Patents

Literature

1203 results about "Oil and gas pipelines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

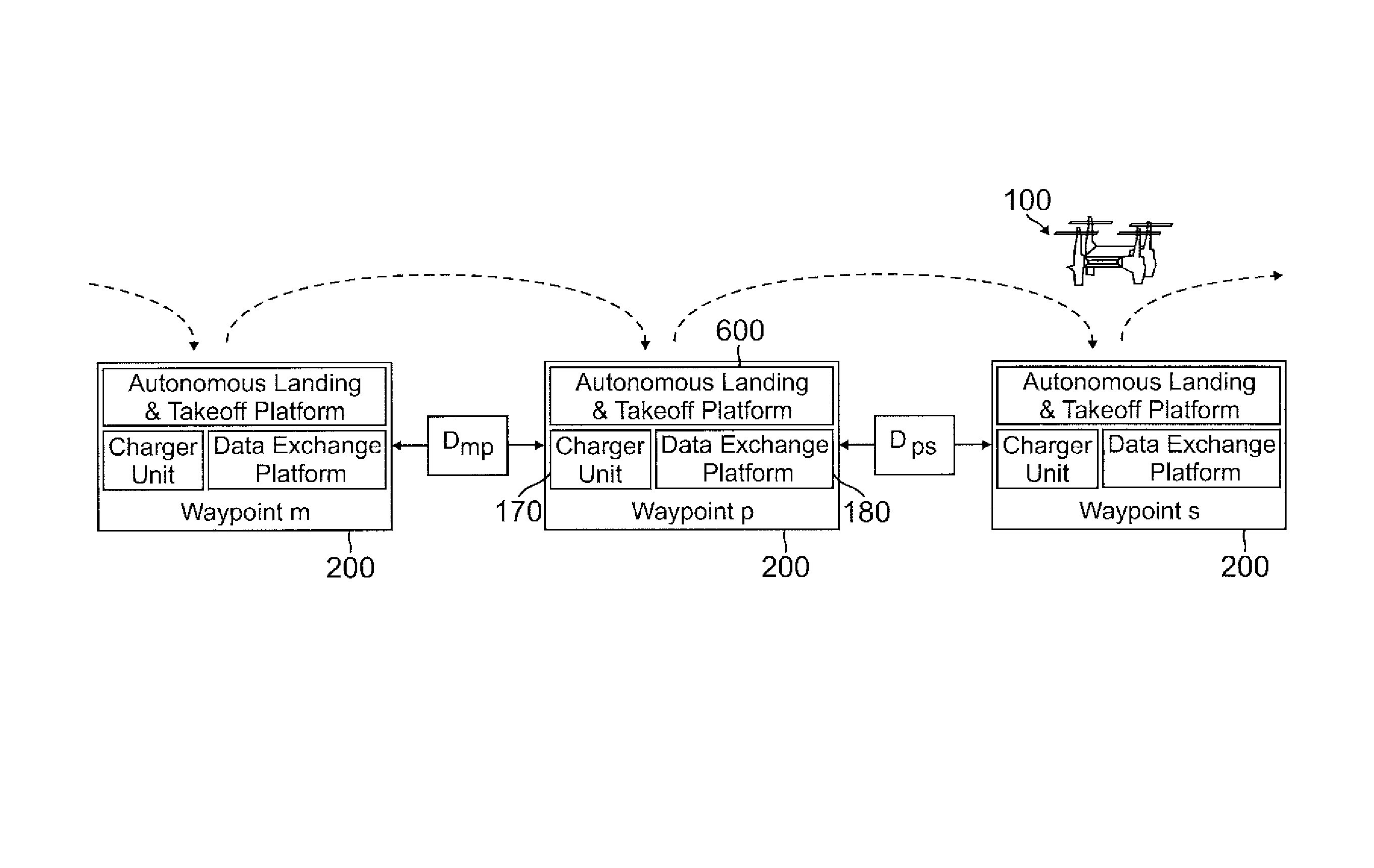

Vertical takeoff and landing (VTOL) small unmanned aerial system for monitoring oil and gas pipelines

Owner:MOHAMADI FARROKH

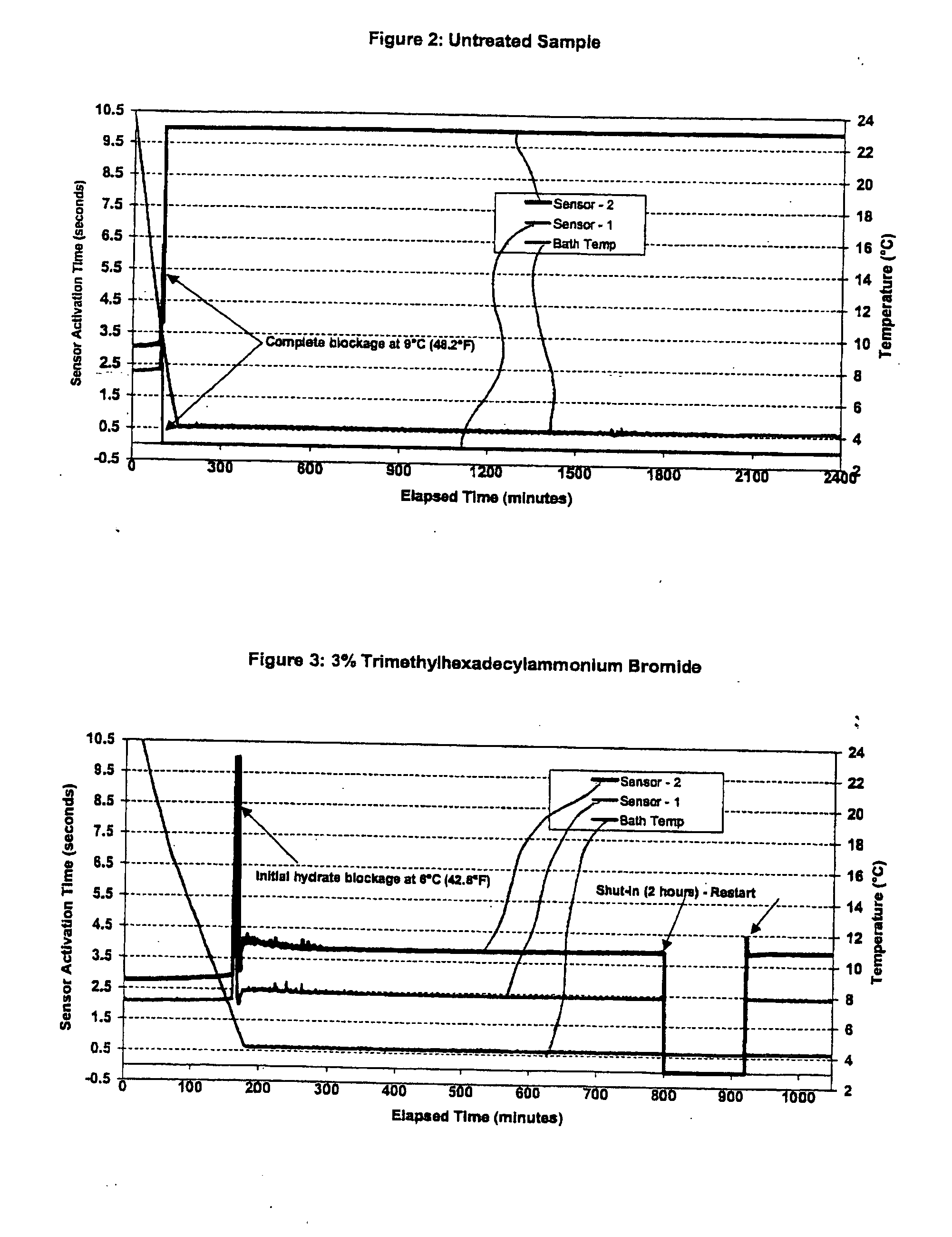

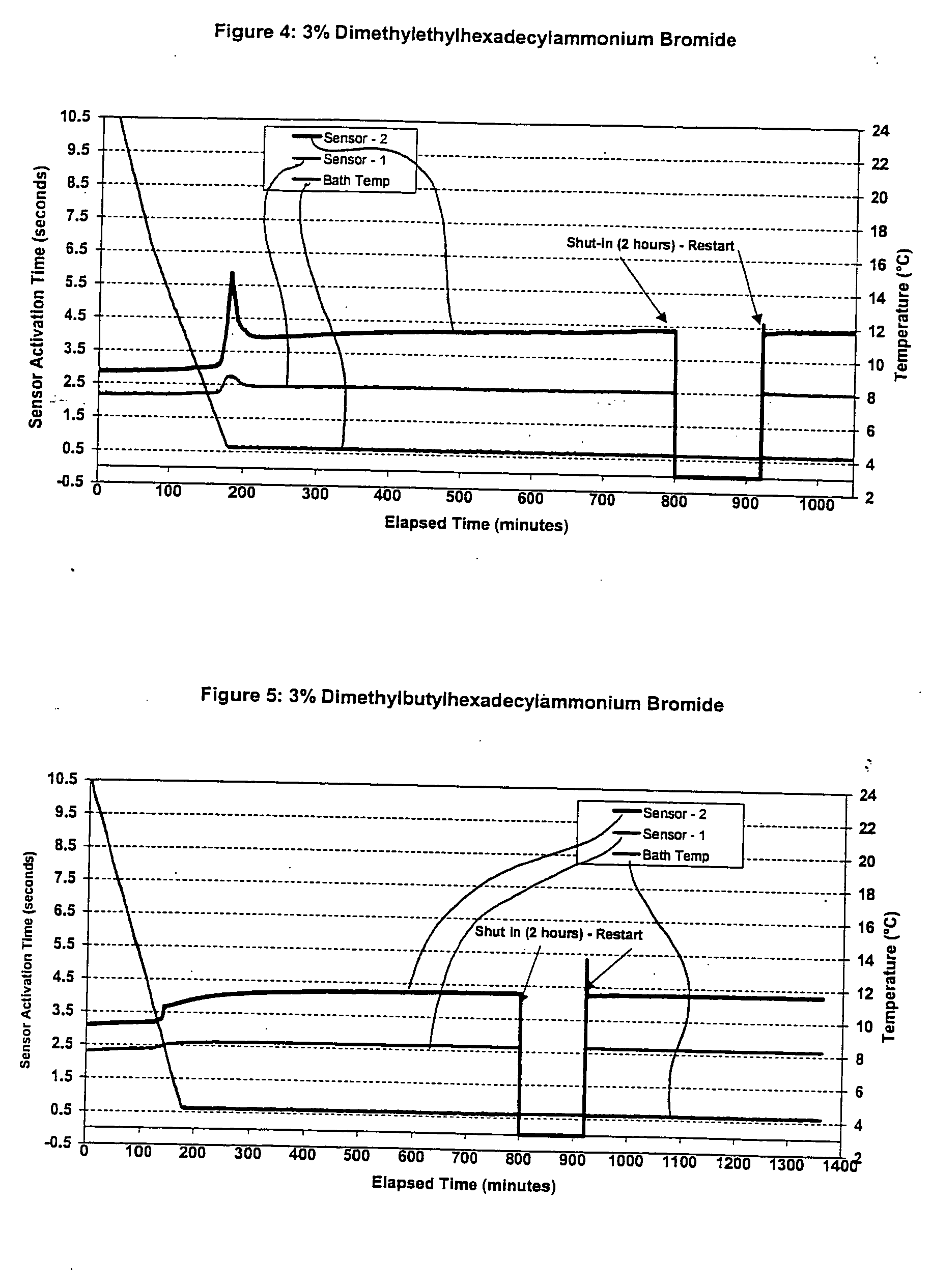

Methods for inhibiting hydrate blockage in oil and gas pipelines using amide compounds

A method and an amide composition used therein for inhibiting, retarding, mitigating, reducing, controlling and / or delaying formation of hydrocarbon hydrates or agglomerates of hydrates. The method may be applied to prevent or reduce or mitigate plugging of conduits, pipes, transfer lines, valves, and other places or equipment where hydrocarbon hydrate solids may form under the conditions. At least one amide compound is added into the process stream, where the compound may be mixed with another compound selected from amino alcohols, esters, quaternary ammonium, phosphonium or sulphonium salts, betaines, amine oxides, other amides, simple amine salts, and combinations thereof.

Owner:CLARIANT INT LTD

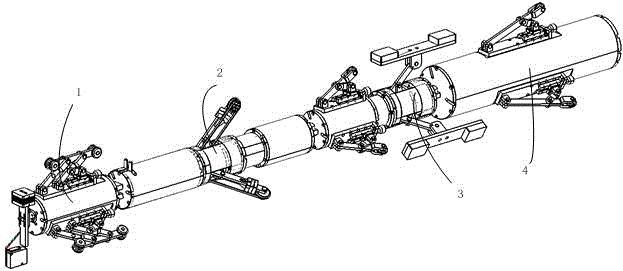

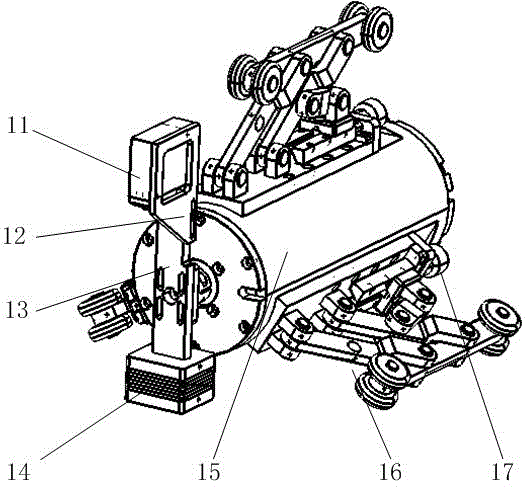

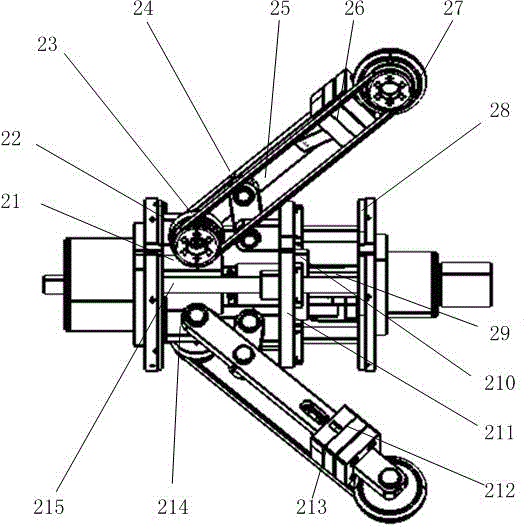

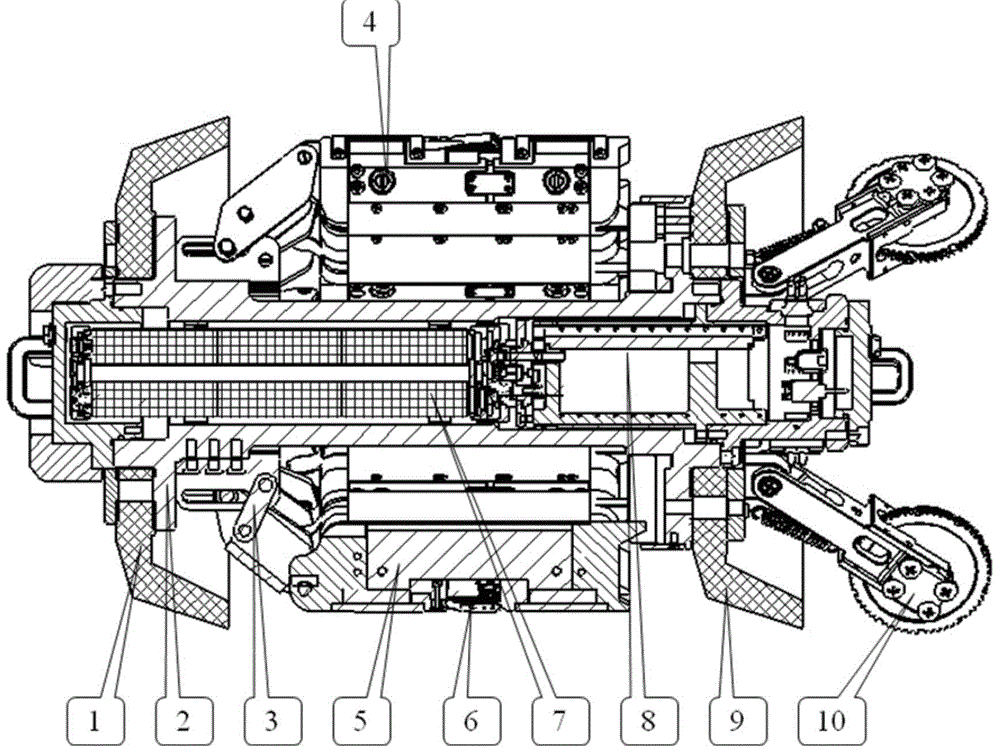

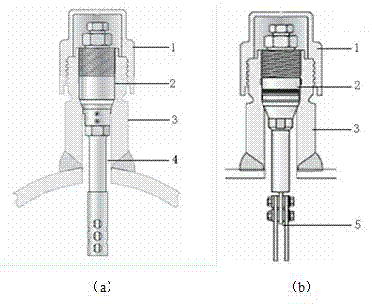

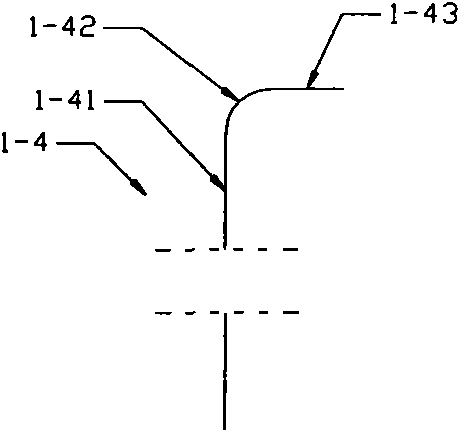

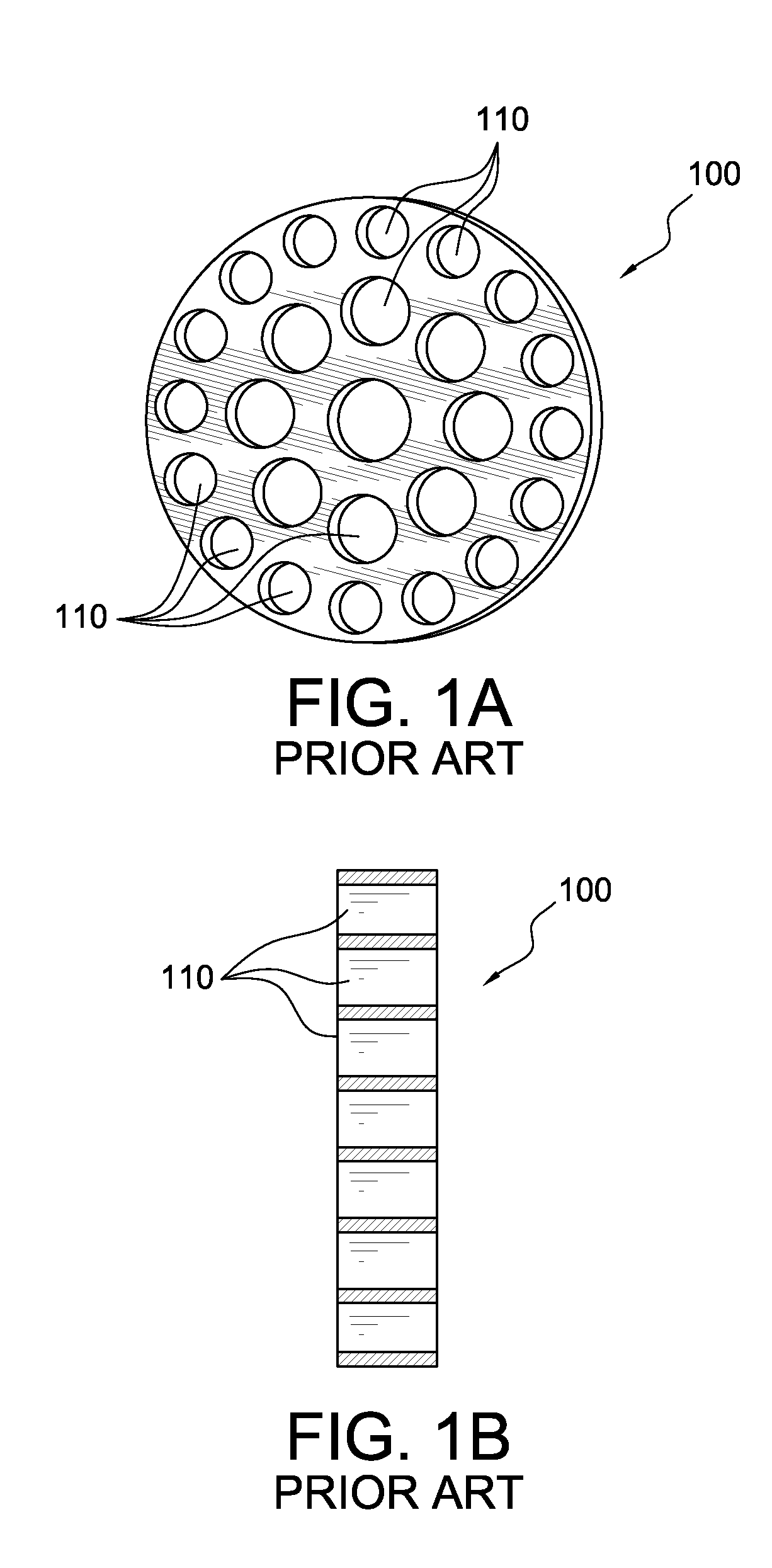

Pipeline detection robot

The invention relates to a pipeline detection robot. The pipeline detection robot mainly comprises a laser detection mechanism (1), a traction mechanism (2), an electromagnetic ultrasonic detection mechanism (3) and an electronic cabin (4), all of which are connected through connecting hinge shafts; the traction mechanism (1) adopts a single-motor all-drive mode and is driven by a turbo-worm synchronous belt to supply a walking power to the robot; the laser detection mechanism (2) comprises a laser displacement sensor, a rotating arm, a counterweight, a support body and the like and is used for measuring surface corrosion and deformation of a pipeline; the electromagnetic ultrasonic detection mechanism (3) comprises a support assembly, a probe and a fixing plate and is used for measuring the wall thickness and the crack defect of the pipeline; the electronic cabin (4) is used for carrying auxiliary components, such as a stepping motor controller, a servo motor driver, a power supply and an FPGA (Field Programmable Gate Array) control panel. The pipeline detection robot disclosed by the invention can be used for finding the defects, such as pipeline corrosion, cracks and deformation, carrying out in-service detection on an oil and gas pipeline in a working process, carrying out targeted repair, maintenance and replacement according to a detection result, reducing the maintenance cost and guaranteeing safe and stable operation of the oil and gas pipeline.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

