Patents

Literature

388 results about "Corrosion monitoring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A corrosion monitoring program provides comprehensive monitoring of all critical components of industrial objects, assets, facilities and plants for signs of corrosion. For reliable operation it is important to identify the location, rate, and underlying causes of corrosion. A corrosion monitoring program identifies any non-conforming alloy components, as these are generally susceptible to accelerated corrosion and can give relatively frequent cause for catastrophic failure. Corrosion Monitoring can provide significant advantages when integrated into both preventative maintenance and the processes inherent to safety management programs. Based on the results of the Corrosion Monitoring program, informed decisions can be made, not only regarding the remaining life of the object affected by corrosion but also regarding life extension strategies, prospective material selection, and cost-effective methods for remedy of corrosion issues and problems.

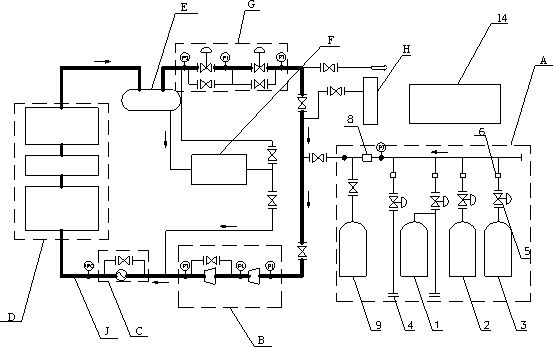

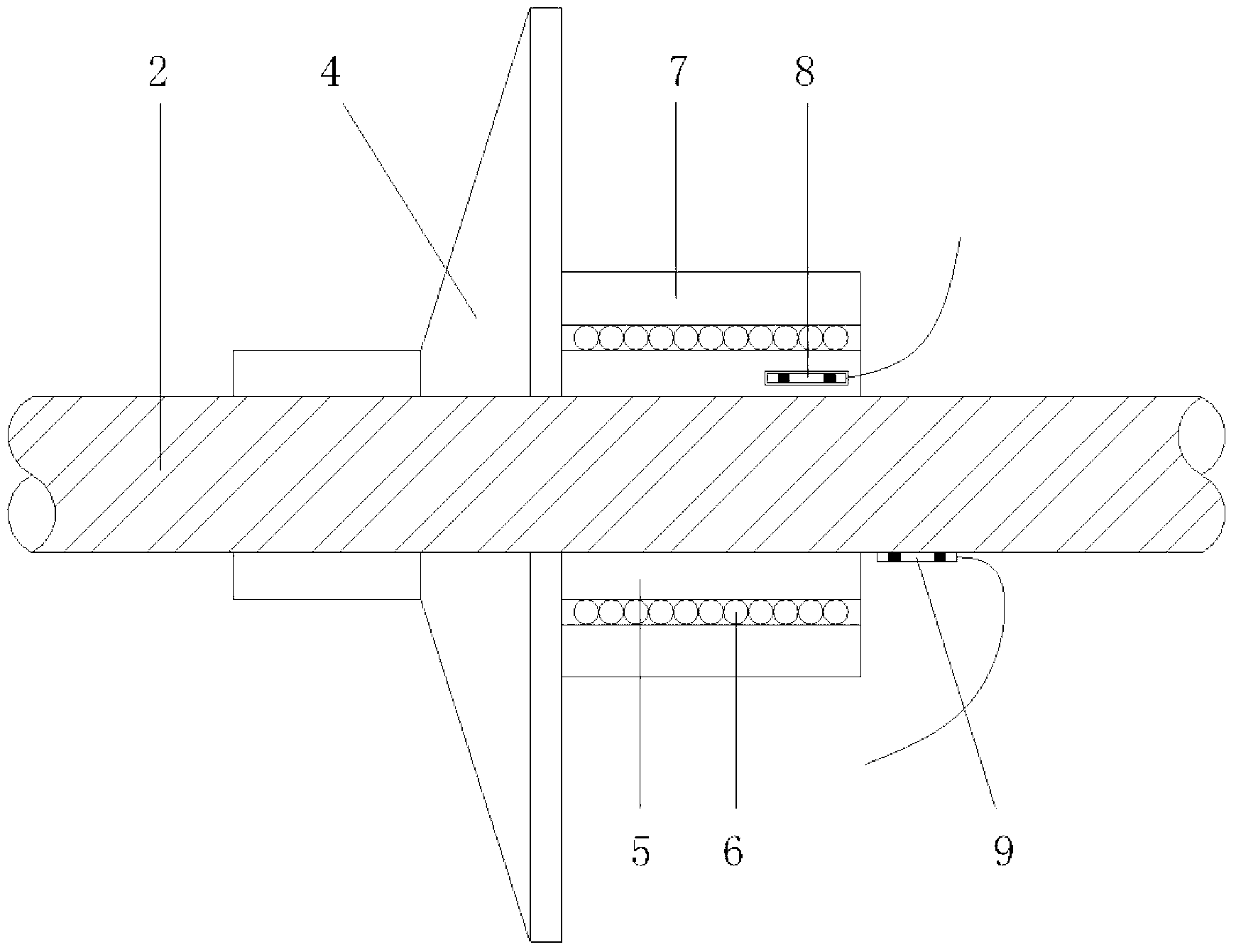

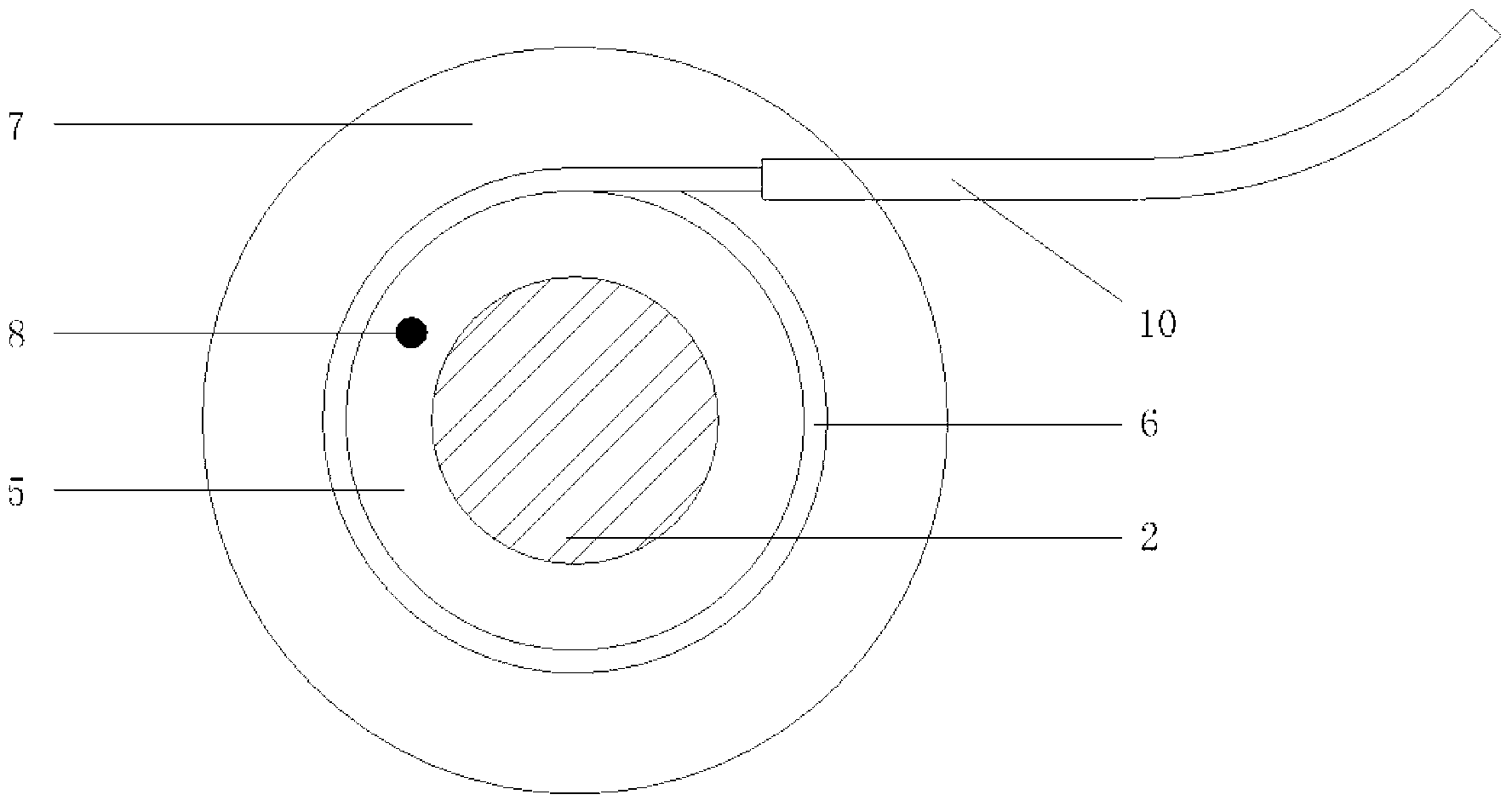

Acid medium transmission pipeline welded joint and parent metal corrosion simulation testing device and method

InactiveCN102305761AIn line with the actual situationWide range of working conditionsWeather/light/corrosion resistanceWashoutStimulation tests

The invention provides a large-scale multifunctional corrosion stimulation test rack taking a test circular road as a main part, which is used for simulating the corrosion condition of high acid natural gas containing H2S, CO2 and Cl on a pipeline parent metal and a welded joint under the pipeline transmission condition. The device and the method provided by the invention can be applied to pipeline parent bodies with different pipe diameters, materials, steel grades and wall thicknesses, or a welded joint corrosion test; and test functions such as test on corrosion of the pipe section parent metal and the welded joint, sulfide stress cracking (SSC), hydrogen induced cracking (HIC), washout, corrosion inhibitor effect, welding process evaluation, corrosion monitoring method comparison, pipeline-corrosion-preventing process optimization and the like are integrated into a whole; and the test functions, such as preference of the corrosion process in the pipeline are integrated into a whole, thus reasonable material selection and safe welding quality are guaranteed, and the corrosion condition of the corresponding corrosion condition on the welded joint and the parent metal is known.

Owner:SOUTHWEST PETROLEUM UNIV

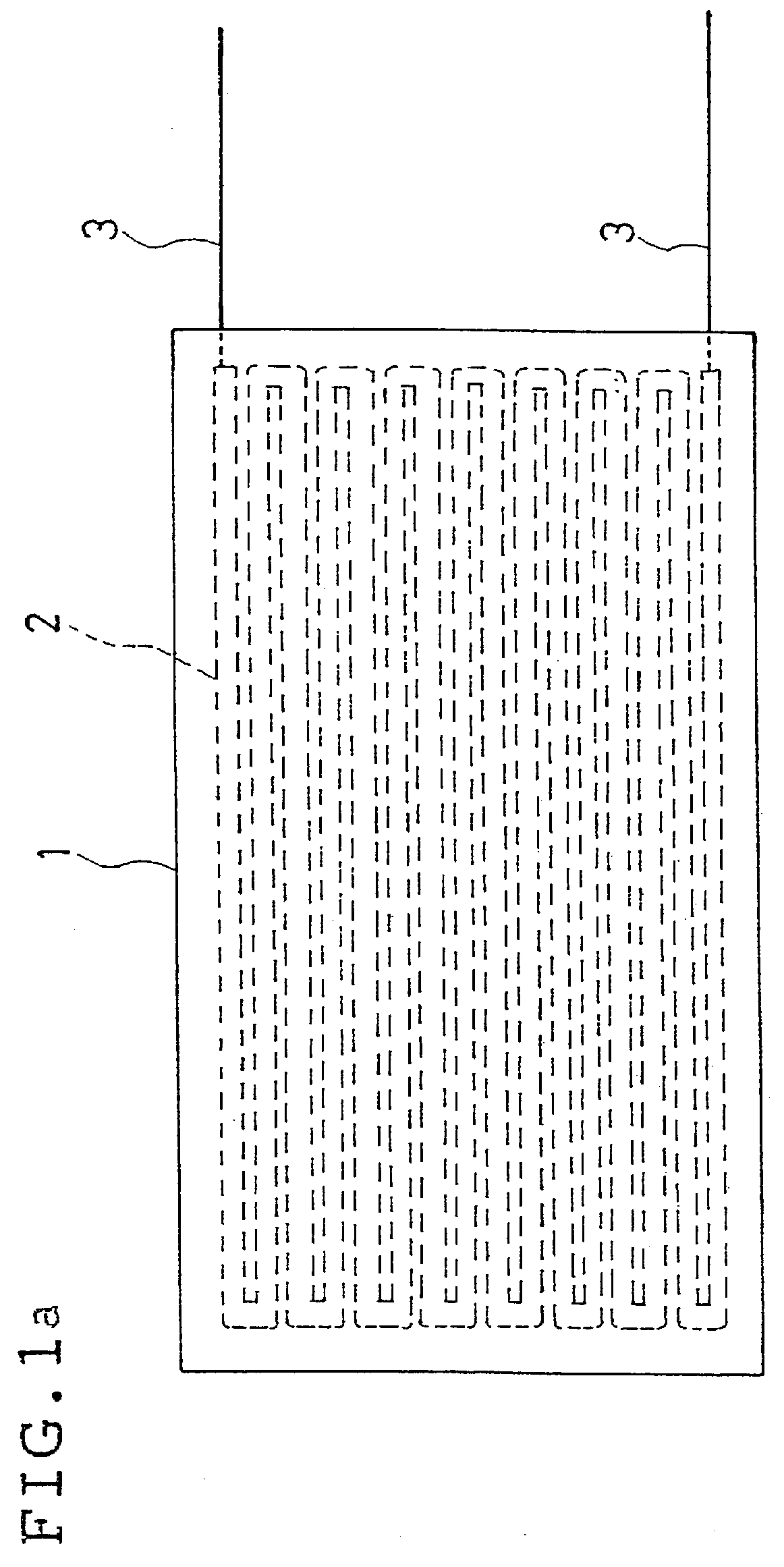

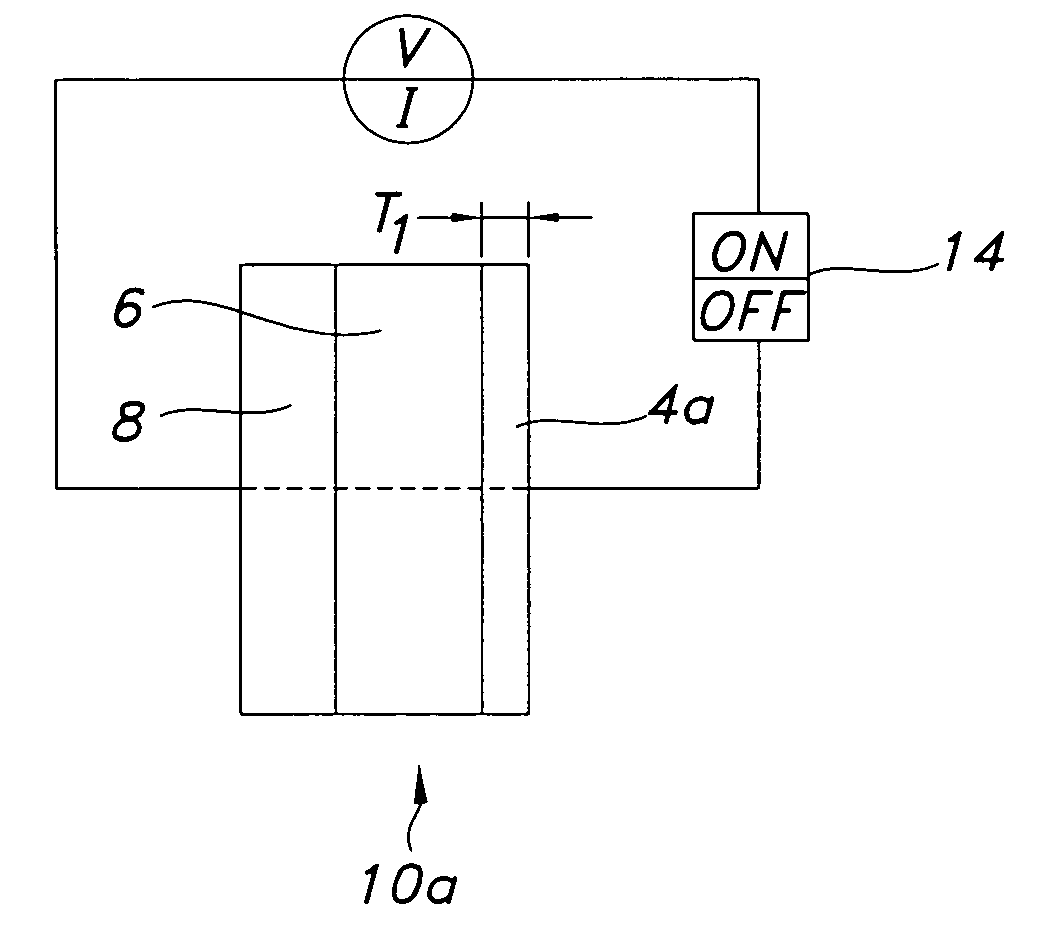

Corrosion monitoring

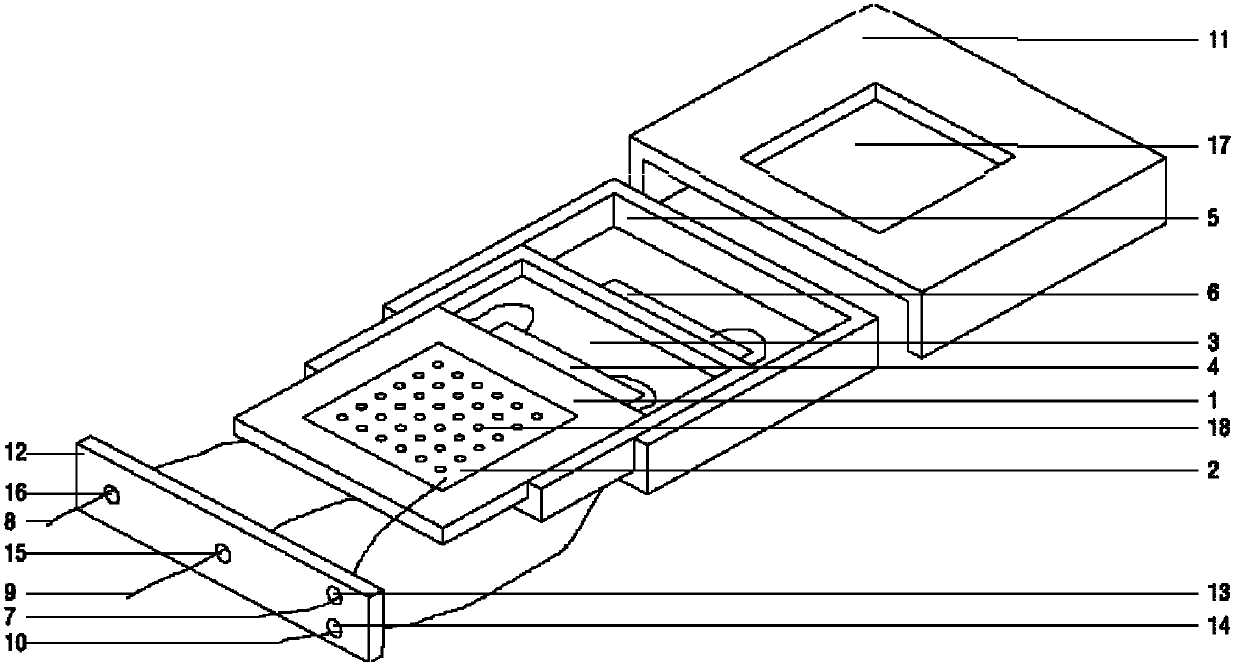

InactiveUS6077418AEasy monitoring (observation)Accurate monitoringWeather/light/corrosion resistanceResistance/reactance/impedenceTest couponMaterials science

Corrosion of a metal member under heat transfer condition is monitored by using a test coupon made of the same material as that of the metal member. The test coupon may have a welded portion and a crevice. One substantial surface of the test coupon is heated by a sheet shaped heating element, and at least one portion of the other surface of the test coupon is contacted with the corrosive fluid. After detecting a status of corrosion of the test coupon, the corrosion of the metal member is monitored based on the results of the detection. In case a counter electrode or reference electrode is used, the electrode is immersed in the corrosive fluid, and electrical signals between the test coupon and the electrode are measured. Then, the corrosion of the metal member is monitored.

Owner:KURITA WATER INDUSTRIES LTD

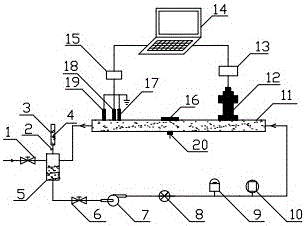

Online monitoring system for corrosion state of oil and gas pipelines and method thereof

InactiveCN102305352APracticalWide range of applicationsWeather/light/corrosion resistancePipeline systemsDigital signal processingMonitoring system

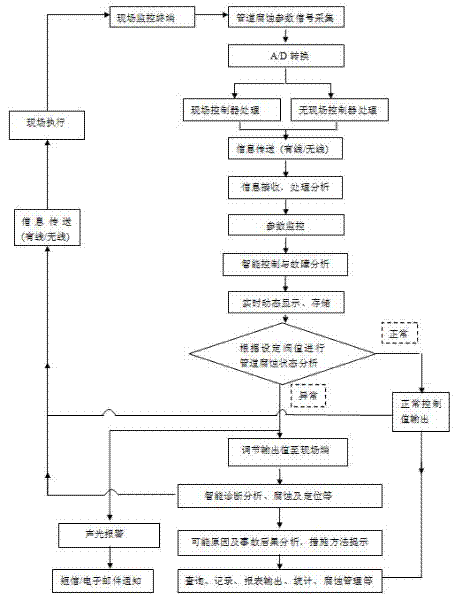

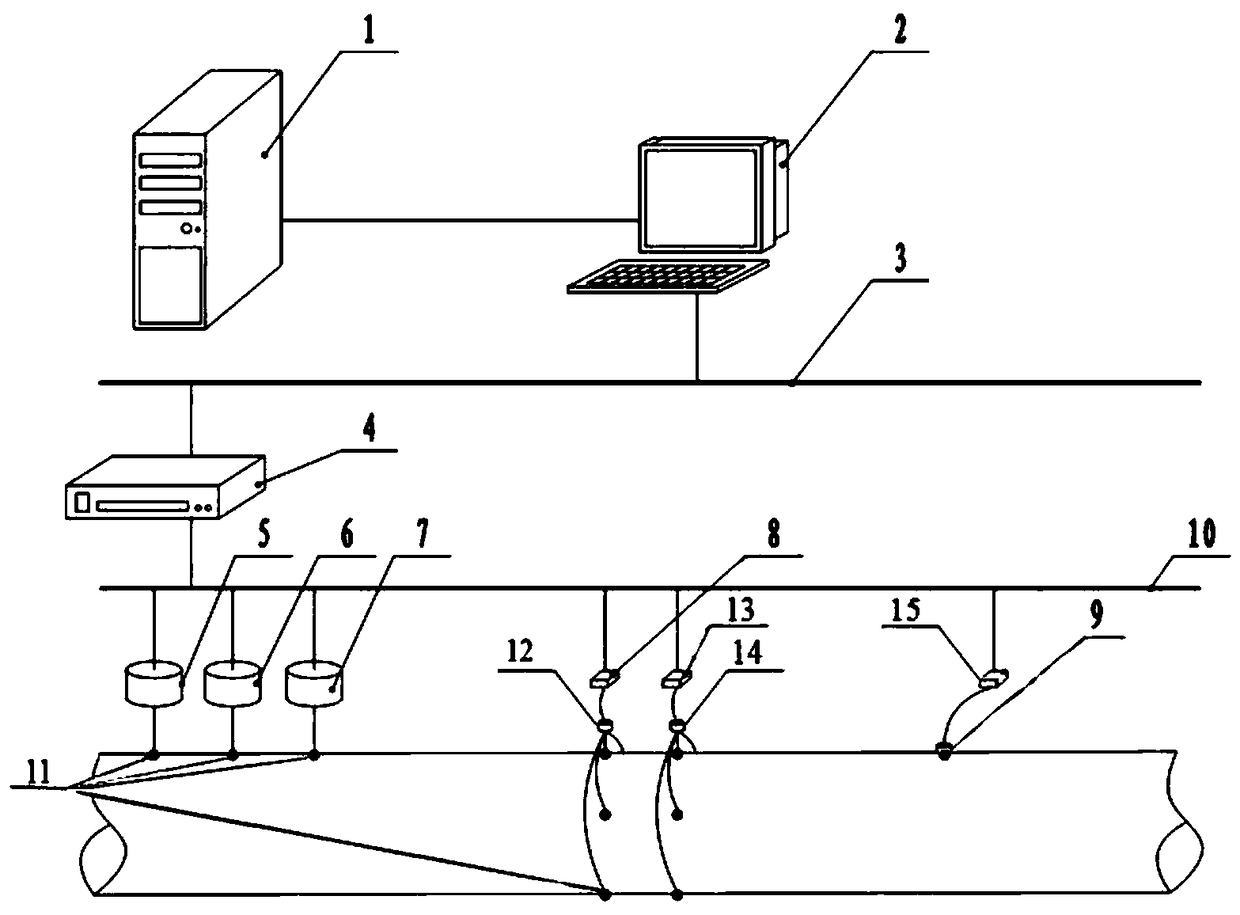

The invention provides an online monitoring system for the corrosion state of oil and gas pipelines and a method thereof, which can monitor sensitive corrosion points, such as an elbow, liquid accumulating parts at upper and lower slopes, and the like and insensitive corrosion points and realize the remote transmission of corrosion monitoring data in a wired or wireless manner, treat the data at a monitoring center, establish the corrosion state parameter of each point of the oil and gas pipelines via a modern digital signal treating method, judge whether the corrosion state is normal or not,and carry out the corresponding treatment and the control of the pipelines to timely monitor the corrosion state of the oil and gas pipelines so as to timely discover hidden troubles and prevent safety accidents. A three-dimensional corrosion state graph of the pipeline can be visually displayed at the monitoring center so that abnormal corrosion parts can be found out. The scheme of the system has the advantages of low cost and high benefit, and the key is that the system can realize real-time monitoring based on the prior art; and more important, the system can be applied to monitoring the corrosion state of newly-built long oil and gas pipelines such as pipelines for transporting the natural gas from the West to the East so that the system has a very wide market prospect. The oil and gas pipelines can be laid on the ground or buried under the ground.

