Patents

Literature

30results about How to "Lower thermal resistivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

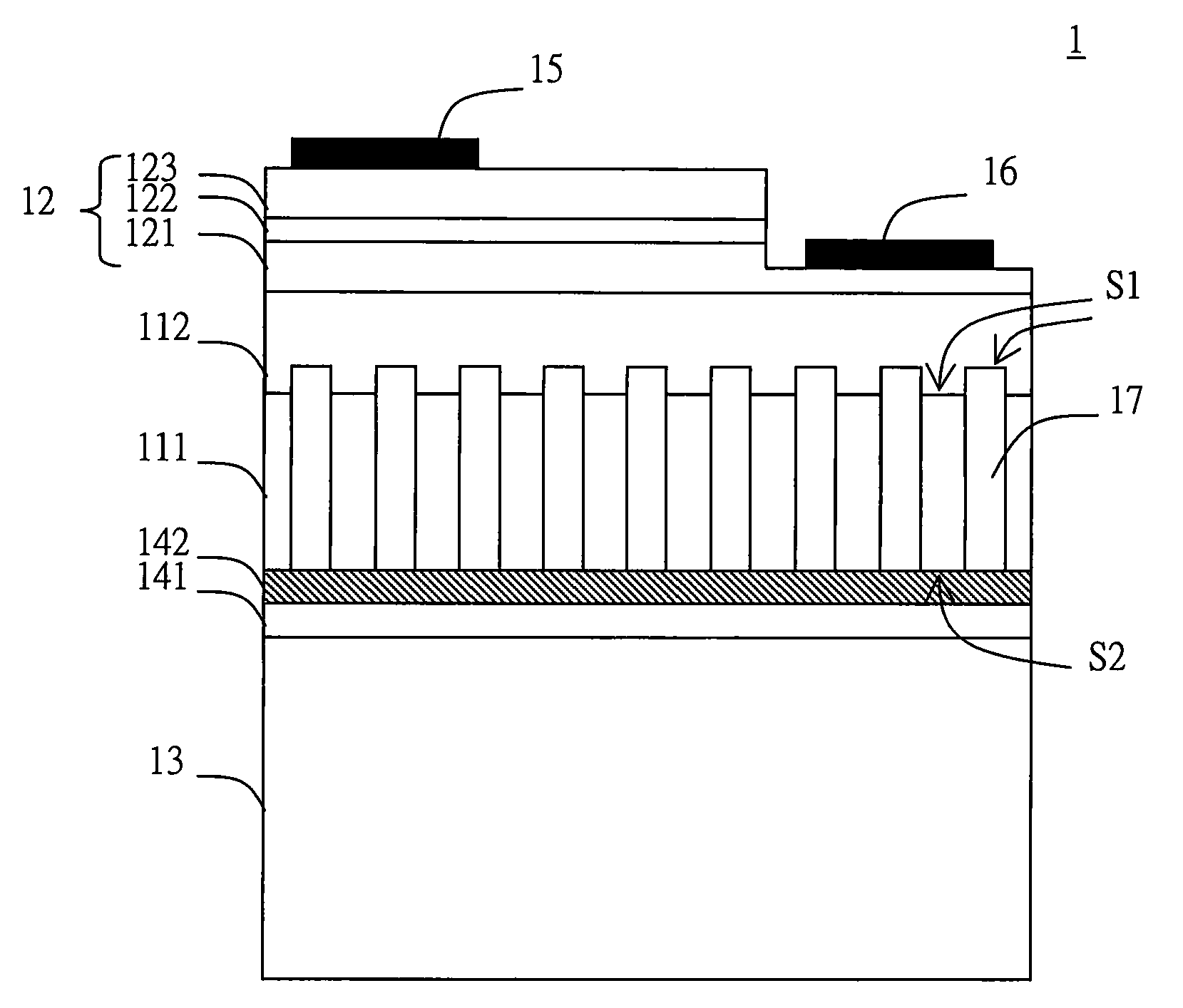

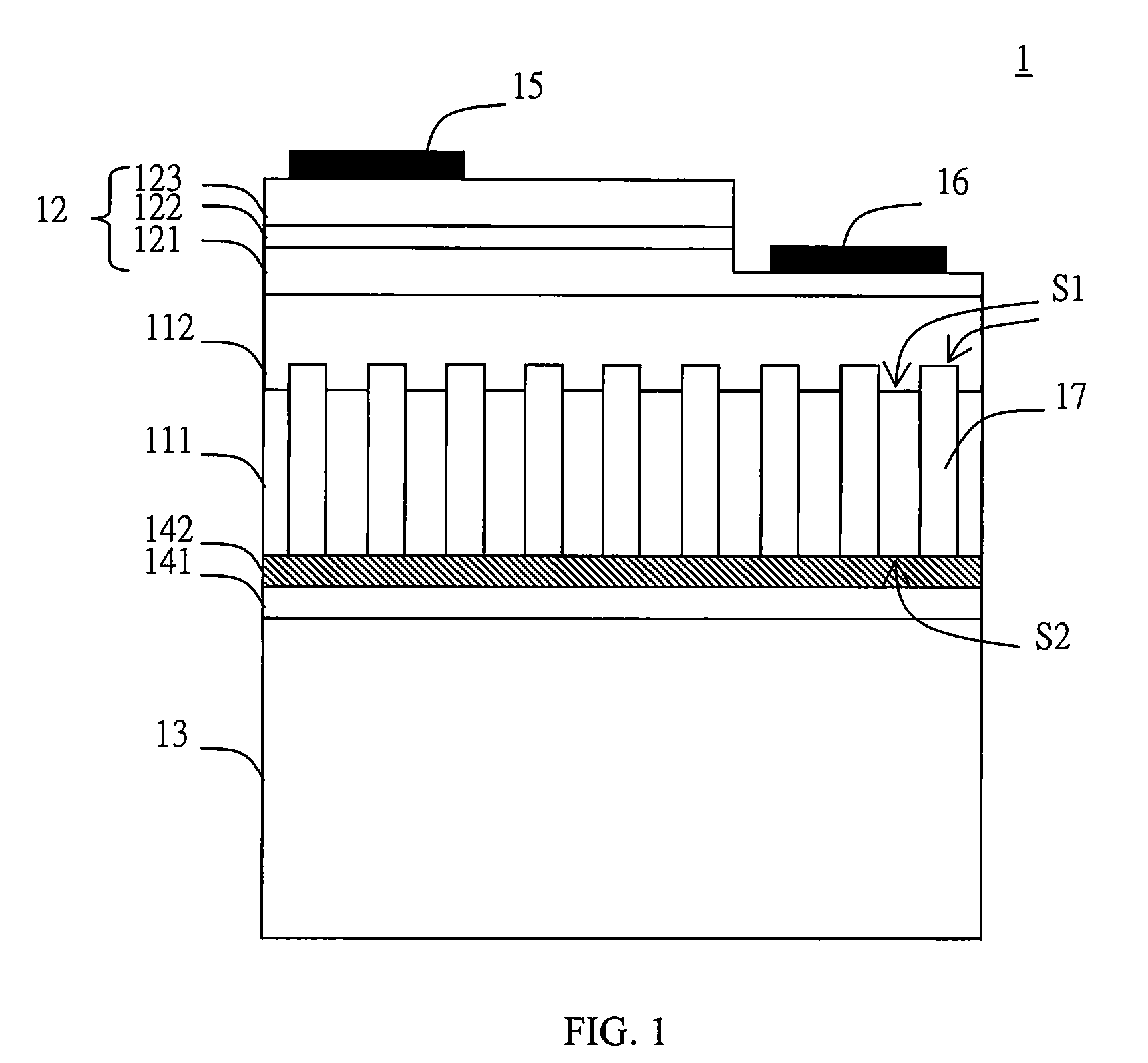

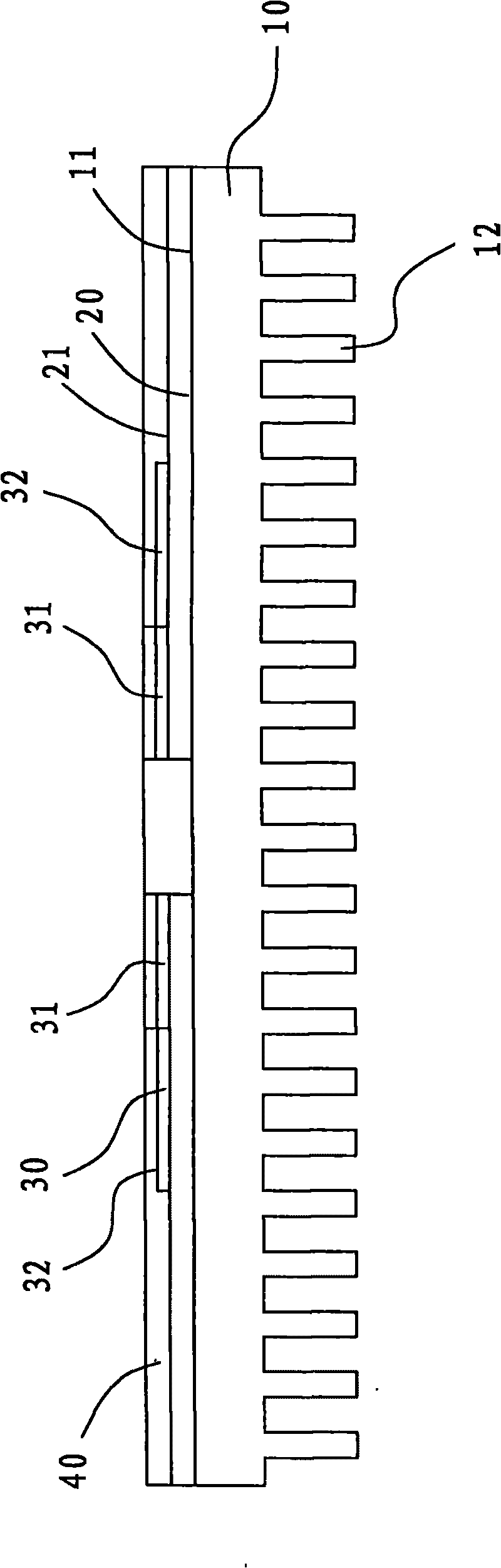

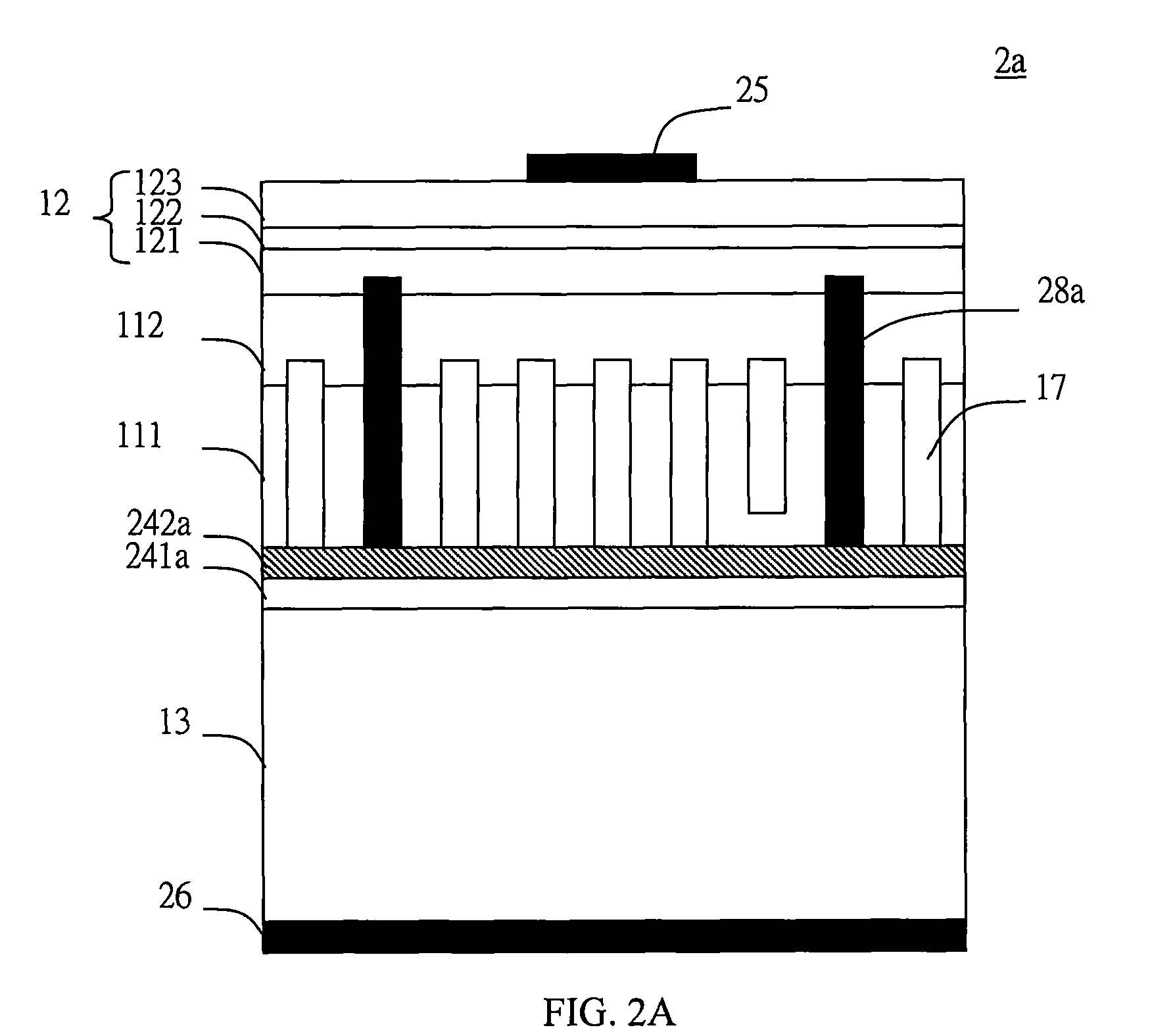

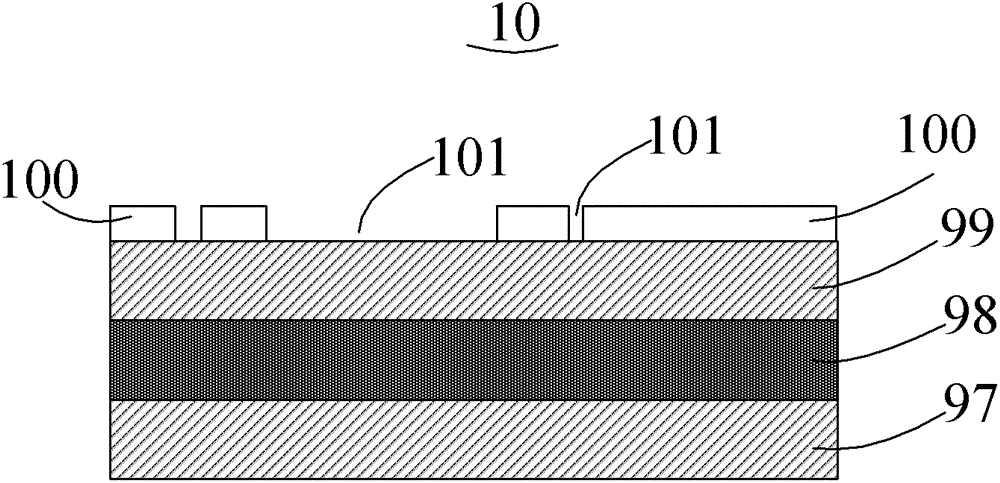

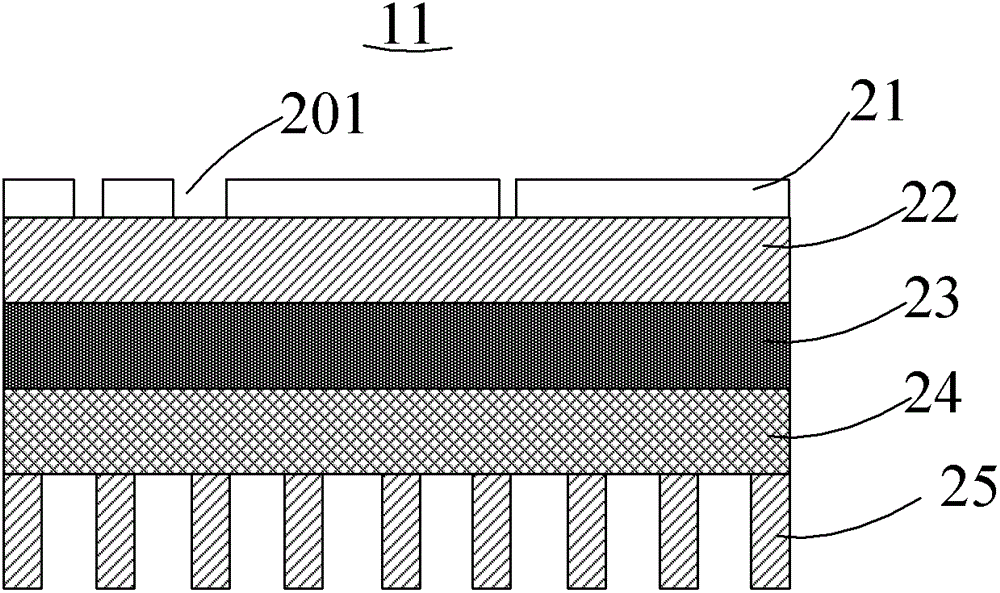

Light-emitting device having a thinned structure and the manufacturing method thereof

ActiveUS20100308355A1Lower thermal resistivityImprove efficiencySemiconductor/solid-state device testing/measurementSolid-state devicesEngineeringLight emitting device

A semiconductor light-emitting device having a thinned structure comprises a thinned structure formed between a semiconductor light-emitting structure and a carrier. The manufacturing method comprises the steps of forming a semiconductor light-emitting structure above a substrate; attaching the semiconductor light-emitting structure to a support; thinning the substrate to form a thinned structure; forming or attaching a carrier to the thinned substrate; and removing the support.