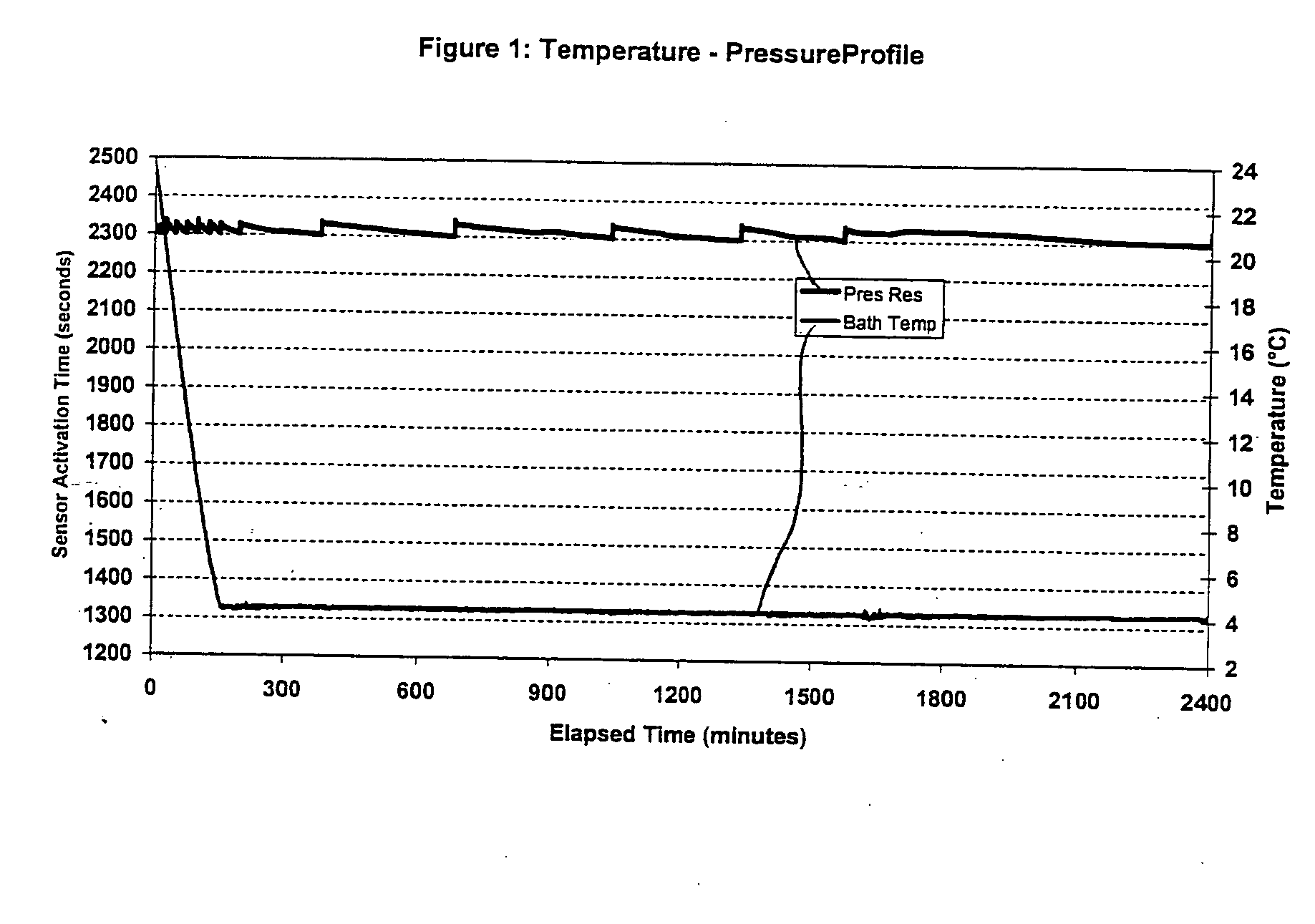

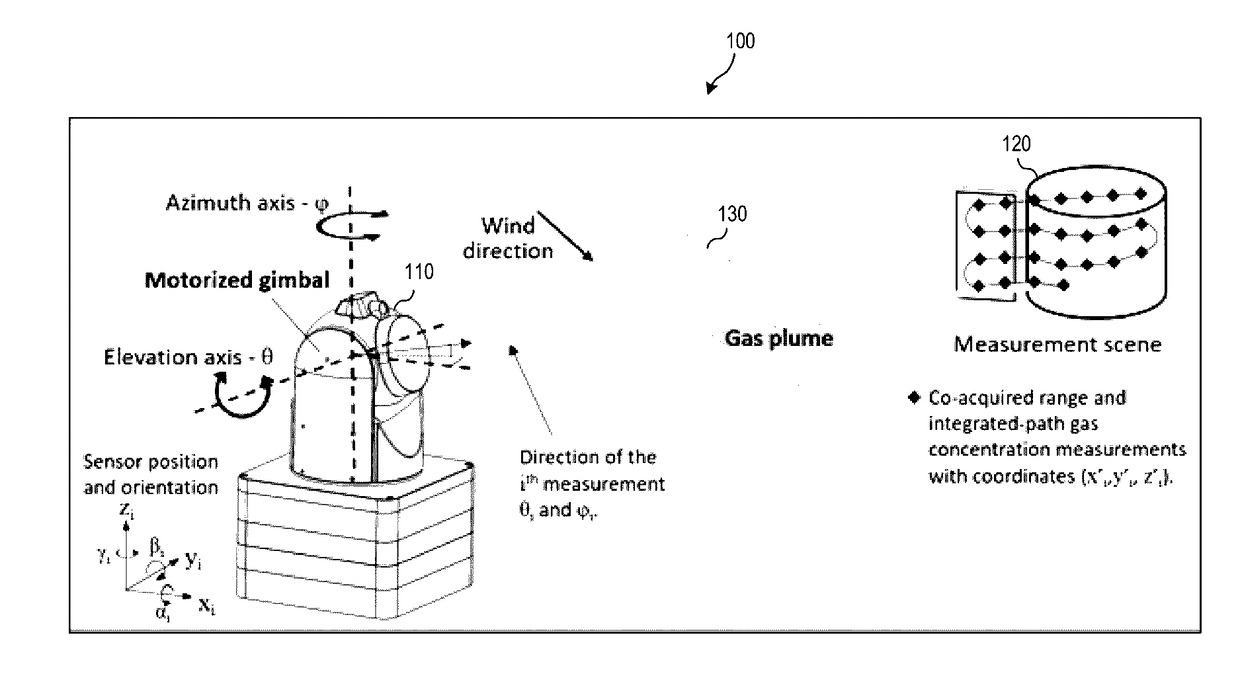

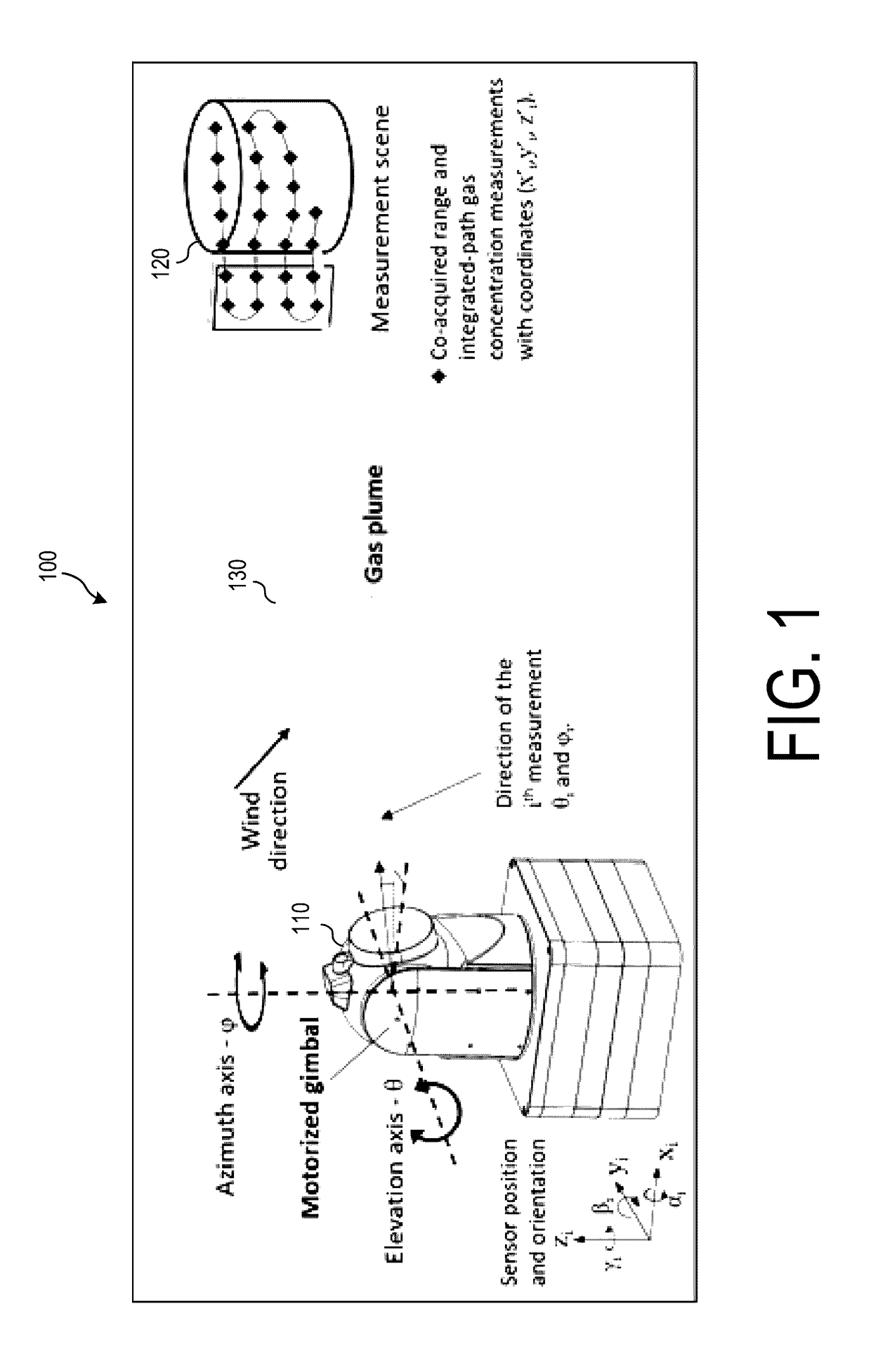

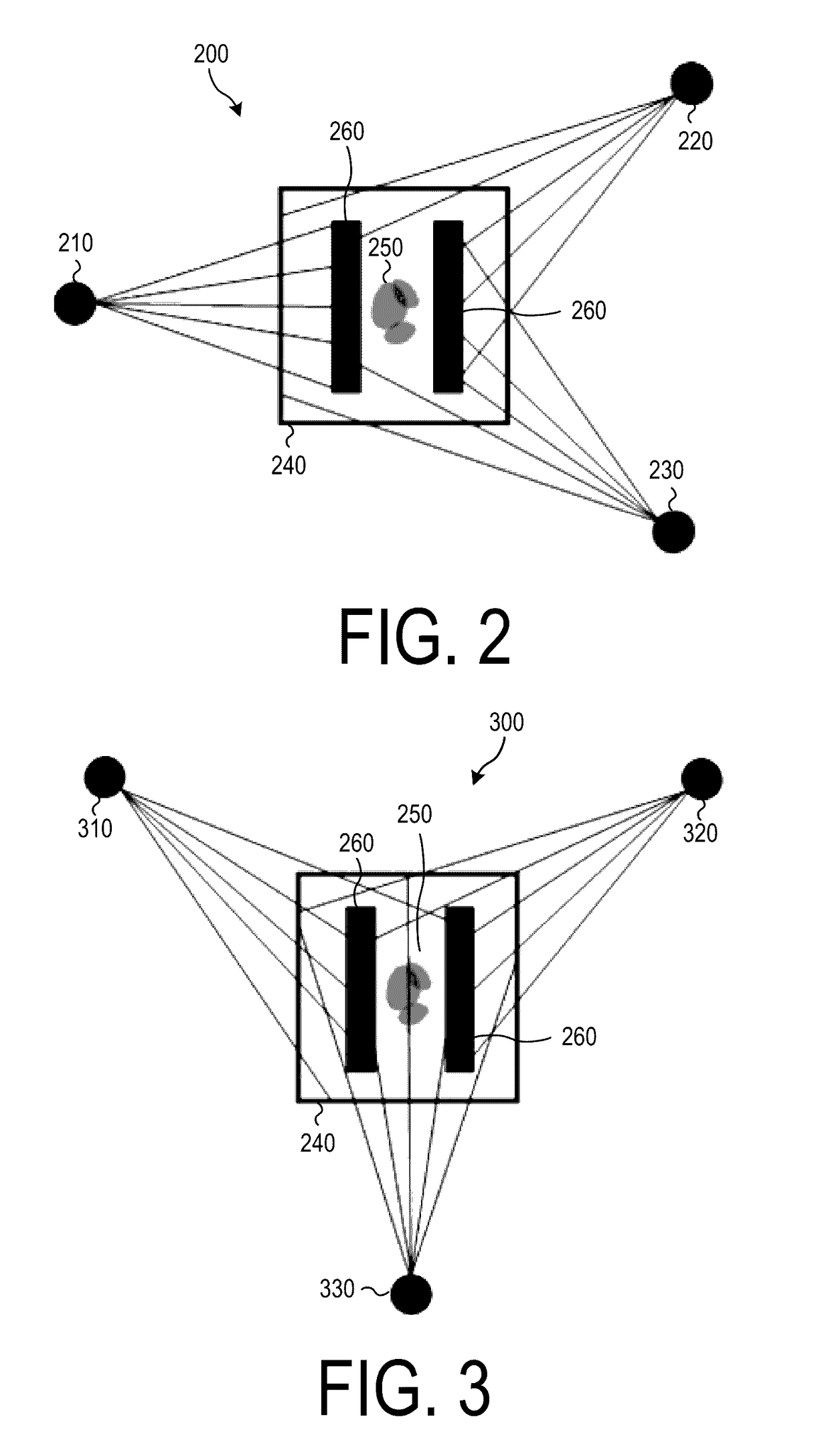

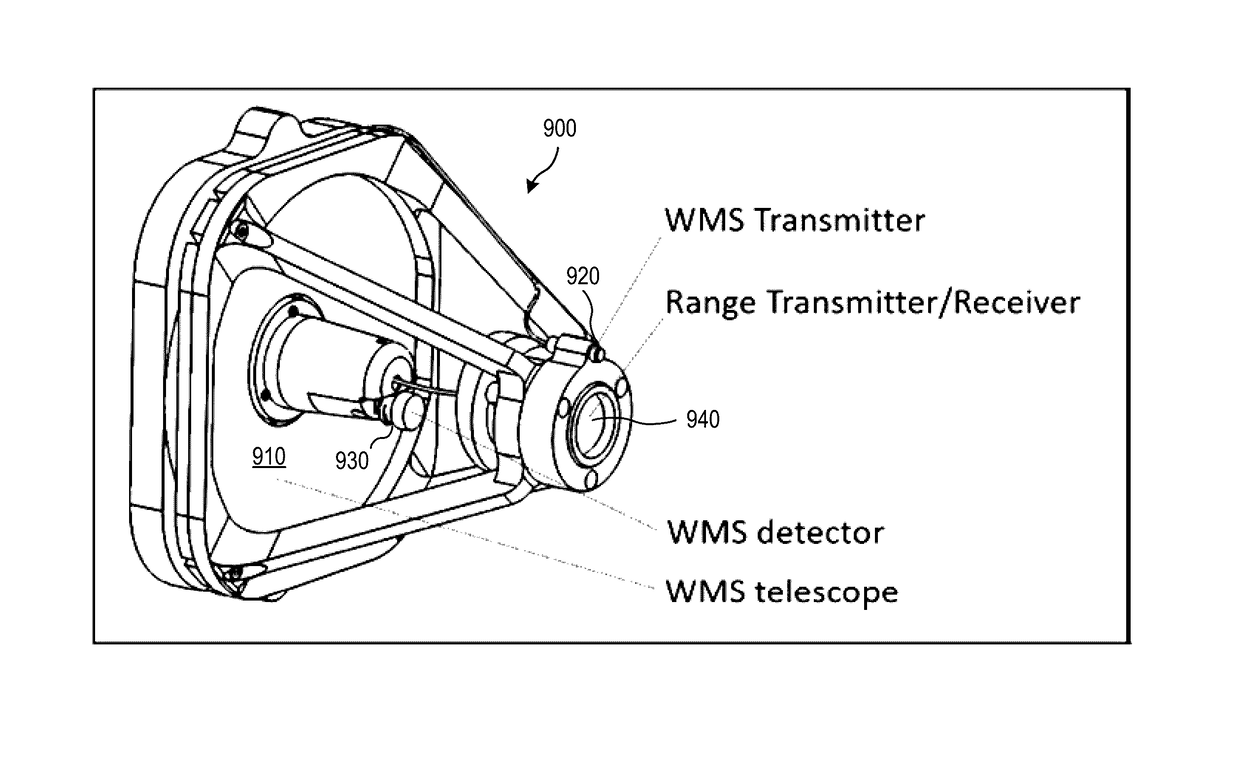

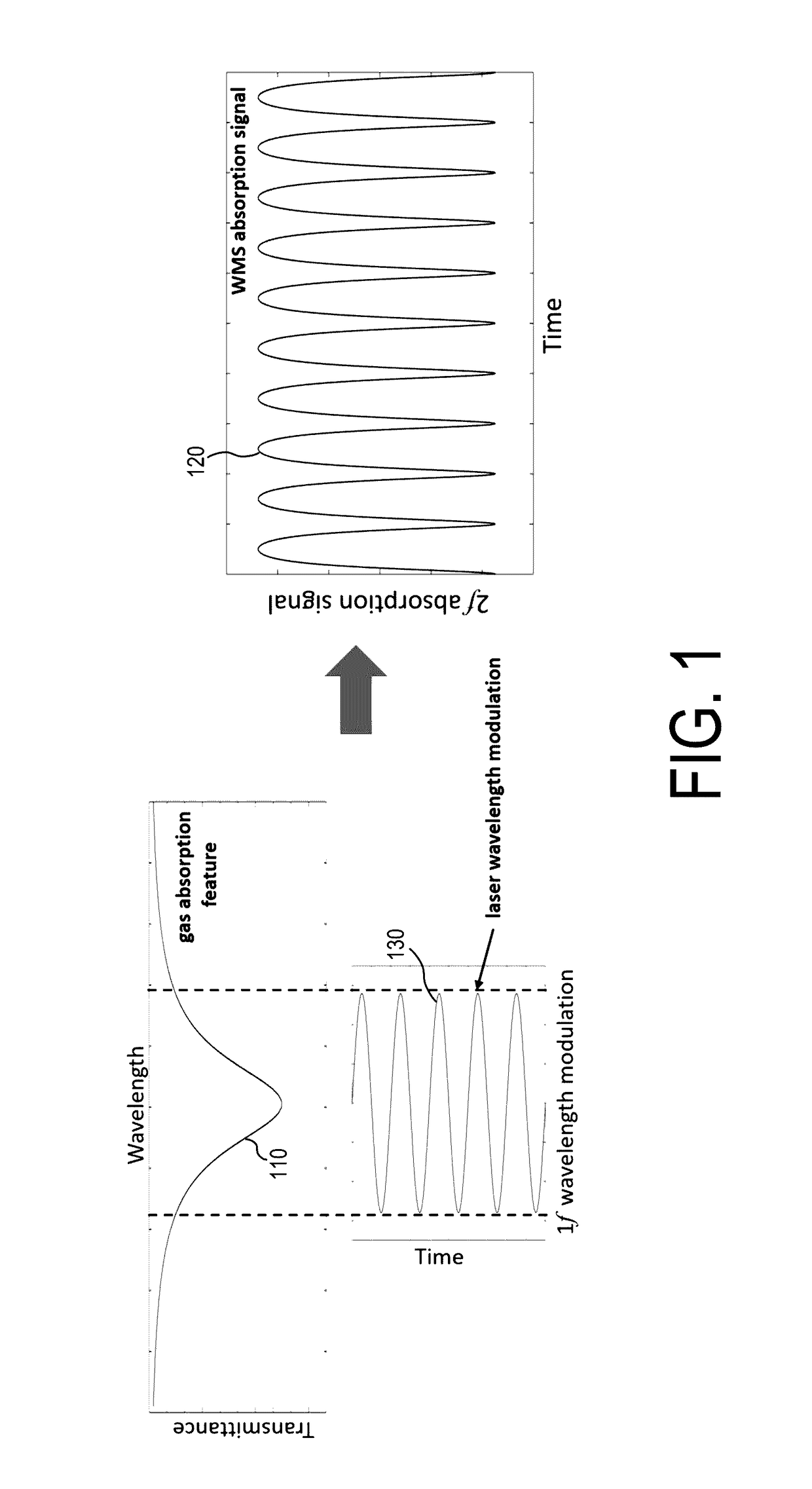

Gas-mapping 3D imager measurement techniques and method of data processing

ActiveUS20170097274A1Shorten the timeReduced measurement timeMeasurement of fluid loss/gain rateScattering properties measurementsConfidence metricEngineering

Measurement approaches and data analysis methods are disclosed for combining 3D topographic data with spatially-registered gas concentration data to increase the efficiency of gas monitoring and leak detection tasks. Here, the metric for efficiency is defined as reducing the measurement time required to achieve the detection, or non-detection, of a gas leak with a desired confidence level. Methods are presented for localizing and quantifying detected gas leaks. Particular attention is paid to the combination of 3D spatial data with path-integrated gas concentration measurements acquired using remote gas sensing technologies, as this data can be used to determine the path-averaged gas concentration between the sensor and points in the measurement scene. Path-averaged gas concentration data is useful for finding and quantifying localized regions of elevated (or anomalous) gas concentration making it ideal for a variety of applications including: oil and gas pipeline monitoring, facility leak and emissions monitoring, and environmental monitoring.

Owner:BRIDGER PHOTONICS

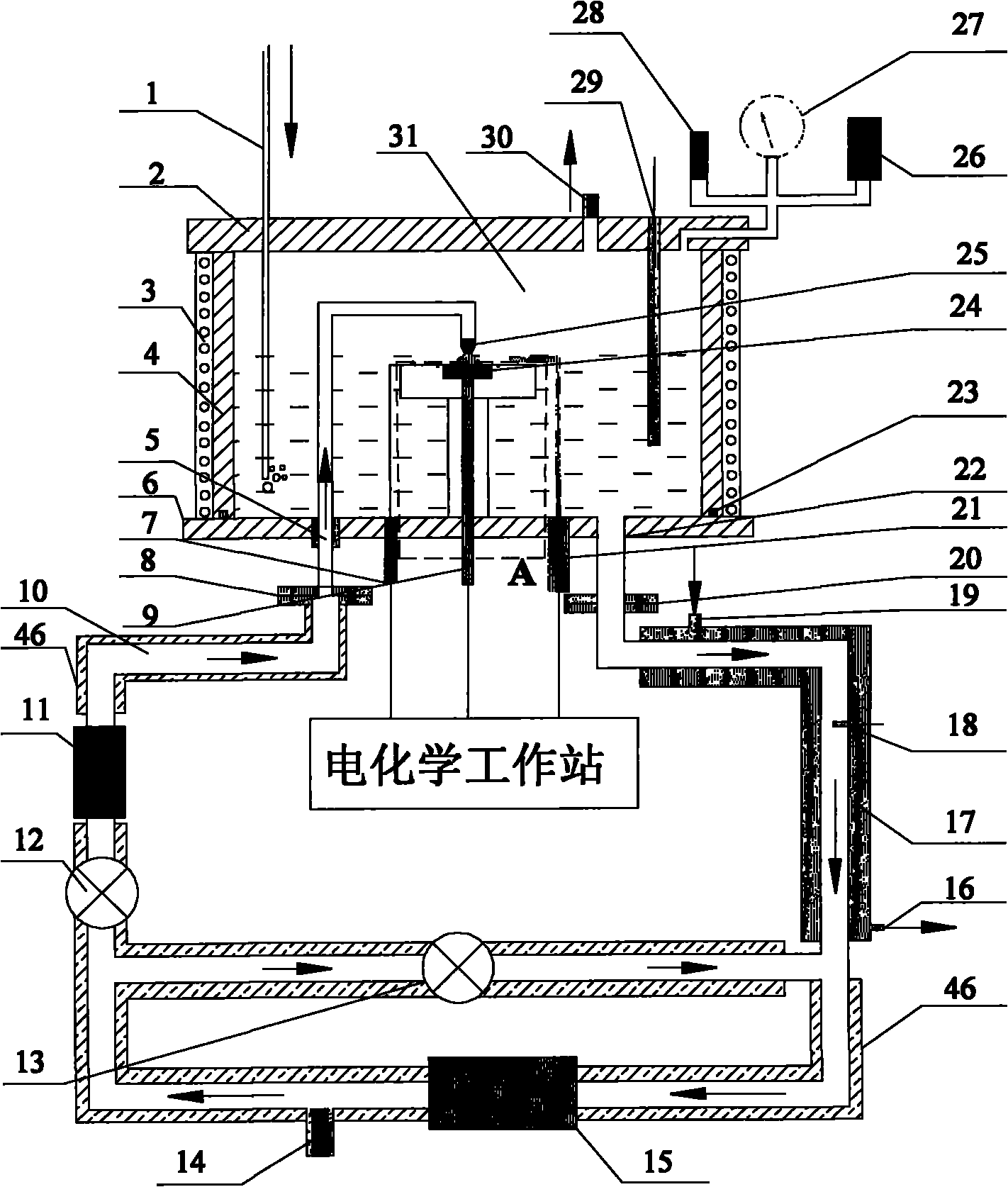

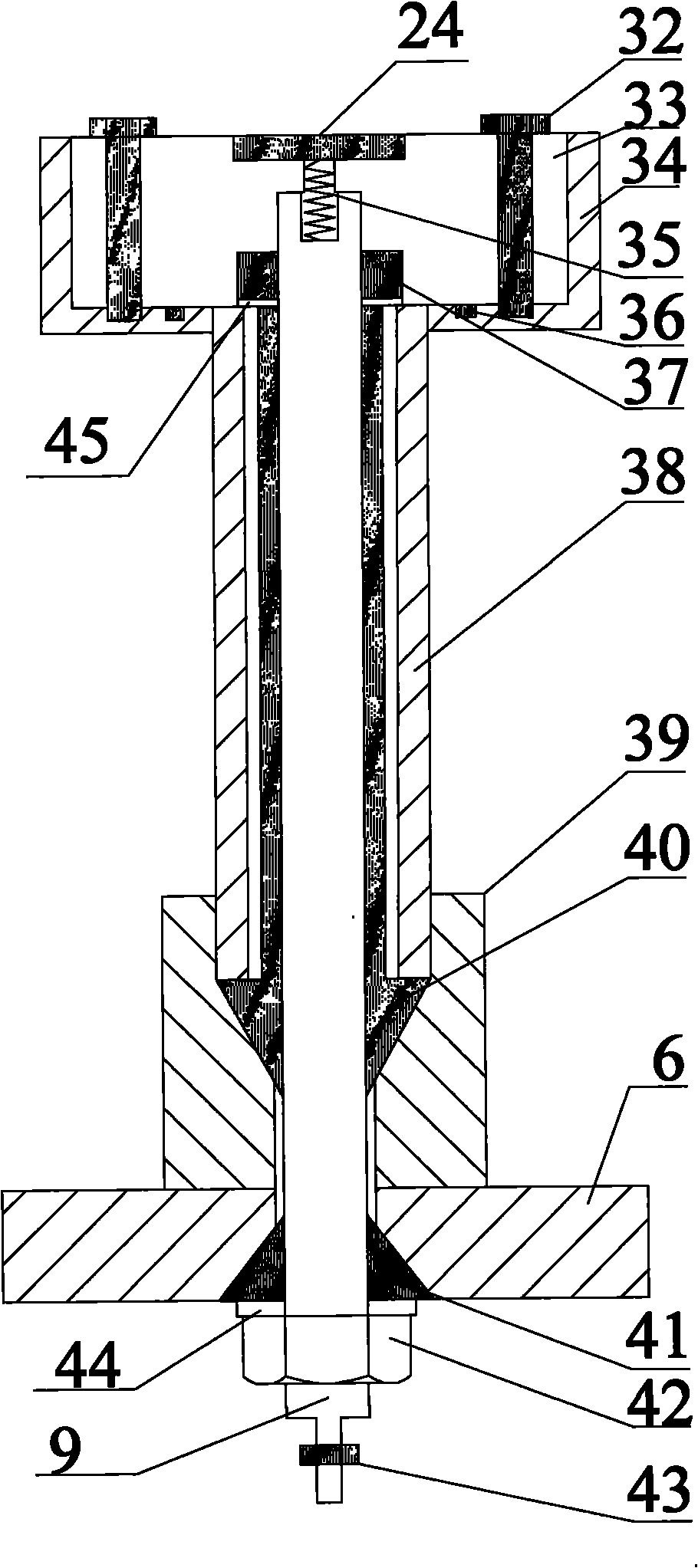

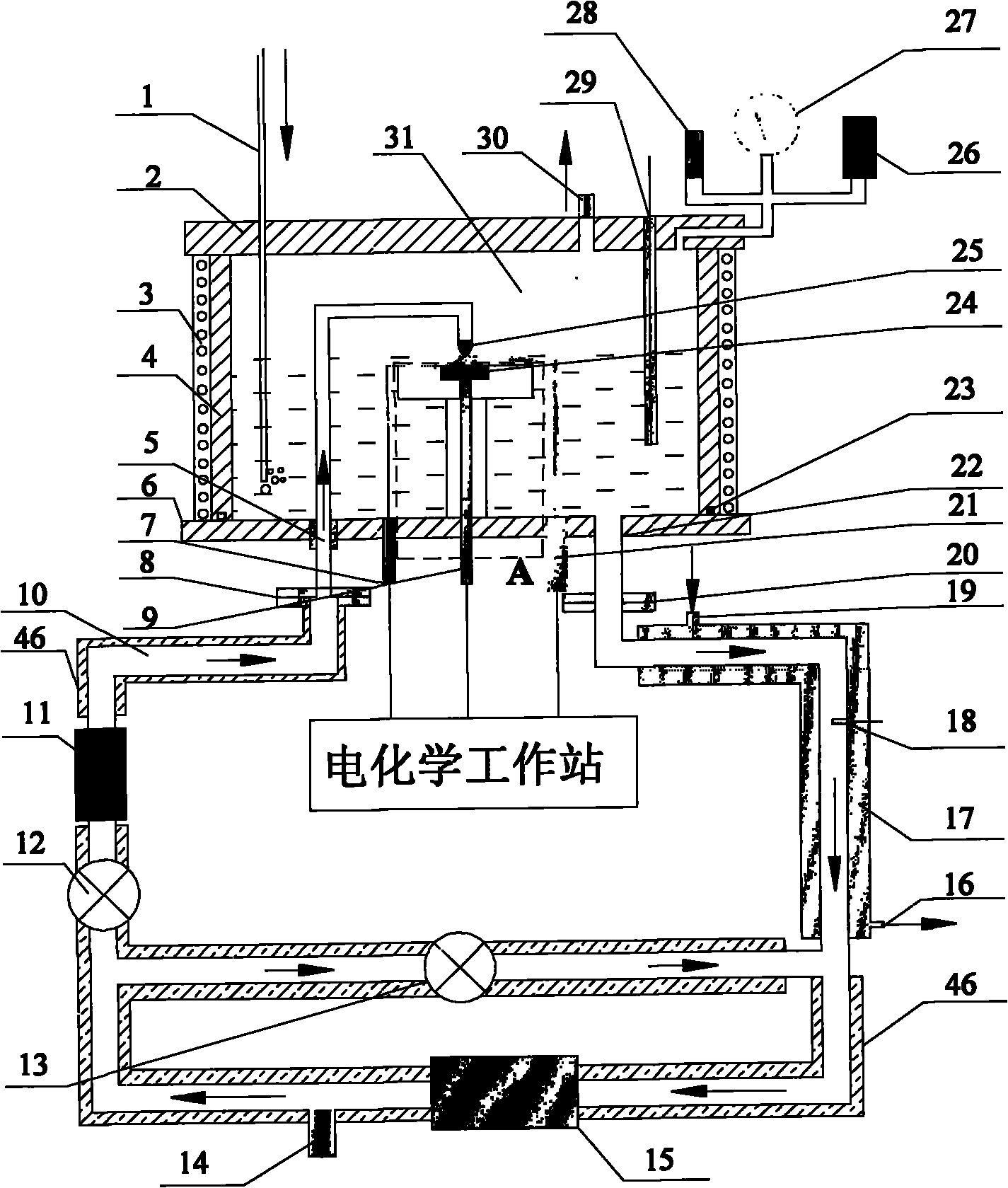

Experimental apparatus for high-temperature high-pressure loop spray corrosion simulation and electrochemical testing

The invention discloses an experimental apparatus for high-temperature high-pressure loop spray corrosion simulation and electrochemical testing, belongs to the electrochemical field, and is particularly suitable for simulation experiment of erosion corrosion caused by simulating the complex components such as elbow, tee and the like in petroleum and gas collection pipes, petroleum and gas conveying pipes and the like so as to convey the high-temperature high-pressure multi-phase fluid pipe components and in-situ electrochemical signal testing of the erosion corrosion of high-temperature high-pressure fluid under erosion conditions. The apparatus comprises a high pressure kettle, a circulating loop, a high-temperature high-pressure flow gauge, a vortex pump, a control box, a circulating condensation system, a three-electrode system, a signal conduction path, an external electrochemical work station and a high pressure gas bottle. The apparatus has the advantages of simulating the erosion corrosion condition of the fluid medium in the oil and gas pipeline well, testing the electrochemical signal of the working electrode under high-speed spray condition such as polar curve, AC impedance and the like and having important significance to the research of the erosion corrosion action, rule and mechanism of the high-temperature high-pressure fluid.