Owner:SOUTHWEST PETROLEUM UNIV

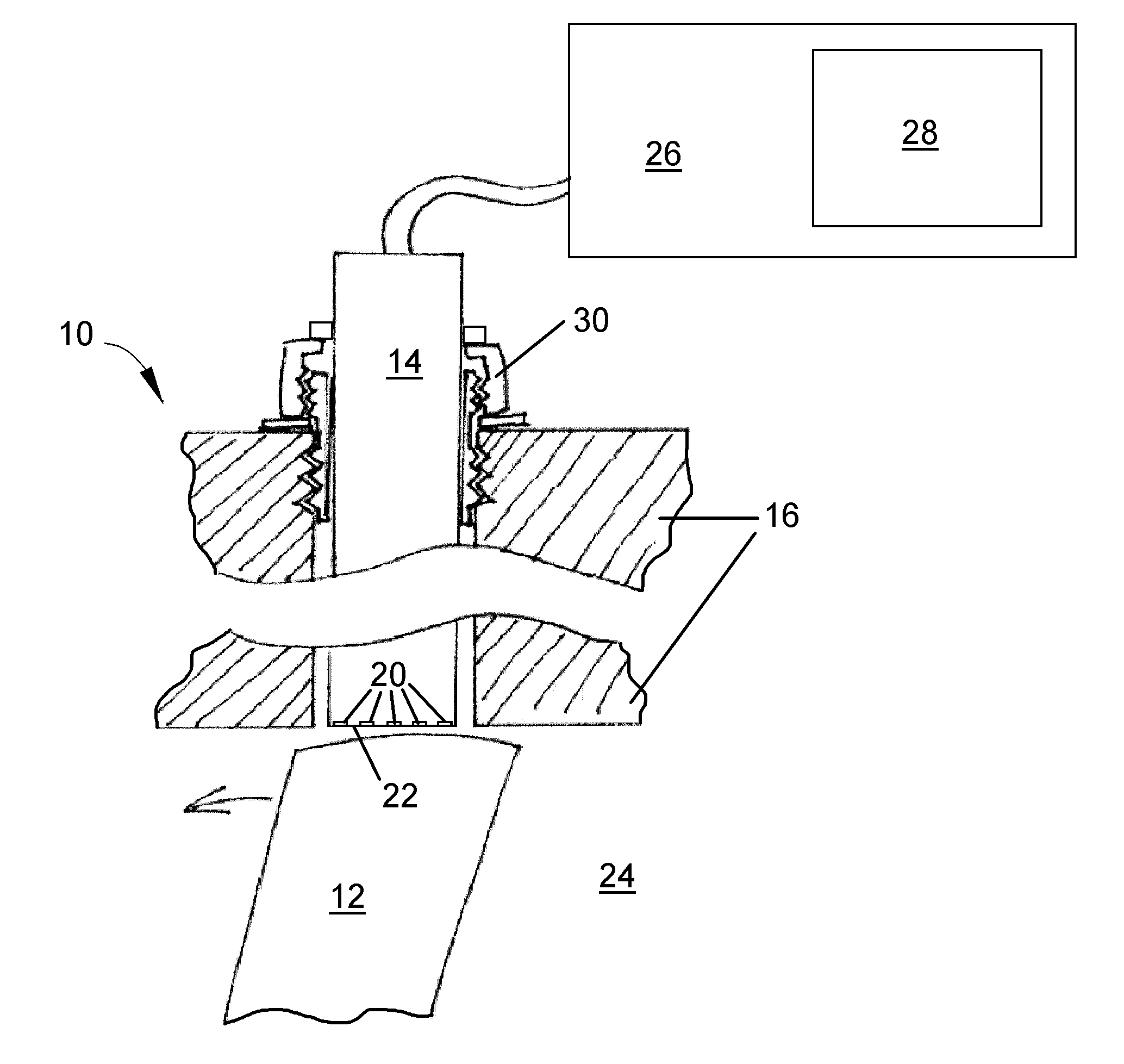

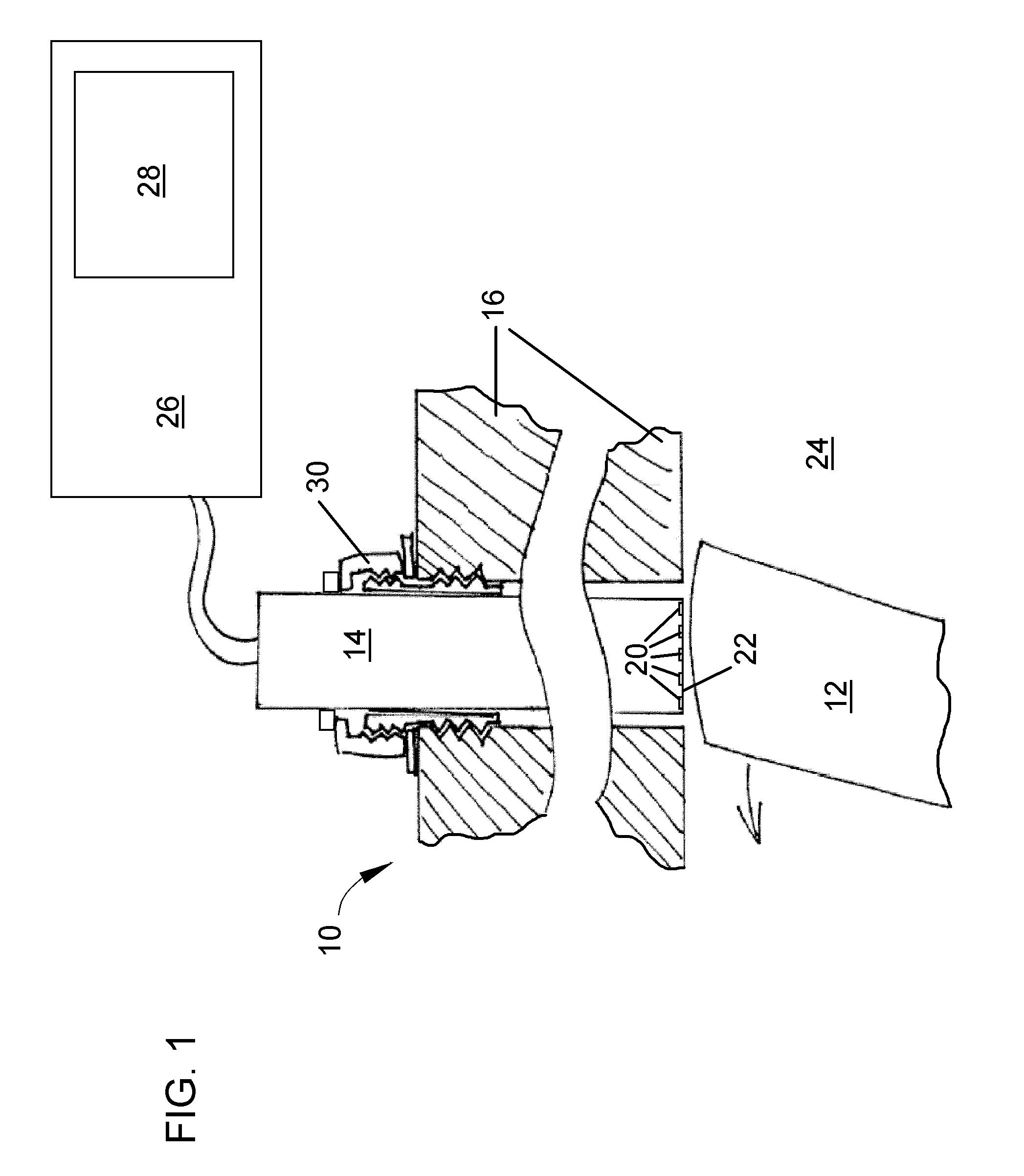

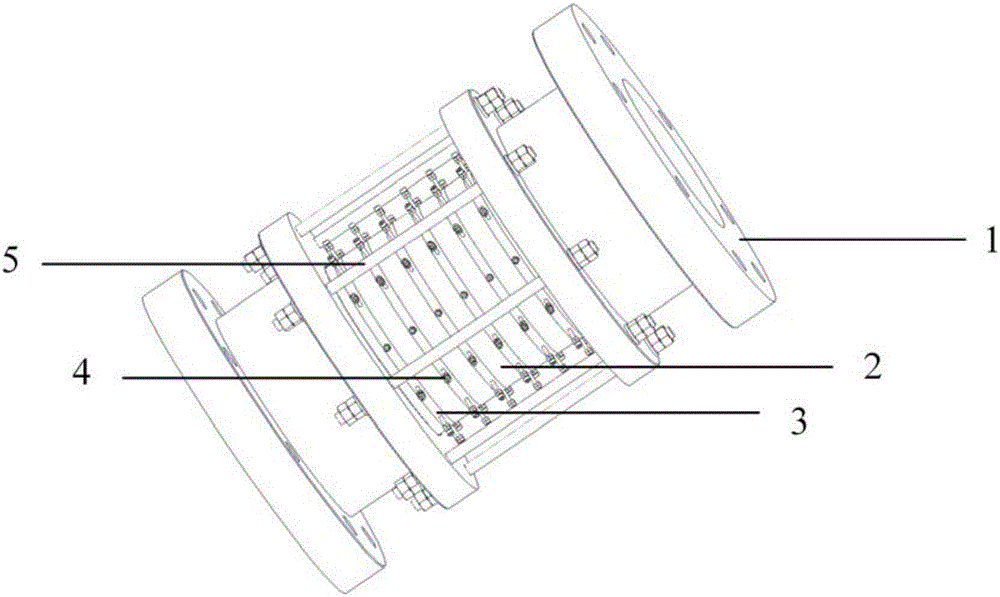

High Precision Corrosion Monitoring Sensor Assembly and System

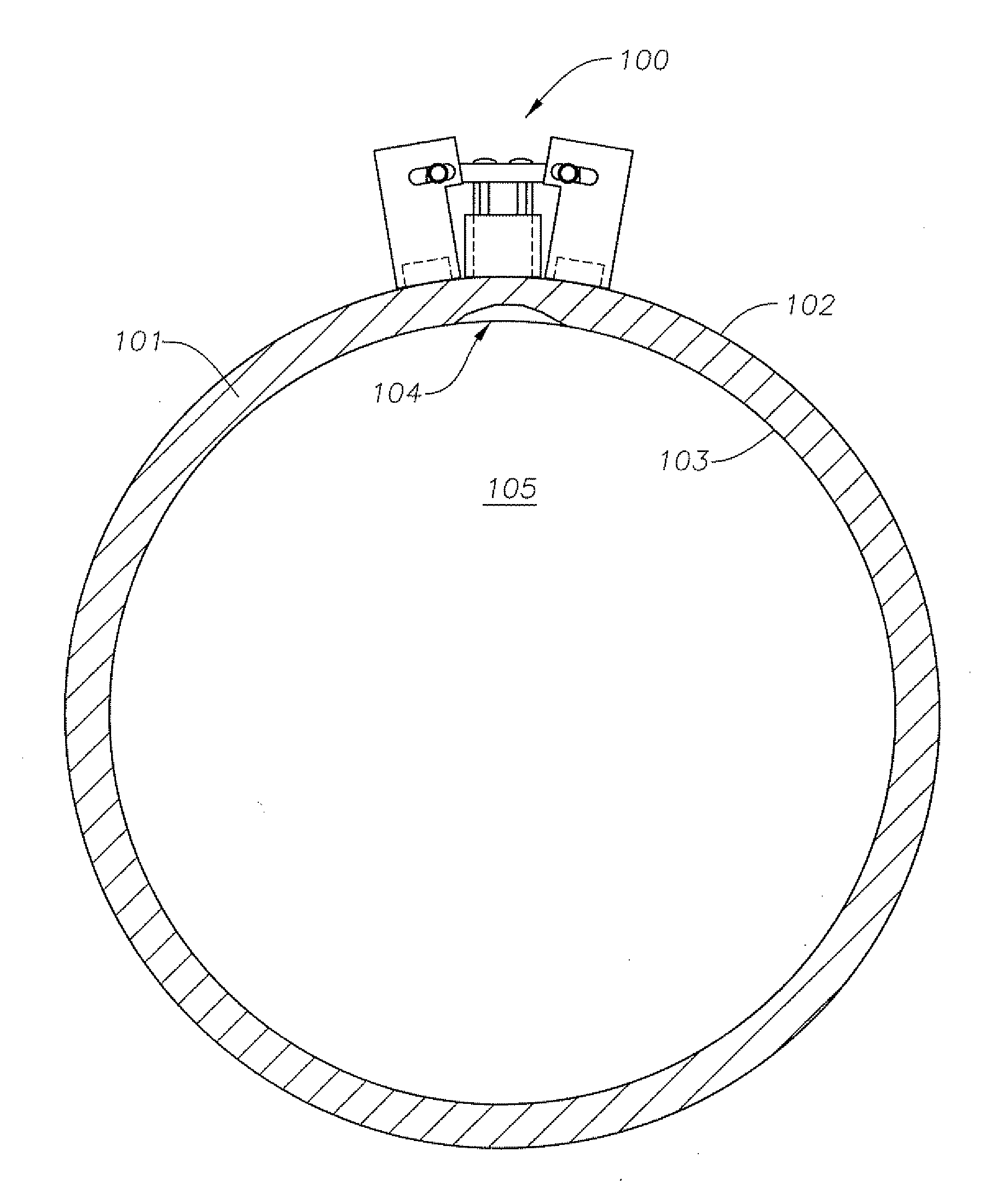

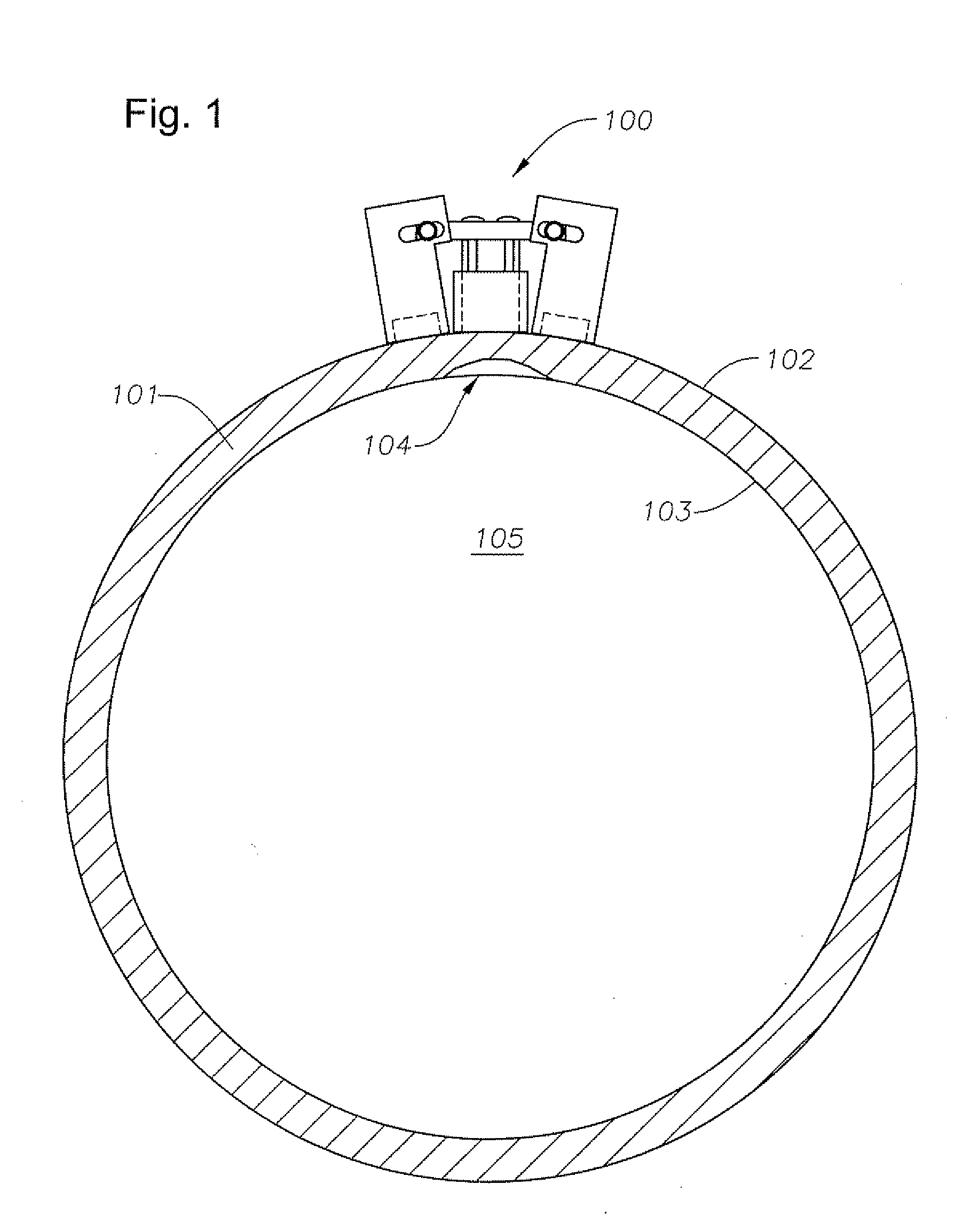

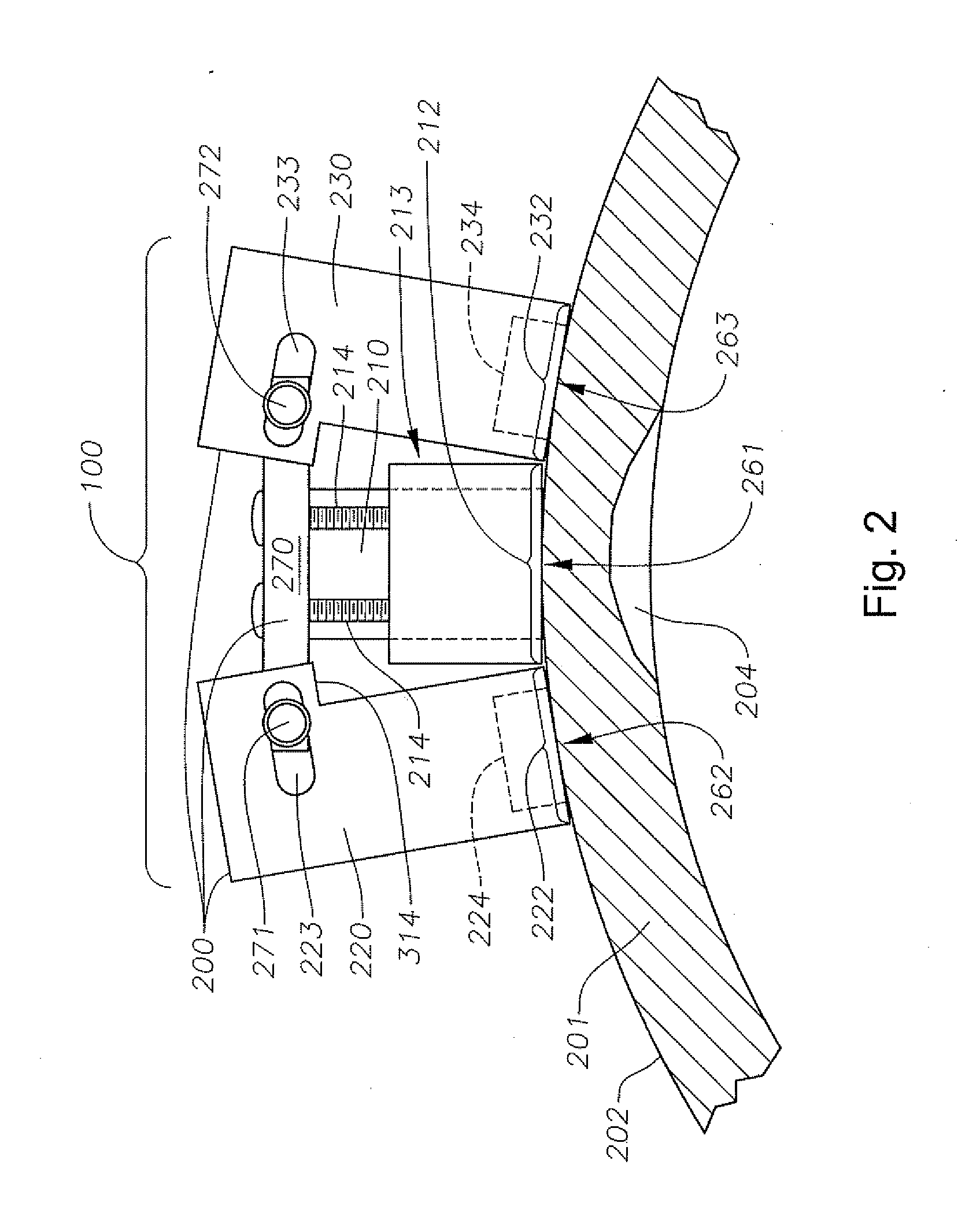

ActiveUS20120167688A1Large and accurateImprove accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansUltrasonic sensorEngineering

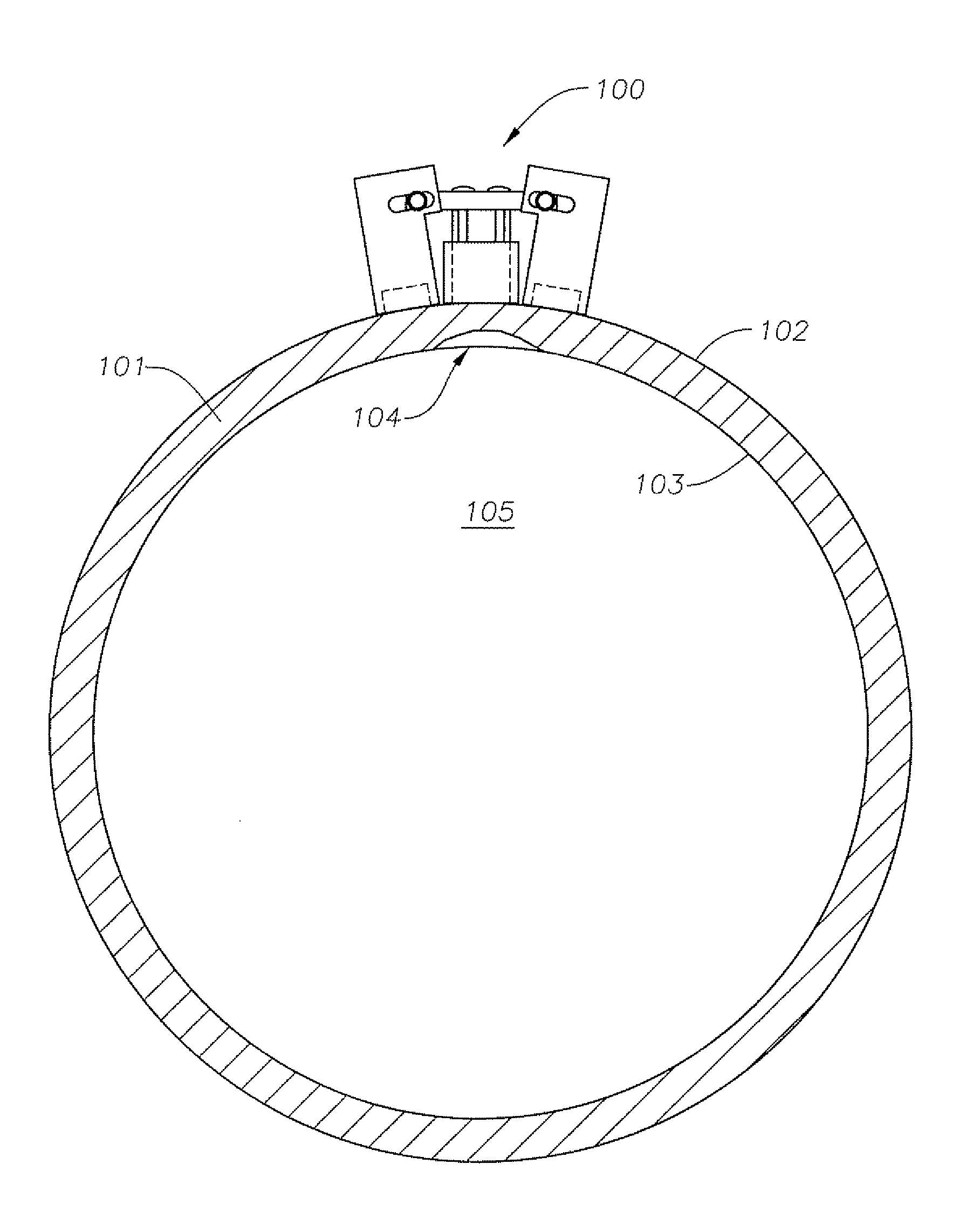

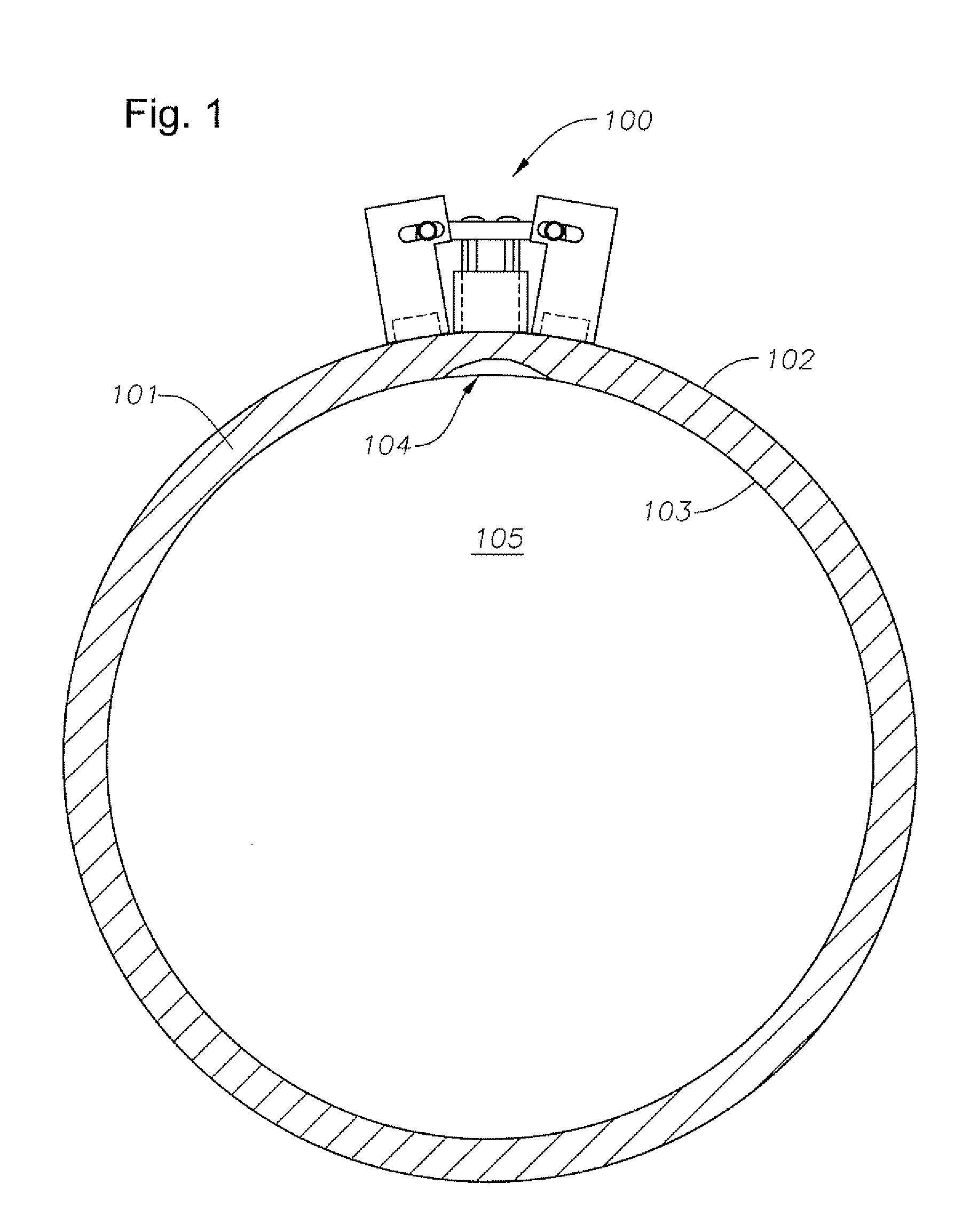

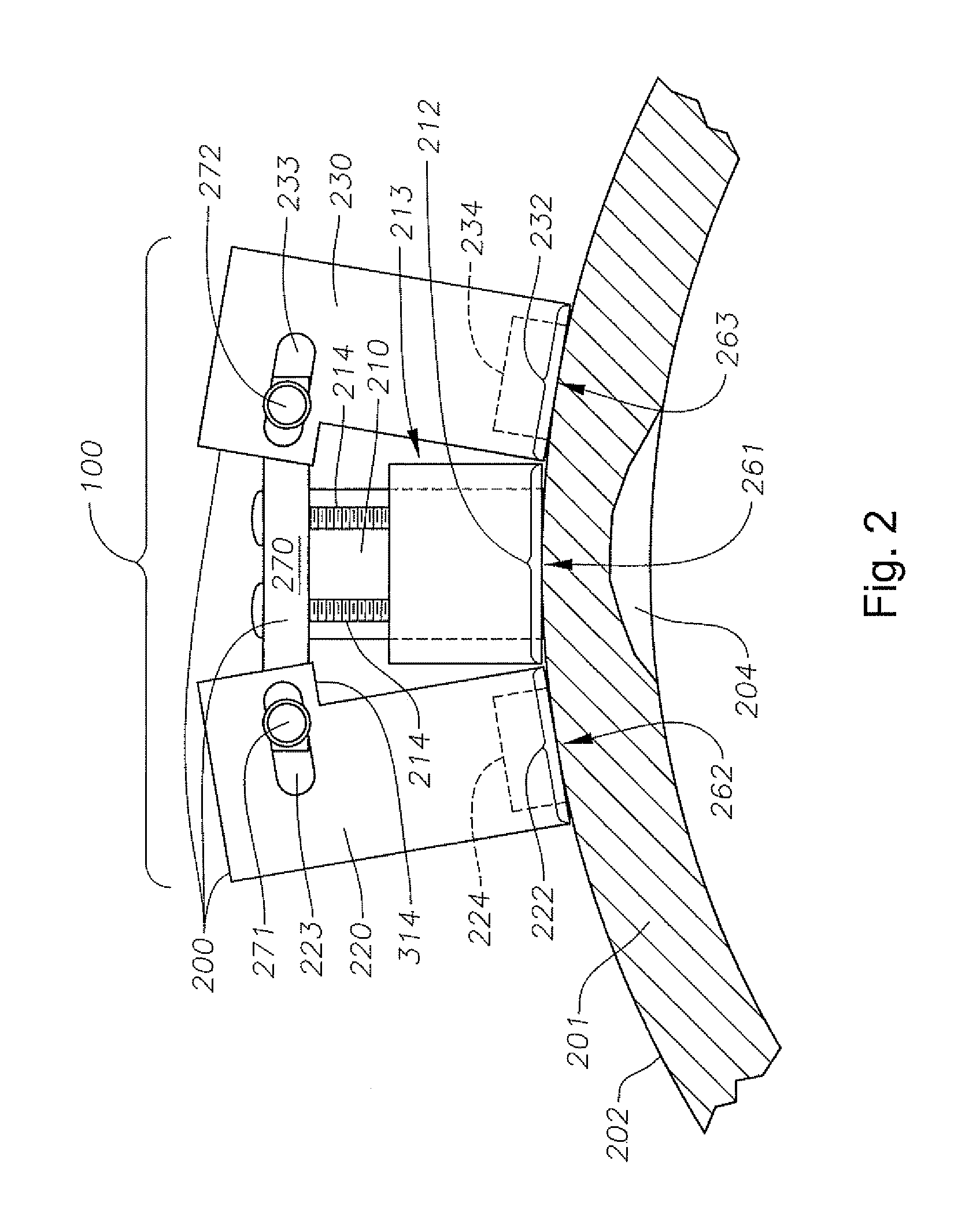

A high-precision corrosion monitoring sensor assembly is provided for permanent mounting on a vessel to measure wall thickness of the vessel. The assembly includes an ultrasonic transducer and a delay line, which are bonded to the vessel wall a first location. The assembly is further bonded to the vessel by an adjustable fixture. The assembly includes a cross-member attached to the ultrasonic transducer, having a pivot pin at each distal end. The pivot pins are attached to a first tower and a second tower, which bond to the outer vessel wall at a second location and a third location. The position of the first and second towers can be adjusted with respect to angle and placement about the pivot pins. Fasteners are attached to the pivot pins and can be tightened to make rigid the fixture, thereby allowing configuration of the assembly for use on flat surfaces and small-diameter pipes.

