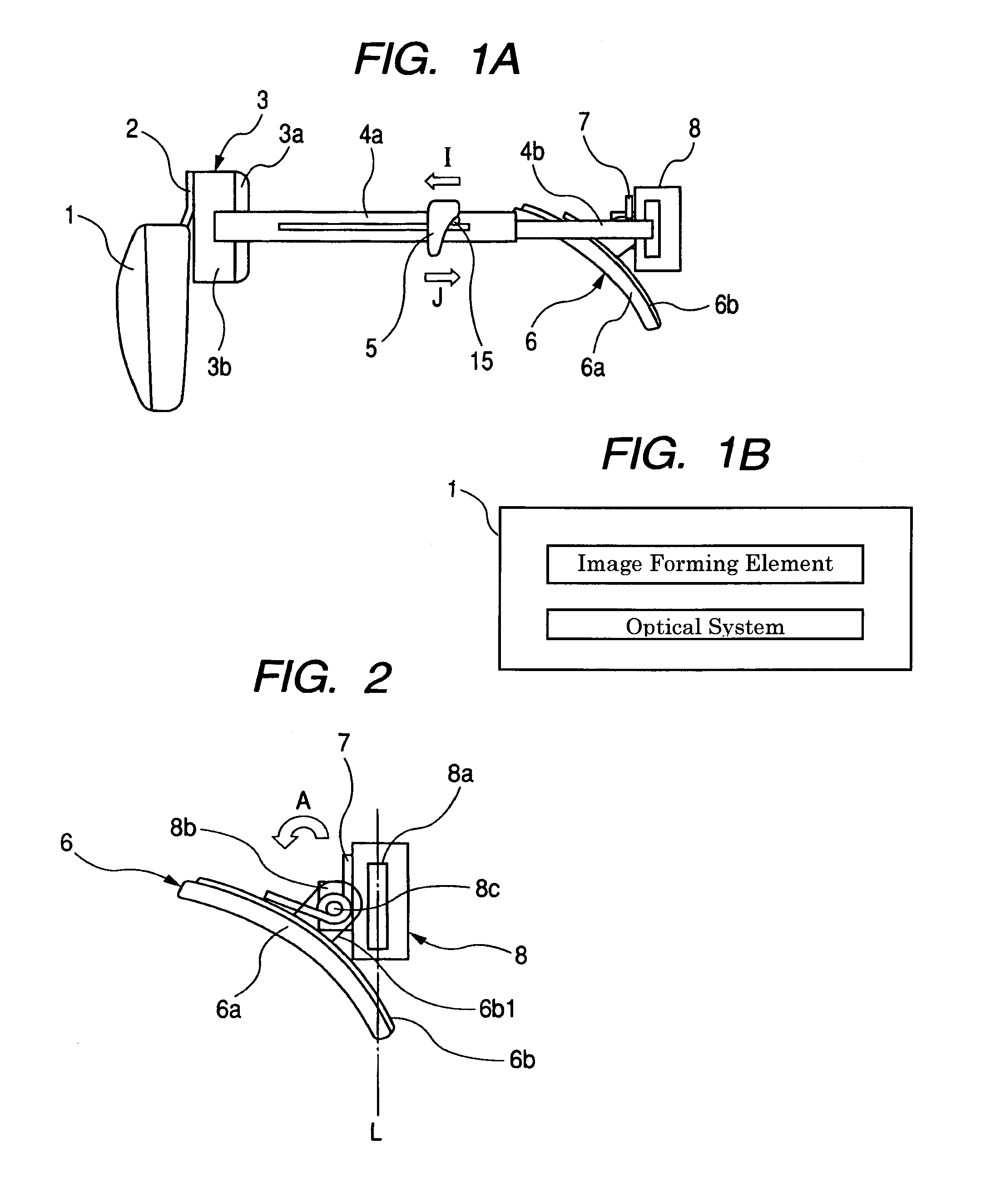

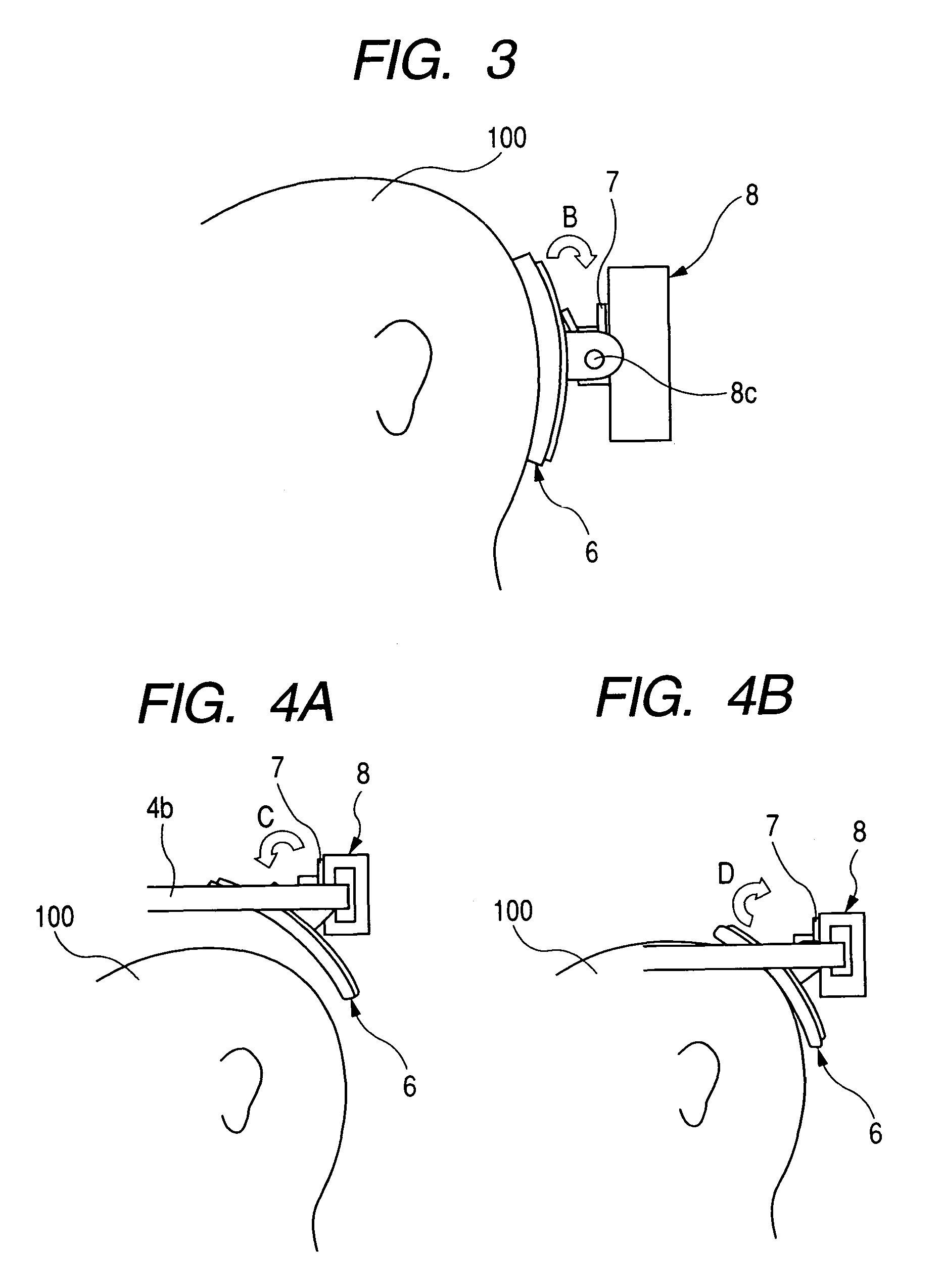

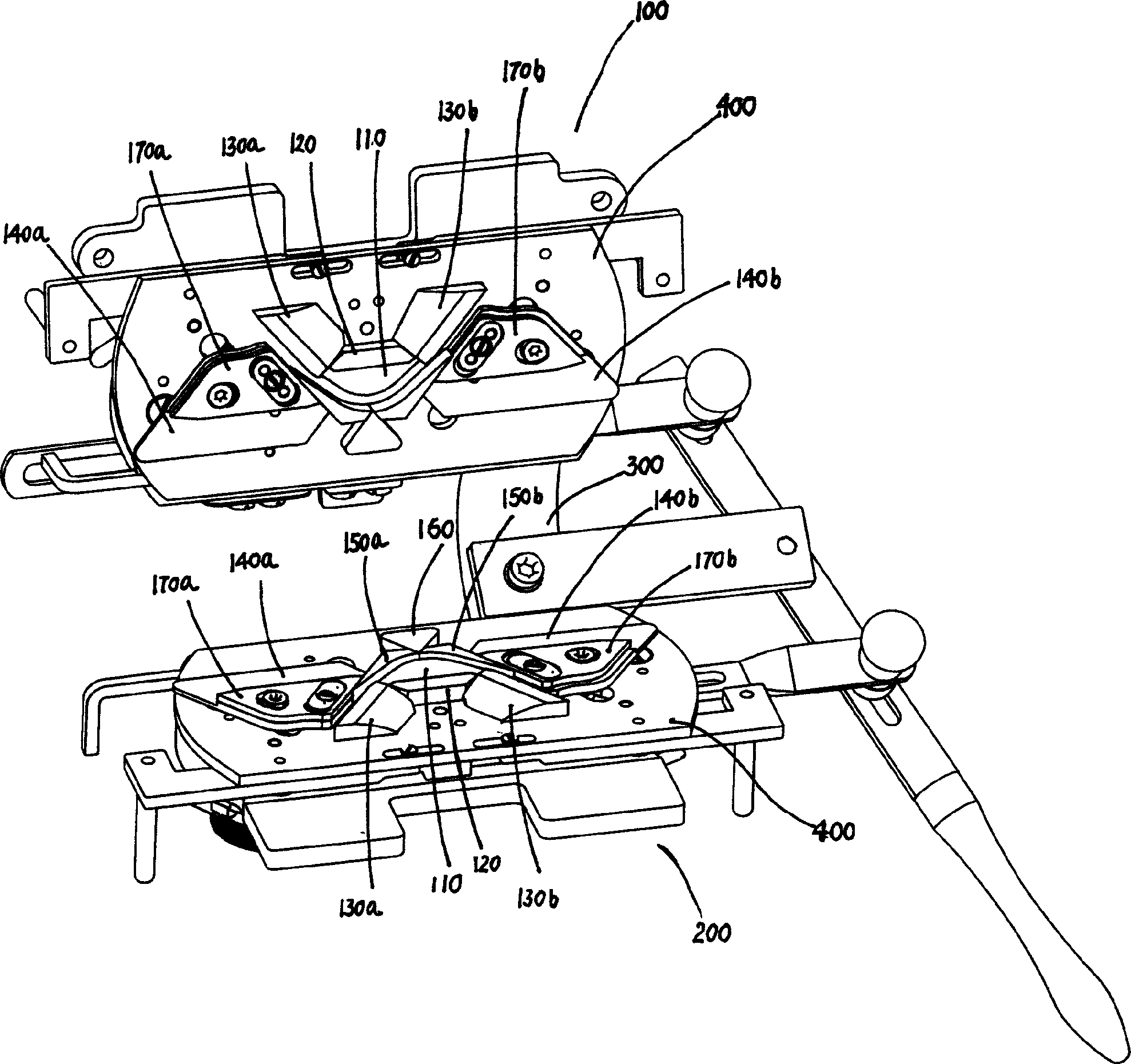

Head mounted device and head mounted system

Owner:CANON KK

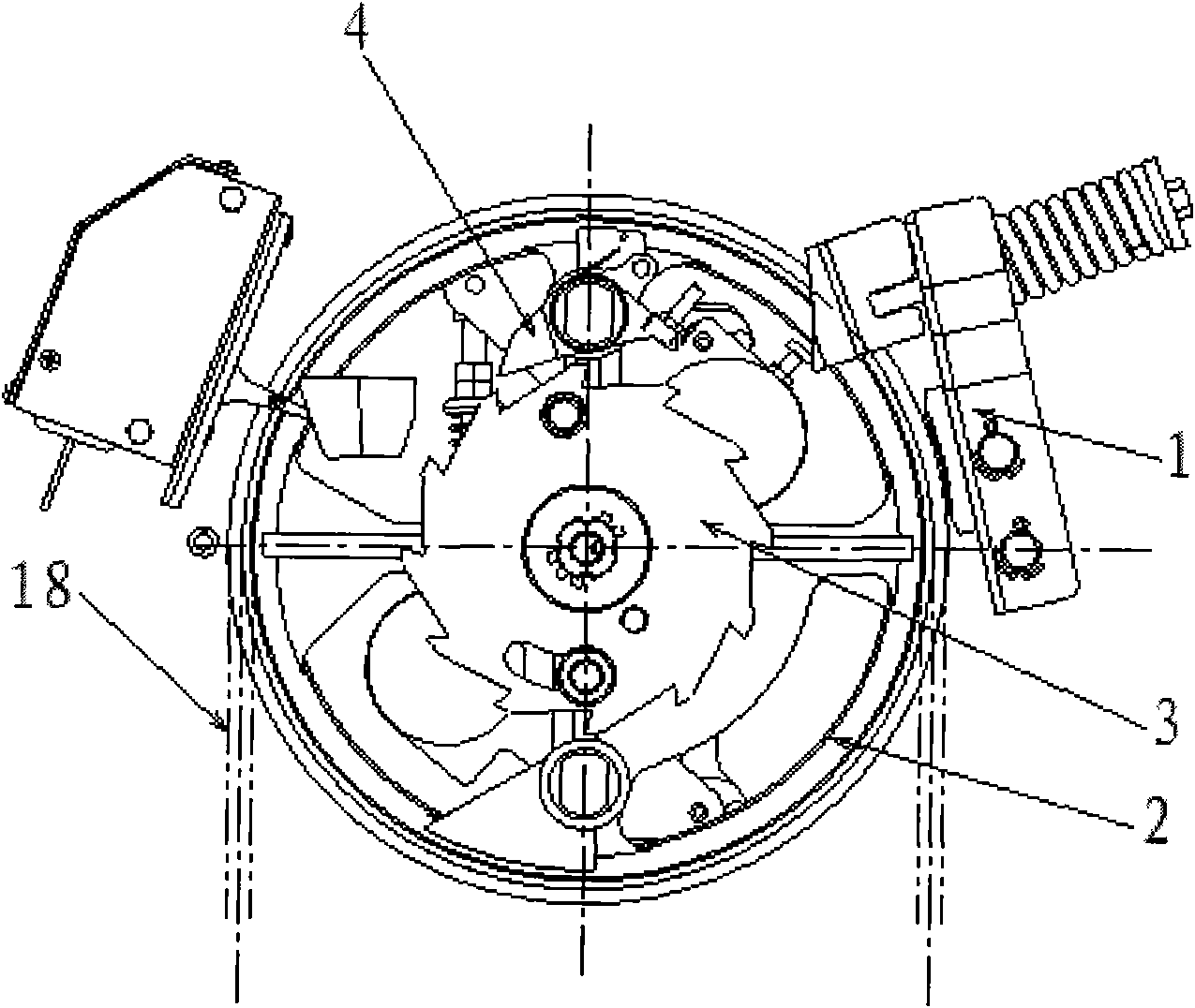

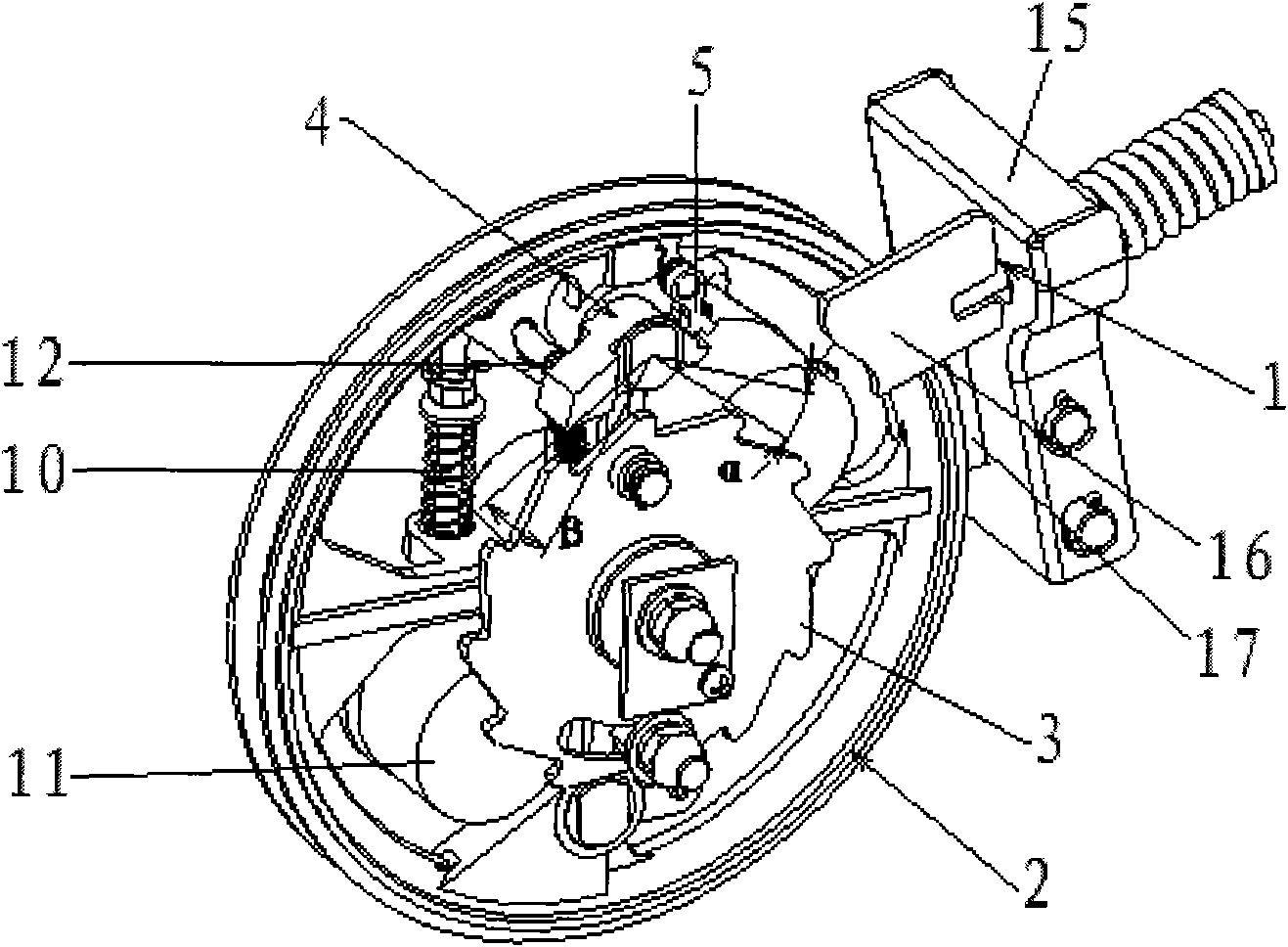

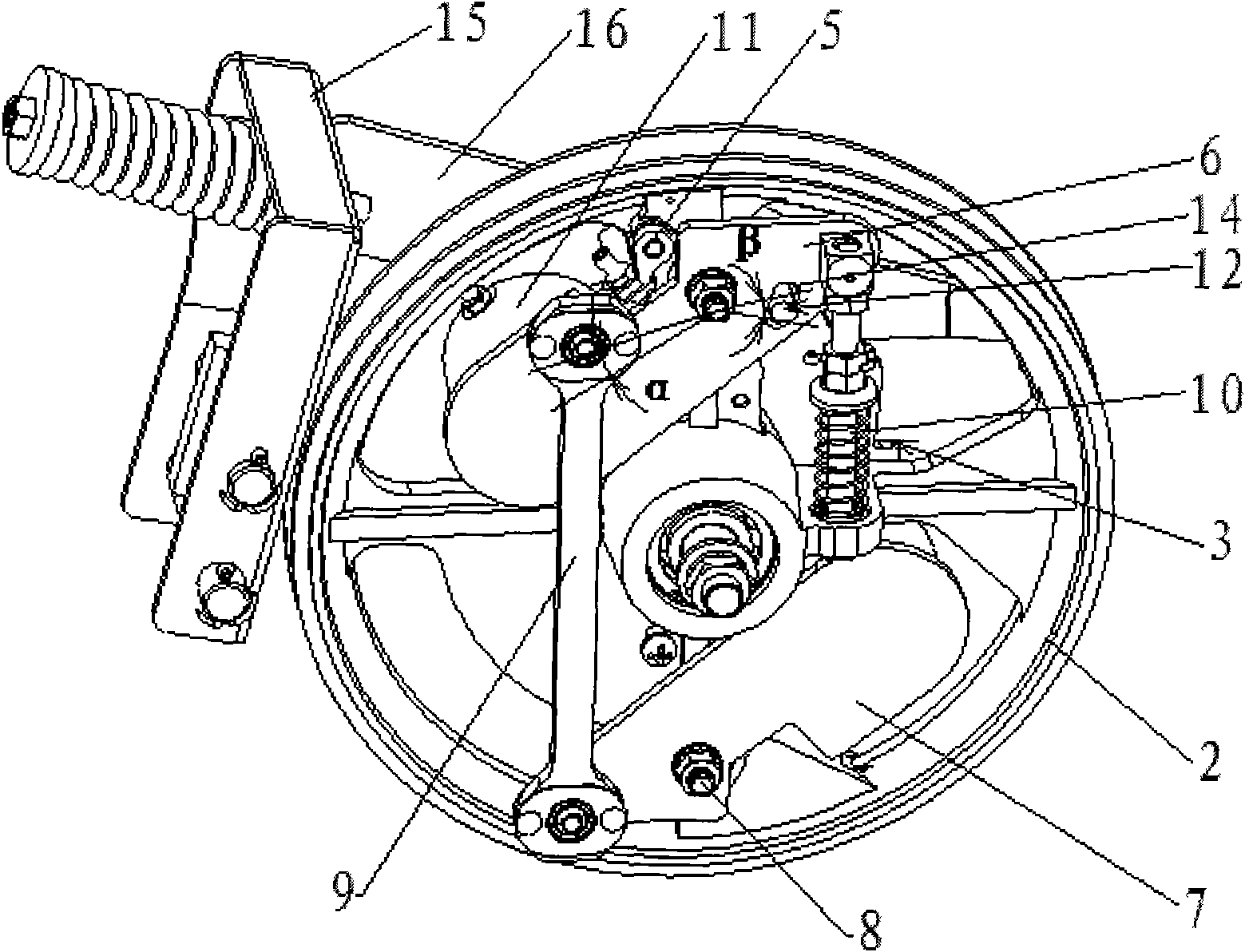

Machine-room-less speed limiter for elevator

InactiveCN101780910AIncrease the scope of supporting useWon't breakElevatorsHoisting equipmentsAgricultural engineeringTorsion spring

The invention relates to a machine-room-less speed limiter for an elevator, which comprises a frame; a limit switch, a brake mechanism, a steel rope wheel and a ratchet which are arranged on the frame; a centrifugal mechanism and a rotatable pawl which are arranged on the steel rope wheel; an anti-back head fork which is clamped against the tail end of the pawl; and a reset shaft pin and a spring, wherein the ratchet is in transmission connection with the brake mechanism; the centrifugal mechanism comprises an upper centrifugal piece, a lower centrifugal piece, two centrifugal hammer shafts, a connecting rod and a compression spring, and centrifugal heavy hammers are arranged at the front parts of the upper centrifugal piece and the lower centrifugal piece; the anti-back head fork is fixed on the steel rope wheel through a torsion spring, a transmission part which is in contact with the upper centrifugal piece is arranged on the anti-back head fork, and a circular arc hole is formed at the back part of the upper centrifugal piece; and one end of the reset shaft pin penetrates the circular arc hole and is fixed with the head end of the pawl, and the spring is tensed between the reset shaft pin and a wheel hub of the steel rope wheel. The machine-room-less speed limiter for the elevator has the advantages of safety, reliability and a wide range of applications.