Owner:UNIV OF SCI & TECH BEIJING

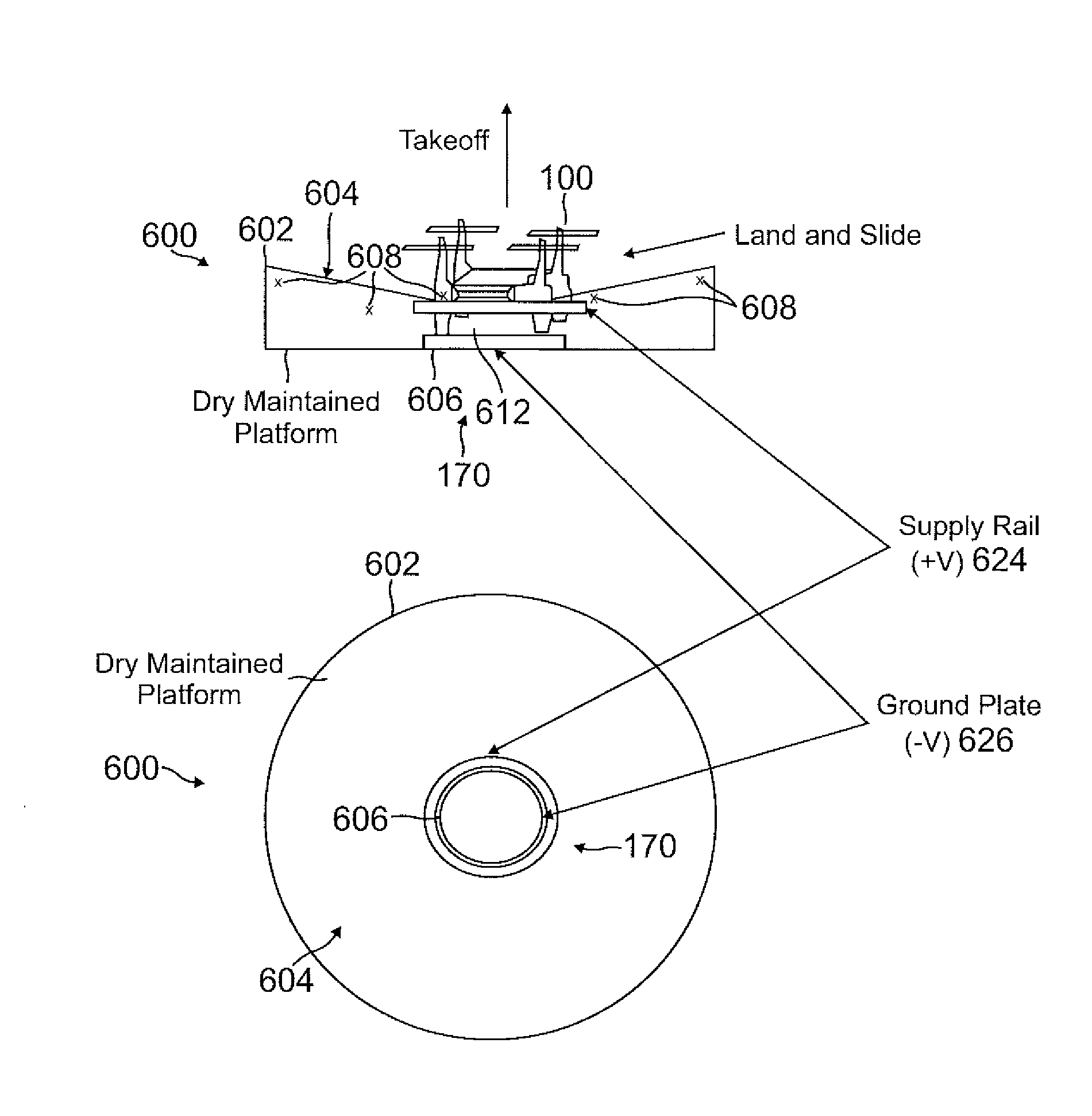

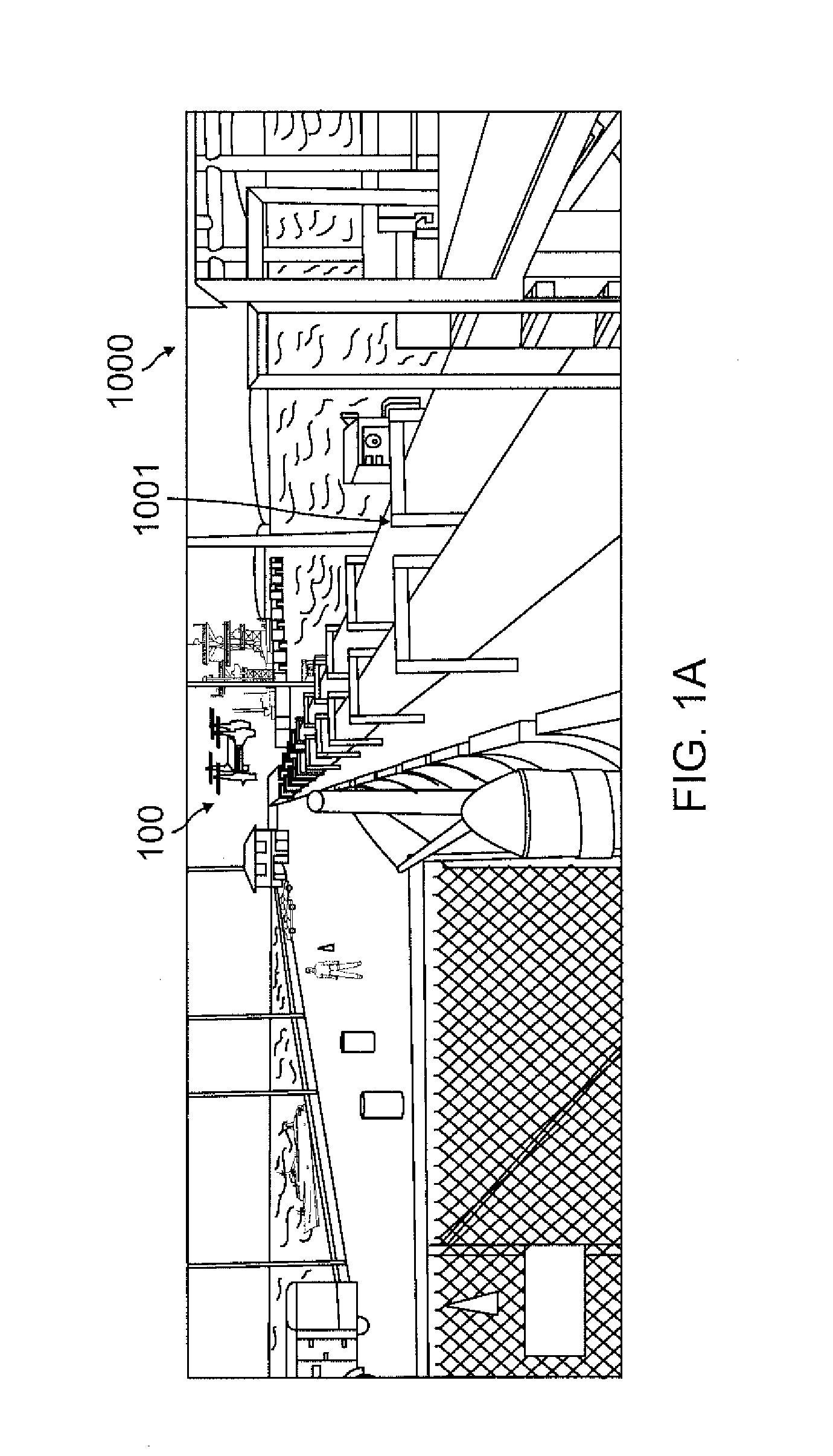

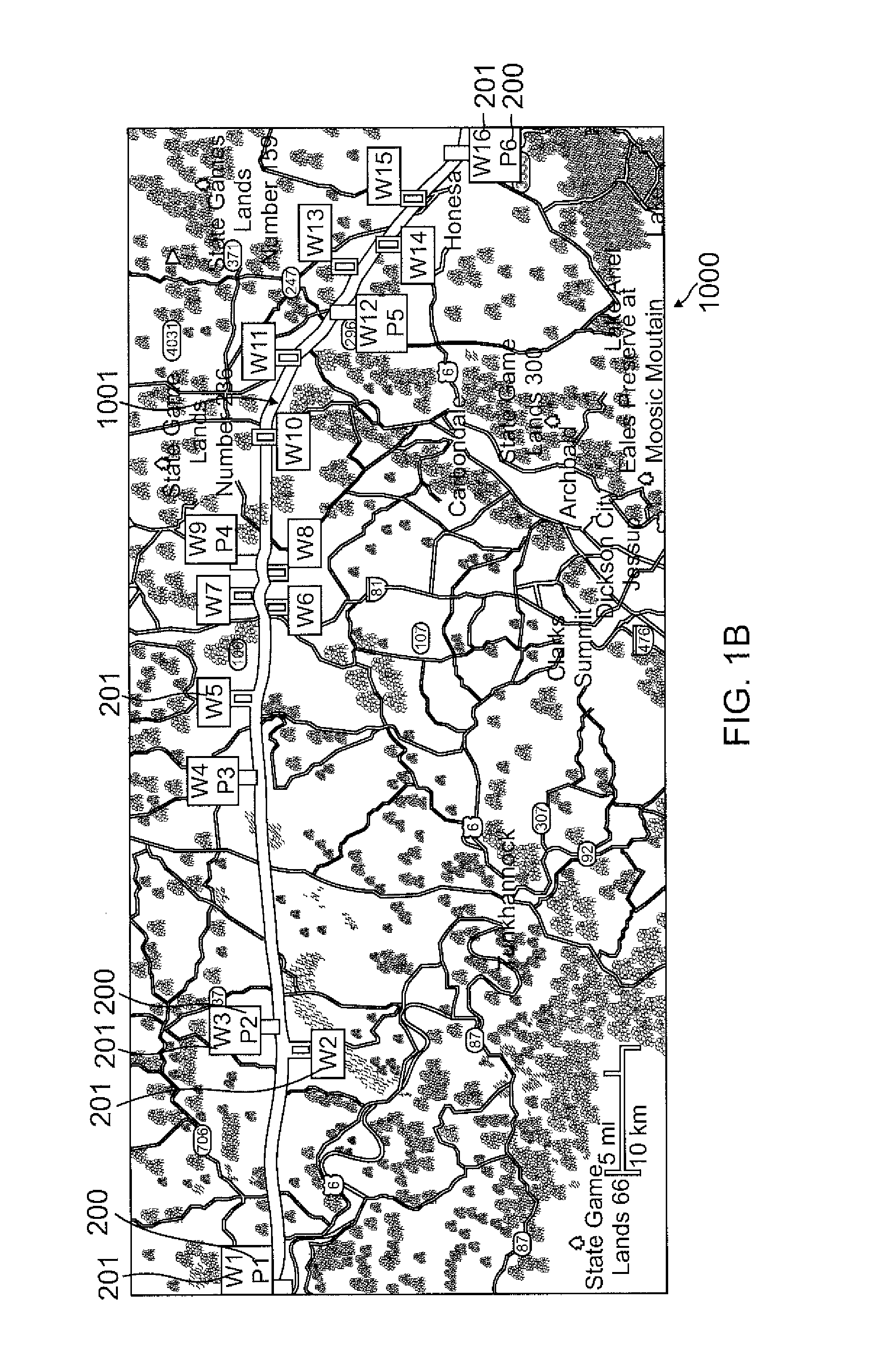

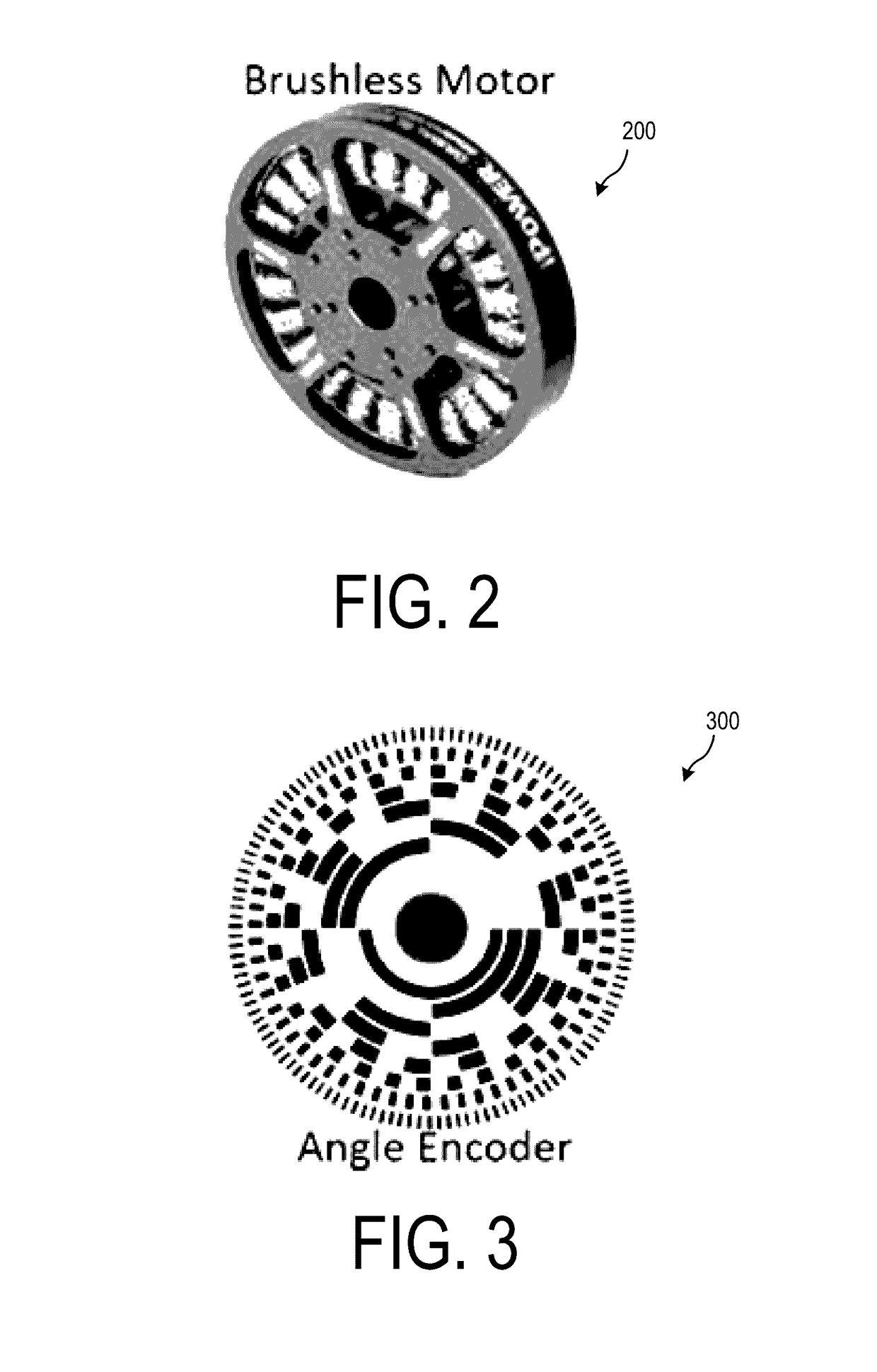

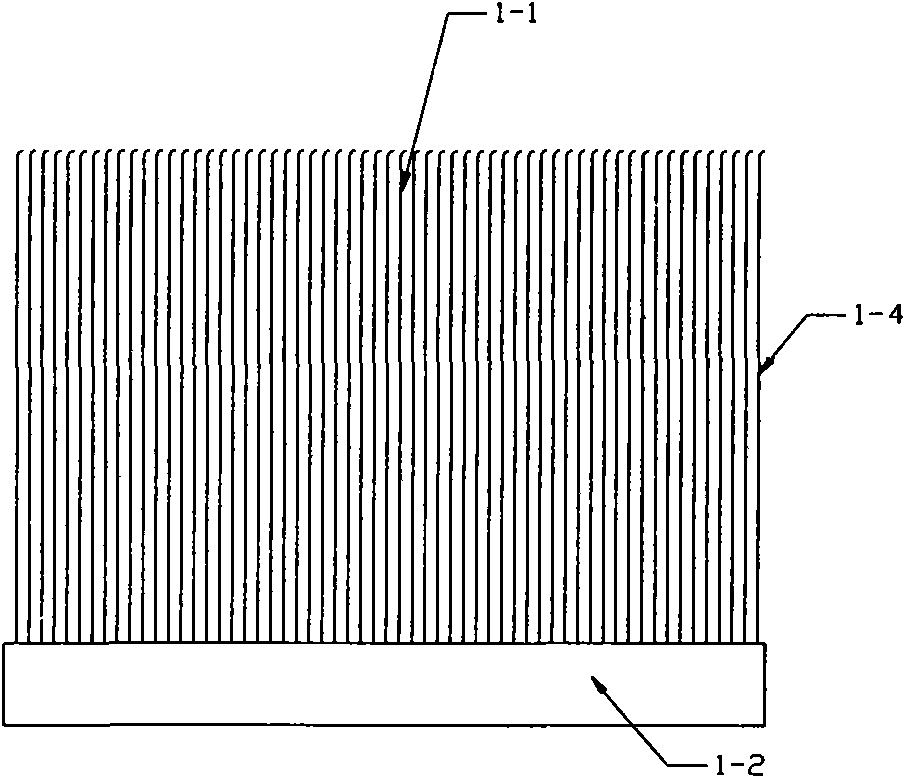

Vertical takeoff and landing (VTOL) small unmanned aerial system for monitoring oil and gas pipelines

ActiveUS8880241B2Analogue computers for vehiclesDigital data processing detailsJet aeroplaneUncrewed vehicle

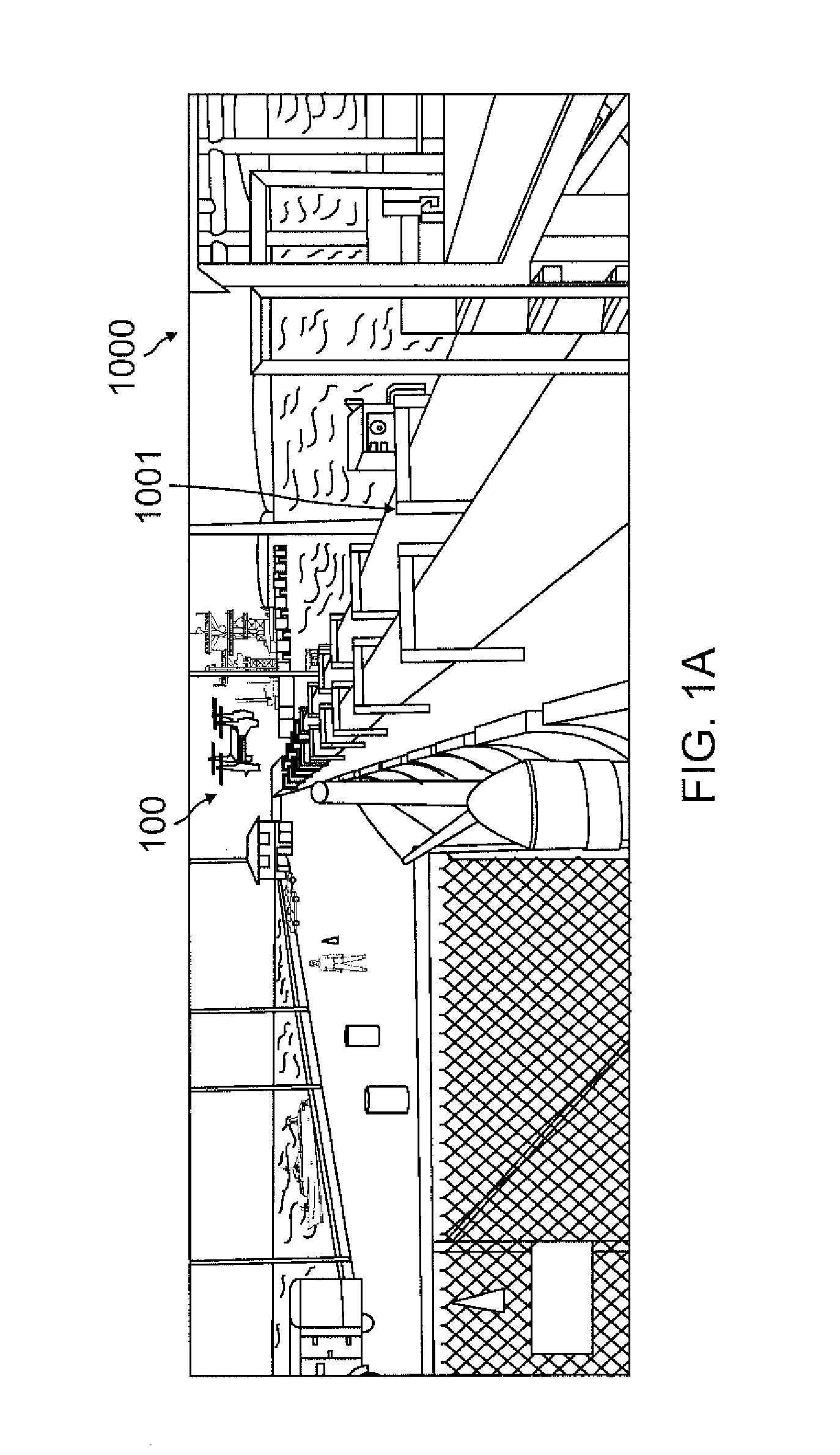

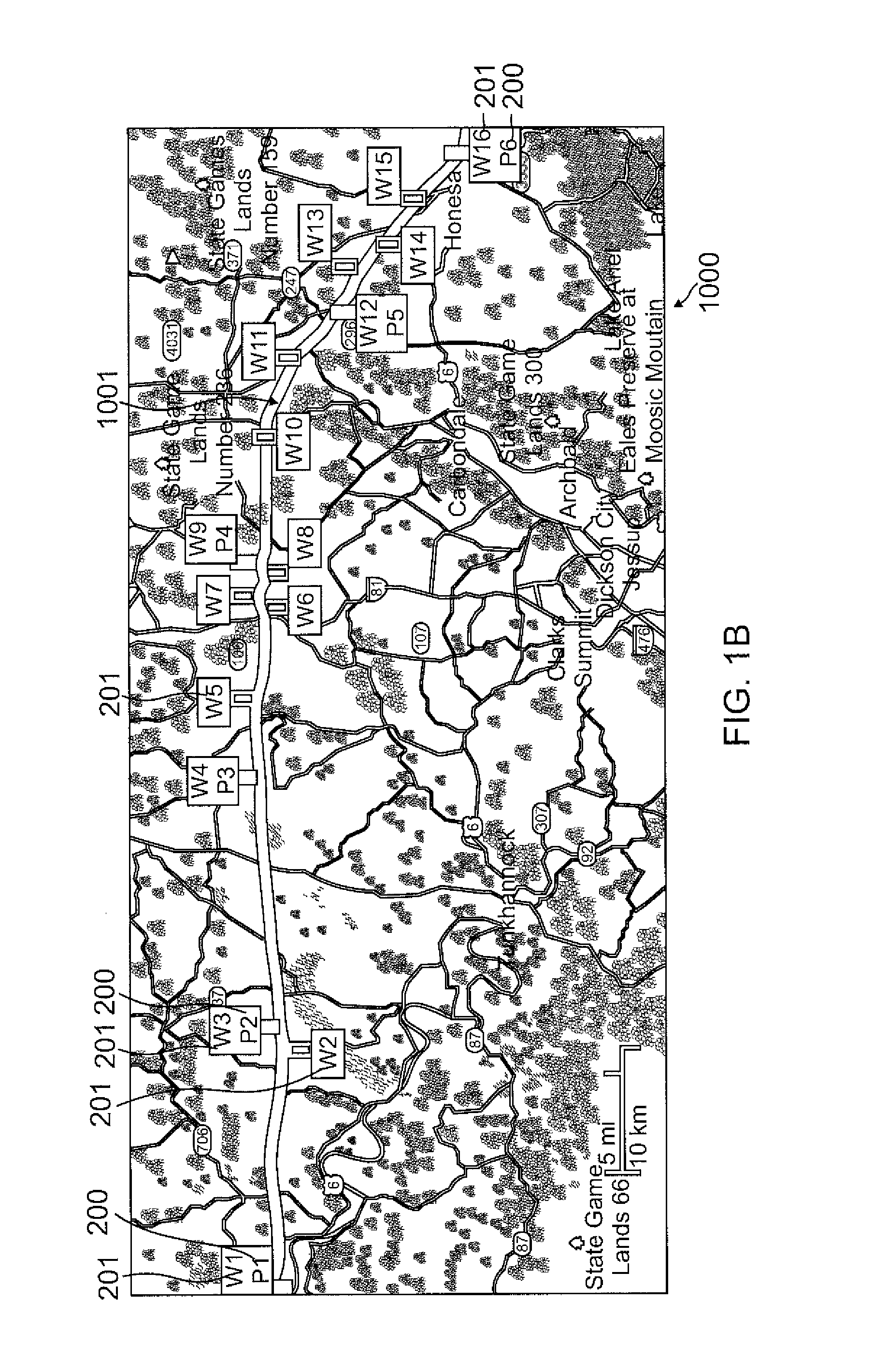

Extended-range monitoring and surveillance of facilities and infrastructure—such as oil, water, and gas pipelines and power lines—employs autonomous vertical take-off and landing (VTOL) capable, small unmanned aerial system (sUAS) aircraft and docking platforms for accommodating the sUAS aircraft. Monitoring and surveillance of facilities using one or more embodiments may be performed continually by the sUAS flying autonomously along a pre-programmed flight path. The sUAS aircraft may have an integrated gas collector and analyzer unit, and capability for downloading collected data and analyzer information from the sUAS aircraft to the docking platforms. The gas collector and analyzer unit may provide remote sensing and in-situ investigation of leaks and other environmental concerns as part of a “standoff” (e.g., remote from operators of the system or the facilities) survey that can keep field operators out of harm's way and monitor health of the environment.