Owner:SAUDI ARABIAN OIL CO +1

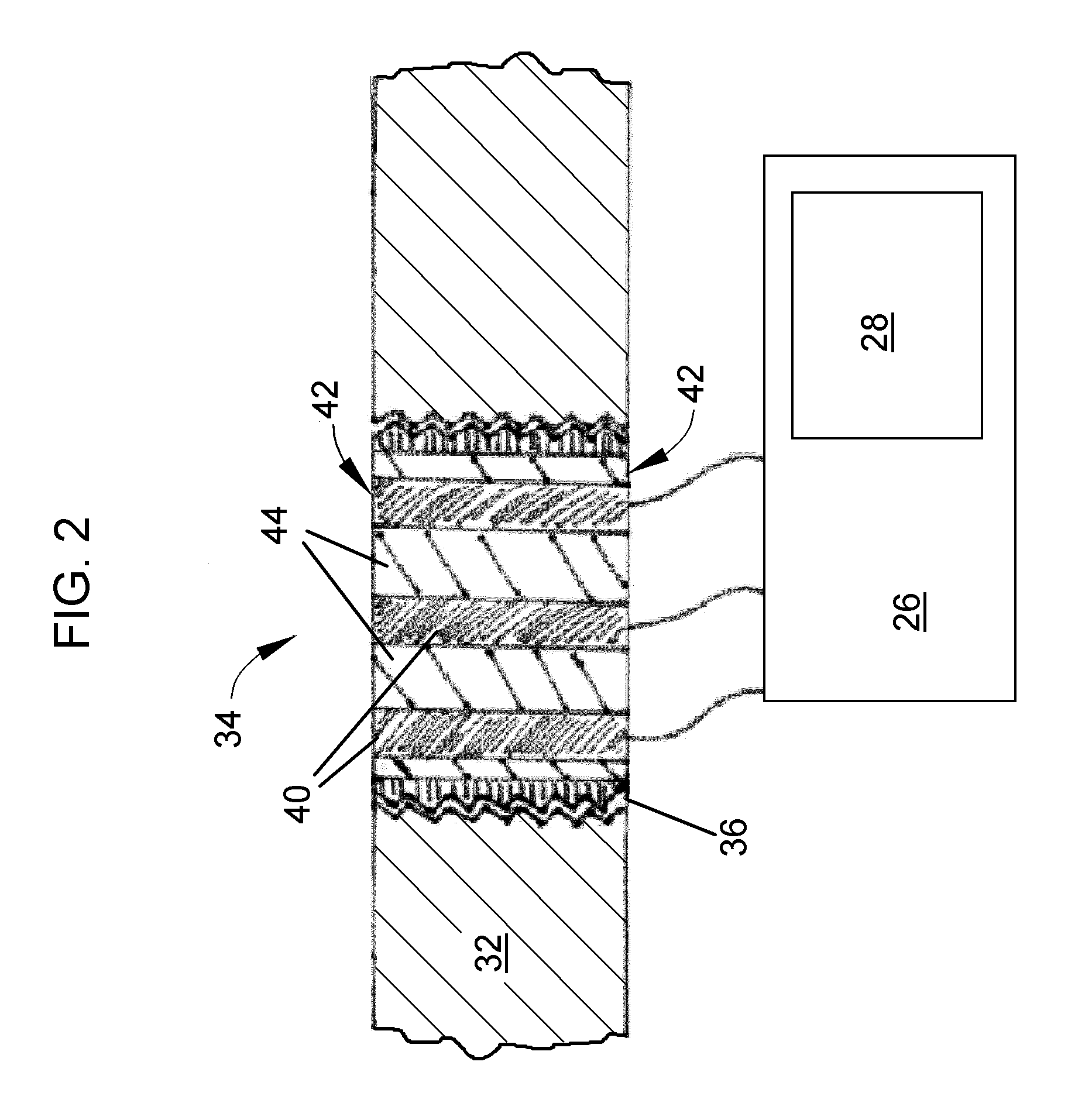

Corrosion inspection and monitoring system

InactiveUS20100312493A1Weight increaseReduce weightMaterial analysis using sonic/ultrasonic/infrasonic wavesWeather/light/corrosion resistanceTransducerMonitoring system

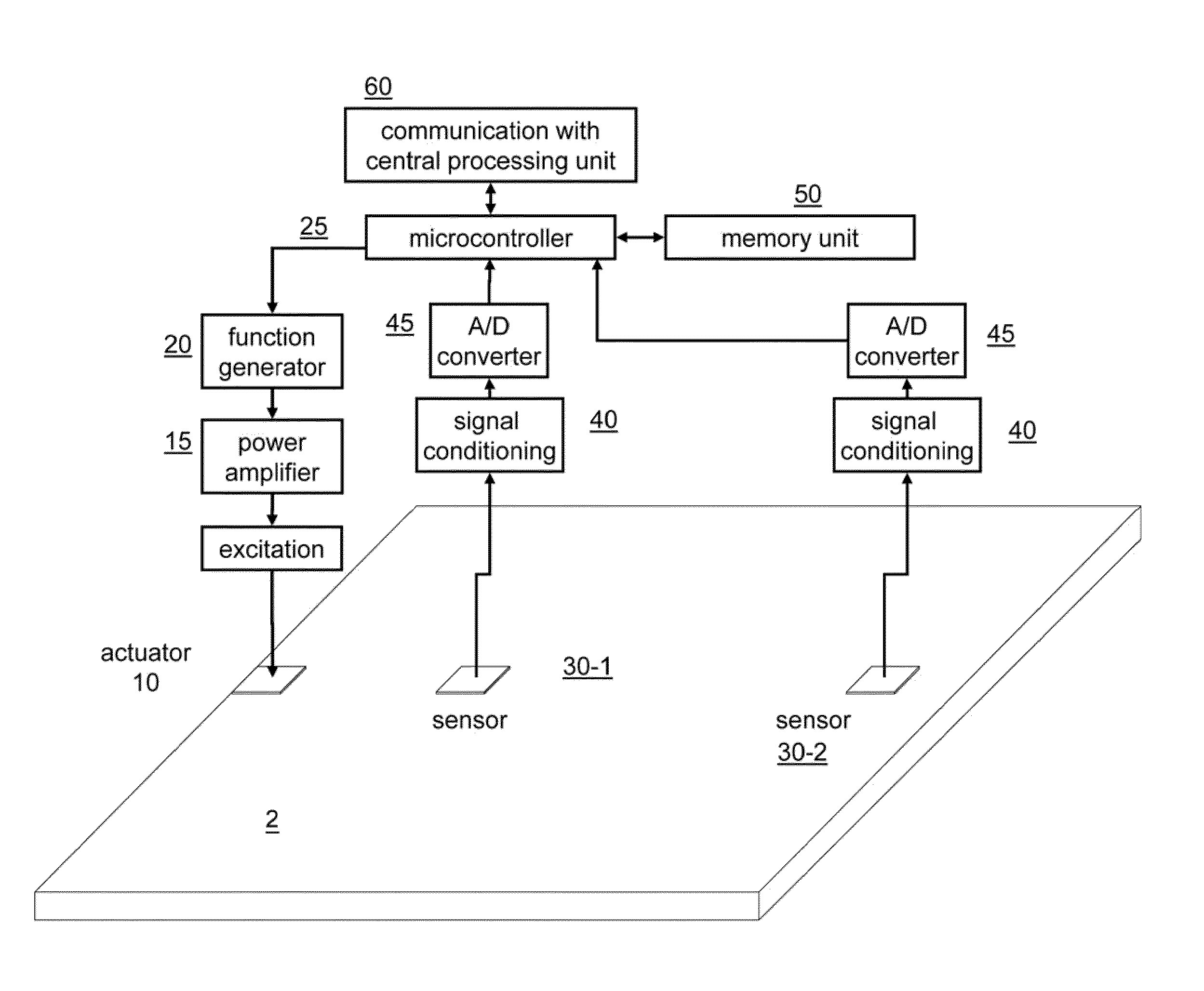

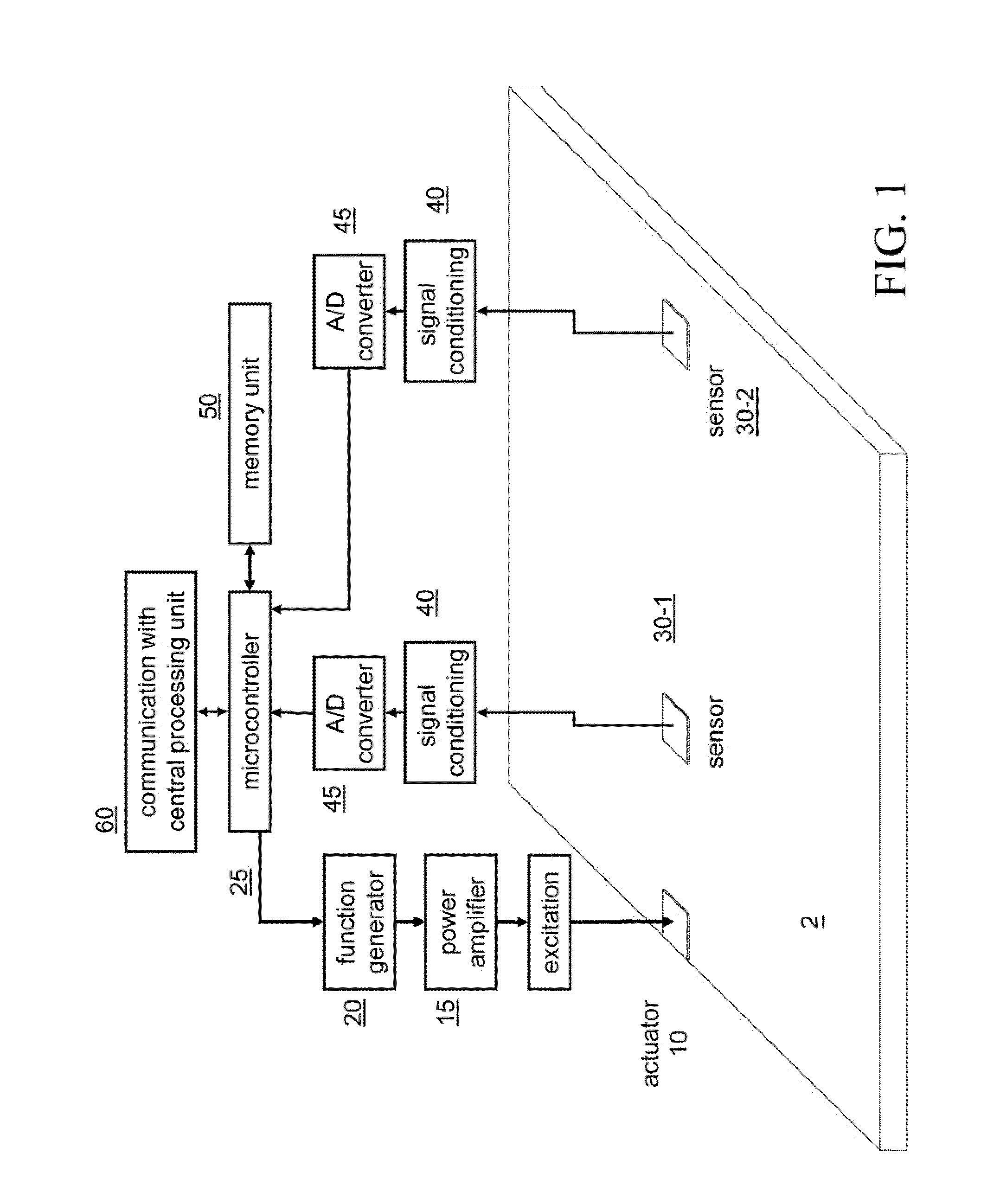

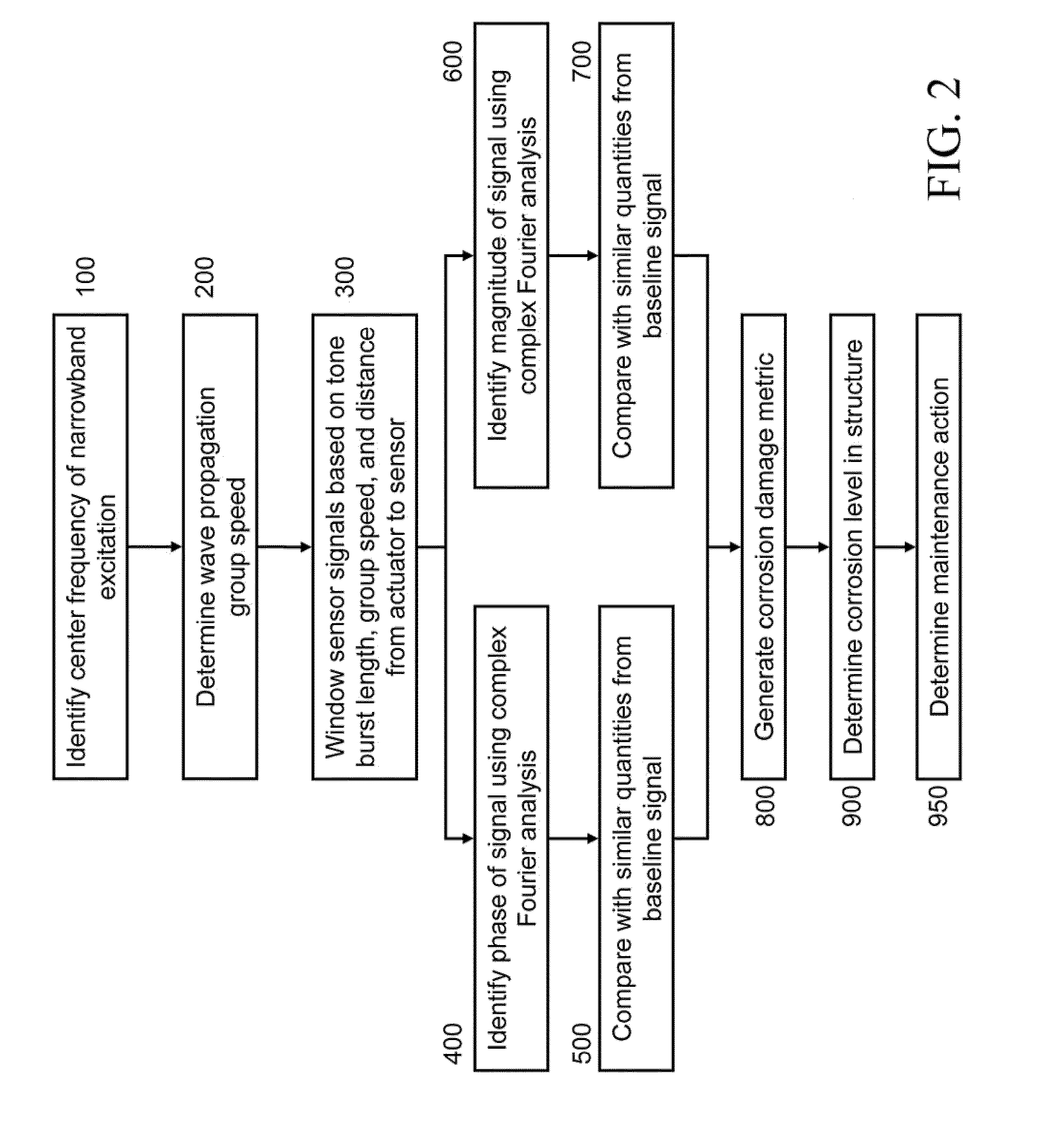

A system for in-situ near-real-time detection and monitoring of corrosion in structures with the ability to directly track the presence and growth of corrosion on a structure by measurement of material loss in the structure attained by analysis of high frequency wave propagation dynamics. The Corrosion Inspection and Monitoring (CIM) system utilizes low-weight in-situ transducers and unique data reduction software for detection and monitoring of corrosion in structural systems in near real-time for corrosion related damage. The CIM system provides a corrosion monitoring and tracking tool that can be deployed in the field with the structural system, and no maintenance personnel are needed for corrosion analysis.

Owner:INNOVITAL LLC +1

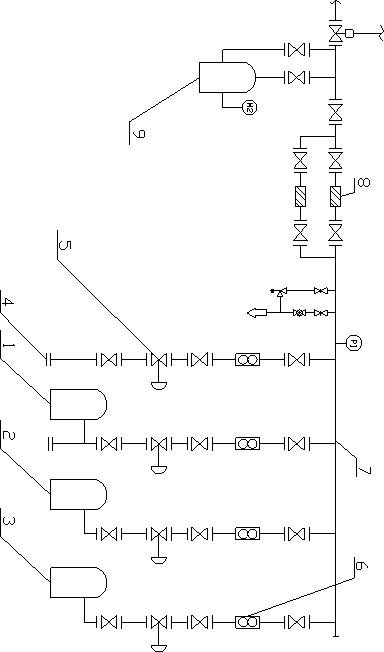

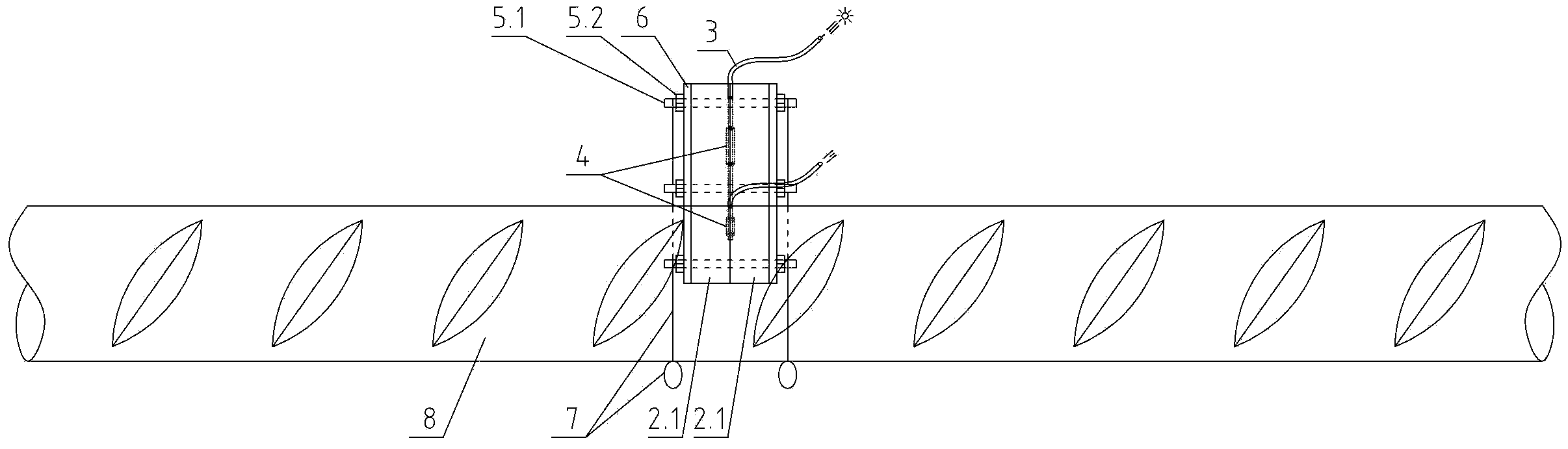

Online monitoring system and method of corrosion protection effect of oil well pipelines

PendingCN108918405AGuaranteed reliabilityReduce limitationsWeather/light/corrosion resistanceData acquisitionProtection layer

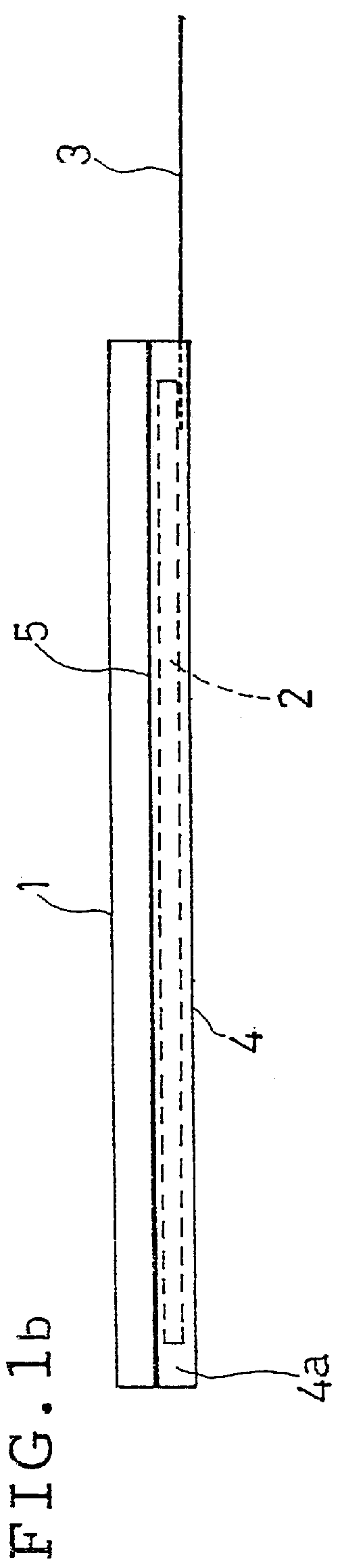

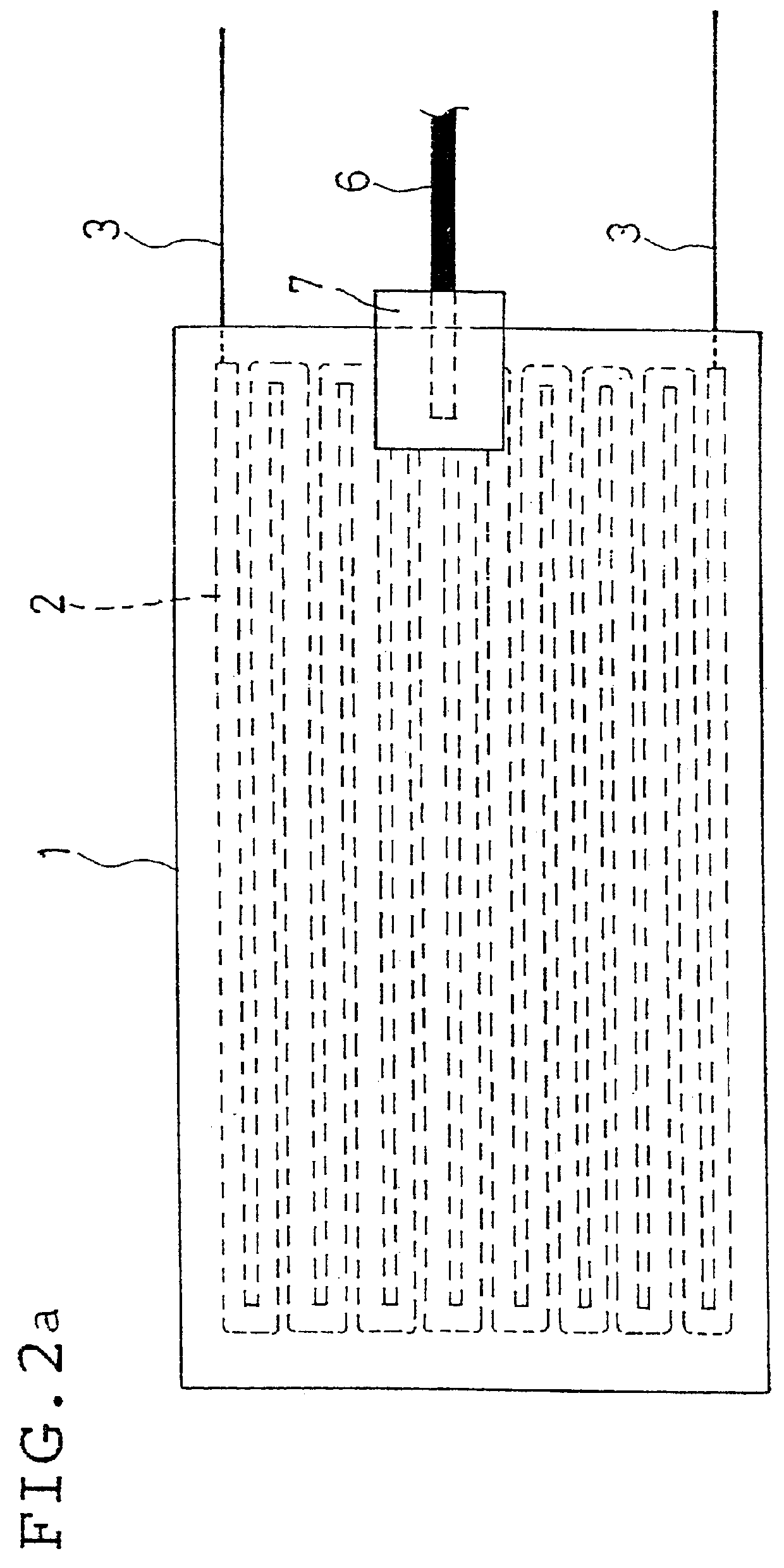

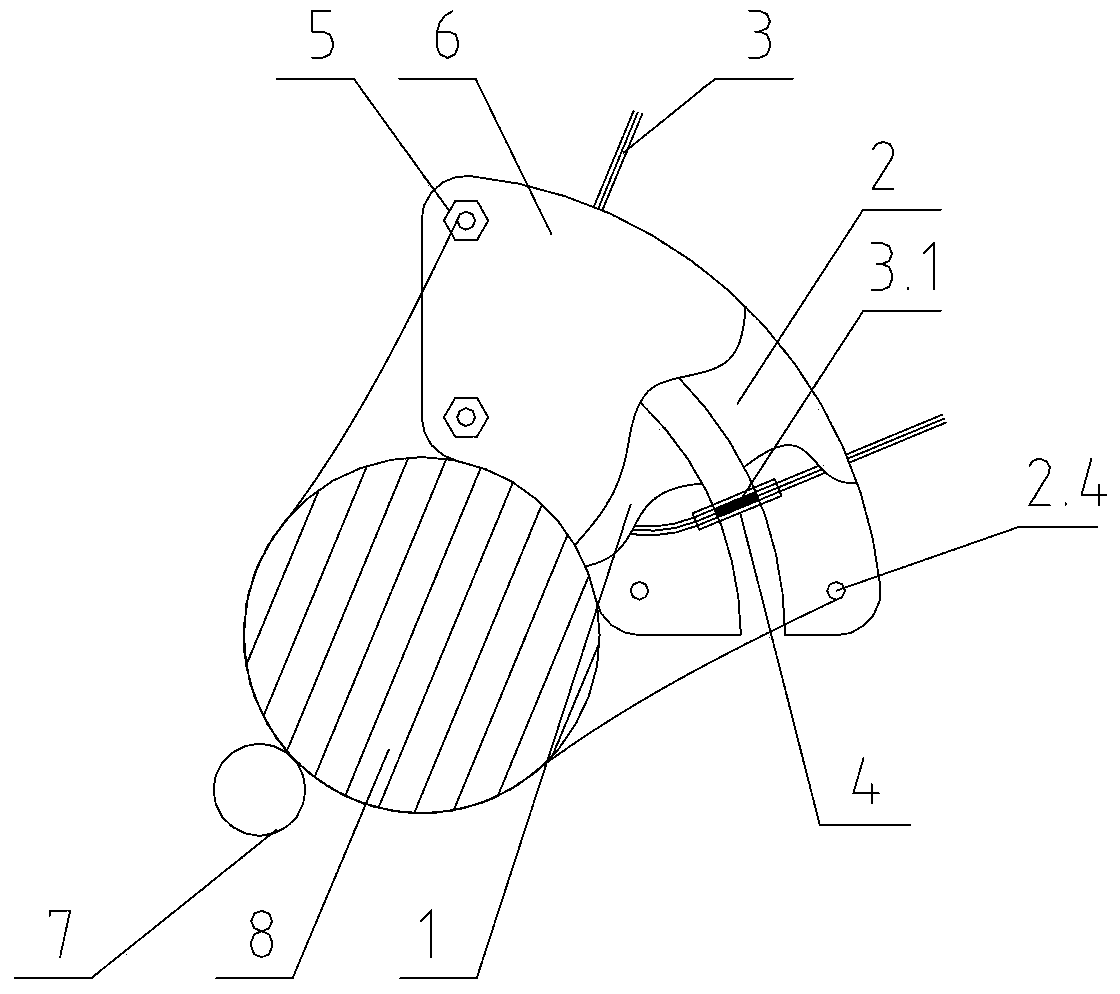

The invention discloses an online monitoring system and method of a corrosion protection effect of oil well pipelines. The system comprises a remote control center (1), an in-situ online corrosion monitoring unit (2), a transmission optical fiber (3), a corrosion data collector (4), a sensor and a network cable (10), wherein the remote control center (1) is connected with the in-situ online corrosion monitoring unit (2), the in-situ online corrosion monitoring unit (2) is connected with the corrosion data collector (4) through the transmission optical fiber (3), and the corrosion data collector (4) is connected with the sensor through the network cable (10). The online monitoring system disclosed by the invention can determine the corrosion damage states of buried oil well pipelines, locate damage points of corrosion layers, and evaluate the aging state of corrosion protection layers to serve as the basis for formulating a maintenance scheme, and can determine the corrosion condition and rate of the oil well pipelines, predict the safe service lives of the oil well pipelines, can avoid potential hazards due to corrosion leakage, can optimize the optimum injection amount of a corrosion inhibitor and can evaluate the forced impressed current cathodic protection effect of the oil well pipelines.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

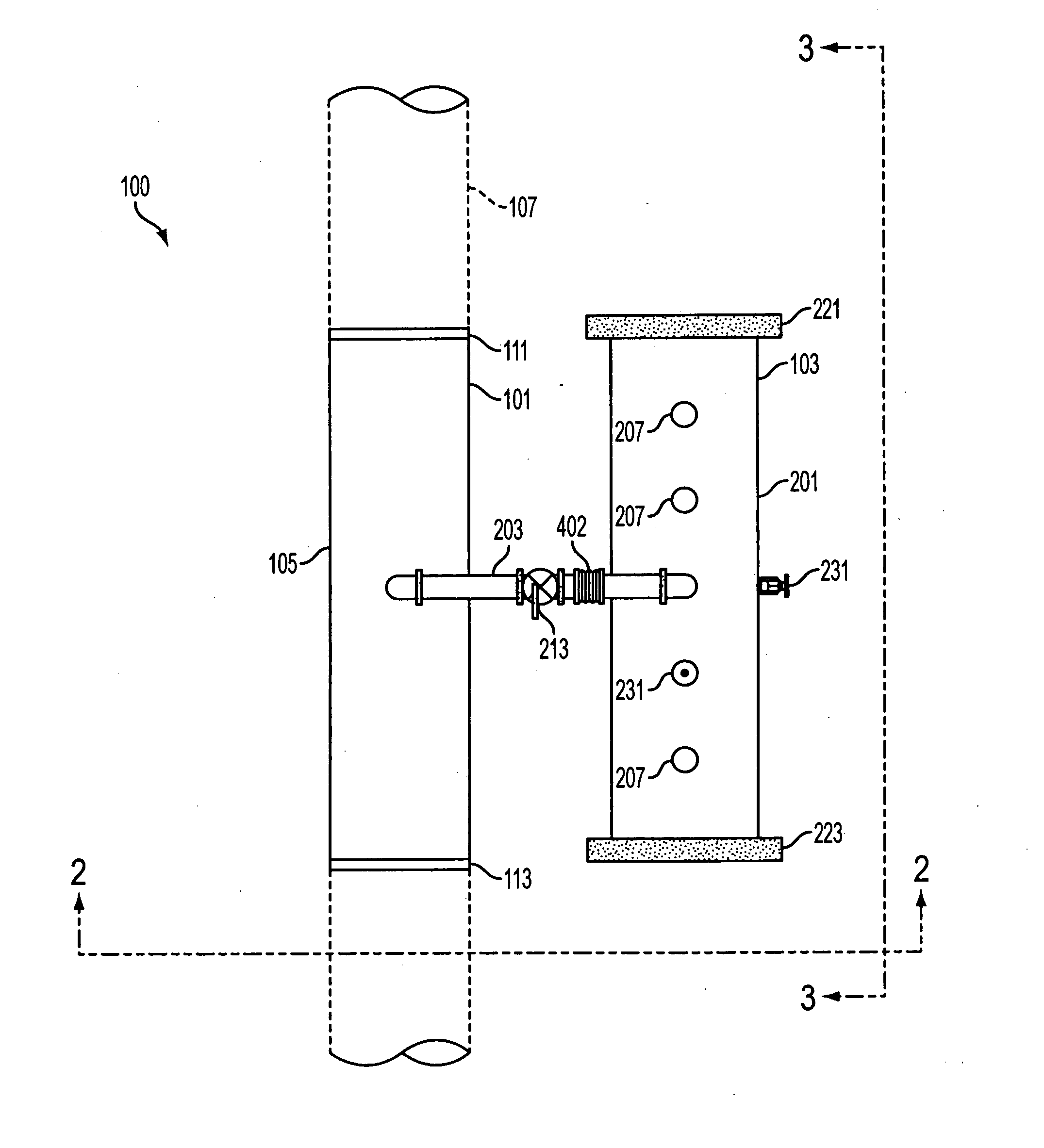

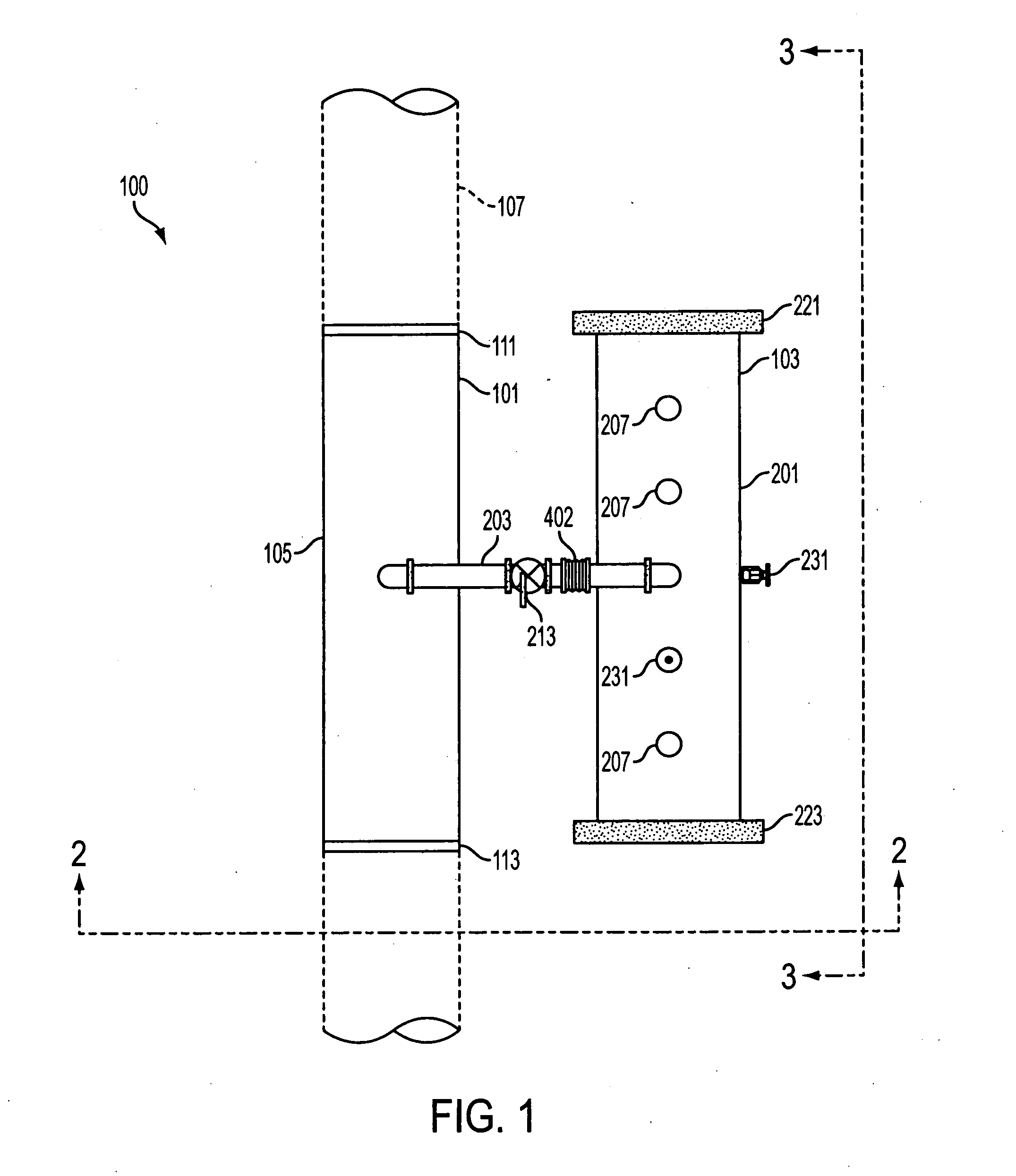

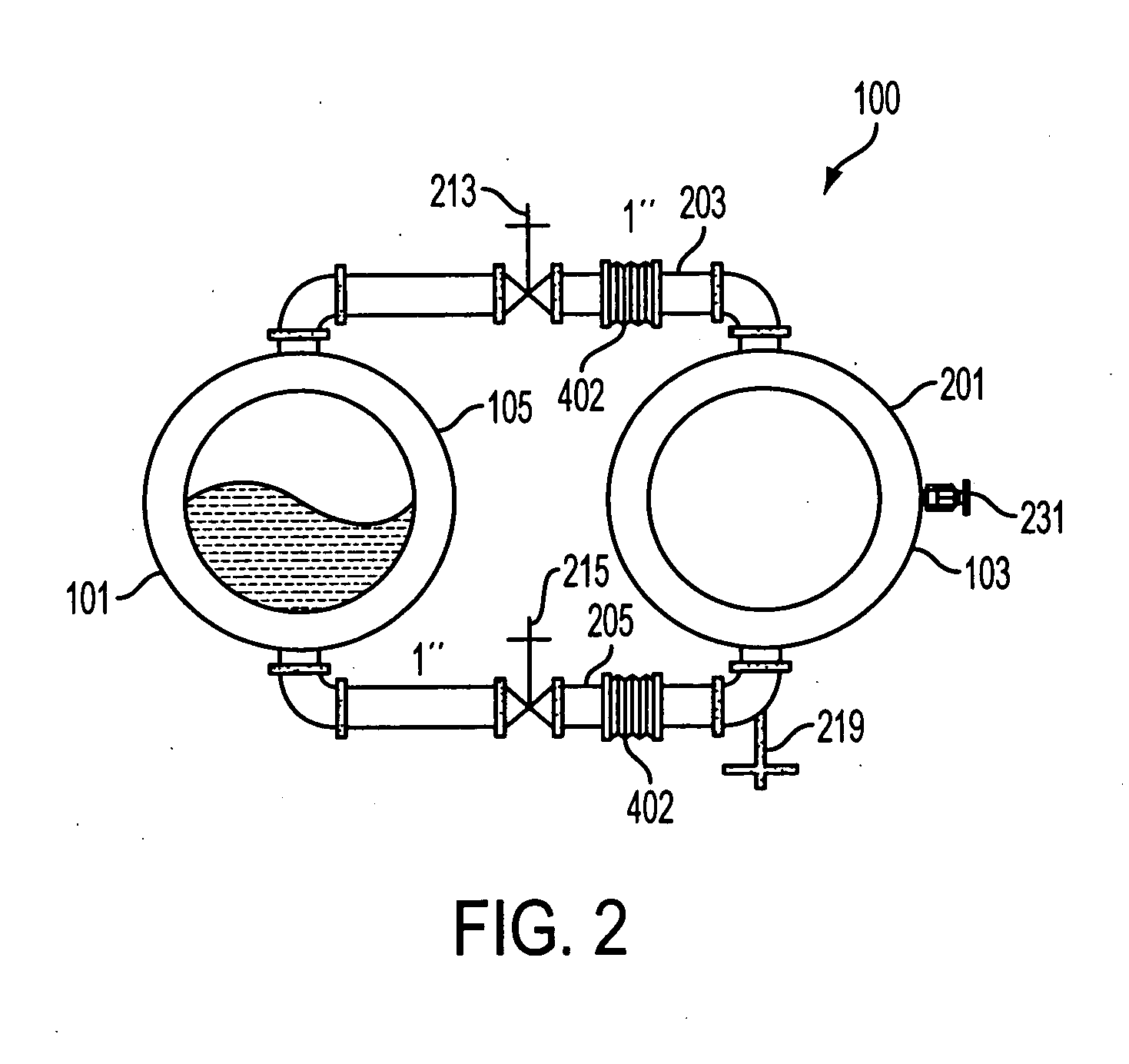

Corrosion monitoring station

A corrosion monitoring station for a water-based fire protection system which allows for test coupons to be removed without having to drain the system. The corrosion monitoring station also generally provides for mimicking of the conditions present in at least a portion of the water-based fire protection system and can provide for a portion of the system which can be easily removed for more extensive testing.