Owner:上海三斯电子有限公司

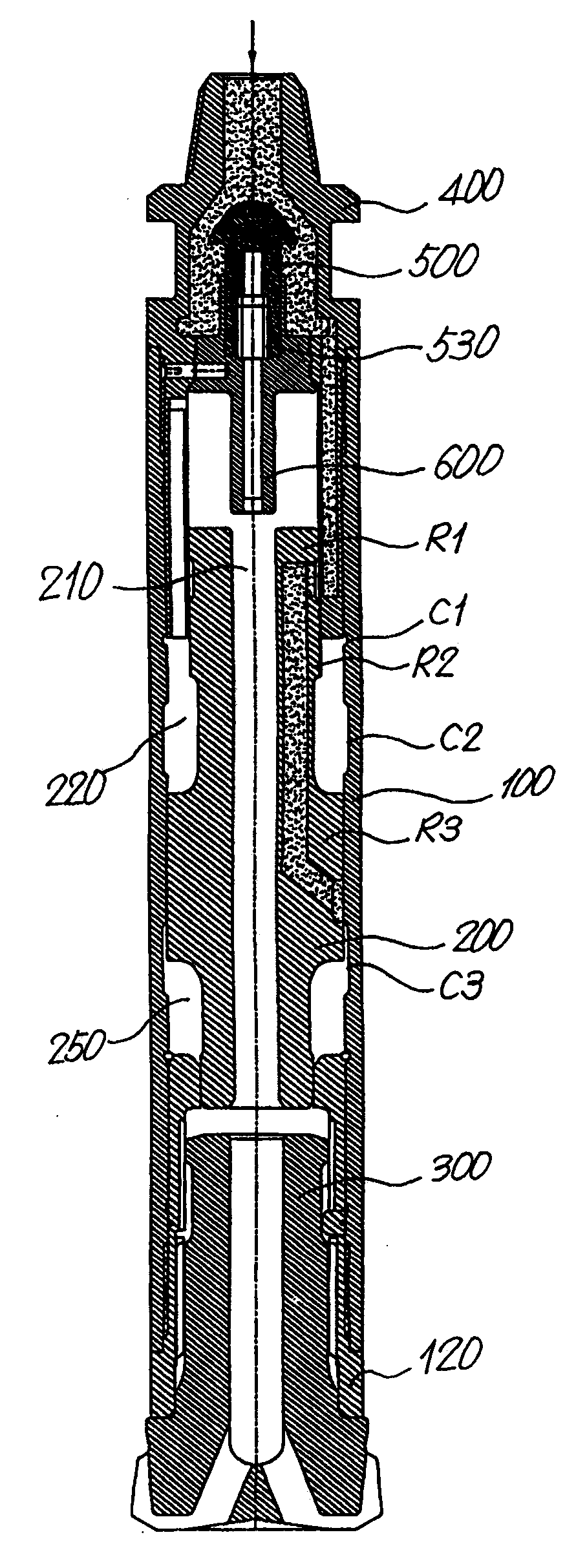

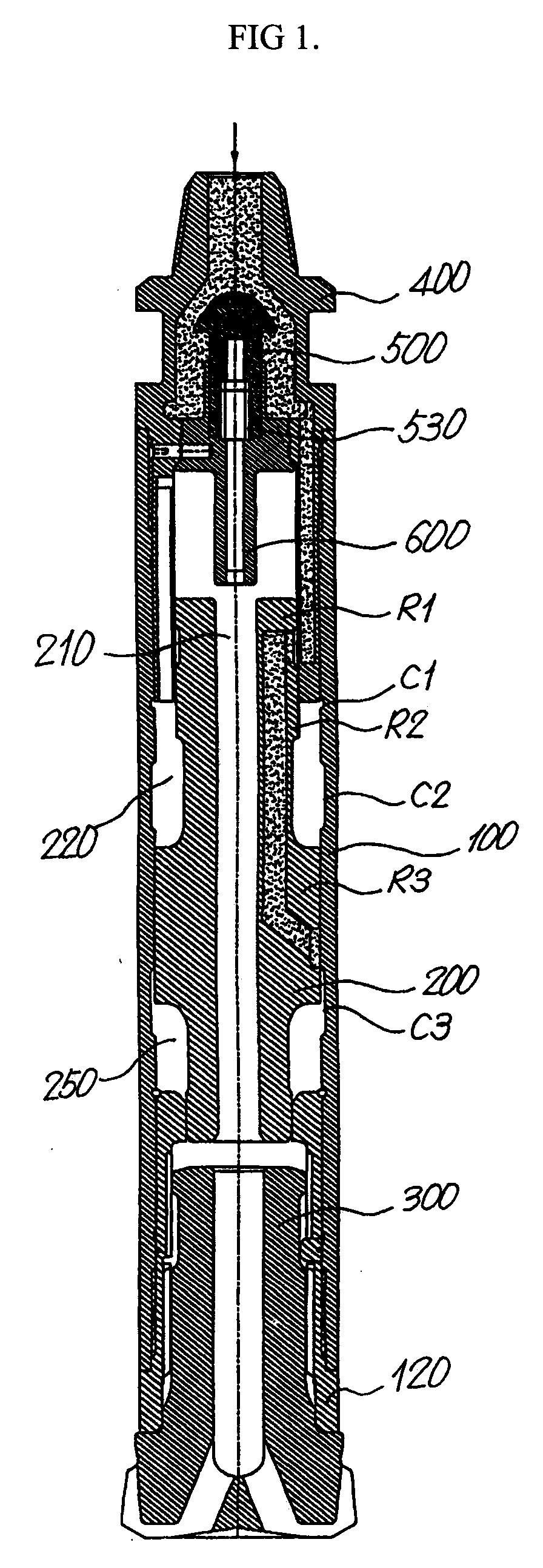

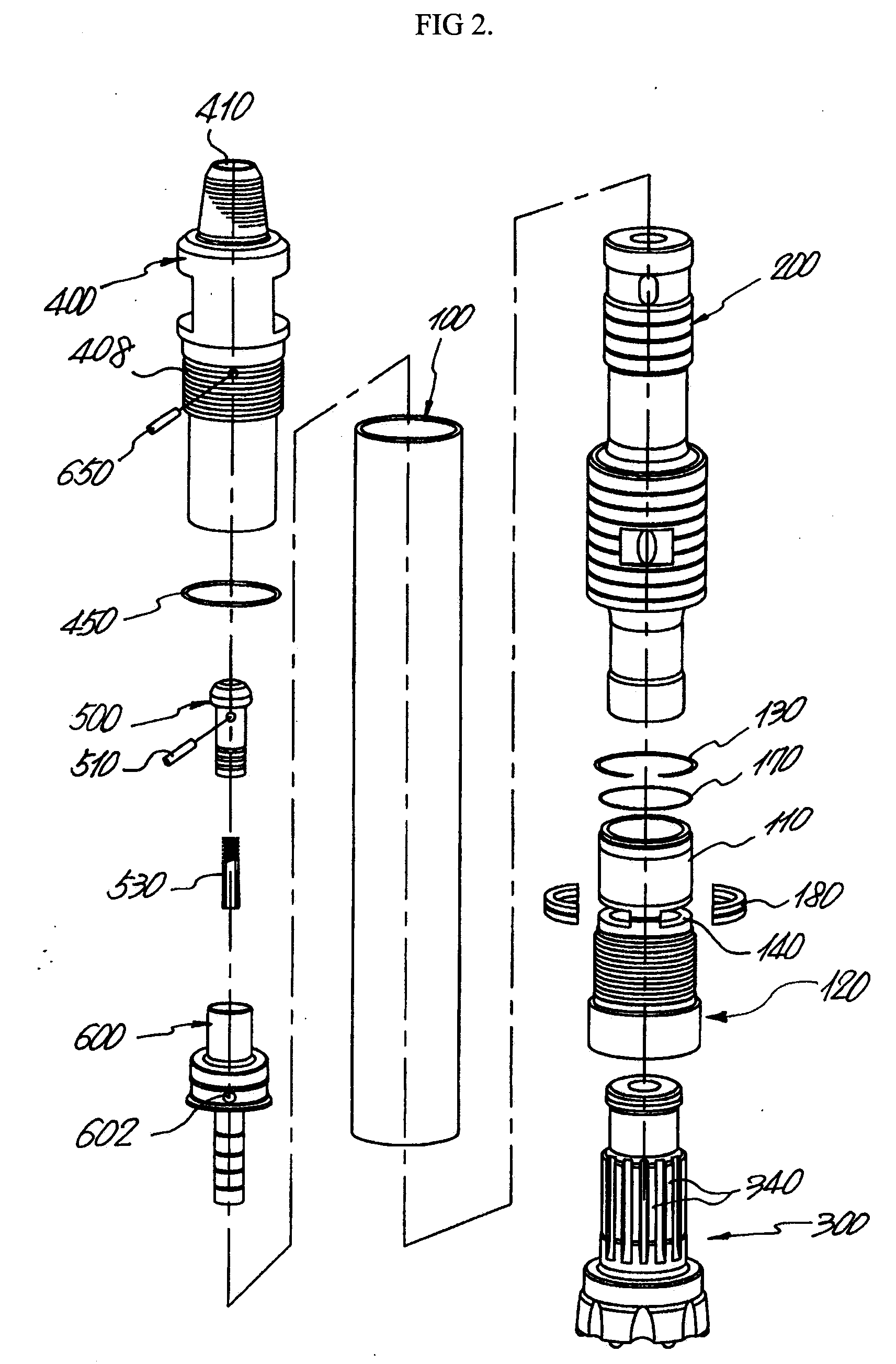

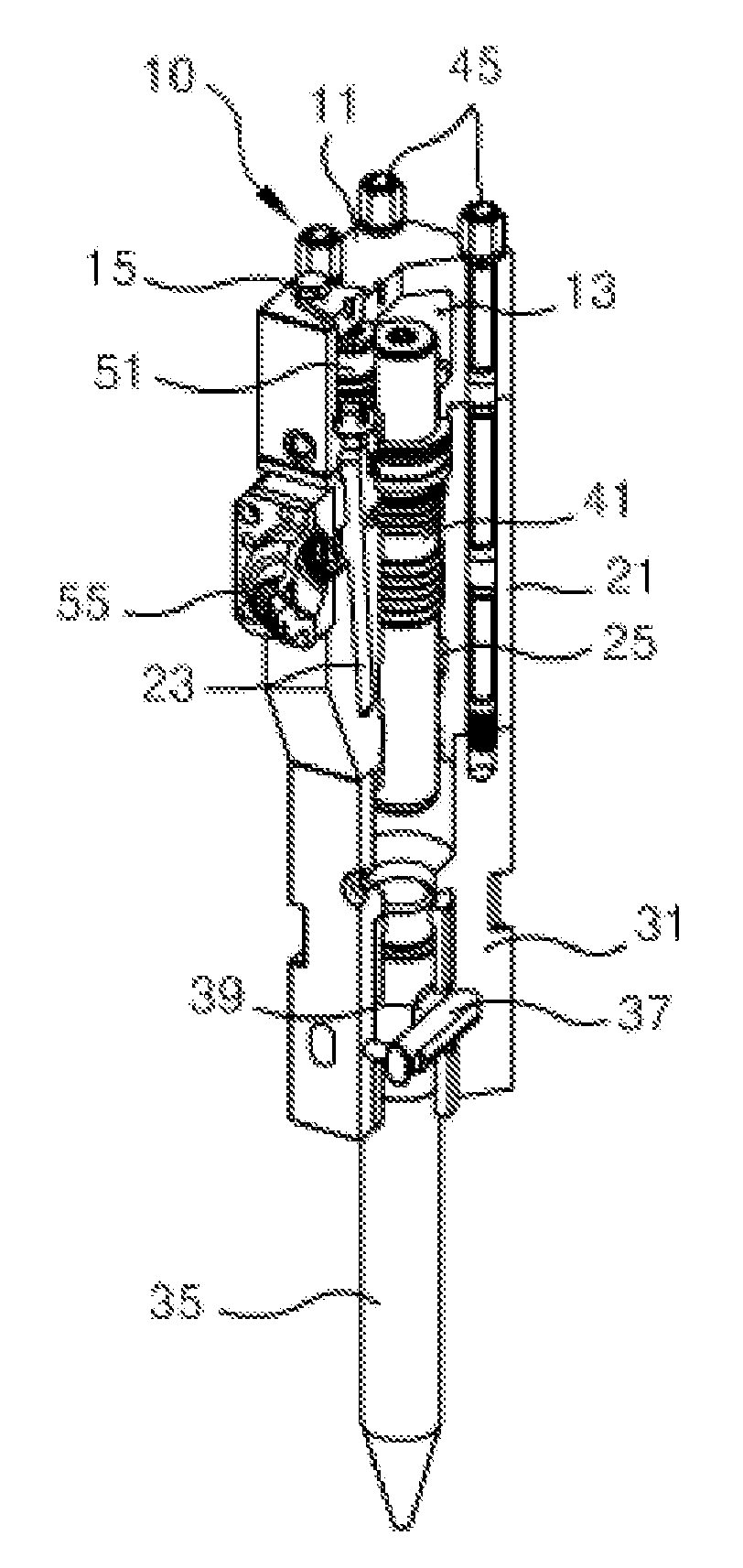

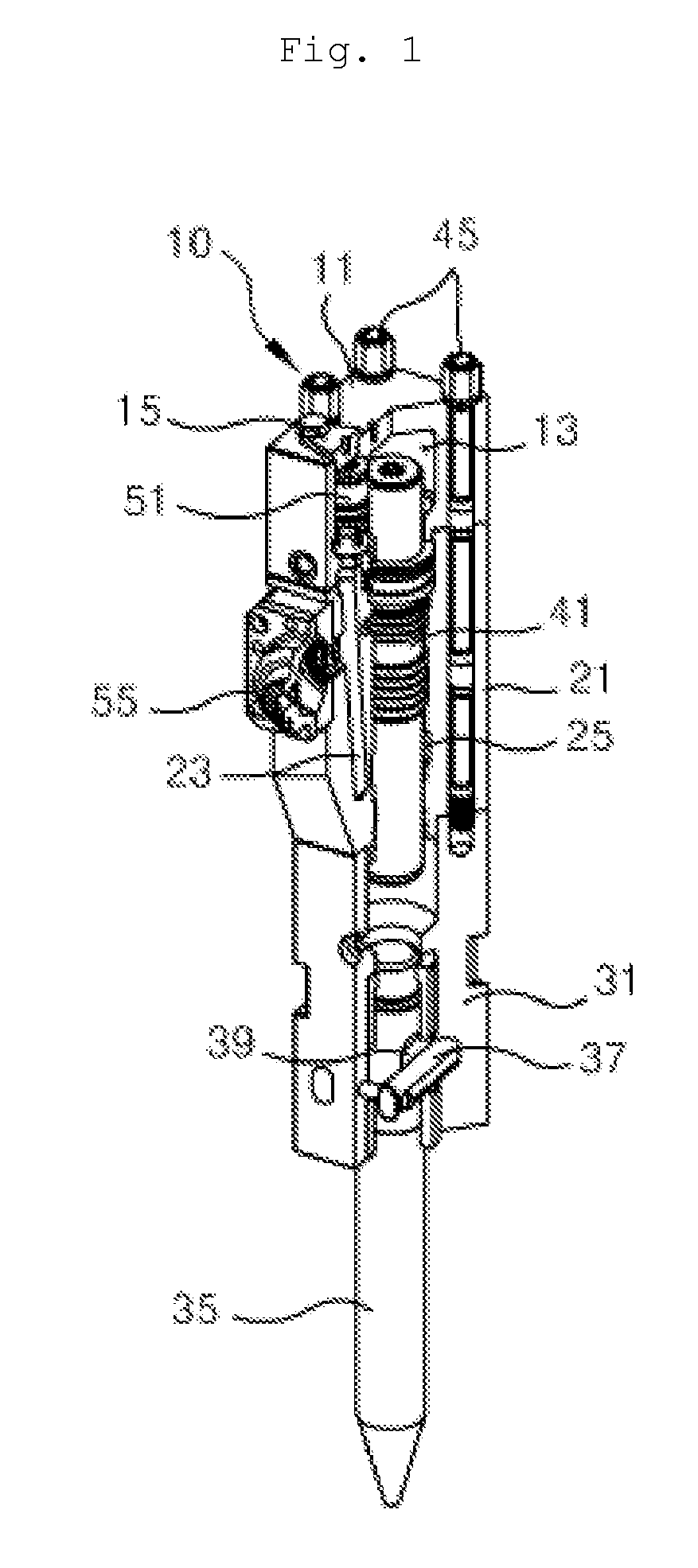

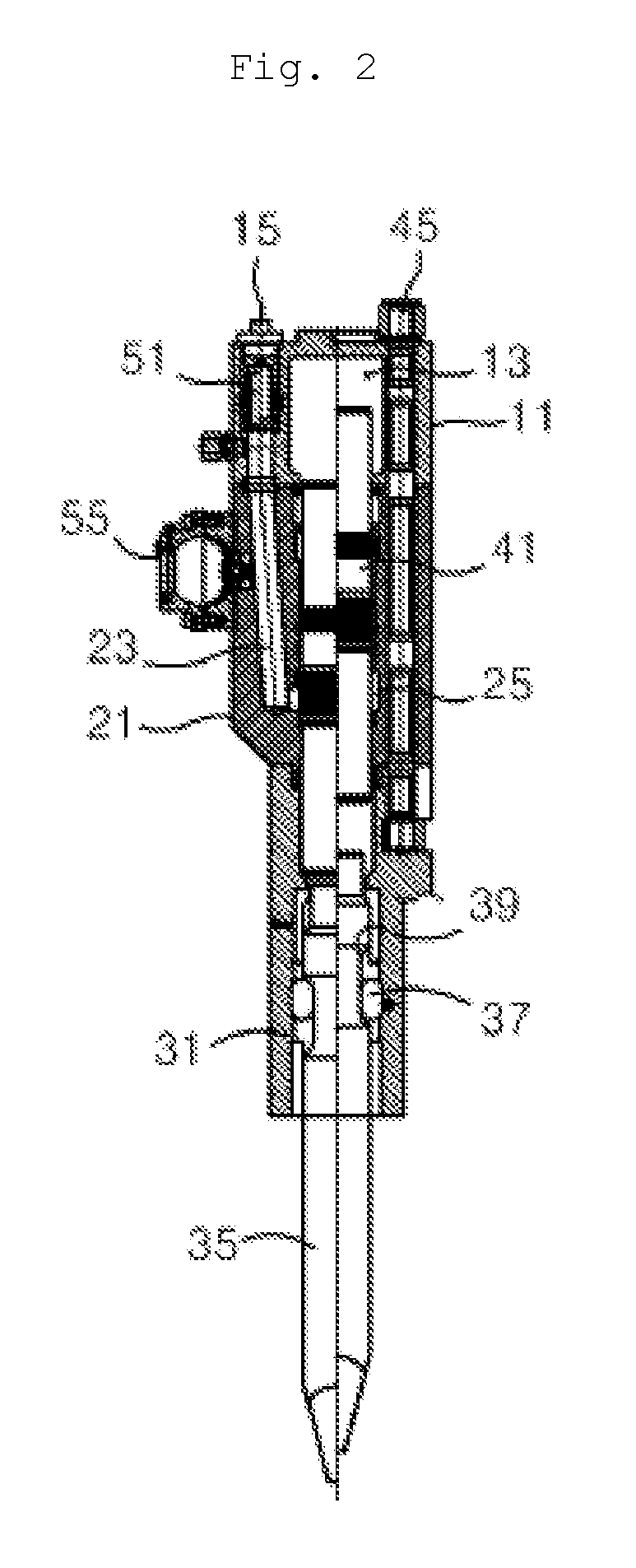

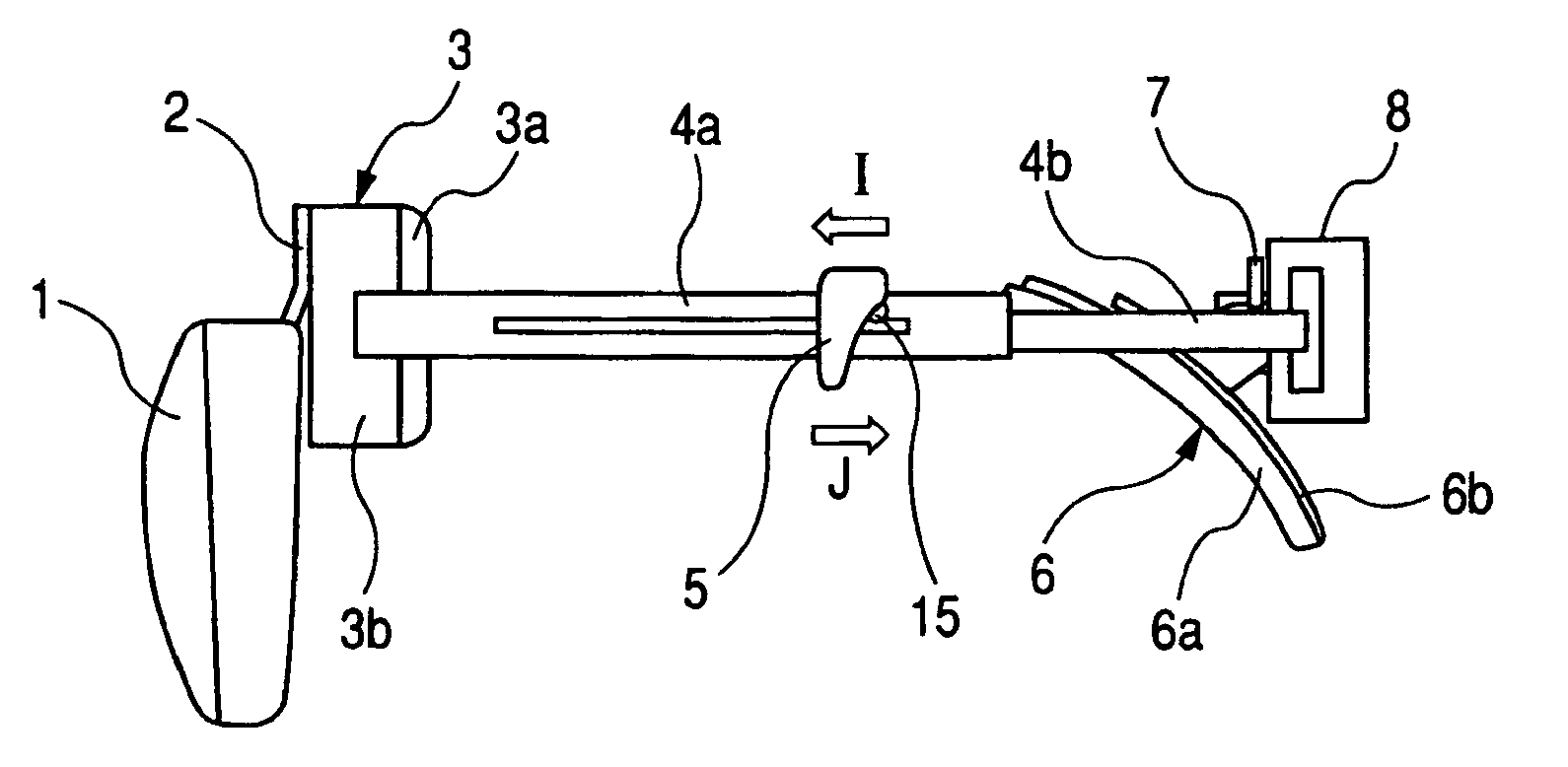

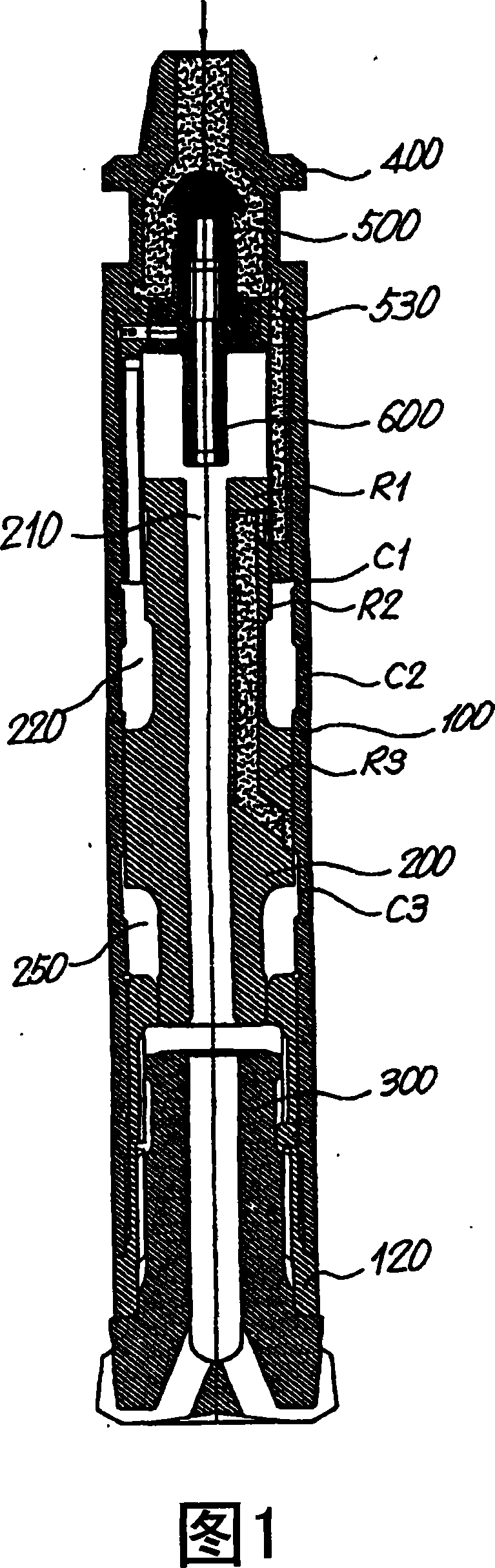

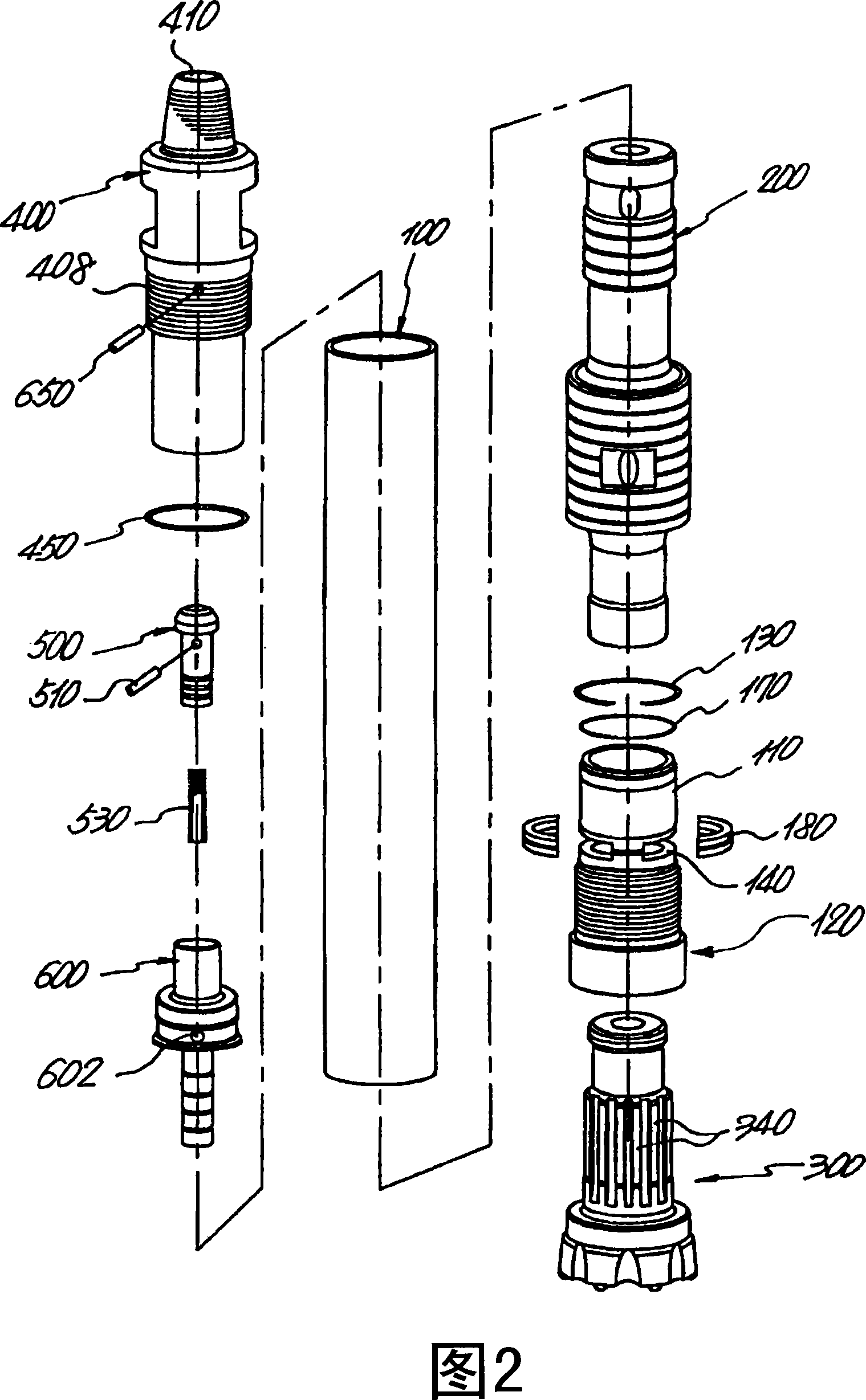

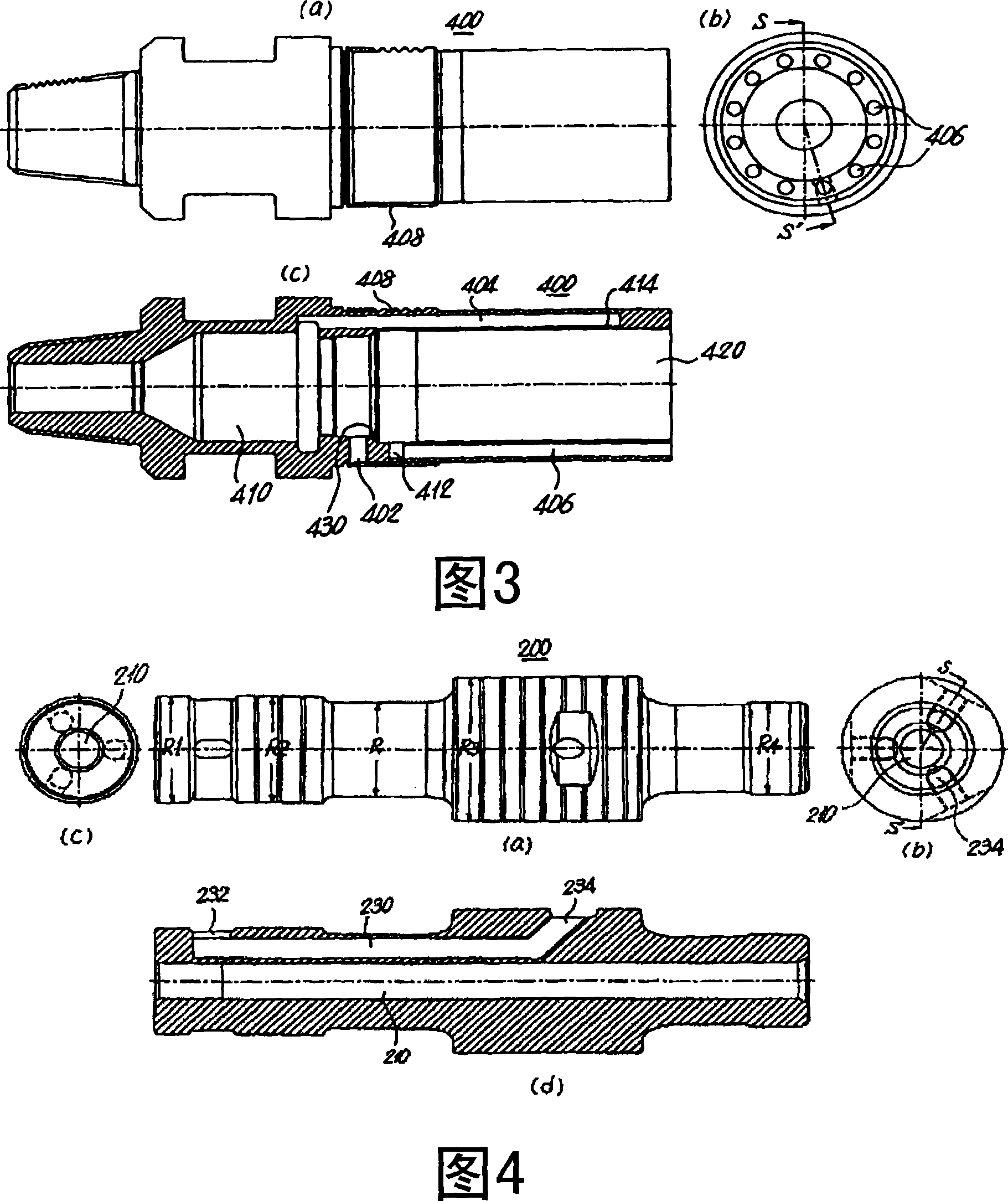

Ground Drilling Hammer and the Driving Method

InactiveUS20070251710A1Prevent functional degradationImprove the environmentReciprocating drilling machinesConstructionsFree stateEngineering

Disclosed herein is a pneumatic operated hammer for rock drilling, the hammer comprising a cylindrical casing, a back head mounted at an upper portion of the casing, a check valve for opening / closing a compressed air passageway in the casing, a guide for supporting the check valve, a piston adapted to ascend and descend with compressed air in the casing, and a button bit for performing a drilling work through the striking of the piston. The piston is extended to a certain length to conform to the work condition of the pneumatic hammer to thereby prevent a water back-flow phenomenon in which underground water, etc., is introduced into the drilling equipment during the drilling work, compressed air passageways and variable compressed air chambers are formed between the piston and the casing so that when the piston ascends by the compressed air, it abruptly ascends at a load-free state, and the piston has axial portions with a reference diameter and different outer diameters so that it is possible to manufacture a hammer bit having a plurality of variable compressed air chambers formed between the casing the piston to fit for the work capacity. The piston ascended in a load-free state strikes the button bit with its rapid and strong striking force produced by the compressed air supplied from the variable chambers while abruptly descending to thereby perform the drilling work.

