Liquefied natural gas cylinder for vehicle and heavy-duty truck using liquefied natural gas cylinder for vehicle

A technology of liquefied natural gas and gas cylinders, applied in the field of liquefied natural gas cylinders for vehicles, can solve the problems of weak gas supply system, abnormal use, failure of self-pressurization equipment, etc., to solve the inconvenience of use and hidden safety hazards, and to ensure the overall size , the effect of increasing the heat conduction path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings.

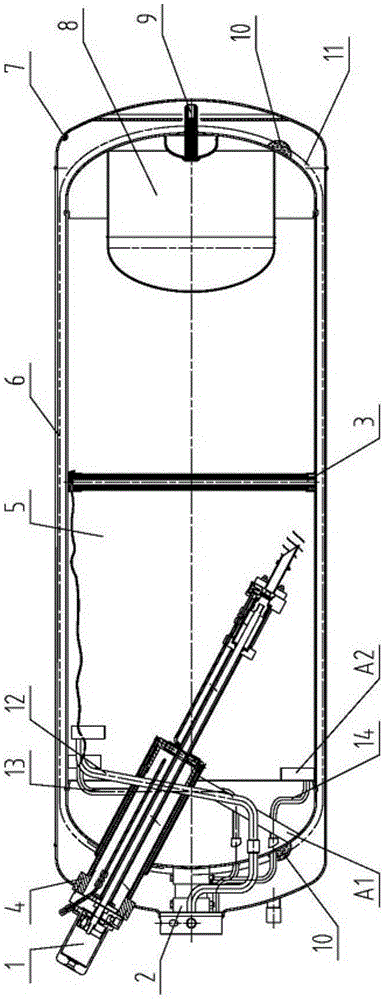

[0044] Such as figure 1 As shown, this kind of liquefied natural gas cylinder for vehicles includes an outer shell 6, an inner tank 5, a cryogenic pump 1 and a liquid level gauge 3. Both the inner tank and the outer shell are provided with front and rear heads. A heat insulating space 12 is formed between them, and the liner 5 is respectively connected to the shell 6 through the front support device 2, the cryopump sleeve device 4 and the rear support device 9, the front support device 2 and the cryopump sleeve device 4 are rigid supports, The rear end supporting device 9 is a soft support.

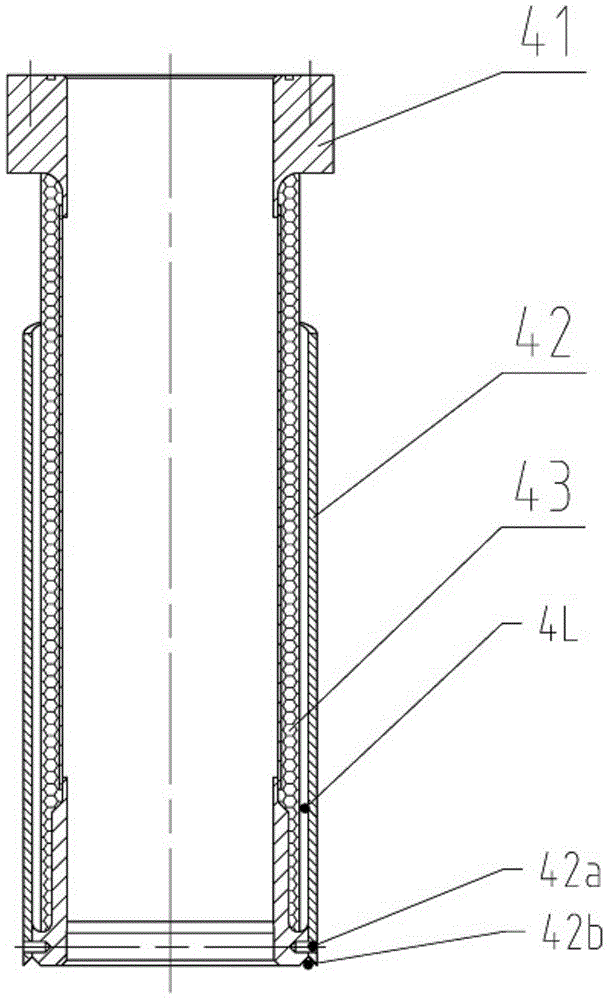

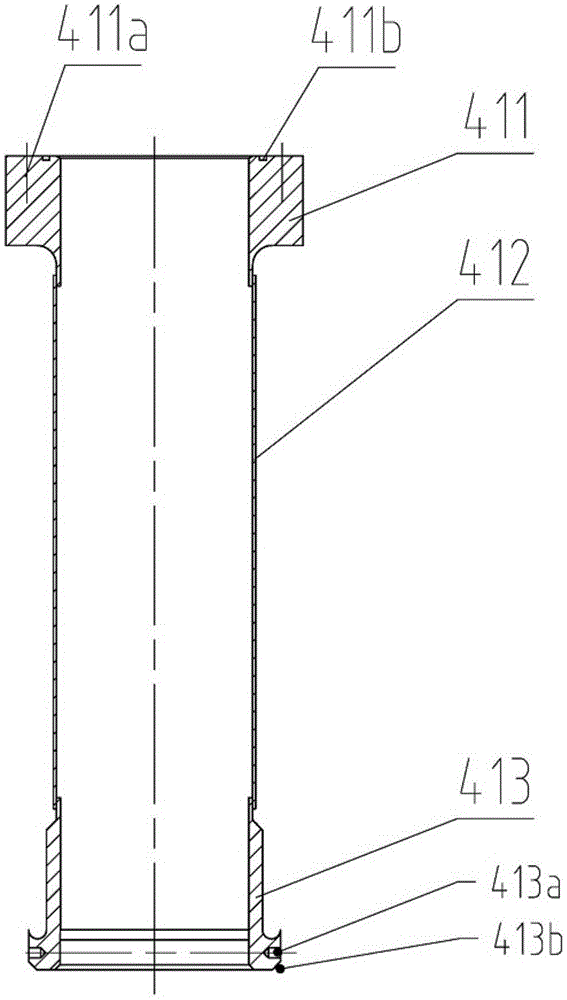

[0045] combine Figure 1~3 As shown, the cryopump sleeve device 4 includes an inner sleeve 41 and an outer sleeve 42. The inner sleeve 41 is arranged in the inner cavity of the outer sleeve 42. The inner sleeve 4 is divided into three parts, and the upper part is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com