Owner:NAT CITY BANK CO

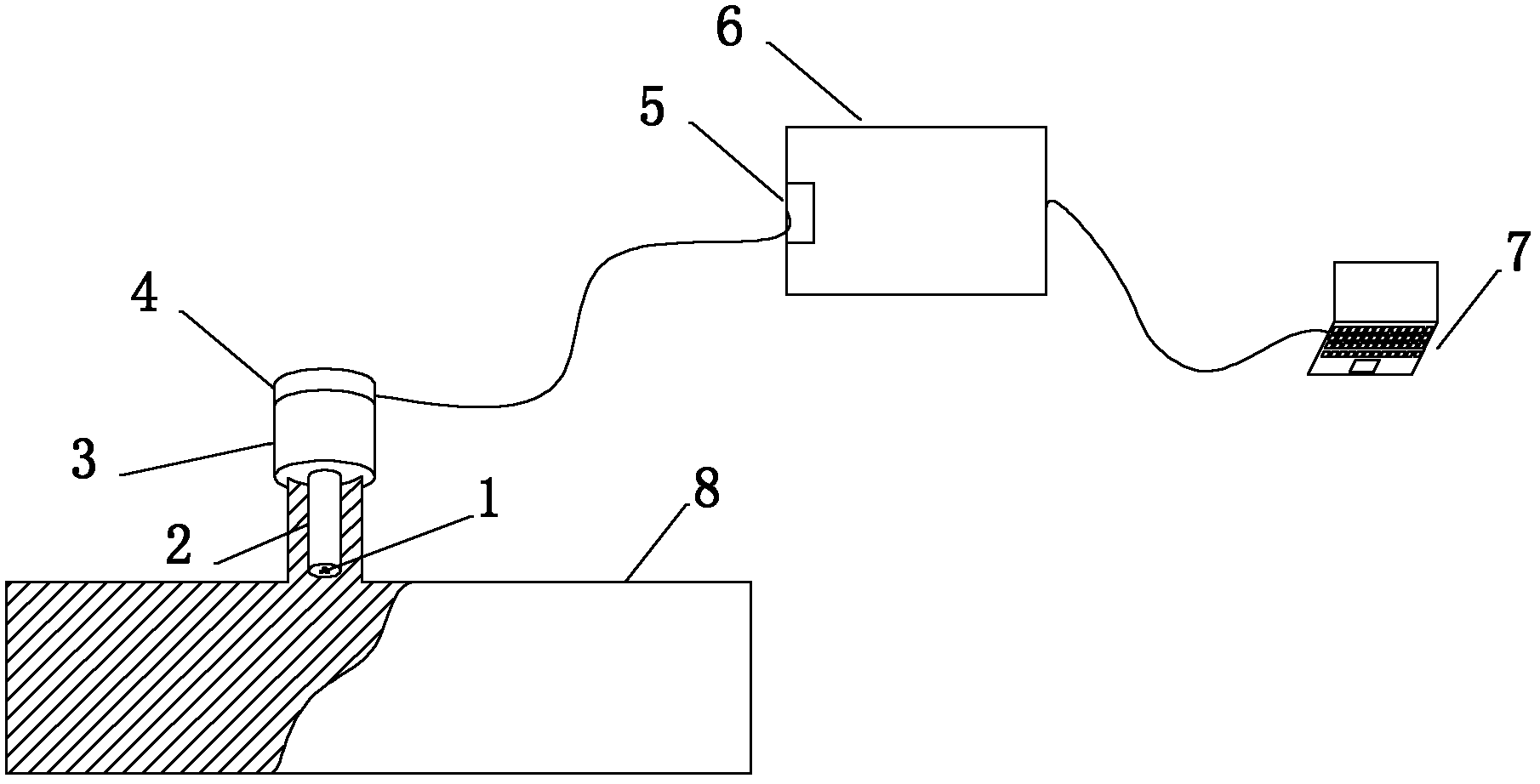

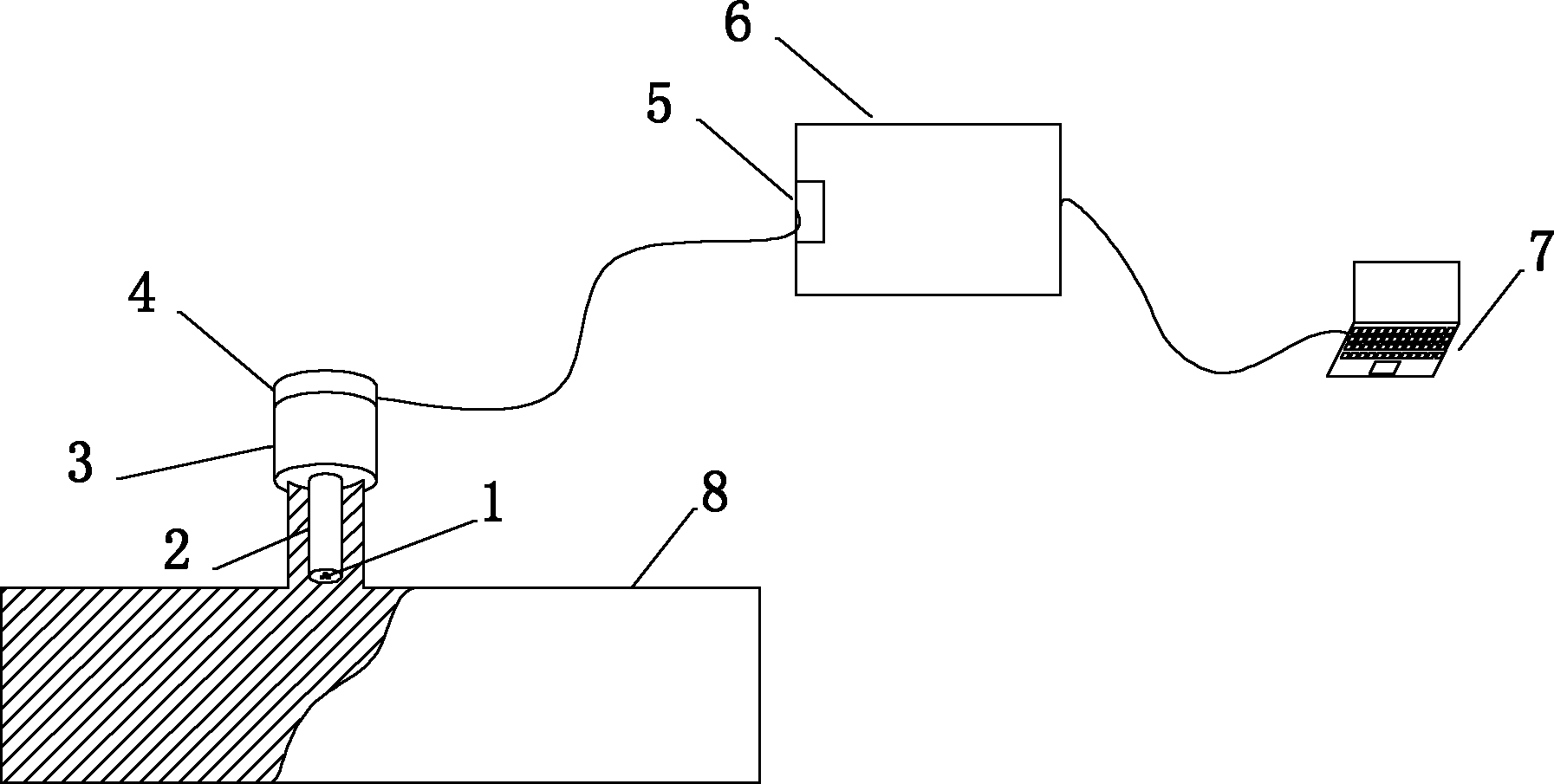

Online monitoring device for corrosion in pipeline

ActiveCN102507430ARealize in-situ online non-destructive testingNo frequent disassemblyWeather/light/corrosion resistanceWireless transmissionComputer module

The invention which relates to an online monitoring device for the corrosion in a pipeline belongs to the technical field of pipeline corrosion monitoring. The online monitoring device for the corrosion in the pipeline is characterized in that the monitoring device comprises a signal acquisition module, a signal transmission apparatus, an A / D converter, a datum analysis module, a datum management module and a computer; the signal acquisition module comprises a three-electrode monitoring probe, a signal generation control unit and a signal buffer memory unit, and the signal generation control unit applies electrochemical excitation and transmits feedback signals to the signal buffer memory unit; the signal transmission apparatus which is a wired or wireless transmission apparatus transmits datum signals to the A / D converter; and the datum signals which go through the datum analysis module and the datum management module enter the computer and are processed by the computer, and online monitoring is displayed. The monitoring device has the advantages of in situ lossless online monitoring, no need of frequent disassembly and assembly, wide suitable medium range, integration of monitoring, analysis and management, real-time detection and the like.

Owner:扬中市冠捷科创有限公司

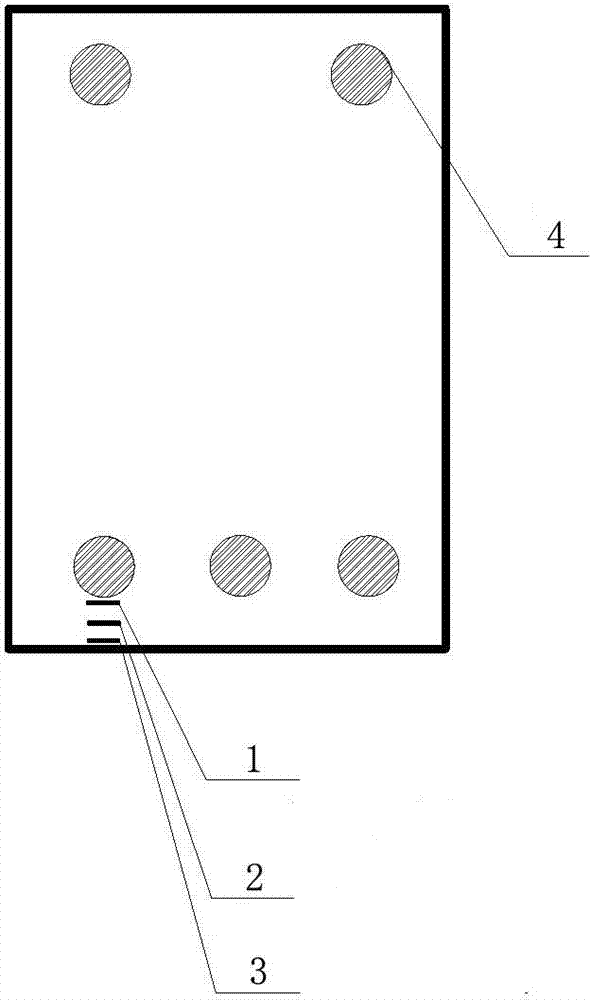

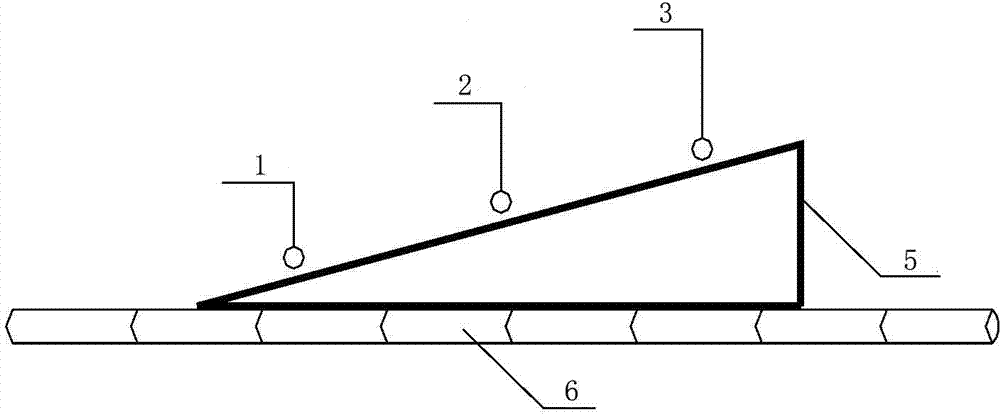

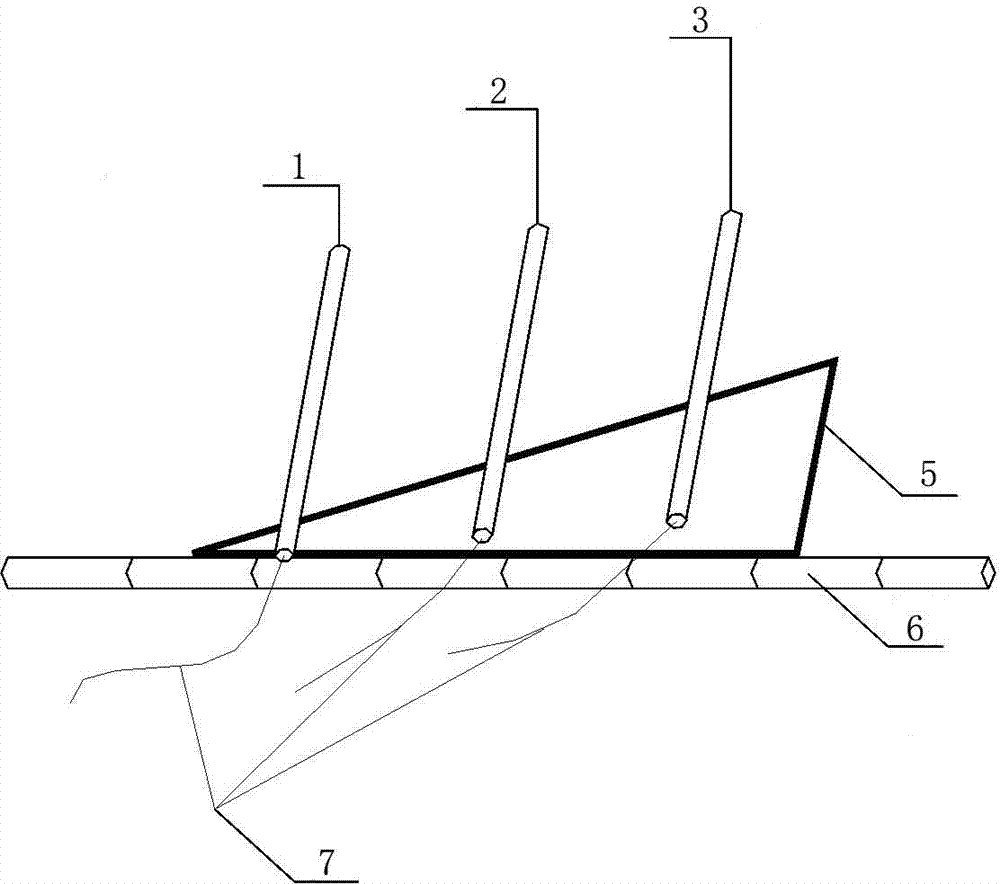

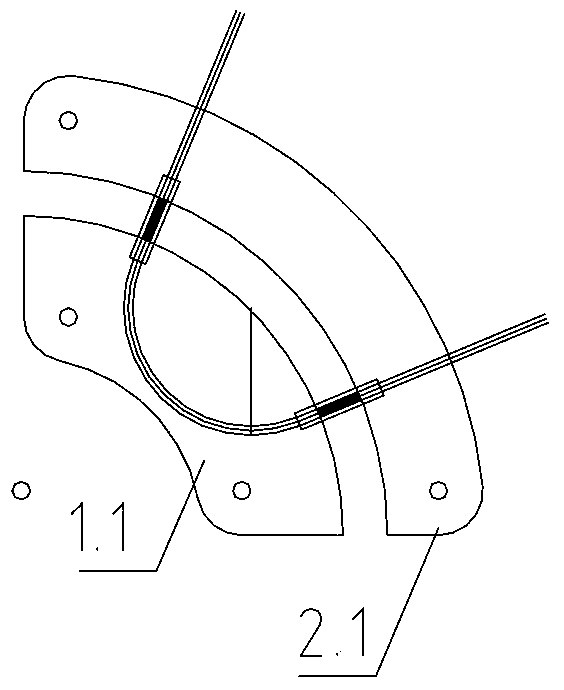

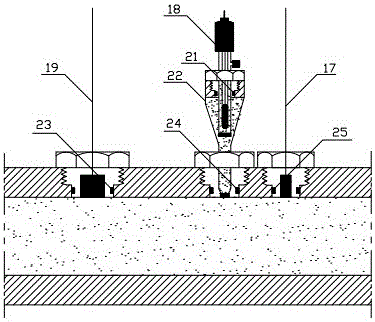

Corrosion monitoring device and method for reinforcement bar in concrete structure

ActiveCN102928580AHigh precisionLong-term real-time online monitoringMaterial testing goodsFiberTensile strain

The invention relates to a corrosion monitoring device and method for a reinforcement bar in a concrete structure. The device comprises at least three fiber grating strain transducers, a signal processing unit, a stainless steel bevel support and conductors, wherein the fiber grating strain transducers are sequentially arranged on the bevel of the bevel support; and signals acquired by all the fiber grating strain transducers are sent to the signal processing unit through the conductors. According to the invention, the fiber grating strain transducers arranged by adopting a special method can measure tensile strain caused by a corrosion expansion force generated by corrosion products of the reinforcement bar in a concrete cover and derive the corrosion rate and the initial corrosion time t0 of the reinforcement bar so as to indirectly monitor the corrosion condition of the reinforcement bar. The corrosion monitoring device for the reinforcement bar is convenient to arrange, higher in test result precision and better in reliability, and can realize long-term real-time on-line nondestructive monitoring of the common concrete structure.