Owner:EVERDIGM ROCK TOOLS CORP

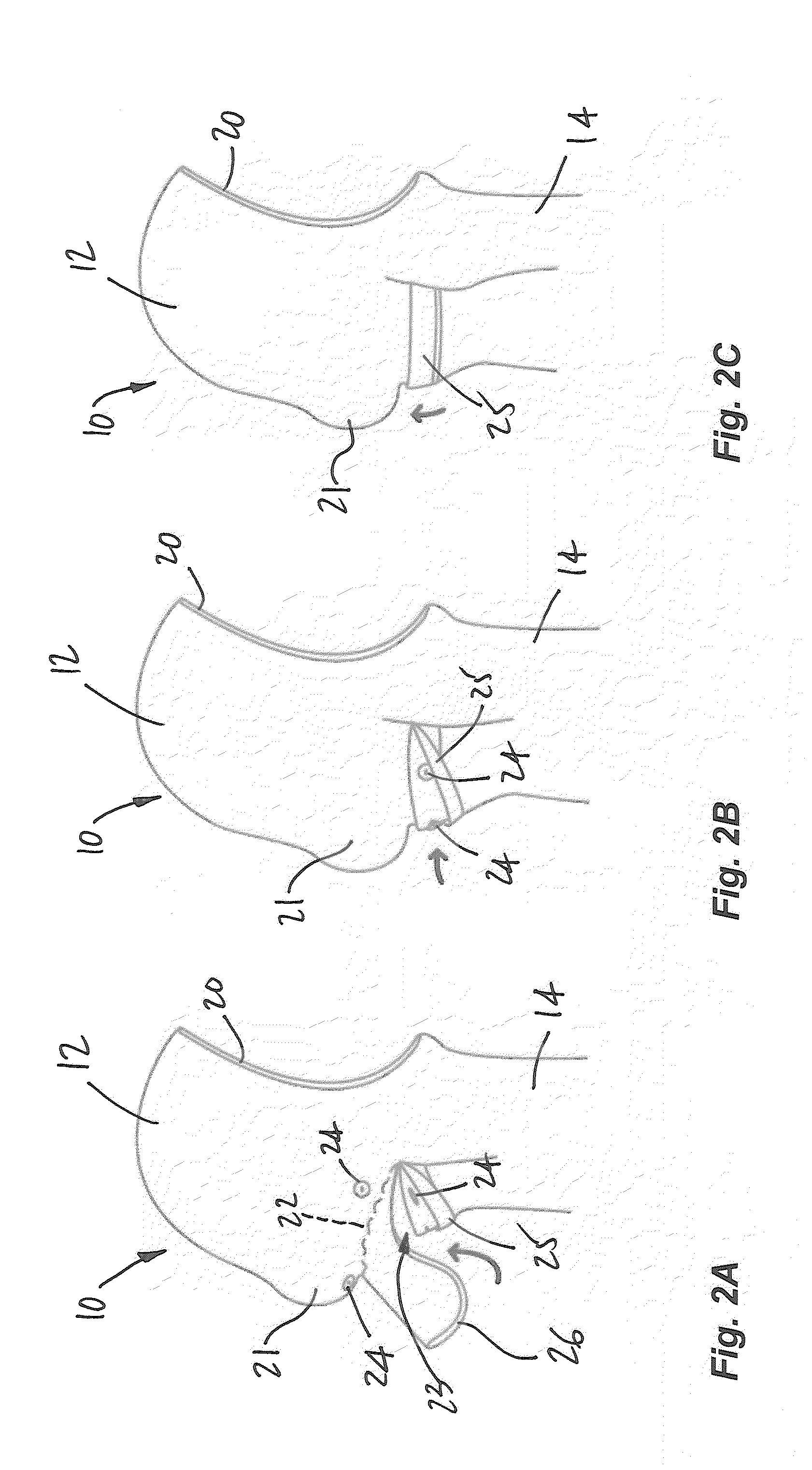

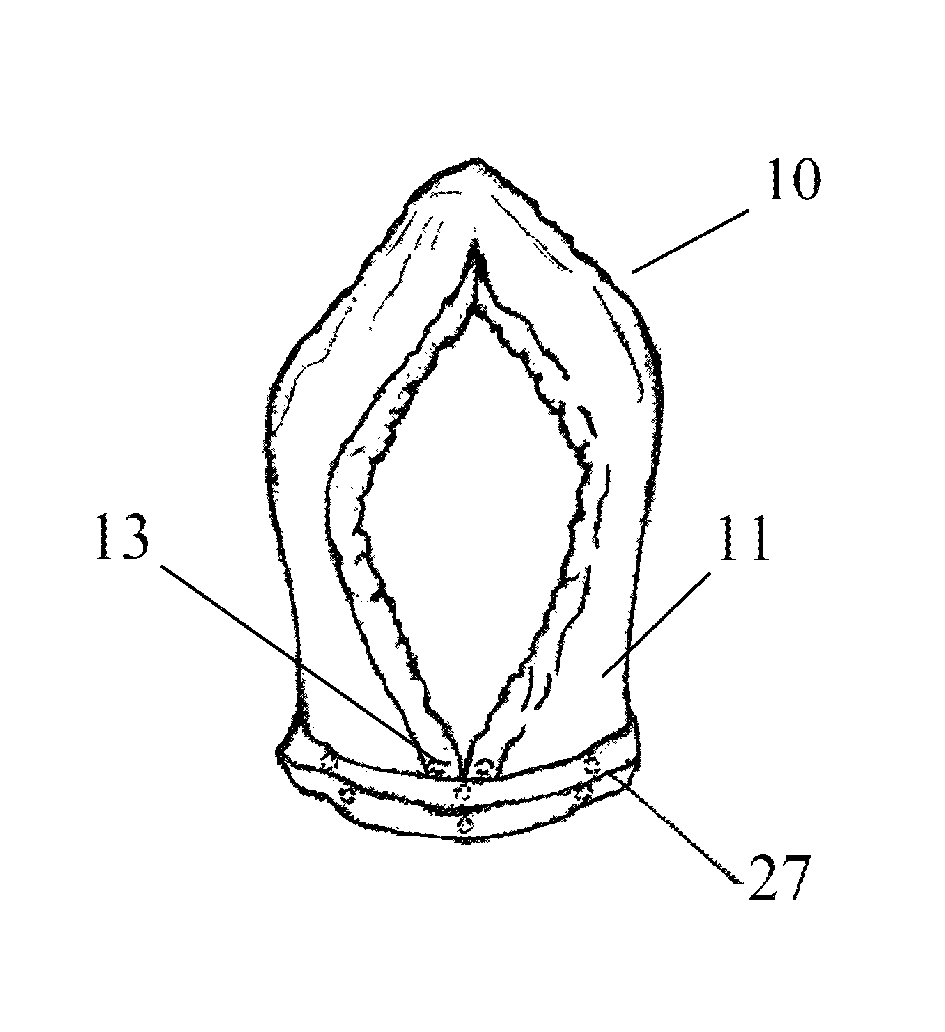

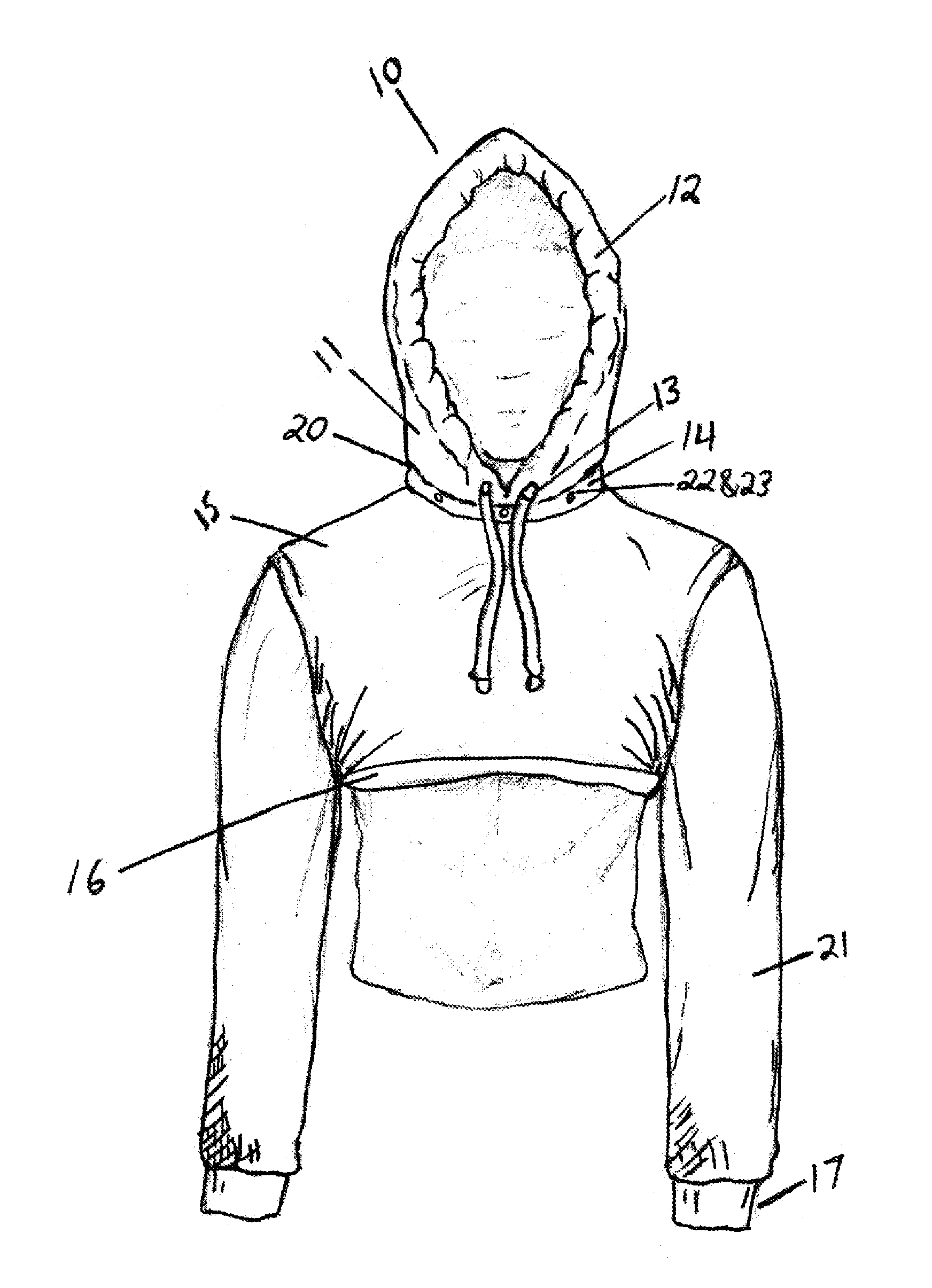

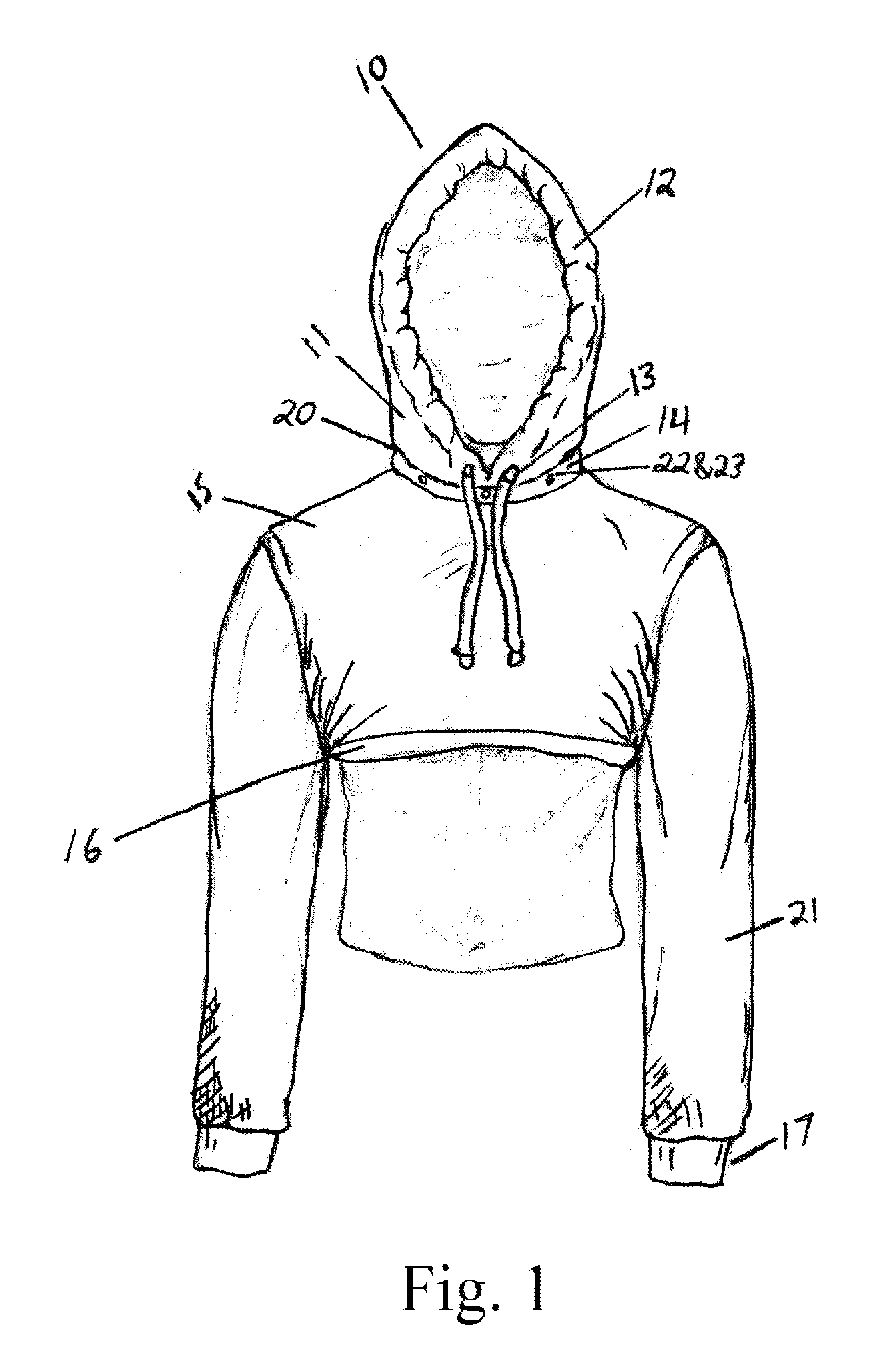

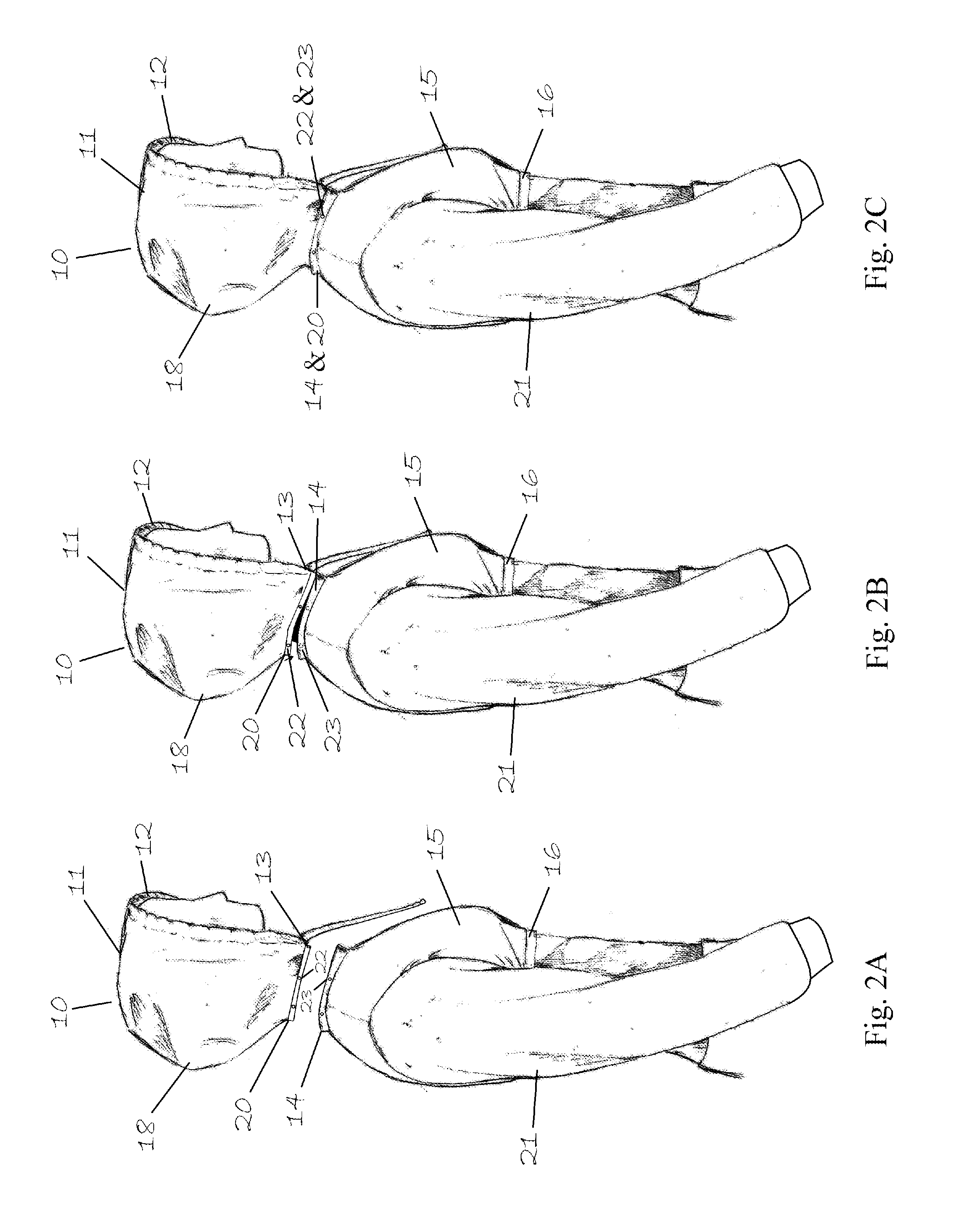

Hooded garment

A hooded garment which is worn by a user and comprising a hood adapted to be worn on a user's head, the hood including a back head portion, a top portion, two opposed lateral portions, a front head portion and a neck portion circumferentially extending around the user's neck, the back head portion and a back of the neck portion forming a back portion of the hood, a face opening defined in the front head portion through which a user's face protrudes, the face opening being located between the top portion, the lateral portions and the neck portion of the hood, an elastic member located on the back portion, and a pocket portion in the back portion above the elastic member, the pocket portion being able to accommodate at least some of a user's loose hair.

Owner:ELHAMSADAT SEYED JAVAD +1

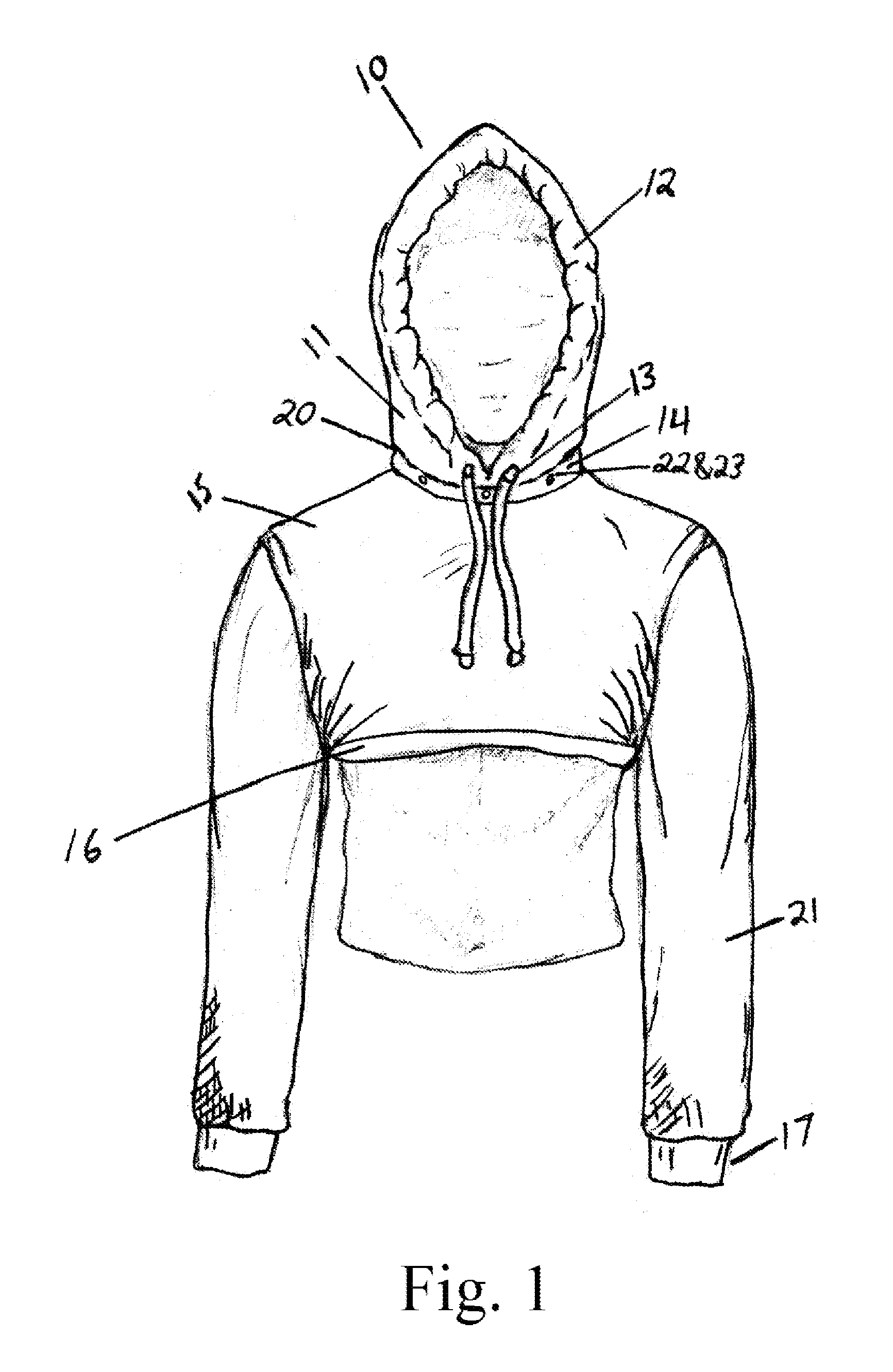

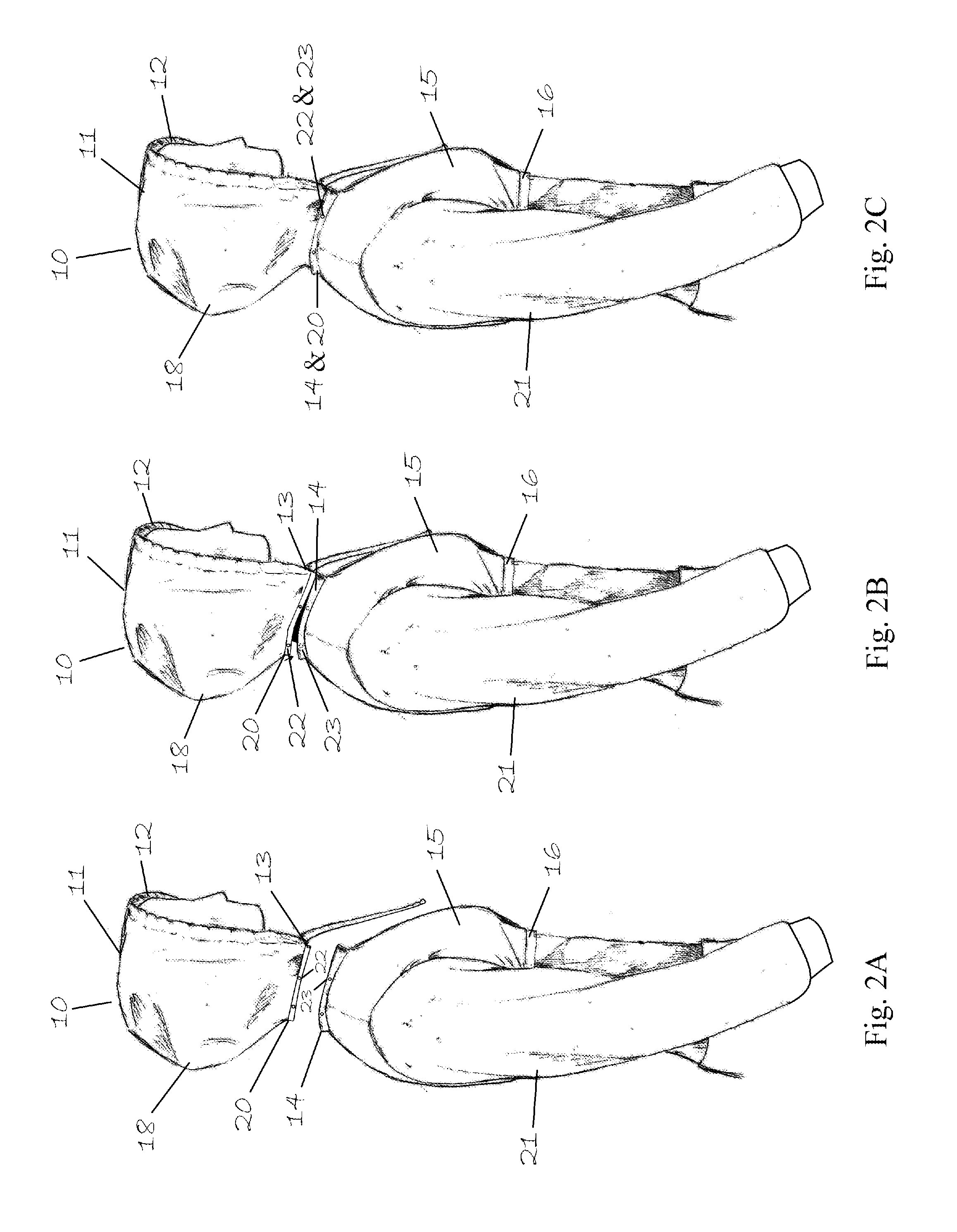

Long sleeved upper torso detachable hooded garment

A long sleeved upper torso hooded garment which is worn by a user and comprising a detachable hood, the detachable hood including a top head portion, two opposed lateral portions, a back head portion, wherein there is a natural pocket portion in the back head portion of hood, above the hem or elastic neckline member, giving the natural pocket portion the ability to accommodate at least some of a user's loose hair; a front head opening portion, and a neck portion circumferentially extending around user's neck, the hood including a circumventing channel that encloses a drawstring at the edge of facial opening which is used to decrease the size of the facial opening, the upper torso portion of garment includes four openings, the two opposed lateral portions for allowing the users arms to pass through ending at the wrists' opening, the top opening for connecting the torso piece to the base of hood piece, and the bottom largest opening in which the user places the head, arms, and upper torso through to put on, or take off garment.

Owner:BARRETT DAVID O A

Optical fibre connector

An optical fiber connector consists of a base and three V-shape slots fixed on the base, which is used for containing reference optical fiber and tested optical fiber. Three concave plates with a concave surface oriented to the front head face of the base are fixed on the base, the rear part of a pressure pad is inserted into the concave positions of the concave plates, and the concave plates and the pressure pad are connected by three axes running through the right side of the concave plates. The pressure pad is provided with screwed holes, and the pressure pad, a spring, and a pressure block are connected together by bolts, the optical fiber is tightly pressed at the lower end surface of the pressure pad. A front nest pin and a back nest pin respectively screwed in the screwed holes in the front and back head faces of the base are used for adjusting the travel route of the pressure pad. The optical fiber connector is characterized by rapid connection, long service life, easy maintenance, and reliably fixing the tested optical fiber.