Owner:EPISTAR CORP

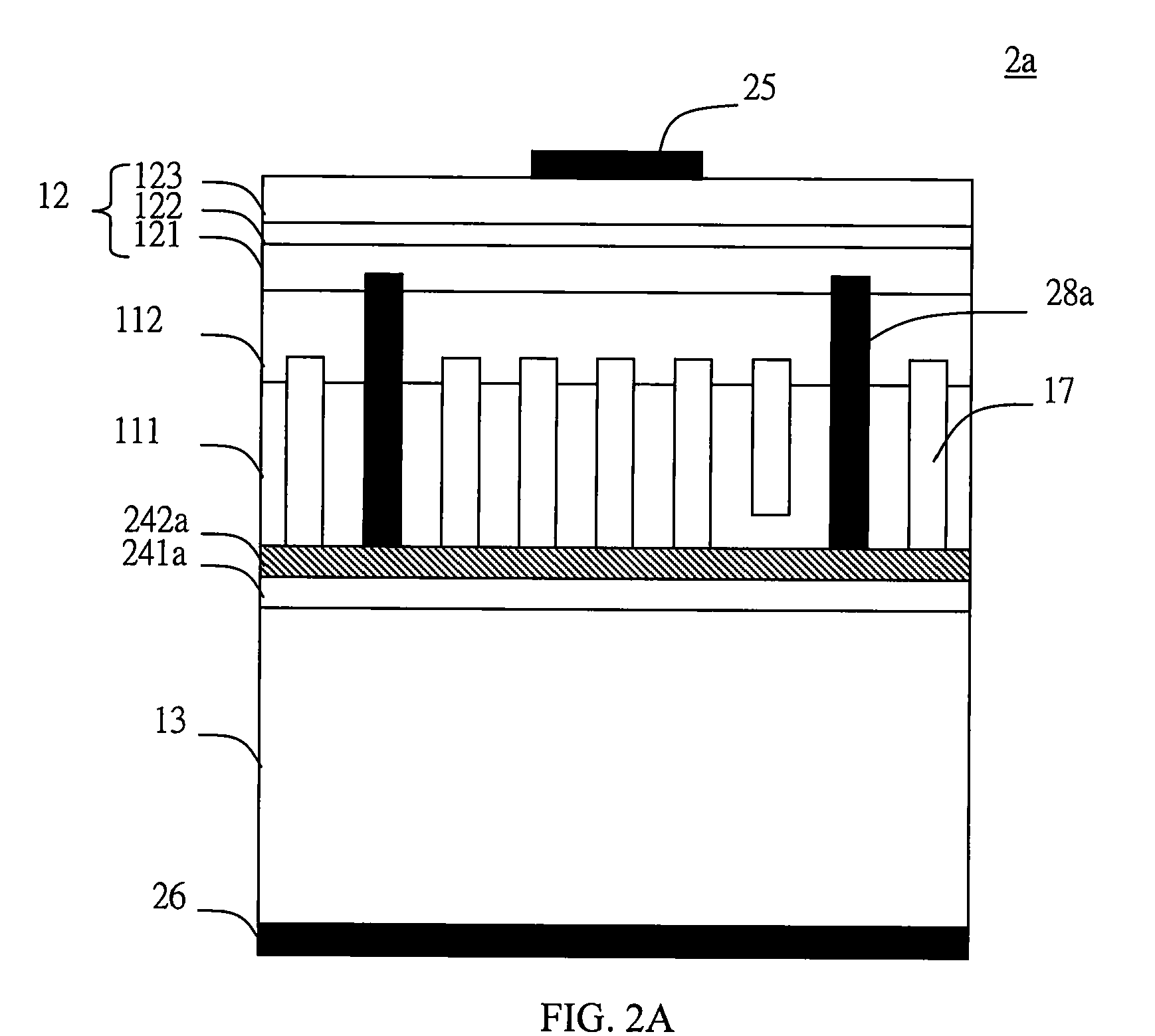

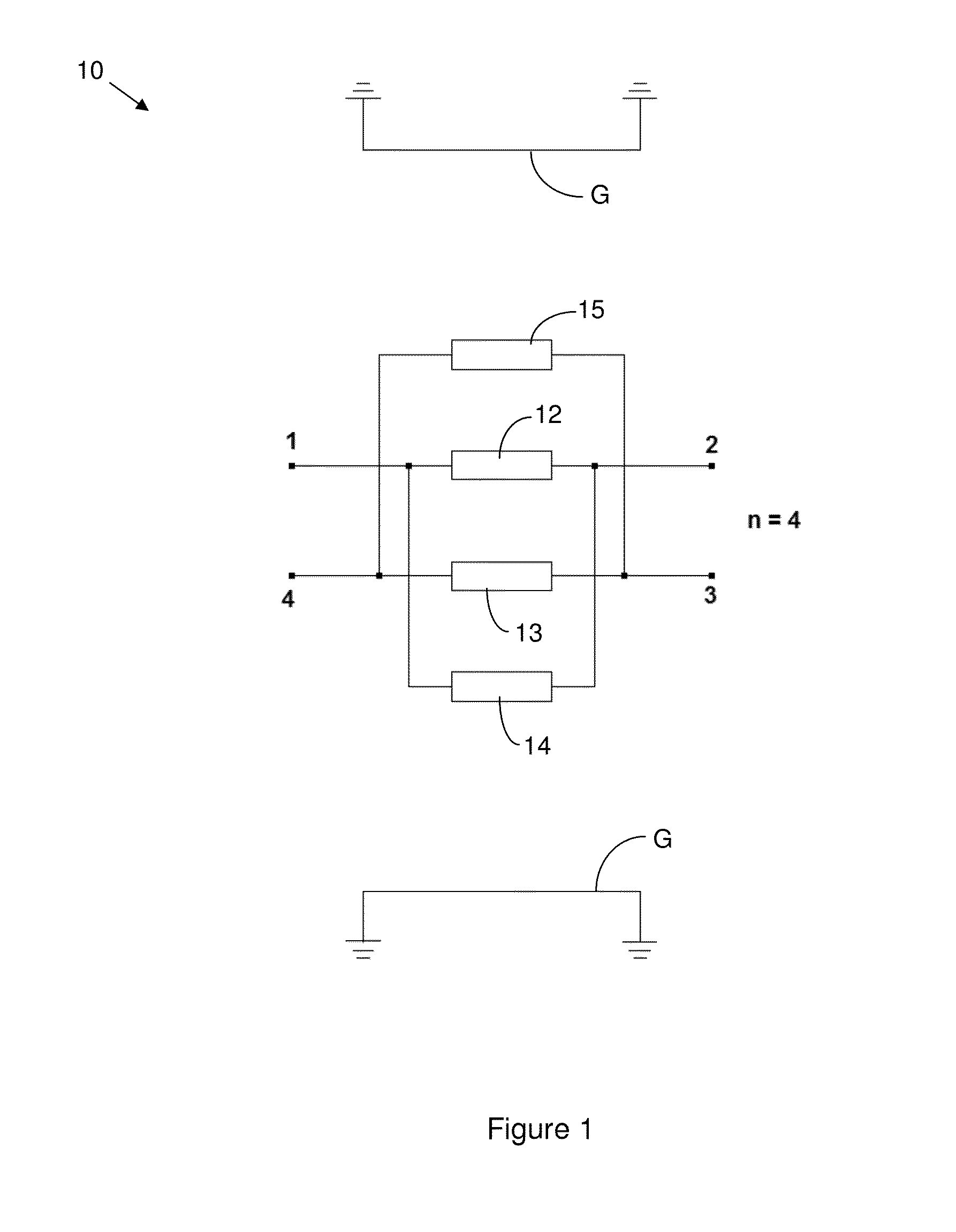

Symmetrical hybrid coupler

The present invention is directed to a hybrid coupler device that includes a first transmission line structure and a second transmission line structure. The first transmission line structure is interdigitally coupled with the second transmission line structure such that each transmission line in the second transmission line structure is disposed adjacent to a transmission line in the first transmission line structure. The coupling or the mutual capacitance Cd between the transmission lines of the present invention need not be equal; in fact, they all can be different.