Owner:ZHENGZHOU UNIV

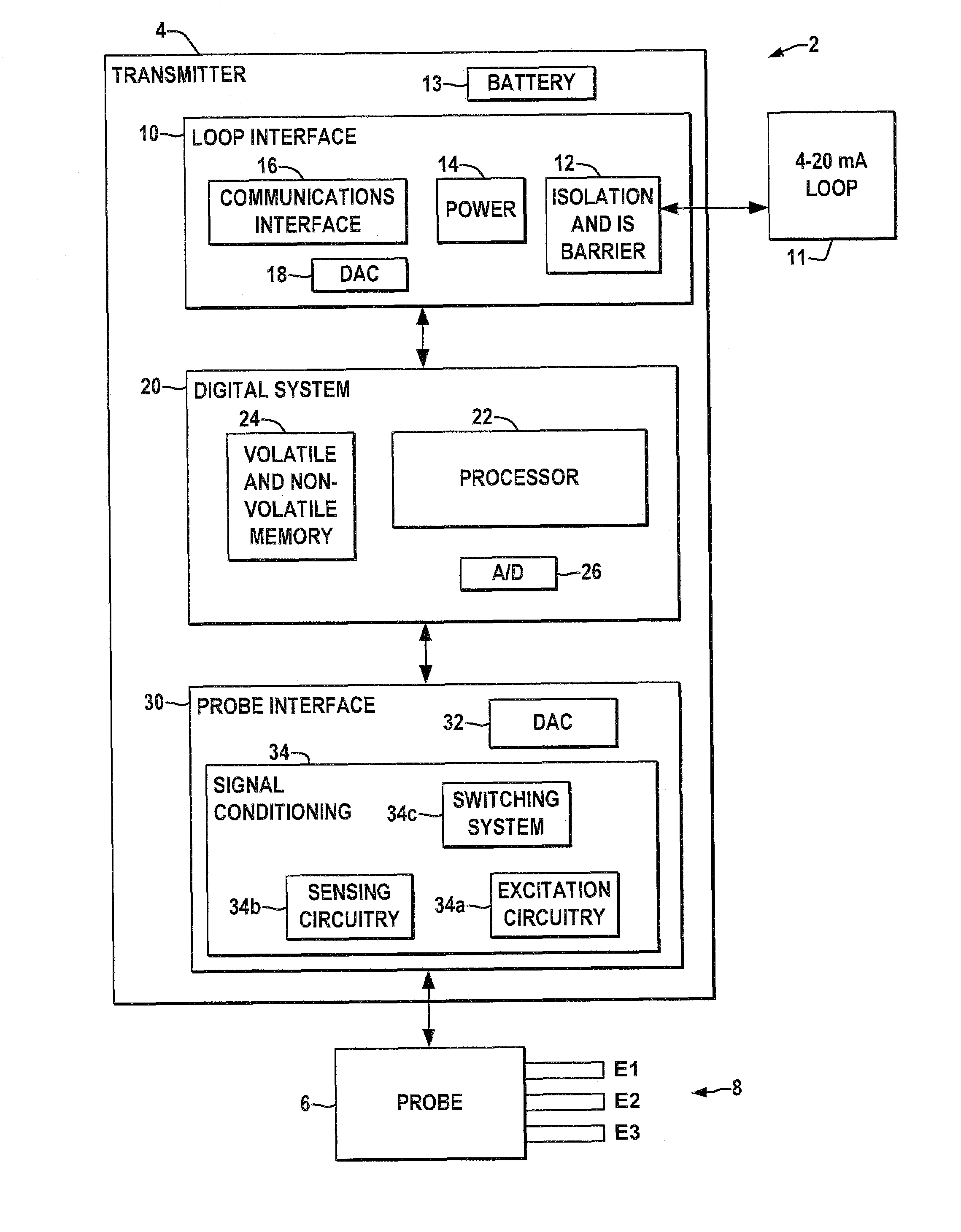

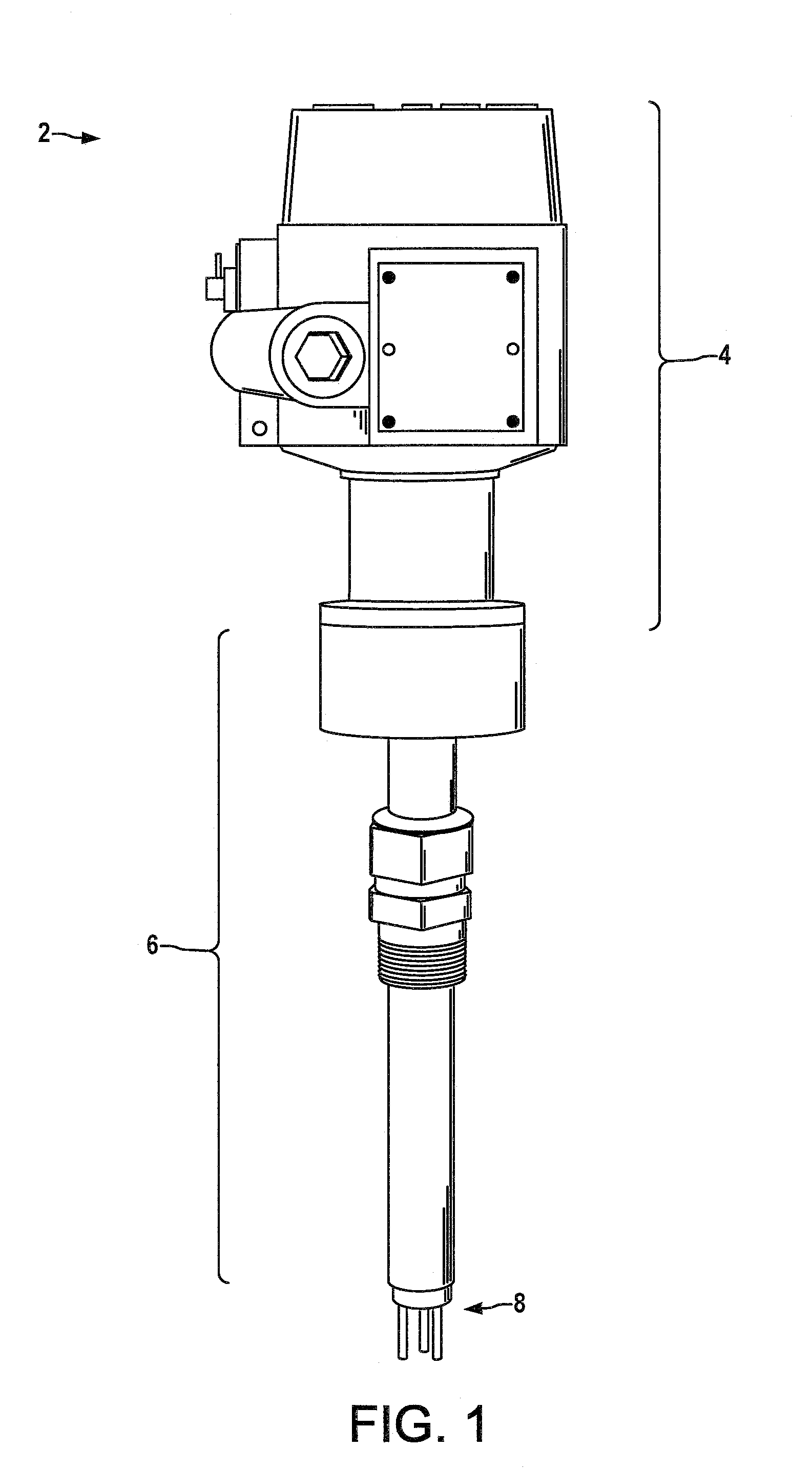

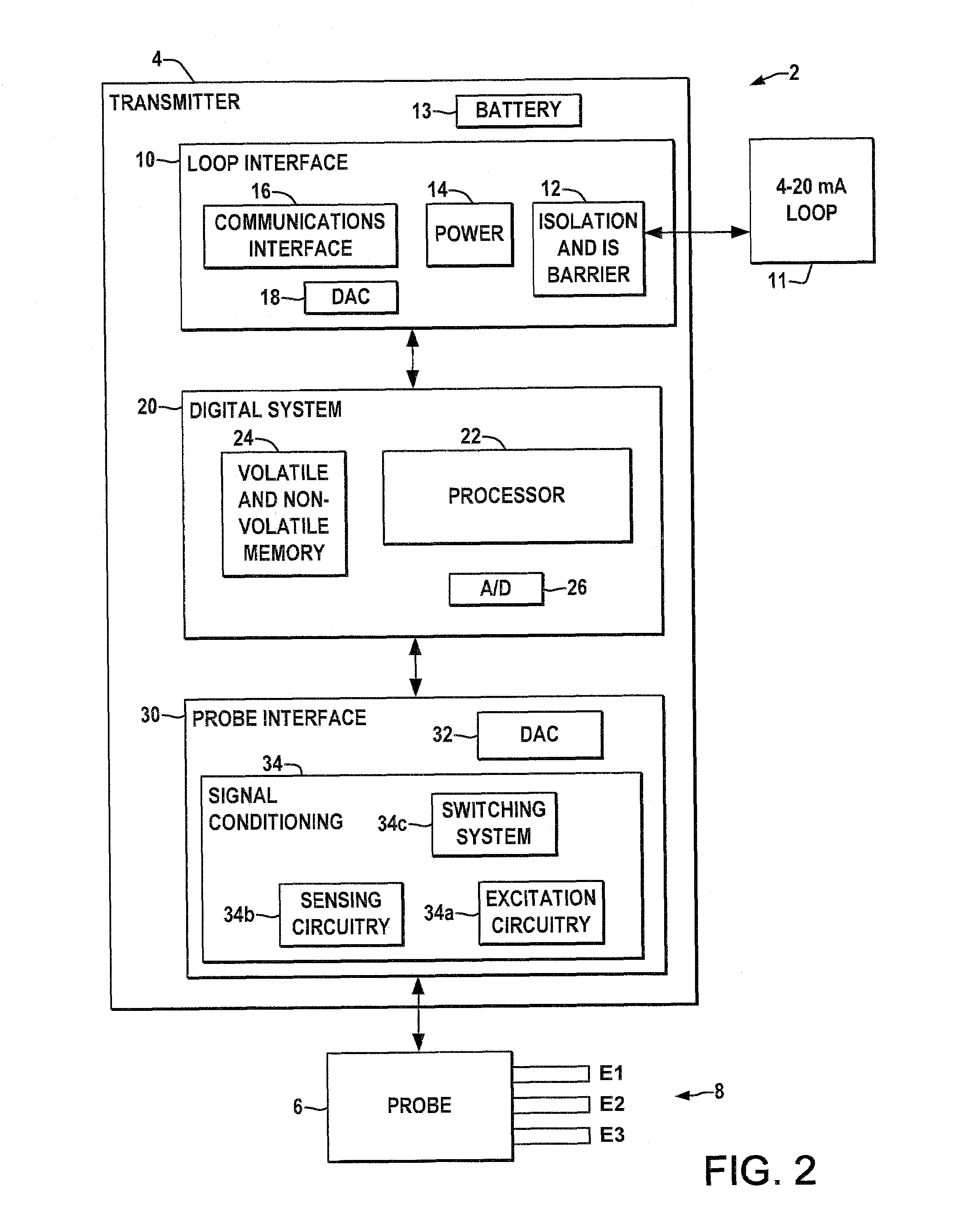

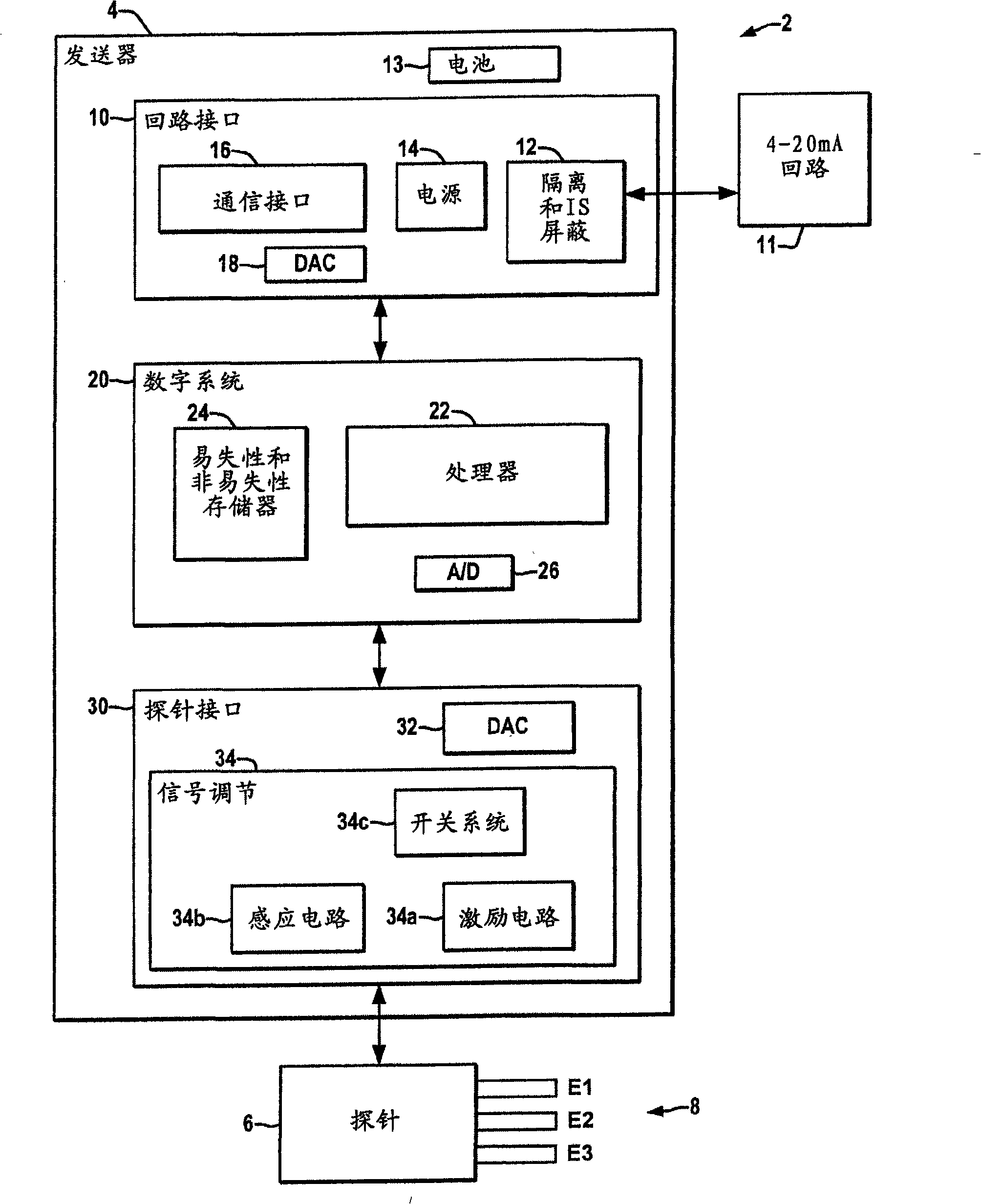

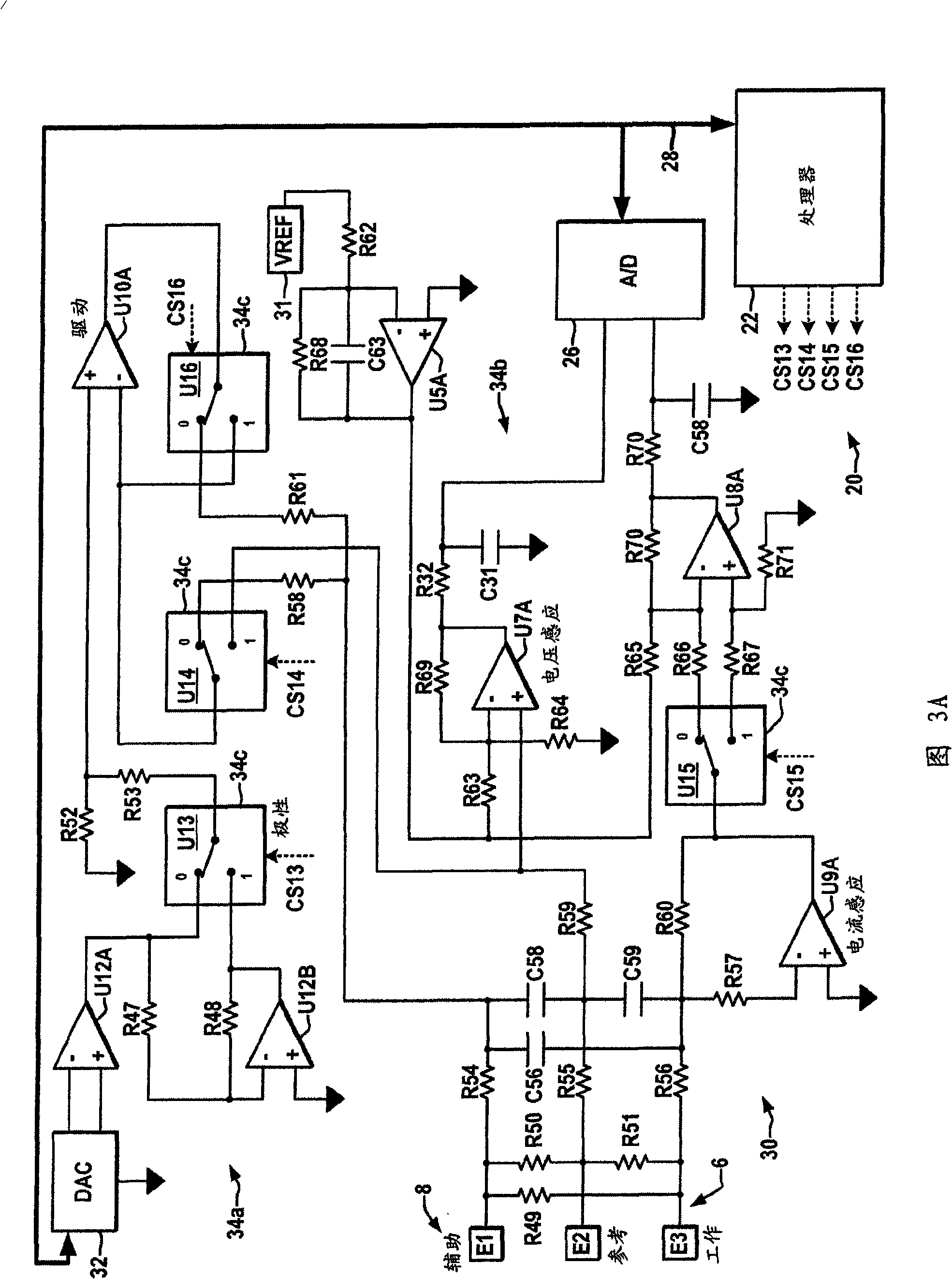

Corrosion measurement field device with improved LPF, HDA, and ECN capability

ActiveUS7282928B1Need can be quite largeReduce in quantityWeather/light/corrosion resistanceVolume/mass flow measurementMeasurement deviceCondensed matter physics

Low power corrosion measurement devices are described with improved LPR, HDA, and ECN measurement capabilities in a field transmitter for online corrosion monitoring or off-line corrosion data logging.

Owner:ALABAMA SPECIALTY PROD

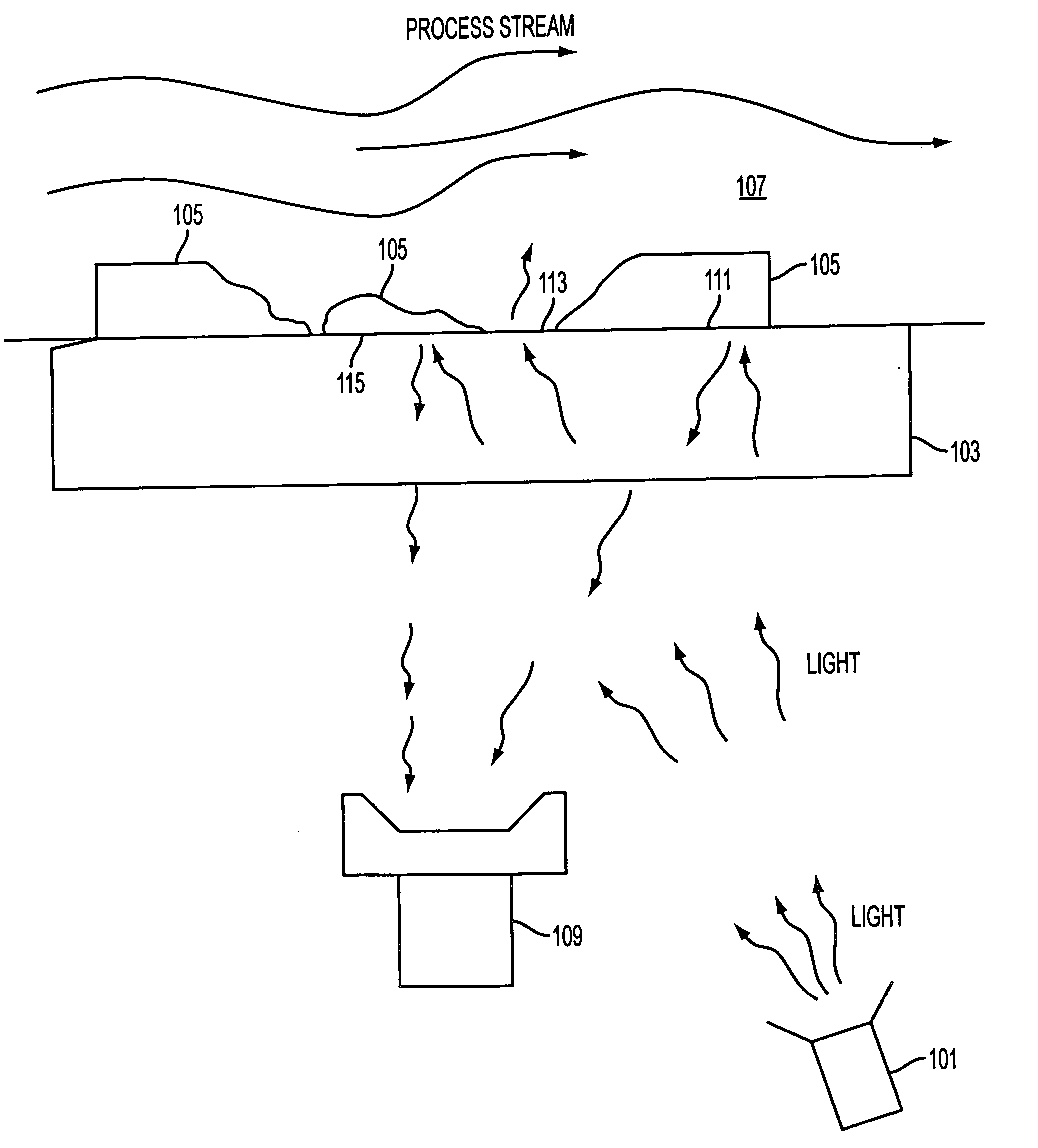

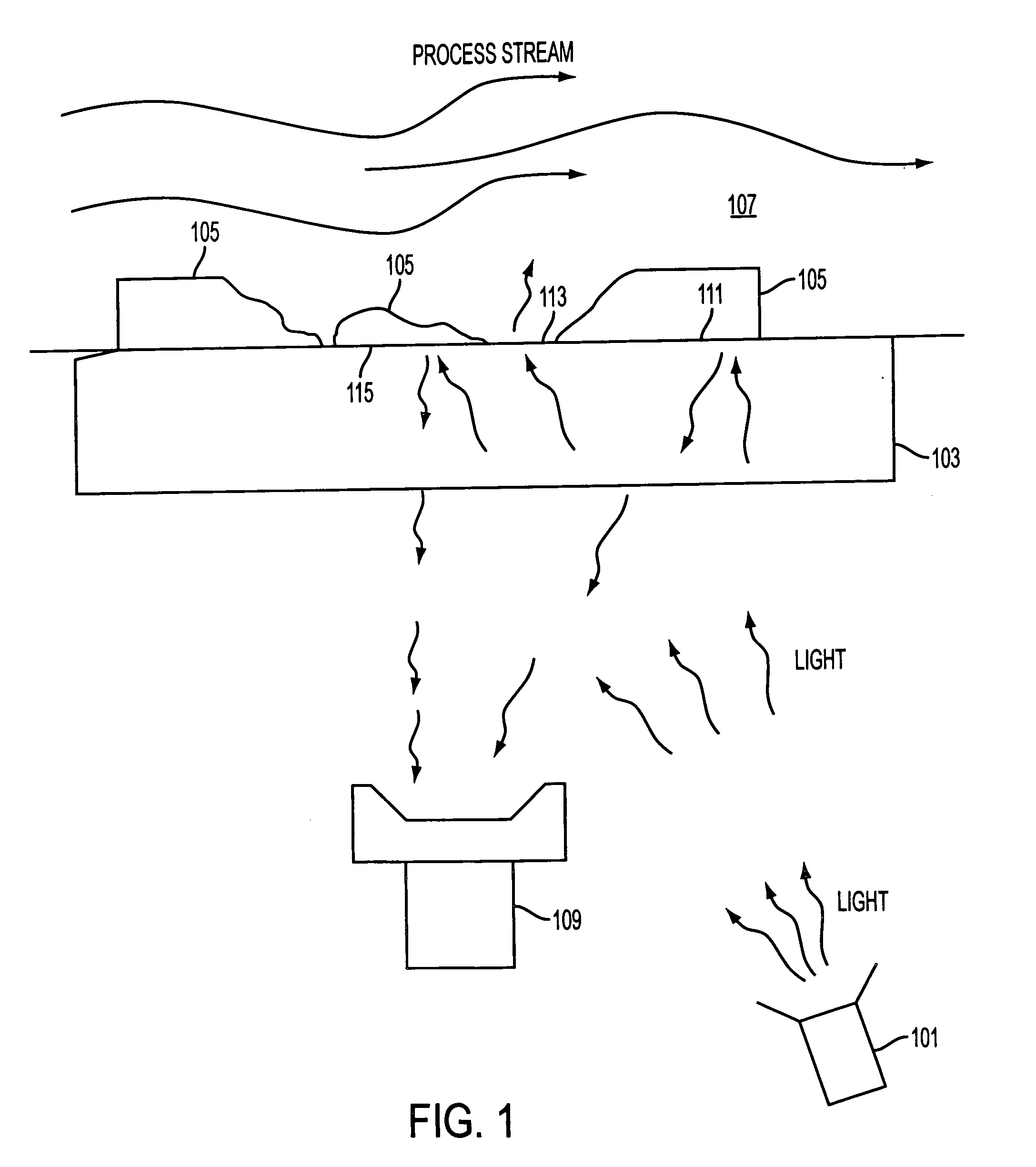

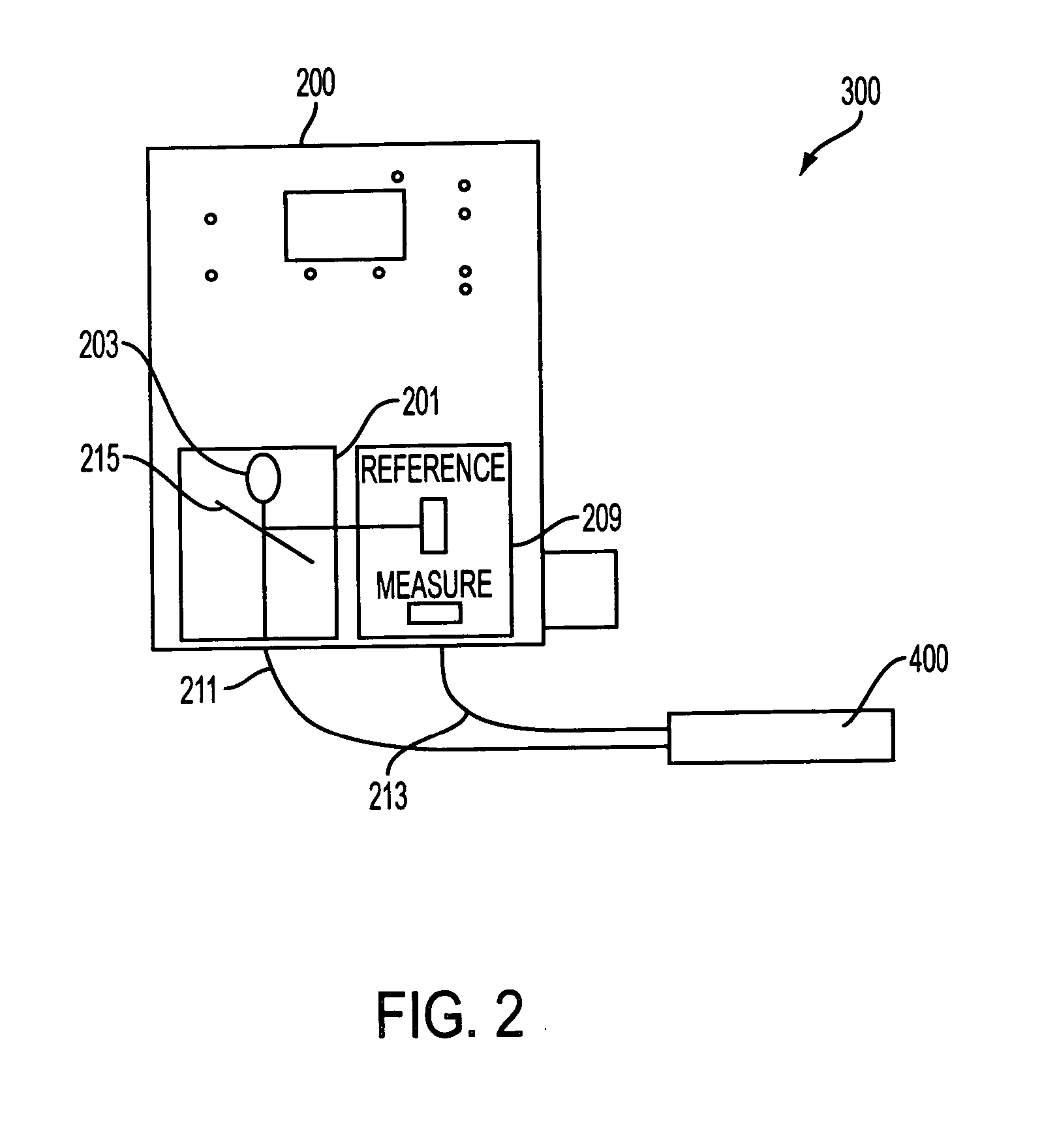

Corrosion monitoring system, optical corrosion probe, and methods of use

ActiveUS20050135546A1Radiation pyrometryScattering properties measurementsElectromagnetic radiationProcess conditions

Optical corrosion monitoring and detection systems as well as methods to detect and monitor corrosion under process conditions and generally in real time using electromagnetic radiation, particularly light. The systems generally provide for incident light to be allowed to reflect from a coating which is exposed to the corroding action of the process stream. As the coating is corroded, the intensity, or other function, of the incident light is changed and this change is detected and used to extrapolate a level of corrosion.

Owner:CUSTOM SENSORS & TECH INC

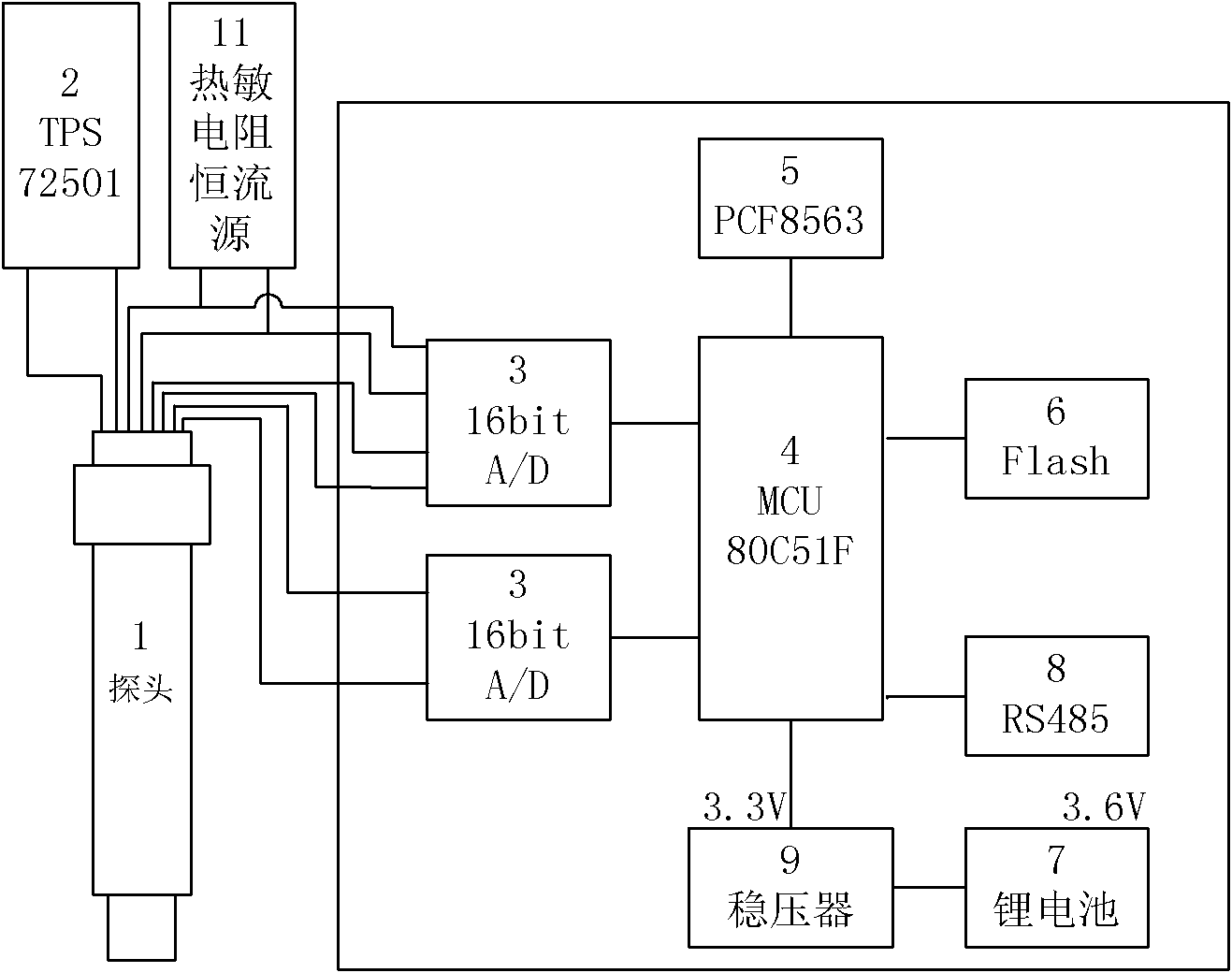

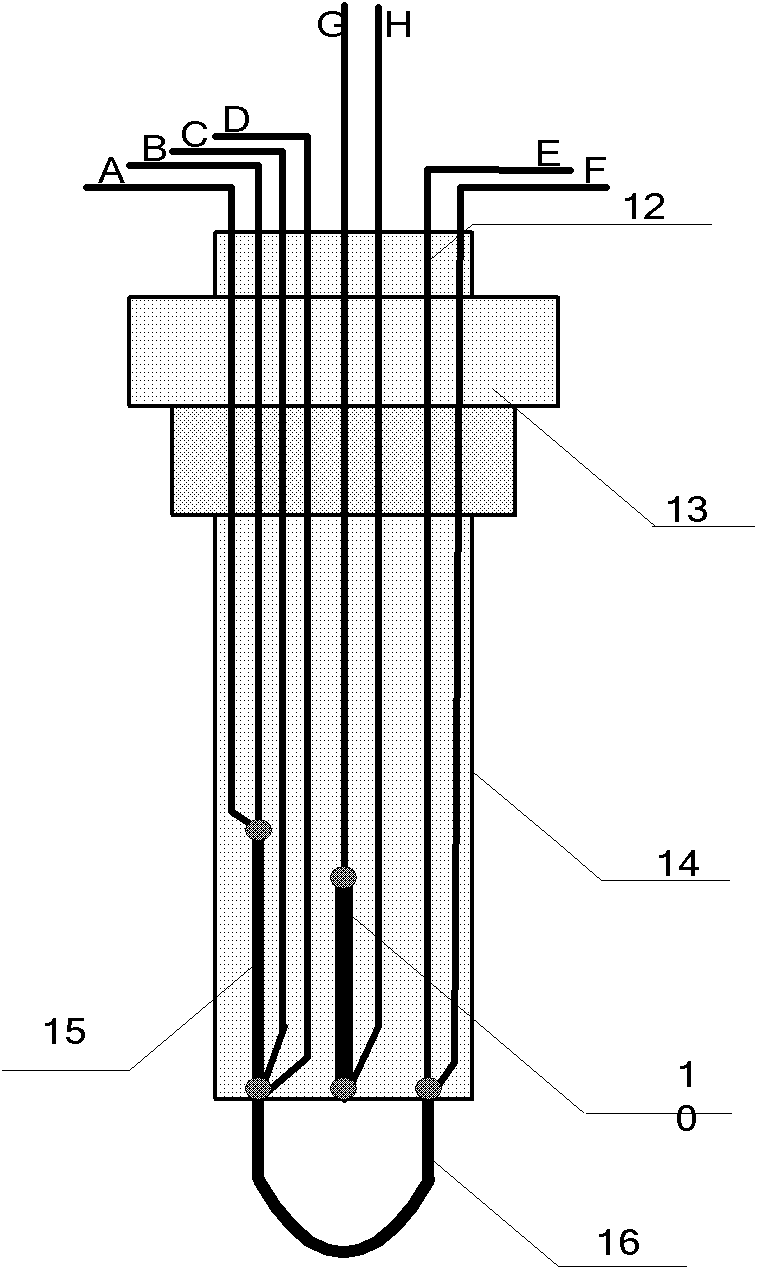

Oil and gas pipeline corrosion online monitor

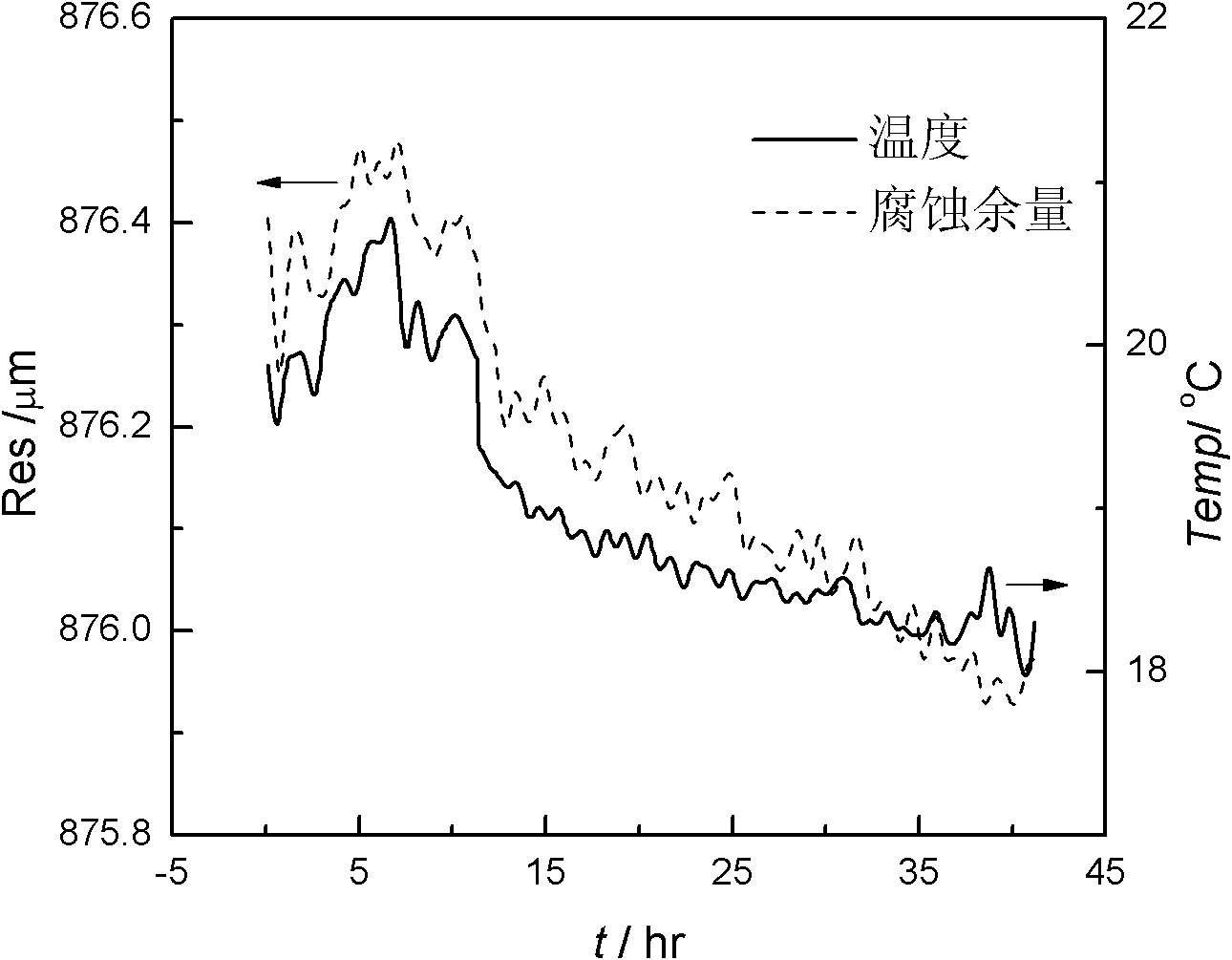

InactiveCN101846644AHigh measurement accuracyResponsiveMaterial resistanceElectrical resistance and conductanceThermodynamics

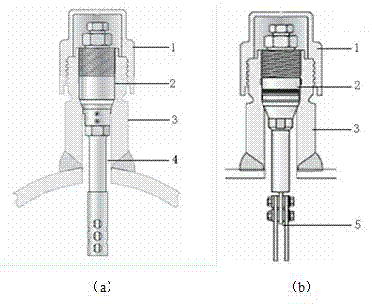

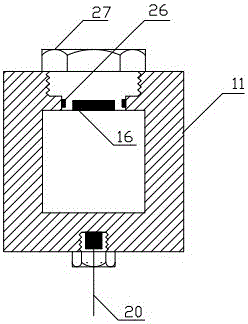

The invention discloses an oil and gas pipeline corrosion online monitor, which measures the corrosion of an oil and gas pipeline by an electric-resistivity method. The monitor comprises a resistance probe, a measurement circuit and a measurement data processing unit, wherein the resistance probe (1) comprises waterproof jacks (12), a sealing screw thread (13) and a probe shell (14); the upper part of the sealing screw thread (13) is connected with the waterproof jacks (12), while a lower part is connected with the probe shell (14) made from stainless steel; a built-in sensing element (15), which is a reference resistor Rf, and a built-in thermal resistor Rt (10) are arranged in the probe shell (14), and are positioned in an identical temperature environment; an exposed sensing element (16), which is a measured resistor Rx, is arranged out of the probe shell (14), and is directly exposed in a corrosion environment in the pipeline; and the built-in sensing element (15) and the exposed sensing element (16) are made from an identical material and have an identical temperature coefficient. The resistance corrosion monitoring device of the invention has the characteristics of quick response, continuous testing capacity, the capacity of sensitively detecting the small change of a corrosion state in the pipeline, high reliability and high data reproducibility.