Owner:杭州万隆光电设备股份有限公司

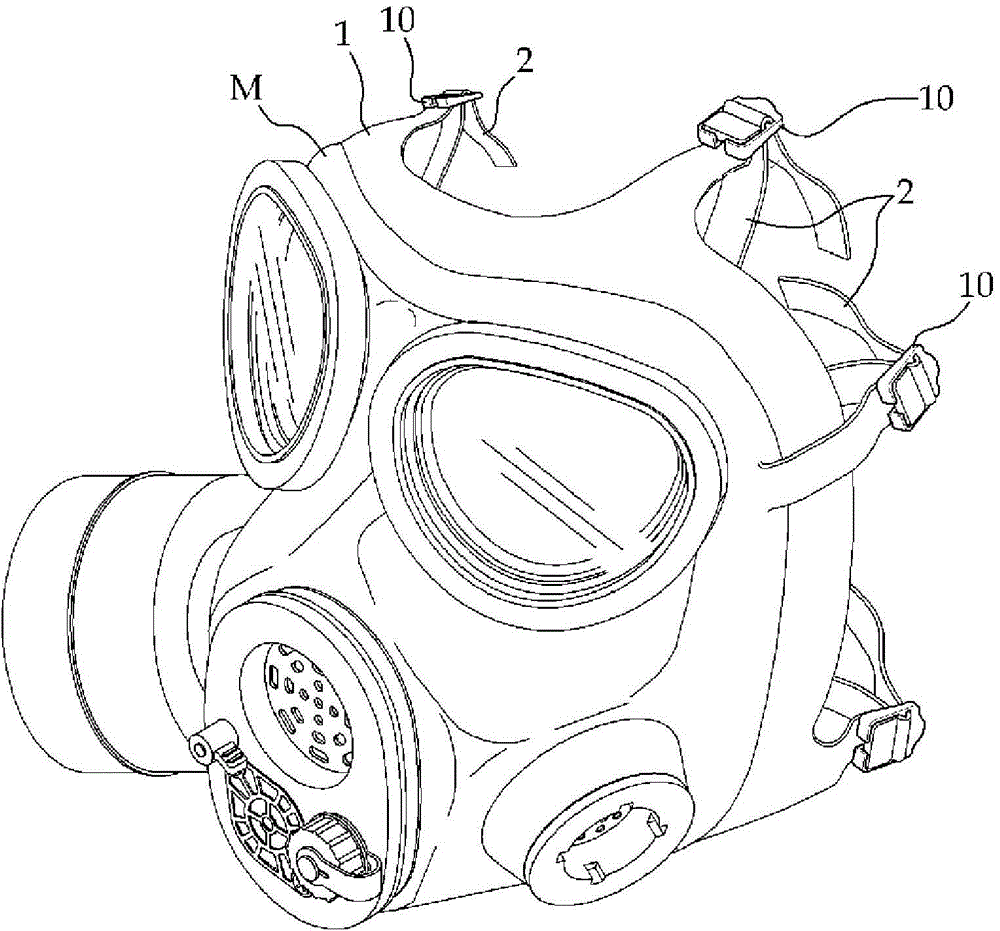

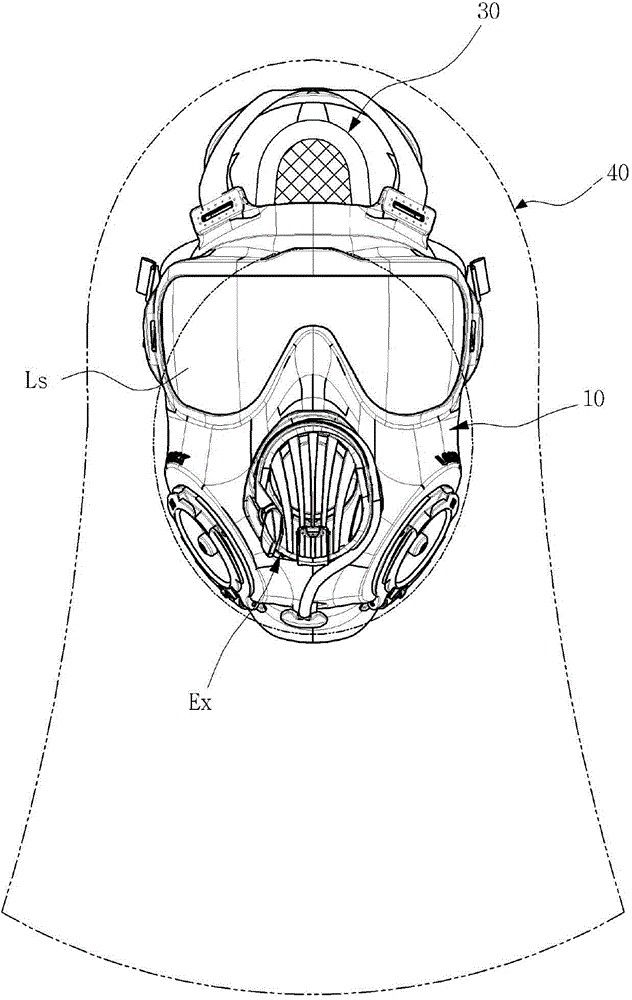

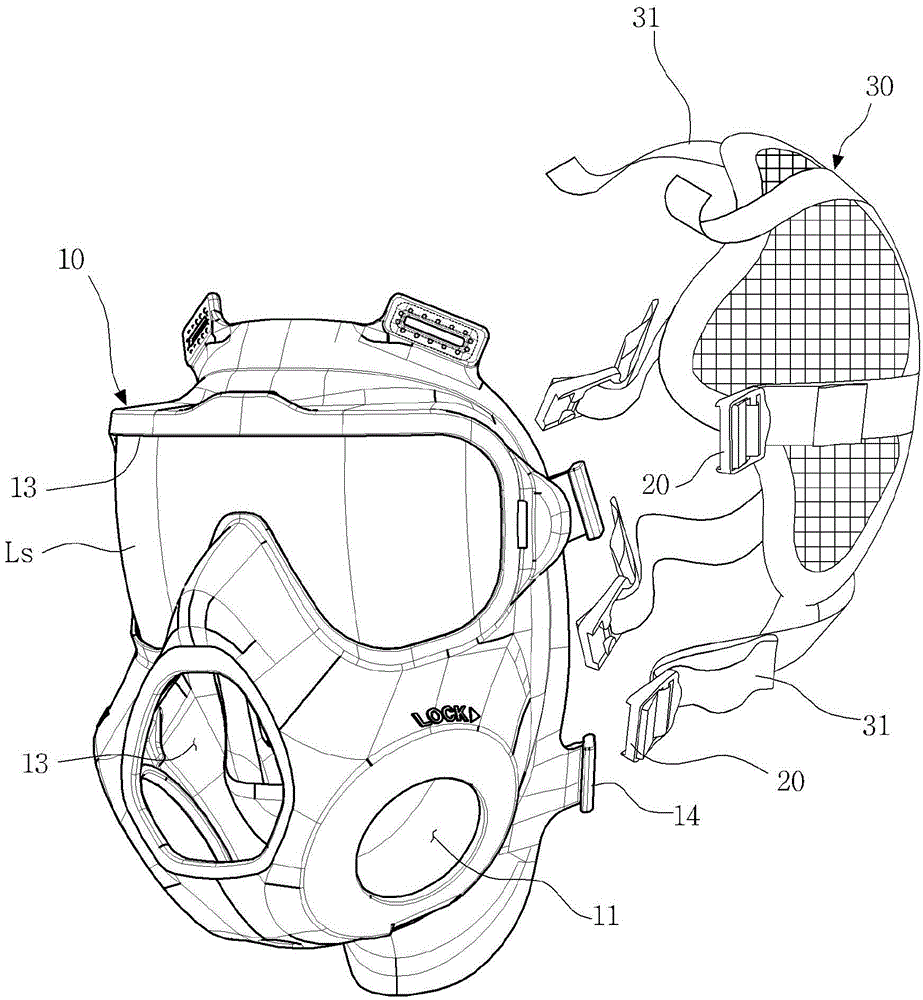

Gas mask

ActiveCN104837429AImprove protectionInviolableBreathing filtersBreathing masksRubber materialCoupling

The present invention relates to a gas mask comprising: a rubber material face mask, which is worn on the face for protecting the face against toxic substances, and which includes a purification container connection hole to which a purification container is connected, a lens hole in which a lens is installed, an exhaust hole in which an exhaust unit for exhausting inside air is installed, and a hook which protrudes toward a back direction; a buckle onto one side of which the hook on the face mask is coupled so as to be separable; a back head cover, which comprises a coupling lace which is coupled to the other side of the buckle so as to be separable, for covering the back head of the wearer by connecting to the back side of the face mask by means of the buckle when the coupling lace is coupled to the buckle; a headscarf, which is provided with an exposure hole through which the front surface of the face mask provided with the connection hole, the lens hole, and the exhaust hole, is exposed, wherein the periphery of the exposure hole is connected to the edge of the front surface of the face mask to shield the head portion of the wearer; and a connector for partially connecting the periphery of the exposure hole, which is formed on the headscarf, to the face mask. In the present invention, the periphery of the exposure hole, which is formed on the headscarf, is connected to the face mask by means of the connector so that the headscarf is securely and quickly connected to the face mask, thereby protecting the head of the wearer from toxic substances.

Owner:株式会社翰科来福开恩

Head support pillow

Owner:FUTSUTO TEKUNO

Coating structure for low-temperature heat insulation container and coating method of coating structure

The invention discloses a coating structure for a low-temperature heat insulation container. Stair-step trapezoid overlapped edges are arranged on one side of a heat insulation quilt of the coating structure, and anti-stair-step trapezoid overlapped edges are arranged on the other side of the heat insulation quilt; front trapezoid heat insulation blocks are arranged at the front end of the heat insulation quilt; a first pipe interface yield hole is formed in one trapezoid heat insulation block which corresponds to a pipe interface; back trapezoid heat insulation blocks are arranged at the back end of the heat insulation quilt; the surface of a cylindrical container is coated with the heat insulation quilt, and the forward trapezoid overlapped edges and the backward trapezoid overlapped edges are bonded; the external surface of a spherical surface front head around a front supporting rod is coated with the front trapezoid heat insulation blocks, thereby forming a front end spherical surface coating layer; the first pipe interface yield hole is sleeved with the pipe interface; the external surface of a spherical surface back head around a back supporting rod is coated with the back trapezoid heat insulation blocks, thereby forming a back end spherical surface coating layer; the external surface of the front end spherical surface coating layer is coated with a front sealing cap, and the external surface of the back end spherical surface coating layer is coated with a back sealing cap. According to the coating structure, the winding and coating efficiency of a thermal insulating material is improved, and the effect of maintaining vacuum is improved.

Owner:湖北三江航天江北机械工程有限公司

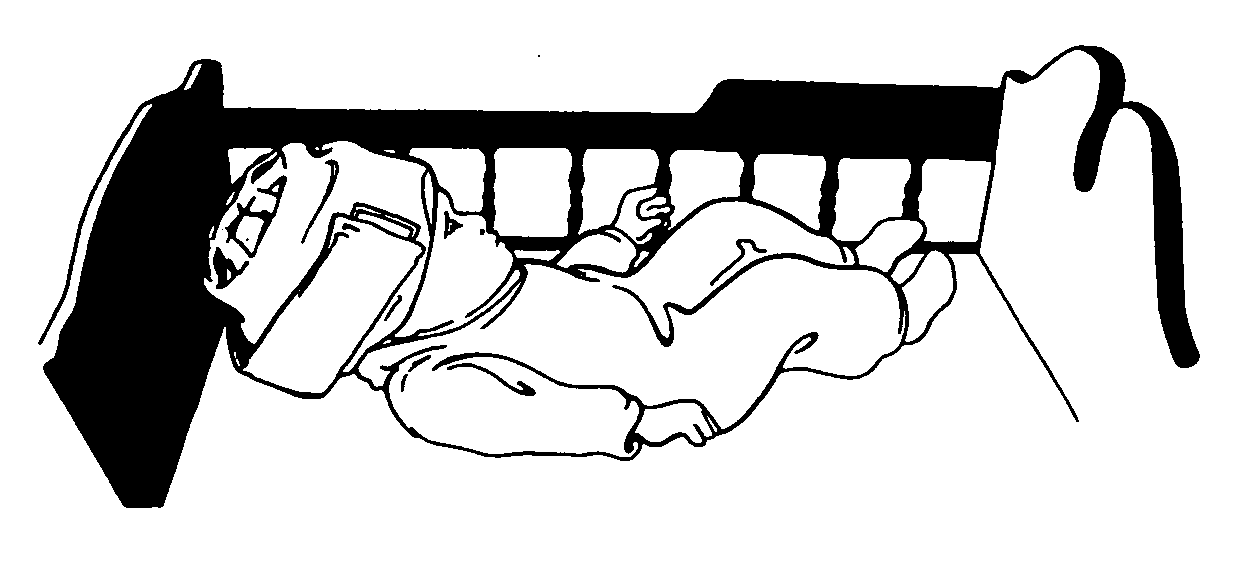

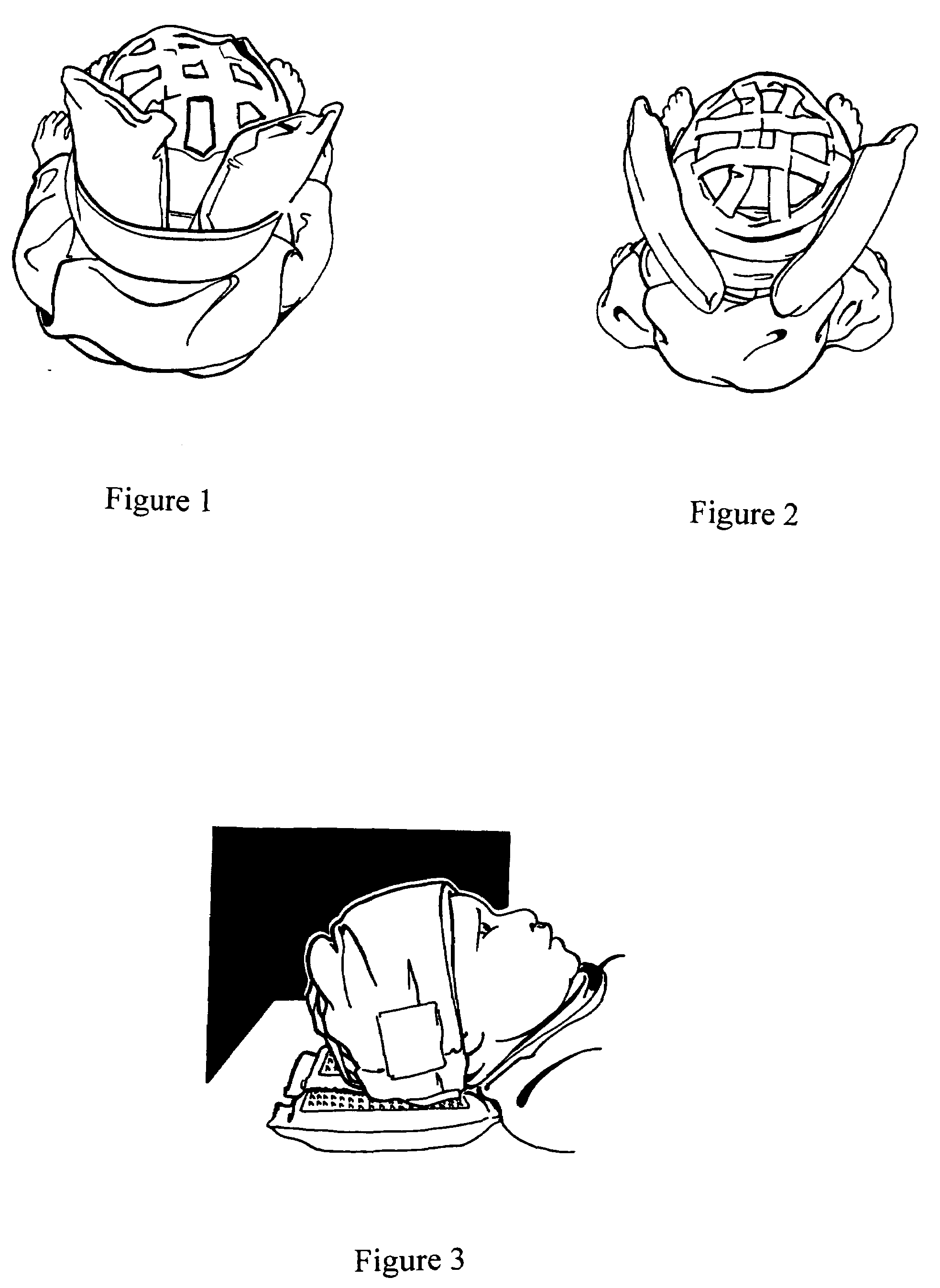

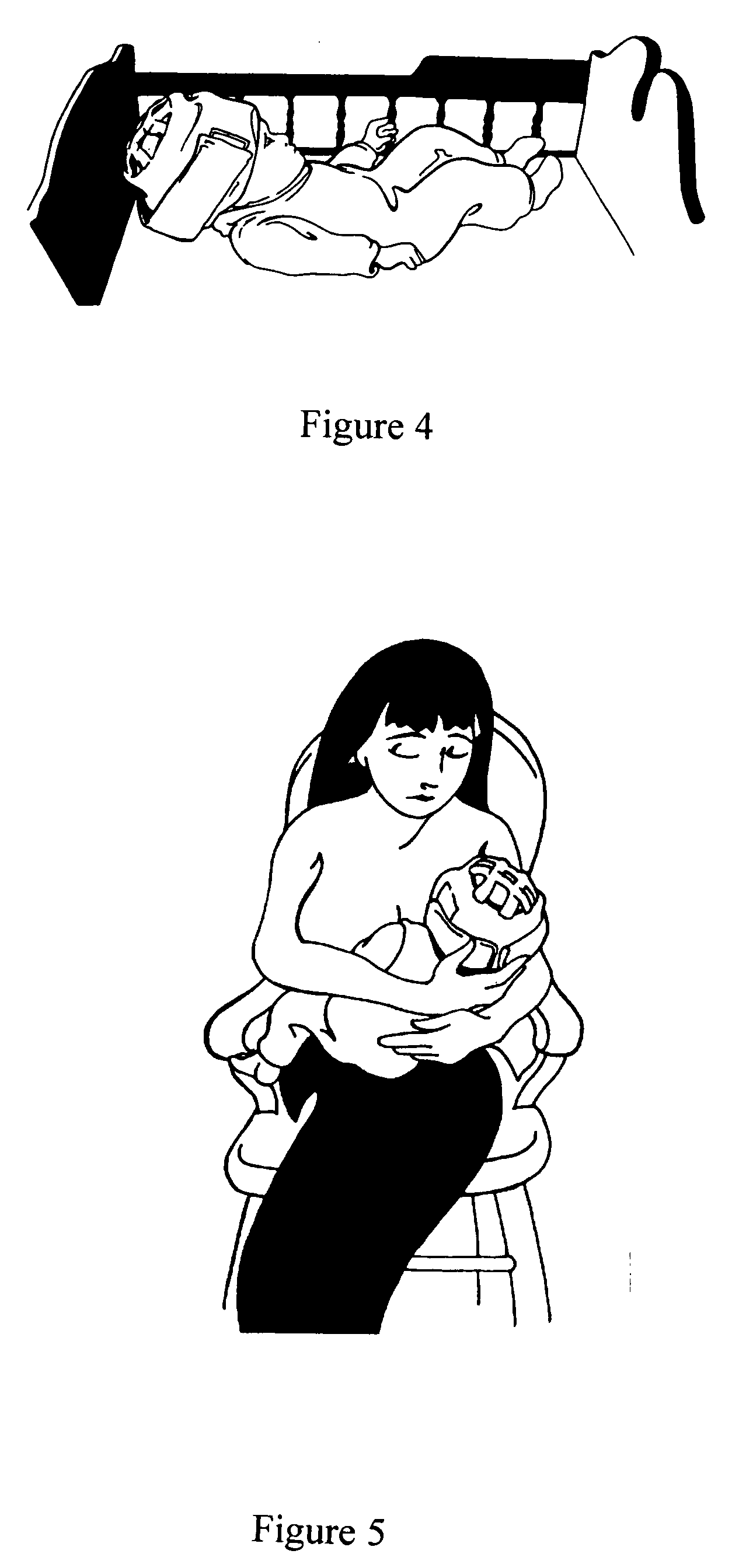

Infant head positioning device

InactiveUS20080184489A1Reduce capacityReduce pressureOperating chairsSofasPhysical medicine and rehabilitationEngineering

An infant head positioning device that provides back head support in order to prevent skull deformities, such as positional plagiocephaly, and provides support to the infant's head in other activities where back head support is needed. Generally, the infant head positioning device comprises: (1) a hat member made of soft, flexible, adjustable materials; and (2) one or more cushioning made of soft, pressure relieving materials placed in various positions in the back and sides of the hat member to redistribute and alleviate the pressure on the back of the infant's head. The cushioning pads can be placed either in the inside or outside of the hat member. In a preferred embodiment of the infant head positioning device, the top of the hat member has an open, aerated grid design that allows excess heat to dissipate.

Owner:PHAM ANNE DOAN TRANG

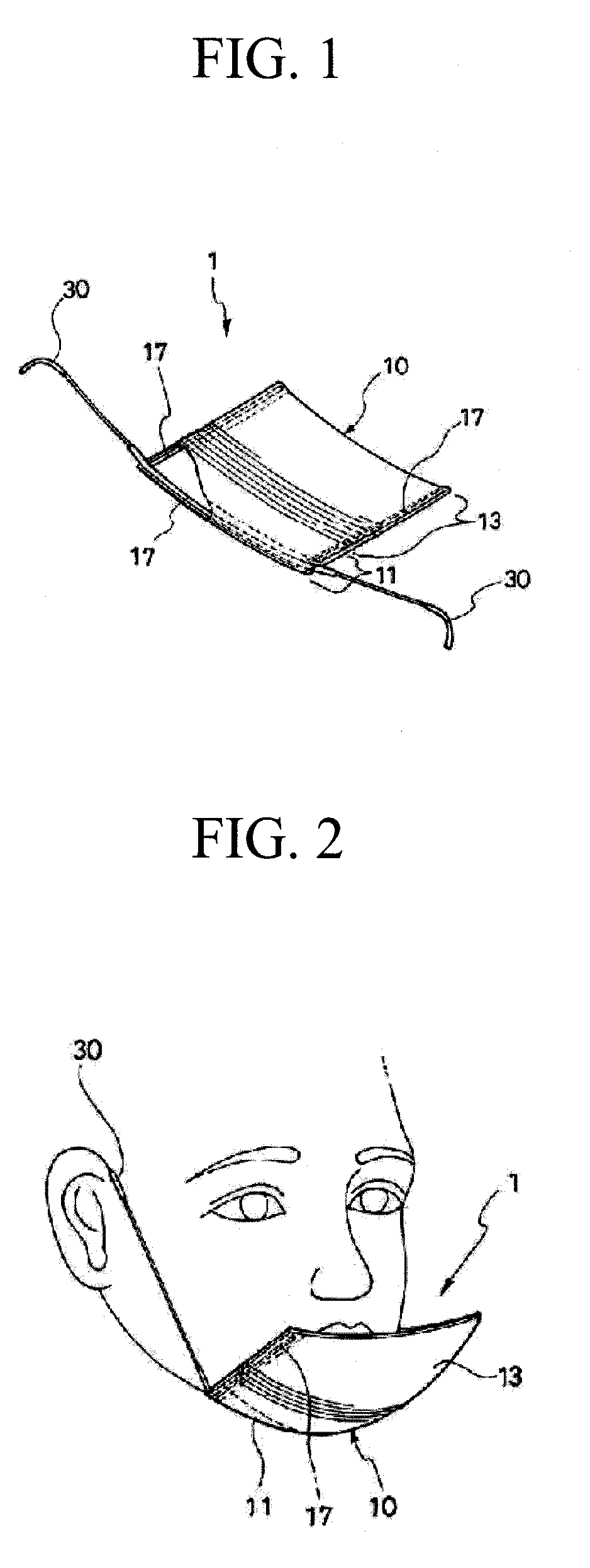

Sanitary mask for the protection of others

ActiveUS20100326444A1Conveniently re-usedSimple structureBreathing filtersBreathing masksRespiratorNose

Disclosed is a sanitary mask for hygienically protecting others that can be conveniently re-used and has a simple structure firmly maintained while the sanitary mask is used, so as to surely achieve the purpose of the sanitary mask, by molding the overall frame of plastics and improving the structure from a structure of preceding Korean Patent Application No. 10-2007-111003, which was filed by the inventor(s) of the present invention before the filing of the present patent application. The sanitary mask for hygienically protecting other people by blocking unsanitary substances provided by respiratory organs including a mouth and a nose of a user from spreading to and contaminating a clean object while exposing the respiratory organs comprising: a lower body molded in a curved shape, i.e., a ‘U’ shape, and including supporters to be hung on the ears of the user or to be wound around a back head of the user at the ends of both sides of the lower body; and a respiratory organ front cover configured to be inclined upward from an upper portion of a front portion of the lower body and cover a front portion of an area around the respiratory organs of the user to thereby expose the respiratory organs of the user.

Owner:SHIM KYU SUNG

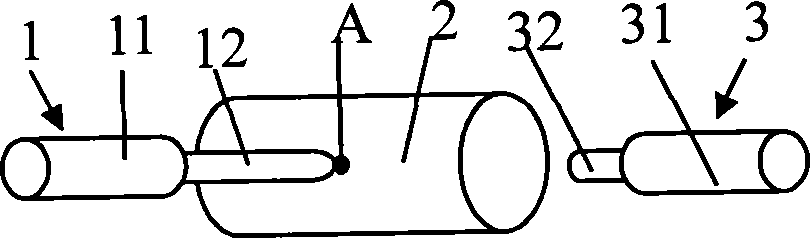

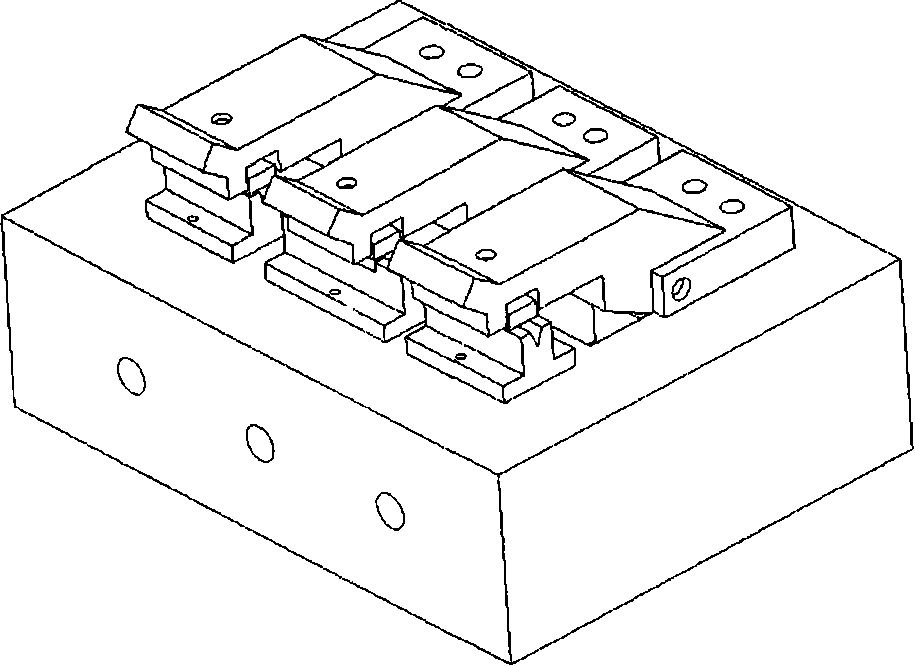

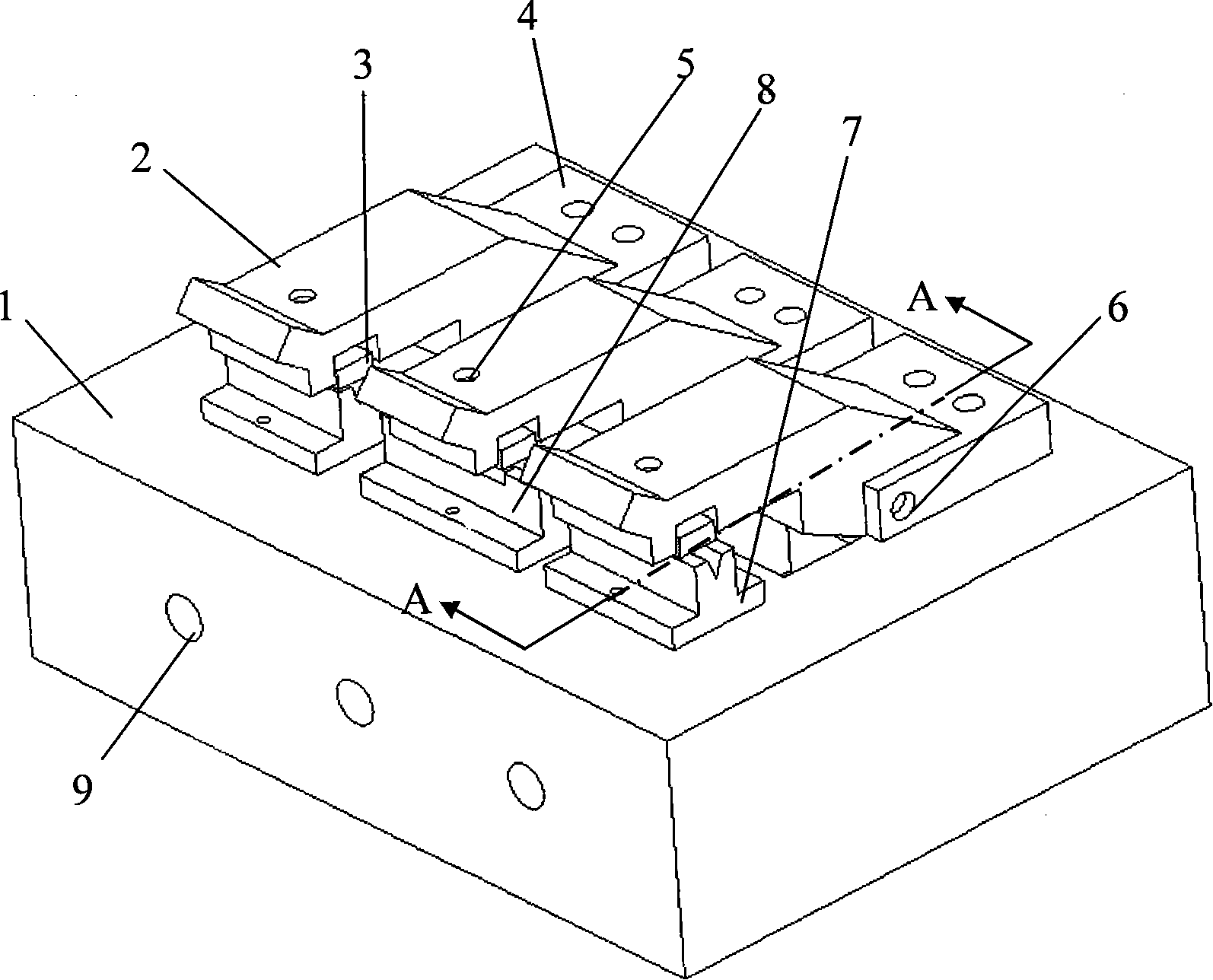

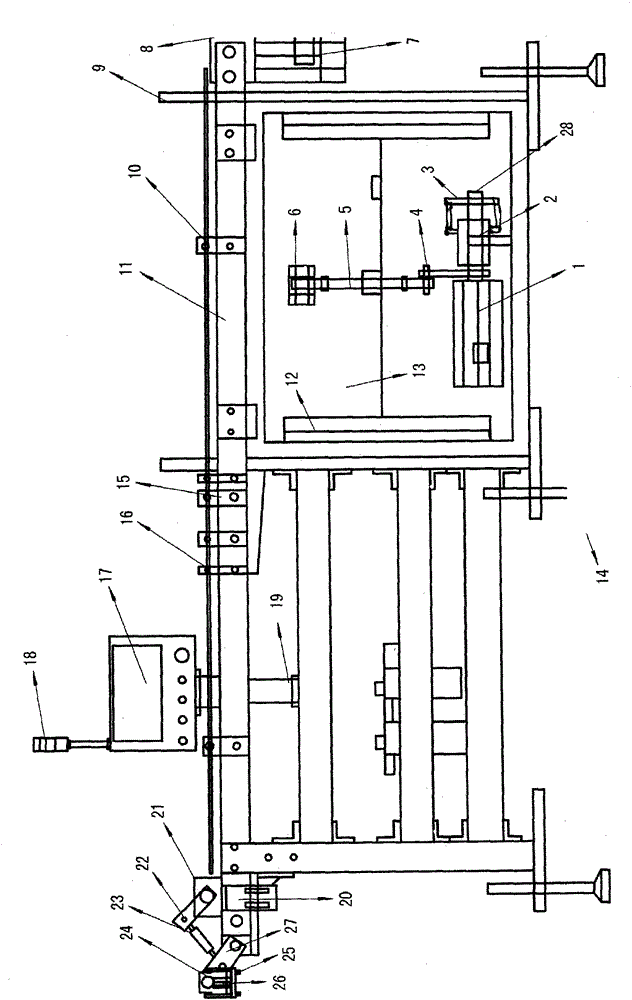

Automatic pipe laying machine

The invention discloses an automatic pipe laying machine. The automatic pipe laying machine consists of four main structures: a flexible pipe jacking and loading mechanism, a belt conveyor line mechanism, a front head and back head distinguishing mechanism and a rotary translation mechanism. According to the automatic pipe laying machine, manual operation is replaced, and a series of actions of automatic pipe trimming, automatic pipe feeding, automatic pipe turning and automatic pipe laying are realized. In this way, automatic continuous production can be realized, and a worker can operate and keep an eye on several pieces of equipment, so that the labor cost is remarkably reduced; and the automatic pipe laying machine has the characteristics of being wide in application range, simple and convenient to operate, high in efficiency and stable in operation.