Owner:TTM TECH INC

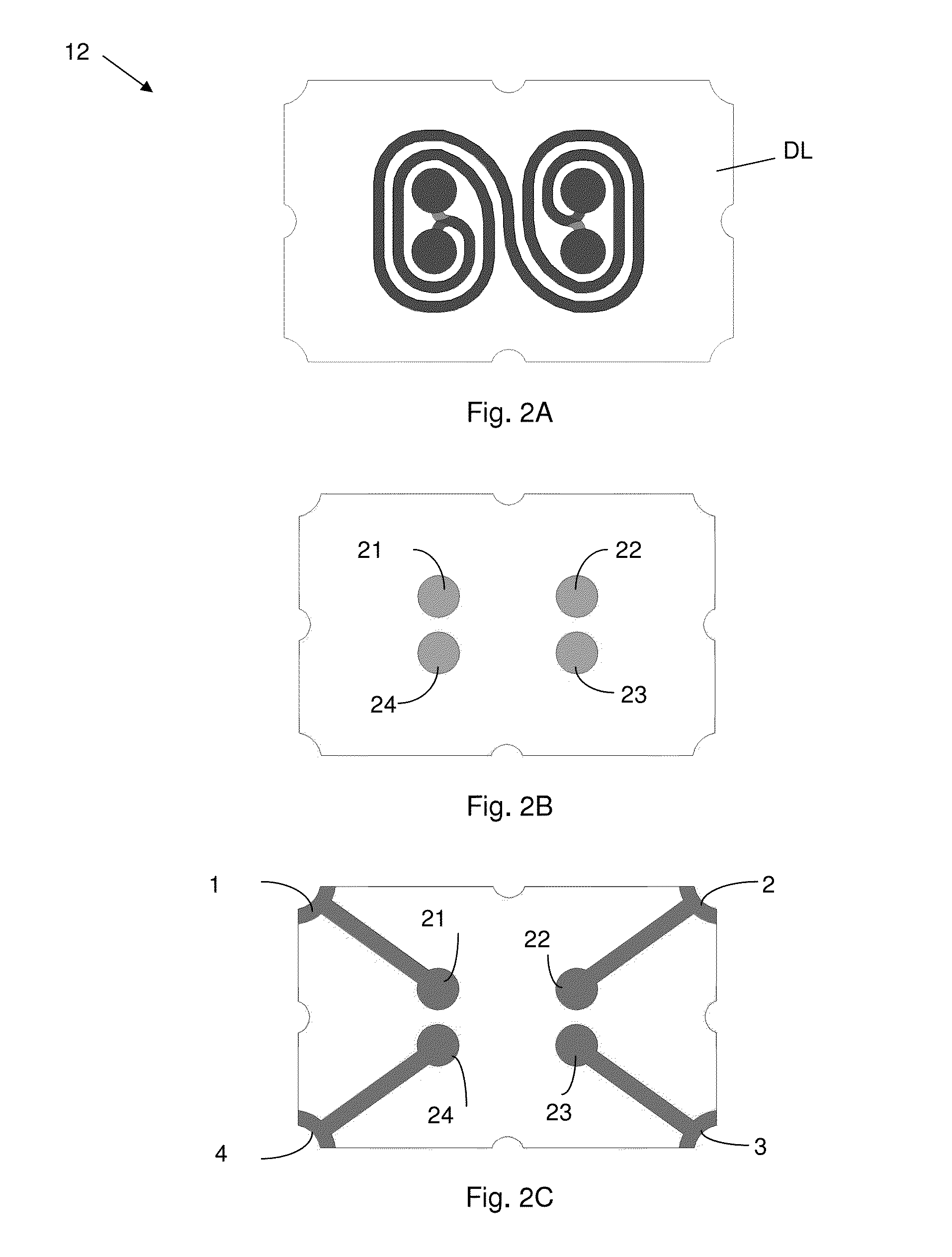

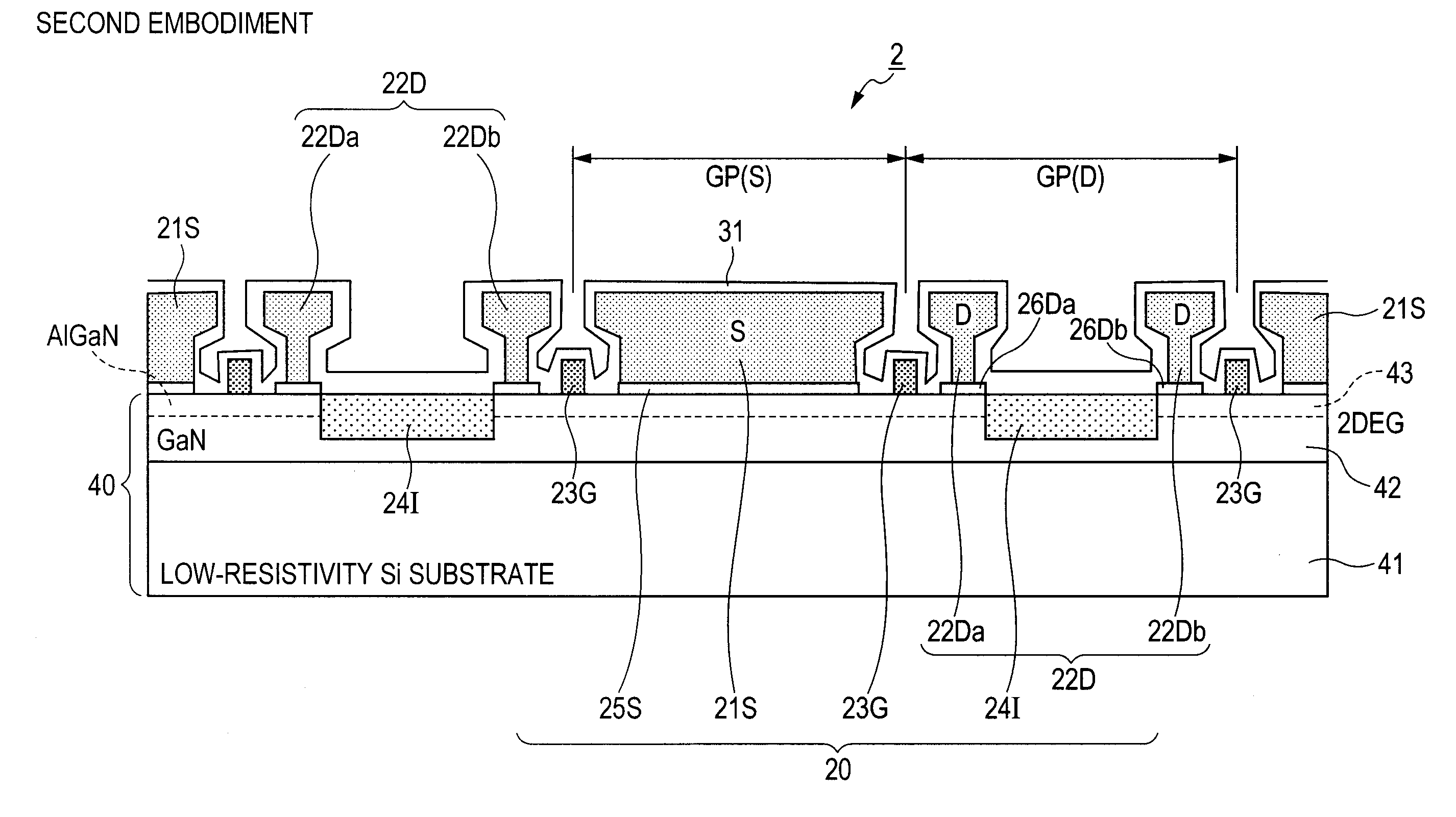

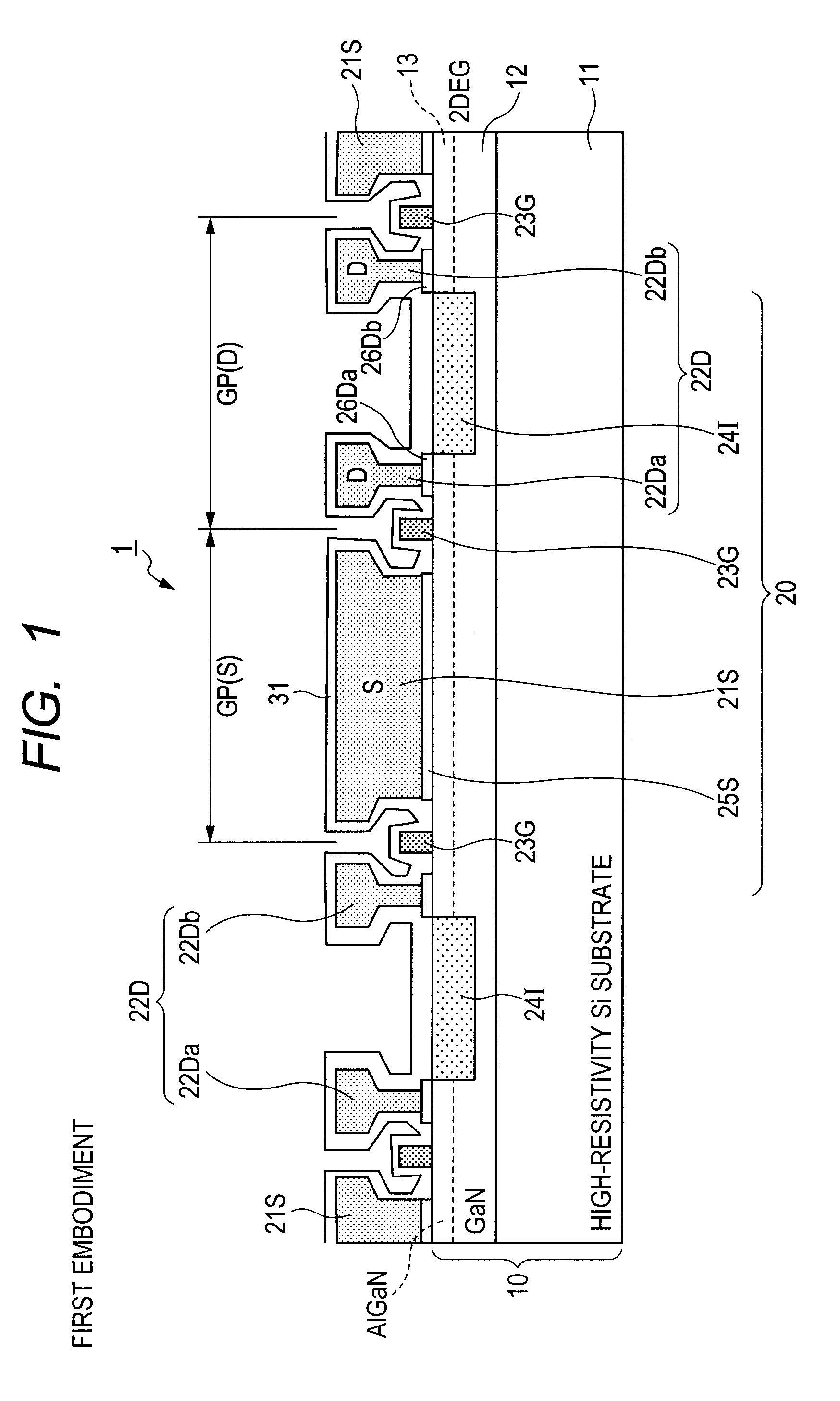

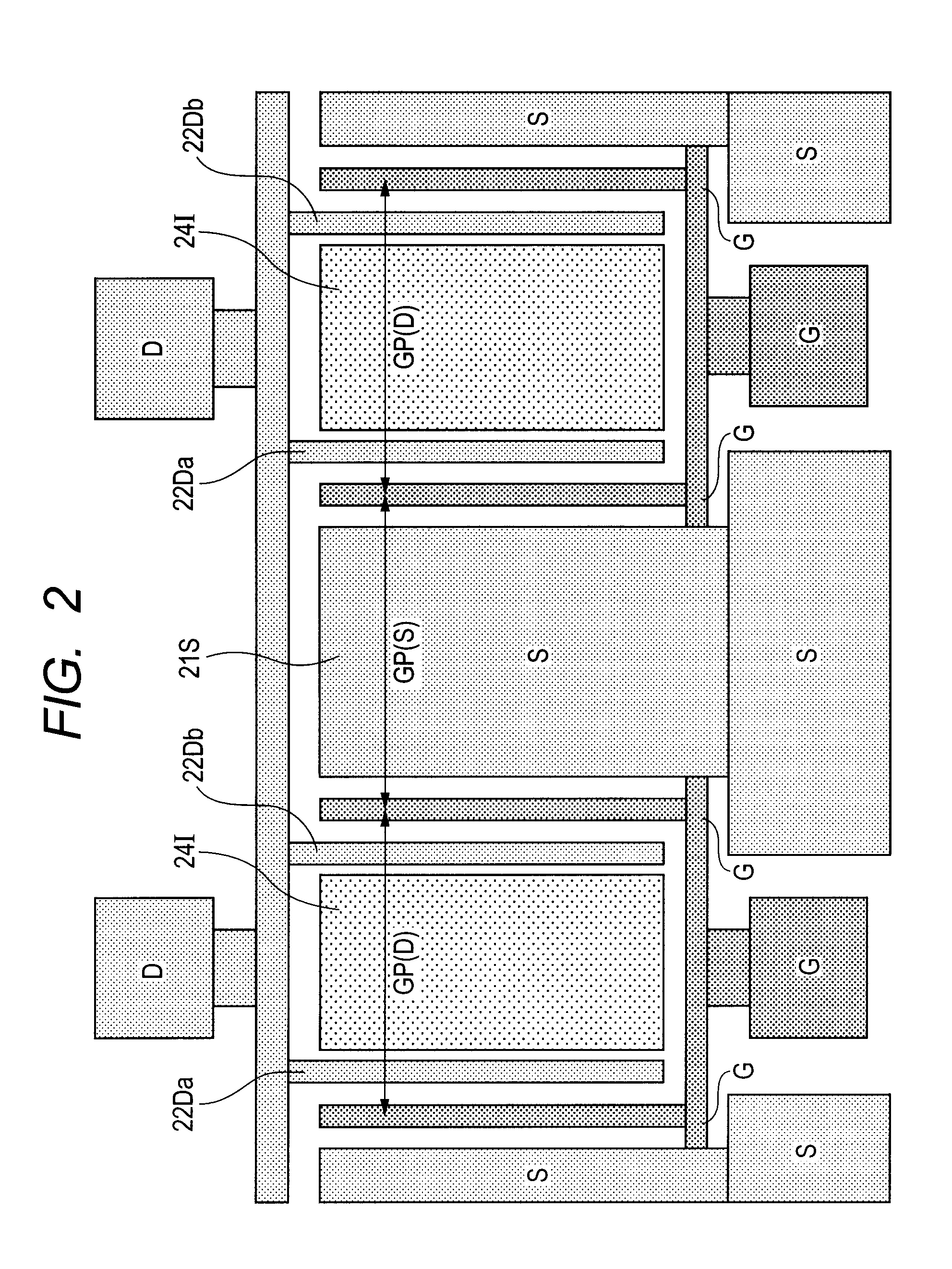

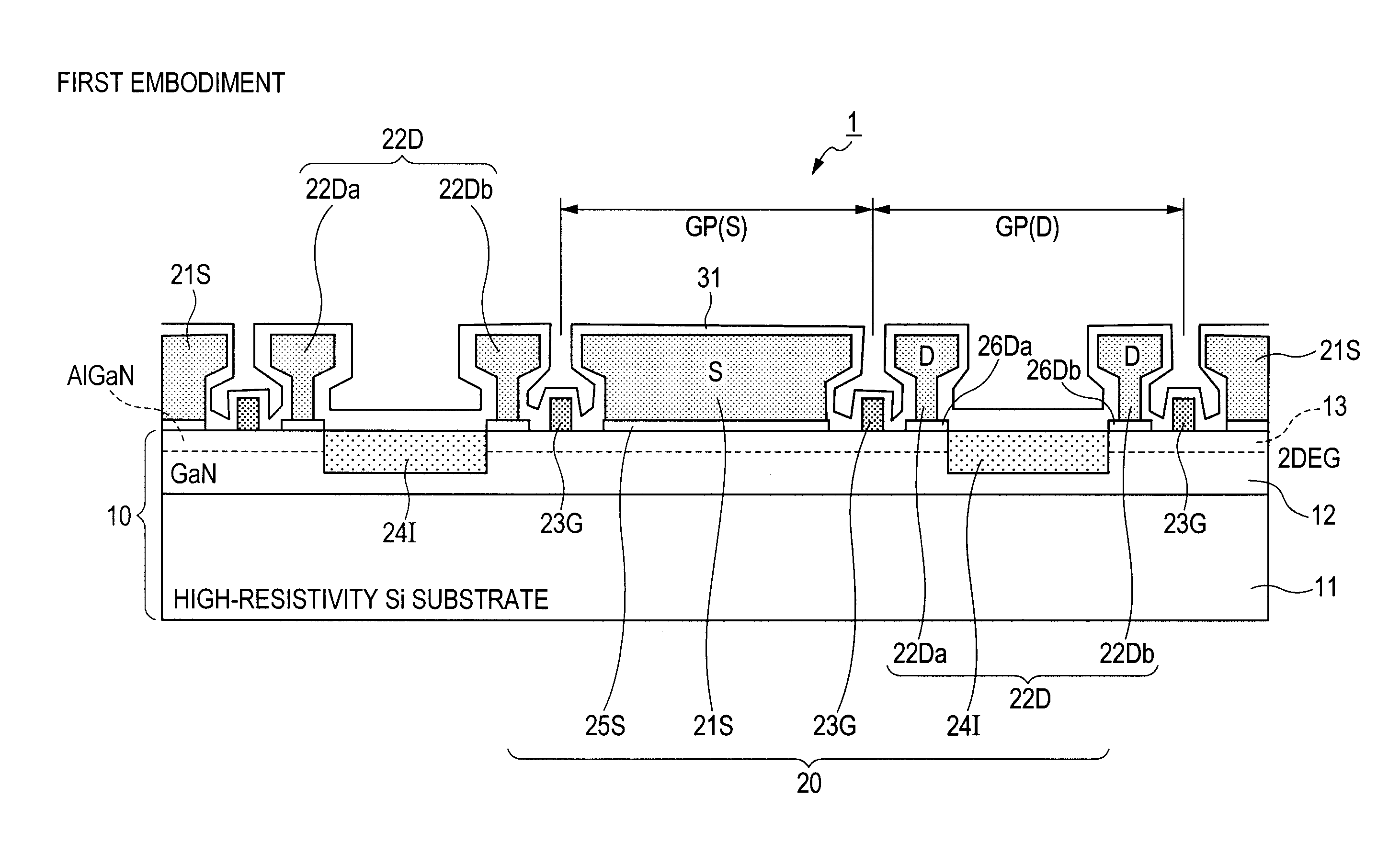

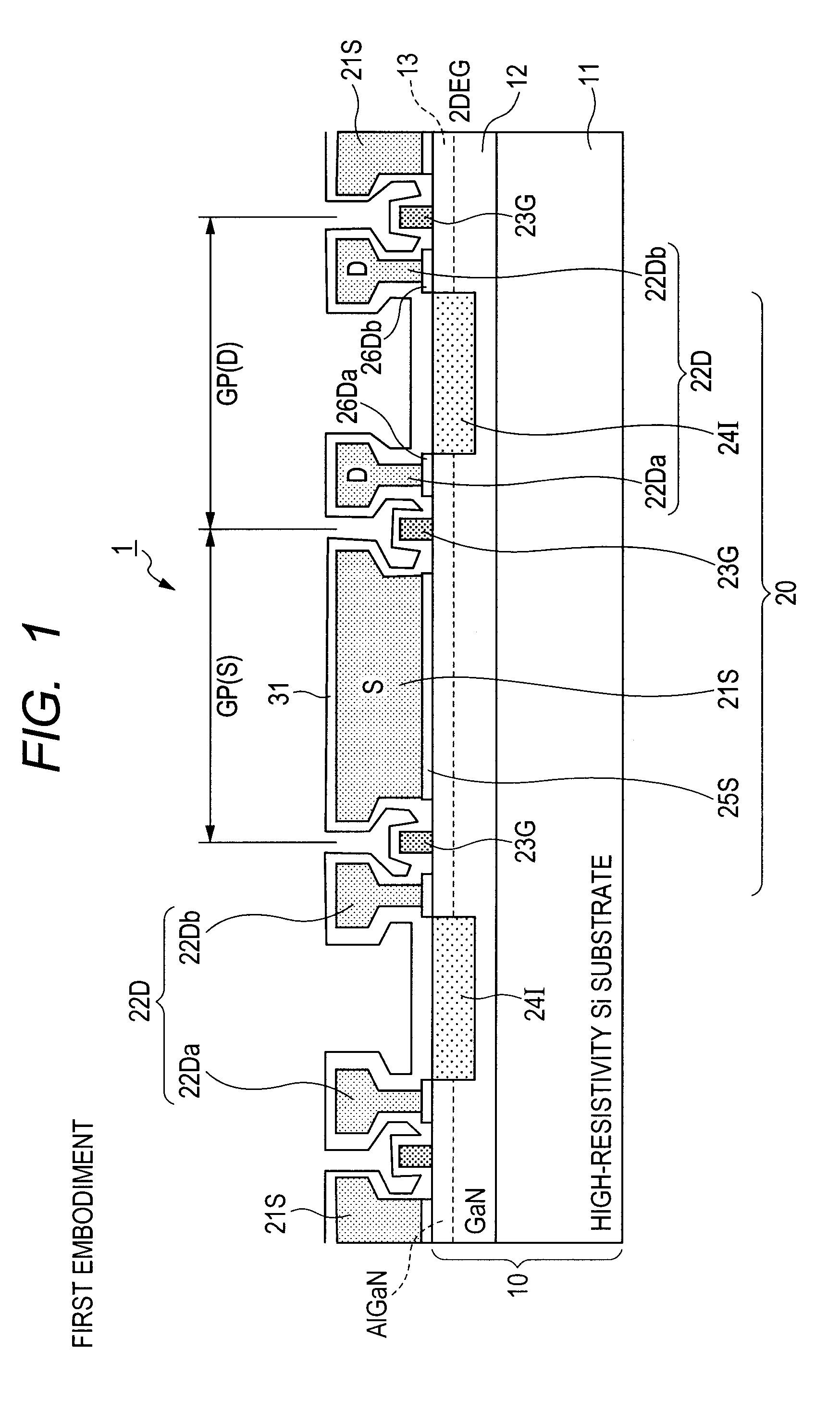

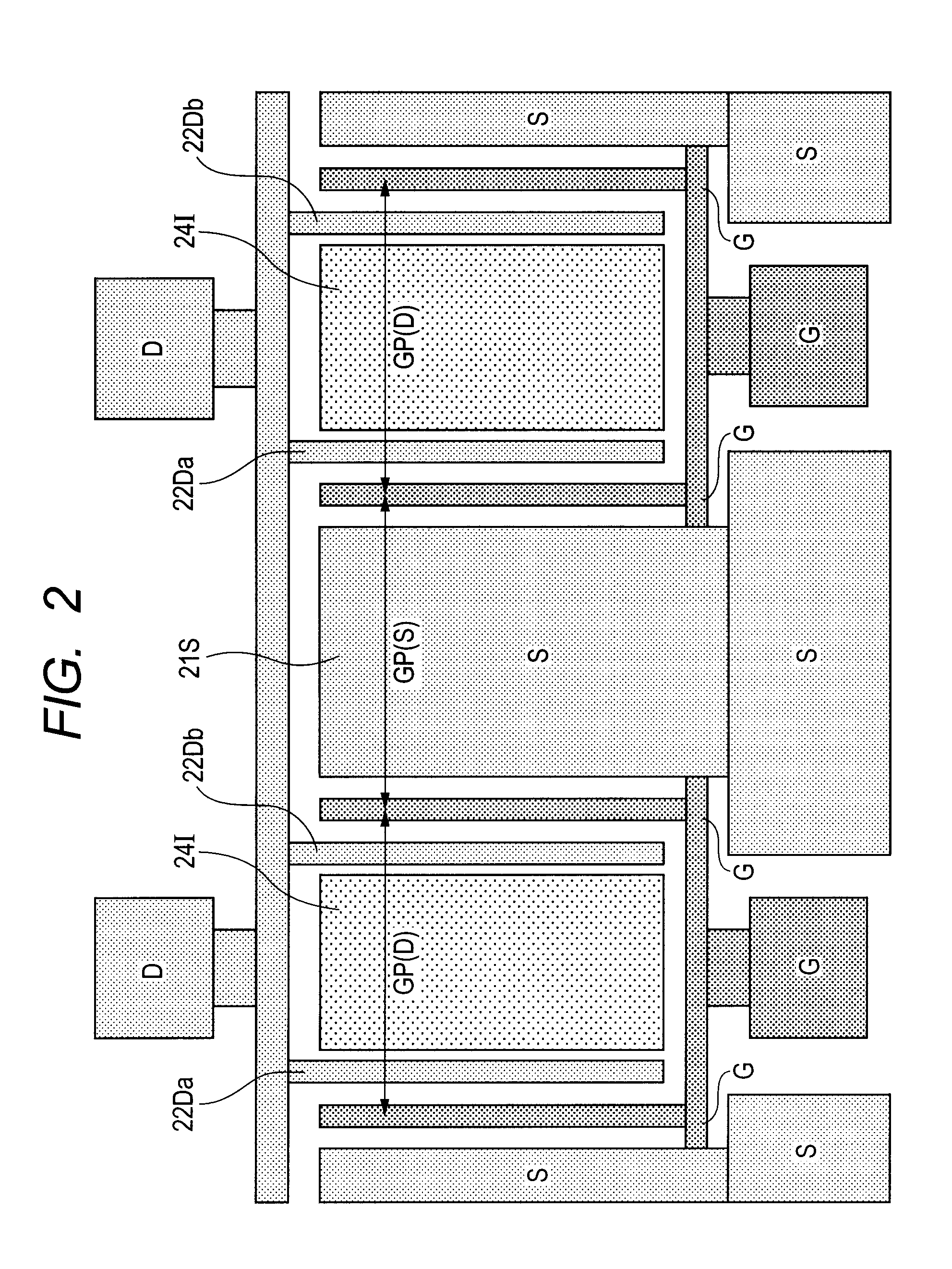

Field-effect transistor

ActiveUS8507919B2Prevent rise in channel temperatureSuppress parasitic capacitanceSemiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactParasitic capacitance

A field-effect transistor (FET) in which a gate electrode is located between a source electrode formed on one side of the gate electrode and a drain electrode formed on the other side, a source ohmic contact is formed under the source electrode and a drain ohmic contact is formed under the drain electrode. In the FET, the rise in the channel temperature is suppressed, the parasitic capacitance with a substrate is decreased, and the temperature dependence of drain efficiency is reduced, so that highly efficient operation can be achieved at high temperatures. The drain electrode is divided into a plurality of drain sub-electrodes spaced from each other and an insulating region is formed between the drain ohmic contacts formed under the drain sub-electrodes.