Owner:MOHAMADI FARROKH

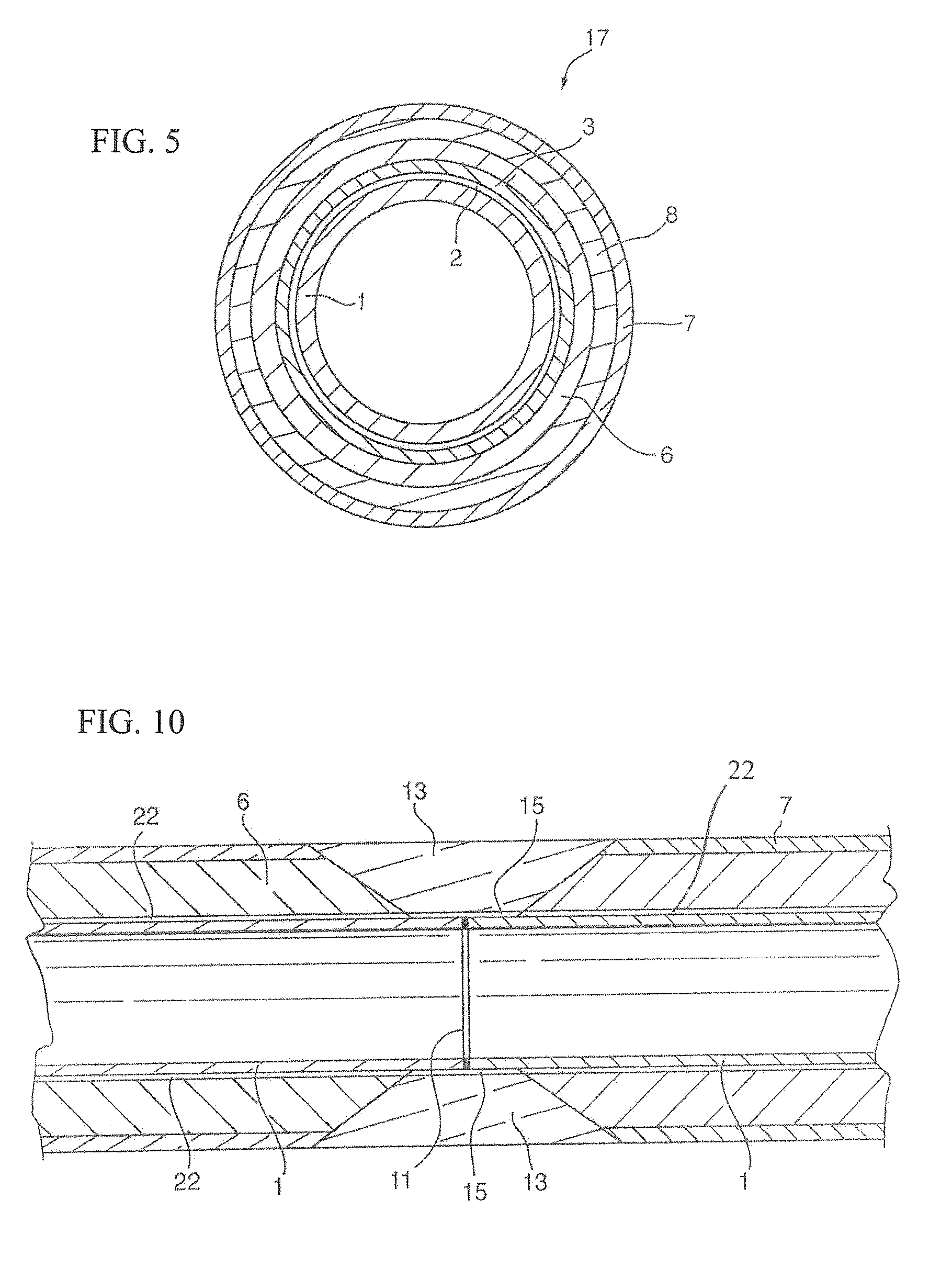

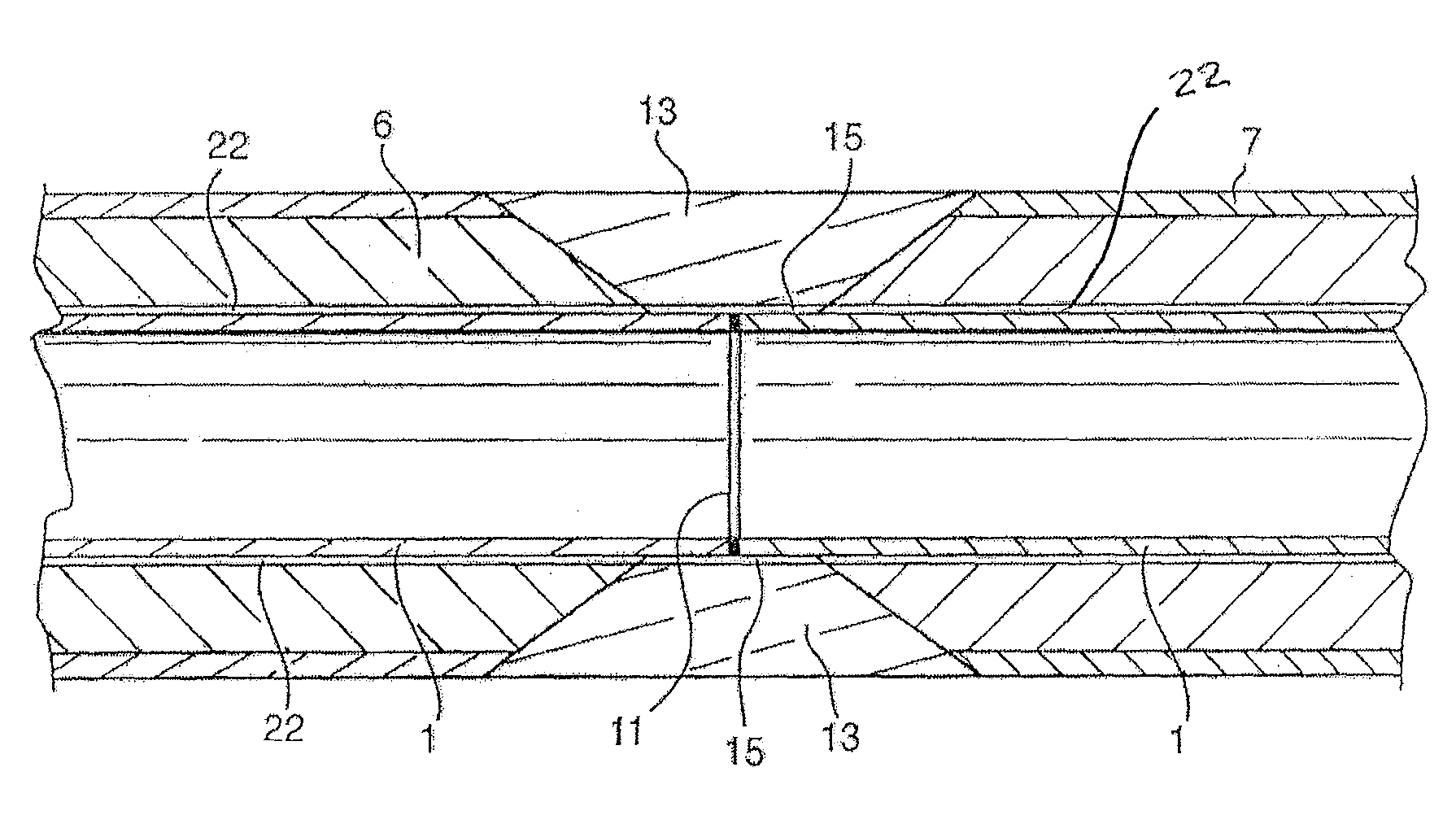

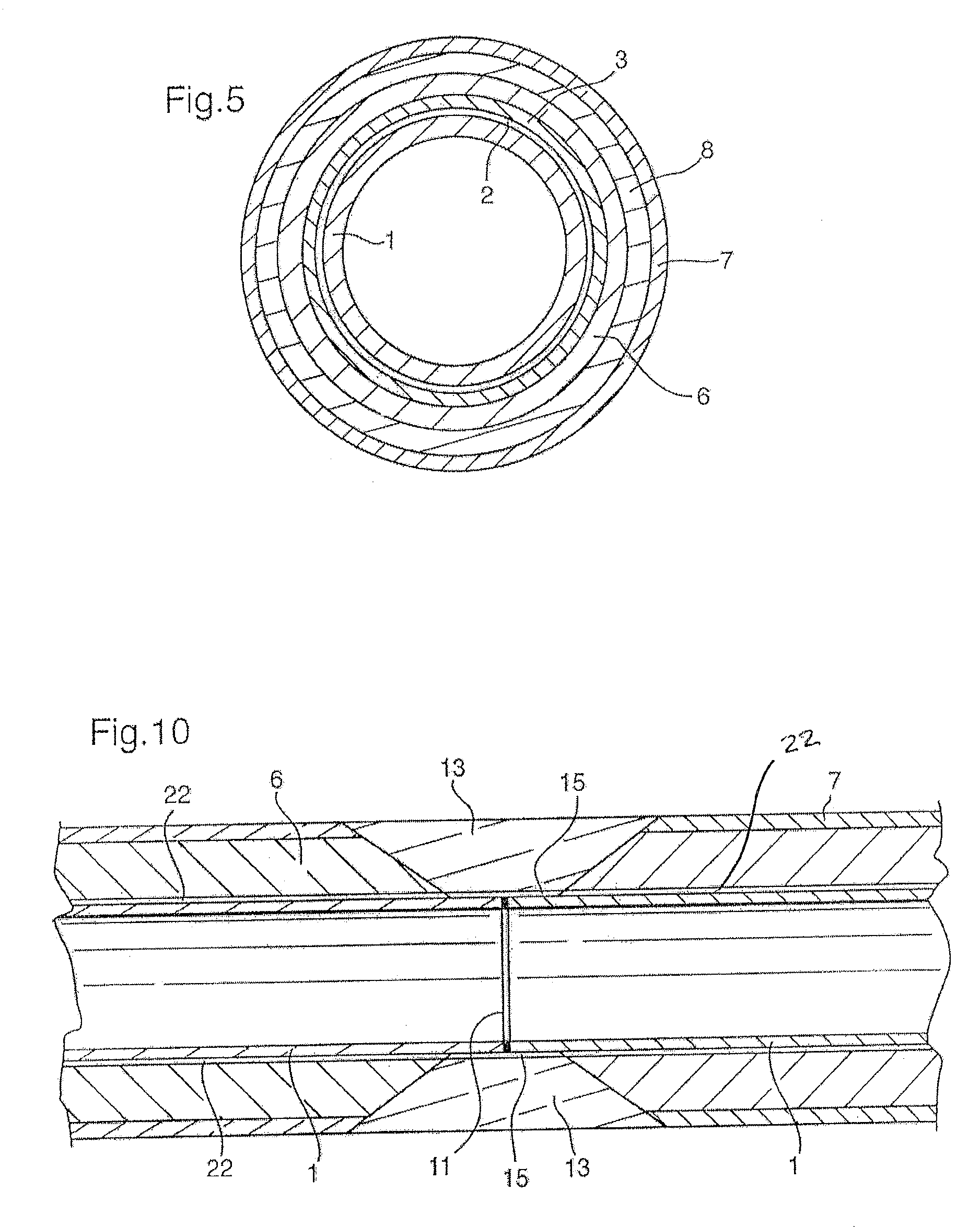

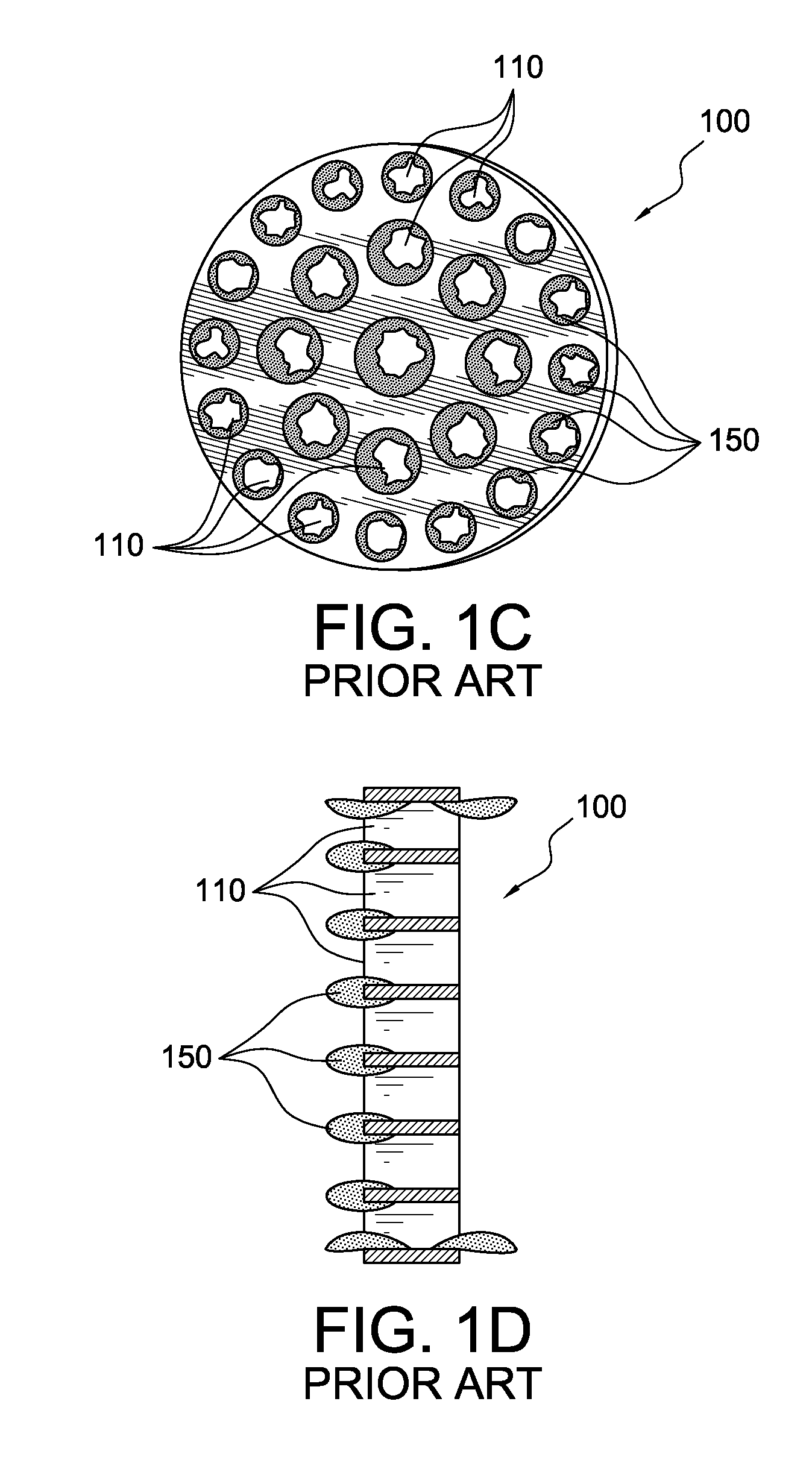

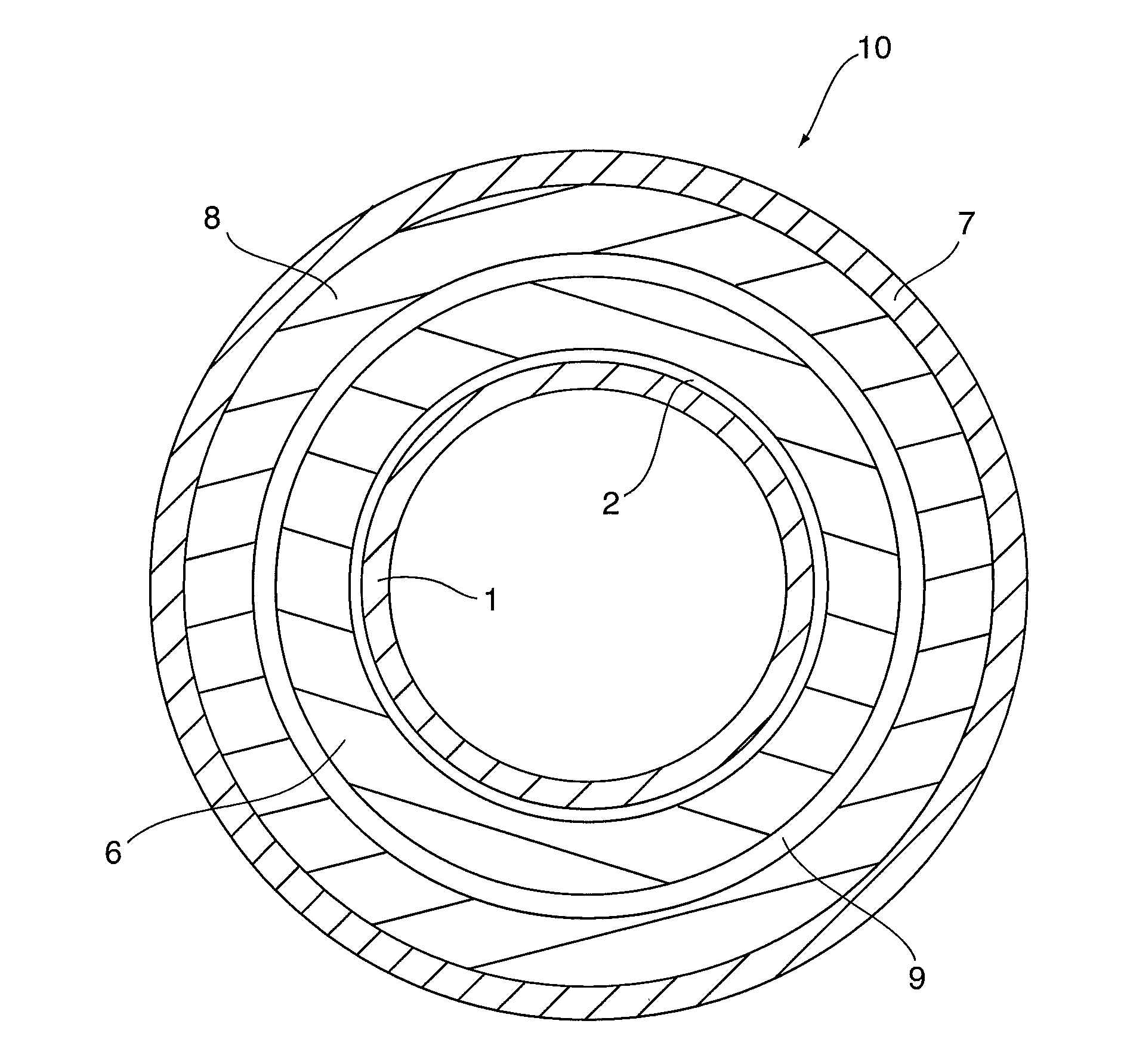

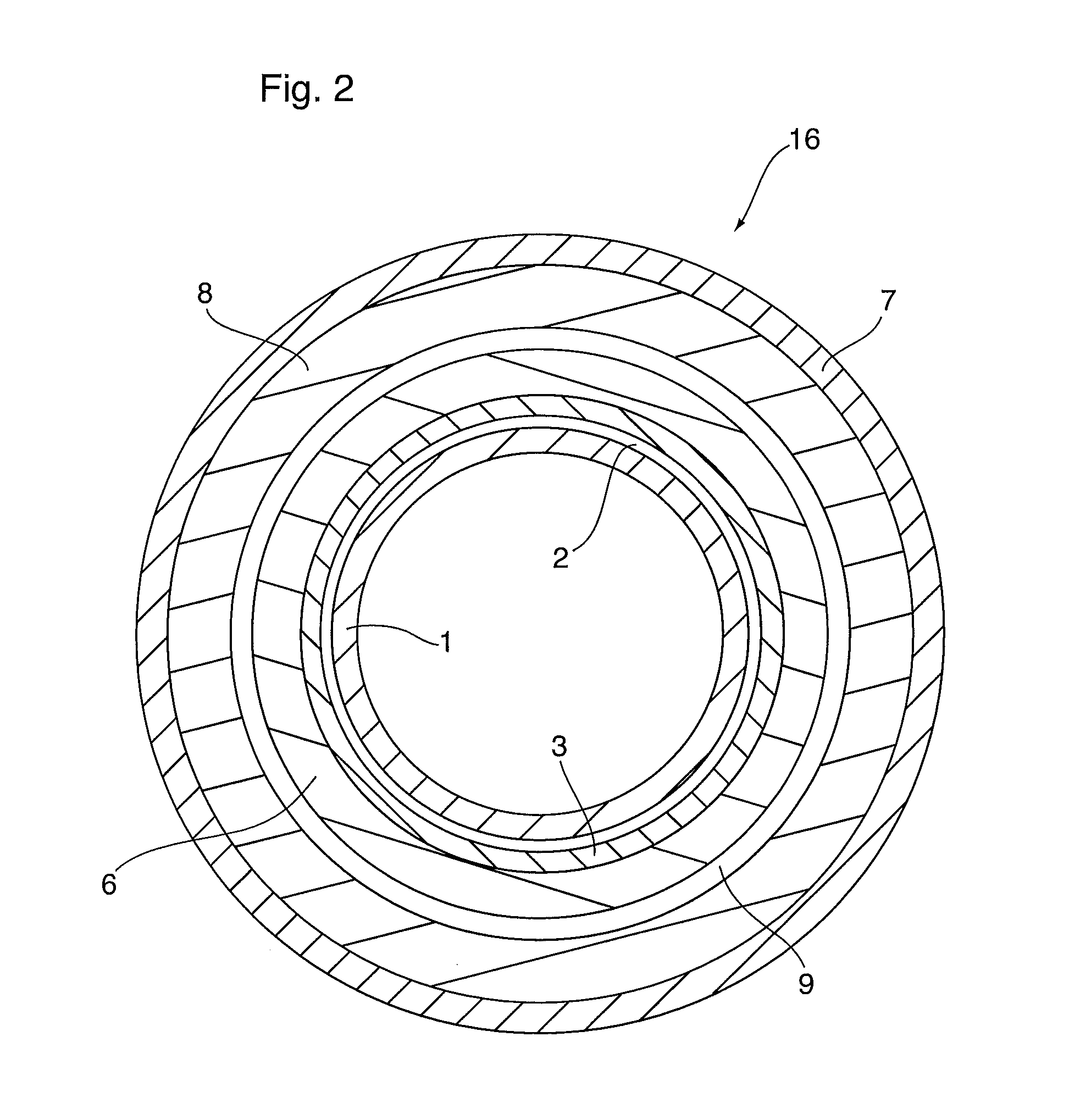

Styrenic insulation for pipe

ActiveUS20090159146A1Improve insulation effectReduce coating thicknessThermal insulationCorrosion preventionThermoplasticCompressive creep

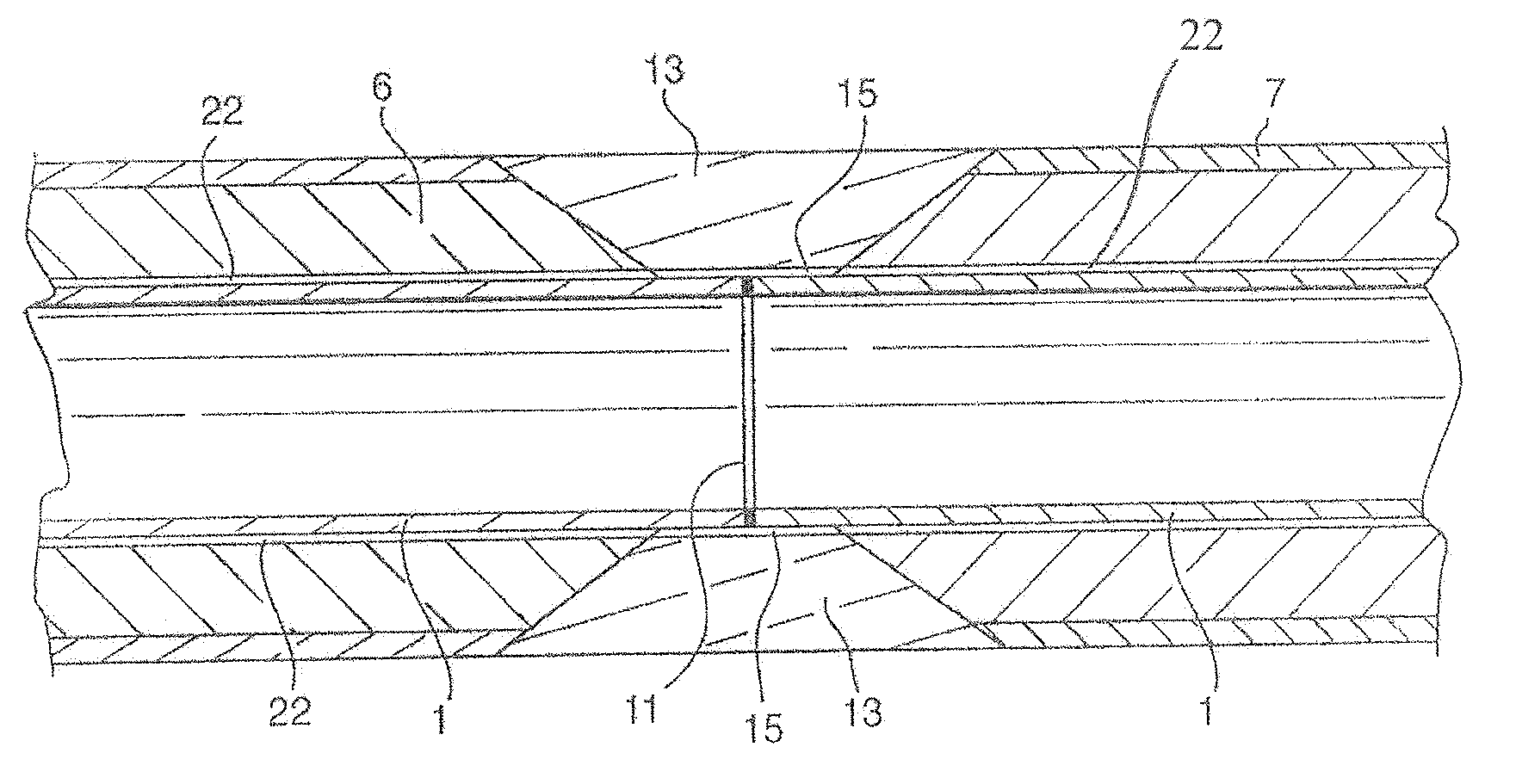

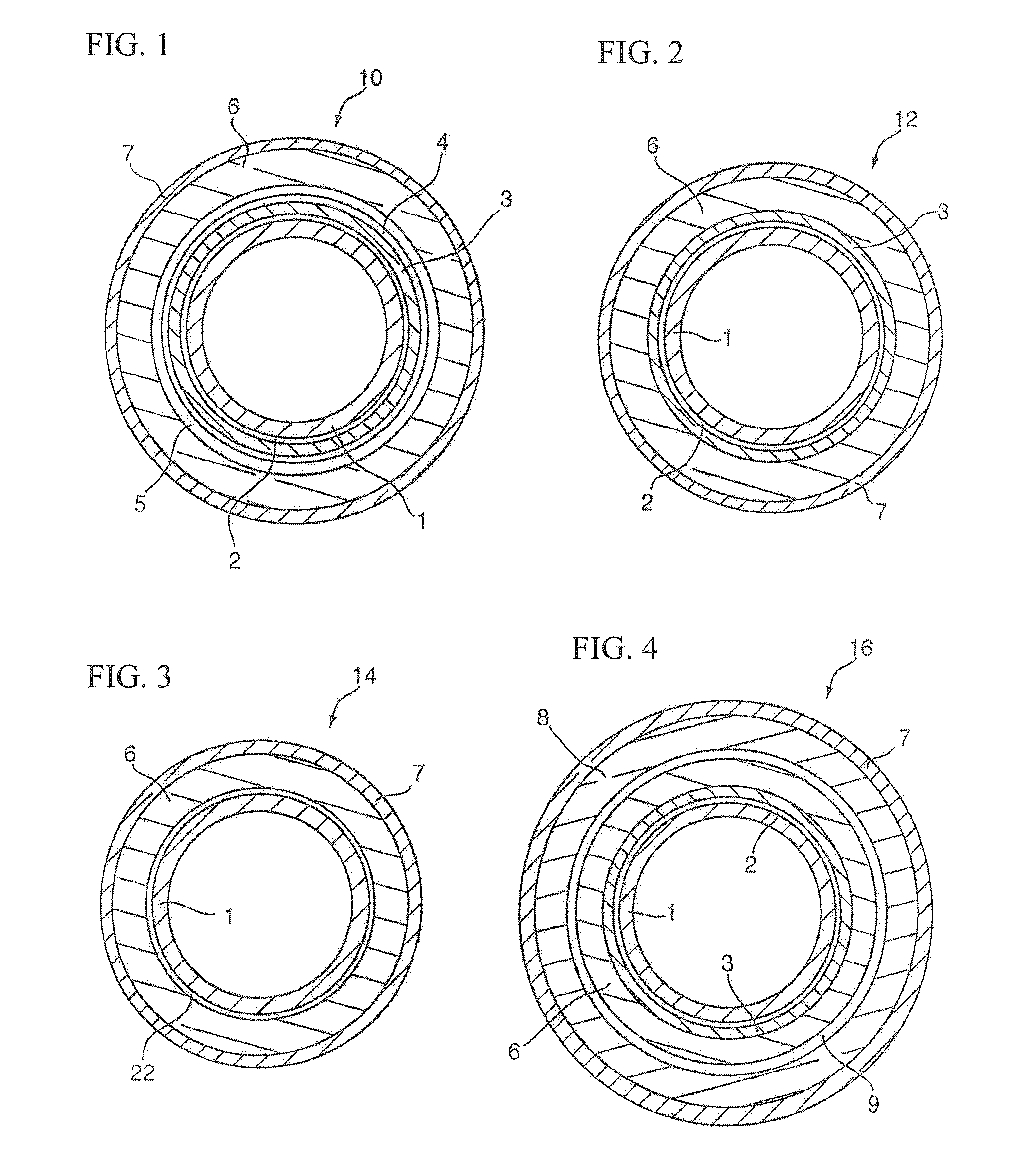

Coatings for protecting and insulating fluid and / or gas transport conduits, such as off-shore oil and gas pipelines operating at temperatures of up to 100° C. in water depths above 1,000 metres. The outer surface of the conduit is provided with at least one layer of thermal insulation comprising polystyrene or styrene-based thermoplastic, having low thermal conductivity, high thermal softening point, high compressive strength and high compressive creep resistance.