Owner:HEBEI ANTAI PLASTIC PACKAGING PROD LTD

Long Sleeved Upper Torso Detachable Hooded Garment

A long sleeved upper torso hooded garment which is worn by a user and comprising a detachable hood, the detachable hood including a top head portion, two opposed lateral portions, a back head portion, wherein there is a natural pocket portion in the back head portion of hood, above the hem or elastic neckline member, giving the natural pocket portion the ability to accommodate at least some of a user's loose hair; a front head opening portion, and a neck portion circumferentially extending around user's neck, the hood including a circumventing channel that encloses a drawstring at the edge of facial opening which is used to decrease the size of the facial opening, the upper torso portion of garment includes four openings, the two opposed lateral portions for allowing the users arms to pass through ending at the wrists' opening, the top opening for connecting the torso piece to the base of hood piece, and the bottom largest opening in which the user places the head, arms, and upper torso through to put on, or take off garment.

Owner:BARRETT DAVID O A

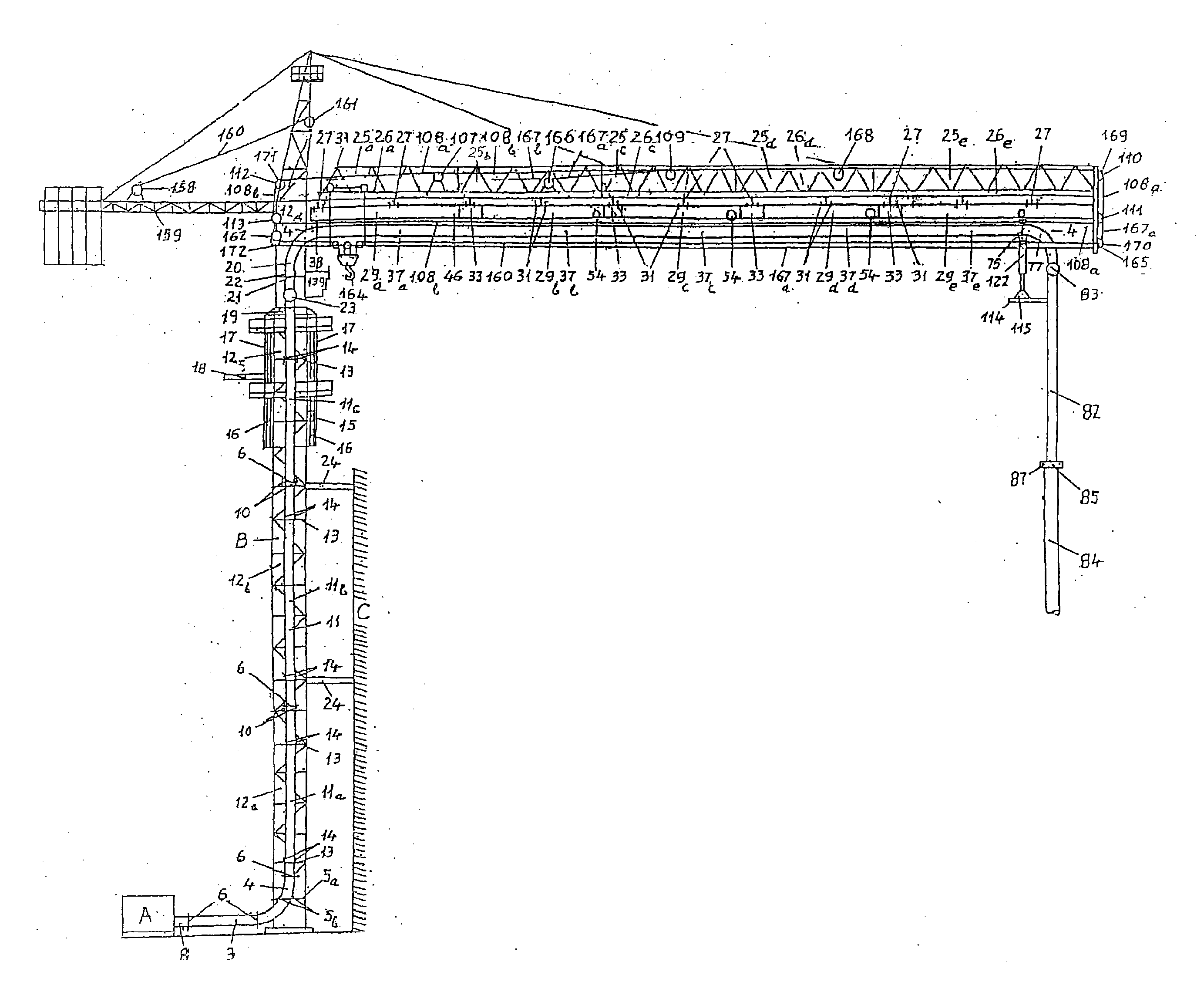

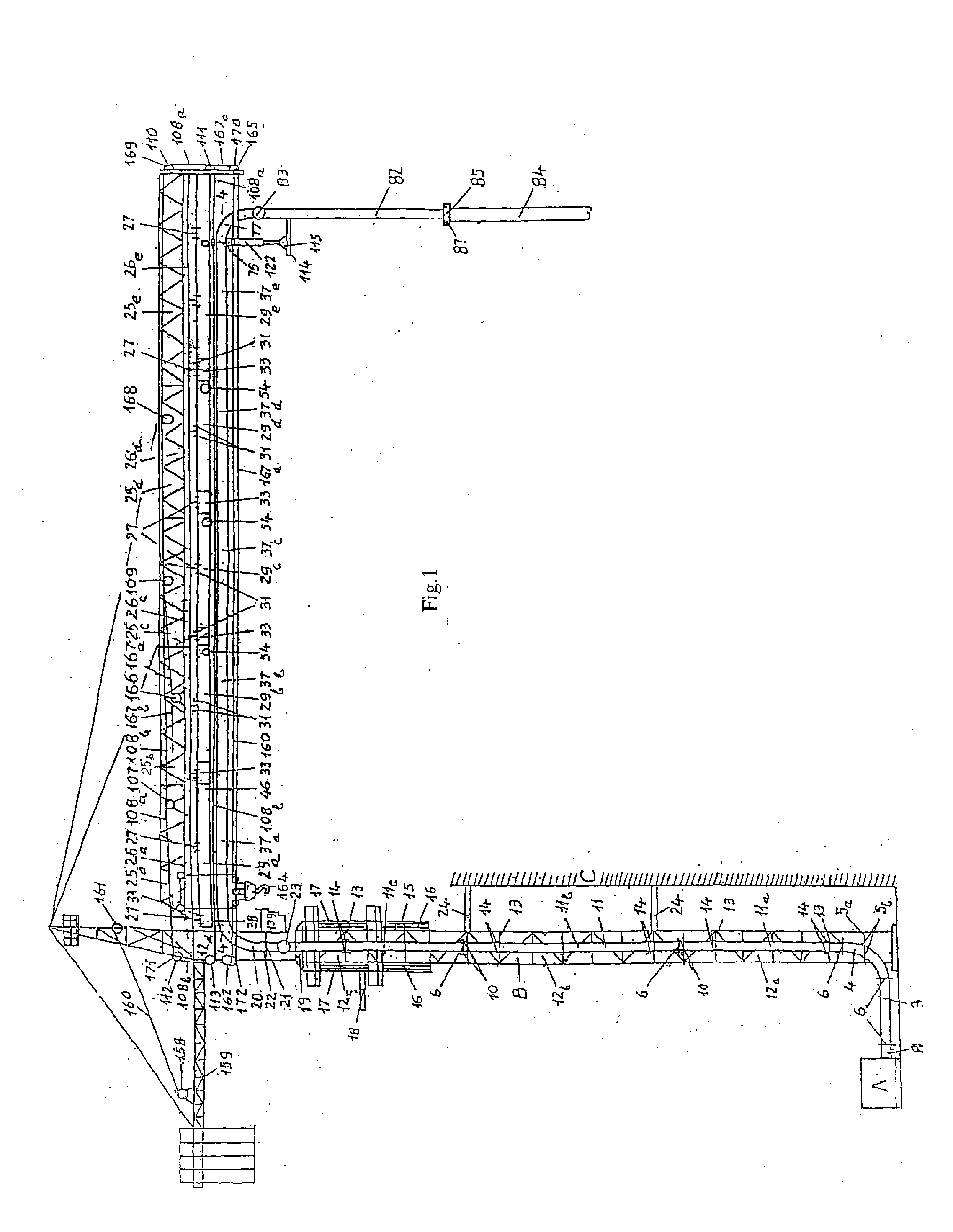

Combination of concrete spreader and crane tower

InactiveUS20150361681A1Improve work efficiencyLiquid transferring devicesFoundation engineeringSteel barTower

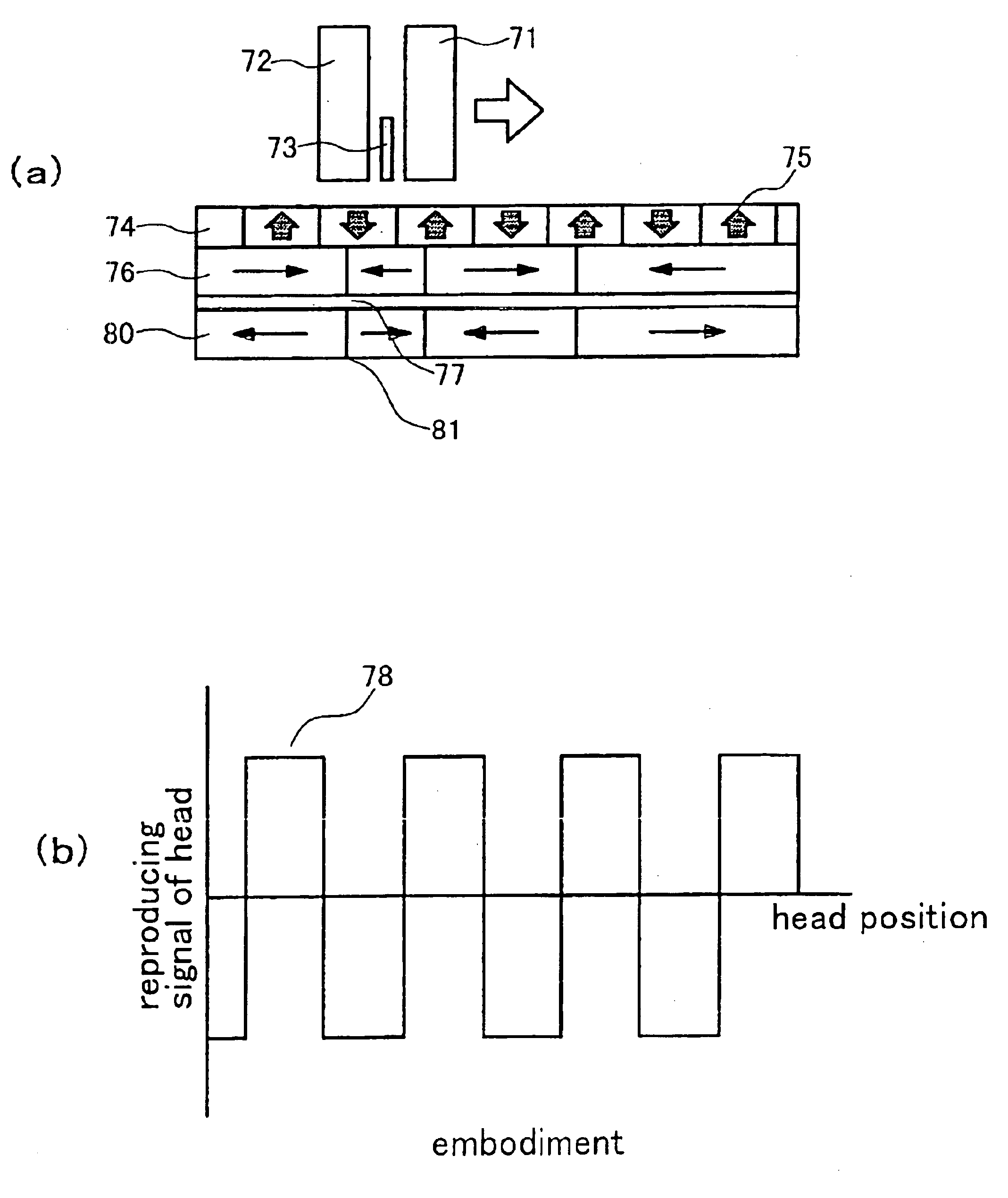

The invention mentions to the complex of concrete spreader (A) and the crane tower (B), including: concrete pump (1), concrete tank (2), to be placed on the ground, sections of tremie pipes (4), (11), (20) and ball bearing (23) are fitted inside the tower sections (12) for use those sections (12) to support tremie pipe sections (11) to stand steadily in the crane tower (B), steel sections (27), (29) are fitted in the lower side of suspension arm (25) and tremie pipe sections (37a), (37b), (37c), (37d) and (37e) are inter-assembled at the lower side of steel bar (29), and steel bar (29) is used for making a guide way for these sleeve sections moving, the tremie pipe sections (77), (82), (84) are fitted with ball bearing (83) and steel hoop (85), the latch structure (88) is fitted in the front and back head of these sleeve sections, the tensile structure of moving sections (37e), (37d), (37c) and (37b) is included an electrical hoist (107), to be fitted into suspension arm (25), cable branches (108a), pulleys (110), (111), (112), (113) are fitted in suspension arm (25) for pulling of sleeve sections (37e), (37d), (37c) and (37b) to be lengthened or shortened at concrete positions, the slanting structure of sections (82), (84) is included steel section (114), oil pump (129), oil tank (133) for piston cylinder (122) to push, pull sections (82), (84) to be inclined backward and ahead at the shortest and longest concrete reach.

Owner:DAO HUAN

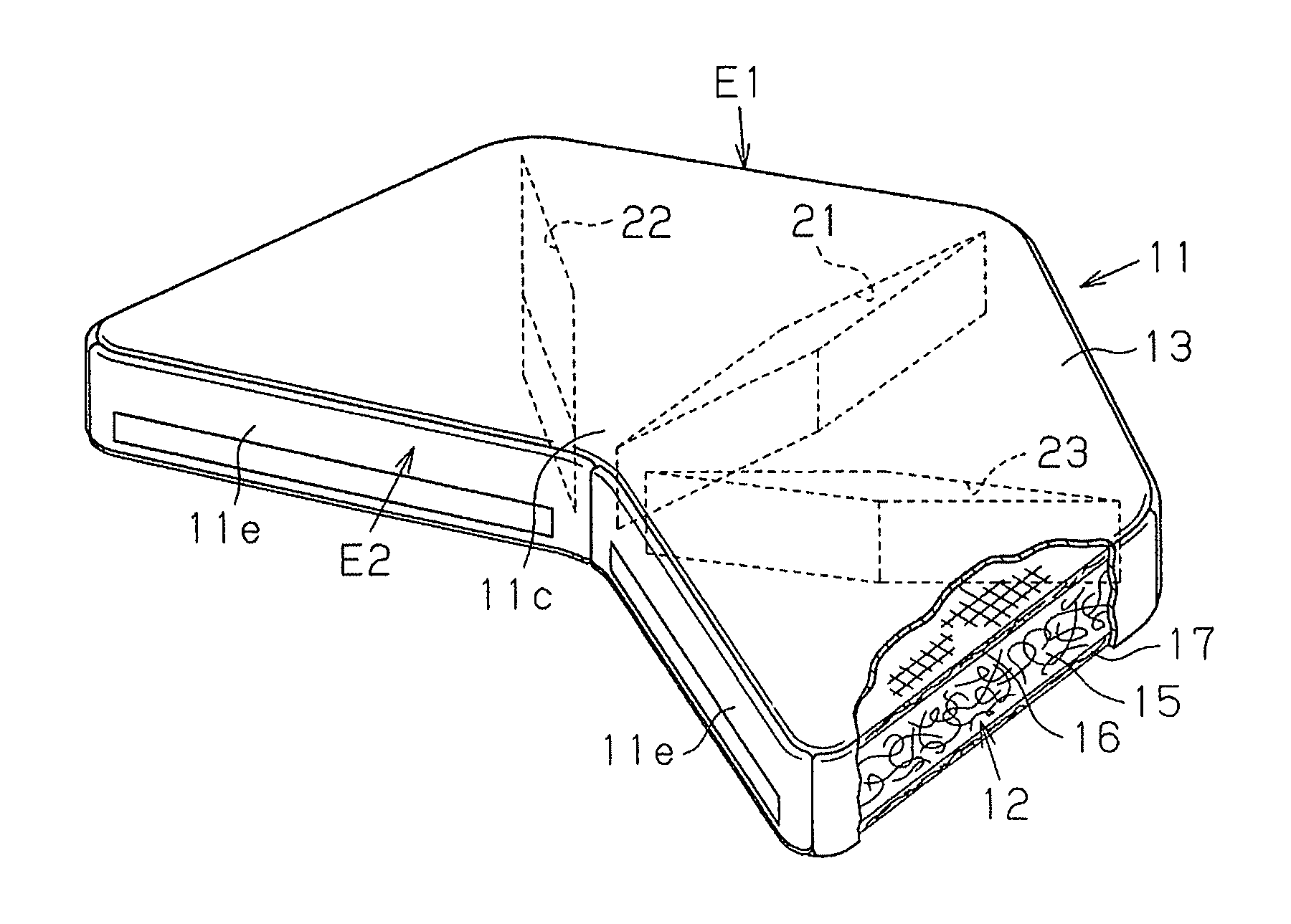

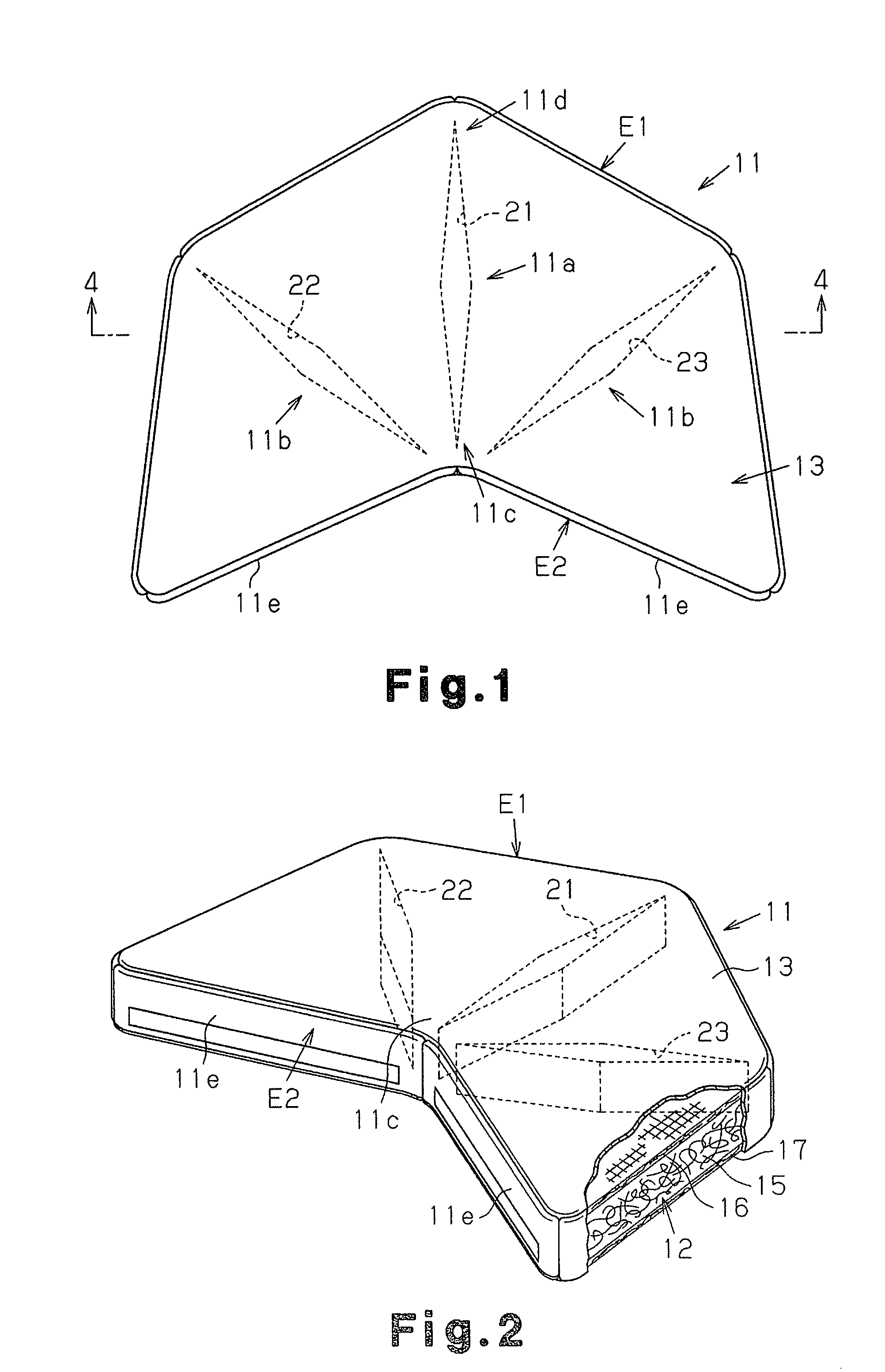

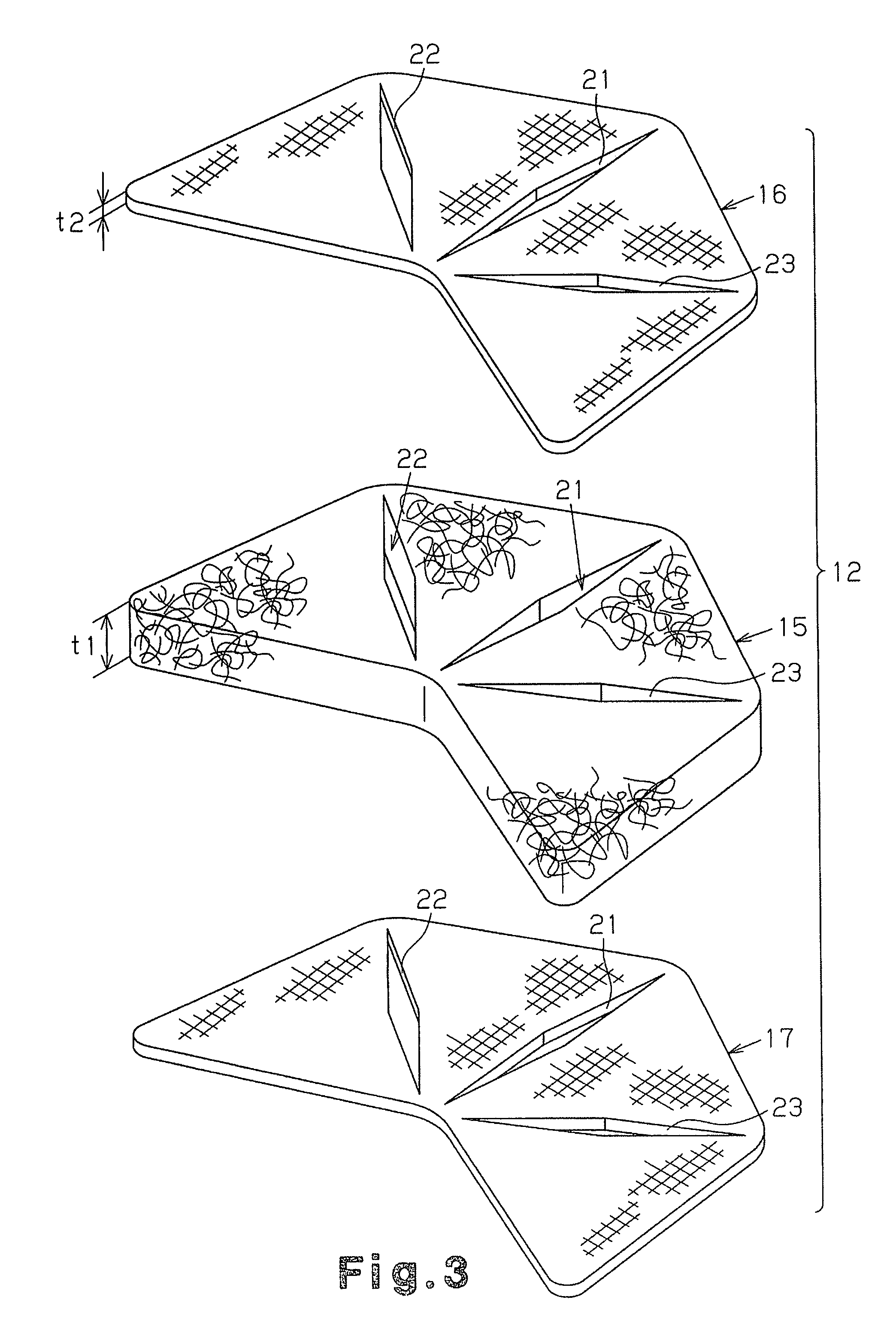

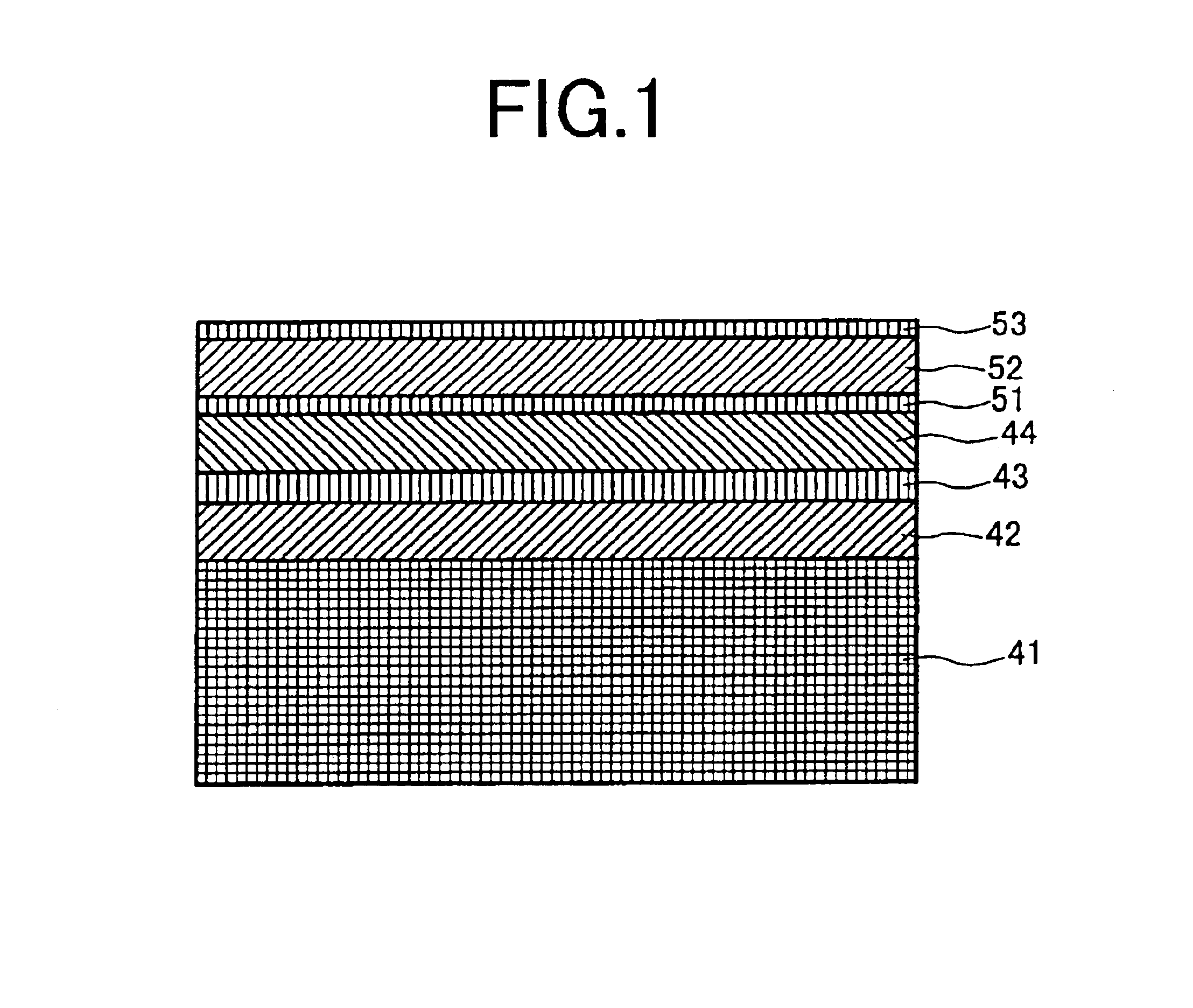

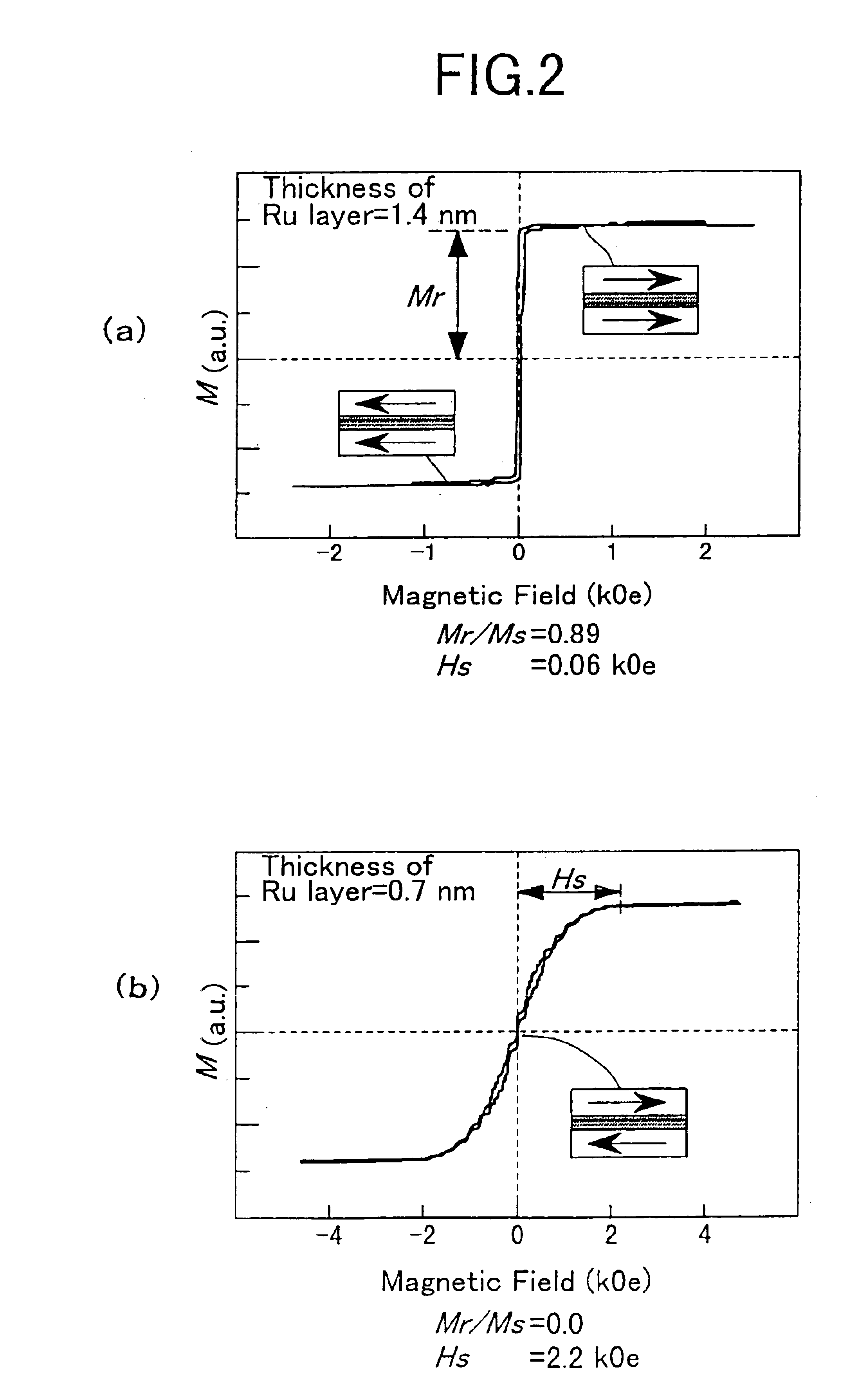

Perpendicular magnetic recording medium and magnetic storage apparatus

InactiveUS6926974B2Low noise characteristicsImprove recording densityRecord information storageMagnetic recordingHigh densityMagnetic storage

An improved perpendicular magnetic recording medium and an improved magnetic storage apparatus are provided, which are suitable for high speed and high density magnetic recording. A magnetic under layer of a two-layered perpendicular magnetic recording medium includes three layers: a ferromagnetic layer; a non-magnetic layer; and a ferromagnetic layer, wherein the ferromagnetic layers are antiferromagnetically coupled with each other, thereby preventing a magnetic flux from a magnetic wall in a magnetic under layer from entering a read back head.

