Optical fibre connector

An optical fiber connector and optical fiber technology, which is applied to the coupling of optical waveguides, etc., can solve the problems of easy breakage of quartz glass optical fibers, delay in construction period, affecting connection testing, etc., to achieve easy maintenance and replacement, speed up docking, and improve docking efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

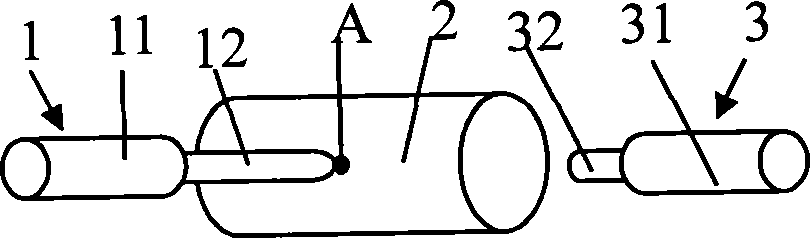

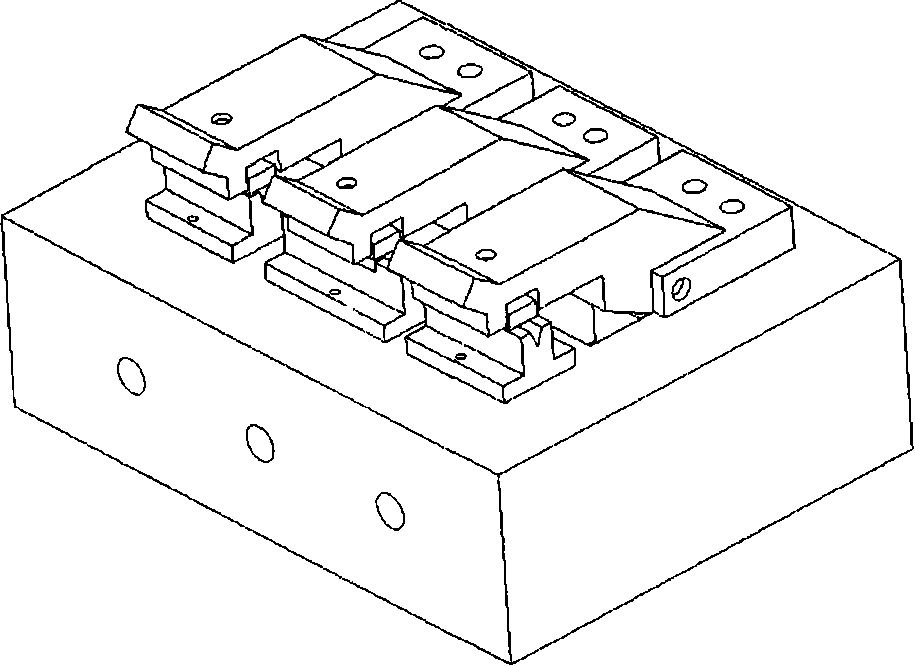

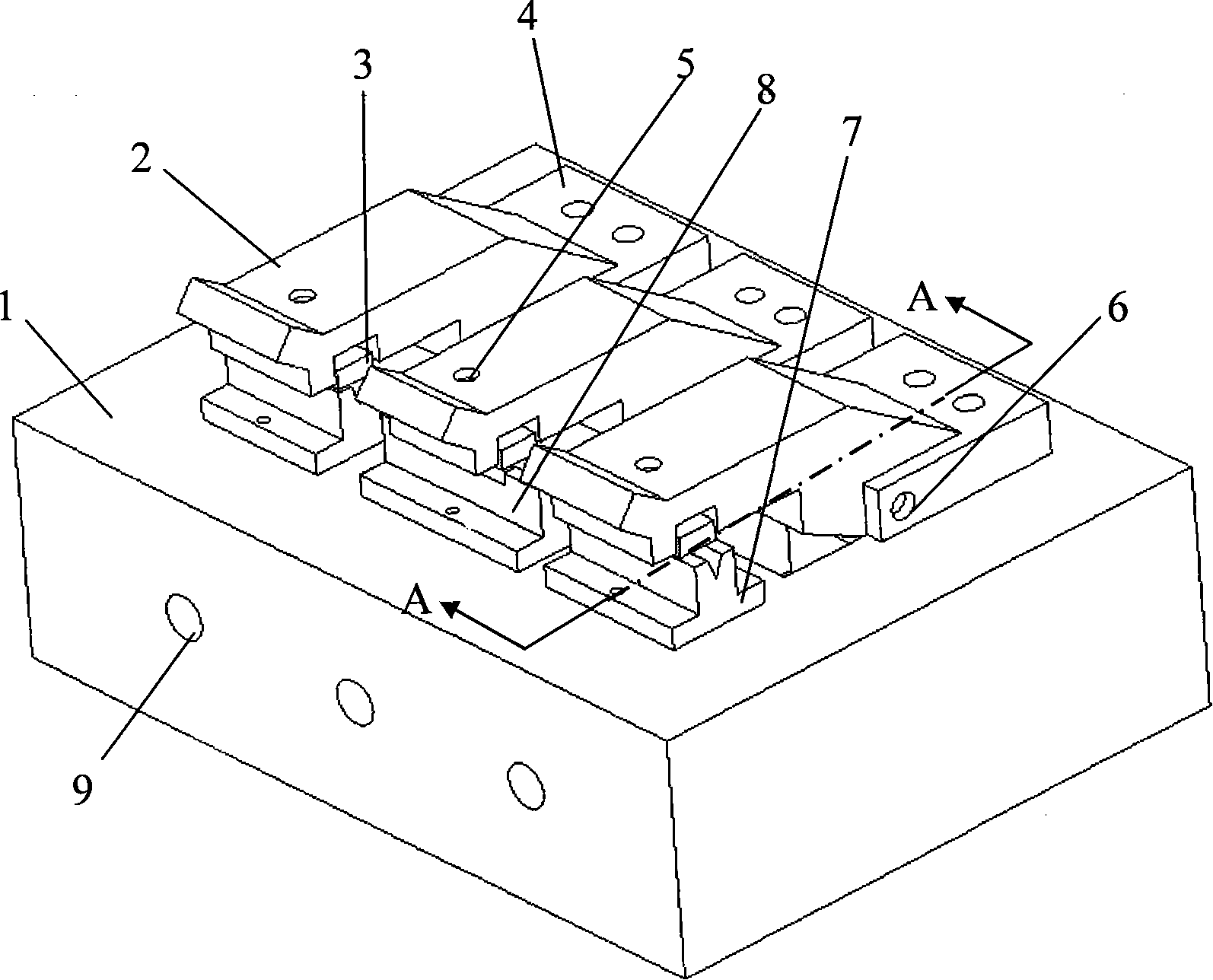

[0017] Such as image 3 and Figure 4 As shown, a fiber optic connector disclosed by the present invention includes: a base 1, the upper bottom surface of the base 1 near the front end is fixed with a V-shaped groove 7 on the left and a right and a V-shaped groove 8 in the middle. The V-shaped groove is used to accommodate the reference optical fiber and the optical fiber to be tested; three concave plates 4 are fixed on the bottom surface of the base 1 near the rear end surface, the concave surface of the concave plate 4 faces the front end of the base 1, and the rear end of the pressure plate 2 is placed into the In the recess of the concave plate 4, three shafts 6 on the right side of the concave plate 4 connect the three concave plates 4 with the three pressure plates 2 respectively, and the upper bottom surface of the pressure plate 2 is provided with a threaded hole near the front end. The pressing plate 2, the optical fiber compaction adjustment spring 5 located in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com