Owner:HUAZHONG UNIV OF SCI & TECH

Distributive stress measurement-based pipeline interior corrosion monitoring method

InactiveCN106198365AReal-time monitoring of security statusHigh measurement accuracyWeather/light/corrosion resistanceNon destructiveStress distribution

The invention provides a distributive stress measurement-based pipeline interior corrosion monitoring method, belonging to the technical field of optical fiber sensing. The monitoring method comprises the following steps: measuring circular and axial strain distribution on the surface of a metal pipeline by adopting an optical fiber monitoring network, and drawing a circular and axial strain cloud picture, and positioning the corrosion position and corrosion range according to the stress distribution on the surface of the metal pipeline; calculating the strain of a corrosion area through the measured circular and axial stress of the corrosion area, and judging whether the pipeline in the corrosion area is invalid according to the stress and strain. The monitoring method has the effects and benefits that the safety situations of the metal pipeline can be monitored in real time, the corrosion defects can be positioned to obtain corrosion range, and whether the pipeline is invalid can be directly judged according to the stress and strain of the pipeline; and the monitoring method has the advantages of being safe and reliable, high in measurement precision, and non-destructive to a structure.

Owner:DALIAN UNIV OF TECH

Large range reinforcing steel corrosion monitoring sensor based on fiber bragg grating sensing technology

ActiveCN103411713AHigh elastic modulusChange space distanceForce measurement by measuring optical property variationFiberGrating

Owner:CCCC FOURTH HARBOR ENG INST +3

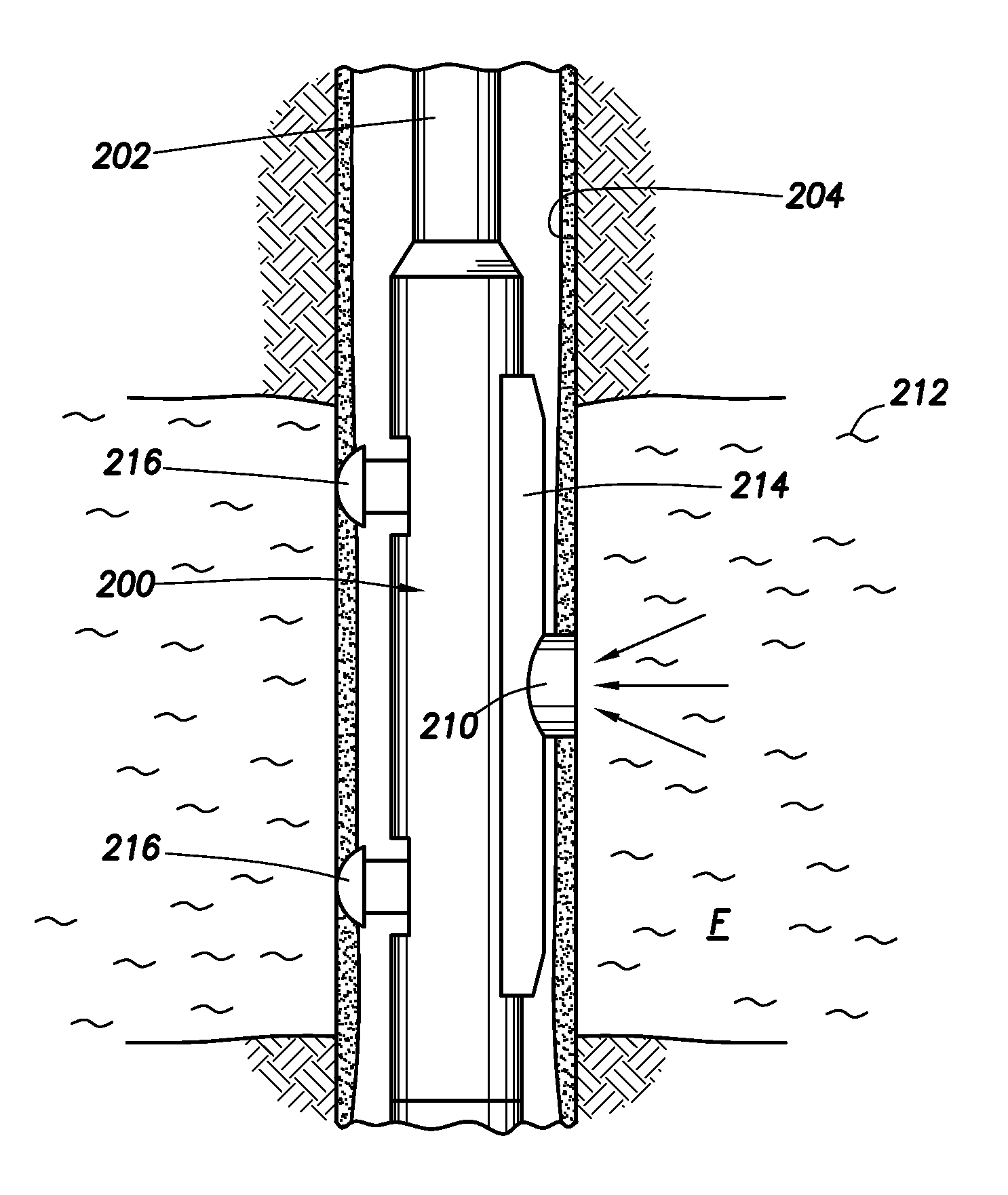

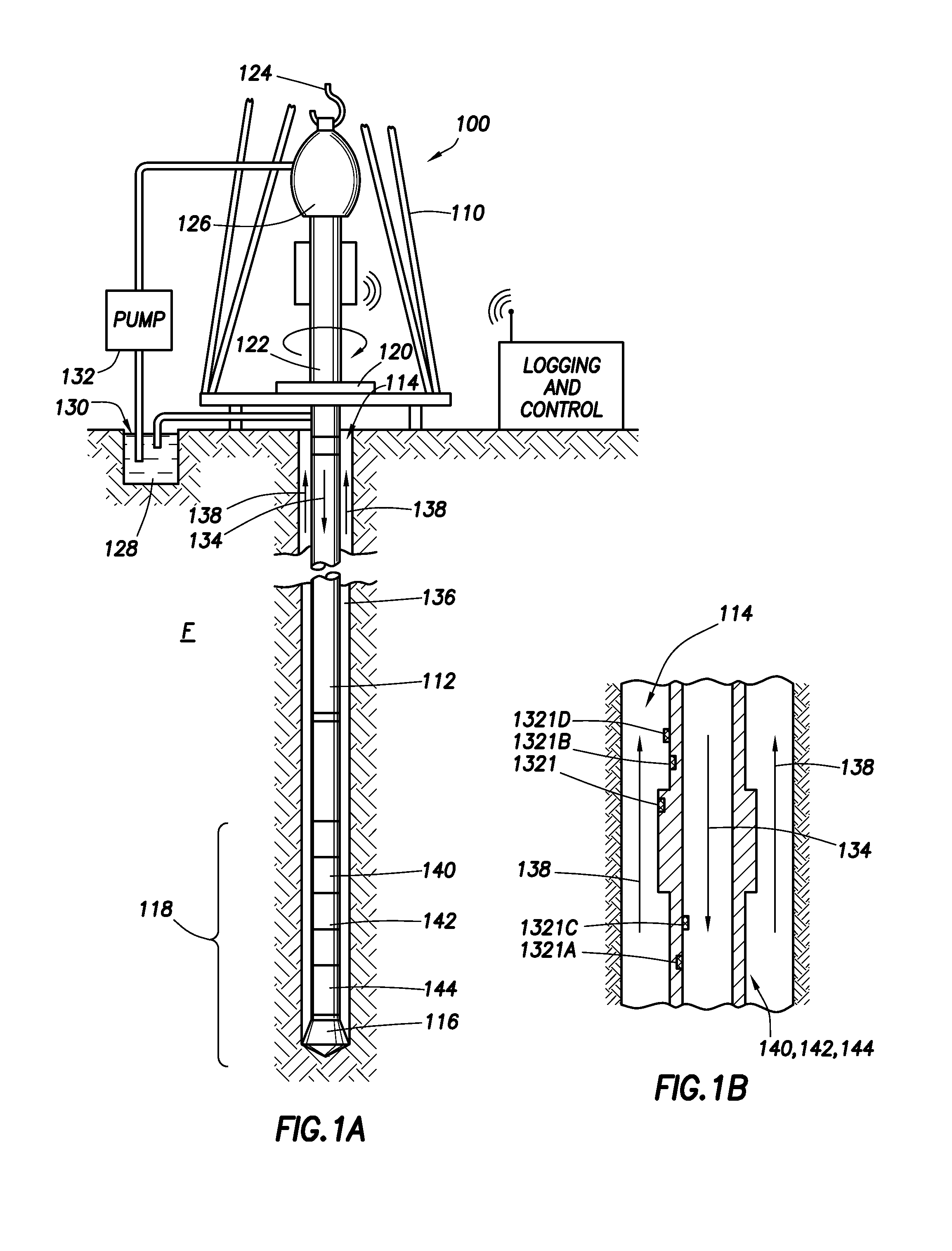

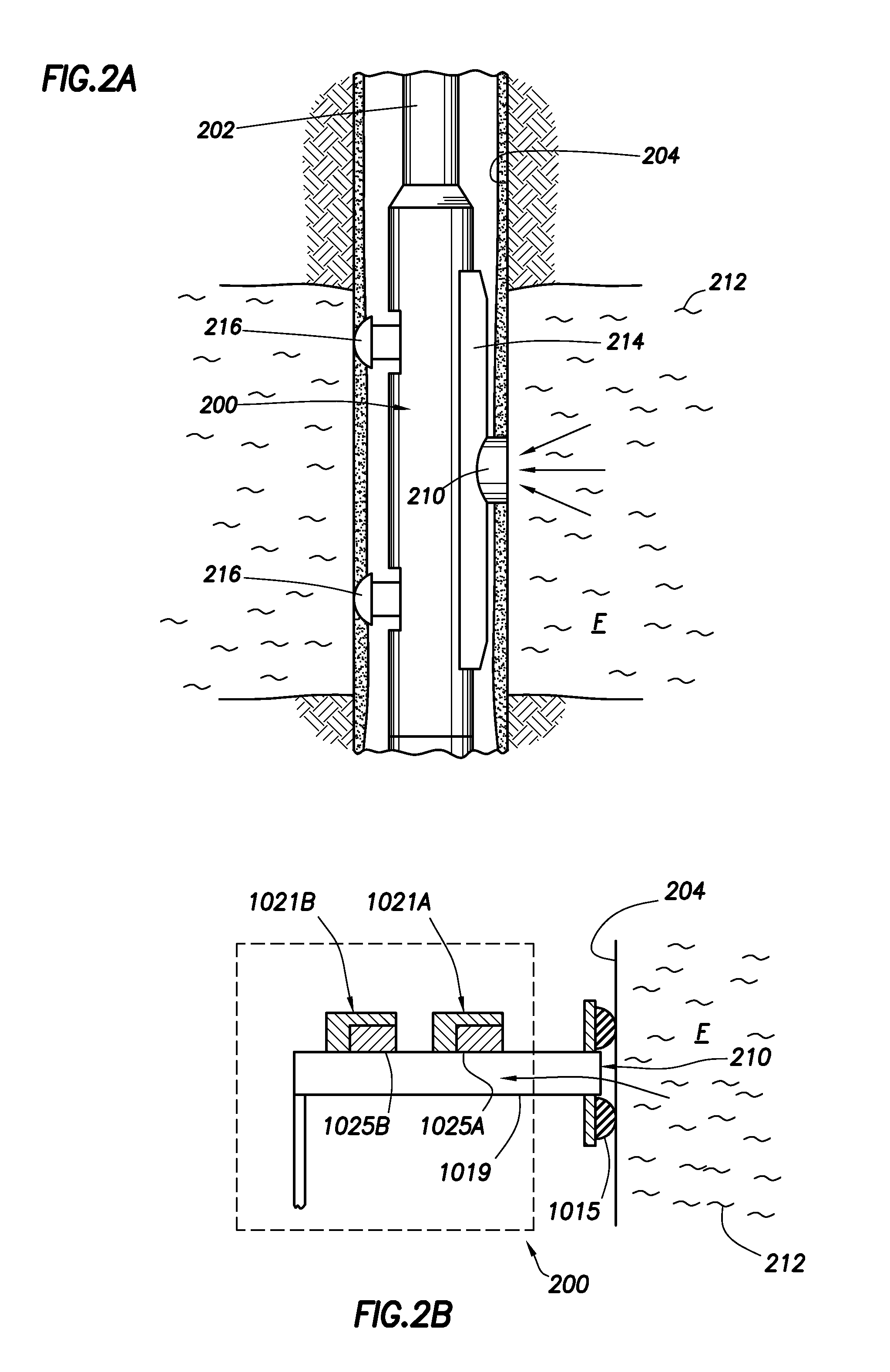

Downhole corrosion monitoring

Apparatus and methods for measuring an effect of corrosion with a corrosion sensor. The apparatus includes at least a portion of a metal material configured to be disposed within a borehole and exposed to a fluid. The apparatus includes a sensor configured to measure an effect of corrosion of the at least portion of the metal material within the fluid.

Owner:SCHLUMBERGER TECH CORP

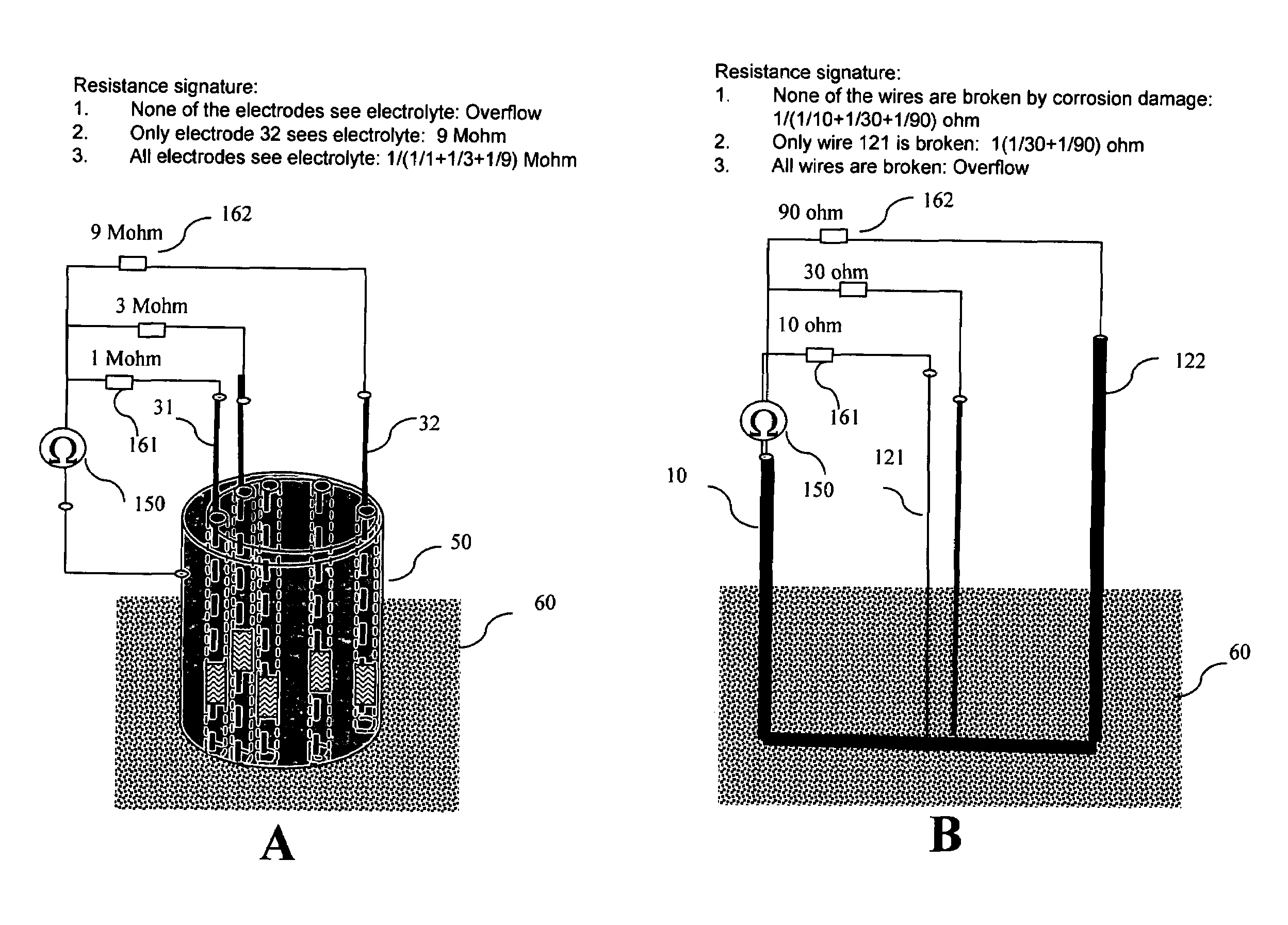

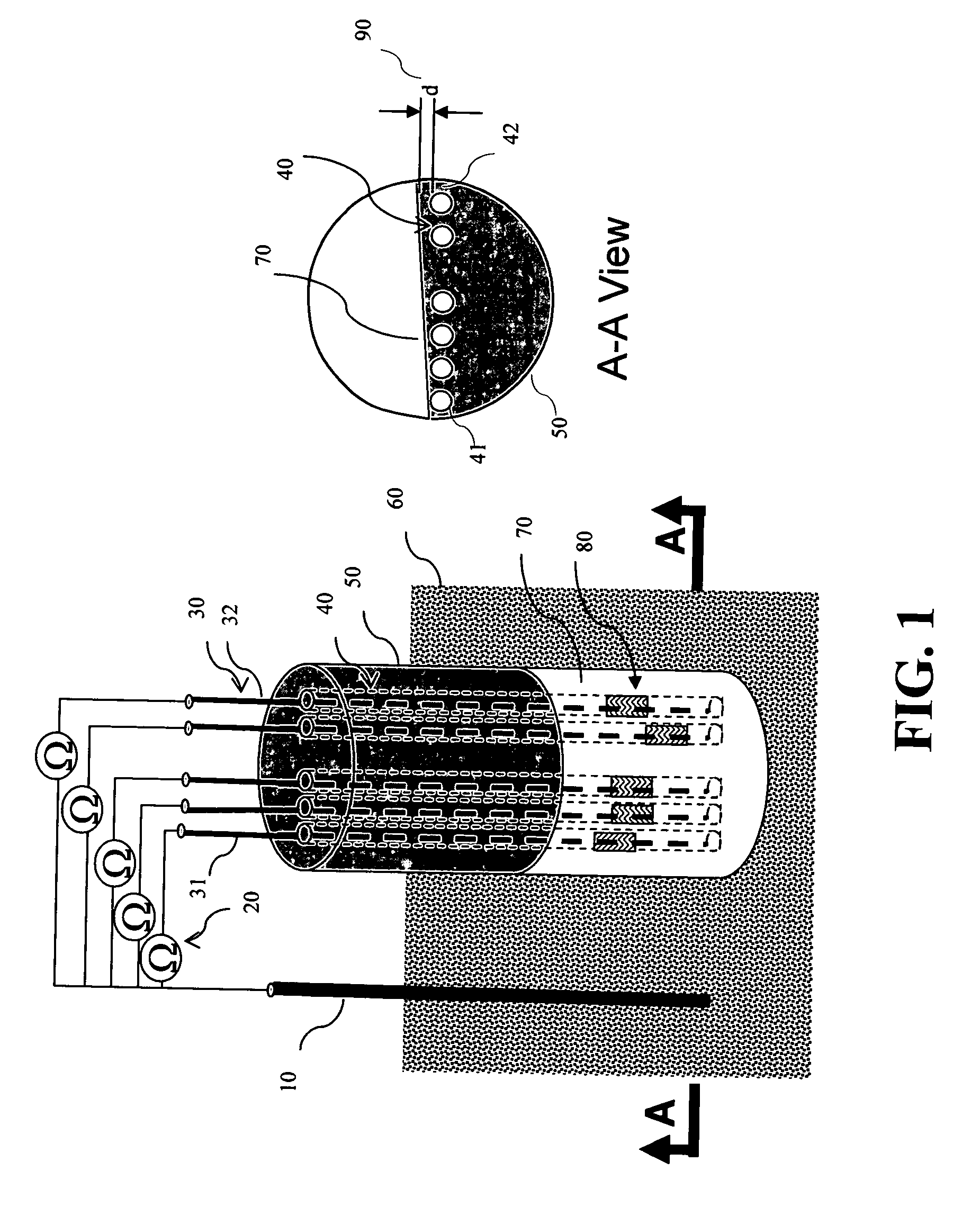

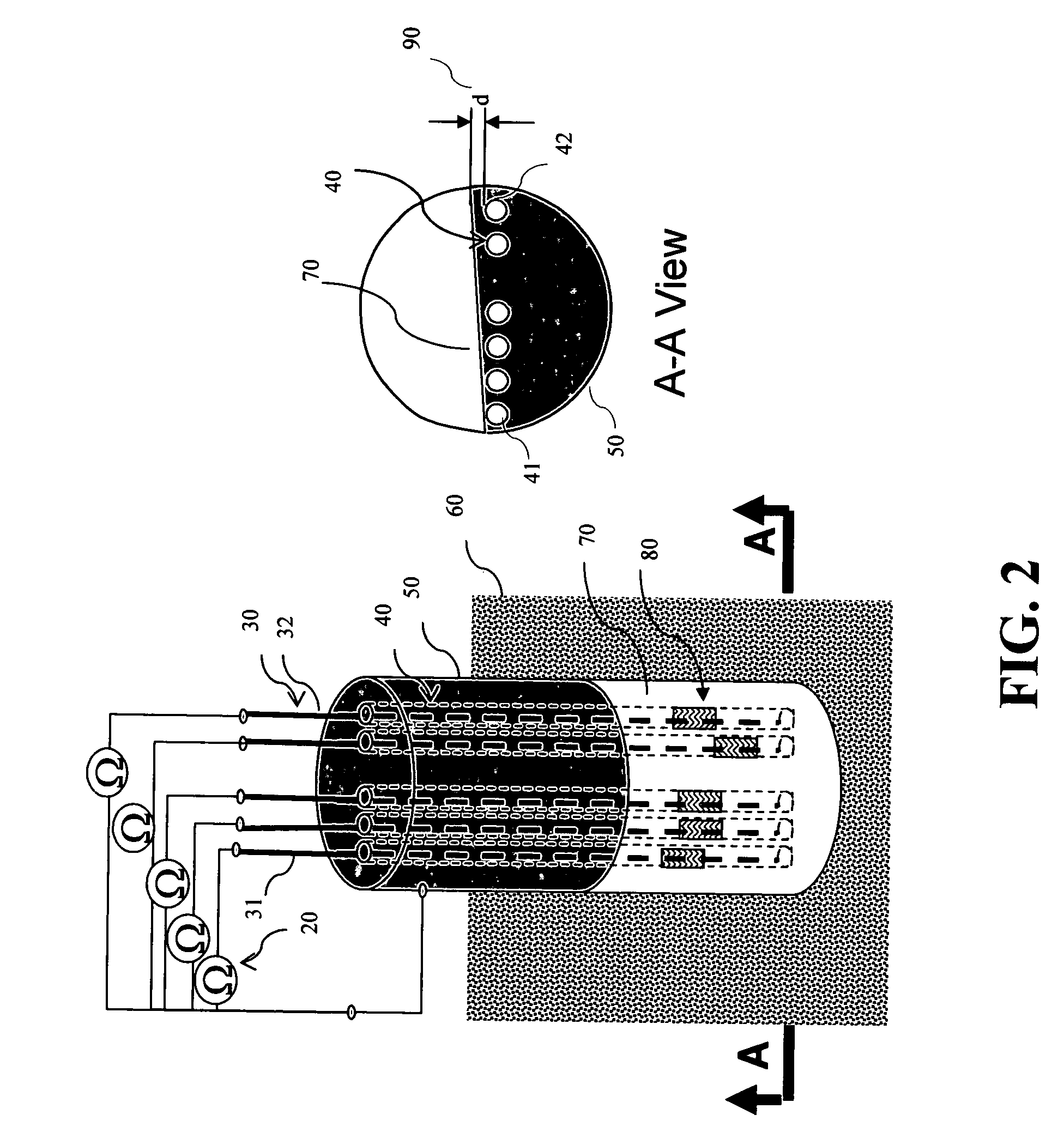

Multihole and multiwire sensors for localized and general corrosion monitoring

ActiveUS7508223B1Weather/light/corrosion resistanceResistance/reactance/impedenceLine sensorElectrical resistance and conductance

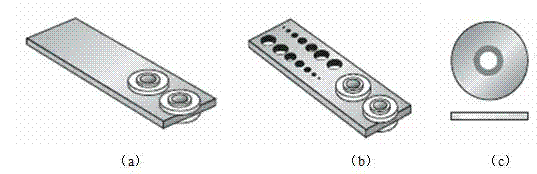

Methods of using multihole and multiwire sensors to measure general and localized corrosion penetration rates near real time are disclosed. The multihole penetration sensor is included of multiple electrodes embedded in individual cavities that are formed by a metal whose external surface is exposed to a corrosion environment. The distance between the inner surface and the external surface of the cavities (wall thickness) varies from one cavity to the other. The electrical resistance or current between each of the electrodes and a common electrode exposed to the same corrosion environment changes significantly when the wall of the cavity in which the electrode resides is perforated by corrosion and the corrosion medium is in contact with the electrode. The corrosion penetration rate is calculated by dividing the wall thickness of the different cavities by the time it takes to penetrate these cavities.

Owner:CORR INSTR

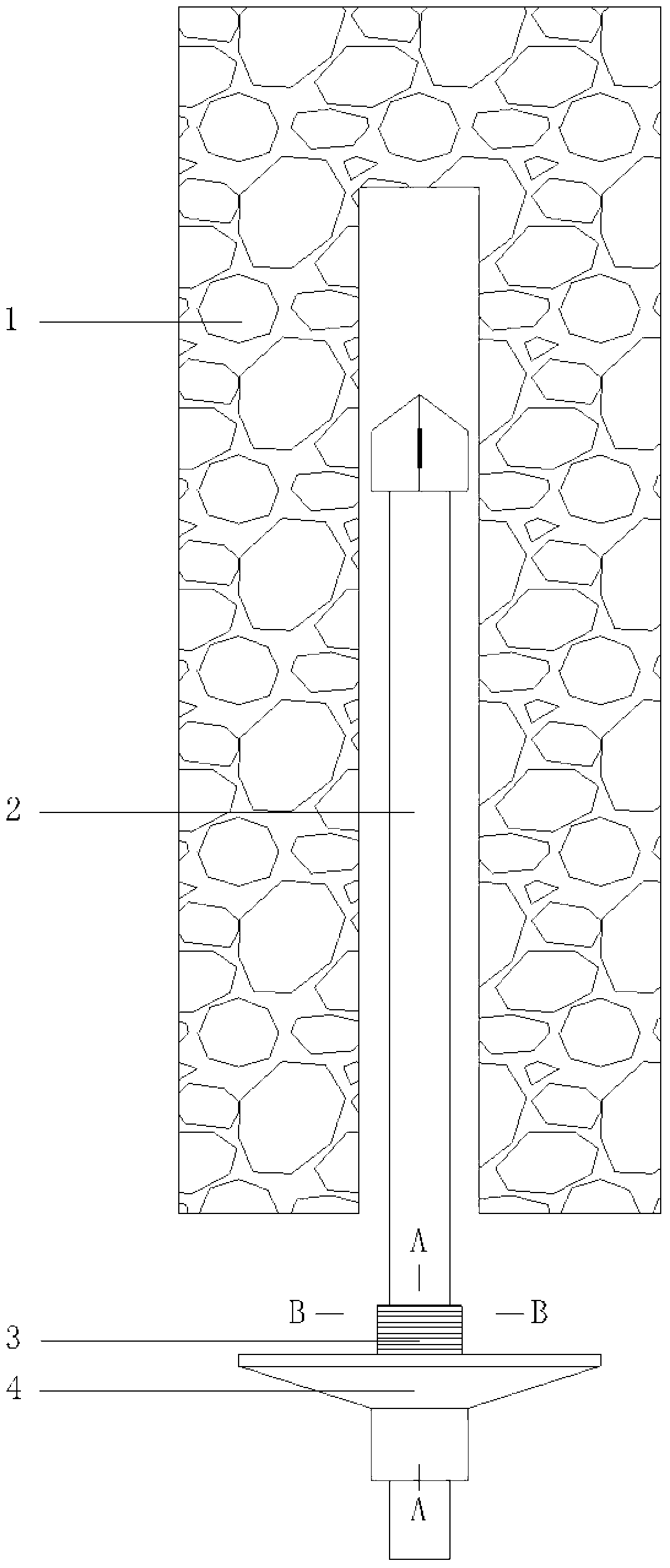

Fiber anchor pole corrosion sensor

InactiveCN103323385AIncreased durabilityInnovative designWeather/light/corrosion resistanceFiberGrating

A fiber anchor pole corrosion sensor, belongs to a geotechnical engineering technology field. The fiber anchor pole corrosion sensor is characterized in that: the sensor is composed of a fiber corrosion expansion monitoring unit, a fiber grating temperature compensating unit and a fiber grating stress correction unit in layers, wherein the fiber corrosion expansion monitoring unit, which is a key component, is composed of a porous medium cushion layer, a bare fiber winding layer, an externally-coated cement mortar protective layer and an armoured signal transmission optical cable. The optical fiber is wound on a steel bar anchor pole and a steel strand anchor pole, protective layers are internally and externally arranged, radial expansion strain of the anchor pole caused by corrosion is measured, and quantitative monitor of corrosion degree of an anchor pole steel bar or a steel strand is implemented. The invention provides an anchor pole corrosion monitoring sensor which has advantages of clear principle, high measurement precision, low cost and high endurance, and the anchor pole corrosion monitoring sensor can implement long-term and stable quantitative monitor on a corrosion state of the anchor pole, and makes sure structural safety of the anchor pole.

