Large range reinforcing steel corrosion monitoring sensor based on fiber bragg grating sensing technology

A technology for monitoring sensors and optical fiber gratings, which is applied in the field of sensors, can solve the problems of small measuring range, broken optical fiber, and high elastic modulus of optical fiber, and achieve the effects of good reliability, high precision, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment approach

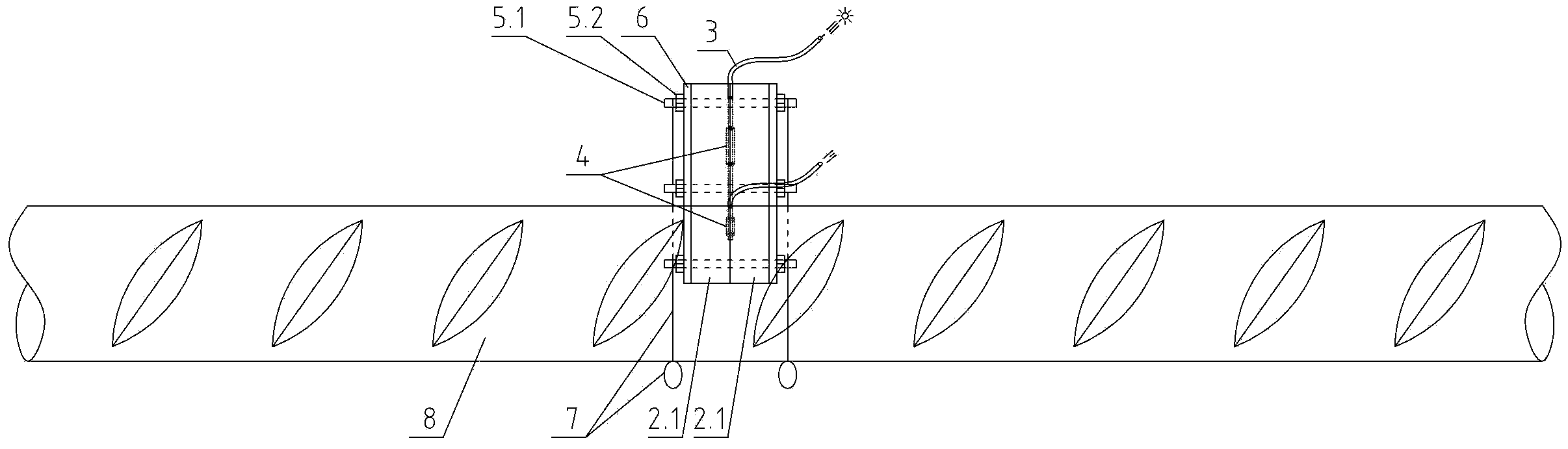

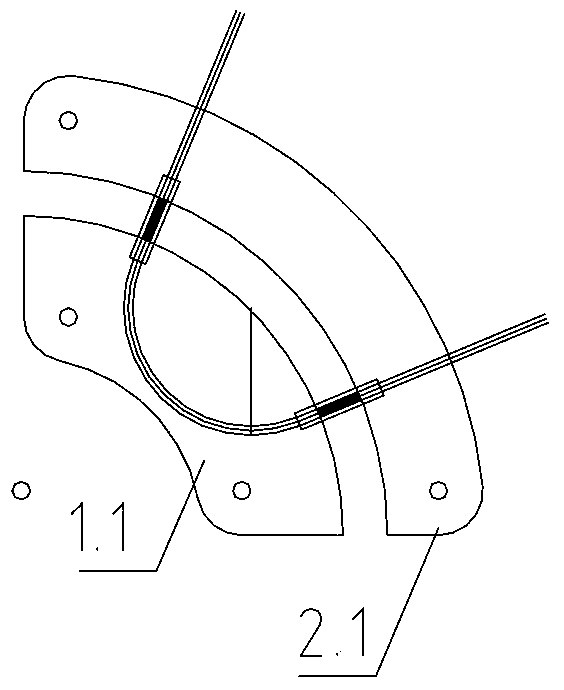

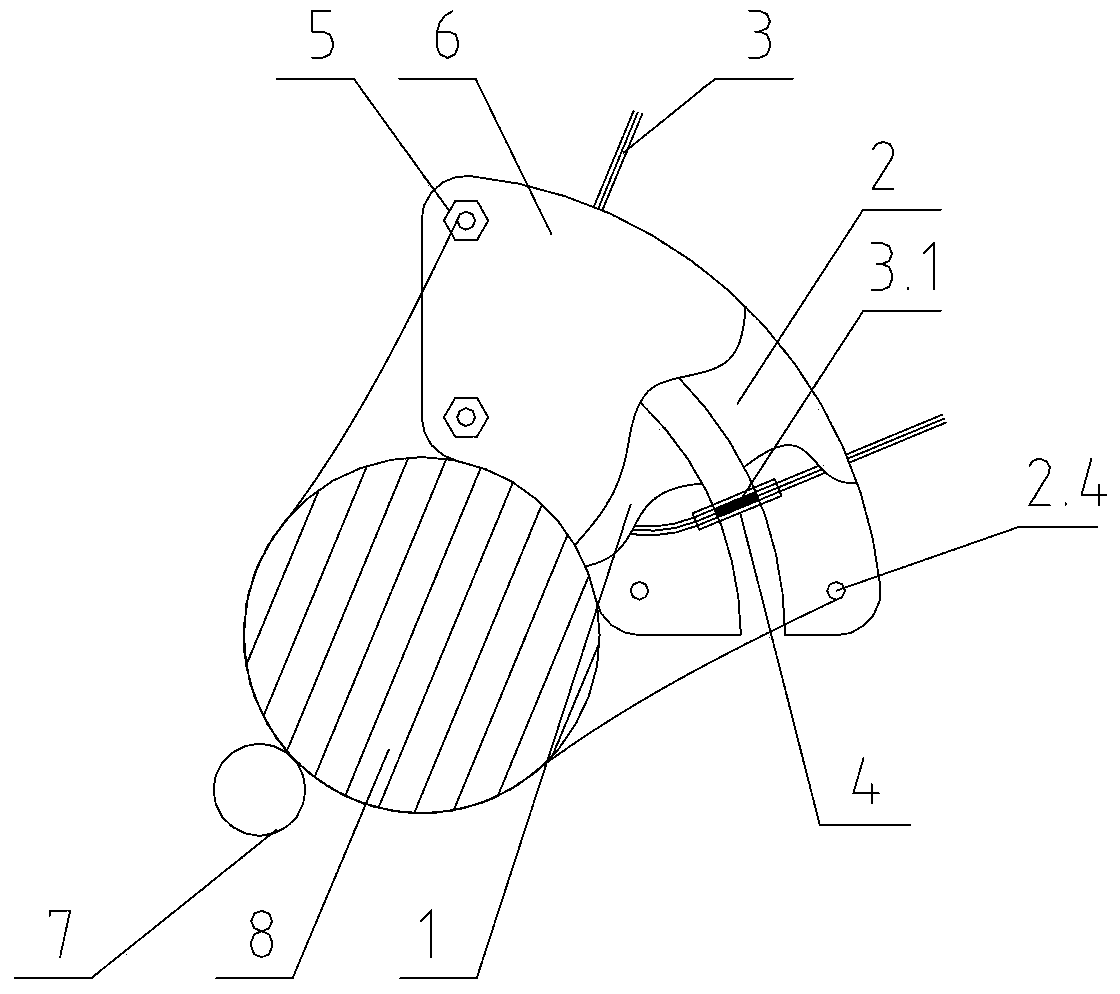

[0030] As an implementation, the arc backing plates 1 and 2 of the sensor are 1 / 4 arc-shaped, that is, a sector with a central angle of 90 degrees, which can be designed with different sizes and specifications according to different diameters of steel bars to be measured. The half backing plate 1 can be close to the surface of the steel bar to be tested, fixed with a steel wire or a nylon cable tie 7, and can be used singly or in combination. The inner fan-shaped backing plate 1 and the outer fan-shaped backing plate 2 are made of high-strength steel. Since the outer fan-shaped backing plate 2 is limited by the external concrete, under the action of the expansion stress of the steel bar 8 to be tested, the inner and outer fan-shaped backing plates Only relative displacement occurs between them without excessive elastic deformation or bending.

[0031] In order to convert the expansion stress of the measured steel bar 8 into the compressive strain of the fiber grating 3.1, 3.2,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com