Owner:WESTERN DIGITAL TECH INC +1

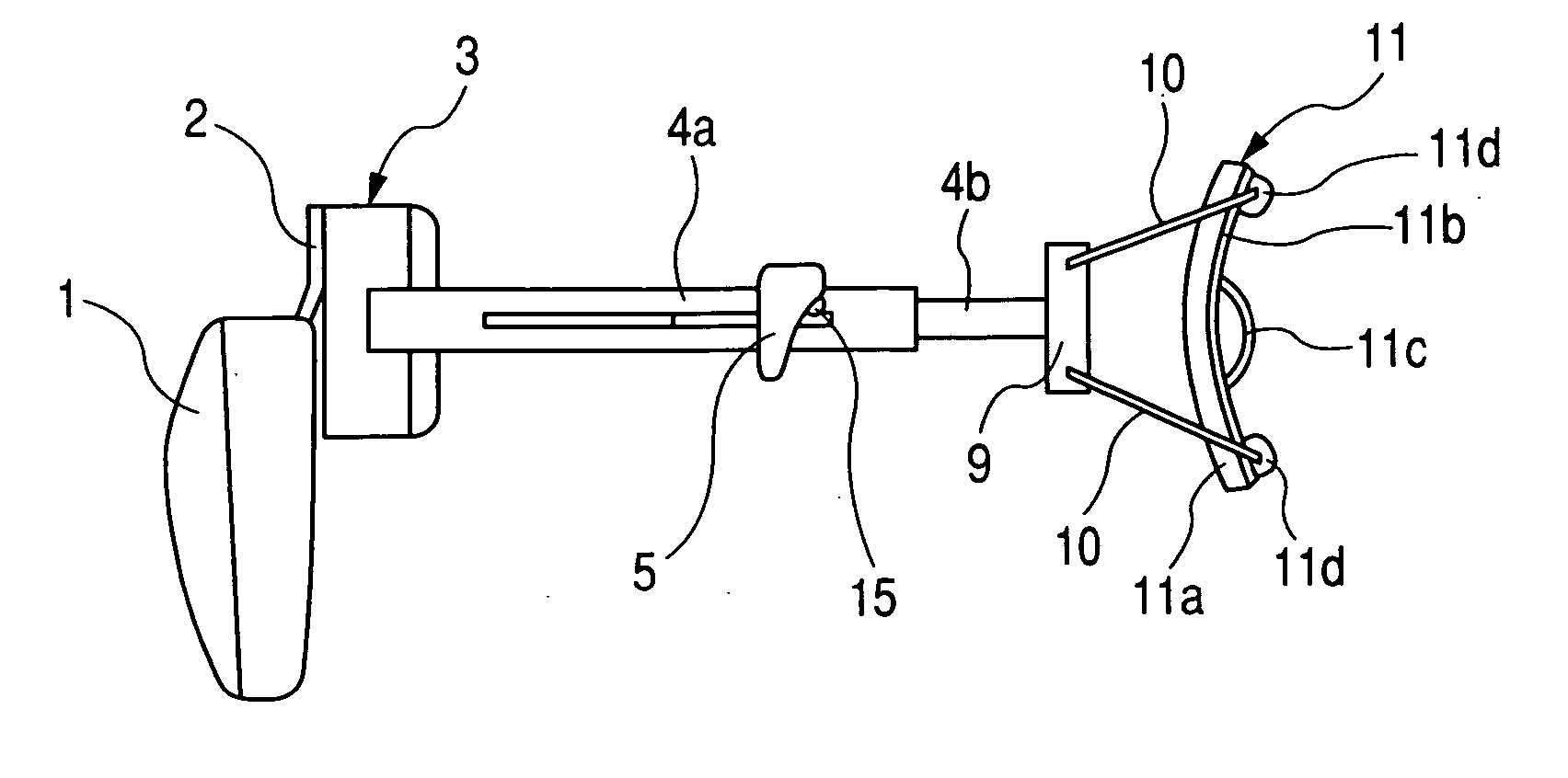

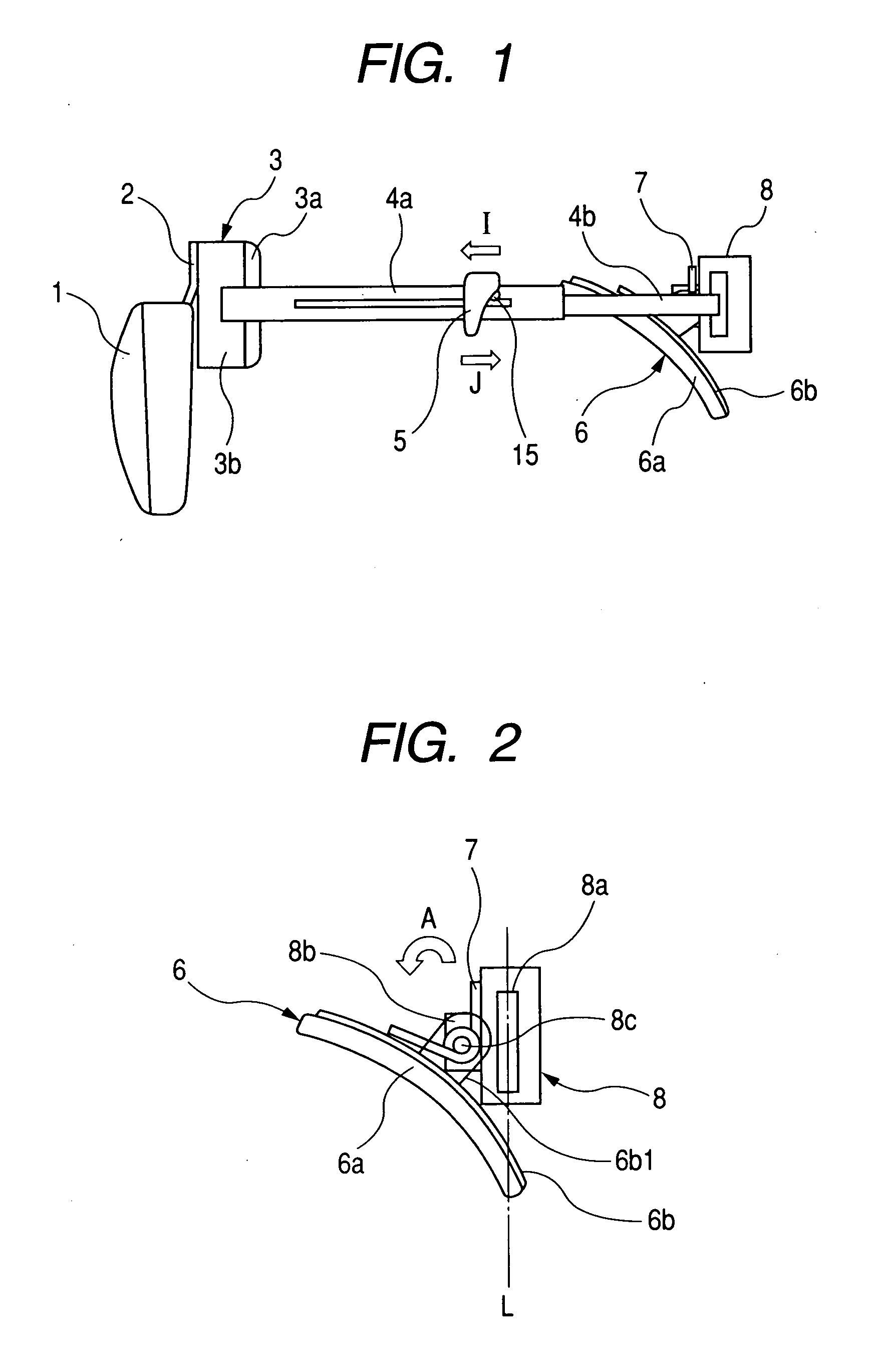

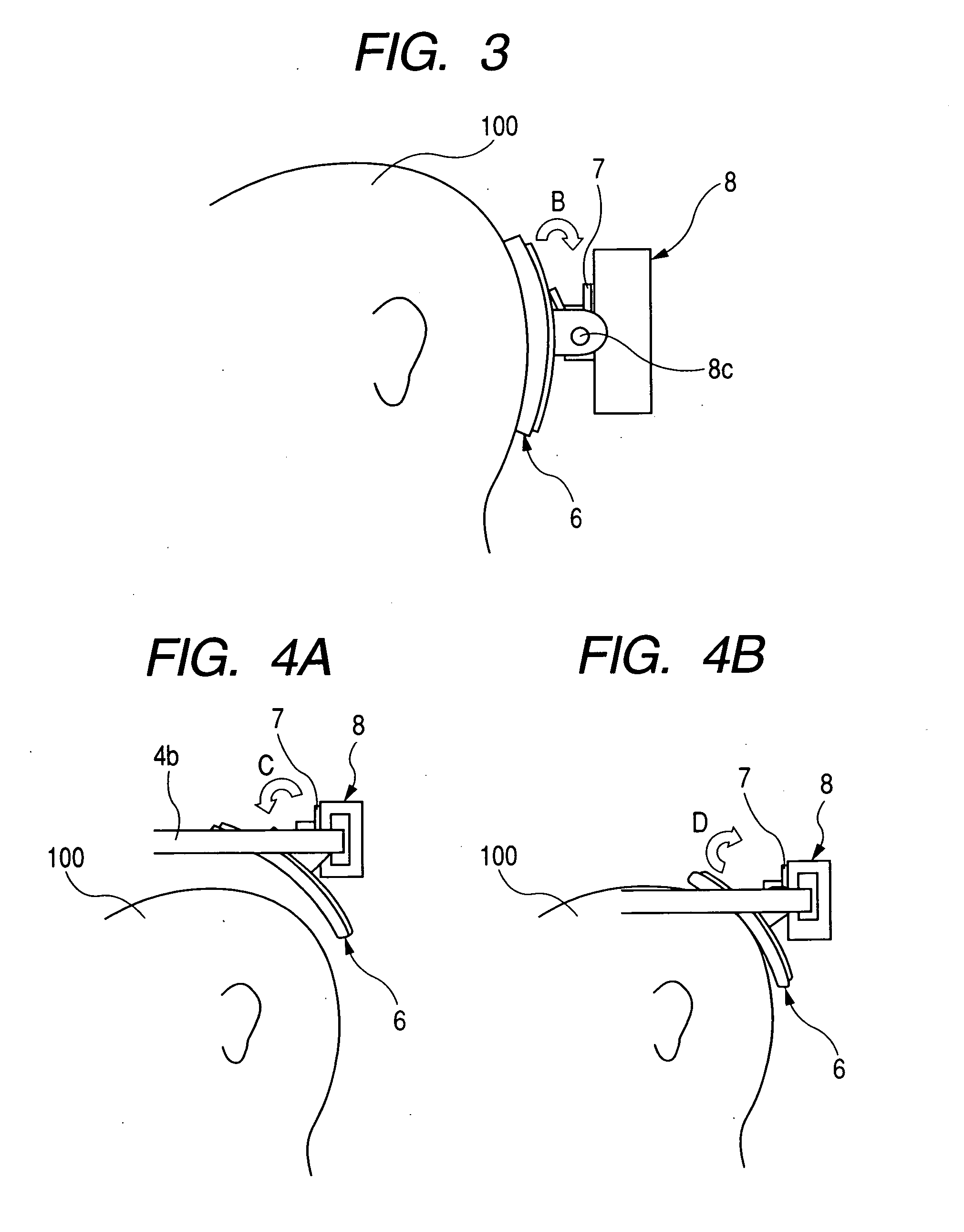

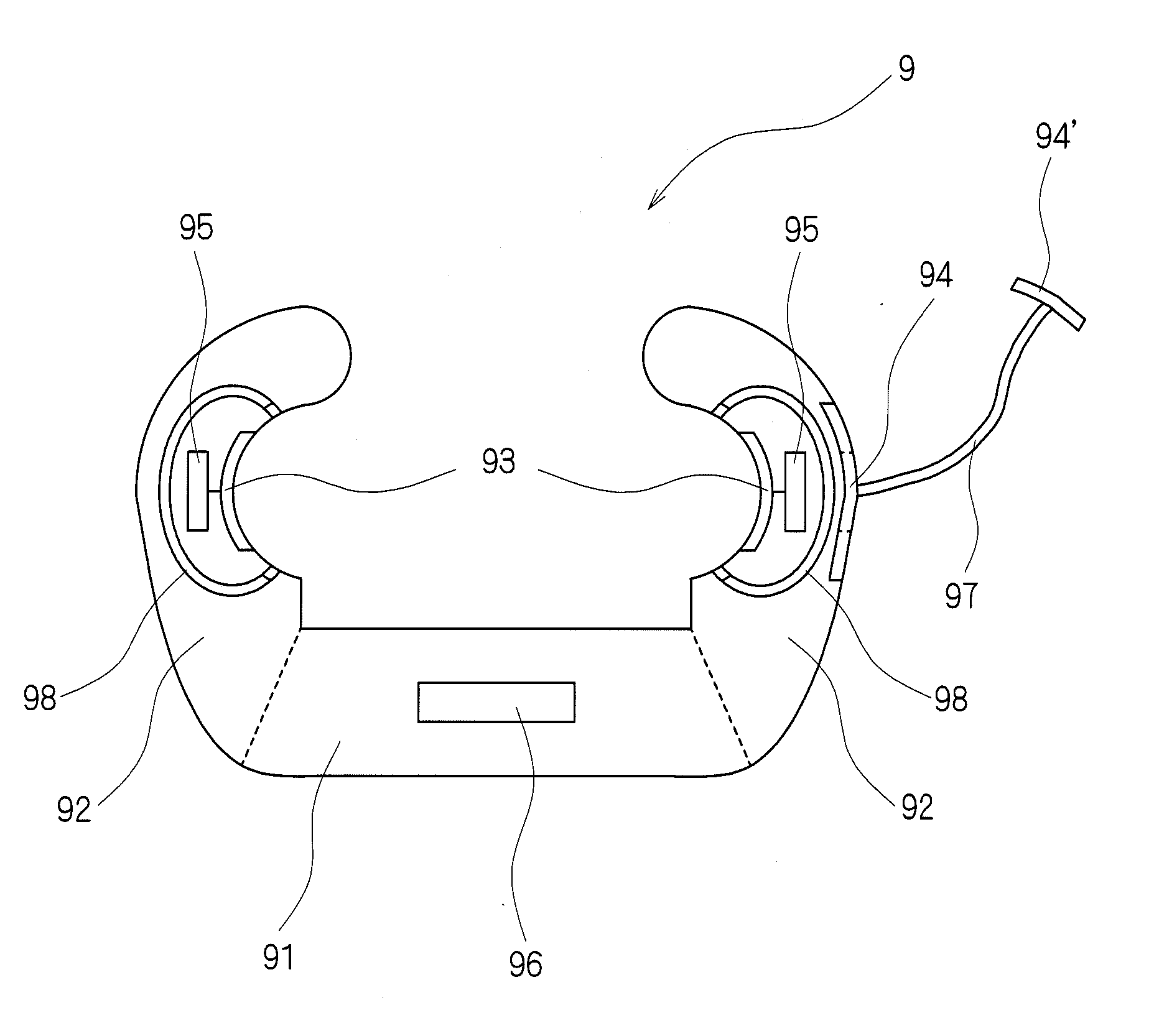

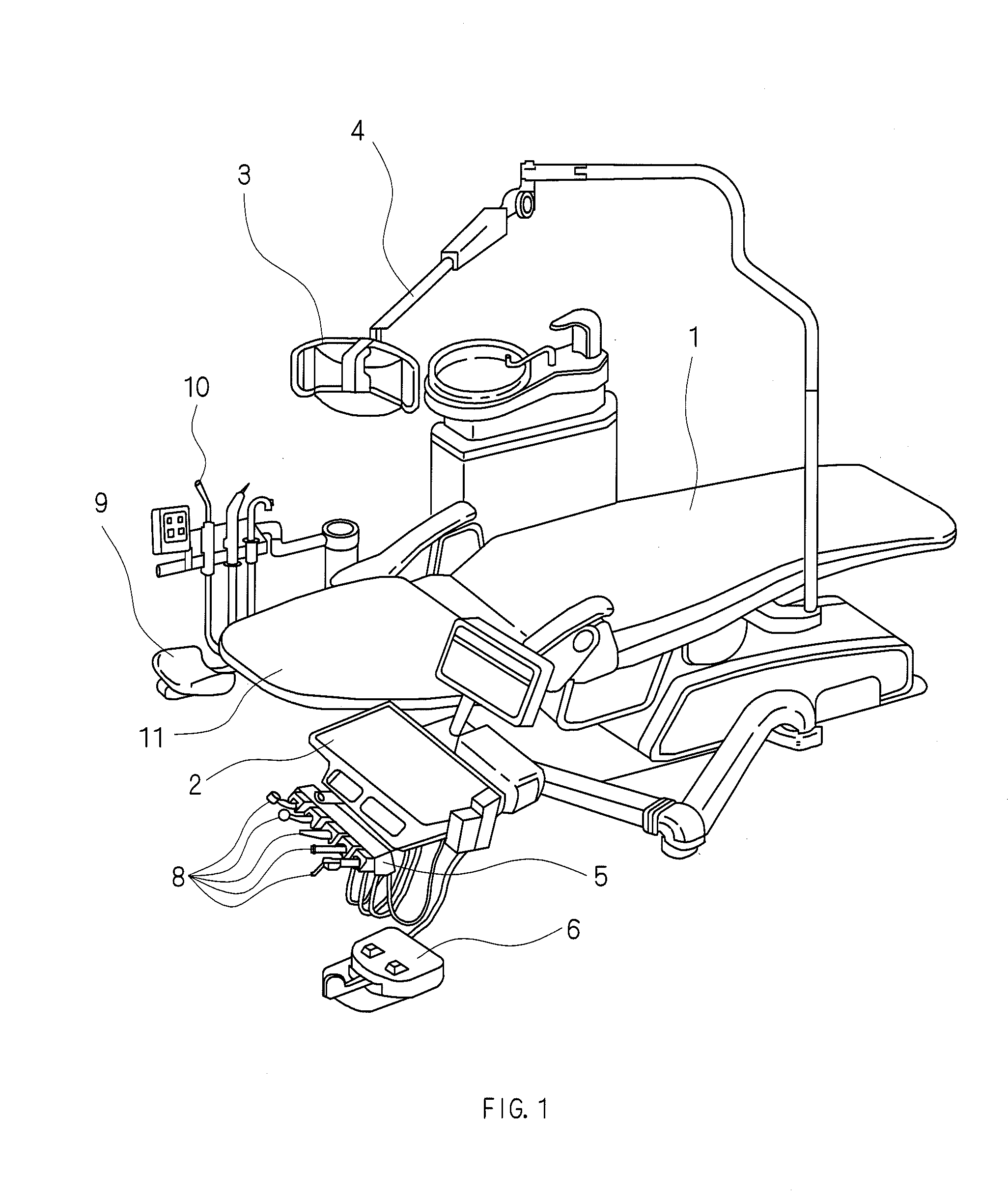

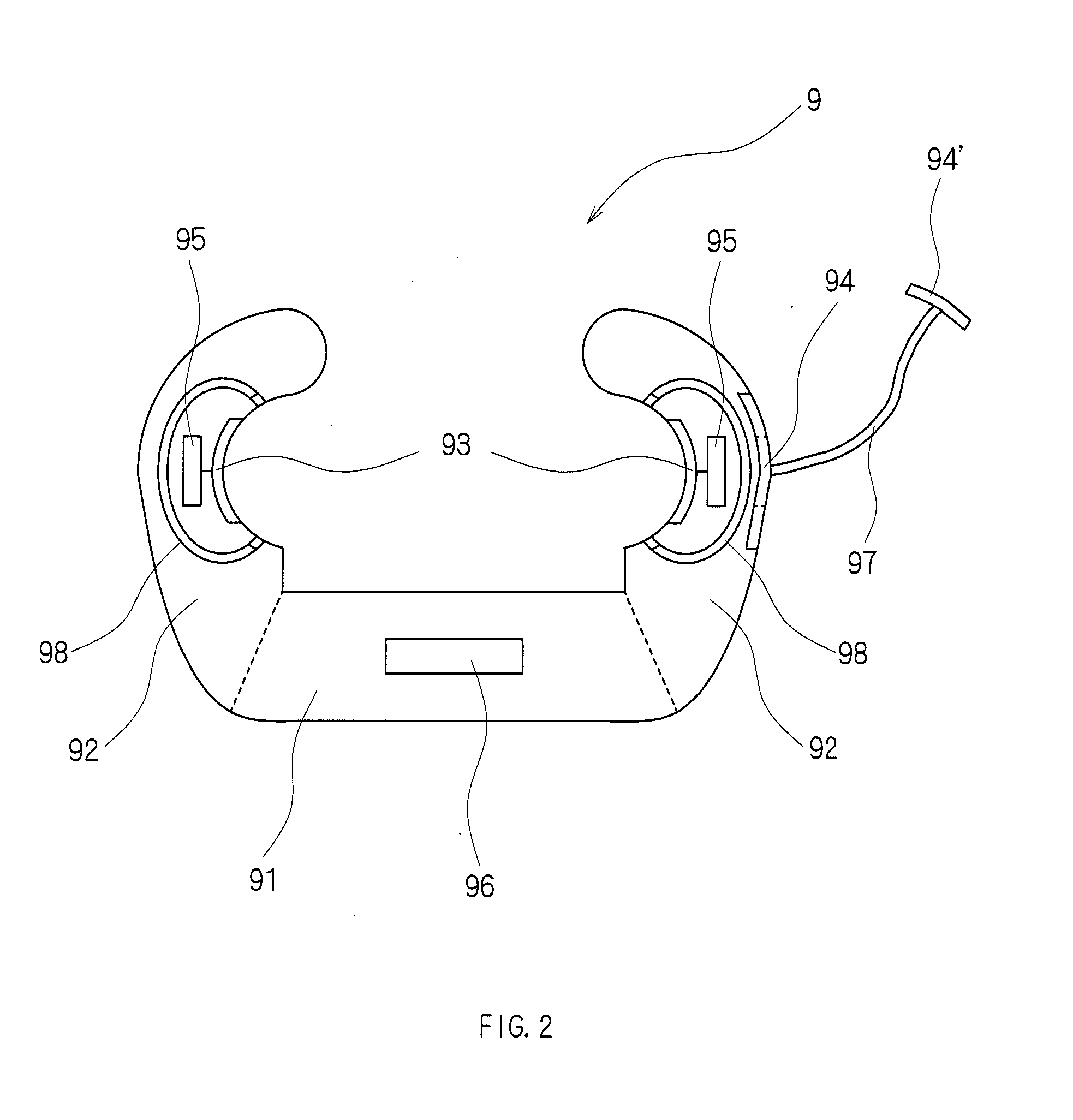

Headrest for dental treatment chair and treatment chair

ActiveUS20110193380A1Minimal communicationReduce noiseOperating chairsDental chairsSound sourcesDental surgeon

The invention provides a headrest for a dental treatment chair and a dental treatment chair wherein discomfort due to noise generated from dental treatment instruments can be reduced and communication between a dentist and a patient can be ensured.The headrest for the dental treatment chair and the dental treatment chair comprise a back head supporting member 91 for supporting a back of the head of the patient during dental treatment and ear supporting members 92 and 92 which can be bent in directions to cover ears of the patient at both ends of the back head supporting member 91. The ear supporting members 92 and 92 or the back head supporting member 91 has sound output sections 93 and 93 each for outputting a sound from a sound source, and the ear supporting members 92 and 92 have a sound collecting section 94 for collecting sounds in a surrounding environment. Acoustic filters 95 and 95 cut off frequencies higher than 8 kHz from a sound signal collected by the sound collecting section 94.

Owner:YAMADA TOMOMI

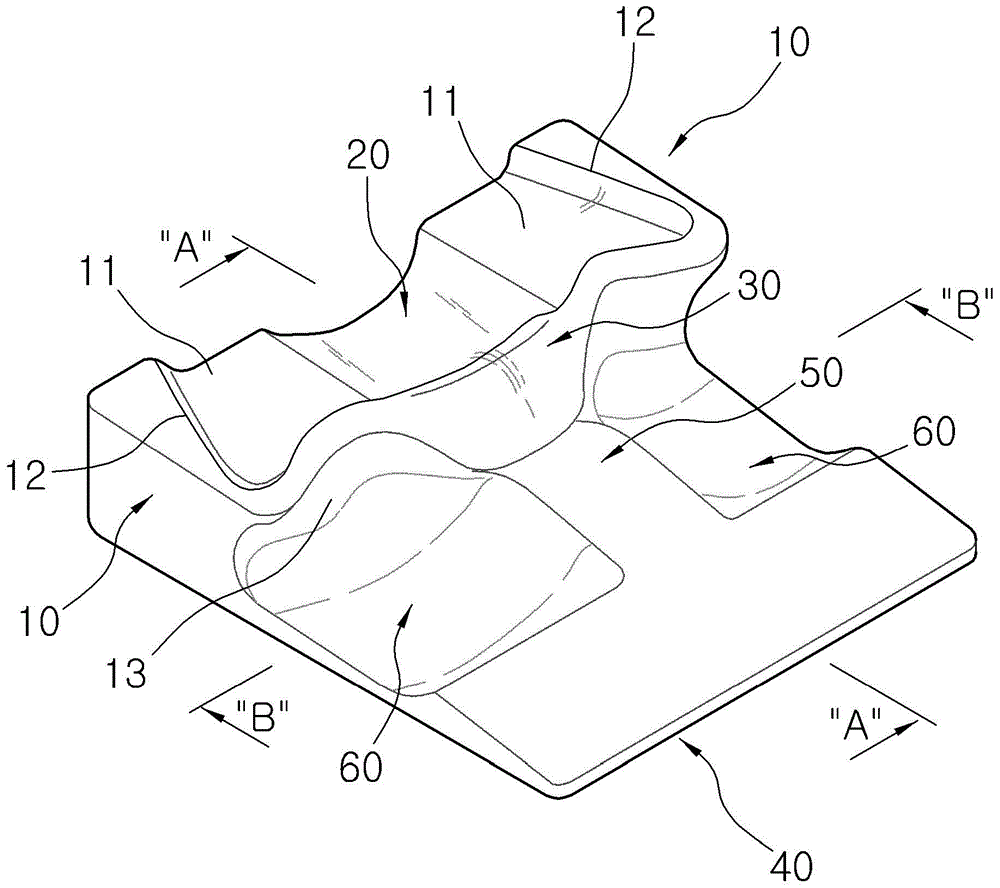

Health pillow capable of body type correction

The present invention relates to a health pillow capable of correcting a body shape, the health pillow comprising: a pillow body including a back head seating part recessed downward, on which a back head of a user lying down straight is seated, the back head seating part being disposed between a pair of, left and right, side head seating parts on which a side head of a user lying on his / her side is seated, and a cervical vertebrae support which is disposed in a front end of the back head seating part, is convex upwardly, and upwardly supports a cervical vertebrae of a user lying straight; and a back supporting body provided in front of the pillow body to allow a back of a user lying straight to be seated thereon, and including a thoracic vertebrae supporting part which has a convex shape at a central portion thereof, and upwardly supports an upper thoracic vertebrae of a user lying down straight. According to the present invention, by supporting the cervical vertebrae and the upper thoracic vertebrae to allow a user to have a good posture, a straightening neck and a swayback may be corrected and a comfortable posture may be maintained without stiffening a neck and shoulders, thereby providing an optimized sleep effect.