Owner:SHAWCOR LTD

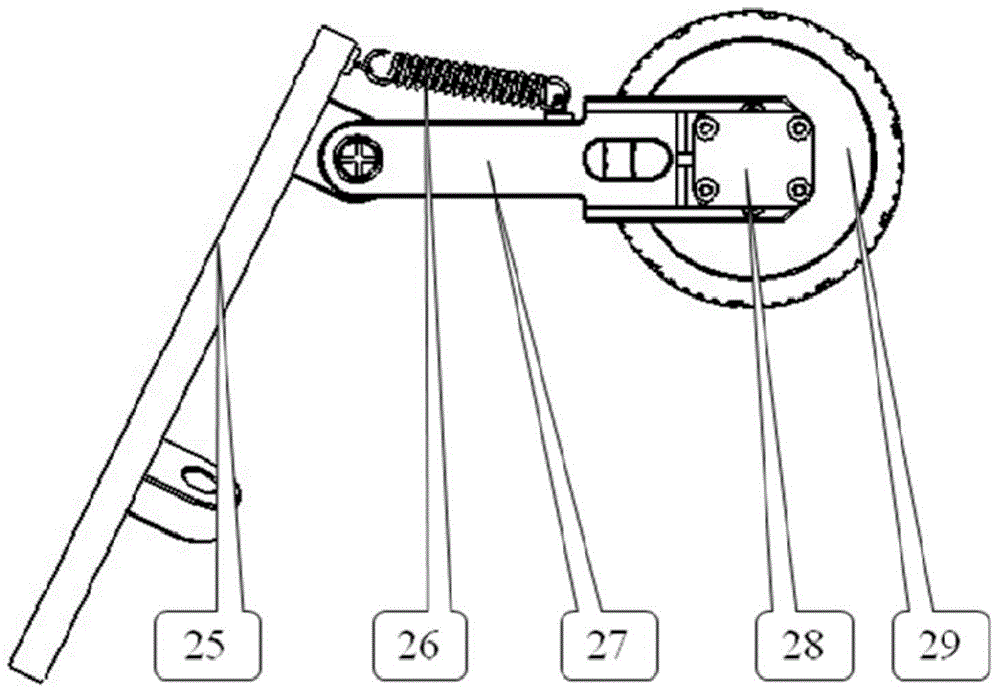

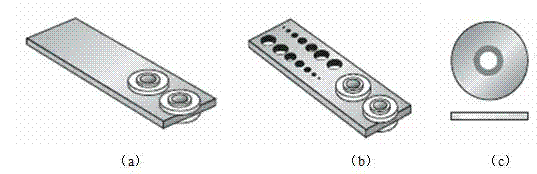

High-precision inner detecting device for seabed oil and gas pipeline flaws

A high-precision inner detecting device for seabed oil and gas pipeline flaws is characterized in that an anti-collision head and a front power packing cup are connected to the front end of a body support shaft, the rear of the front power packing cup is connected with a floating magnetization detecting block through a hinge mechanism, and a lateral jacking spring is disposed on each of the front side and the rear side of the floating magnetization detecting block to form a floating magnetization circuit and a magnetic flux leakage detecting block unit. A finger probe is disposed on the floating magnetization detecting block. A guide groove and a limit ring are arranged at the rear end of the body support shaft. A rear power packing cup is disposed at the rear of the guide groove. The front packing cup and the rear packing cup jointly form a power drive system. A battery pack unit and an electronic recorder are respectively disposed at the front and the rear of a seal cabin in the body support shaft in an opposite insertion manner. A detector odometer wheel unit is mounted at the tail of the body support shaft. By the floating magnetization detecting structure, online inner detection of oil and gas pipeline flaws under complex working conditions can be well achieved.

Owner:TSINGHUA UNIV

X80 steel bend pipe and bending technique thereof

The invention relates to an X80 steel bent pipe and a process for bending the same, wherein the bent pipe is made of X80 steel. The weight percentage compositions of the steel are: 0.06 to 0.15 percent of C, 0.1 to 0.3 percent of Si, 1.4 to 2.0 percent of Mn, less than or equal to 0.015 percent of P, 0.01 percent of S, 0 to 0.45 percent of Cr, 0 to 0.3 percent of Mo, 0 to 0.3 percent of Cu, 0 to 0.5 percent of Ni, 0.05 to 0.15 percent of Nb, 0 to 0.06 percent of Ti, 0 to 0.06 percent of V, Ceq controlled between 0.36 and 0.44 percent, Pcm controlled between 0.17 and 0.23 percent. The steel controlled rolled steel plate is made into steel pipe and is formed into bent pipe by induction heating bending process. The properties of the bent pipe can completely meet the technical requirement on X80 steel pipes by controlling parameters of heating temperature of the induction heating, bending velocity, cooling velocity, etc. during the bending process, thereby being suitable to be used as bent pipes for oil and gas pipelines.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

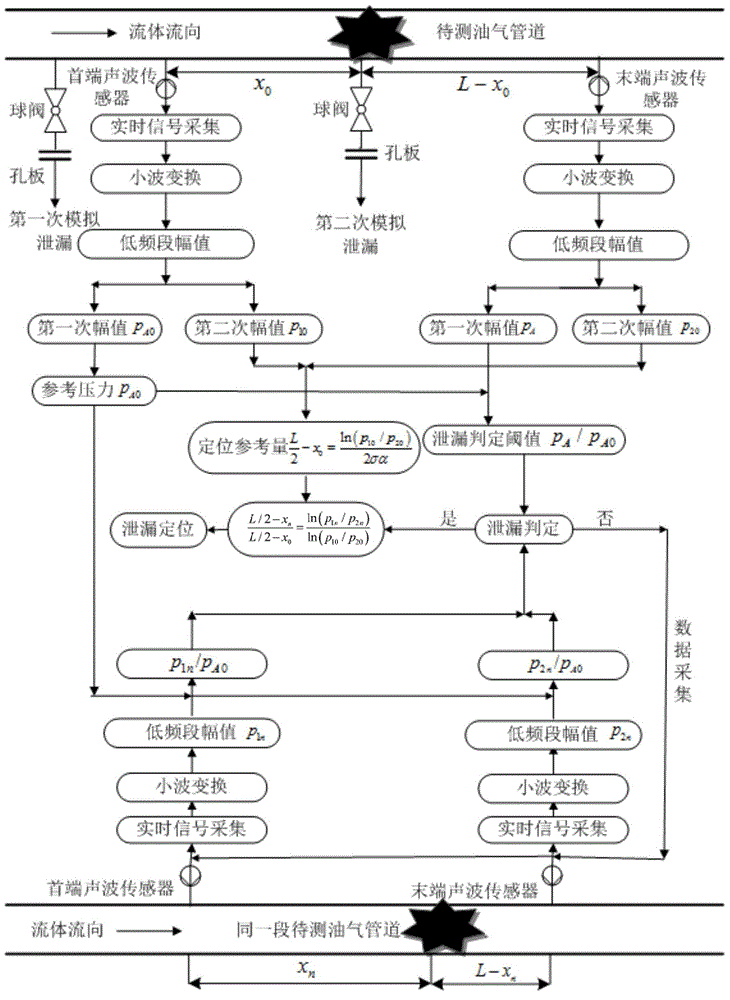

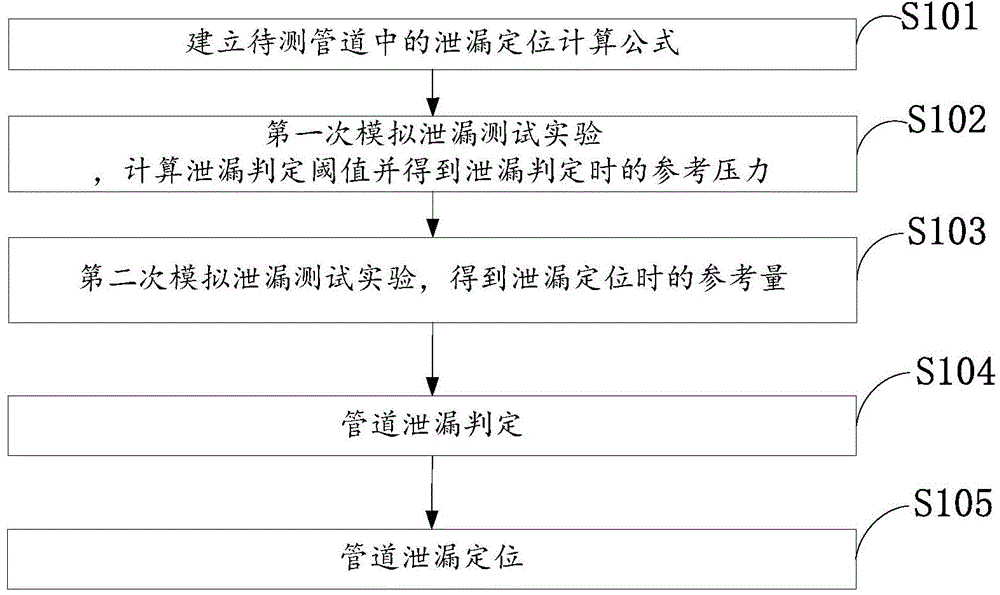

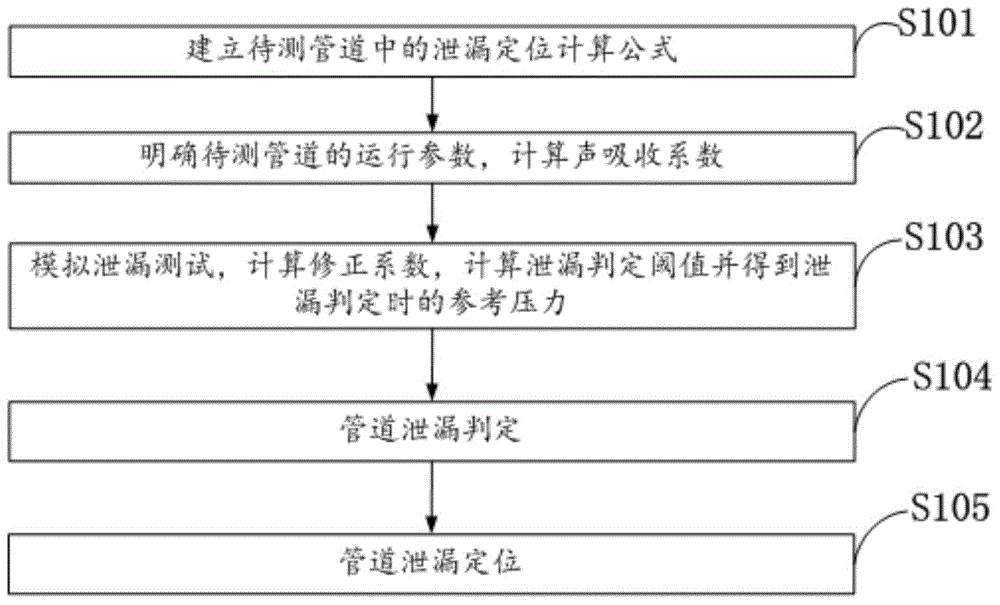

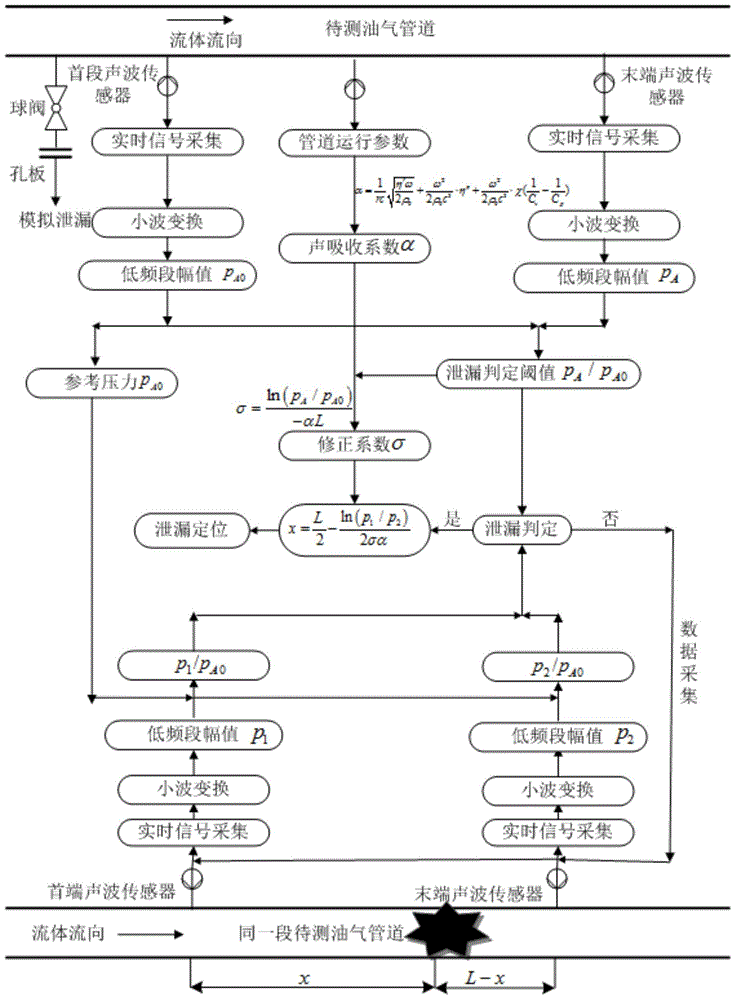

Oil and gas pipeline leakage positioning method based on sound wave amplitude

The invention discloses an oil and gas pipeline leakage positioning method based on sound wave amplitude. The oil and gas pipeline leakage positioning method comprises the following steps of establishing a leakage positioning computing formula in a to-be-tested pipeline; performing the first simulating leakage testing experiment at the upstream of a sensor at the head end, enabling sound wave sensors at the head end and the tail end to collect leakage sound wave signals which are propagated along the pipeline medium, and obtaining a leakage detection threshold value and the reference pressure; performing the second simulating leakage testing experiment between the sensors at the two ends of the to-be-tested pipeline, enabling the sound wave sensors at the head end and the tail end to collect leakage sound wave signals which are propagated along the pipeline medium, and obtaining the amplitude of a low-frequency sound wave signal; normally monitoring the to-be-tested pipeline, and detecting the leakage according to the leakage detection threshold value obtained by the first leakage testing experiment; according to the second leakage testing experiment and the positioning computing formula, positioning the leakage. The oil and gas pipeline leakage positioning method has the advantage that by not considering the computing of the sound wave propagation speed and the computing of the time difference, the mounting of a GPS (global positioning system) clock is avoided, the cost is low, the sensitivity is high, and the suitability for the oil and gas pipeline is high.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

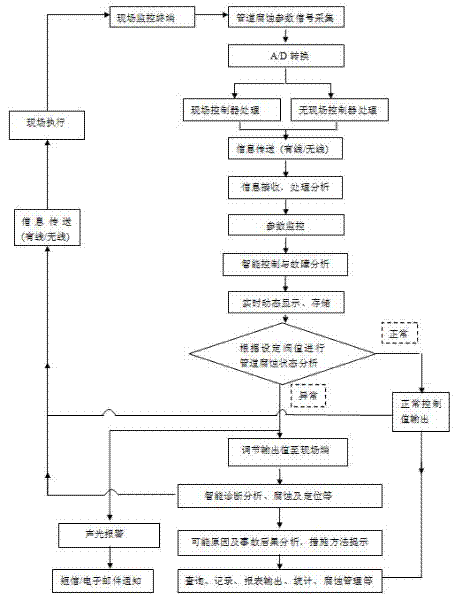

Online monitoring system for corrosion state of oil and gas pipelines and method thereof

InactiveCN102305352APracticalWide range of applicationsWeather/light/corrosion resistancePipeline systemsDigital signal processingMonitoring system

The invention provides an online monitoring system for the corrosion state of oil and gas pipelines and a method thereof, which can monitor sensitive corrosion points, such as an elbow, liquid accumulating parts at upper and lower slopes, and the like and insensitive corrosion points and realize the remote transmission of corrosion monitoring data in a wired or wireless manner, treat the data at a monitoring center, establish the corrosion state parameter of each point of the oil and gas pipelines via a modern digital signal treating method, judge whether the corrosion state is normal or not,and carry out the corresponding treatment and the control of the pipelines to timely monitor the corrosion state of the oil and gas pipelines so as to timely discover hidden troubles and prevent safety accidents. A three-dimensional corrosion state graph of the pipeline can be visually displayed at the monitoring center so that abnormal corrosion parts can be found out. The scheme of the system has the advantages of low cost and high benefit, and the key is that the system can realize real-time monitoring based on the prior art; and more important, the system can be applied to monitoring the corrosion state of newly-built long oil and gas pipelines such as pipelines for transporting the natural gas from the West to the East so that the system has a very wide market prospect. The oil and gas pipelines can be laid on the ground or buried under the ground.

Owner:SOUTHWEST PETROLEUM UNIV

Waterborne residual rust antirust coating and preparation method thereof

ActiveCN103897510AExcellent physical and chemical anti-rustFunction increaseAnti-corrosive paintsEpoxy resin coatingsAcrylic resinMechanical equipment

The invention discloses a waterborne residual rust antirust coating and a preparation method thereof. The waterborne residual rust antirust coating is prepared from styrene-acrylic emulsion, water soluble epoxy resin, water soluble acrylic resin, iron oxide red, graphene, zinc oxide, barium sulphate, transforming agents, a transformation accelerator, a levelling agent, a defoaming agent, a dispersing agent, a thickening agent and water. The waterborne residual rust antirust coating contains no organic solvent, is environment-friendly and pollution-free, has the characteristic that bottom and surface are combined and has an excellent physical and chemical antirust and rust transforming function, is applicable to rust protection of the surface of steel with rust, a hard oxidation skin layer or an oil paint film and is also applicable to rust protection of the surface of rust-free steel, the preparation method is simple, construction is easy, two transforming agents are complexed in the waterborne residual rust antirust coating, so that a binding force between the waterborne residual rust antirust coating and rust is increased, the waterborne residual rust antirust coating can be directly brushed and coated on the surface of rusty steel and is applicable to multiple construction ways such as spraying, brushing and showering, the coating cost is low, and the rust protection requirements of urban road facilities, bridges, oil and gas pipelines, engineering mechanical equipment, ships and the like can be met.

Owner:重庆南方漆业有限公司

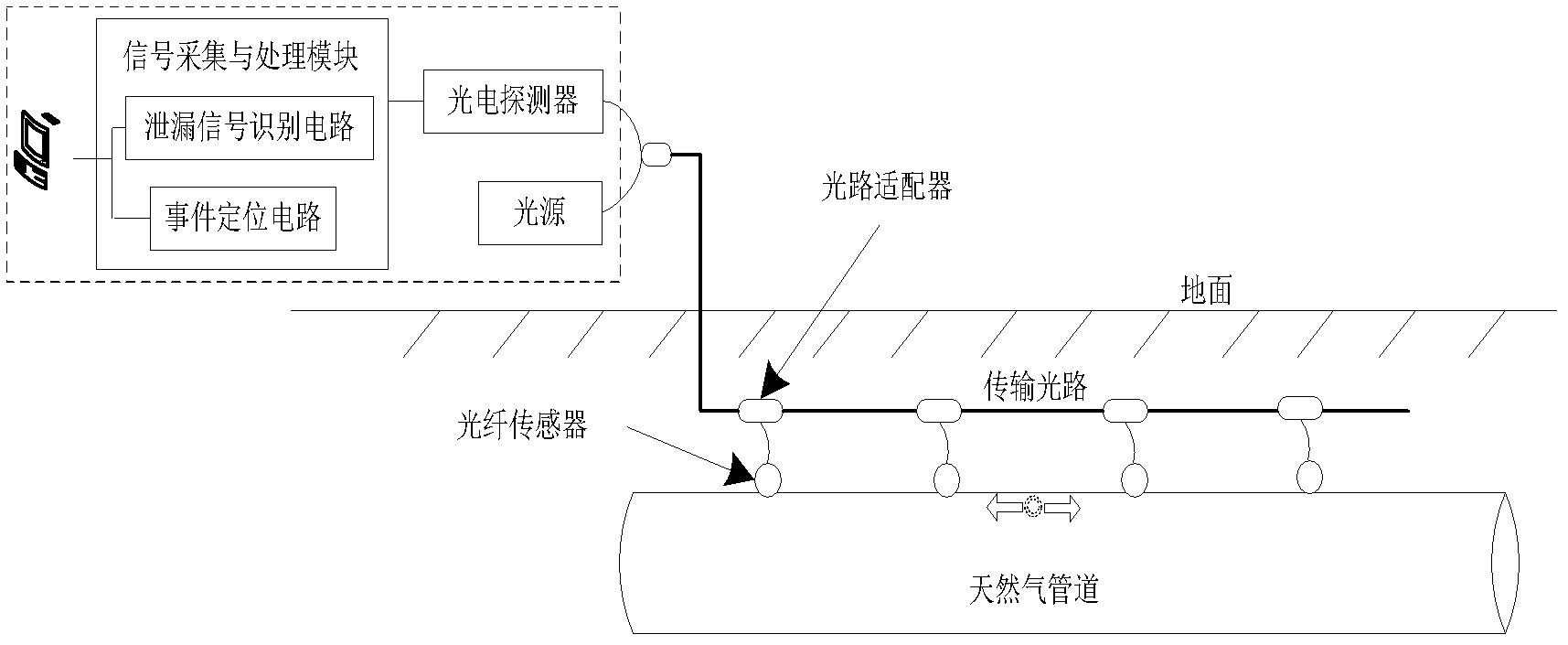

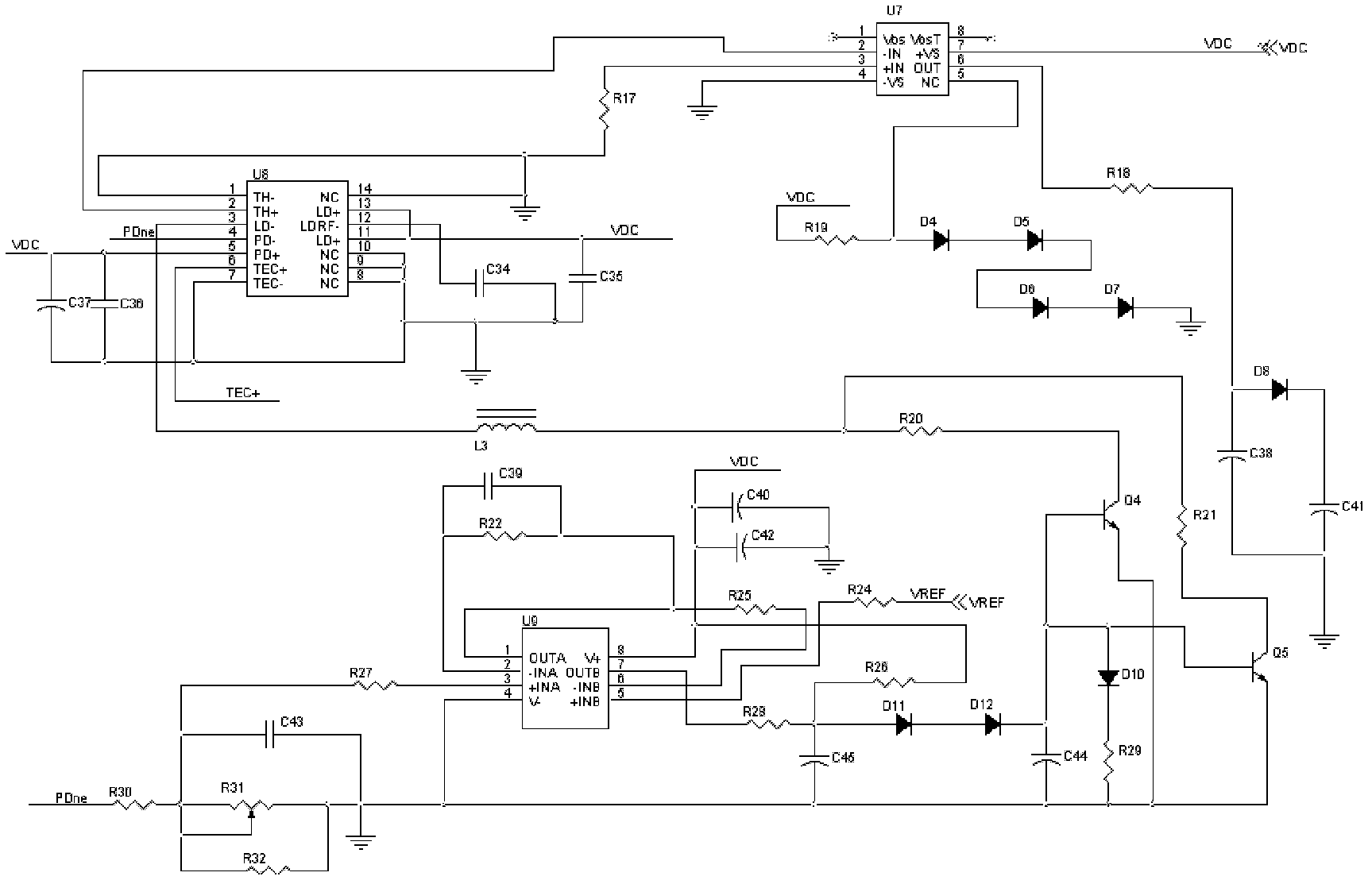

Optical fiber sensor-based natural gas pipeline leakage monitoring method and system

InactiveCN102997051ASolve power problemsSolve the distance problemPipeline systemsTime delaysBeam splitting

The invention discloses an optical fiber sensor-based natural gas pipeline leakage monitoring method and an optical fiber sensor-based natural gas pipeline leakage monitoring system. Optical fibers in a communication optical cable which is laid in the same channel of an oil and gas pipeline respectively serve as a transmitting optical fiber and a returning optical fiber; pipeline leakage optical fiber sensors are connected in parallel between transceiving transmitting optical fibers to form an optical path by an optical multiplexing technology; the pipeline leakage optical fiber sensors are uniformly arranged along the pipeline; laser light emitted from a light source is subjected to beam splitting through a transmission optical path and is transmitted to the sensors arranged on the wall of the pipeline; after the sensors pick up leakage vibration signals and noises propagated along the pipeline, the leakage vibration signals and the noises are returned to a photoelectric detector part of the system through the transmission optical path; the acquired vibration wave signals are analyzed and processed; and the position of a vibration wave source is determined by combining the propagation speed of the vibration wave on a pipeline body according to the time delay of the vibration waves propagated to a plurality of adjacent optical fiber sensors. By the method and the system, the flexibility is high; and the positioning accuracy is high.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High temperature resistant insulation for pipe

ActiveUS8397765B2Low thermal conductivityImprove thermal stabilityThermal insulationSynthetic resin layered productsElastomerPolyetherimide

A polymeric composition for insulating fluid and / or gas transport conduits, such as off-shore oil and gas pipelines operating at temperatures of 130° C. or higher in water depths above 1,000 meters. The outer surface of the conduit is provided with at least one layer of solid or foam insulation comprising a high temperature resistant thermoplastic having low thermal conductivity, high thermal softening point, high compressive strength and high compressive creep resistance. The high temperature resistant thermoplastic is selected from one or more members of the group comprising: polycarbonate; polyphenylene oxide; polyphenylene oxide blended with polypropylene, polystyrene or polyamide; polycarbonate blended with polybutylene terephthalate, polyethylene terephthalate, acrylonitrile butadiene styrene, acrylonitrile styrene acrylate, or polyetherimide; polyamides, including polyamide 12 and 612 and elastomers thereof; polymethylpentene and blends thereof; cyclic olefin copolymers and blends thereof; and, partially crosslinked thermoplastic elastomers, also known as thermoplastic vulcanizates or dynamically vulcanized elastomers.