Owner:MITSUBISHI ELECTRIC CORP

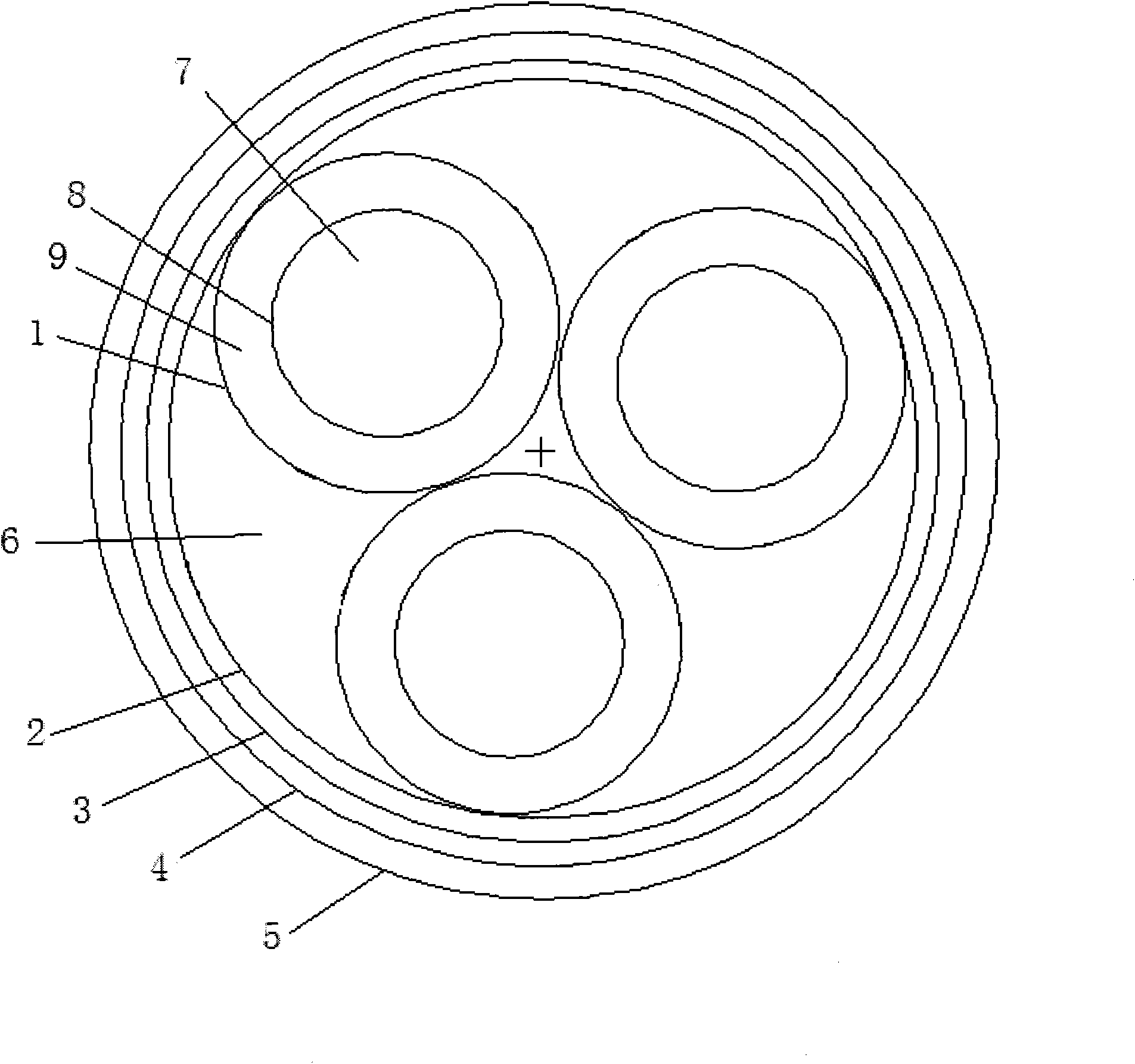

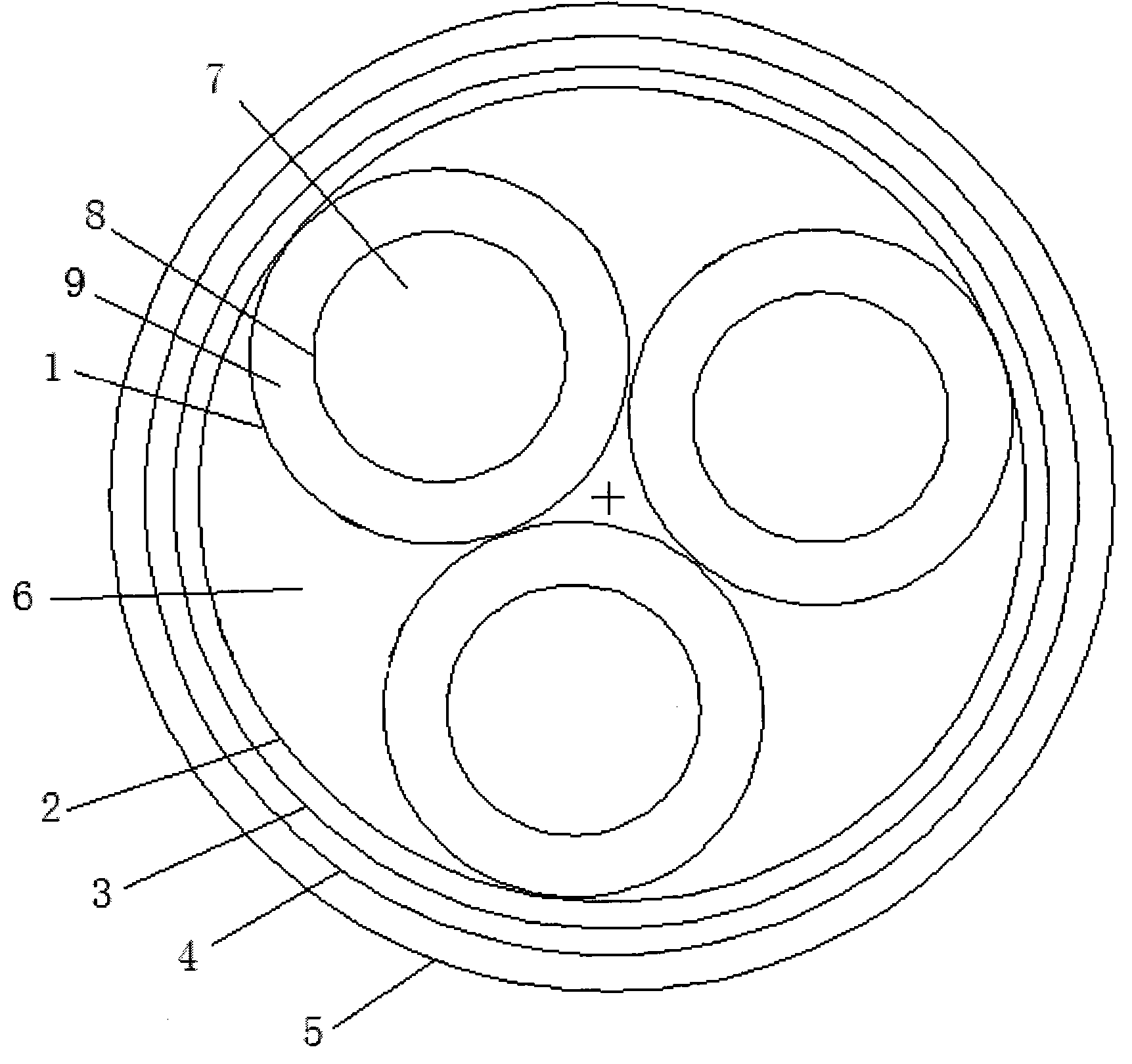

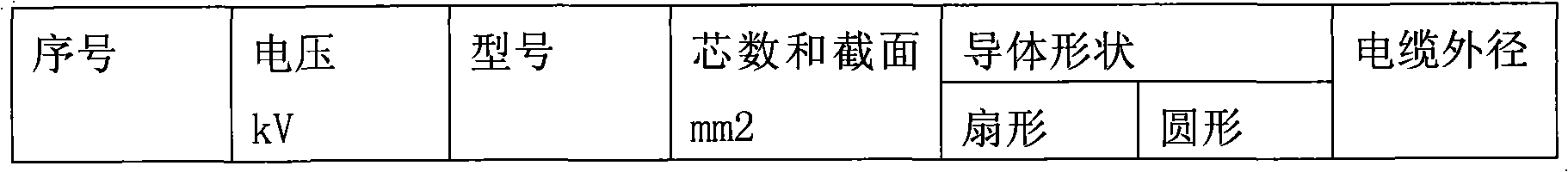

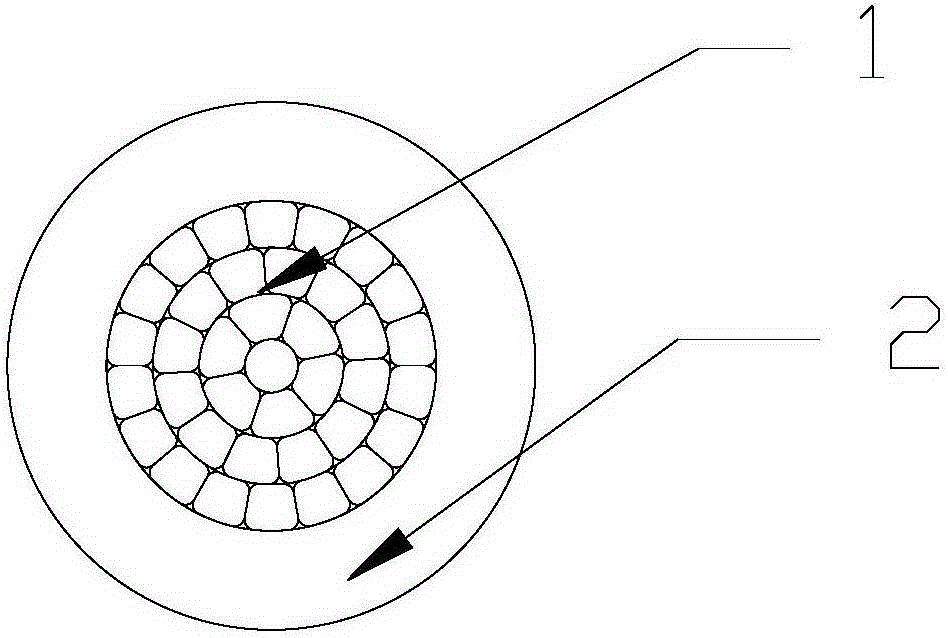

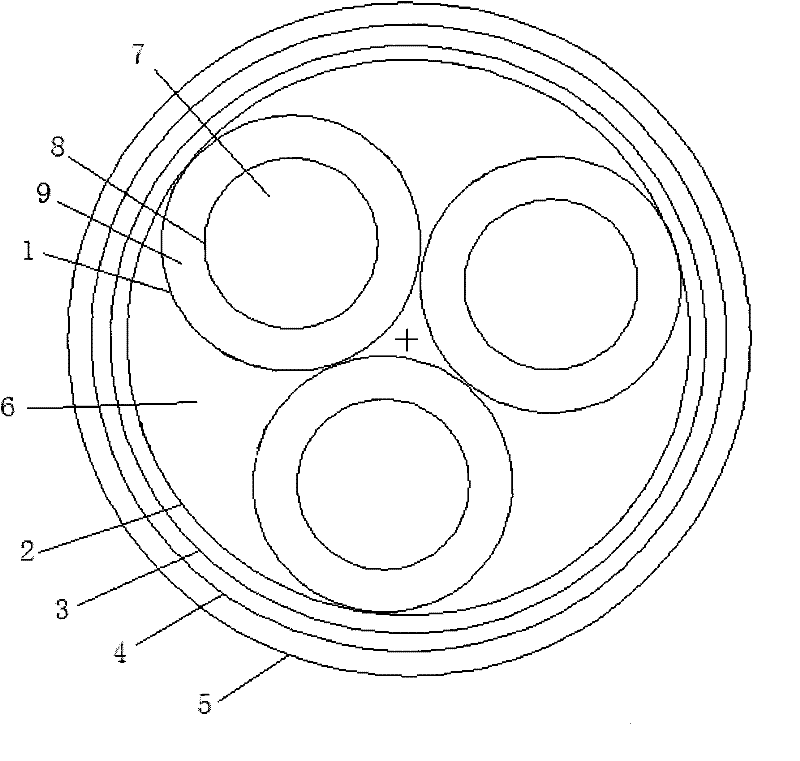

Fireproofing and heat resistant environmental-friendly power cable

InactiveCN101834029AEvenly distributedReduce the temperaturePlastic/resin/waxes insulatorsPower cables with screens/conductive layersElectricityPower cable

The invention discloses an environmental-friendly power cable which comprises a core wire, an aluminum tape layer lapping outside the core wire and steel-tape armoring arranged outside the aluminum tape layer, wherein the gap between the core wire and the aluminum tape layer is provided with silicon carbide mineral composite fillers, a polyethylene inner sheath is arranged between the aluminum tape layer and the steel-tape armoring, and a polyethylene outer sheath is arranged outside the steel-tape armoring. The invention has the advantages of good heat radiation property, long service life, strong flame retarding property, electricity saving, no toxicity and environmental protection.