Owner:南文植

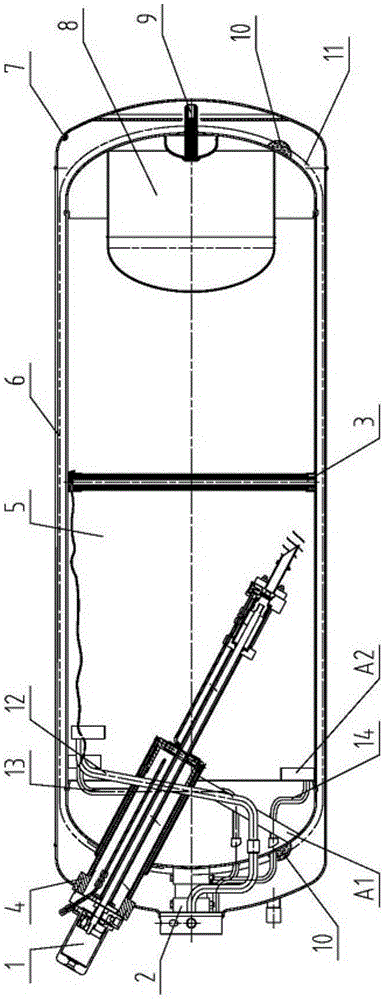

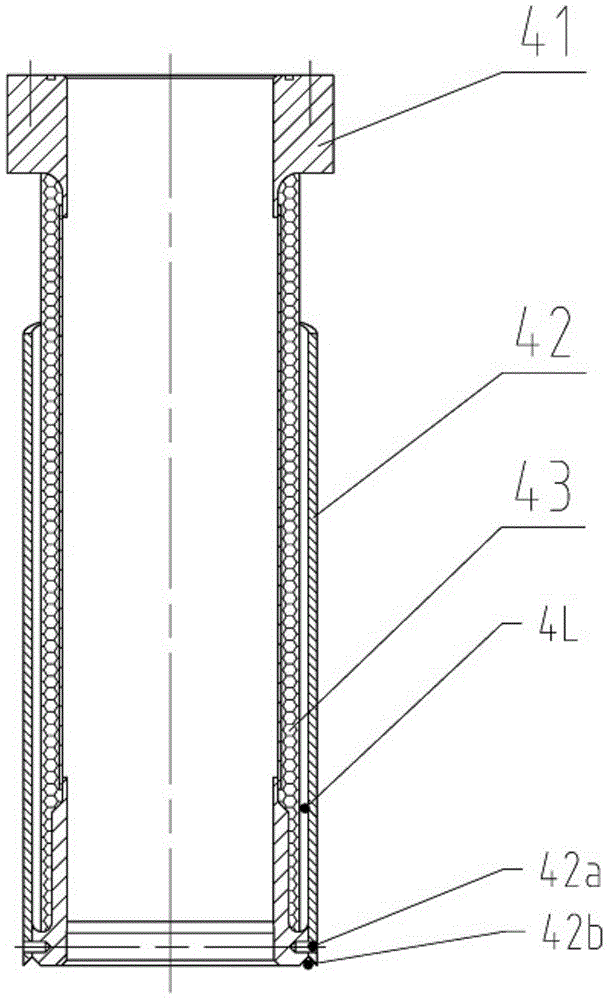

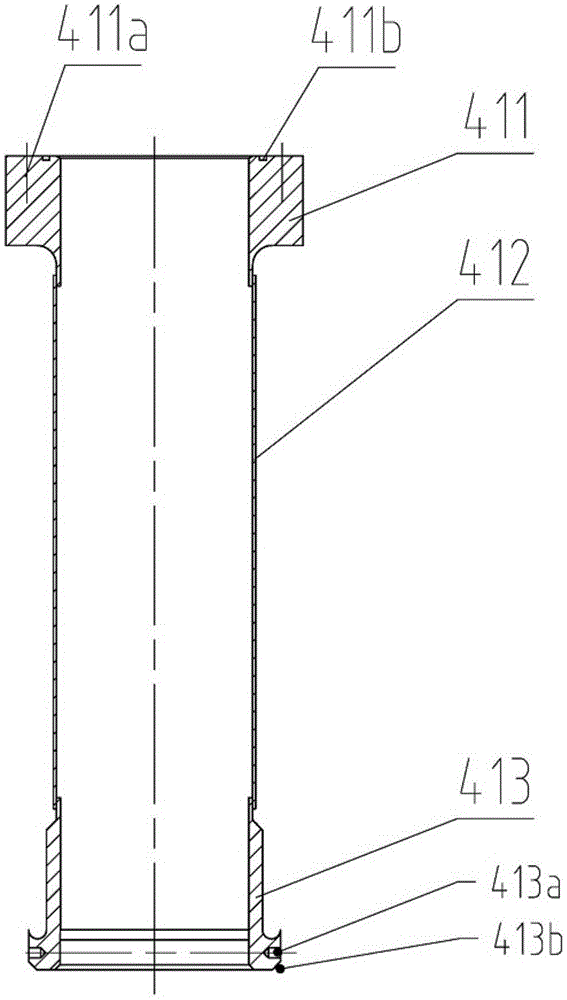

Liquefied natural gas cylinder for vehicle and heavy-duty truck using liquefied natural gas cylinder for vehicle

ActiveCN105443972AFix security issuesReduce heat leakageContainer filling methodsPressure vesselsThermal insulationGas cylinder

The invention provides a liquefied natural gas cylinder for vehicle and a heavy-duty truck using the liquefied natural gas cylinder for vehicle. A cryopump is connected to a hydraulic control system, a split type inside sleeve comprises a flange, a thin walled tube and a pedestal, and a thermal insulation layer is provided on the outer wall of the thin walled tube as well as between the flange and the pedestal; an overlay welding is carried out for an outside sleeve and the inside sleeve after positioning through a corresponding through hole and a corresponding tapped hole, grooves are respectively formed at bottom parts of the inside sleeve and the outside sleeve, an inverted V-shaped part is combined after connection, and a welding is carried out; a valve seat in a front end supporting device is provided with multifunctional holes, a liquid inlet tube, a liquid outlet tube, a blow-down tube, a liquidometer tube or a safety valve tube are installed in the holes, an over-filling preventing head and an over-filling preventing cylindrical shell are equipped, and the bottom of the over-filling preventing head is provided with a small hole; a rear end supporting device is provided with a small hole on a supporting head, so that the internal space of the supporting head is communicated with the space of the cylinder; a rear end supporting shaft sleeve is made of epoxy glass fiber reinforced plastic; front and back heads of an inner container are provided with molecular sieves; a head of a housing is provided with palladium oxide. The cryopump can be stably installed on the liquefied natural gas cylinder, and heat leakage is effectively reduced.

Owner:SHAANXI AUTOMOBILE GROUP +1

Hydraulic breaker

InactiveUS20170274516A1Easy to replaceImprove productivityMechanical machines/dredgersPortable percussive toolsChiselReciprocating motion

The present invention relates to a hydraulic breaker comprising: a back head having a gas chamber provided therein; a cylinder disposed at the lower part of the back head, and having a hydraulic passage and a hydraulic space; a front head disposed at the lower part of the cylinder; a chisel provided inside the front head; a piston provided to reciprocate in the cylinder so as to hit the chisel; and a breaker main body having a plurality of penetration bolts integrally connecting the back head, the cylinder, and the front head, wherein the back head of the breaker main body is provided with a control valve for supplying and blocking hydraulic pressure to / from the hydraulic passage and the hydraulic space.

Owner:AYHEAVY IND

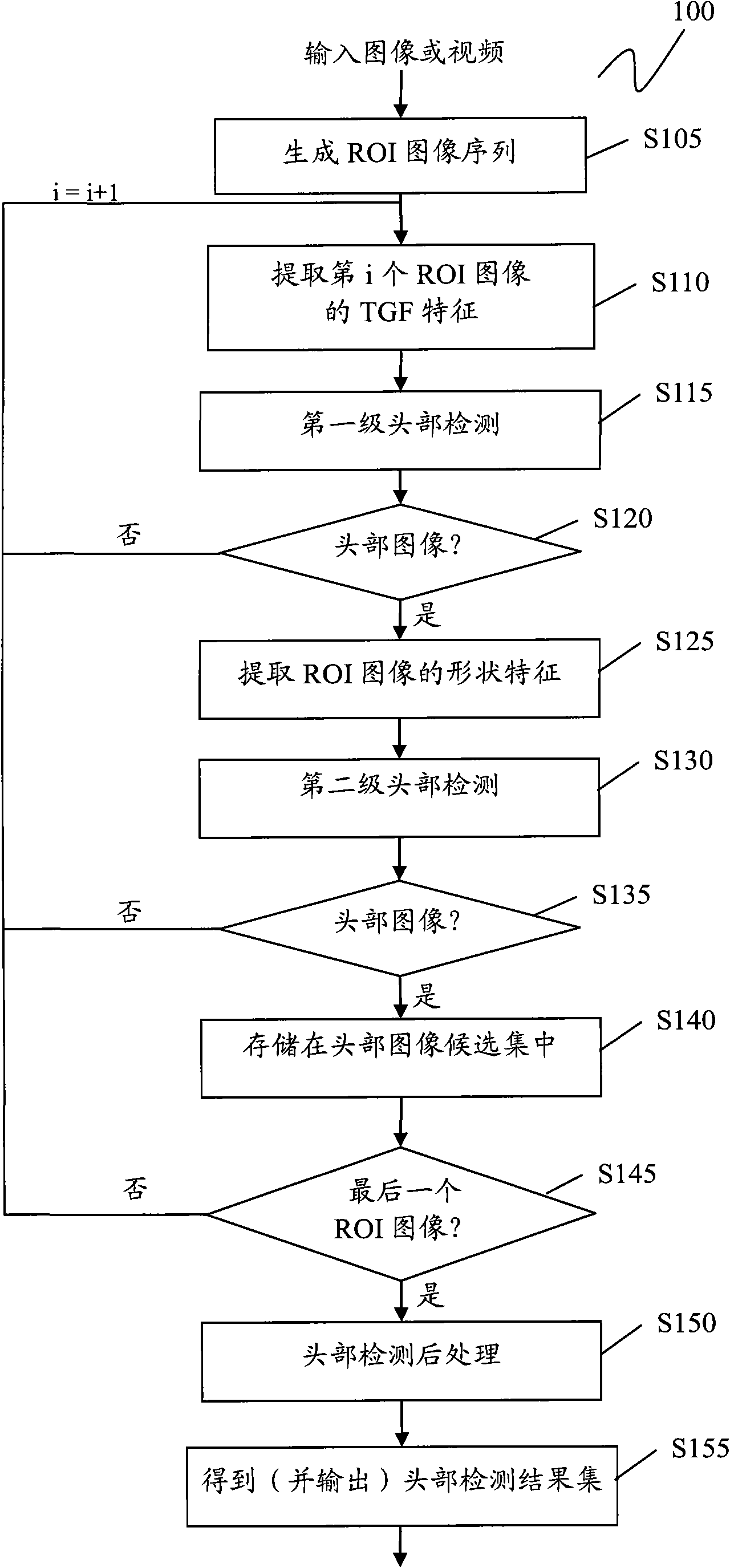

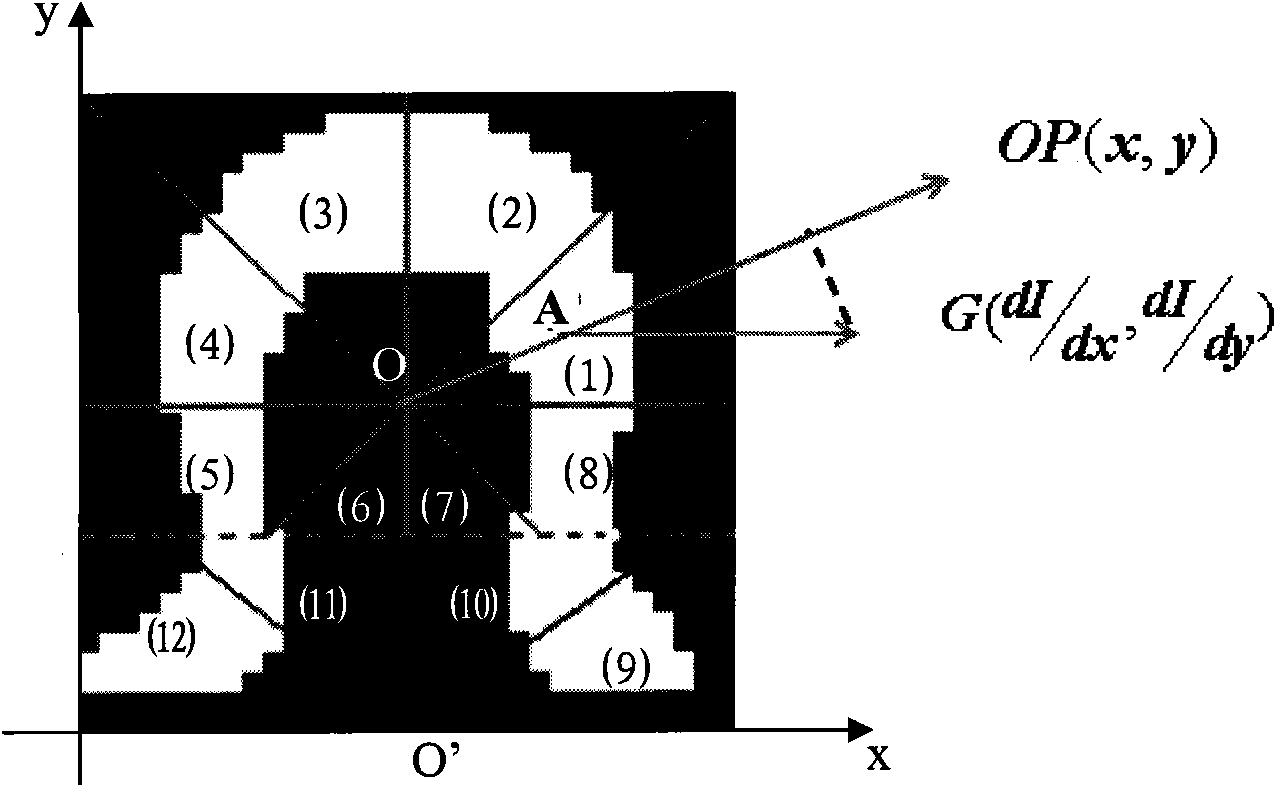

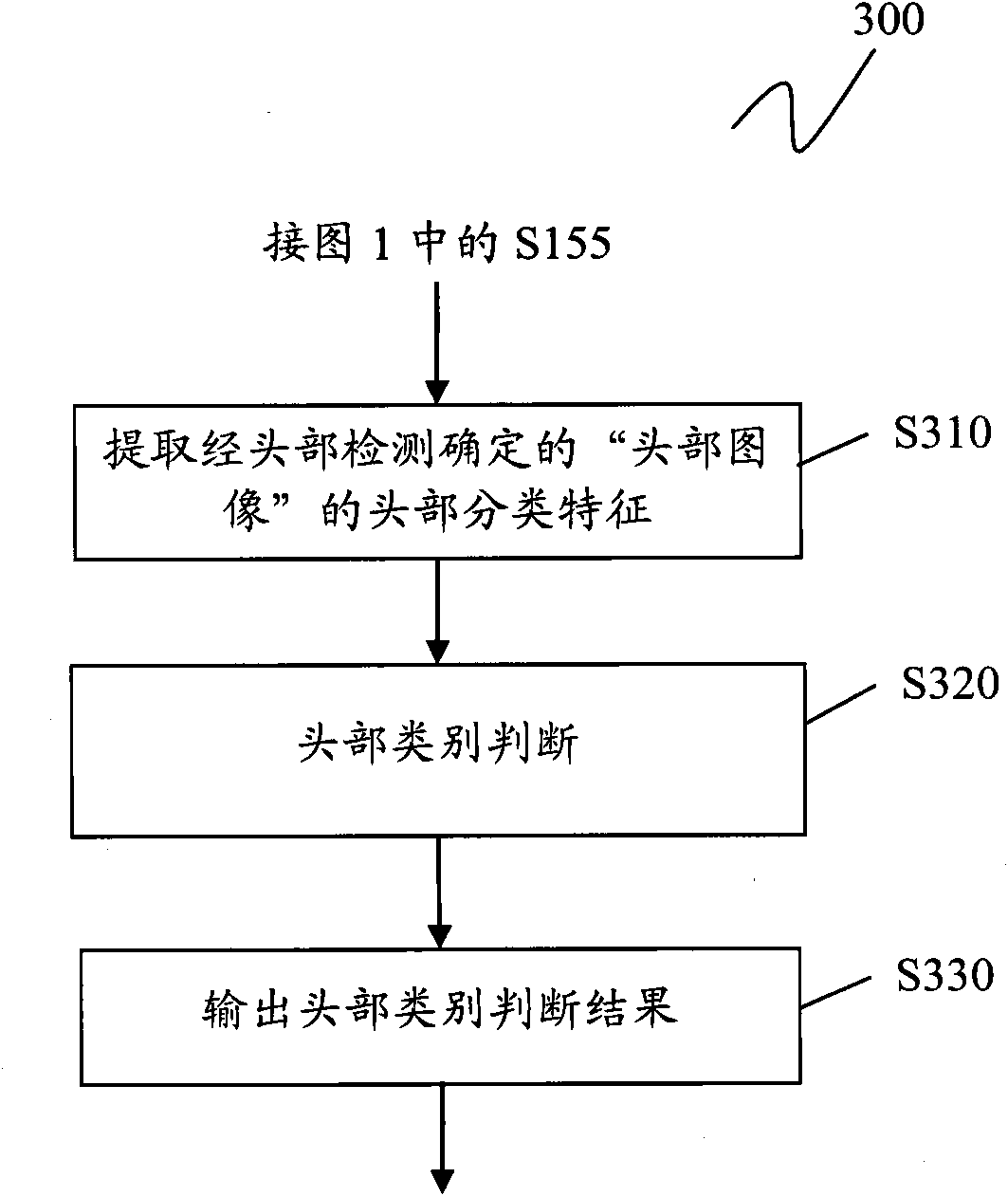

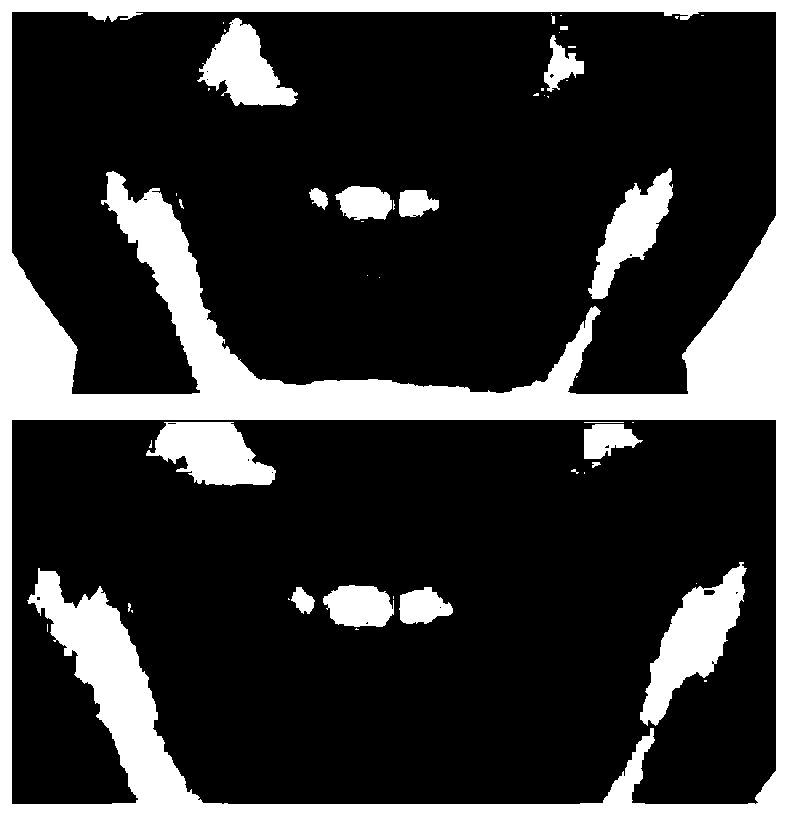

Head detection method and device and head detection and category judgment method and device

InactiveCN101826150AImprove accuracyQuick cullingCharacter and pattern recognitionPattern recognitionFalse detection

The invention discloses a head detection method and a device, which is used for detecting head images from input original images, as well as a head detection and category judgment method and a device, which is used for detecting head images from input original images and carrying out category judgment. By using the embodiment of the invention, region of interest (ROI) images which are not the head images obviously are quickly removed from the original images by a first-level head detection based on TGF characteristics and then head images are selected from the rest ROI images by a second-level head detection based on shape characteristics. In addition, if required, confirmation and category judgment can be further carried out on the ROI images which are head images based on results of two levels of head detections to distinguish front / profile / back head images or even non-head images which are detected as head images by mistake. The invention can secure low omission rate, improve accuracy of head detection and reduce false detection rate.

Owner:SONY CORP

Head mounted device and head mounted system

Owner:CANON KK

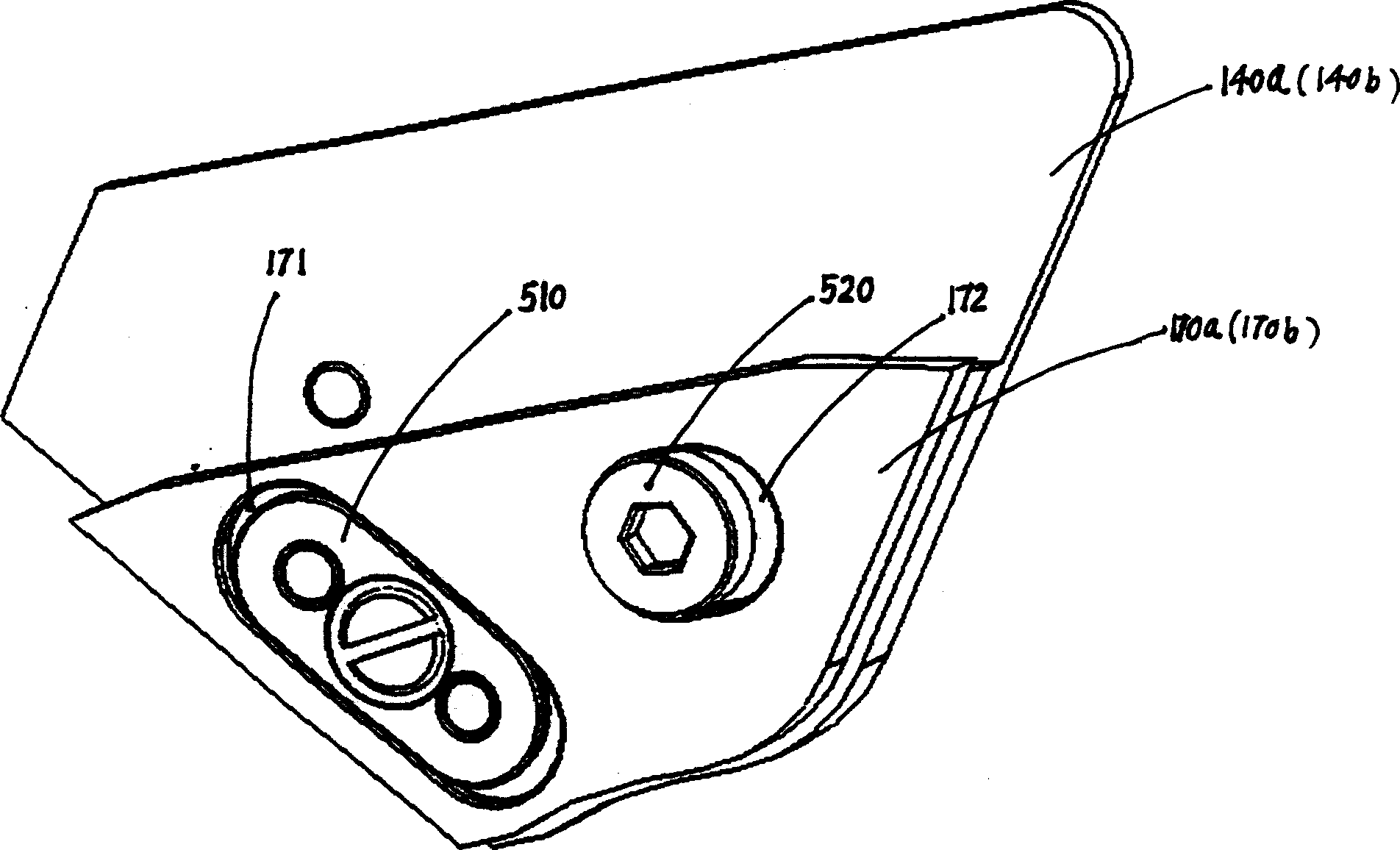

Machine head structure of knitting flat machine

A head structure of flak knitting machine features that on the base plate of its front and back heads there are central jacquard cam, fixing cam, needle raising cam, big knit cam, leaf and right herringbone cams, return cam, movable kit cam and regulation mechanism for generating different densities and varying pattern.

Owner:陈焜镛

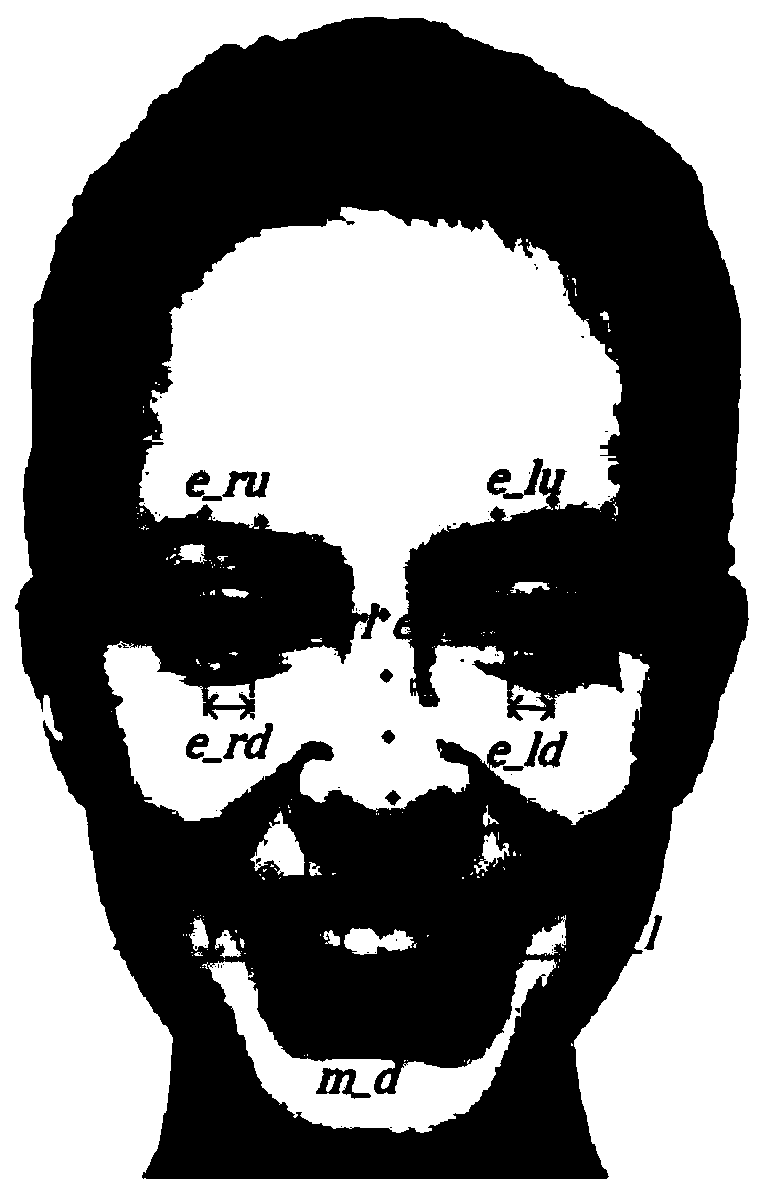

Driver face characteristic distance correction method based on facial expression fatigue driving detection algorithm

InactiveCN109934207AHigh precisionImprove real-time performanceCharacter and pattern recognitionDistance correctionRectangular coordinates

The invention discloses a driver face characteristic distance correction method based on a facial expression fatigue driving detection algorithm. The method comprises: when a driver shakes up and downand shakes the head or tilts the head leftwards and rightwards, the actual value of the transverse or longitudinal feature distance between the mouth and eyes is derived by changing the included angle between the transverse or longitudinal feature line segments of the mouth and the eyes and the positive direction of the camera; a right hand space rectangular coordinate system is established withthe head of the driver as the center, the x-axis direction is the left ear pointing to the right ear, the y-axis direction is the head pointing direction, and the z-axis direction is the forehead pointing to the back head spoon. The rotation angles of the head on the three coordinate axes are obtained; wherein the pitch angle yaw represents the angle of rotation of the head of the driver around the y axis, the yaw angle pitch represents the distance of rotation of the head of the driver around the x axis, and the roll angle roll represents the angle of rotation of the head of the driver aroundthe z axis, namely the Euler angle of the head of the driver in the three-dimensional space. The obtained Euler angle is used for correcting the characteristic distance, so that the driver facial expression fatigue driving detection accuracy and precision are improved.

Owner:EAST CHINA NORMAL UNIV

Self-luminous projection display system and micro-display full-color optical machine

The invention provides a self-luminous projection display system and a micro-display full-color optical machine. The self-luminous projection display system comprises a plurality of light-emitting units used for emitting light of different colors and an optical light-combining unit arranged on a light path of a light beam emitted by each light-emitting unit, wherein the light emitted by the plurality of light-emitting units is combined and emitted to the outside in the same direction. The self-luminous projection display system of the invention has the beneficial effects that the light-emitting units are adopted to directly emit light with different colors, and the light beams emitted by the light-emitting units are combined by the optical light-combining units and emitted along the same direction, thus the design of the traditional back head reflection type projection light path is changed, a self-luminous projection mode is realized, the light path structure is simplified, and the volume is reduced.