Owner:SHAWCOR LTD

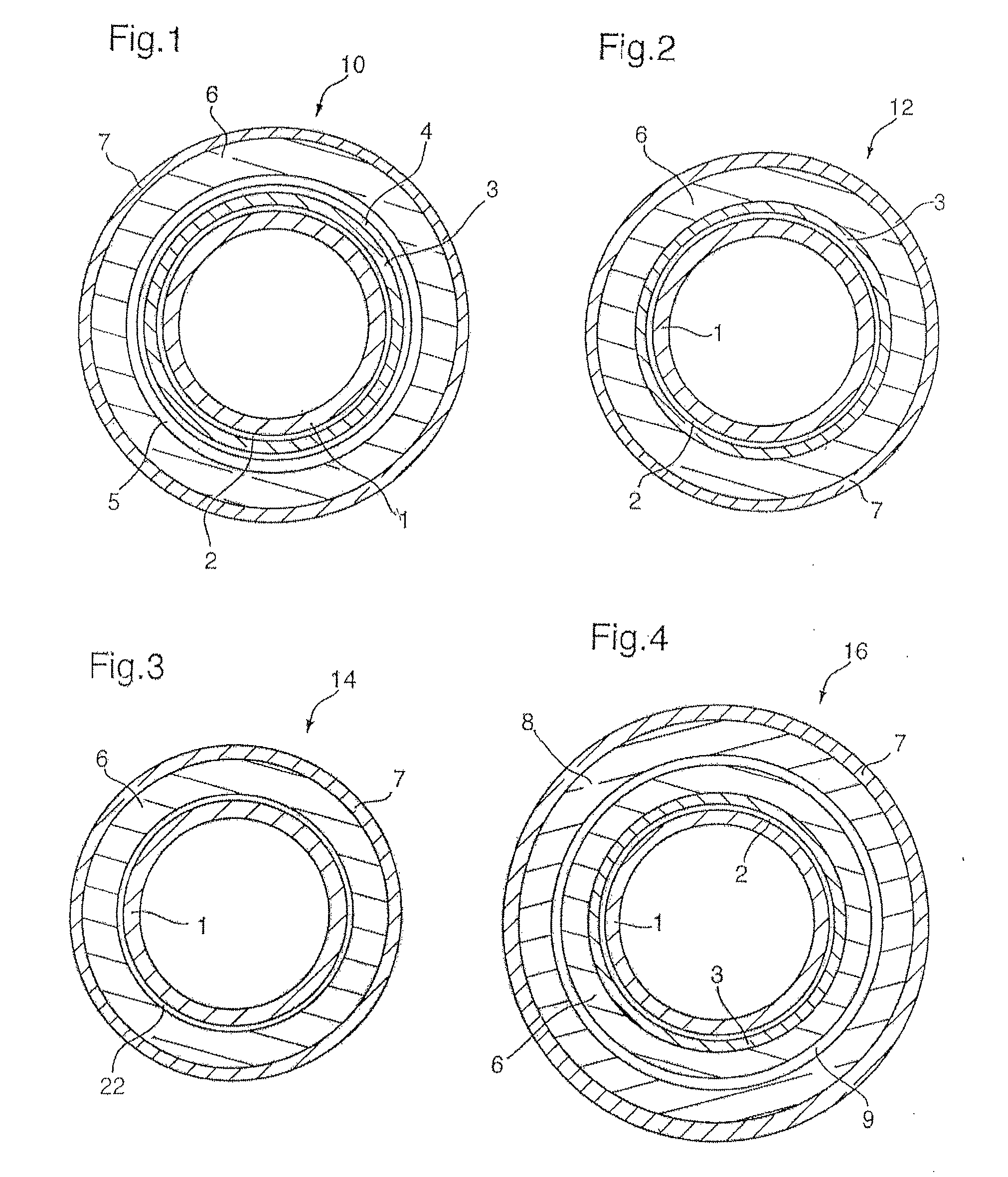

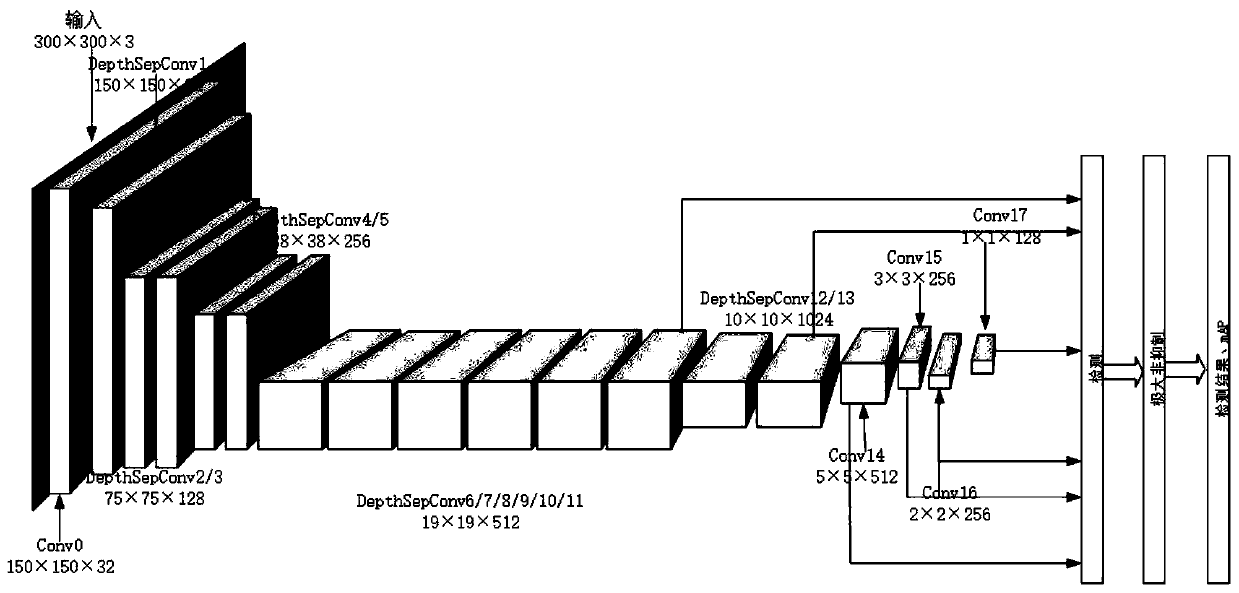

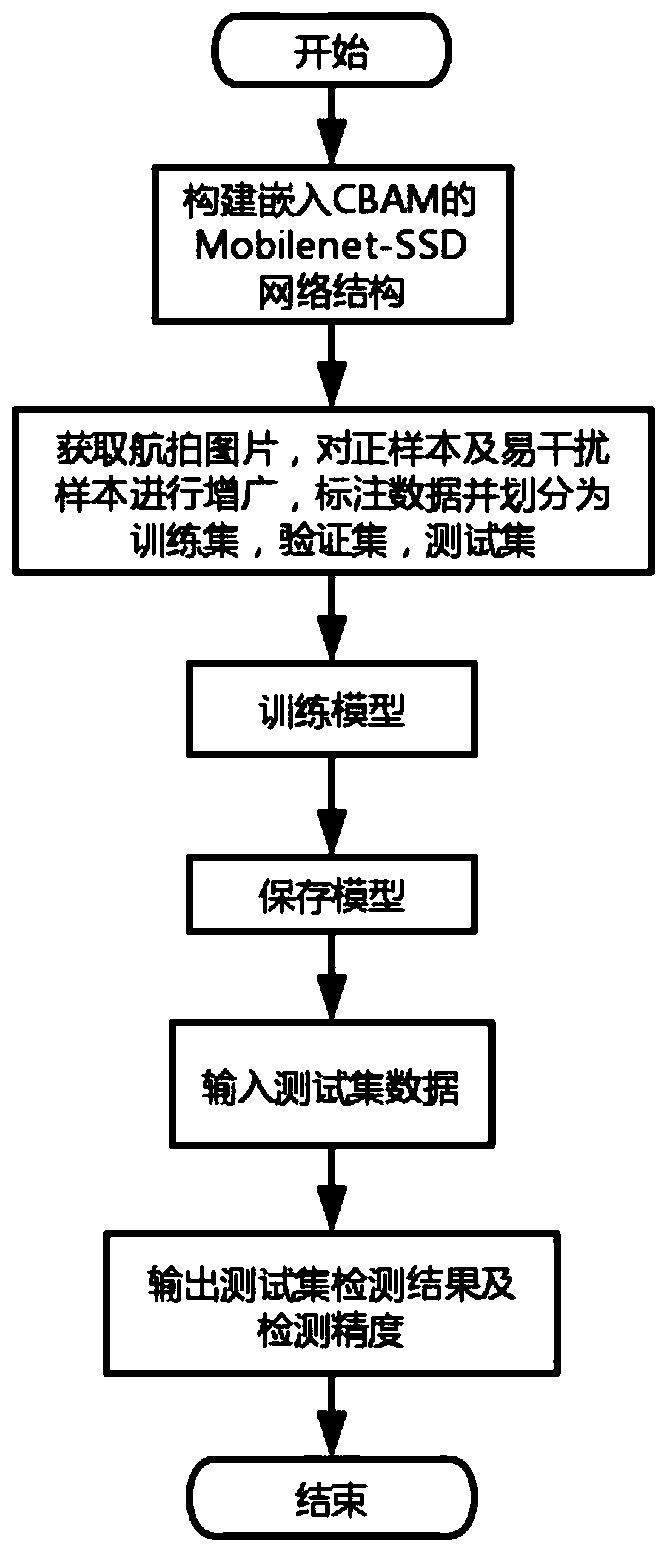

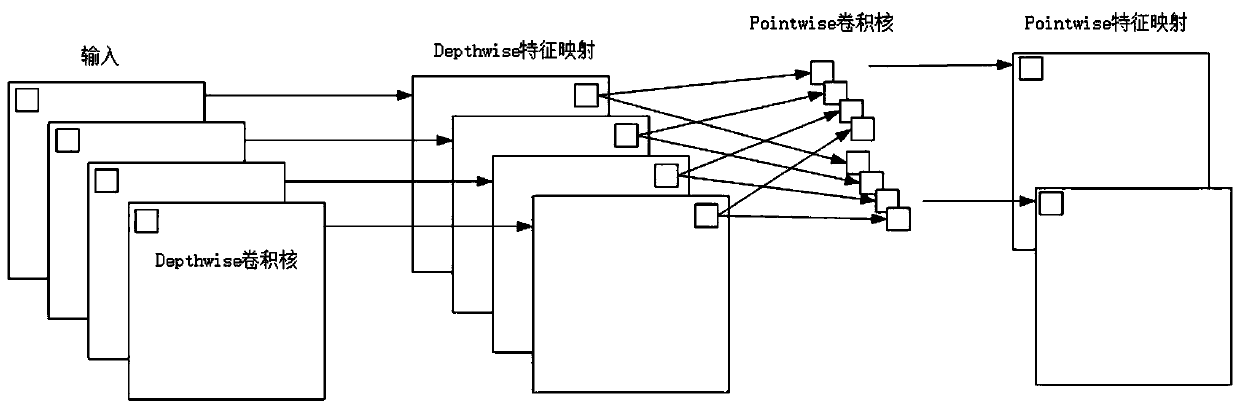

Oil and gas pipeline marker identification method based on neural network

ActiveCN111339858AHigh precisionObject Detection ImplementationScene recognitionNeural architecturesEngineeringData mining

The invention provides an oil and gas pipeline marker identification method based on a neural network. The method comprises the steps of constructing a model, obtaining a training set, a verificationset and a test set, obtaining an optimal model through training, performing testing by adopting the test set, obtaining a detection result and calculating detection precision. According to the method,the Mobilenet with few parameters is used as a basic network, the SSD algorithm directly regressing on multi-scale feature mapping is used as a target detection algorithm, multi-scale target detection is achieved, a detection model is small, the detection speed is high, the detection model is deployed at a mobile terminal, and markers of the oil and gas pipeline are detected in real time; the significant characteristics of the marker are highlighted from the global and local ranges through a CBAM attention mechanism, and a better detection effect is obtained; and meanwhile, the attention mechanism is embedded behind each layer of the basic network, so that the feature expression capability can be enhanced layer by layer from the first layer, interference information is effectively eliminated, and the detection precision is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

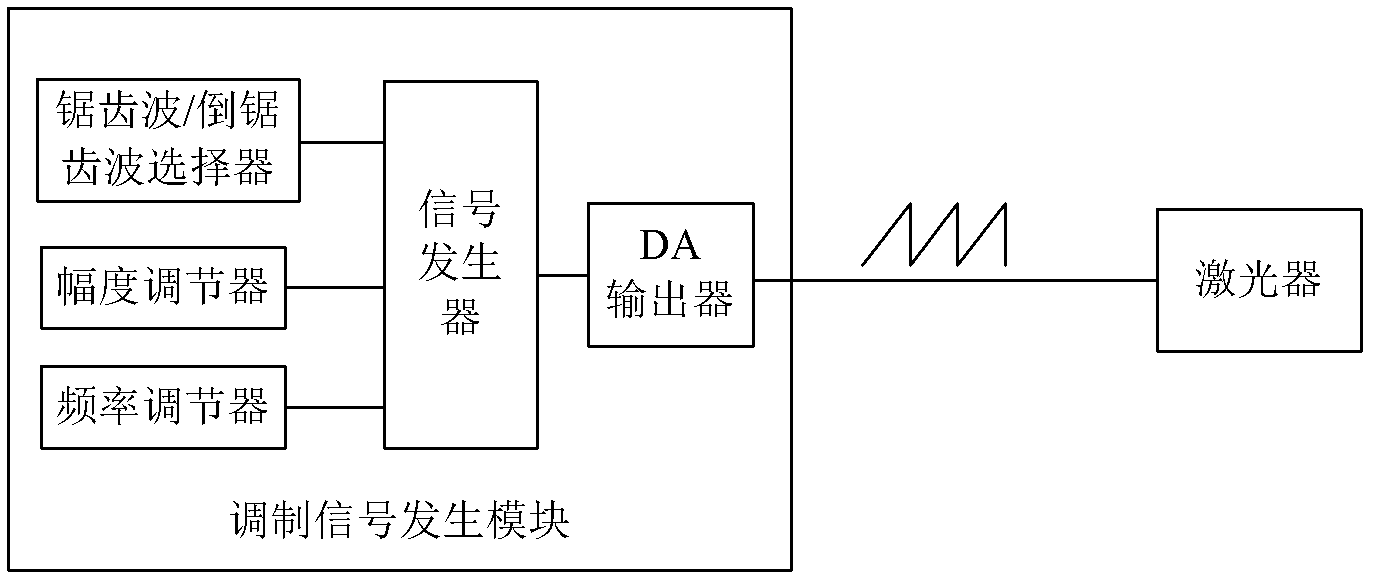

High-sensitivity gas-mapping 3D imager and method of operation

ActiveUS20170097302A1Measurement of fluid loss/gain rateScattering properties measurementsChemical treatmentComputer vision

Measurement apparatuses and methods are disclosed for generating high-precision and -accuracy gas concentration maps that can be overlaid with 3D topographic images by rapidly scanning one or several modulated laser beams with a spatially-encoded transmitter over a scene to build-up imagery. Independent measurements of the topographic target distance and path-integrated gas concentration are combined to yield a map of the path-averaged concentration between the sensor and each point in the image. This type of image is particularly useful for finding localized regions of elevated (or anomalous) gas concentration making it ideal for large-area leak detection and quantification applications including: oil and gas pipeline monitoring, chemical processing facility monitoring, and environmental monitoring.

Owner:BRIDGER PHOTONICS

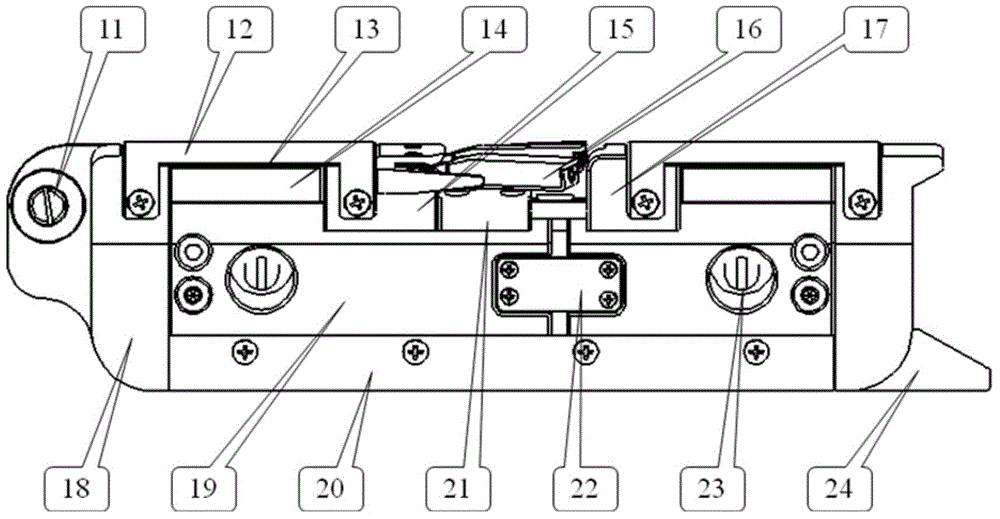

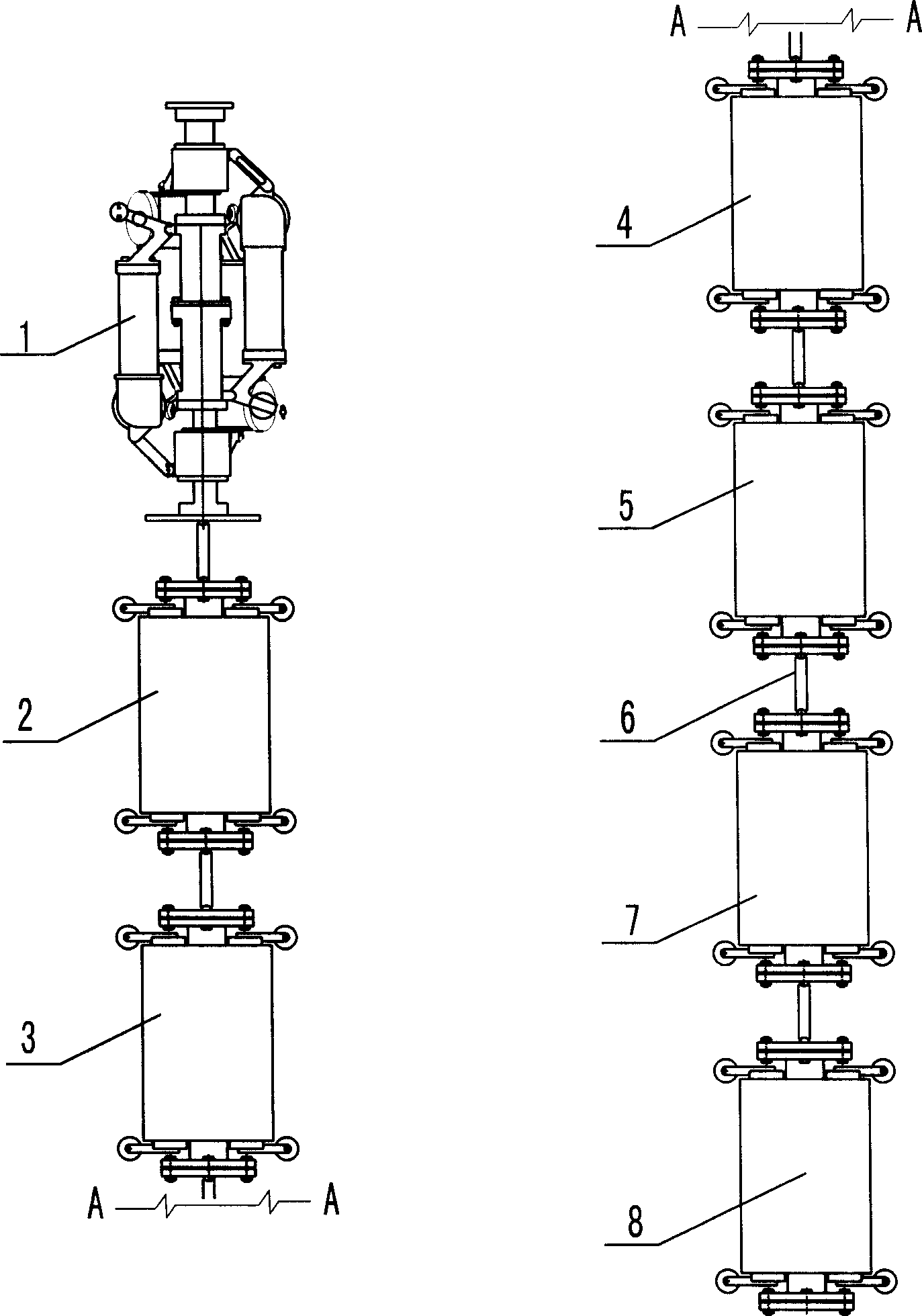

Oil and gas pipeline intelligent internal detection device based on multi-module combined location

ActiveCN103470959AReduce resistancePrevent pulling outPipeline systemsSpeed control systemElectromagnetic pulse

The invention discloses an oil and gas pipeline intelligent internal detection device based on multi-module combined location. The device comprises an internal detector arranged inside an oil and gas pipeline and a floor marker arranged outside the oil and gas pipeline. The internal detector comprises a driving system, a magnetic leakage detecting system, a speed control system, a distance measuring system and a low frequency emitting system, wherein the driving system, the magnetic leakage detection system, the speed control system, the distance measuring system and the low frequency emitting system are relatively fixedly connected together; the floor marker at least comprises a low frequency receiving system; the low frequency emitting system is used for sending detection results obtained by the magnetic leakage detection system out of the oil and gas pipeline; the low frequency receiving system is used for receiving low frequency electromagnetic pulse signals transmitted by the low frequency emitting system. The oil and gas pipeline intelligent internal detection device based on the multi-module combined location can timely obtain the detection data of the pipeline detector and analyze the detection data and accordingly rapidly determine the defect conditions of the pipeline.

Owner:BEIJING APC PETROCHEM TECH

Subsea oil and gas pipeline detecting and locating apparatus and process

InactiveCN101046466ARealize real-time detectionThe recognition effect is accurateAnalysing solids using sonic/ultrasonic/infrasonic wavesPosition fixationOcean bottomLine tubing

The present invention discloses subsea oil and gas pipeline detecting and locating apparatus and process. The subsea oil and gas pipeline detecting and locating apparatus consists of an electrically driven creeping device, a creeping device controller, a high energy power source, an intelligent controller, a real-time locater, an ultrasonic acquiring processor, and an ultrasonic eddy flow detector connected through shaft couplings. The operation process includes the following steps: hose sweeping the pipeline and throwing the apparatus into the pipeline, moving the apparatus with the electrically driven creeping device under the control of the intelligent controller, detecting and locating the fault to be repaired, etc.

Owner:SHENGLI PETROLEUM ADMINISTRATION BUREAU DRILLING TECH ACAD SINOPEC

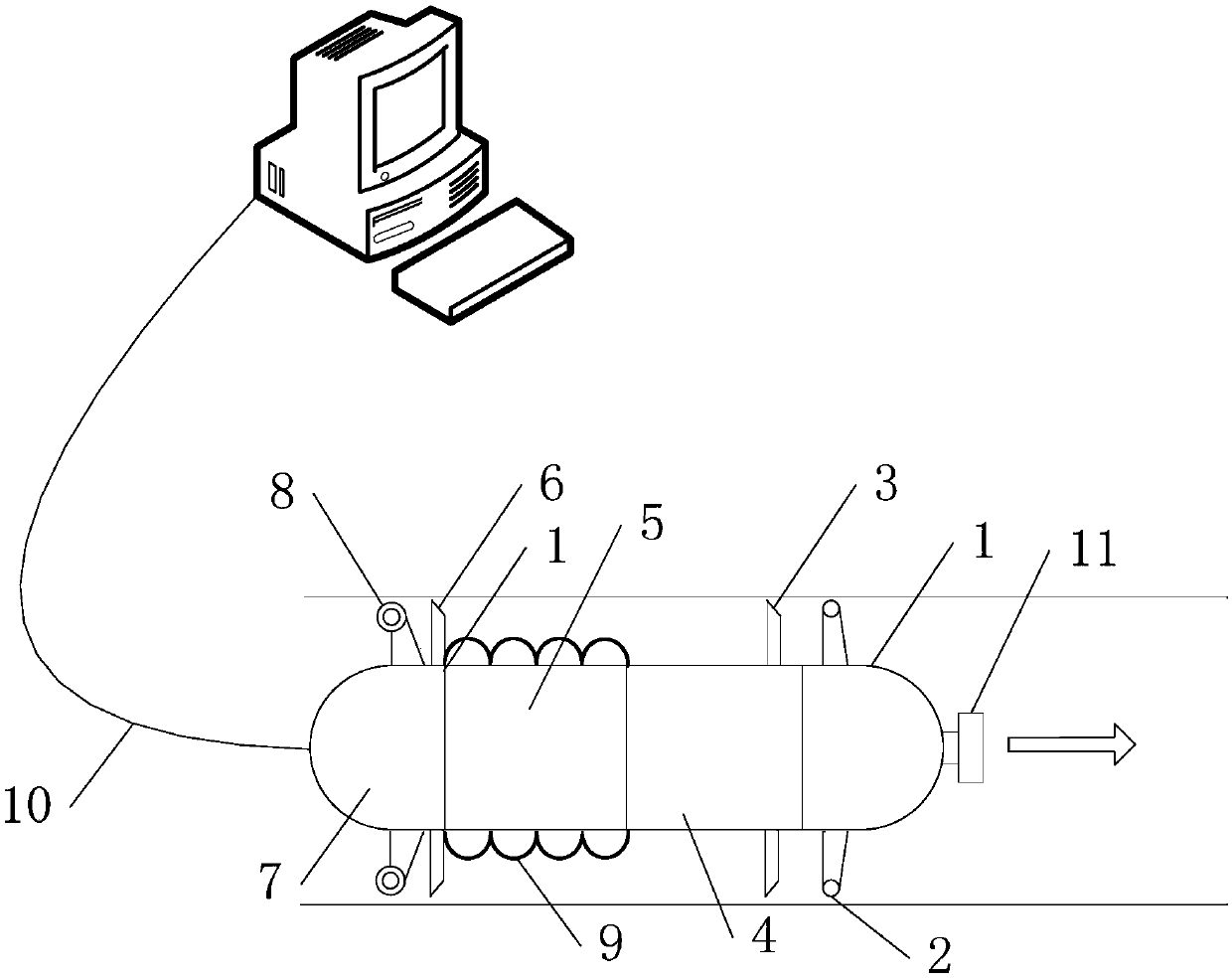

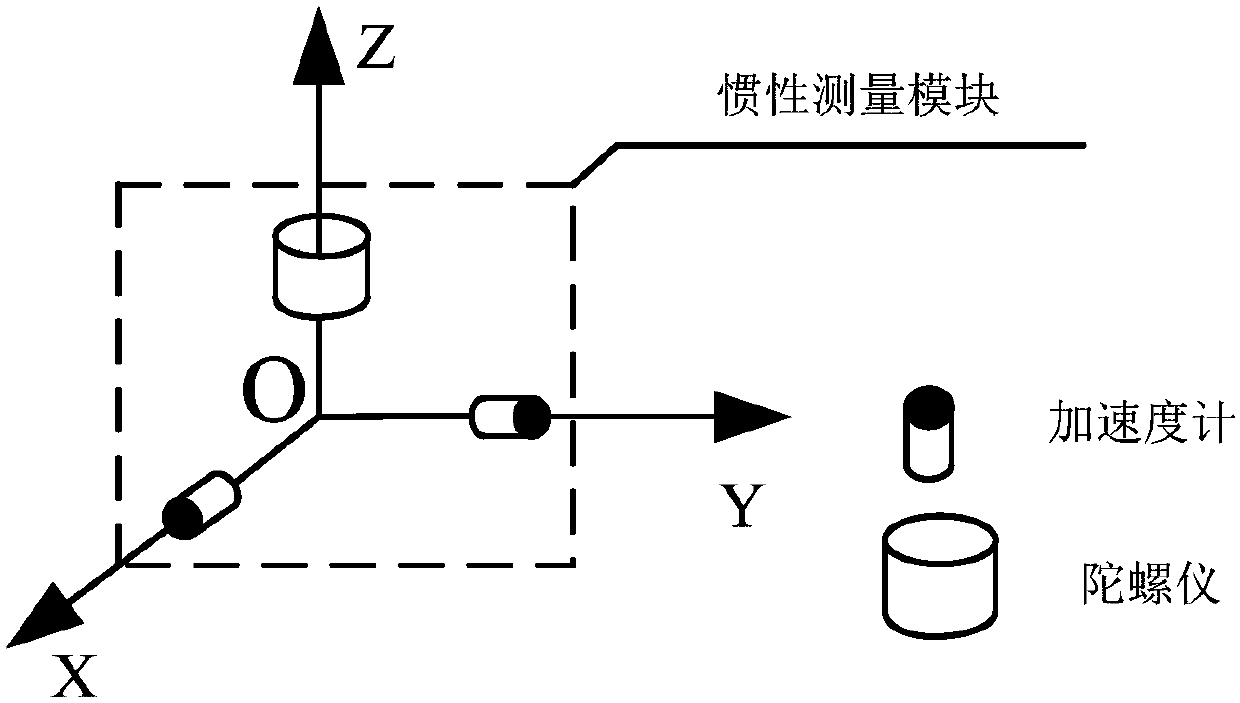

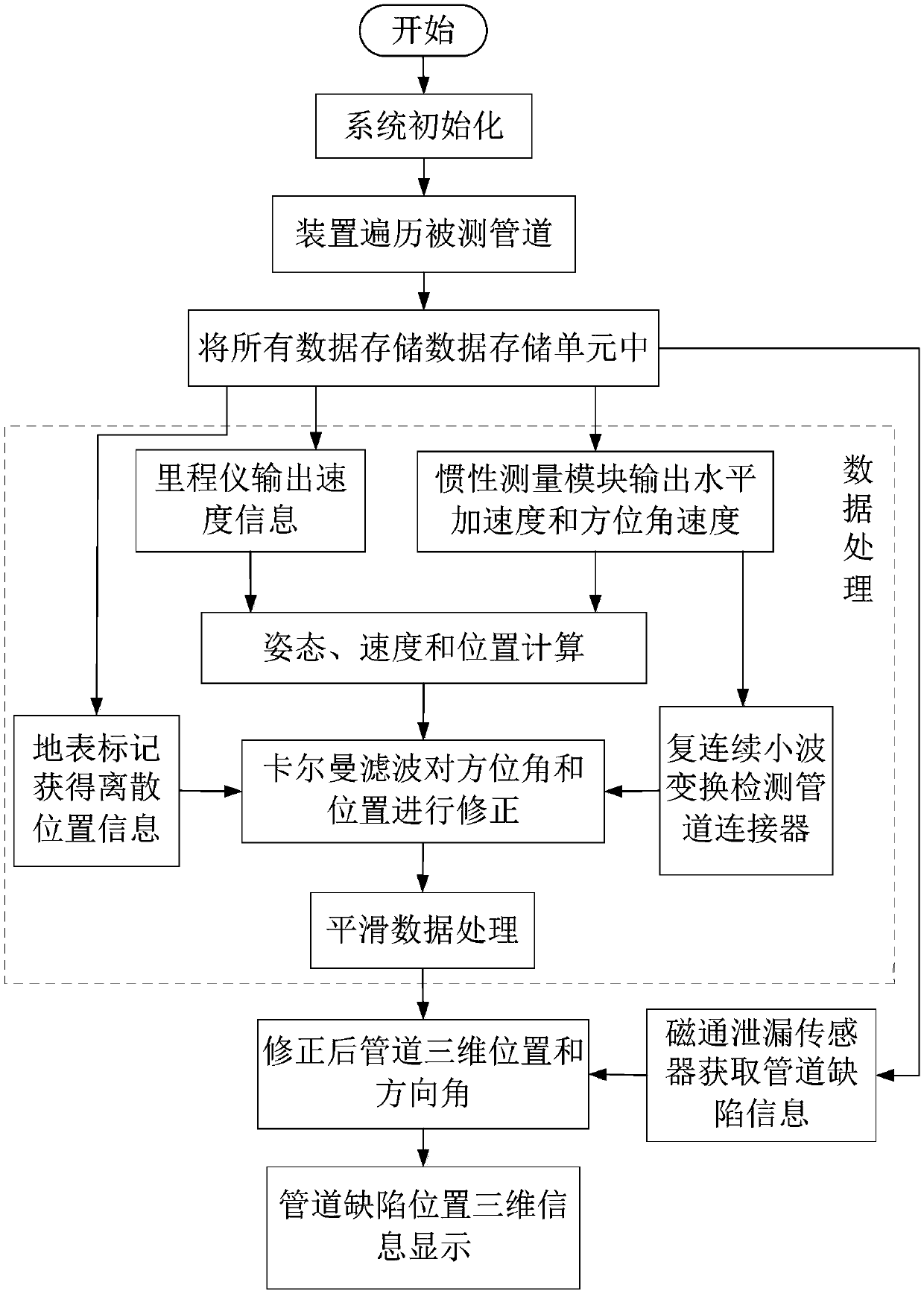

Positioning device and method for pipeline detection

InactiveCN107664266ARealize detection and positioningAvoid error accumulationNavigation by speed/acceleration measurementsPipeline systemsMagnetic trackingGyroscope

The invention relates to the technical field of pipeline geographic information measurement, in particular to a positioning device and method for pipeline detection. The problems that in the prior art, the precision is low, and remote measurement cannot be achieved are solved. The positioning device comprises a power supply module, two supporting rollers, a first plastic sealing ring, an inertia measuring module, a data processing unit, a second plastic sealing ring, a data storage unit, a mileage instrument, a flux leakage sensor, a communication cable and a magnetic tracking module. The inertia measuring module is composed of a gyroscope and two accelerometers; on the basis of the mileage instrument, and three-dimensional attitude angle, speed and position coordinate measurement inside the pipeline can be achieved. According to the positioning method, a complex continuous wavelet transform method is adopted for analyzing operating data of the inertia measuring module inside the pipeline, a pipeline connector is detected, and the method is used for correcting azimuth angle errors of the positioning device for pipeline detection. The device and method are applicable to detection ofland and underwater oil and gas pipelines.