Owner:无锡市黄浦电线电缆有限公司

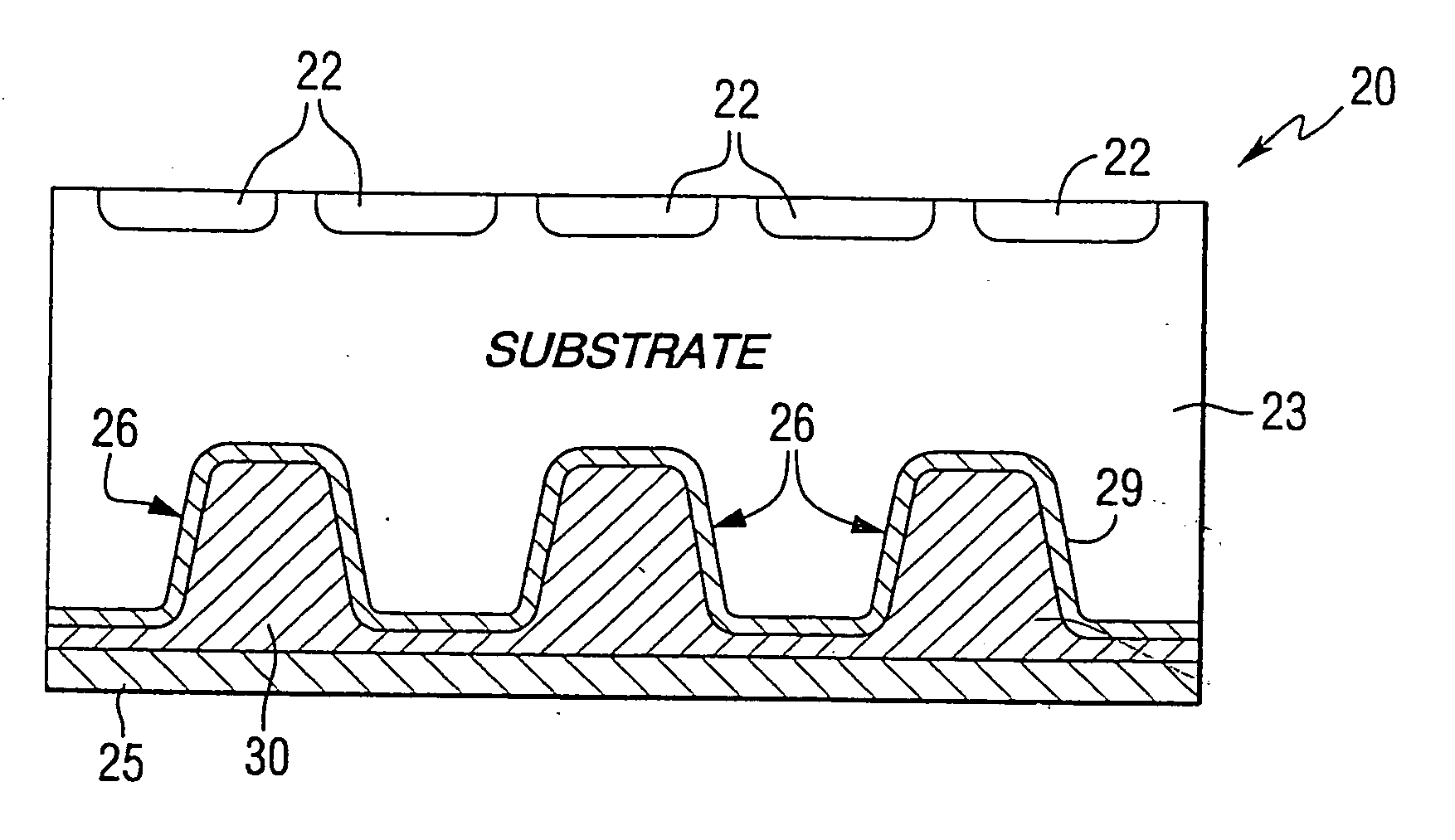

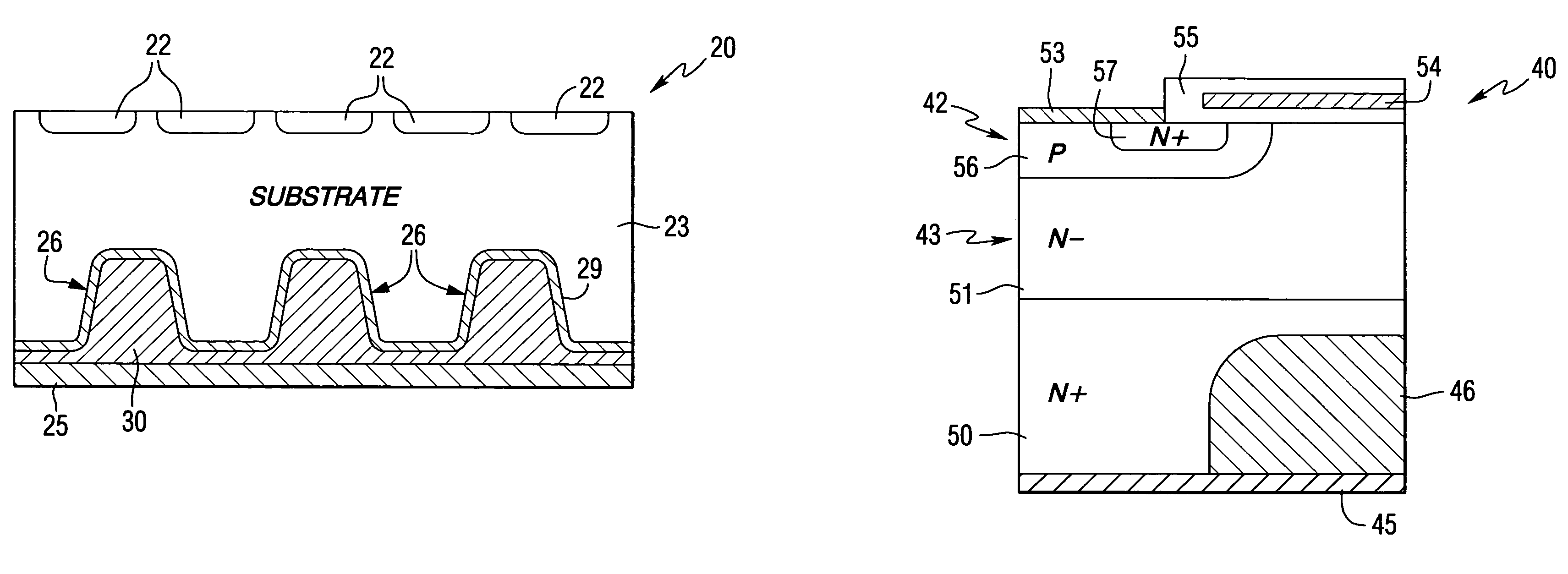

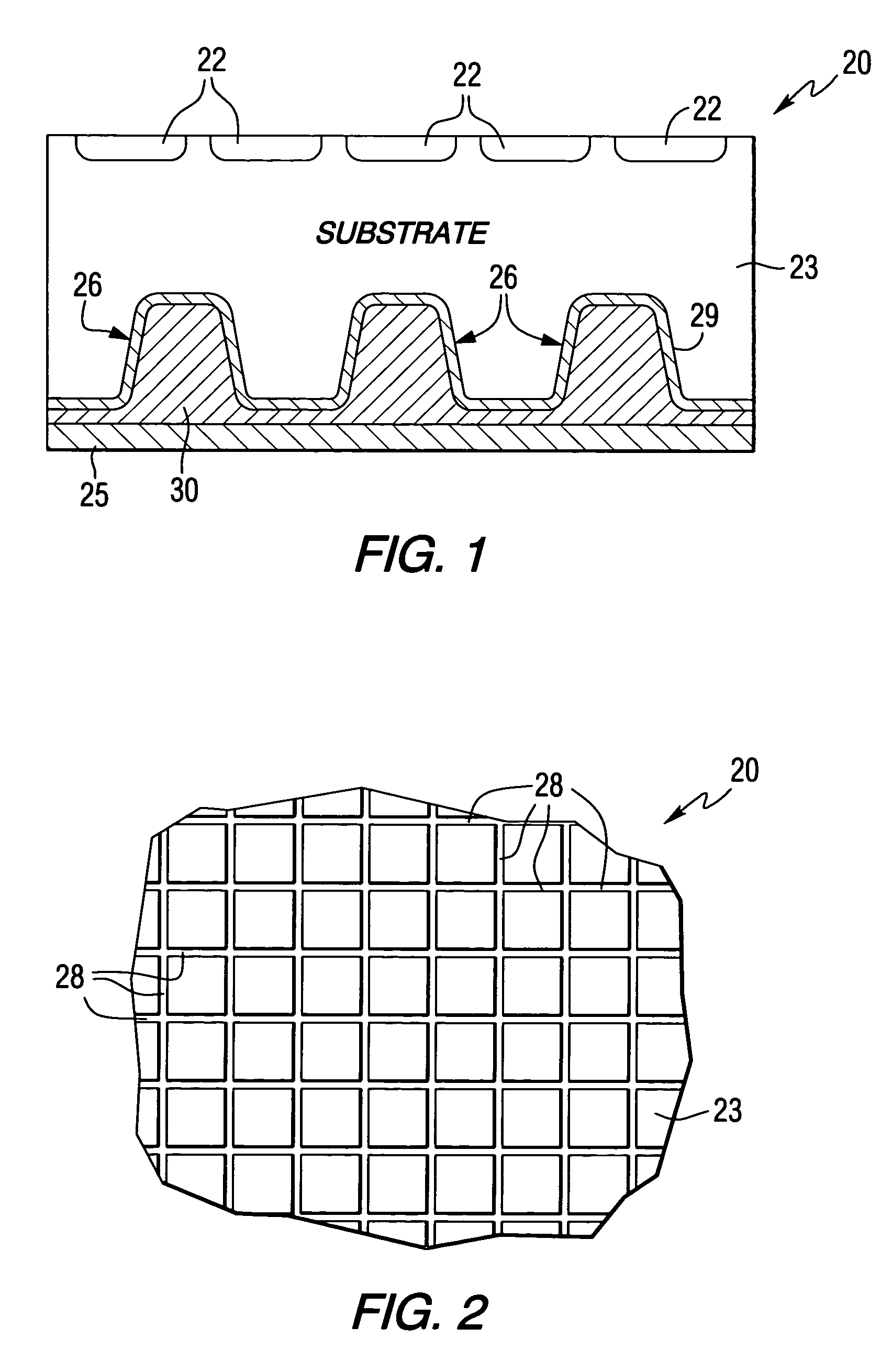

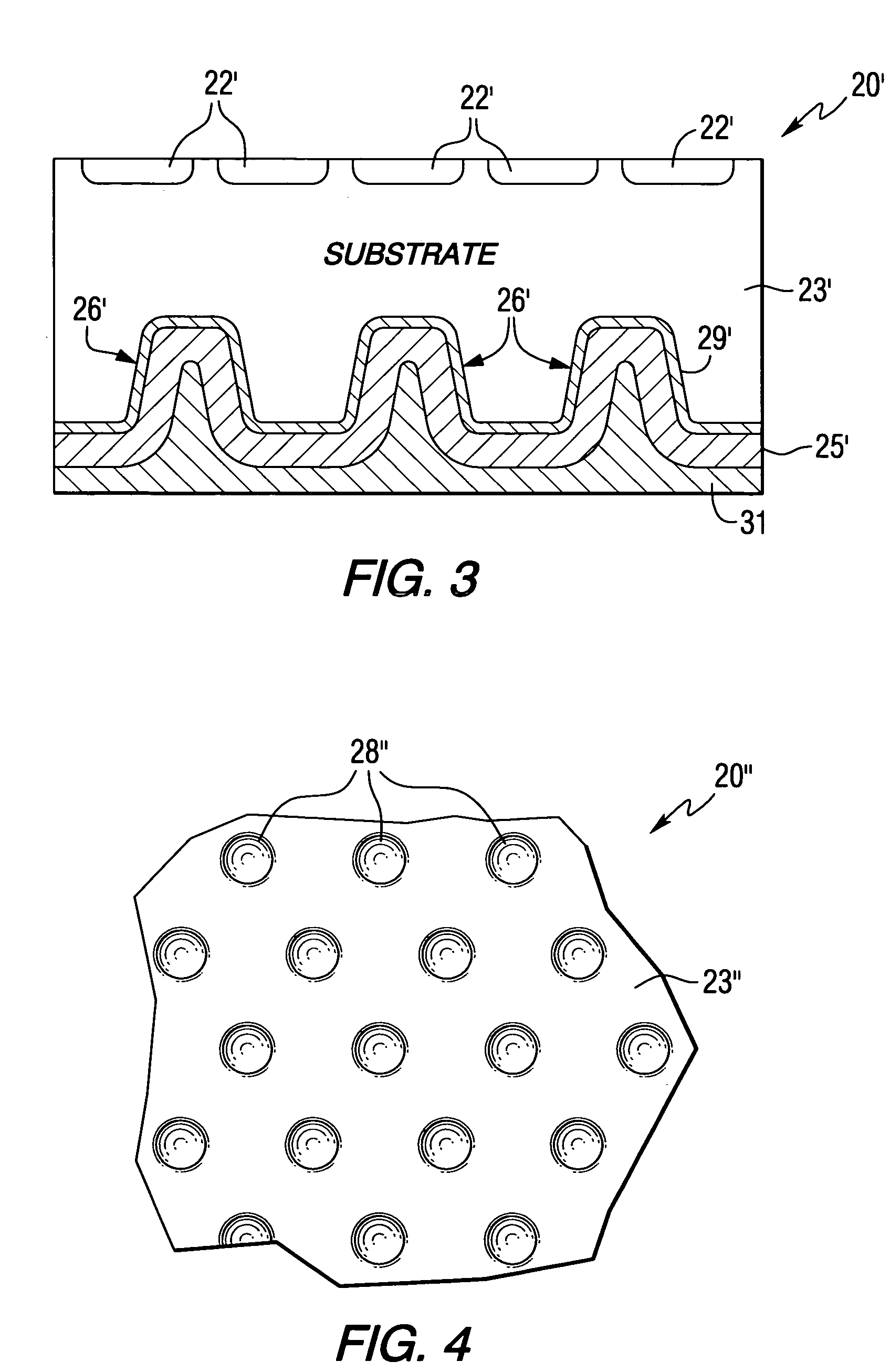

Semiconductor device having reduced effective substrate resistivity and associated methods

InactiveUS20070042549A1Reducing effective substrate resistivityReducing the effective substrate resistivitySolid-state devicesSemiconductor/solid-state device manufacturingMOSFETElectrical resistance and conductance

A semiconductor device includes at least one device active region formed in a first surface of a semiconductor substrate, an electrical contact layer on a second surface of the semiconductor substrate, and at least one resistivity-lowering body positioned in a corresponding recess in the substrate and connected to the electrical contact layer. The body preferably comprises a material having an electrical resistivity lower than an electrical resistivity of the semiconductor substrate to thereby lower an effective electrical resistivity of the substrate. The device active region may be an active region of a power control device, such as a MOSFET or IGBT, for example. The body may preferably comprise an electrical conductor such as copper, aluminum, silver, solder, or doped polysilicon. The at least one recess and associated resistivity-lower body preferably defines a proportion of the semiconductor substrate area adjacent the device active region greater than about 0.4 percent, and may extend into the semiconductor substrate a distance greater than about 25 percent of a thickness of the substrate.

Owner:FAIRCHILD SEMICON CORP

Field-effect transistor

ActiveUS20110233559A1Block riseReduce parasitic capacitanceSemiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactParasitic capacitance

A field-effect transistor (FET) in which a gate electrode is located between a source electrode formed on one side of the gate electrode and a drain electrode formed on the other side, a source ohmic contact is formed under the source electrode and a drain ohmic contact is formed under the drain electrode. In the FET, the rise in the channel temperature is suppressed, the parasitic capacitance with a substrate is decreased, and the temperature dependence of drain efficiency is reduced, so that highly efficient operation can be achieved at high temperatures. The drain electrode is divided into a plurality of drain sub-electrodes spaced from each other and an insulating region is formed between the drain ohmic contacts formed under the drain sub-electrodes.