Owner:DALIAN UNIV OF TECH

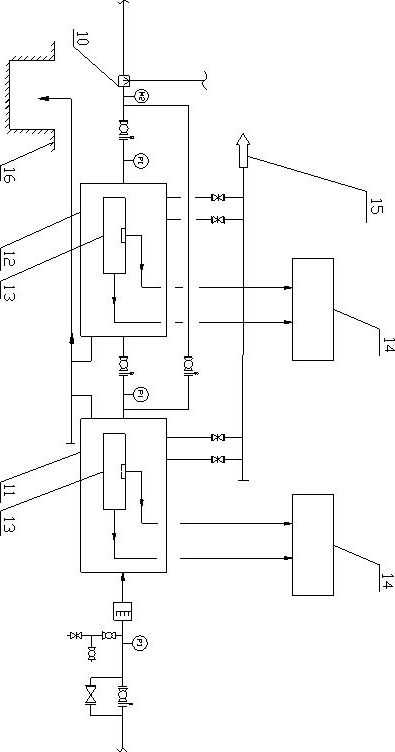

Device and method for evaluating inhibitor film integrity under scouring work conditions

InactiveCN105823703AAccurate measurementReal-time online monitoring Online monitoring of corrosion statusWeather/light/corrosion resistanceMaterial analysis by optical meansObservation unitEngineering

The invention discloses a device and method for evaluating inhibitor film integrity under scouring work conditions and belongs to the technical field of petrochemical engineering corrosion and protection. The device comprises a supplied flow circulating unit, a shear force measuring unit, an electrochemical monitoring unit, a camera shooting observation unit, a test piece testing unit and an inhibitor injection unit. By means of the device and method, evaluation of integrity of an inhibitor film can be achieved. Firstly, flow shear force is measured through the shear force measuring unit under different scouring work conditions, the corrosion rate is measured through the test piece testing unit, online corrosion monitoring is conducted through the electrochemical monitoring unit, the surface appearance of a test piece is observed and recorded through the camera shooting observation unit, integrity of the inhibitor film is comprehensively evaluated through data comparison and analysis, critical parameters are obtained when integrity of the inhibitor film is damaged, finally an inhibitor is injected through the inhibitor injection unit so that the inhibitor film can be repaired to be complete, and therefore monitoring and evaluation of stability, damage and repair of the inhibitor film are achieved.

Owner:SOUTHWEST PETROLEUM UNIV

High precision corrosion monitoring sensor assembly and system

ActiveUS8365601B2Improve accuracyRigid enoughAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansUltrasonic sensorEngineering

A high-precision corrosion monitoring sensor assembly is provided for permanent mounting on a vessel to measure wall thickness of the vessel. The assembly includes an ultrasonic transducer and a delay line, which are bonded to the vessel wall a first location. The assembly is further bonded to the vessel by an adjustable fixture. The assembly includes a cross-member attached to the ultrasonic transducer, having a pivot pin at each distal end. The pivot pins are attached to a first tower and a second tower, which bond to the outer vessel wall at a second location and a third location. The position of the first and second towers can be adjusted with respect to angle and placement about the pivot pins. Fasteners are attached to the pivot pins and can be tightened to make rigid the fixture, thereby allowing configuration of the assembly for use on flat surfaces and small-diameter pipes.

Owner:SAUDI ARABIAN OIL CO +1

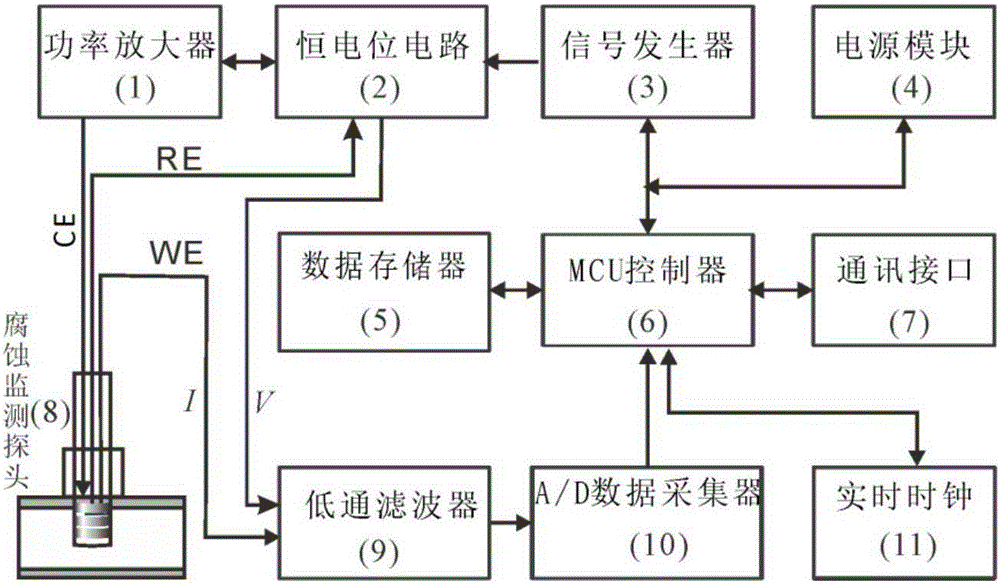

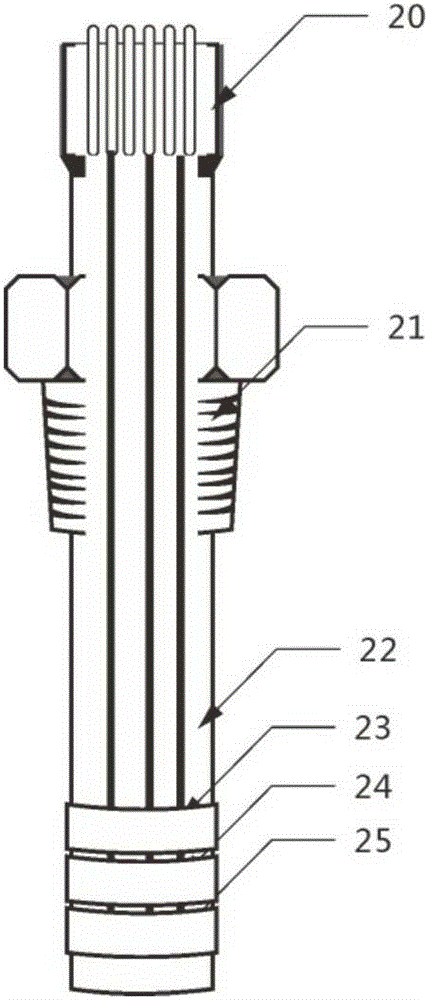

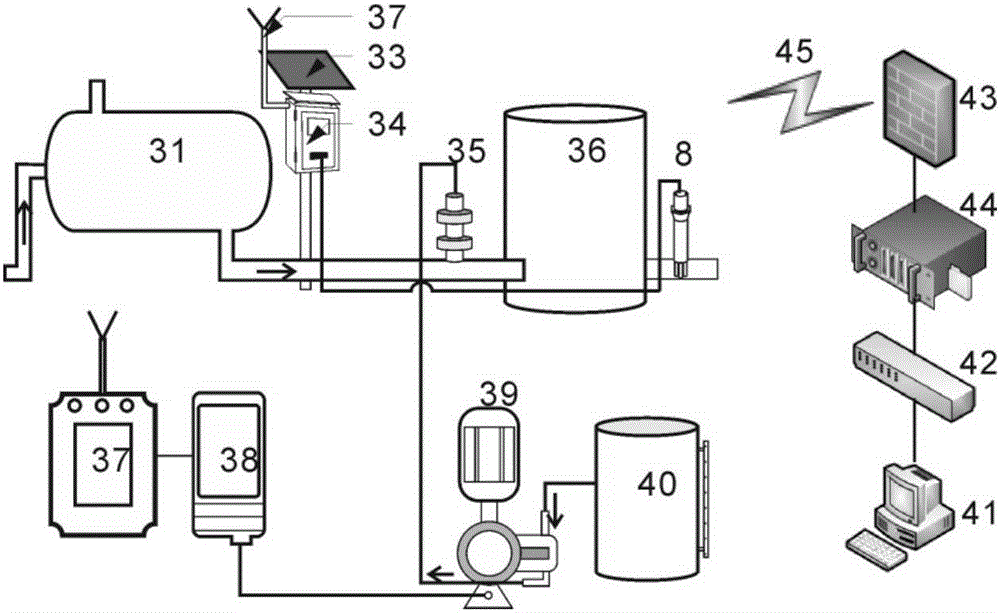

Device for monitoring corrosion of oil and gas field gathering pipelines and corrosion inhibitor filling system

ActiveCN105181568AImprove anti-interference abilityImprove accuracyWeather/light/corrosion resistanceCorrosion preventionLow-pass filterEngineering

The invention discloses a device for monitoring corrosion of oil and gas field gathering pipelines. The device comprises an MCU, a signal generator, a constant-potential circuit, a power amplifier, a corrosion monitoring probe low-pass filter and an A / D data acquisition unit. The MCU controller is used for transmitting waveform data to the signal generator to generate sine waves at certain frequency, loading the sine waves to the constant-potential circuit to form polarization current and outputting the polarization current to a corrosion monitoring probe through the power amplifier. Polarization potential and the polarization current of the corrosion monitoring probe are filtered through the low-pass filter and then transmitted to the A / D data acquisition unit to be acquired, the MCU is used for processing acquired potential and current data, dielectric resistance and polarization resistance of a working electrode can be obtained, the corrosion rate of the working electrode can be obtained, and then pipeline corrosion monitoring is achieved. The invention further discloses an intelligent corrosion inhibitor filling device. The filling concentration of corrosion inhibitor can be adaptively and dynamically adjusted according to the measured value of the pipeline corrosion rate and a fuzzy control algorithm, and therefore the pipeline corrosion control strategy is optimized accordingly, and scientific filling of the corrosion inhibitor is achieved.

Owner:WUHAN CORRTEST INSTR

System and method for online monitoring of corrosion of gas turbine components

ActiveUS8475110B2Accurate predictionPropellersVolume/mass flow measurementEngineeringCorrosion behavior

Owner:GENERAL ELECTRIC CO

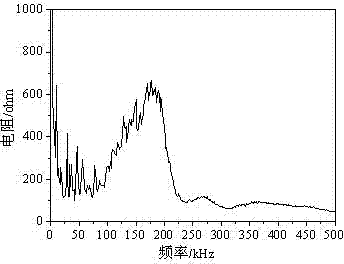

Piezoelectric sensor for steel-bar corrosion monitoring and steel-bar corrosion monitoring method

InactiveCN103575769AEnable long-term monitoringRealize long-term non-destructive monitoringWeather/light/corrosion resistanceMaterial resistanceRebar corrosionFirming agent

The invention relates to a piezoelectric sensor for steel-bar corrosion monitoring and a steel-bar corrosion monitoring method, and belongs to the technical field of monitoring of an intelligent sensor in a reinforced concrete structure. The sensor is composed of piezoelectric ceramics, an electrode face, an encapsulation layer composed of cement, epoxy resin and curing agent, and shielded conducting wires. The monitoring method based on the sensor comprises the following steps: coupling the piezoelectric sensor and steel bars by adopting a mixture of cement, epoxy resin and curing agent as a bonding agent, testing an electrical impedance-frequency spectrogram of the sensor at different periods, then carrying out root-mean-square deviation calculation, and taking a calculation result as quantification index of judging the condition of steel-bar corrosion inside concrete. The piezoelectric sensor provided by the invention has the characteristics of simpleness in preparation, convenience in use, good in durability and the like; the monitoring method based on the sensor has the characteristics of being accurate, reliable, convenient and intuitive.

Owner:UNIV OF JINAN

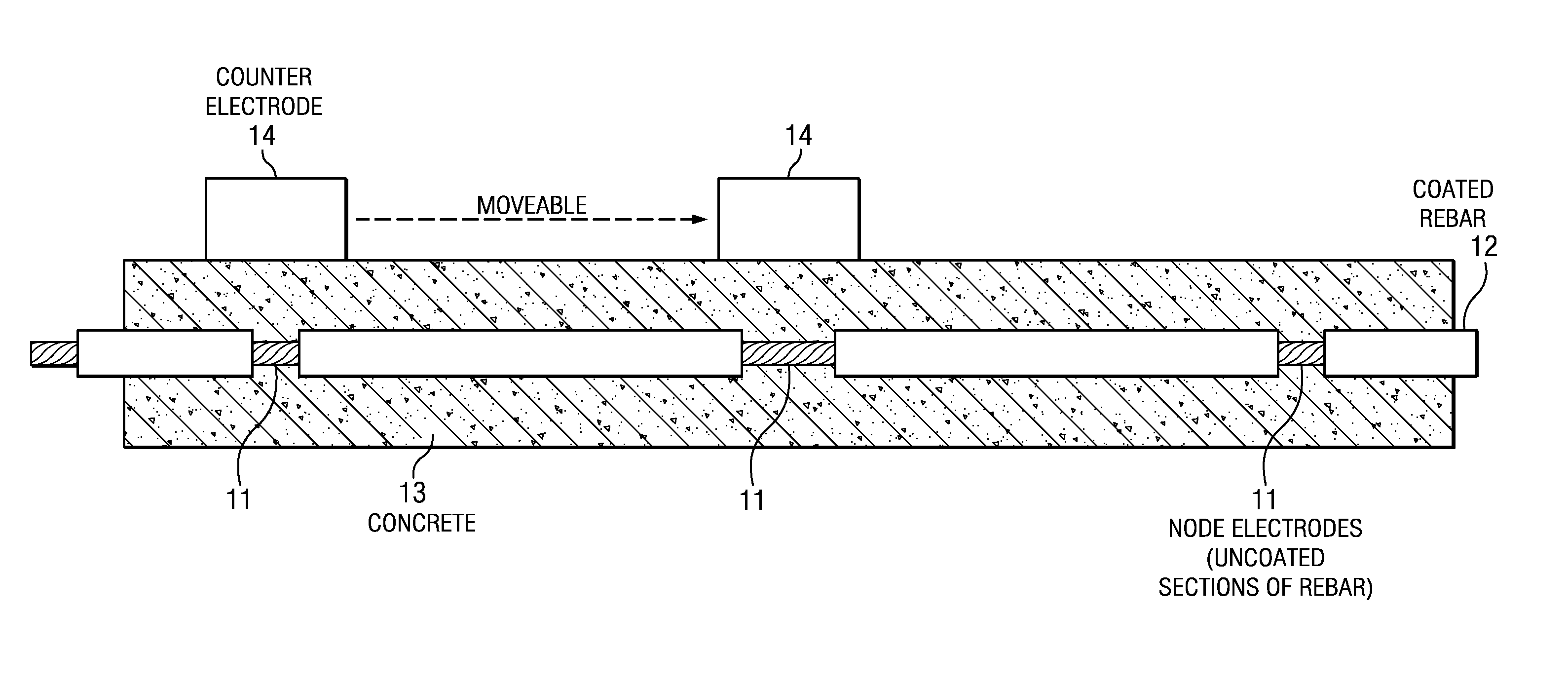

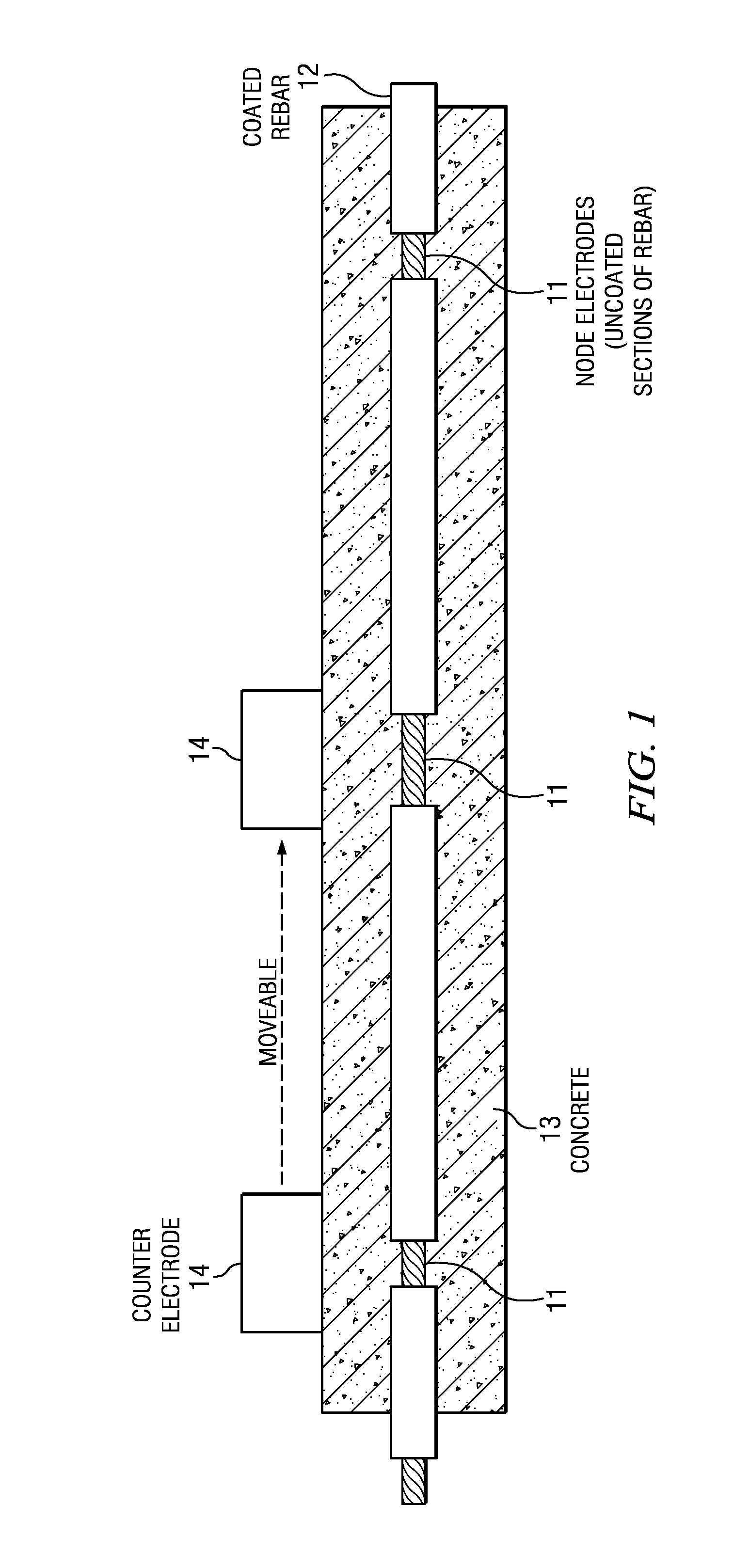

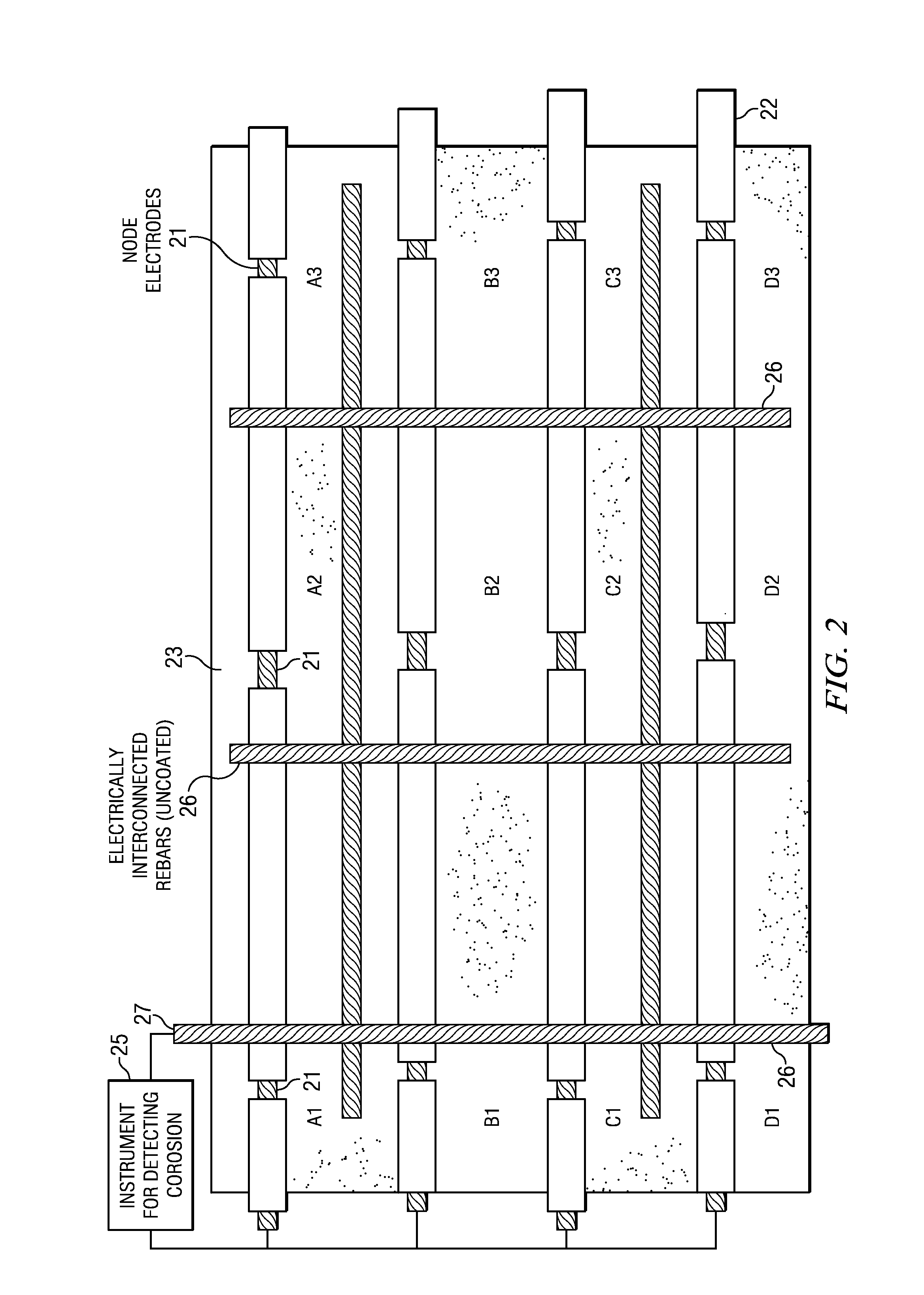

Corrosion Monitoring of Concrete Reinforcement Bars (Or Other Buried Corrodable Structures) Using Distributed Node Electrodes

ActiveUS20120043981A1Weather/light/corrosion resistanceResistance/reactance/impedenceElectricityStructure of the Earth

Systems and methods for real time detection of corrosion of rebars embedded in a concrete structure. Test bars are selected for corrosion testing purposes, and may or may not also be part of the concrete reinforcement structure. These test bars are coated, and exposed sections of these test bars form a network of node electrodes. Electrical measurement from a counter electrode near a node electrode provides an indication of corrosion at that node electrode. Using a system of node electrodes and counter electrodes, a large concrete area may be monitored, and if corrosion is indicated, a methodical selection of electrodes can be used to locate the corrosion. The same concepts may be applied to detect corrosion in buried structures, such as pipelines and tanks.

