Test system for monitoring pipe leakage and early warning safety

A technology for pipeline leakage and safety early warning, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve oil and gas pipeline leakage, affect system application stability and reliability, and cannot directly provide leakage, drilling, etc. Destructive experimental environment and other issues to achieve accurate evaluation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

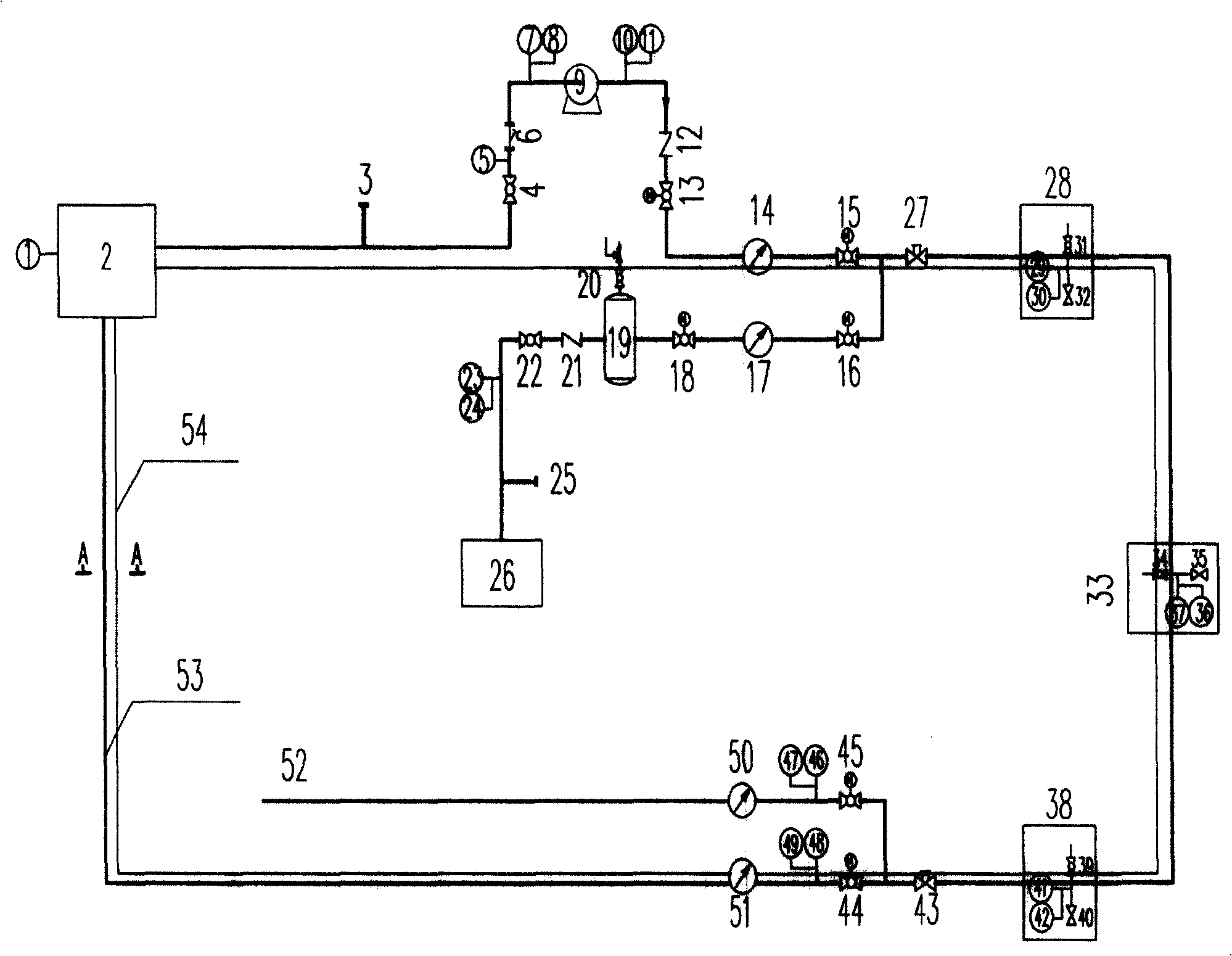

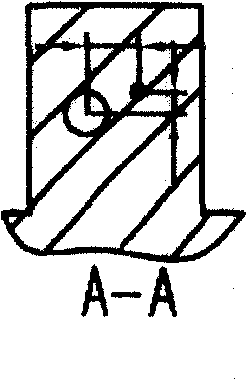

[0051] Embodiment: use this example to illustrate the specific implementation of the present invention and further explain the present invention. This example is an experimental circuit, its composition is as follows figure 1 shown. The test ring pipe 53 of the system is 1 km long, with a diameter of Φ159mm, coated with epoxy powder anti-corrosion coating, buried at a depth of 1.5m underground (from the center of the pipe to the ground surface), and laid in the same ditch 20cm away from the upper edge of the pipe on the right side Optical cable 54 also uses 6-core single-mode sensing optical cable FD6-B1.1-ZU-A, GYSTA53-6B1 armored cable and LSZH six-core single-mode distribution optical cable (passed in silicon core tube) produced by Guangzhou Keyan Optoelectronics Co., Ltd. , the silicon tube is 40 / 33 type produced by Cangzhou Mingzhu Plastic Co., Ltd.); the storage tank area 2 has a capacity of 60m 3 Vault tank; pump 9 is German Baumann HC232-100 twin-screw pump; compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com