Owner:哈尔滨航士科技发展有限公司 +3

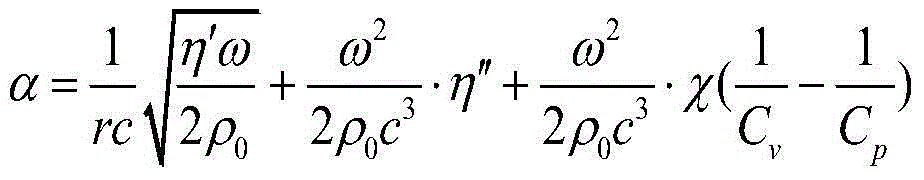

Oil and gas pipeline leakage positioning method based on sound wave amplitude attenuation model

ActiveCN104595730AImprove applicabilityAvoid installationPipeline systemsUltrasound attenuationSound wave

The invention discloses an oil and gas pipeline leakage positioning method based on a sound wave amplitude attenuation model. The oil and gas pipeline leakage positioning method comprises the following steps of establishing a leakage positioning computing formula in a to-be-tested pipeline; computing the sound absorbing coefficient; detecting the minimum detectable leakage amount or leakage hole diameter of the to-be-tested pipeline, performing the simulating leakage testing experiment at the upstream of a sensor at the head end of the to-be-tested pipeline, computing the correction coefficient according to the obtained amplitude, and further obtaining a leakage judging threshold value and the reference pressure during leakage judging; processing the signals collected by the sensors at the two ends of the to-be-tested pipeline, dividing by the reference pressure, and comparing the result and the leakage judging threshold value obtained by the simulating leakage testing experiment; when the leakage occurs, positioning the leakage of the pipeline according to the positioning formula. The oil and gas pipeline leakage positioning method has the advantages that by computing the sound absorbing coefficient and the correction coefficient in the leakage positioning computing formula, the leakage is detected and positioned; the mounting of a GPS (global positioning system) clock is avoided, the cost is low, the sensitivity is high, and the suitability for the oil and gas pipeline is high.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

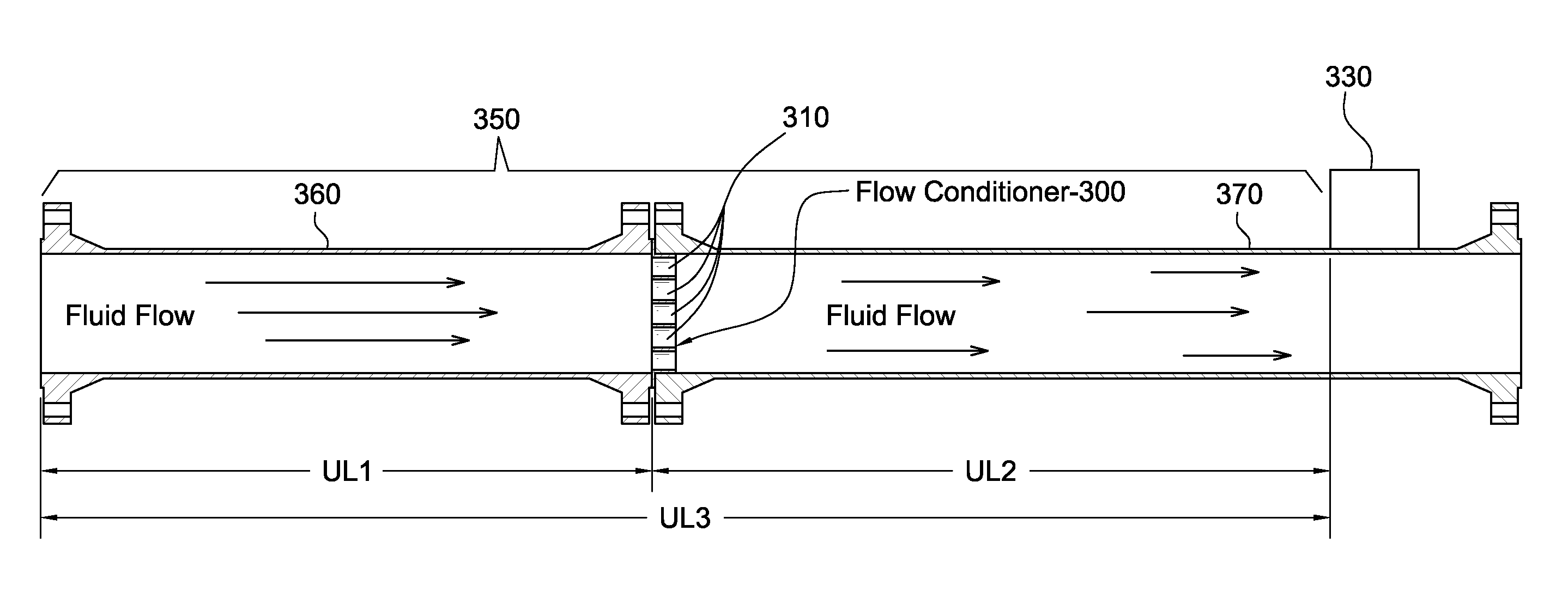

Electroless Plated Fluid Flow Conditioner and Pipe Assembly

InactiveUS20120247223A1Avoid material accumulationImprove accuracyPretreated surfacesCorrosion preventionElectroless nickelHardness

A method and system for electroless nickel plating of fluid flow measurement components used in oil and gas pipelines provides uniformly and consistently plating of all surfaces of the fluid flow components, including flow conditioners, with an electroless nickel plating that imparts the component with desirable characteristics related to hardness, smoothness, wear and abrasion resistance, and corrosion and oxidation resistance, such that the build up of contaminant deposits on the component is reduced and repeatable and accurately fluid flow measurements can be made.

Owner:CANADA PIPELINE ACCESSORIES

High temperature resistant polysulfone insulation for pipe

A polymeric composition for insulating fluid and / or gas transport conduits, such as off-shore oil and gas pipelines operating at temperatures of about 200° C. or higher in water depths above 1,000 metres. The outer surface of the conduit is provided with at least one layer of solid or foam insulation comprising a high temperature resistant polysulfone having sulfone, ether and isopropylidene bridging groups, and / or a polyphenylsulfone or a polyethersulfone.

Owner:SHAWCOR LTD

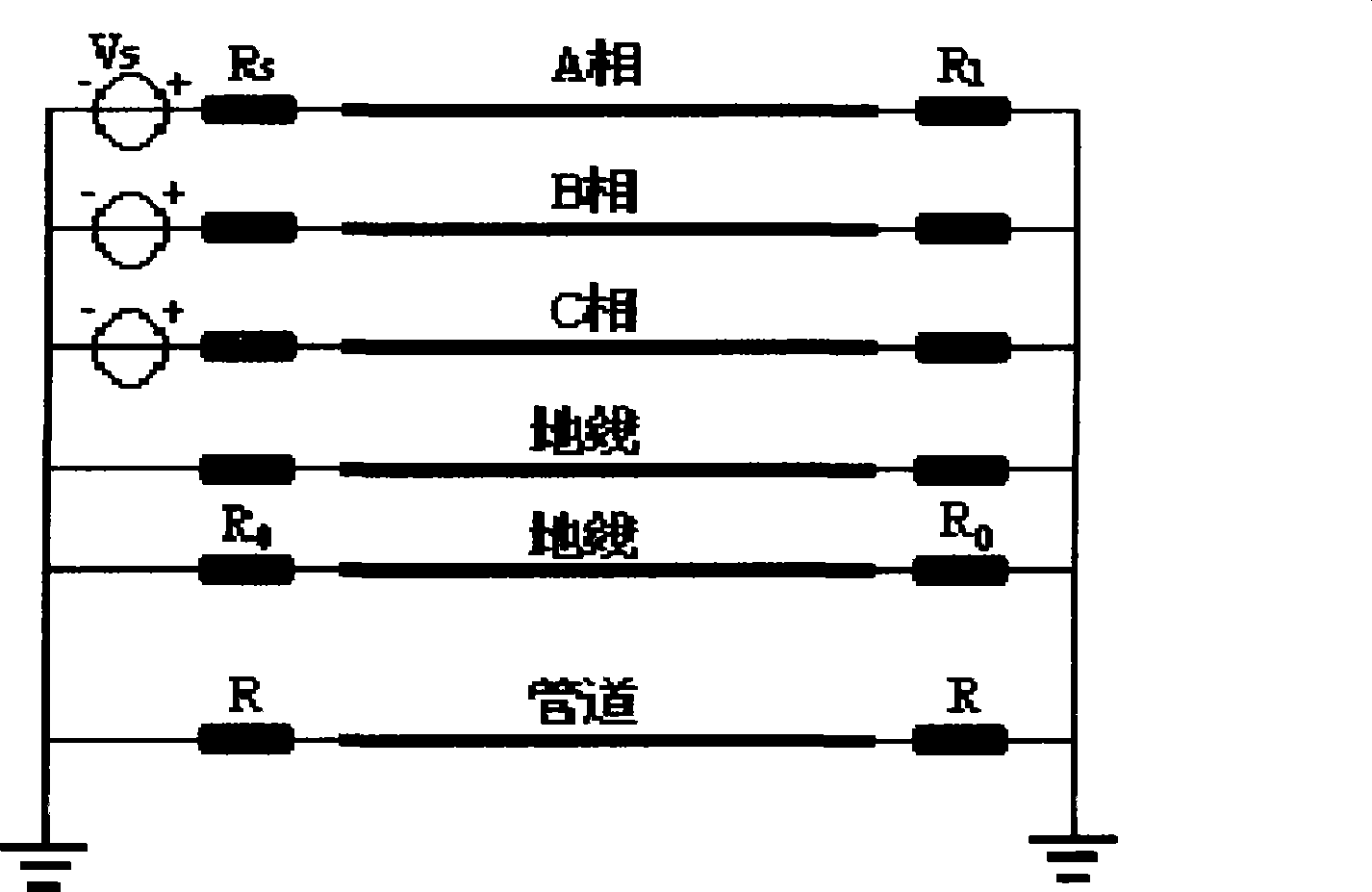

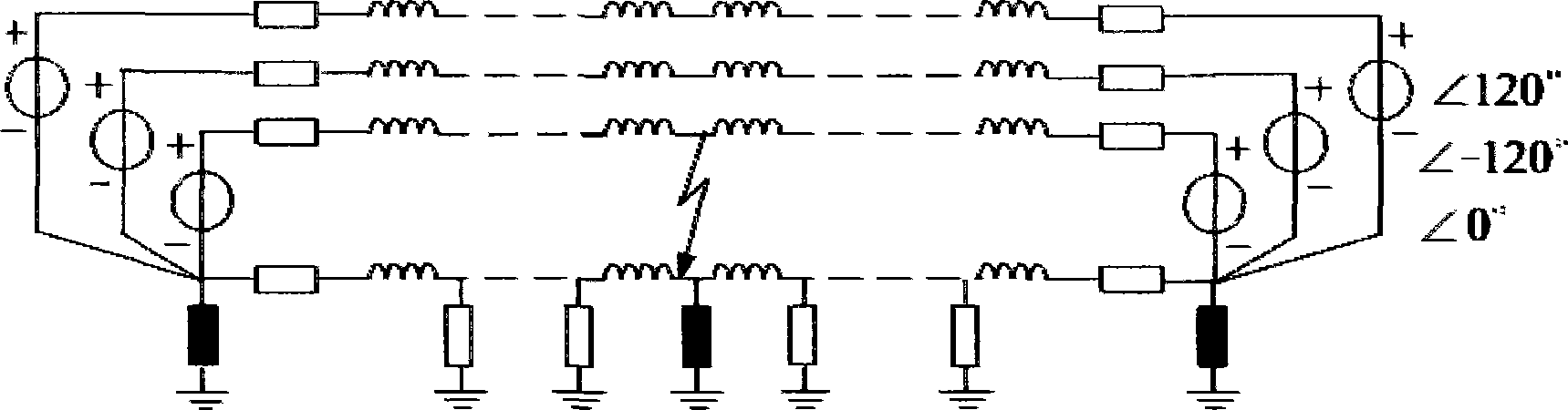

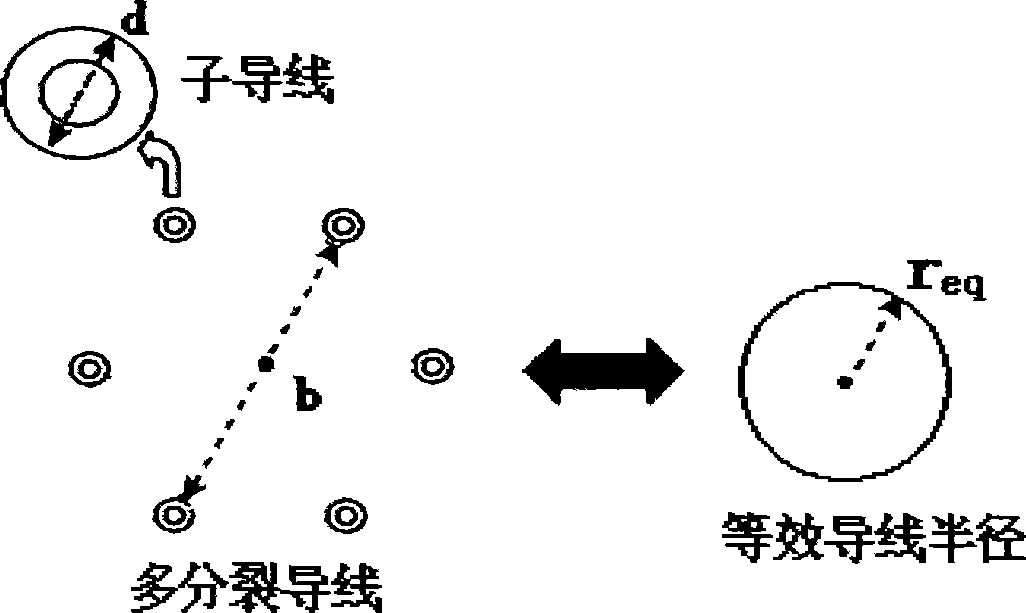

Determining and protecting method for influence of extra-high voltage AC pipeline on petroleum and nature gas pipeline

The invention relates to a determination and protection method for influence of super-high voltage alternating current line on an oil and gas pipeline. The method comprises the following steps: firstly, building an equivalent circuit model of a multi-conductor transmission system consisting of a super-high voltage alternating current transmission line and a buried metal pipeline; calculating and adding the interferences of the transmission line on the pipeline through inductive coupling in a normal state and a short circuit state to get a total interference; calculating and analyzing factors leading to the fact that the transmission line influences the degree of the electromagnetic interference of the transmission line on the metal pipeline under different conditions, and calculating and analyzing the influence of an alternating current on corrosion of the metal pipeline; meanwhile, carrying out simulation experiments of inductive coupling and resistive coupling respectively; and summarizing the analysis of the influence factors and putting forward effective protection measures. Comparison of experimental data obtained in the experiments shows that the method has high accuracy. So the method can be used for accurate calculation of electromagnetic protective distance, parallel length and crossing angle of high voltage transmission lines and buried metal pipelines as well as for research on corrosion and protection of buried metal pipelines.

Owner:STATE GRID ELECTRIC POWER RES INST

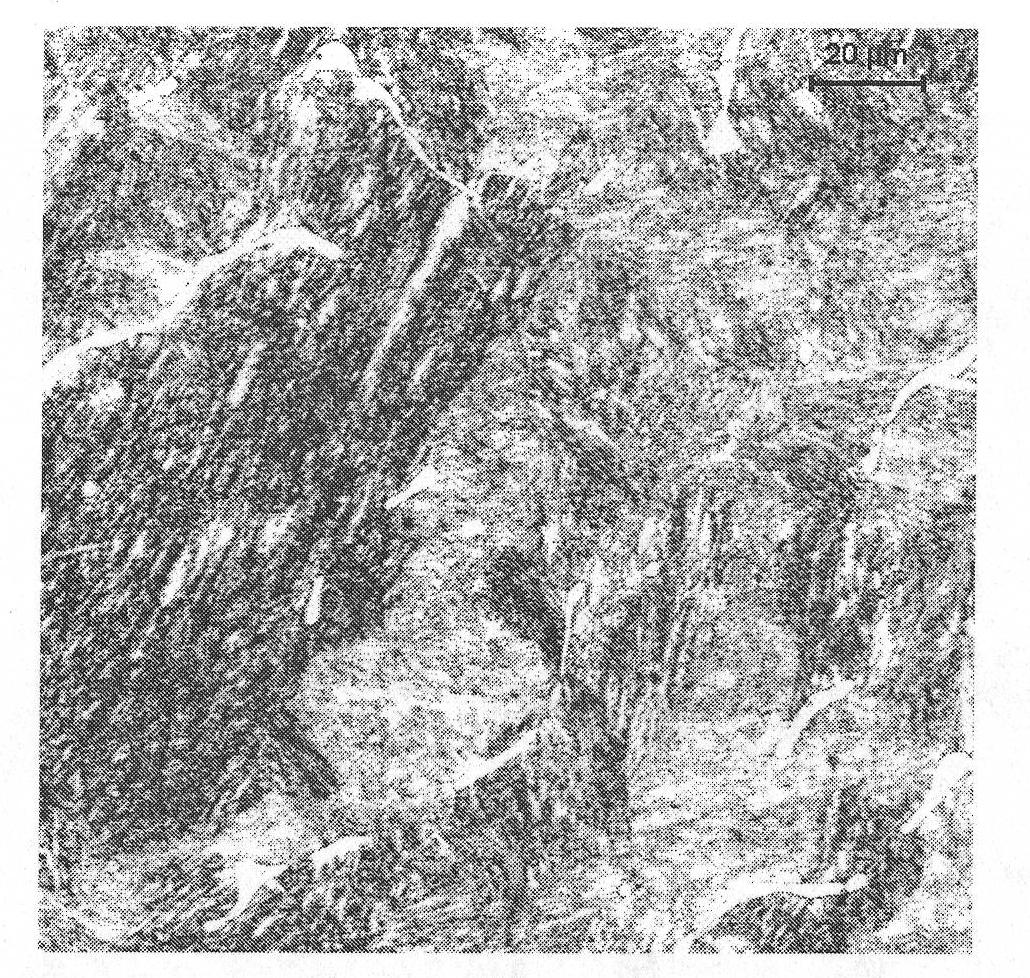

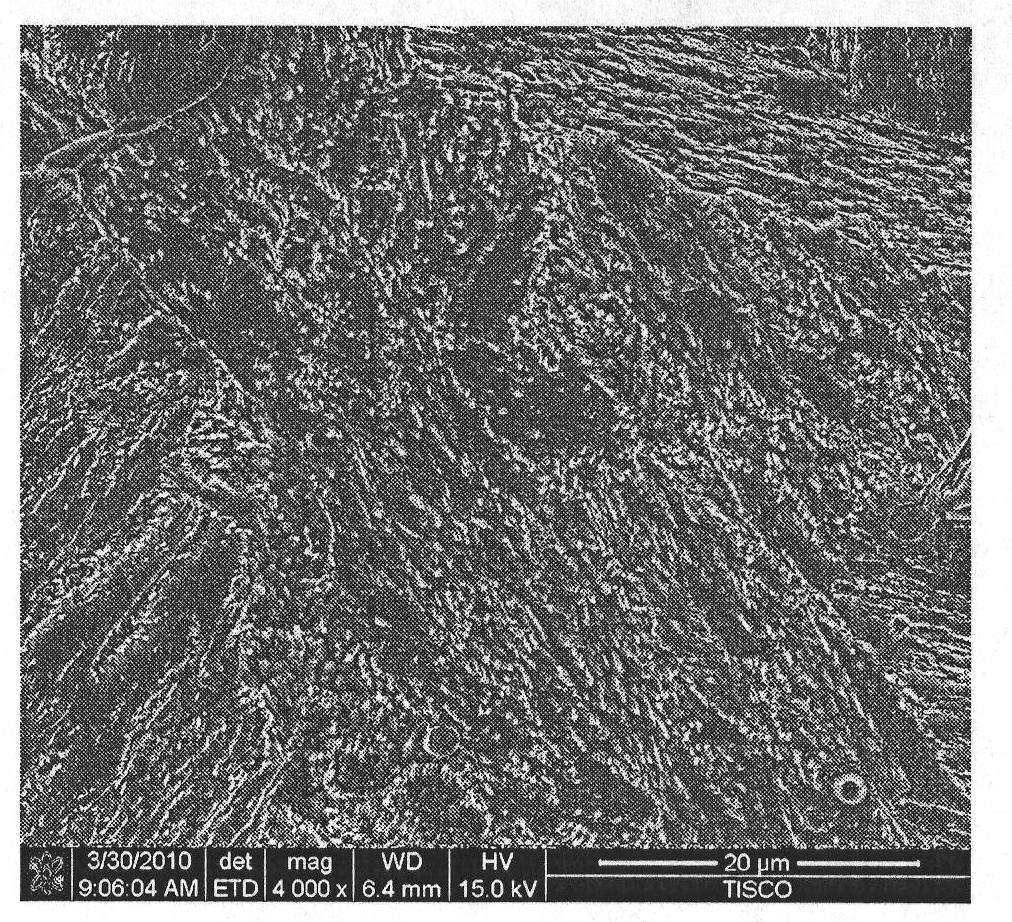

High strength super-martensitic stainless steel for oil and gas pipelines and preparation method thereof

InactiveCN101956146AReduce usageLess impact from price fluctuationsChemical compositionMartensitic stainless steel

The invention relates to high strength super-martensitic stainless steel for oil and gas pipelines and a preparation method thereof. The super-martensitic stainless steel consists of the following chemical compositions in percentage by mass: 0.01 to 0.03 percent of C, 0.5 to 1 percent of Si, 0.2 to 2.0 percent of Mn, 11.0 to 17.0 percent of Cr, 5.0 to 8.0 percent of Ni, 0.5 to 3.5 percent of Mo, less than or equal to 0.015 percent of P, less than or equal to 0.035 percent of S, 0.02 to 0.08 percent of N, 0.02 to 0.5 percent of Nb, less than 0.1 percent of W, and the balance of Fe and inevitable impurities. The preparation method for the high strength super-martensitic stainless steel comprises process steps of: smelting; casting; forging or rolling; quenching; tempering and the like. The steel can be used as a material for deep well and ultra deep well oil and gas pipelines and a material for crude oil and gas conveying equipment.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