Owner:JADE BIRD DISPLAY SHANGHAI LTD

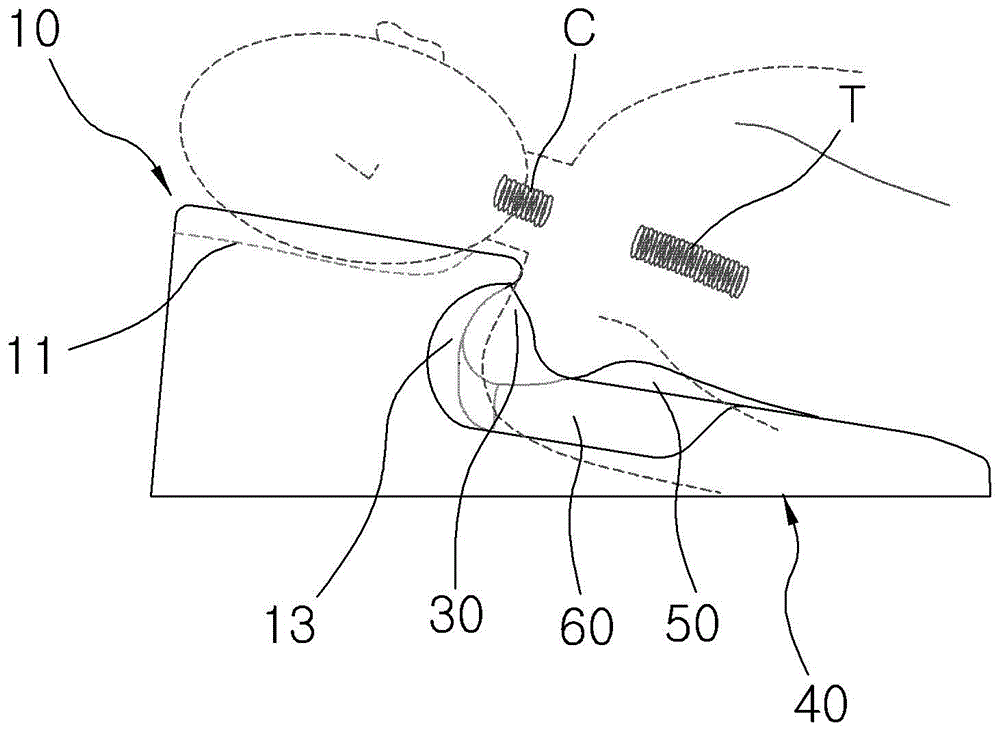

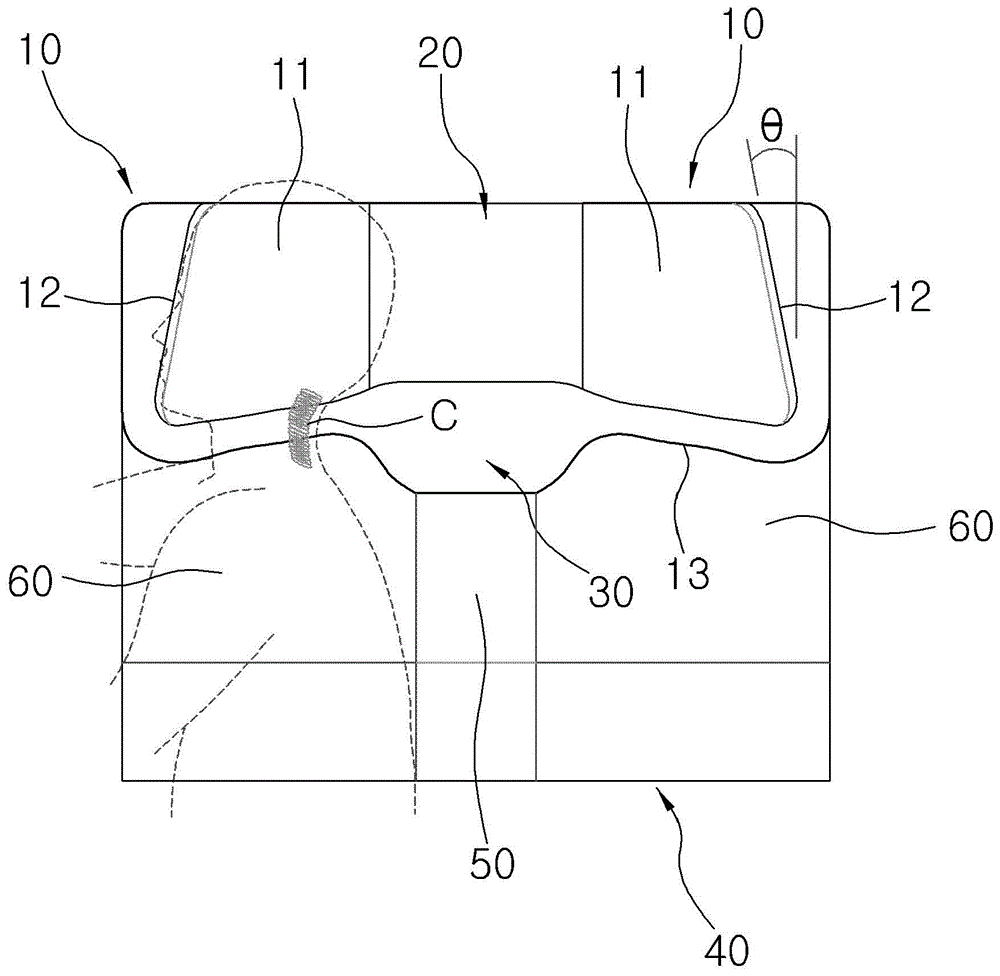

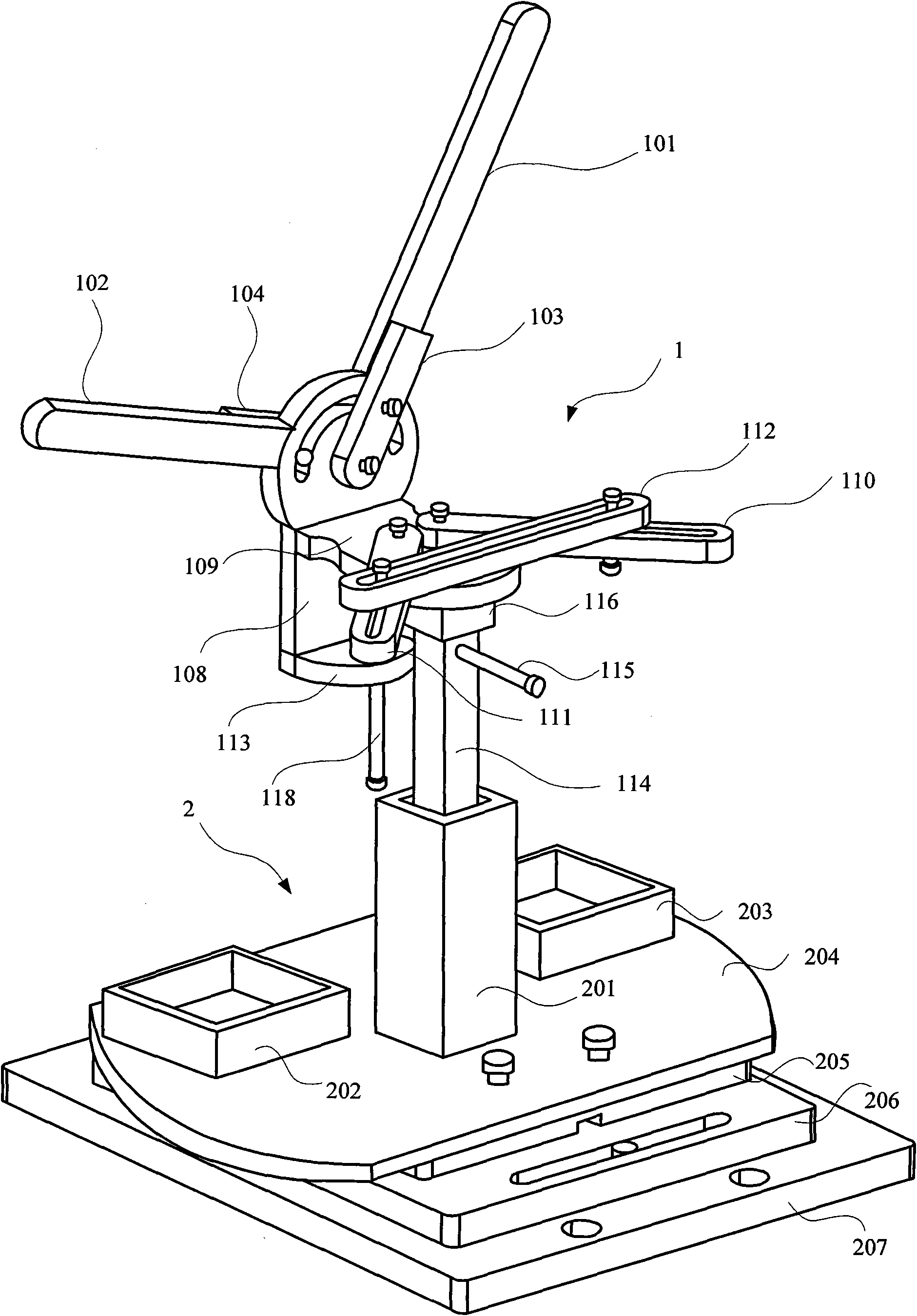

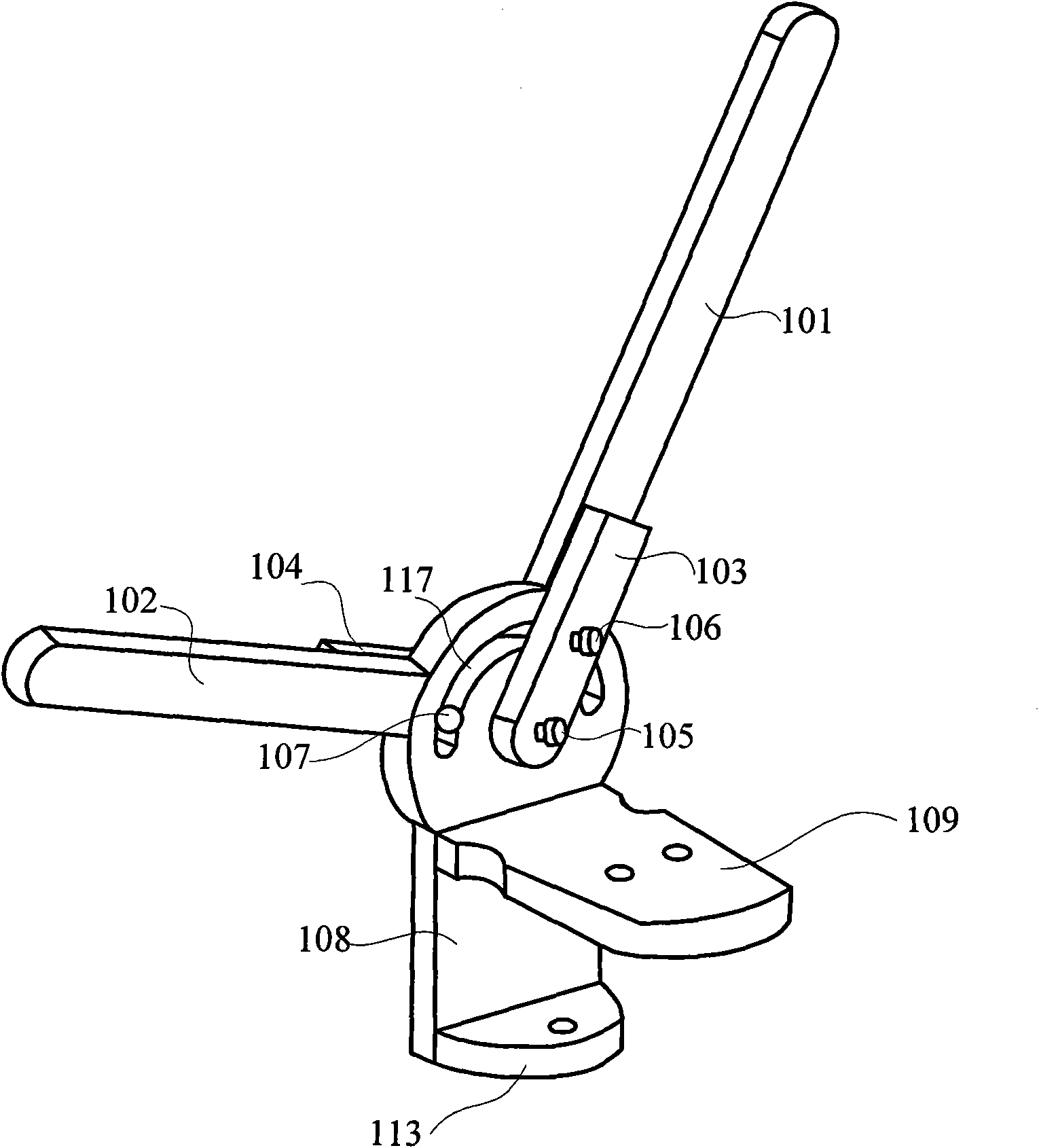

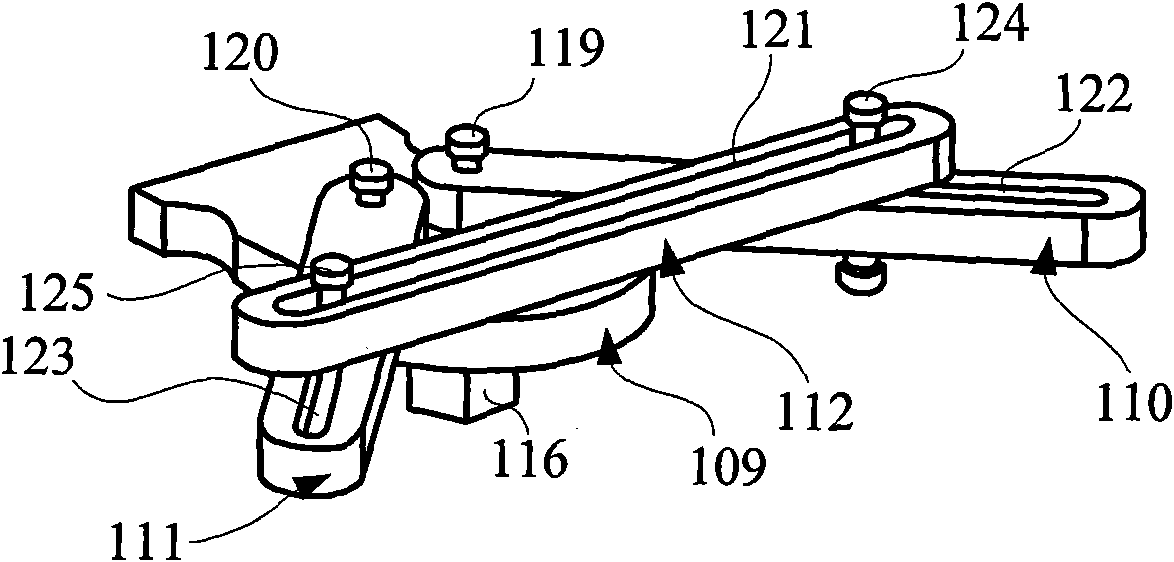

Stationary fixture for pelvis biomechanics experiment

InactiveCN101653380AReduce repetitive workDiagnosticsSurgeryPubic tuberclePhysical medicine and rehabilitation

The invention discloses a stationary fixture for pelvis biomechanics experiment. The fixture is connected to a mechanical testing machine by a base. A first anterior superior iliac spine baffle and asecond anterior superior iliac spine baffle of the fixture are respectively connected to a pubic tubercle baffle by a first sacrum stationary jaw and a second sacrum stationary jaw. A top tray of upper margin of pubic bone and a bottom board of lower margin of pubic bone are respectively vertically connected to the pubic tubercle baffle. The first sacrum stationary jaw and the second sacrum stationary jaw are connected to the top tray of upper margin of pubic bone. A sacrum fixing cross slab is fixed on the first sacrum stationary jaw and the second sacrum stationary jaw. A connecting rod is arranged on the lower surface of the top tray of upper margin of pubic bone. A back head of pubic bone is horizontally connected to the connecting rod. The lower head of pubic bone is vertically drilled through the bottom board of lower margin of pubic bone. With the fixture of the invention, the pelvis can be fixed by taking a standing posture to do experiment, and the substance of bone and the structure of pelvic are not destroyed by assembling or detaching the fixture.

Owner:BEIHANG UNIV

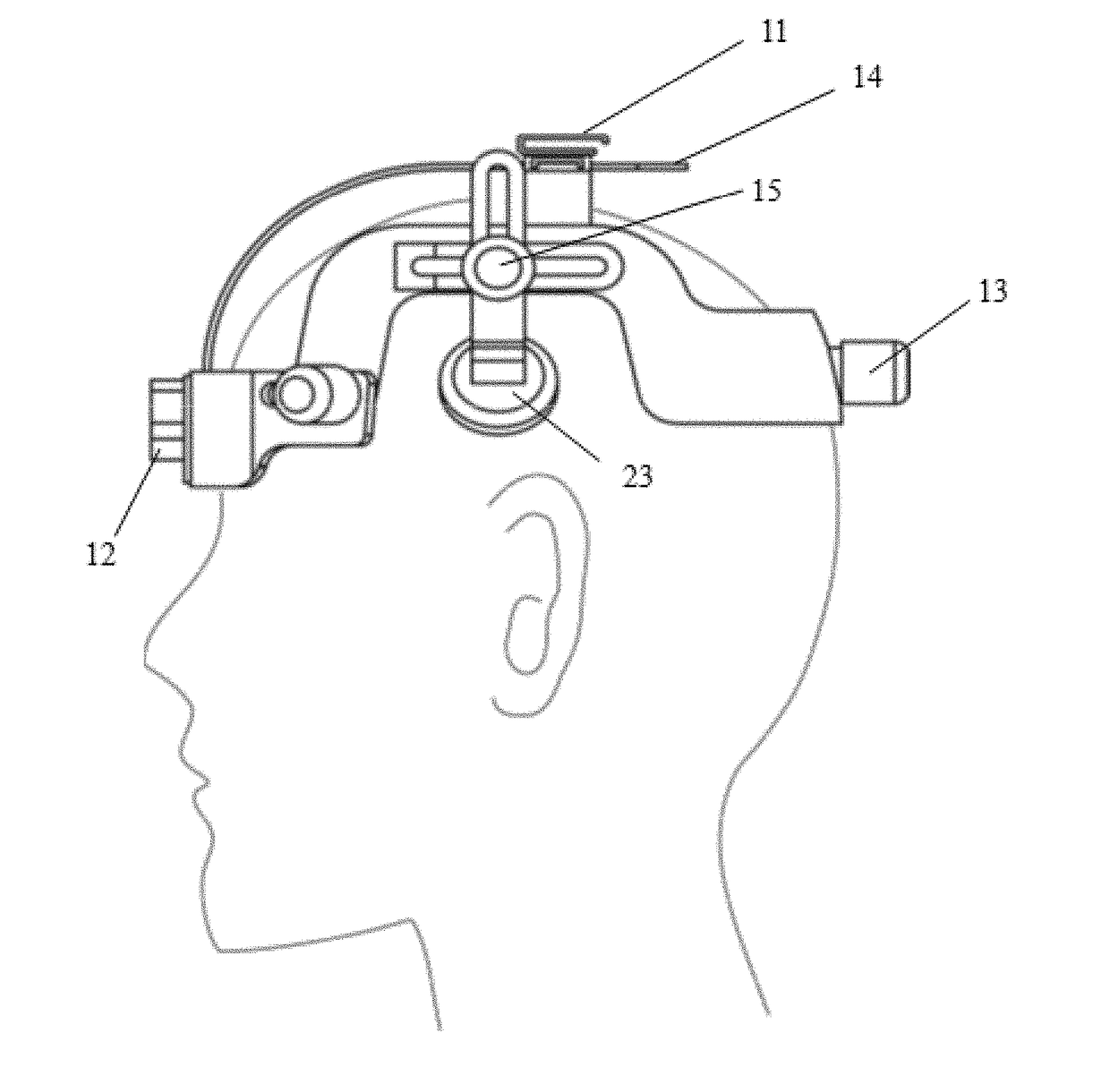

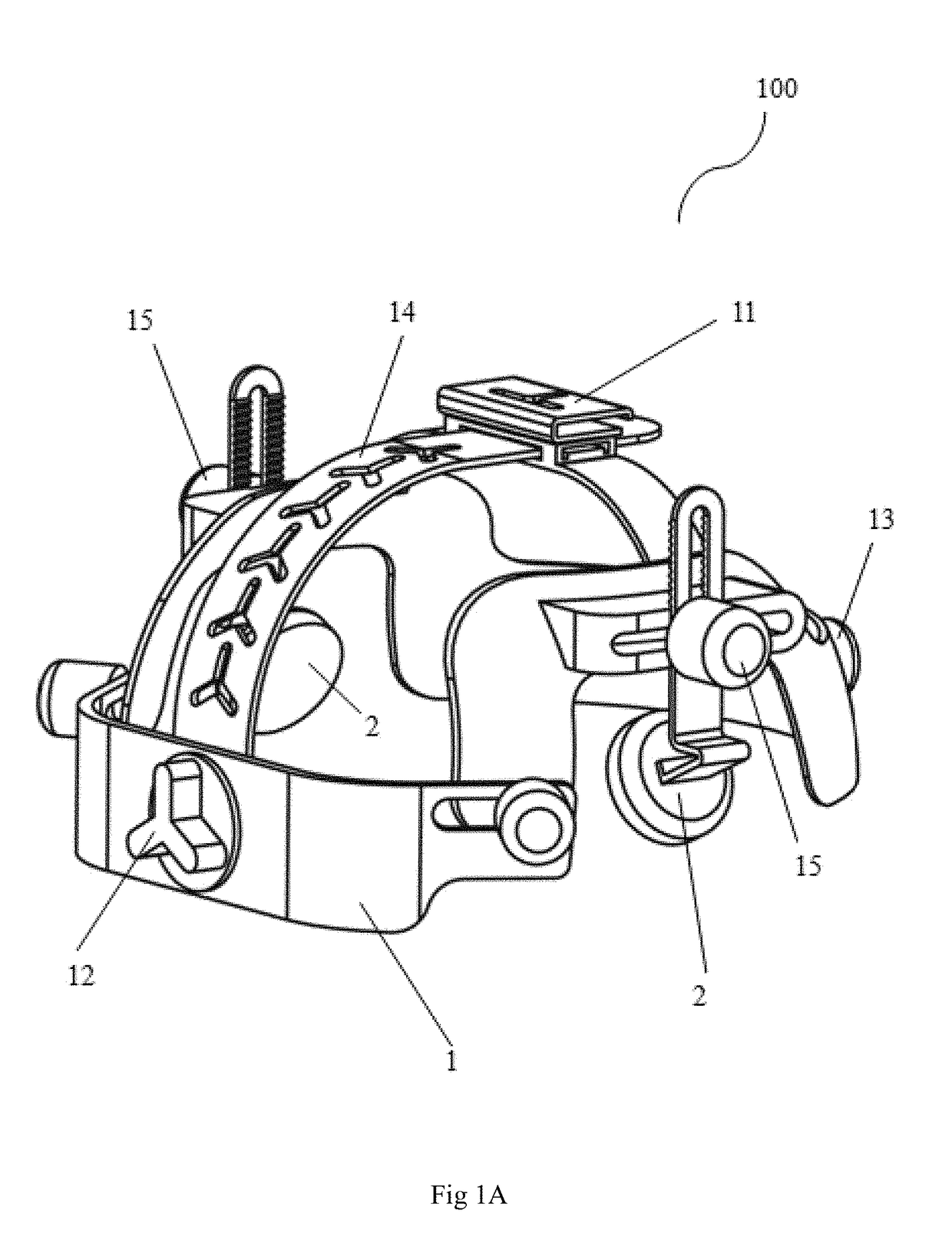

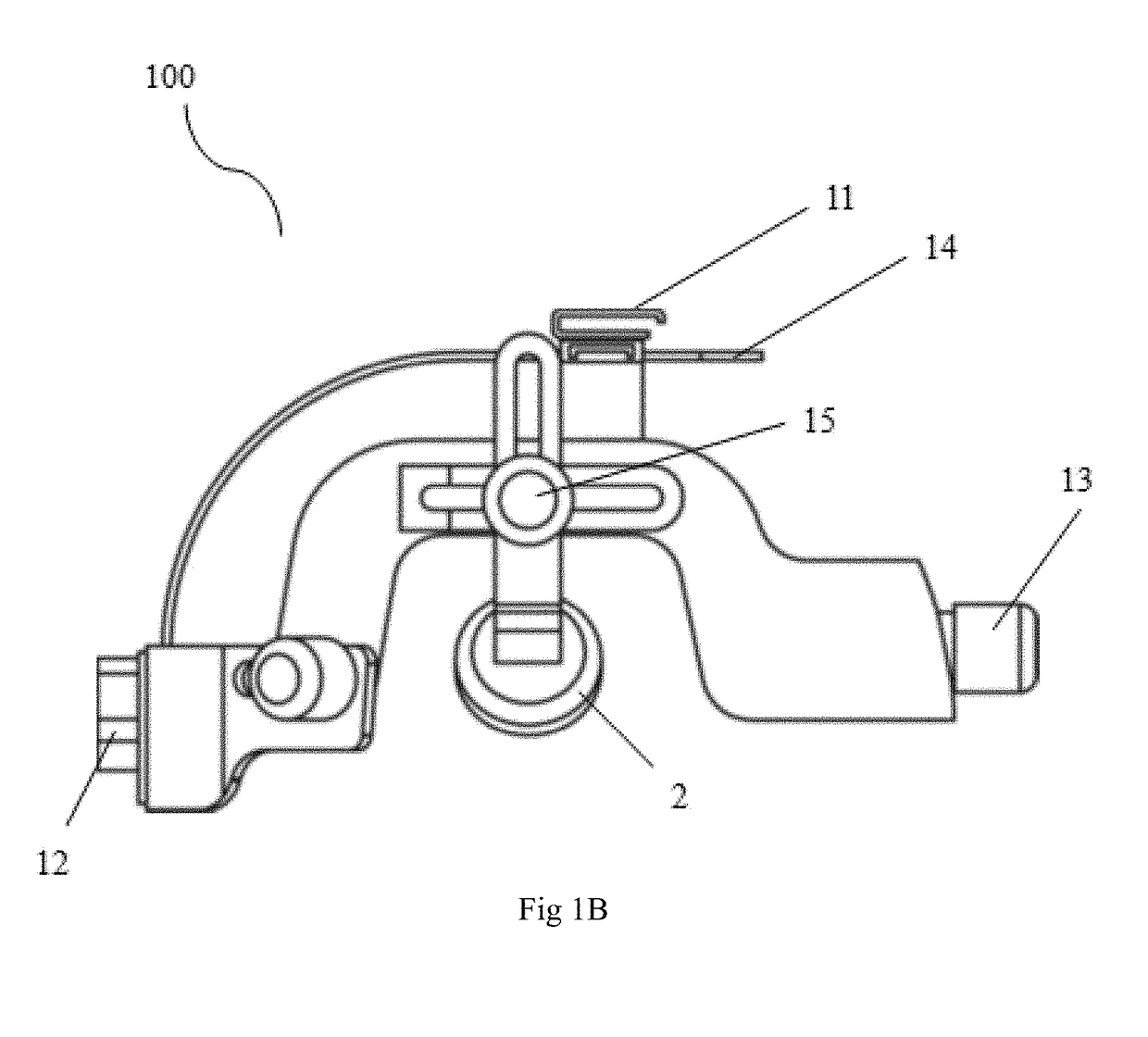

Ultrasound stimulation helmet

ActiveUS20180304101A1Increase and decrease levelUltrasound therapySurgeryDiseaseUltrasound stimulation

An ultrasound stimulation helmet (100) configured to regulate an endogenous neurotrophic factor in a brain or expression of proteins related to a neurodegenerative disease comprises: a main body (1) having a forehead perimeter adjustment knob (12), a back head perimeter adjustment knob (13), a fastening support frame (14), and multiple position adjustment knobs (15); and multiple ultrasound probes (2) detachably mounted on the main body (1), wherein the ultrasound probe (2) has a frequency adjustment button and an intensity adjustment button to respectively control an output frequency and output intensity of the ultrasound probe (2), and other ultrasound parameters and an angle of the ultrasound probe (2) itself are adjustable as well. The fastening support frame (14) can be used to adjust the length of the main body (1) according to the size of a head of a patient, and the ultrasound probes (2) are connected to the position adjustment knobs (15) to enable the ultrasound probes (2) to move upward, downward, or toward the left or right with respect to the head of the patient.

Owner:NAT YANG MING CHIAO TUNG UNIV

Ground drilling hammer and the driving method

InactiveCN101146978AAvoid attenuationAvoid damageDrill bitsReciprocating drilling machinesFree stateCheck valve

Disclosed herein is a pneumatic operated hammer for rock drilling, the hammer comprising a cylindrical casing, a back head mounted at an upper portion of the casing, a check valve for opening / closing a compressed air passageway in the casing, a guide for supporting the check valve, a piston adapted to ascend and descend with compressed air in the casing, and a button bit for performing a drilling work through the striking of the piston. The piston is extended to a certain length to conform to the work condition of the pneumatic hammer to thereby prevent a water back-flow phenomenon in which underground water, etc., is introduced into the drilling equipment during the drilling work, compressed air passageways and variable compressed air chambers are formed between the piston and the casing so that when the piston ascends by the compressed air, it abruptly ascends at a load-free state, and the piston has axial portions with a reference diameter and different outer diameters so that it is possible to manufacture a hammer bit having a plurality of variable compressed air chambers formed between the casing the piston to fit for the work capacity. The piston ascended in a load-free state strikes the button bit with its rapid and strong striking force produced by the compressed air supplied from the variable chambers while abruptly descending to thereby perform the drilling work.

Owner:EVERDIGM ROCK TOOLS CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com