Owner:MITSUBISHI ELECTRIC CORP

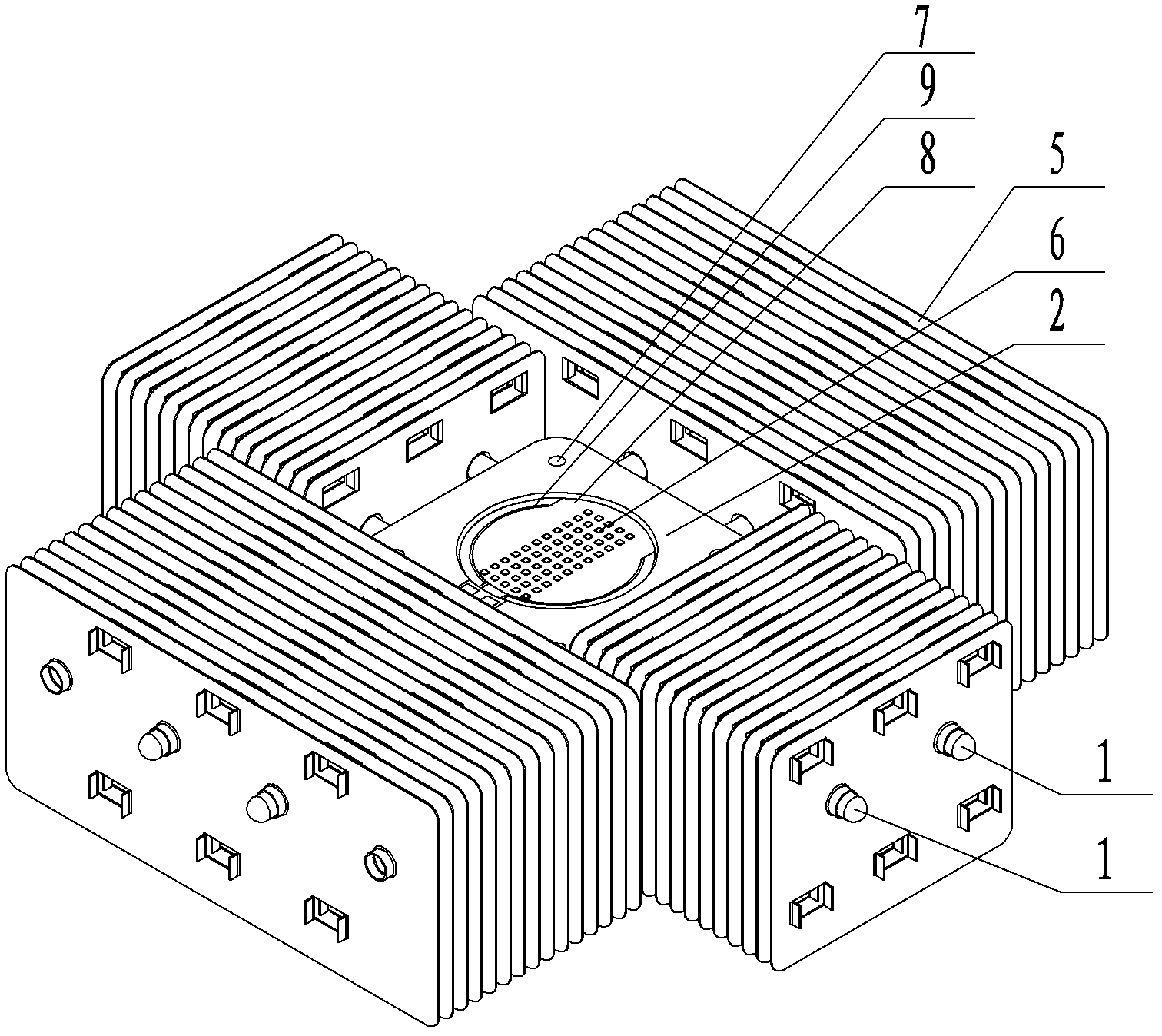

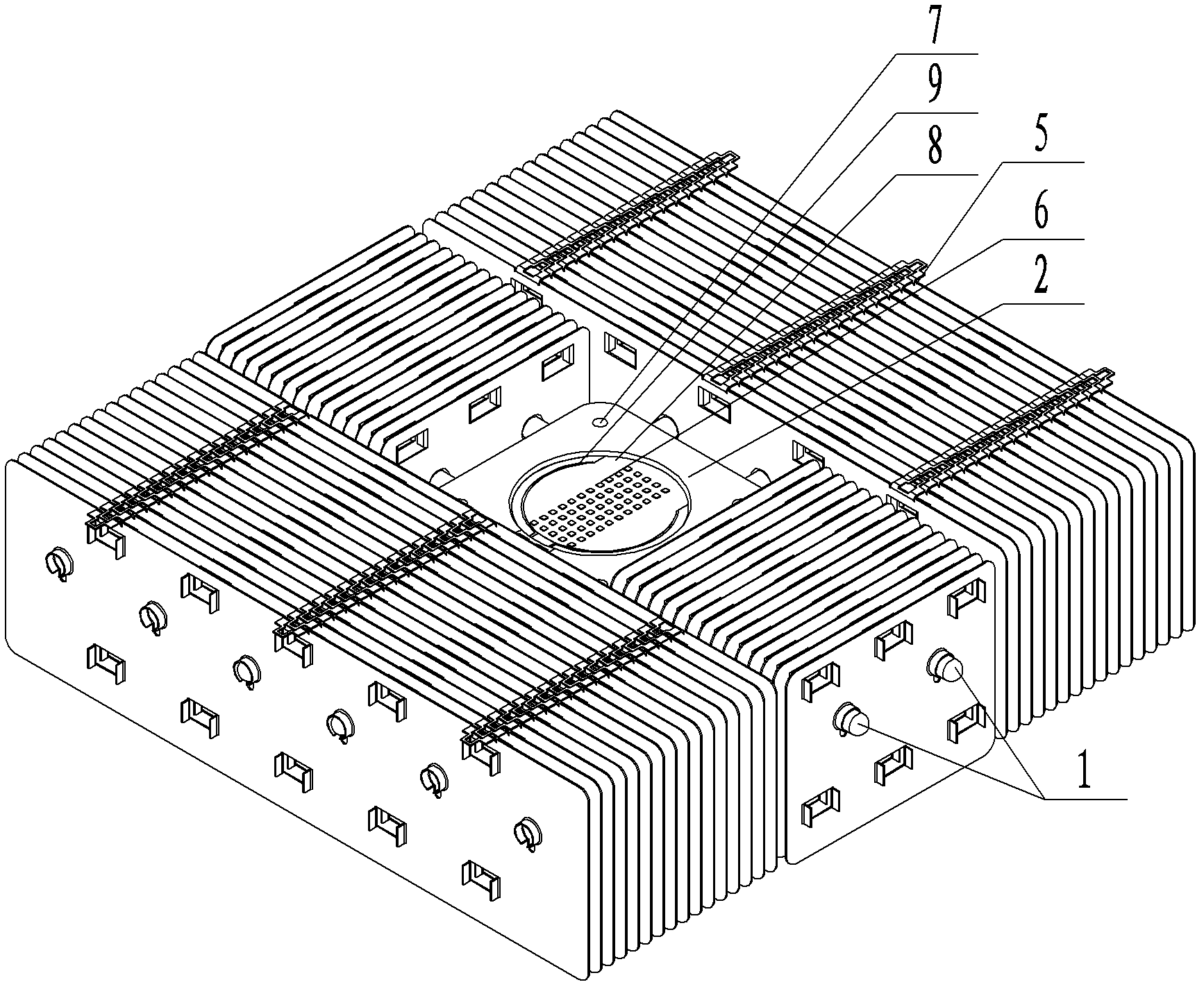

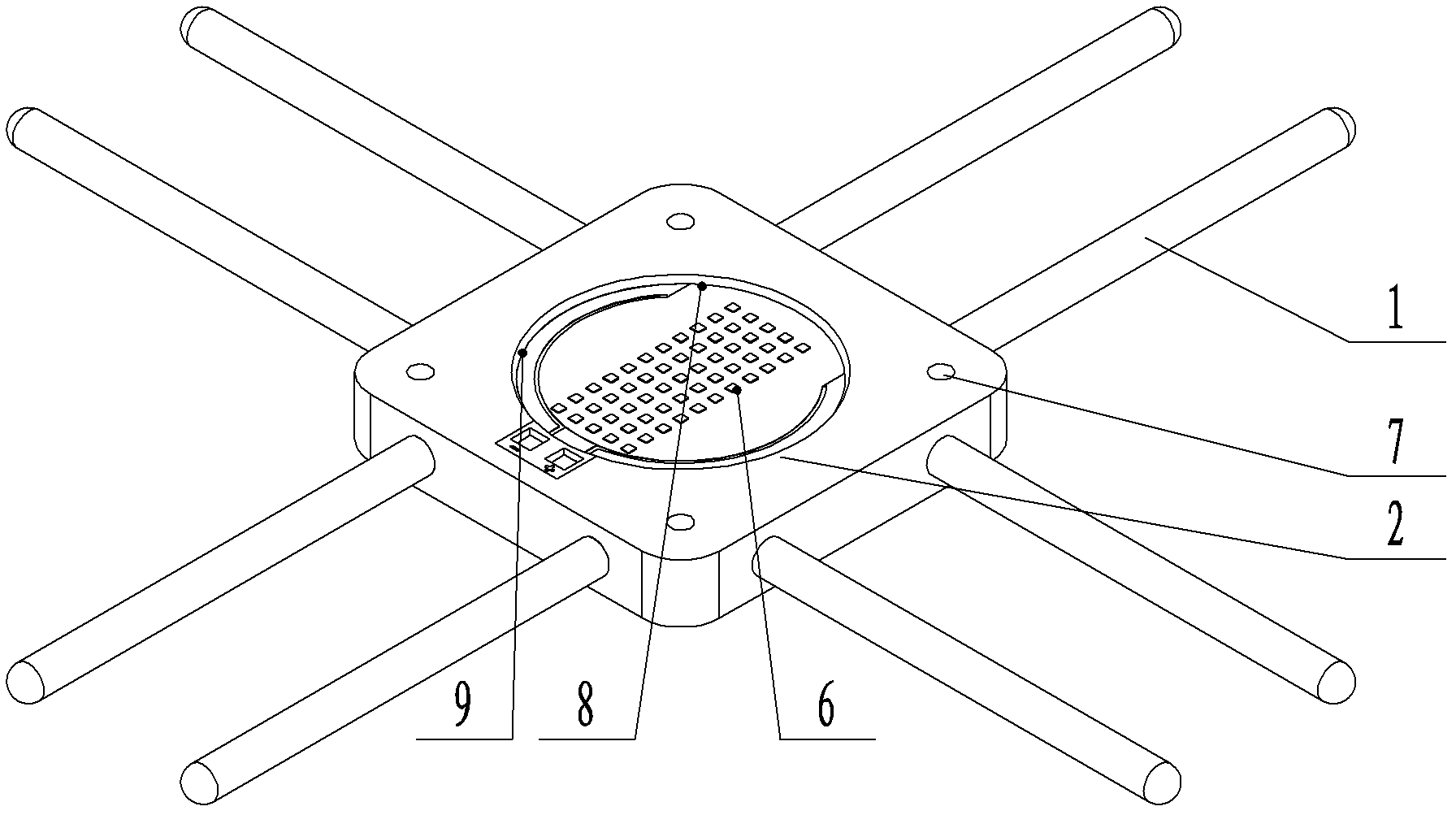

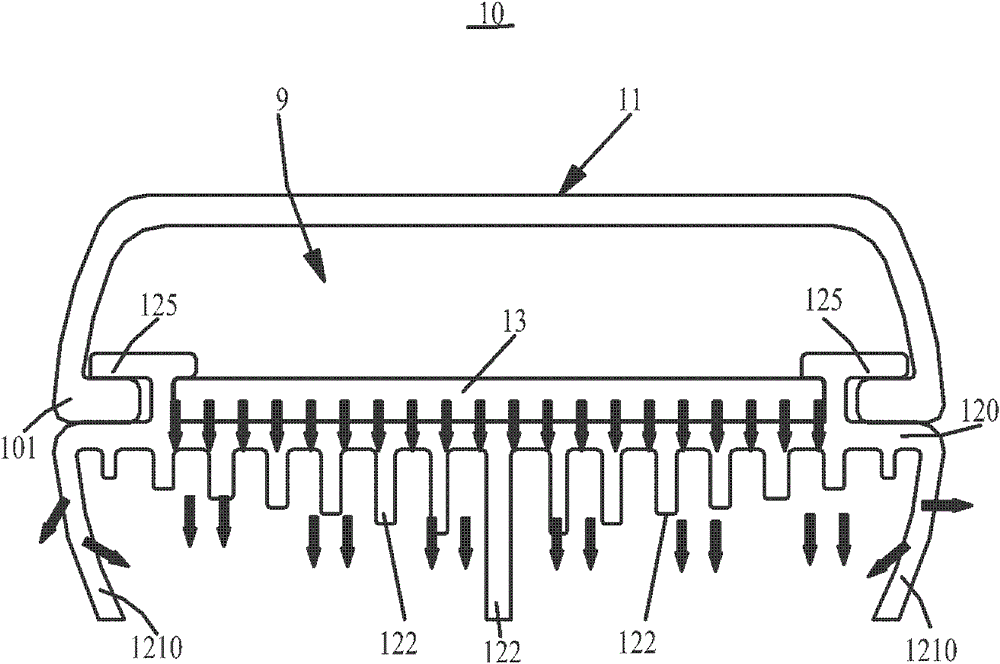

Packaging-free UVLED solidification light source module

InactiveCN103794603AMeet the curing wavelengthMeet needsSolid-state devicesSemiconductor devicesSealantHeat spreader

The invention relates to a packaging-free UVLED solidification light source module which comprises a silicon substrate. The packaging-free UVLED solidification light source module is characterized in that the front face of the silicon substrate is provided with a reflecting interconnection layer, and the upper surface of the reflecting interconnection layer is provided with a plurality of sets of positive and negative eutectic layers which are composed of P eutectic electrodes and N eutectic electrodes and provided with LED chips; the surfaces of the LED chips are covered with pouring sealants, and the LED chips are formed by integrating the LED chips with four wavelengths of 365 nm, 380 nm, 395 nm and 405 nm according to a ratio of 1:1:1:1; the back face of the silicon substrate is connected with a water cooling radiator through a welding layer, and the water cooling radiator is provided with a water inlet pipe and a water outlet pipe. Due to driving currents of the chips with the different wavelengths, the requirements for solidification wavelength and energy ratio of the majority of UV ink and glue can be met, the test heat resistance coefficient of the test light source module is lower than 3 DEG C / W, and the maximum driving power of the single LED chip can reach 5 W.

Owner:JIANGSU XINGUANGLIAN TECH

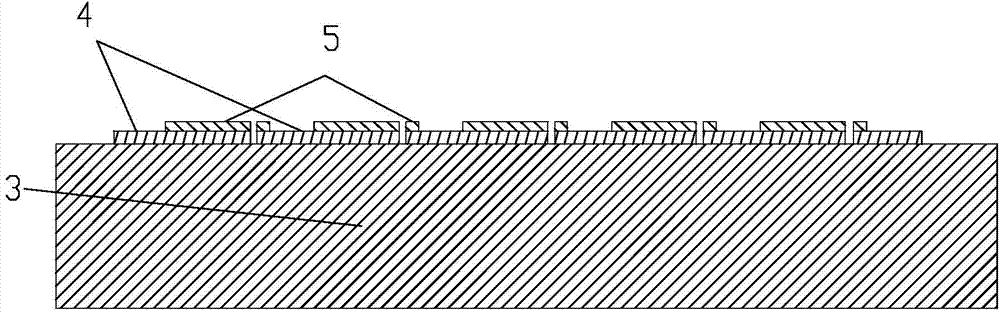

Composite heat sink of electrical circuit

InactiveCN101737750AEfficient dischargeLower thermal resistivityPoint-like light sourceSemiconductor/solid-state device detailsPlastic materialsEngineering

A composite heat sink of an electrical circuit comprises a radiator. One side of the radiator is provided with a plurality of radiating fins and the other side thereof is provided with a thermally conductive insulating layer. The thermally conductive insulating layer contains uniformly distributed thermally conductive powder. An electrical circuit layer is arranged on the thermally conductive insulating layer and contains uniformly distributed plastic materials and low-impedance electrically conductive powder. The electrical circuit layer is provided with connection points so that the electrical circuit layer can be electrically connected with an electronic component via the connection points. An insulating paint layer is arranged outside the thermally conductive insulating layer and the electrical circuit layer and has anti-soldering effect, so that the component or IC with heat source on the circuit can directly diffuse to rapidly dissipate heat in an overall manner to substantially reduce the thermal resistivity and ensure the effectivity and service lives of the electrical and electronic components.