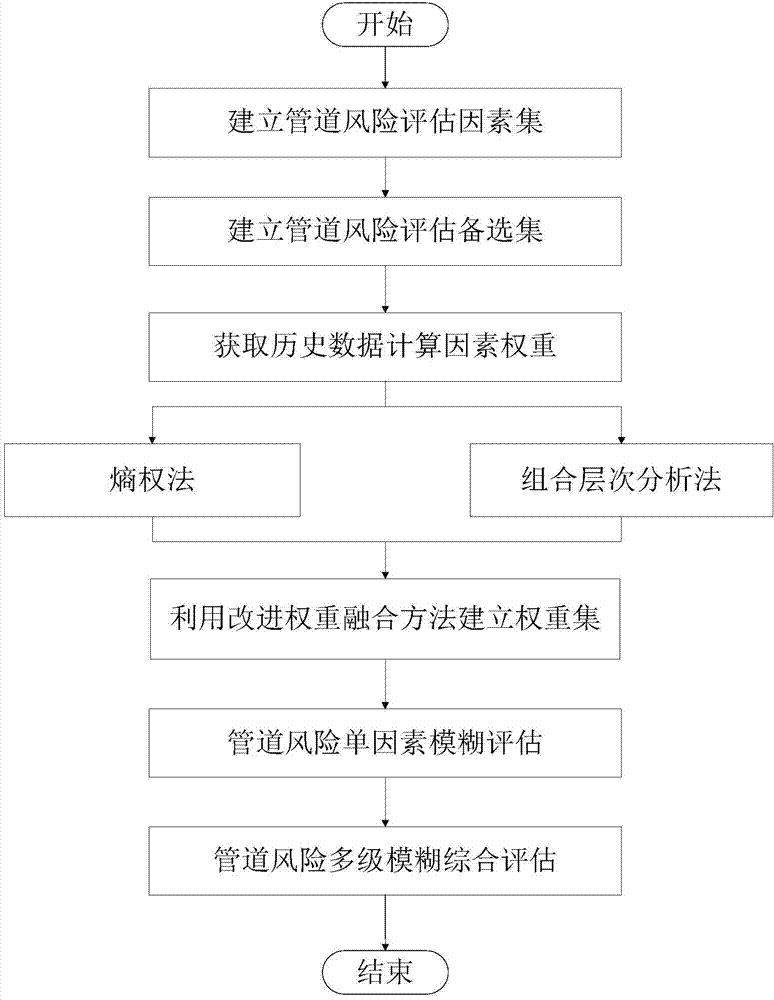

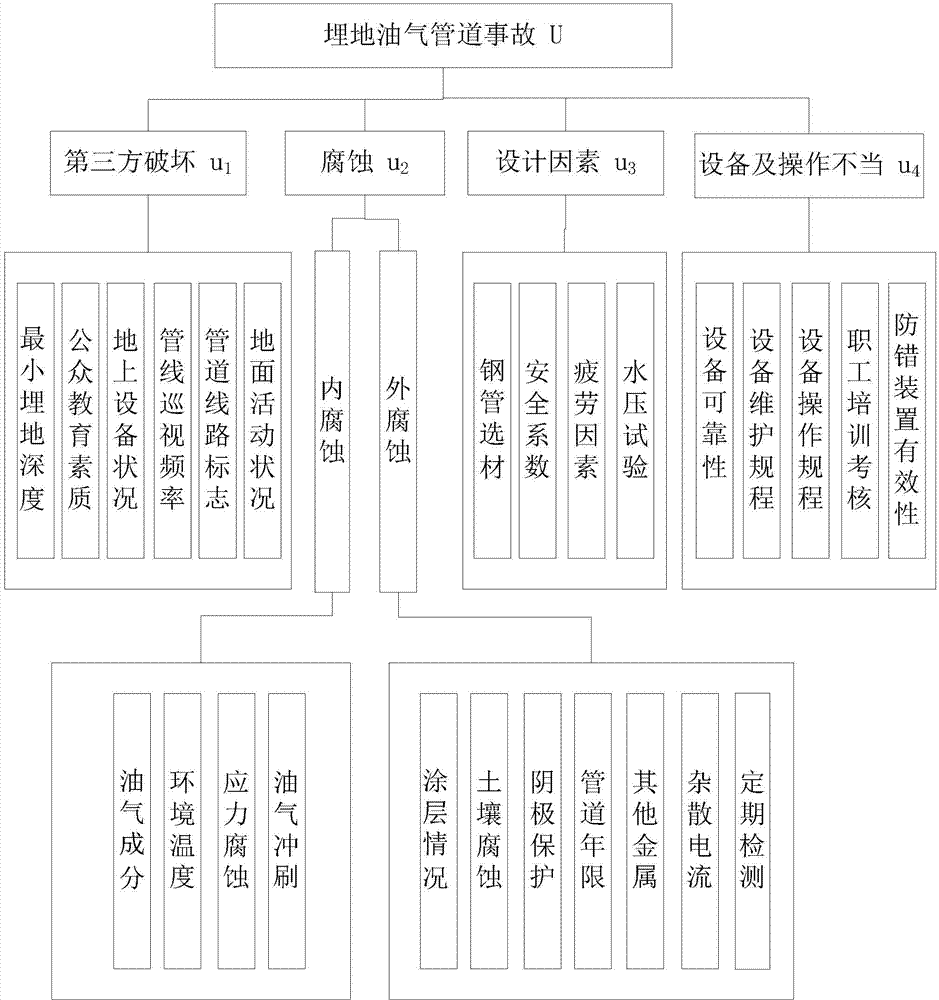

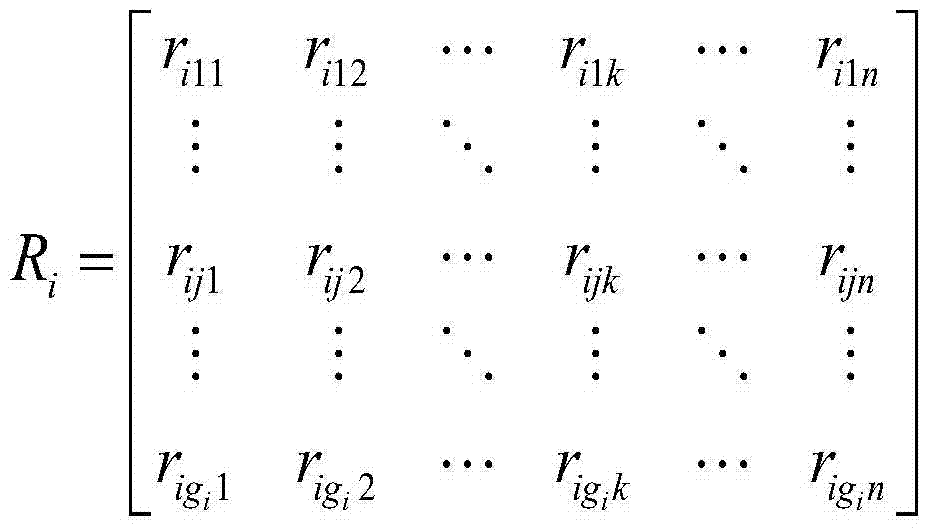

Risk assessment method for underground oil and gas pipeline

InactiveCN104715163AThe risk assessment results are accurateThe risk assessment results are objectiveComplex mathematical operationsEntropy weight methodEngineering

The invention discloses a risk assessment method for an underground oil and gas pipeline. The risk assessment method comprises the following steps: A, determining a factor set which affects the pipeline risk assessment; B, determining a pipeline risk assessment alternative set according to assessment requirement; C, calculating the weight of each factor in the pipeline risk factor set by adopting a entropy weight method; D, calculating the weight of each factor in the pipeline risk factor set by adopting a combination analytic hierarchy process, and integrating the weights calculated in the step C into the calculation process of the analytic hierarchy process so as to obtain a final weight for each factor; E, performing fuzzy evaluation on single factors of pipeline risks by utilizing the weights obtained in the step D; F, iterating the calculation process of the step E so as to realize multilevel fuzzy comprehensive assessment on the risk of the underground oil and gas pipeline. By adopting the method, the problem that the weights of the factors of the risk of the pipeline are too objective or too subjective is avoided, and the calculated weight of each factor is more subjective and accurate; meanwhile, the risk of the underground oil and gas pipeline is assessed by establishing a fuzzy comprehensive assessment model, so that the assessment result is more accurate, subjective and reasonable.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Oil and gas pipeline comprehensive protection method for high-voltage direct-current grounding electrode interference

ActiveCN103899883AComprehensive and Holistic ProtectionImprove targetingCorrosion preventionPipe protection against corrosion/incrustationHigh-voltage direct currentMonitoring system

The invention discloses an oil and gas pipeline comprehensive protection method for high-voltage direct-current grounding electrode interference. The oil and gas pipeline comprehensive protection method includes steps of improving integrity of an anti-corrosion layer; setting insulation joints on a main pipeline and sectionally isolating the pipeline; subjecting the pipeline to drained current protection; protecting a negative electrode of the pipeline: additionally arranging a negative electrode protection station on the pipeline close to the high-voltage direct-current grounding electrode, subjecting the pipeline to the negative electrode protection by an impressed current method via a bidirectional forced electrical drainage device, and rectifying fluctuation of abnormal pipeline ground potentials; monitoring drainage protection effect via a remote monitoring system and a corrosion coupon. The oil and gas pipeline comprehensive protection method has the advantages that comprehensive and integral protection can be provided for the high-voltage direct-current grounding electrode interference, and pertinence, protection effect and safety are all improved as compared with those of a conventional stray current protection technology.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

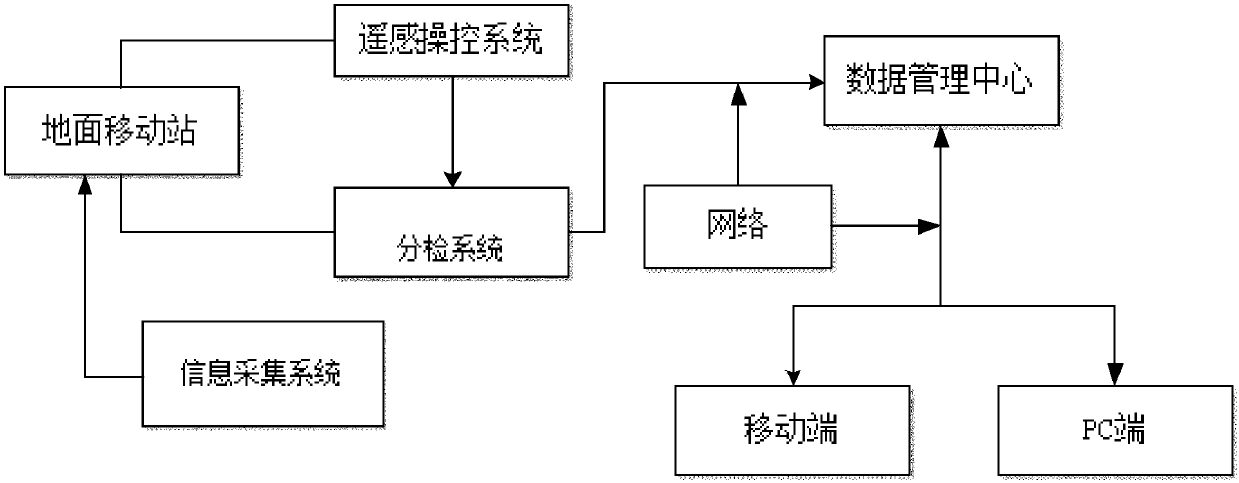

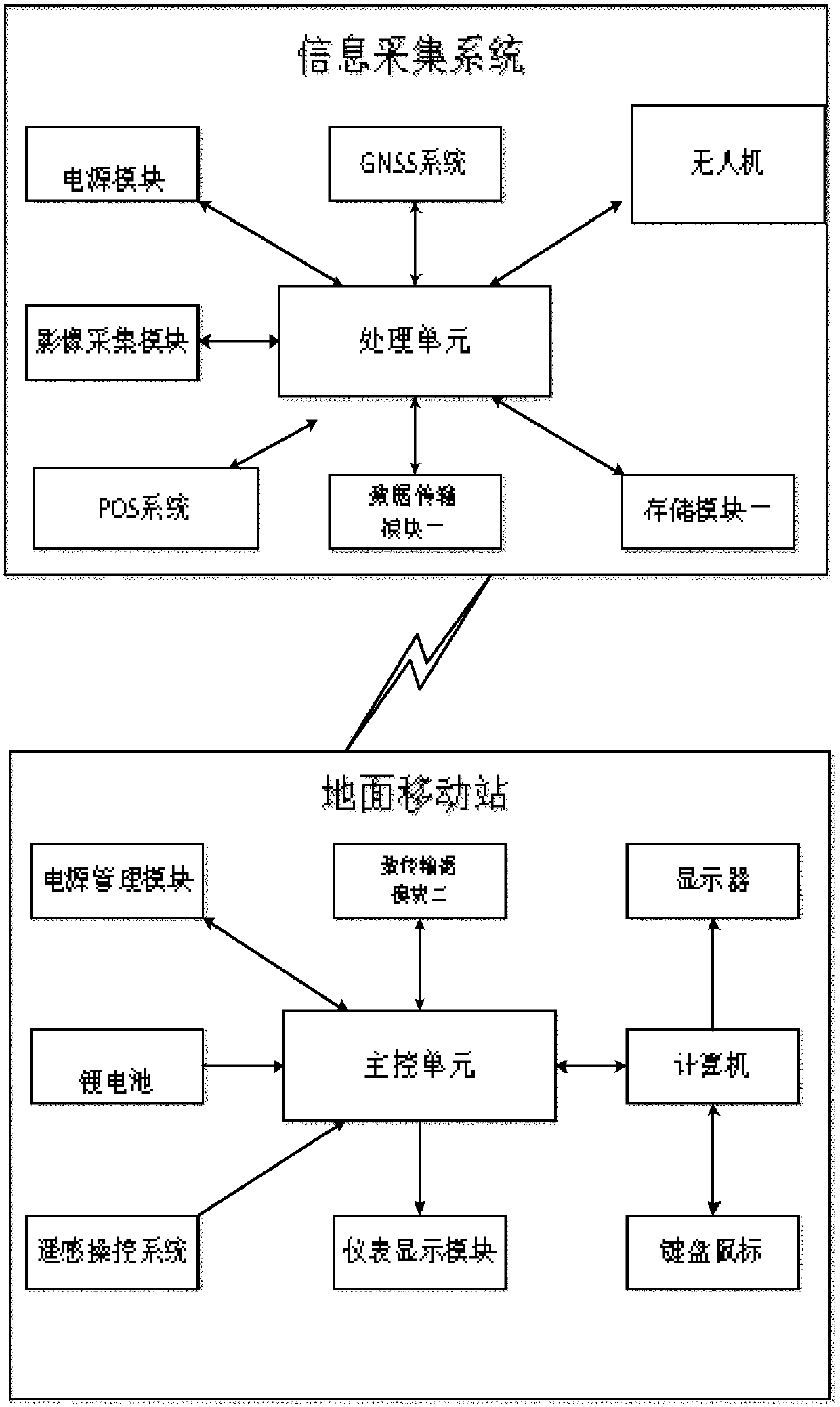

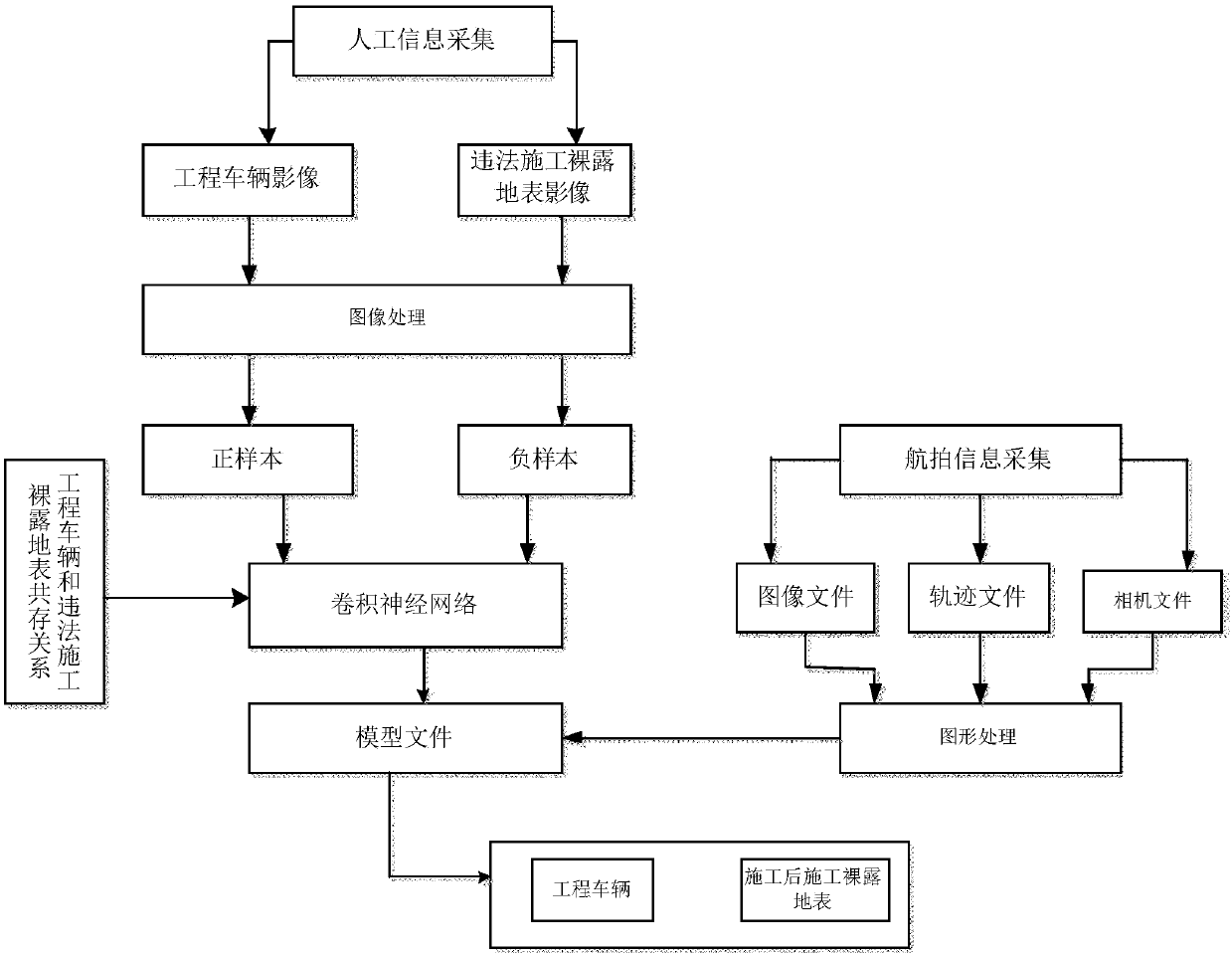

Oil and gas pipeline inspection system based on unmanned aerial vehicle aerial photo images and inspection method thereof

PendingCN107808425AImprove the level of security management and controlEasy to classify and storeChecking time patrolsCharacter and pattern recognitionCollection systemMobile end

The invention discloses an oil and gas pipeline inspection system based on unmanned aerial vehicle aerial photo images and an inspection method thereof. The system comprises an information collectionsystem, a ground mobile station and a data management center, wherein the information collection system is used for collecting image information along oil and gas pipelines and determining geographical location information of the images; the ground mobile station is used for reshipping equipment and processing and uploading collected data; and the data management center is used for communication with the ground mobile station and information interaction with a PC and a mobile terminal. According to the oil and gas pipeline inspection system based on unmanned aerial vehicle aerial photo imagesdisclosed by the invention, quick inspection can be realized along the oil and gas pipelines, and the dangerous conditions for the oil and gas pipelines such as irregular construction vehicles, illegal construction buildings and exposed ground surface appearing along the peripheries of the oil and gas pipelines can be automatically recognized, the inspection efficiency is greatly improved, and thelabor intensity of manual inspection is reduced.

Owner:刘松林

X80 steel made pipe fittings and manufacture technique thereof

ActiveCN101205594AMeet technical requirementsFurnace typesRigid pipesChemical compositionPipe fitting

The invention relates to a pipeline made of X80 steel and a method for manufacturing the same. The chemical compositions are that: 0.06 to 0.1 percent of C, 0.1 to 0.3 percent of Si, 1.4 to 2.0 percent of Mn, less than or equal to 0.015 percent of P, 0.01 percent of S, 0 to 0.45 percent of Cr, 0 to 0.3 percent of Mo, 0 to 0.3 percent of Cu, 0 to 0.5 percent of Ni, 0.05 to 0.15 percent of Nb, 0 to 0.06 percent of Ti, 0 to 0.06 percent of V, Ceq controlled between 0.36 and 0.44 percent, Pcm controlled between 0.17 and 0.23 percent. The pipeline manufactured with the controlled rolled steel plate of the compositions by means of controlling the forming temperature, hardening heat, drawing temperature, cooling velocity, etc. has low-temperature impact toughness more than 90 J, completely meets the technical requirement on the X80 pipelines and is suitable to be used as X80 steel pipelines for oil and gas pipelines.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

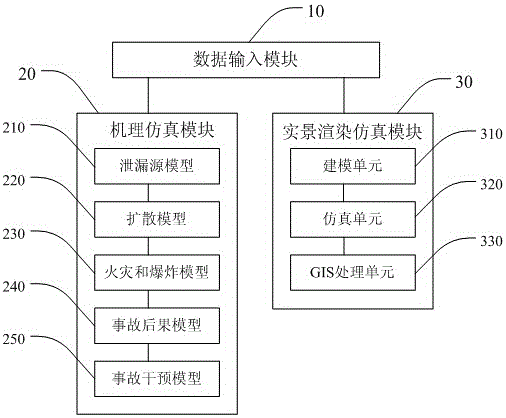

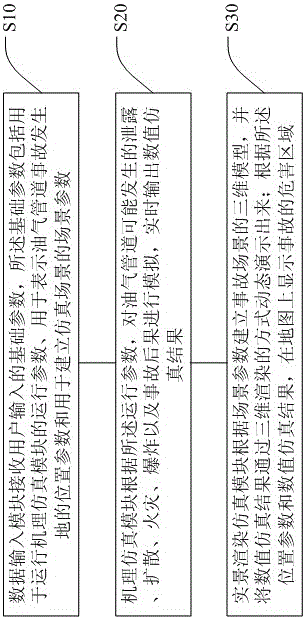

Oil and gas pipeline accident simulation system and method

ActiveCN105701322AImprove securityImprove stabilitySpecial data processing applicationsDiffusionUser input

The invention discloses an oil and gas pipeline accident simulation system and method.The system comprises a data input module, a mechanism simulation module and a live-action rendering simulation module.The data input module receives basic parameters input by a user, and the basic parameters comprise running parameters, position parameters and scenario parameters.The mechanism simulation module simulates leakage, diffusion, fires and explosions possibly happening to an oil and gas pipeline and accident consequences according to the running parameters and outputs a numerical simulation result in real time.The live-action rendering simulation module builds a three-dimensional model of an accident scenario according to the scenario parameters and dynamically demonstrates the numerical simulation result in a three-dimensional rendering mode.The harm area of an accident is displayed on a map according to the position parameters and the numerical simulation result.Therefore, the occurring process of the oil and gas pipeline accident and the consequences possibly caused by the accident can be simulated simply by inputting the basic parameters, the reason for the accident can be analyzed conveniently, and the running safety and stability of the oil and gas pipeline are improved.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST +1

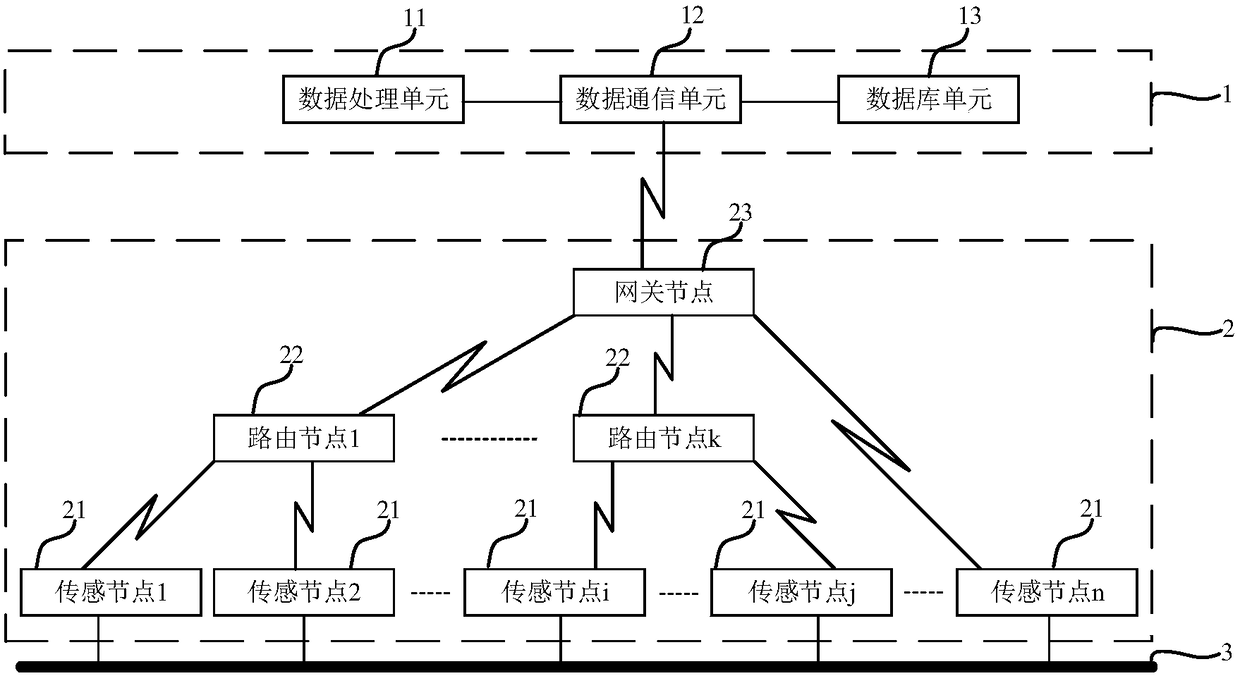

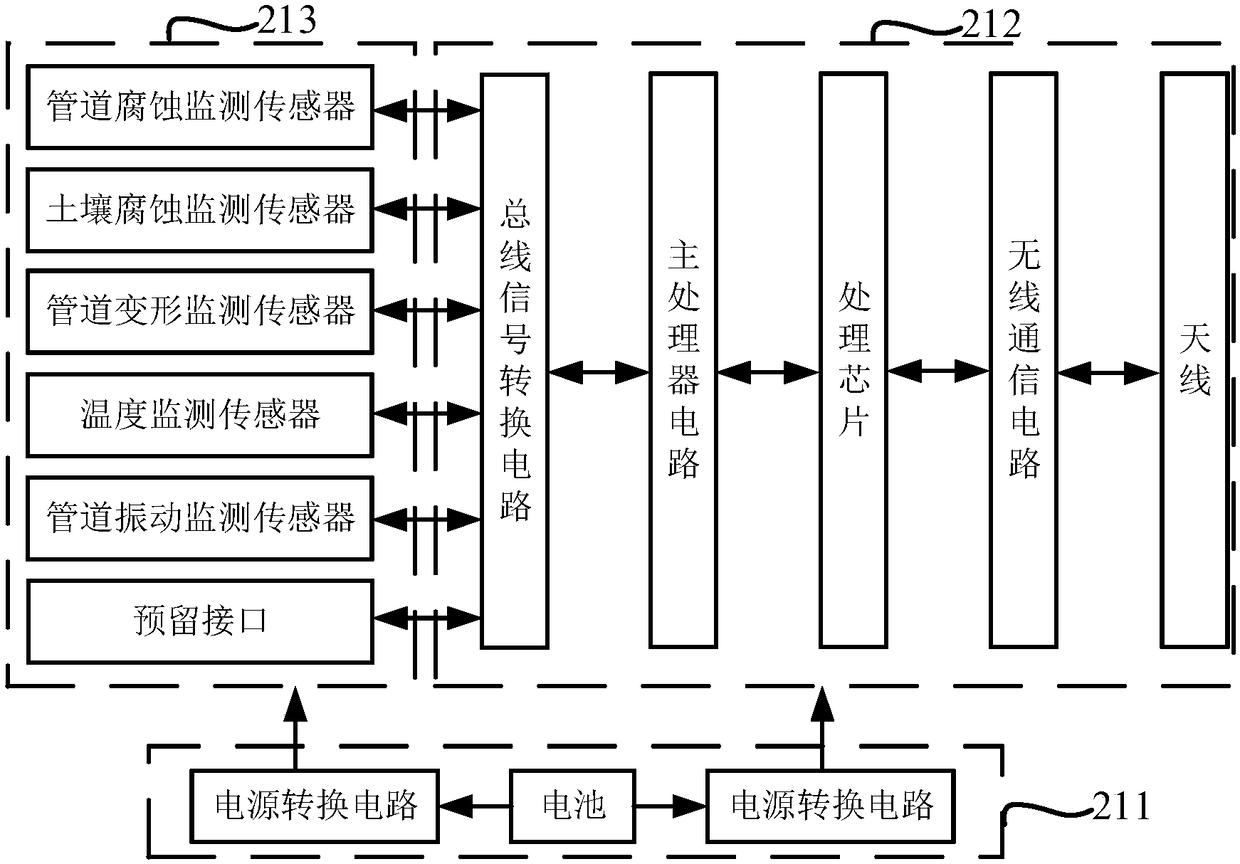

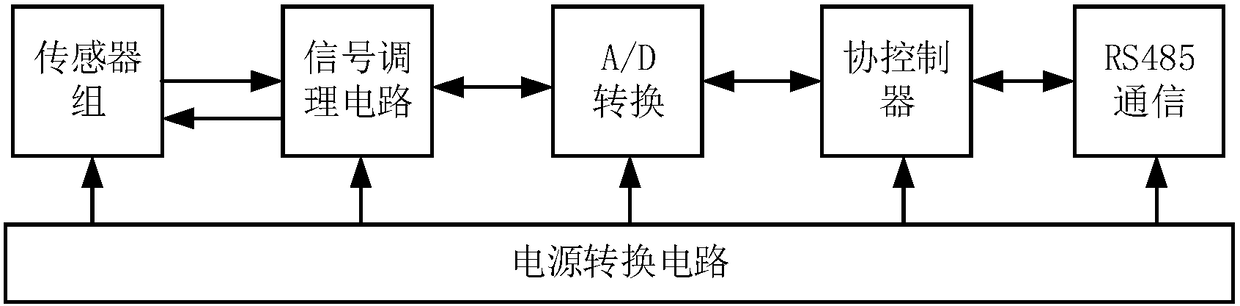

Multi-parameter modular oil and gas pipeline safety monitoring system and method

ActiveCN108343844ATimely discovery of potential safety hazardsSave energyPipeline systemsData switching networksData acquisitionEngineering

The invention relates to a multi-parameter modular oil and gas pipeline safety monitoring system and method. The system comprises a data analysis early warning device and at least one data collectionand storage device. The data analysis early warning device is in communication connection with the data collection and storage devices. Each data collection and storage device is arranged at the preset position of an oil and gas pipeline and used for collecting and storing safety data formed through multiple parameters at the preset positions of the oil and gas pipeline at the preset collection frequency, and transmitting the safety data to the data analysis early warning device. The data analysis early warning device is used for analyzing the safety data to obtain analysis results, and generating corresponding early warning information and adjusting the preset collection frequency according to the analysis results. Multiple parameters of multiple oil and gas pipelines can be collected, and potential safety hazards can be conveniently found in time. By adjusting the preset collection frequency, battery energy can be saved, working time can be prolonged, and the workload of maintenancestaff is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com