Owner:SOUTHWEST RES INST

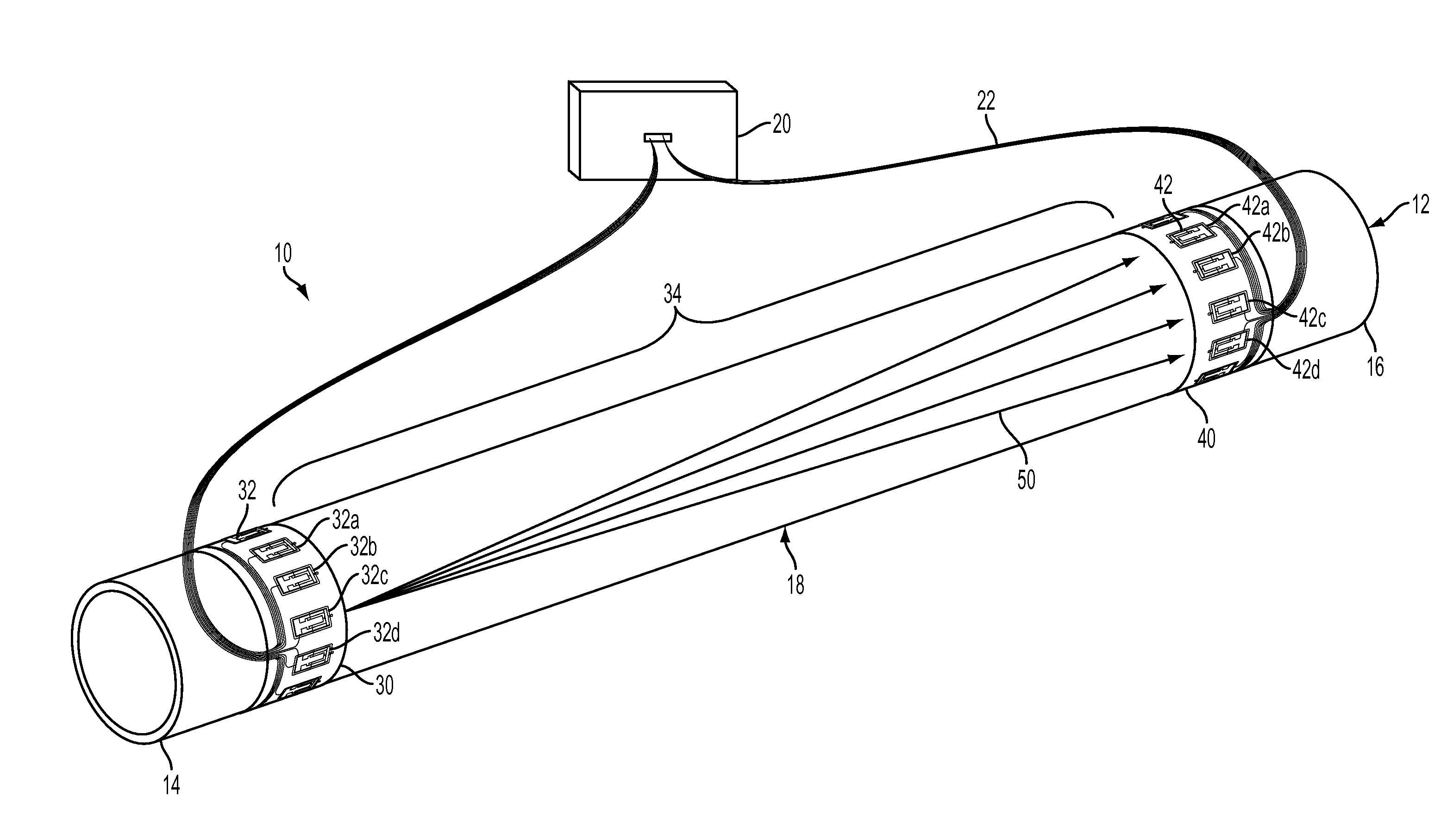

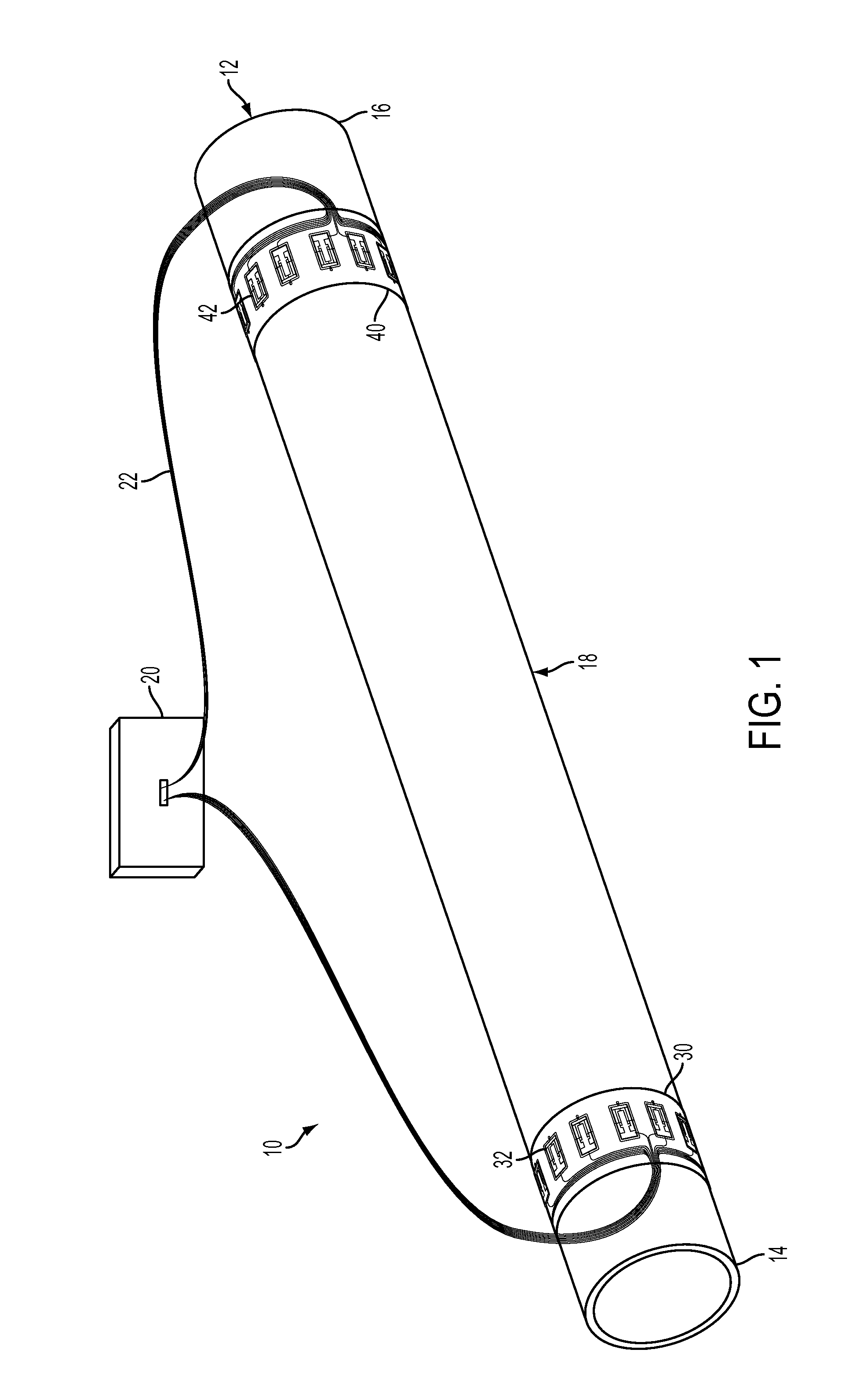

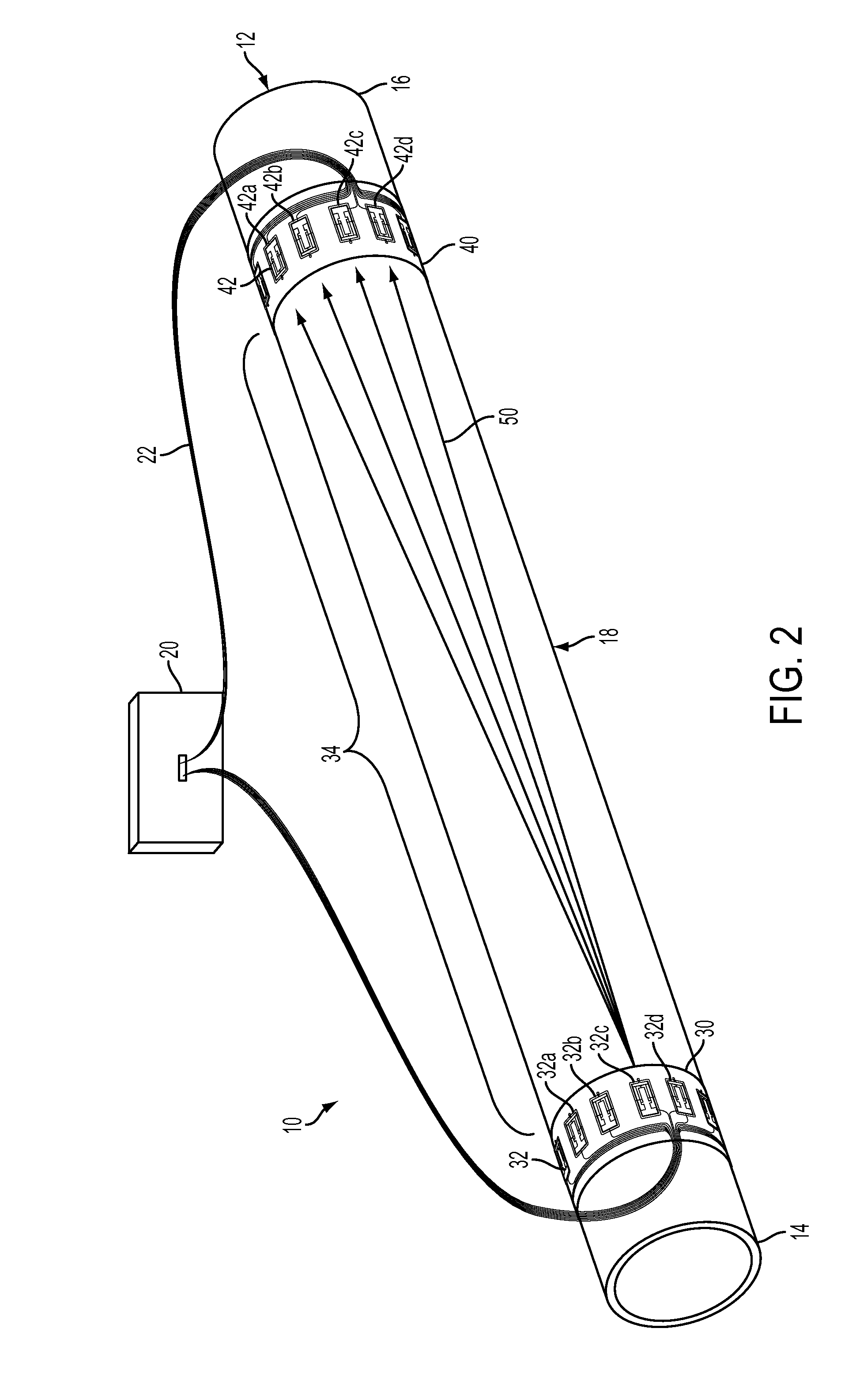

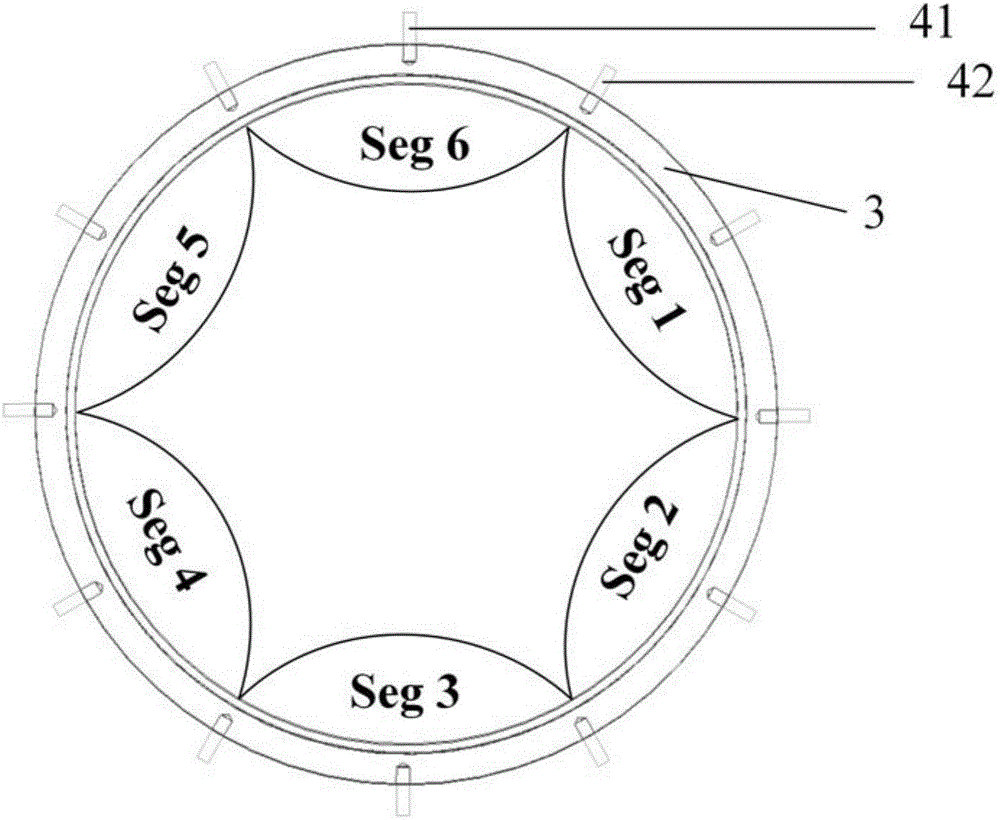

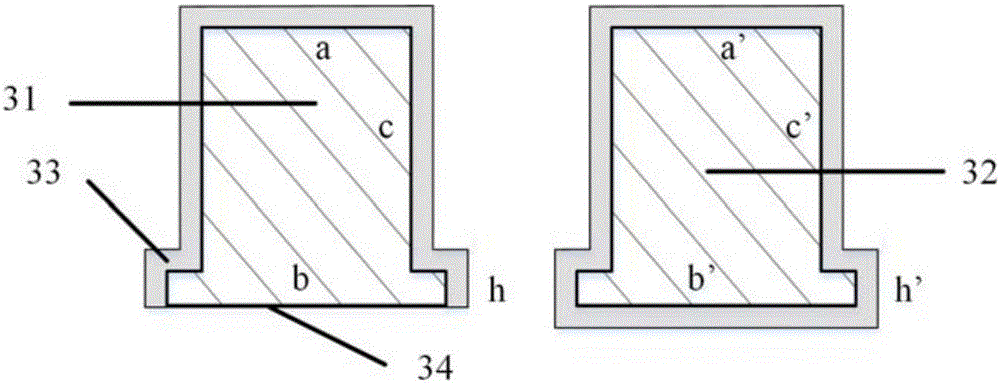

Sensor positionig with non-dispersive guided waves for pipeline corrosion monitoring

ActiveUS20140202249A1Analysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic sensorTransducer

An ultrasonic sensor assembly for testing a pipe includes a first and second transducer rings attached to the pipe and spaced apart along a length of the pipe. The first transducer ring includes a plurality of transmitters for transmitting a wave, such as a non-dispersive guided wave. The first transducer ring transmits the wave along the pipe. The second transducer ring includes a plurality of receivers for receiving the wave. A relative position of the first transducer ring with respect to a circumferential position of the second transducer ring is determined based on characteristics of the wave received by the second transducer ring. A method of positioning the ultrasonic sensor assembly on the pipe is also provided.

Owner:BAKER HUGHES INC

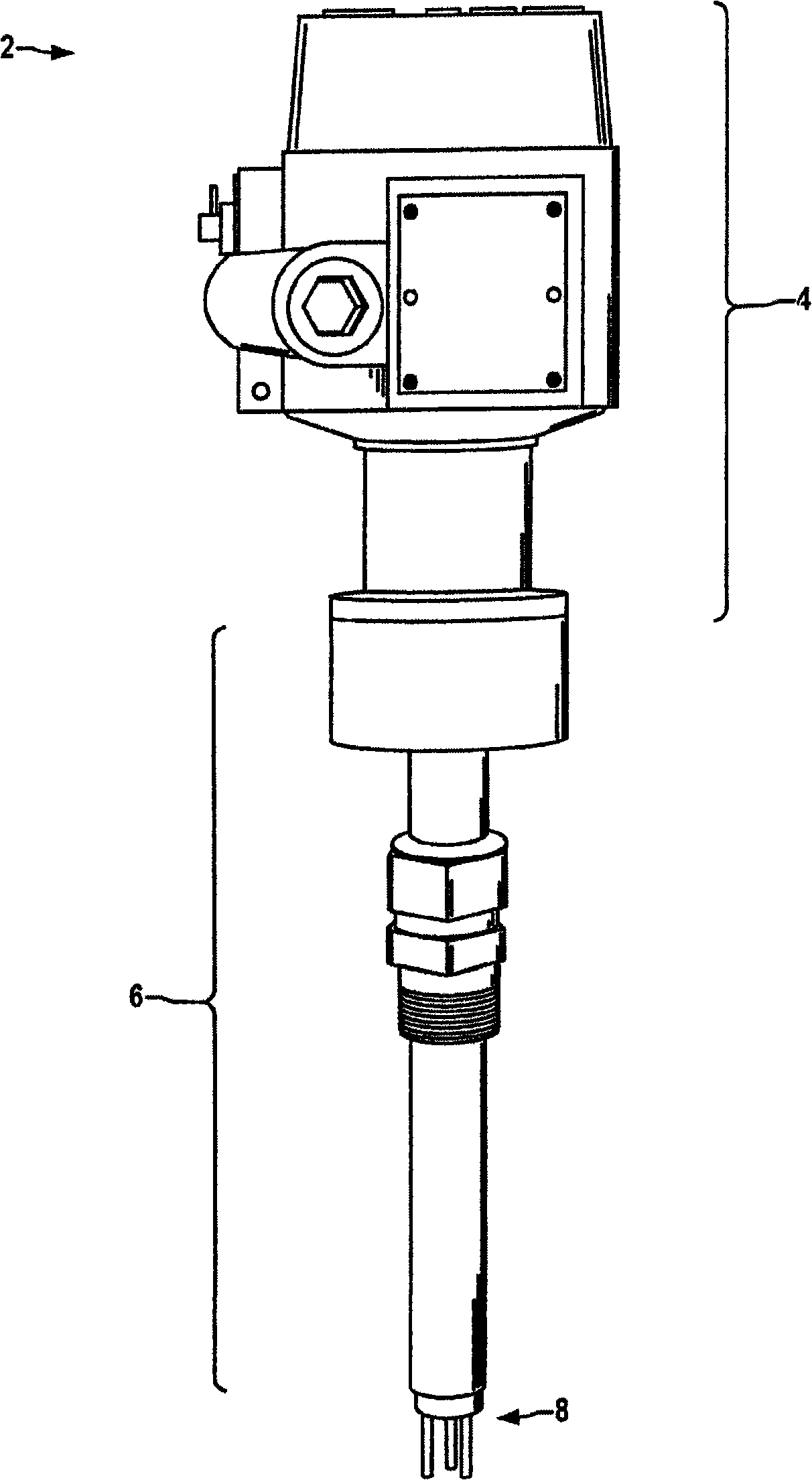

Corrosion measurement field device

InactiveCN101517420AImprove noise immunityWeather/light/corrosion resistanceResistance/reactance/impedenceField deviceTransmitter

Low power corrosion measurement (2) devices are described with programmable configuration for implementing one or more advanced corrosion measurement (2) types to provide conductivity, general corrosion, and / or localized corrosion values in a field transmitter (4) for online corrosion monitoring or off-line corrosion data logging.

Owner:ALABAMA SPECIALTY PROD

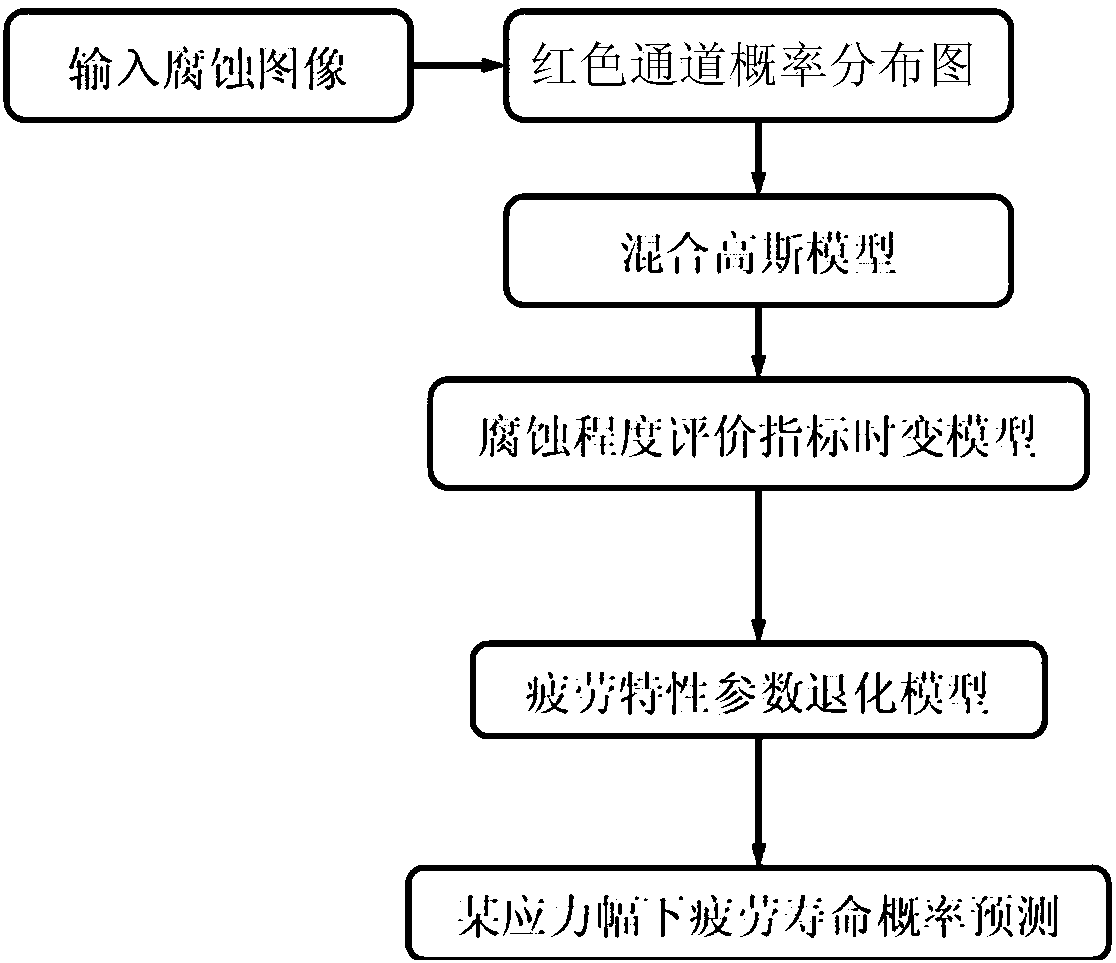

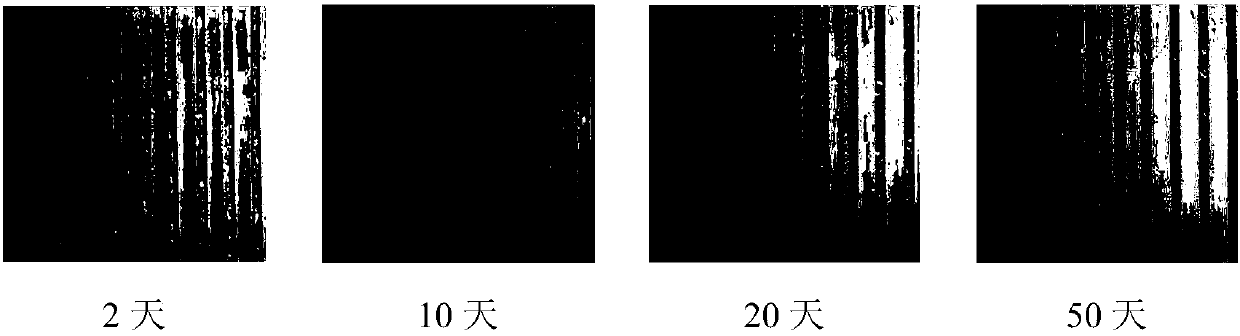

Method for monitoring and recognizing pulling rope corrosion and evaluating fatigue life on basis of computer vision

ActiveCN108225906AImprove accuracyImprove stabilityWeather/light/corrosion resistanceStrength propertiesPattern recognitionData set

The invention provides a method for monitoring and recognizing pulling rope corrosion and evaluating a fatigue life on the basis of computer vision. The method comprises the following steps: shootingan image of a corroded high-strength steel wire by a perspective inspection window at an anchoring end of a pulling rope, extracting image characteristics from the image, then building a corrosion-degree evaluation model, then building a fatigue-life characteristic energy number evaluation model, matching with a performance degrading state of the corrosion and the fatigue of the steel wire under an artificially accelerated corrosion test, and finally finishing the corrosion-state recognition and the fatigue-life evaluation of the in-service pulling rope. The method provided by the invention has the beneficial effects that the recognition accuracy is high, the speed is fast and the cost is low; the requirement for real-time data processing of online monitoring and early warning of corrosionand fatigue of the pulling rope also can be met, i.e., the image acquired by a consumer-grade ordinary camera is directly recognized without data-set updating; the automation, intelligentization, accuracy and robustness of corrosion monitoring and recognition and fatigue-life evaluation of the pulling rope are improved, and a solution is provided for automatic monitoring and recognition of the corrosion and the fatigue of the pulling rope of a bridge structure.

Owner:HARBIN INST OF TECH

Method and apparatus for corrosion detection

ActiveUS7388386B2Inhibiting the flow of current through the deviceSimple digital signal approachWeather/light/corrosion resistanceResistance/reactance/impedenceMultiple sensorOutput device

Owner:BL TECH INC

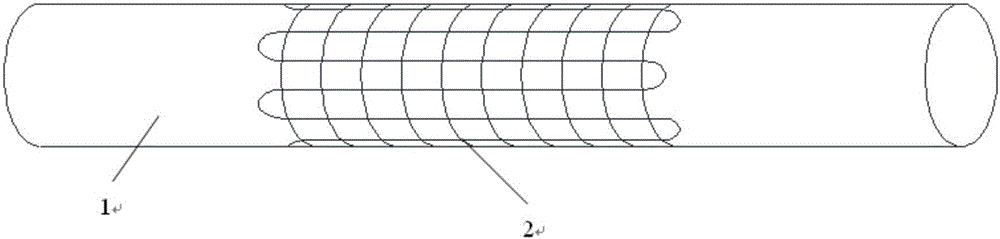

Monitoring device and monitoring method for corrosion of inner wall of pipeline

ActiveCN106706506AMonitoring for localized corrosion problemsMonitor galvanic currentWeather/light/corrosion resistanceElectrical resistance and conductanceControl system

The invention discloses a monitoring device and a monitoring method for corrosion of an inner wall of a pipeline. The device comprises an array annular resistance corrosion sensor, a zero-resistance galvanometer, micro-ohm meters and a signal acquisition control system, wherein the array annular resistance corrosion sensor comprises n corrosion elements and n reference elements; the n corrosion elements and the n reference elements are arranged at intervals through connecting parts; each corrosion element is matched with a relay switch and is coupled through the n micro-ohm meters; the micro-ohm meters are arranged in an external electronic cabin; each annular electrode element is connected to the corresponding micro-ohm meter through the relay switch; the micro-ohm meters are arranged in the external electronic cabin; the signal acquisition control system is used for acquiring and storing measured data of the zero-resistance galvanometer and the micro-ohm meters and controlling the movement of the relay switches. The device disclosed by the invention can be used for accurately monitoring a partial corrosion condition of the pipeline and the defect in the prior art that the partial corrosion monitoring along a pipeline direction cannot be monitored is overcome.

Owner:DALIAN UNIV OF TECH

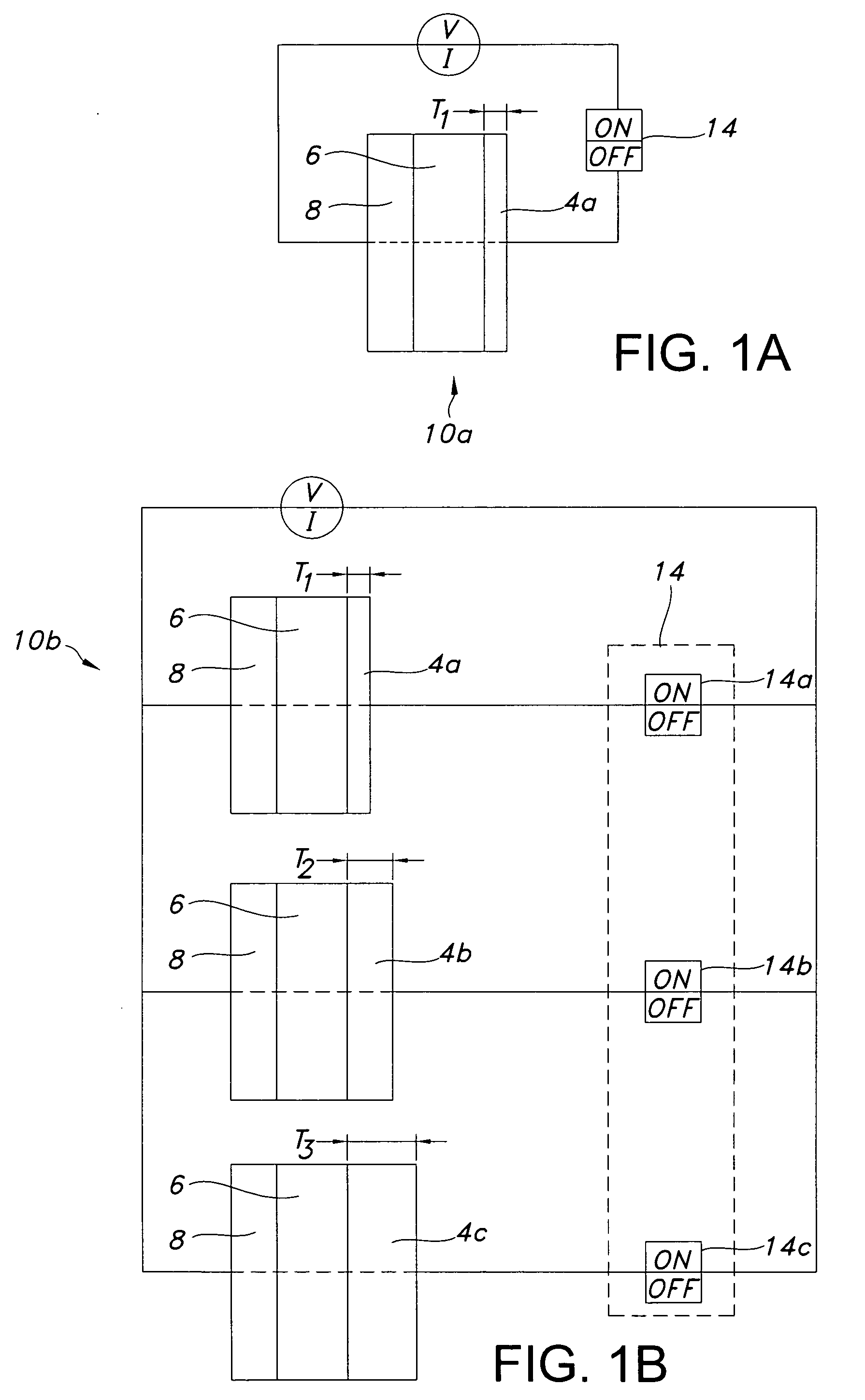

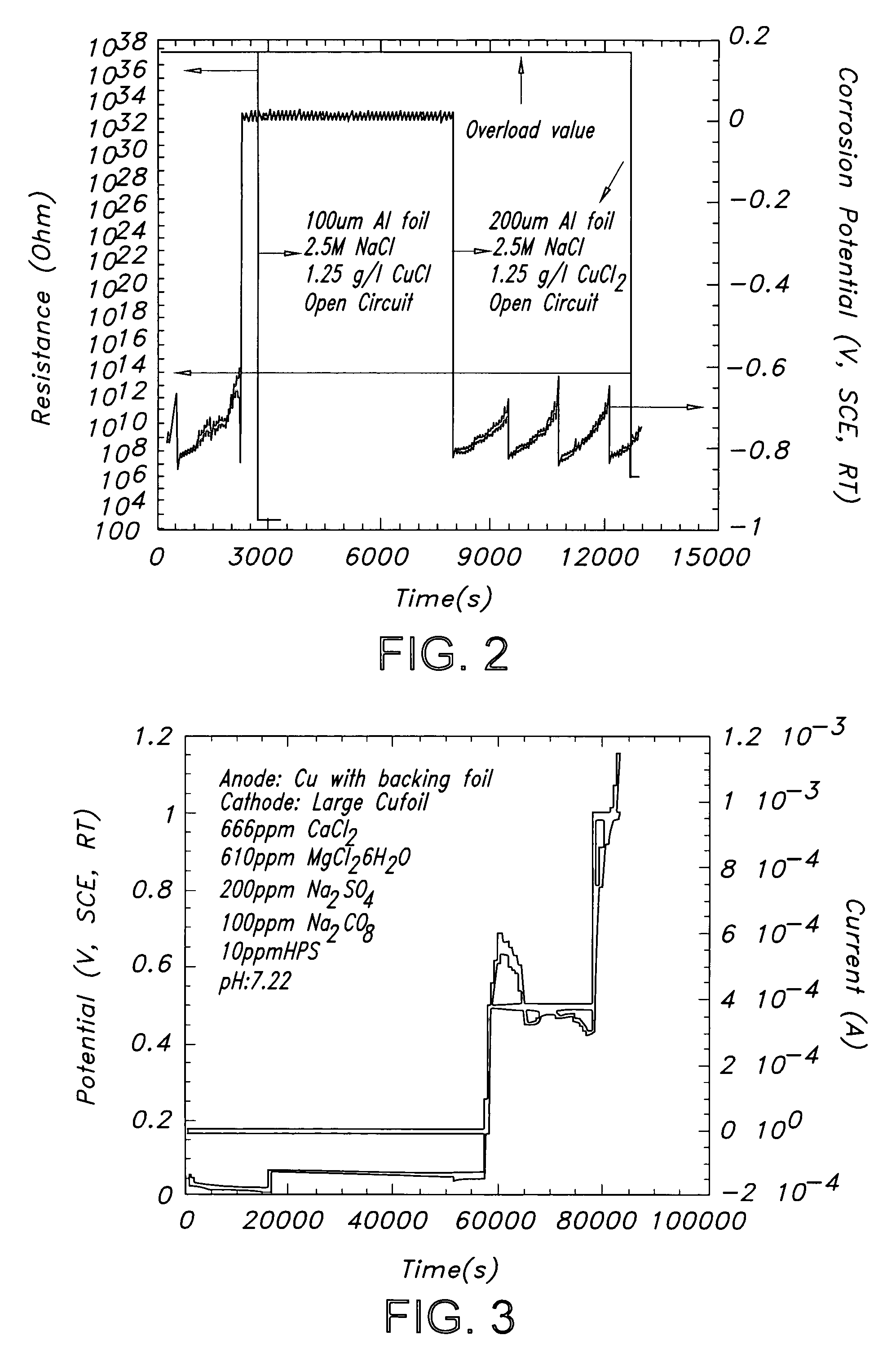

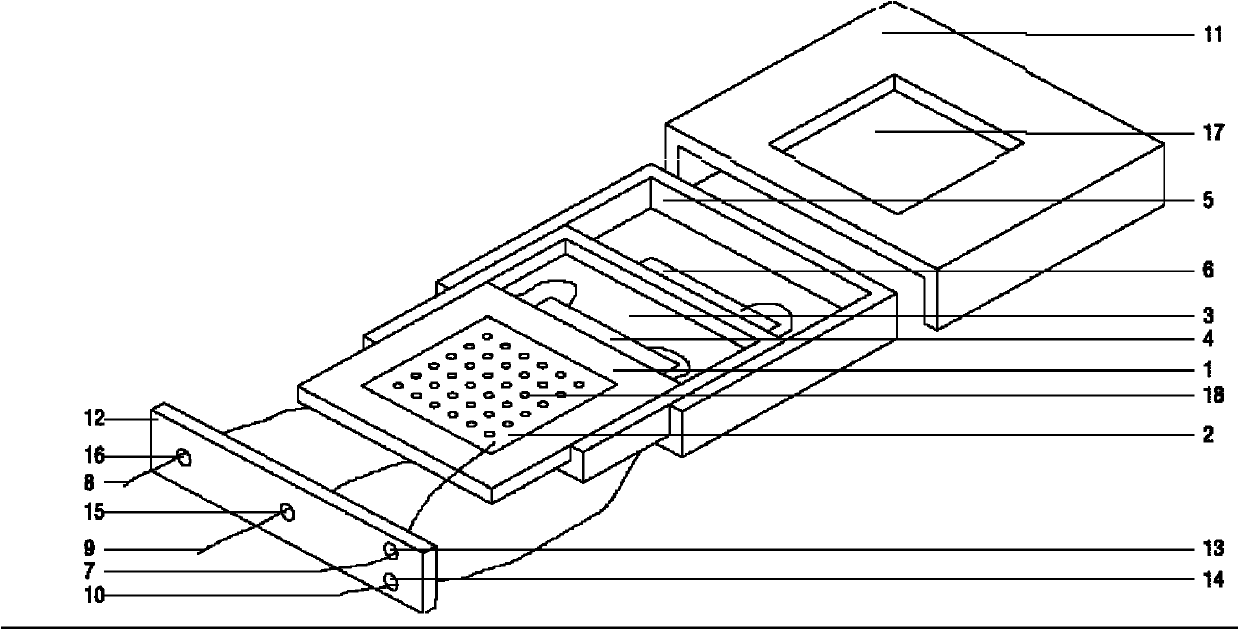

Method and apparatus for corrosion detection

ActiveUS20070229095A1Simple digital signal approachImpedanceWeather/light/corrosion resistanceResistance/reactance/impedenceMultiple sensorEngineering

A corrosion monitoring device for monitoring corrosion in fluid containing systems and other equipment exposed to a corrosive environment comprising sensor elements having a composition substantially the same as the equipment being monitored, the sensor elements having a predetermined thickness for exposure to a corrosive solution of the fluid containing system. An electrical property of the monitoring device changes when corrosion penetrates through the thickness of the sensor element. A digital output device generates a first binary signal when corrosion has not penetrated through the thickness of the sensor elements, and a second binary signal when corrosion has penetrated through the thickness of the sensor elements. Multiple sensor elements may be used to provide multiple binary signals. Information from the digital outputs may be processed to provide a cumulative log of corrosion measurements.

Owner:BL TECH INC

Variable capacitance-based sensor for corrosion monitoring of steel structure surface and manufacturing method thereof

InactiveCN102519865ASimple structureEasy to installWeather/light/corrosion resistanceElectric/magnetic area measurementsElectrical resistance and conductanceStructure of the Earth

The invention discloses a variable capacitance-based sensor for corrosion monitoring of a steel structure surface and a manufacturing method thereof. The variable capacitance-based sensor for corrosion monitoring of a steel structure surface comprises an insulating housing with a top open mouth. The interior of the variable capacitance-based sensor for corrosion monitoring of a steel structure surface is divided into an upper layer, a middle layer and a lower layer. Each one of the upper layer, the middle layer and the lower layer comprises an insulating medium plate and a corroded steel material layer pasting on the insulating medium plate. Lead wires are leaded out from the corroded steel material layers. The lead wires respectively pass through holes of an insulating plate. The manufacturing method comprises the following steps of 1, preparing the insulating medium plates, 2, carrying out a drill process on a drilling zone located in the centre of each one of the insulating medium plates, 3, preparing the corroded steel material layers, 4, leading out the lead wires from the corroded steel material layers, 5, carrying out assembling, 6, plugging all gaps of the variable capacitance-based sensor for corrosion monitoring of a steel structure surface by silicon rubber, and 6, based on an area-alterable capacitance sensor work principle, determining a corrosion loss area according to capacitance change, and determining a corrosion depth according to interlayer resistance change. The variable capacitance-based sensor for corrosion monitoring of a steel structure surface has a simple structure, can be installed conveniently, has high reliability, can realize real-time on-line monitoring of the surface of a steel-structure material, and satisfies requirements of steel structure composition monitoring and assessment.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com