Owner:SOLVETEK TECH CORP +2

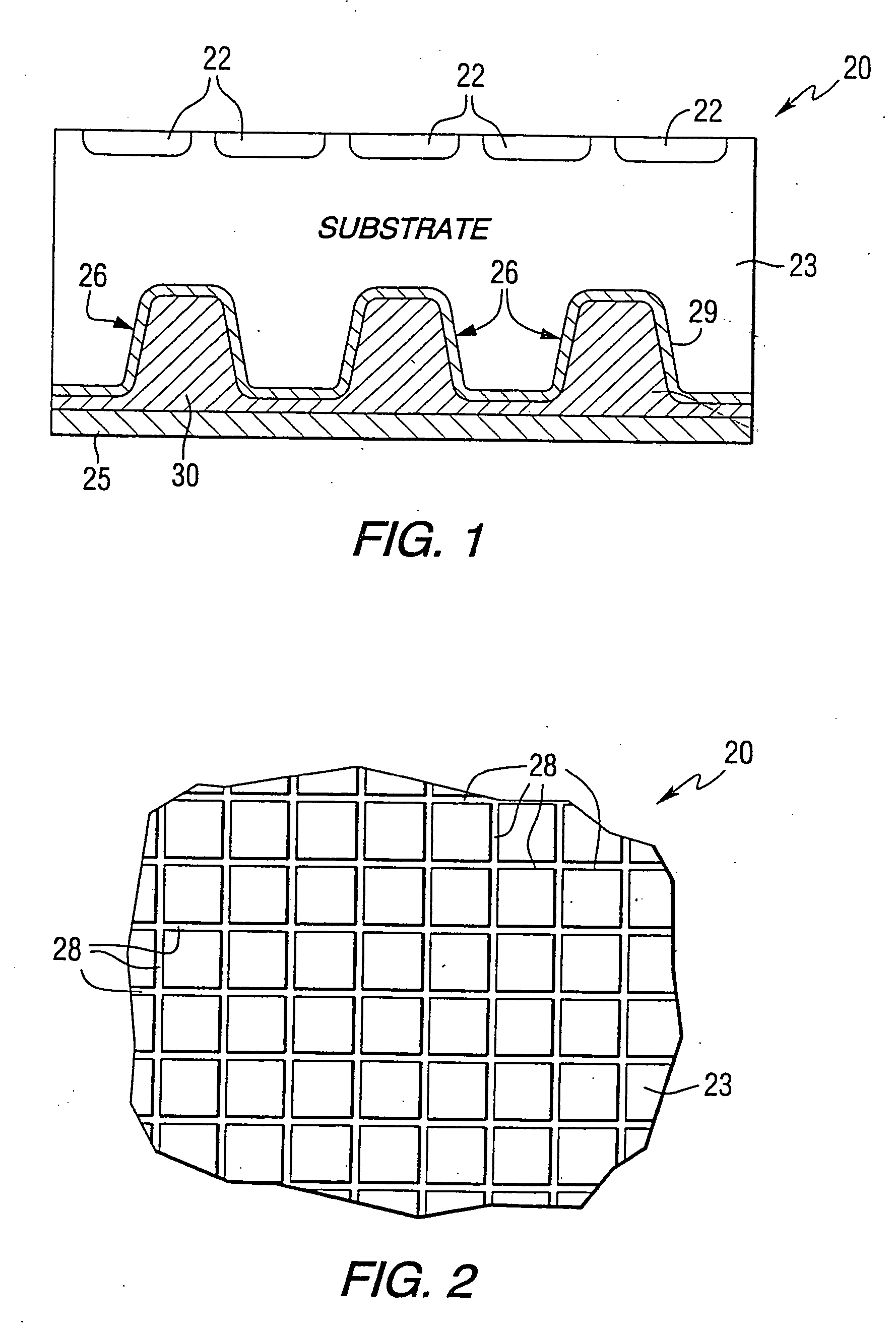

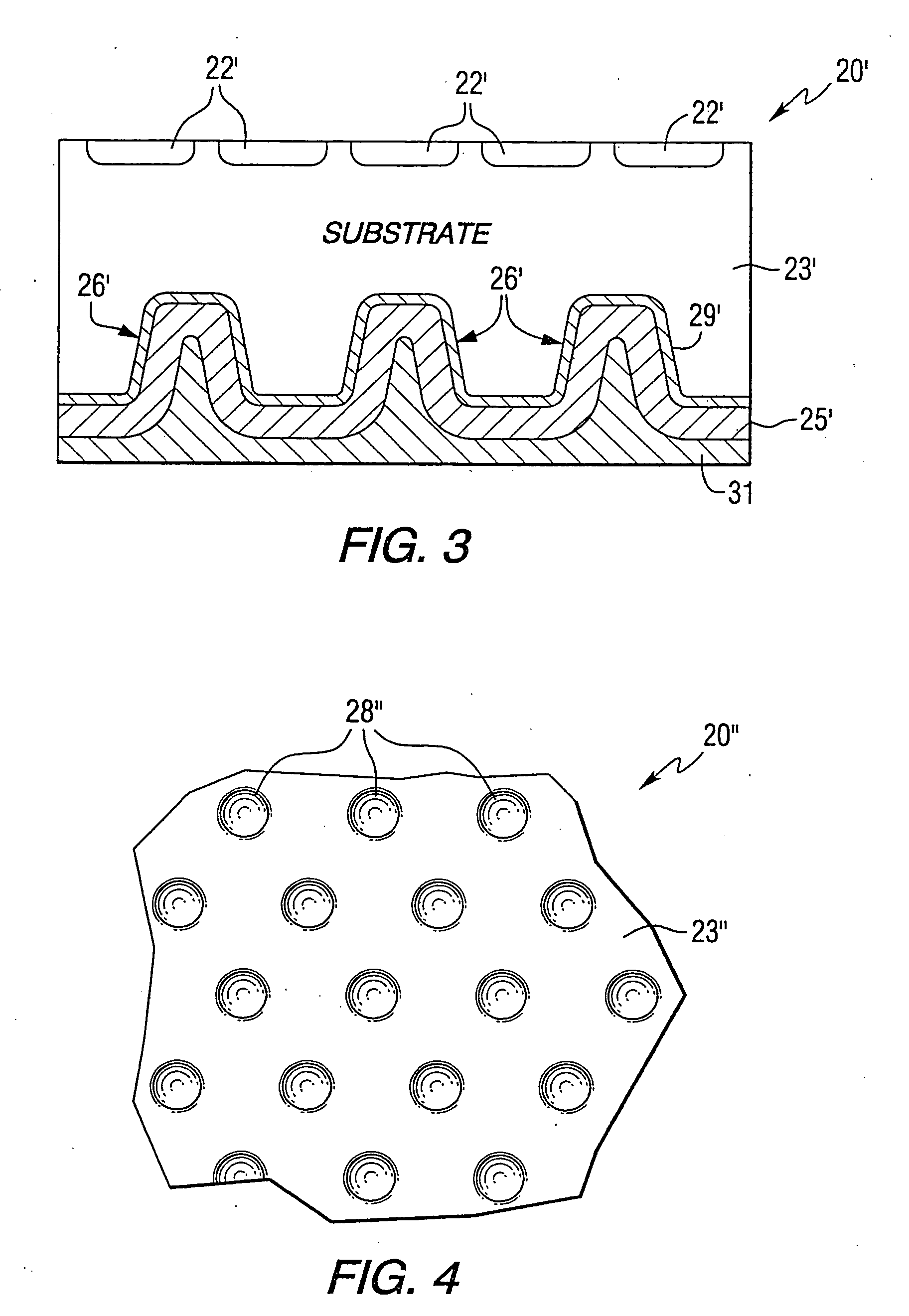

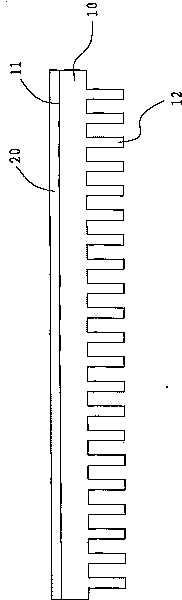

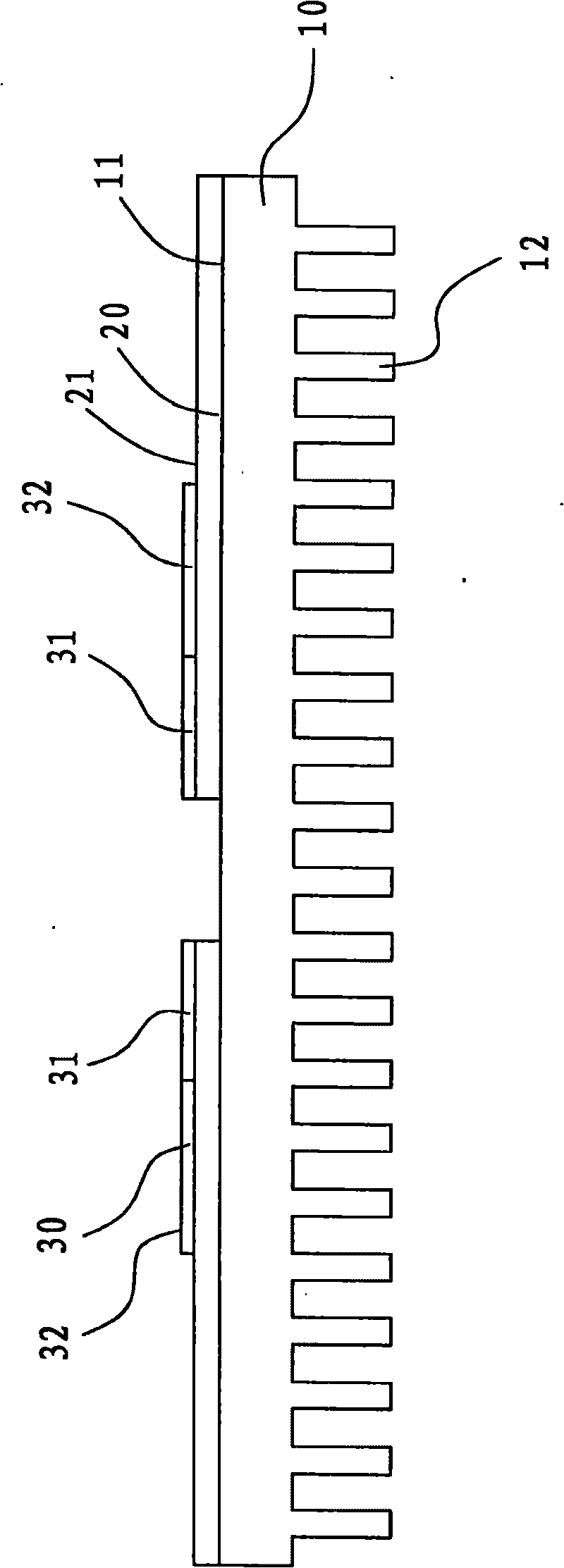

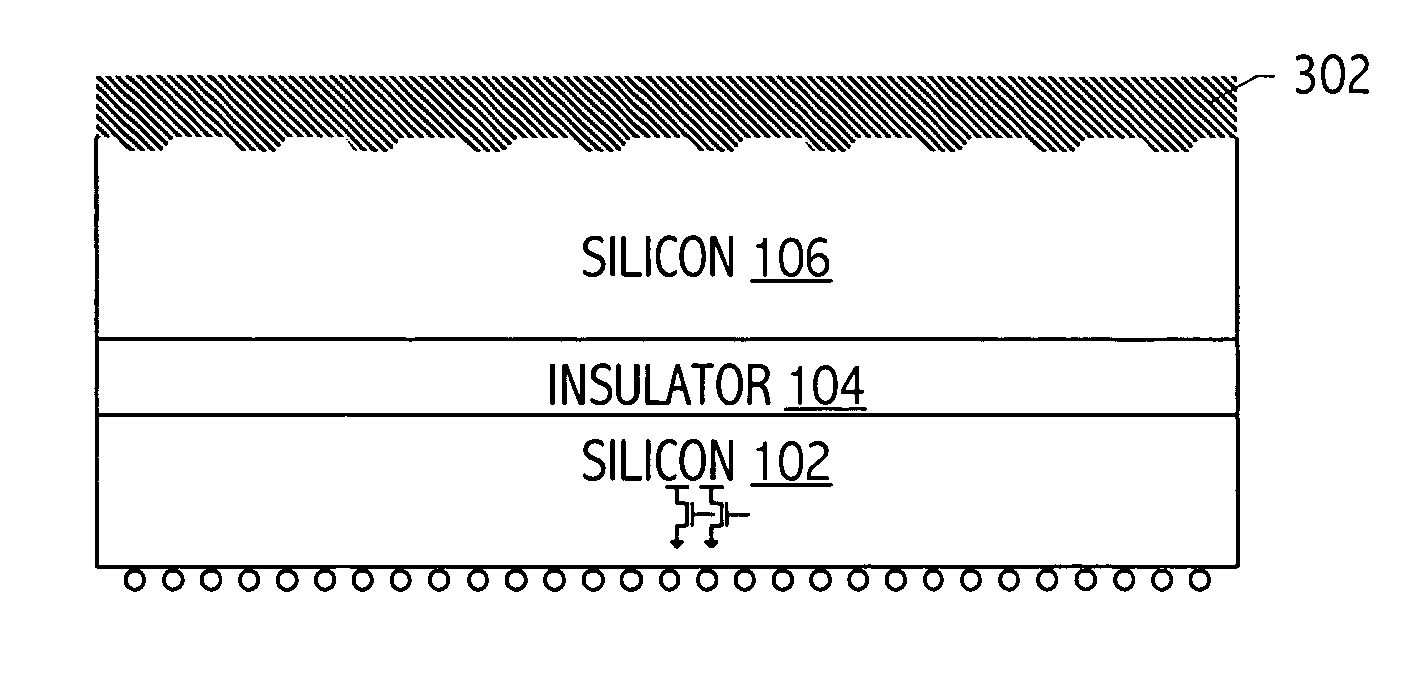

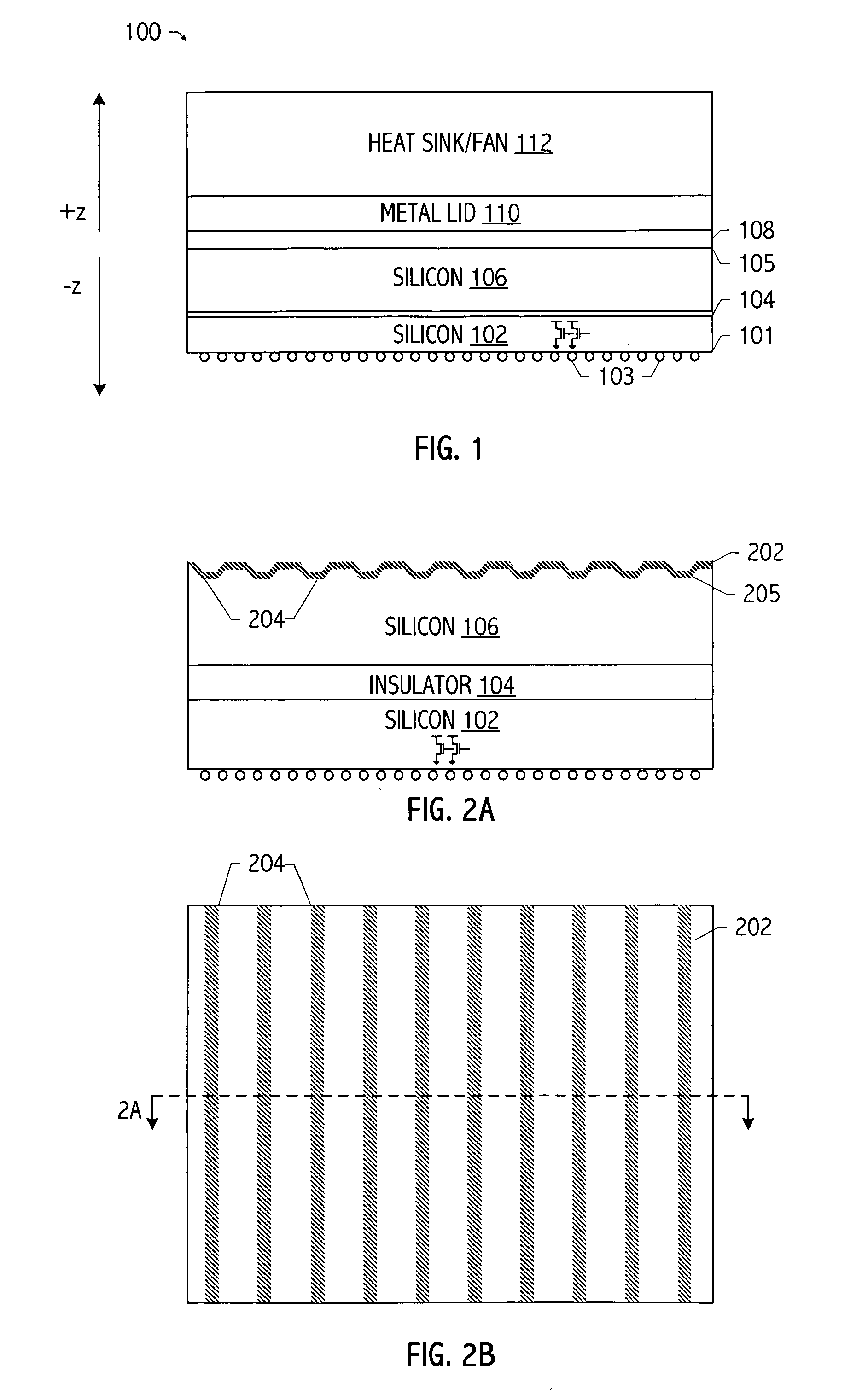

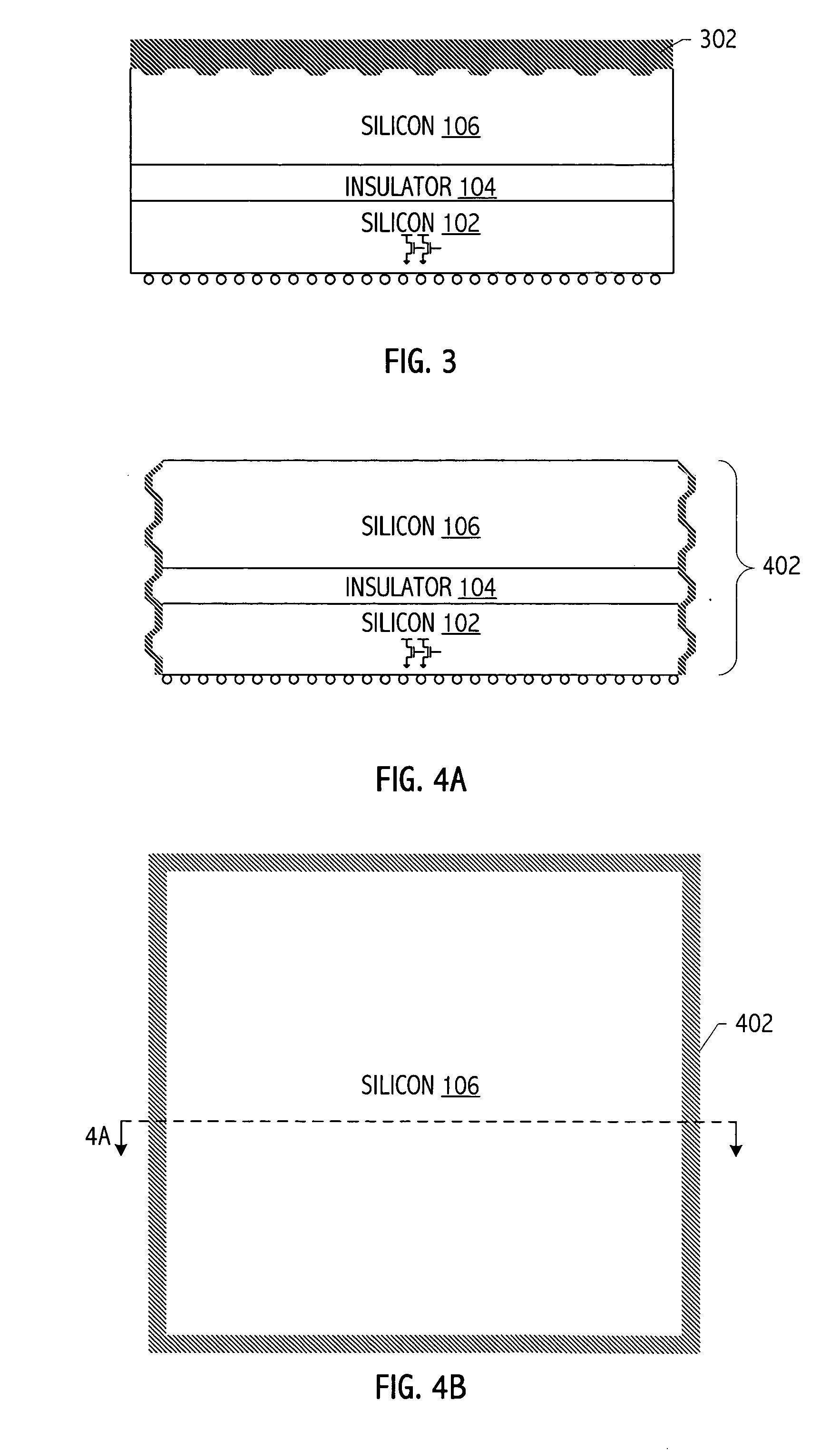

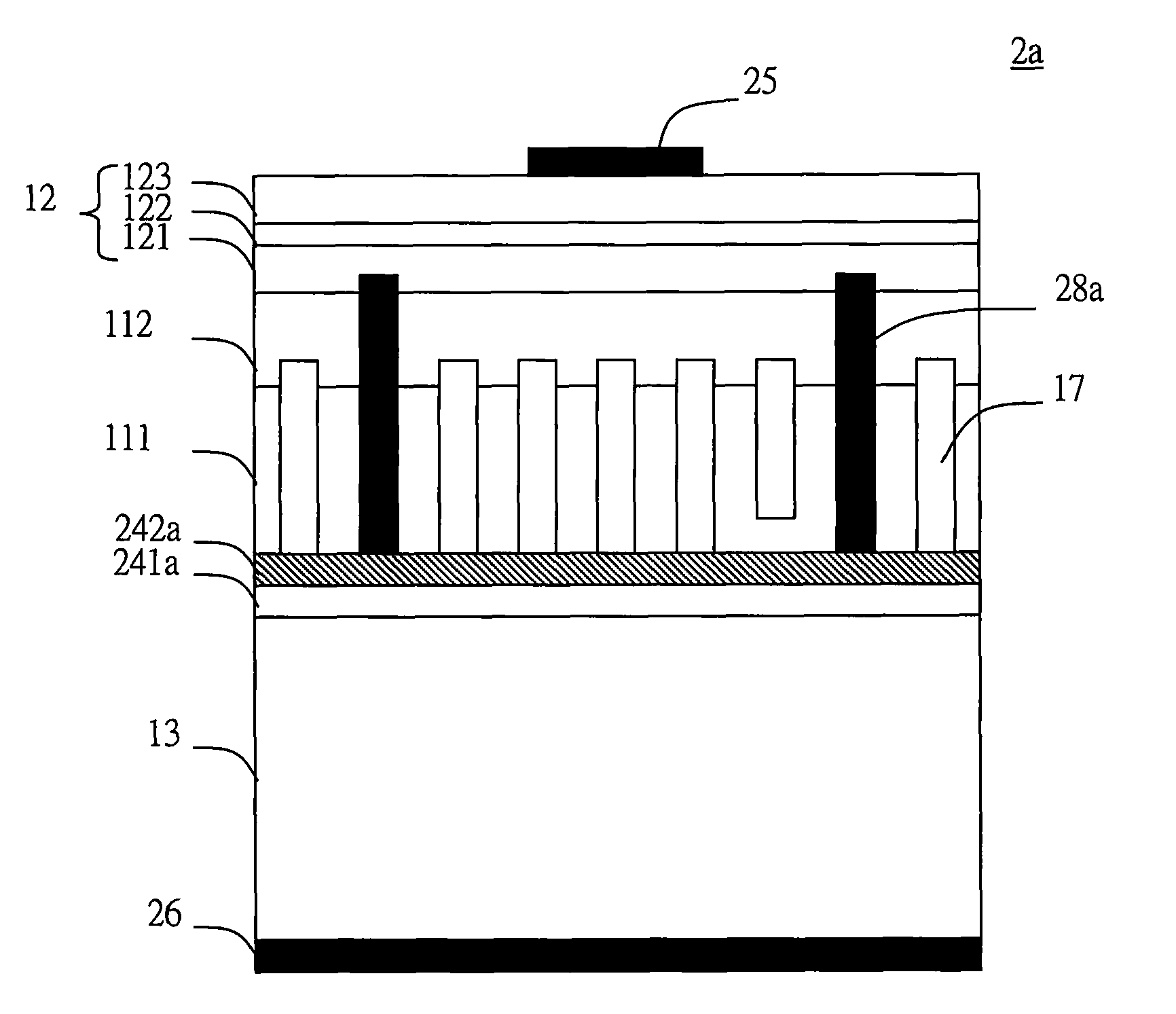

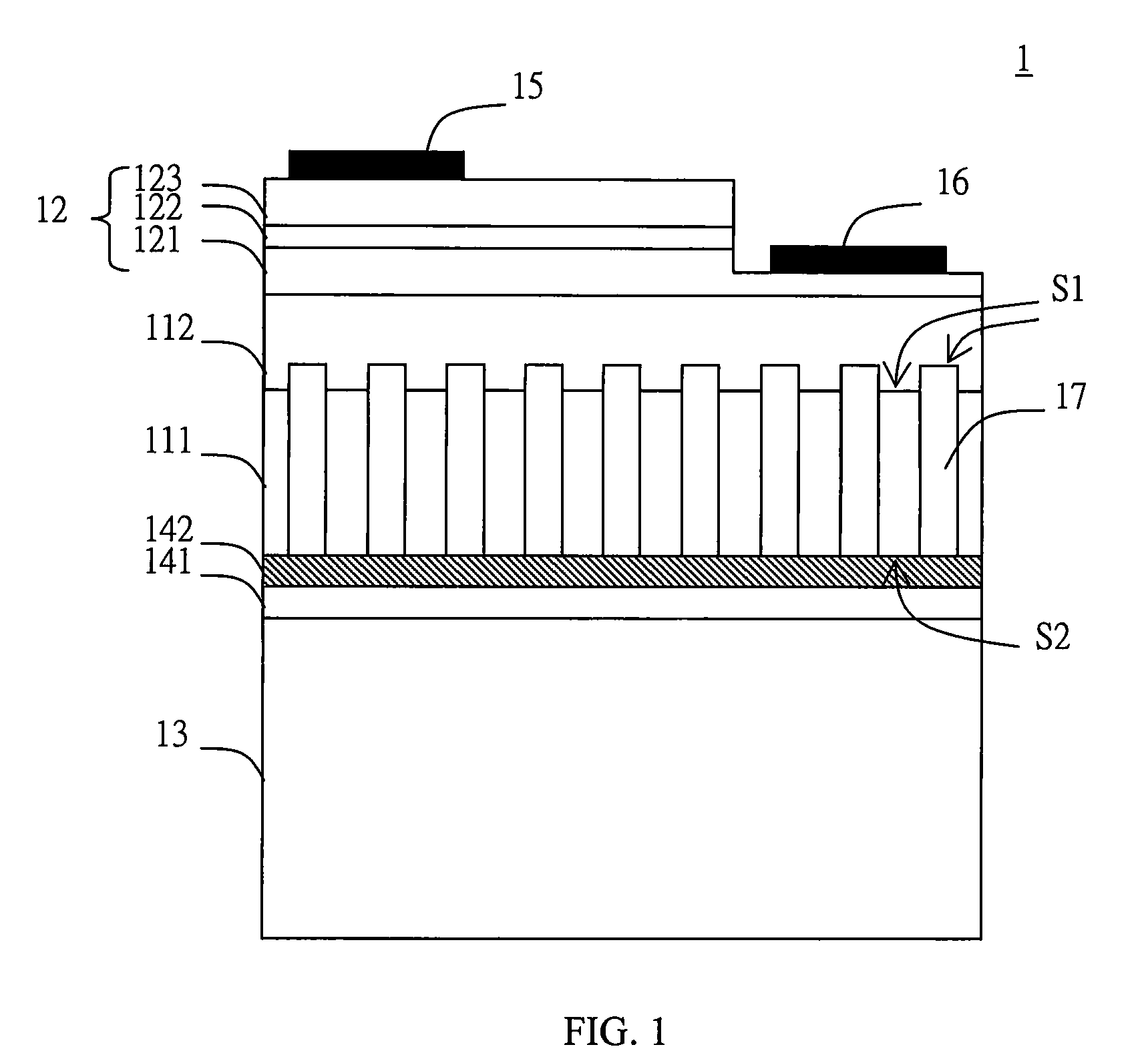

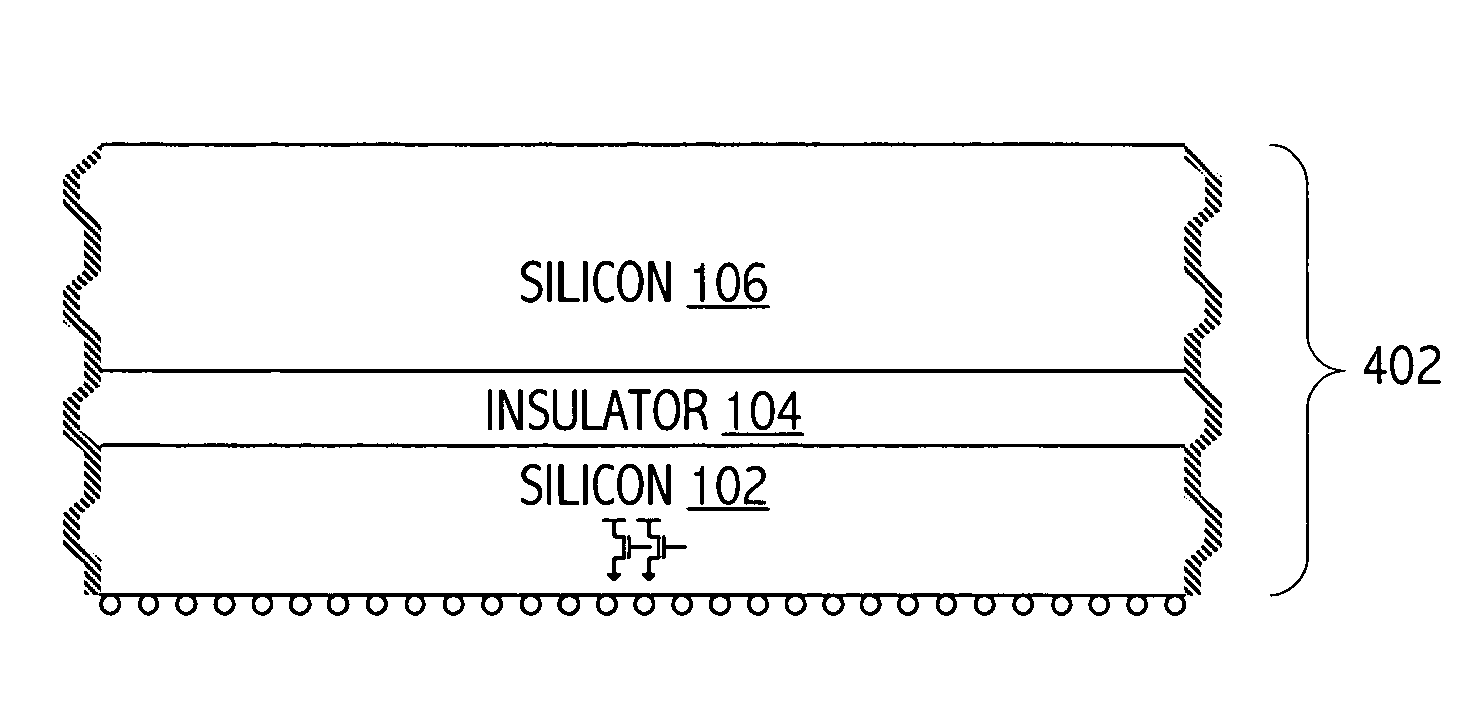

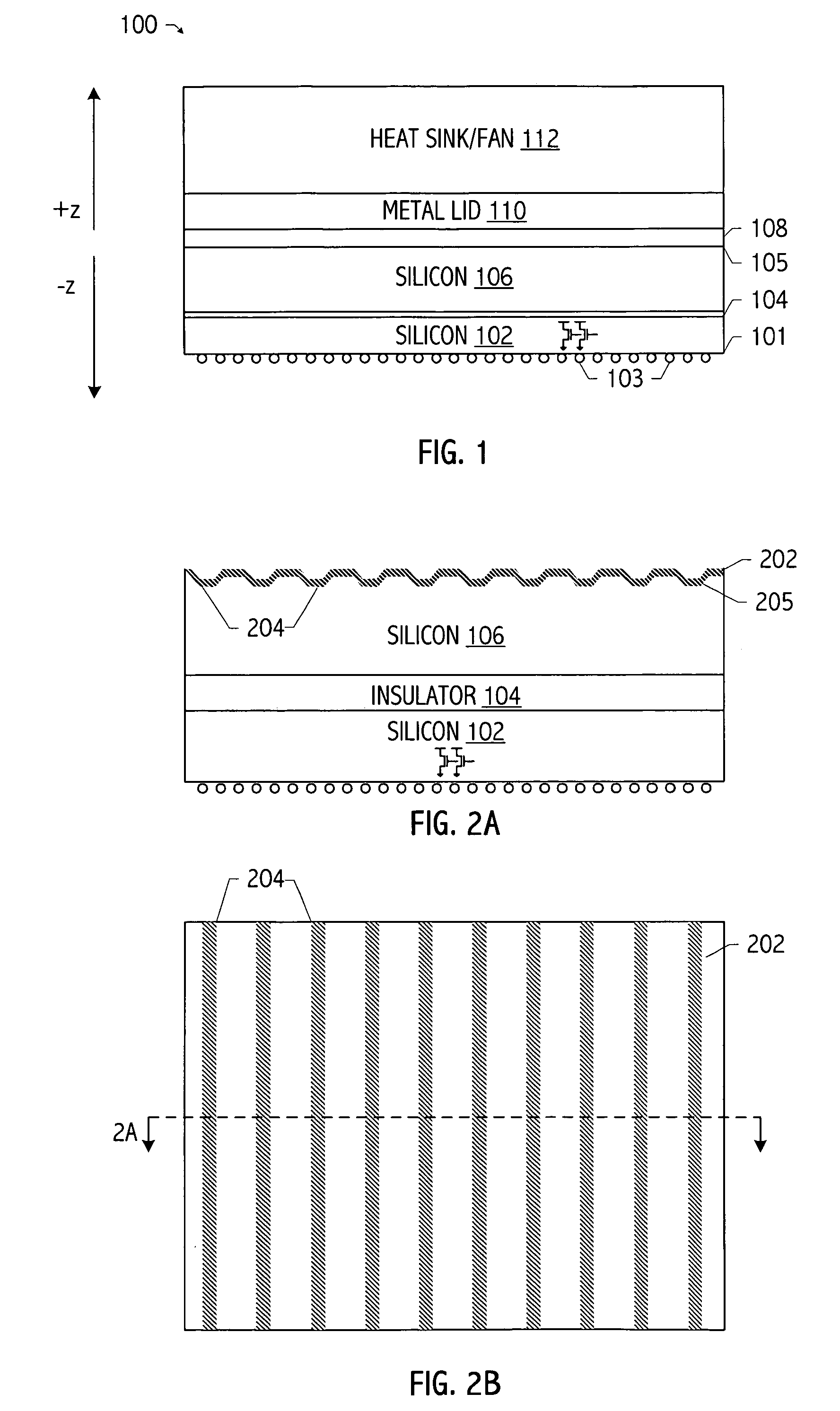

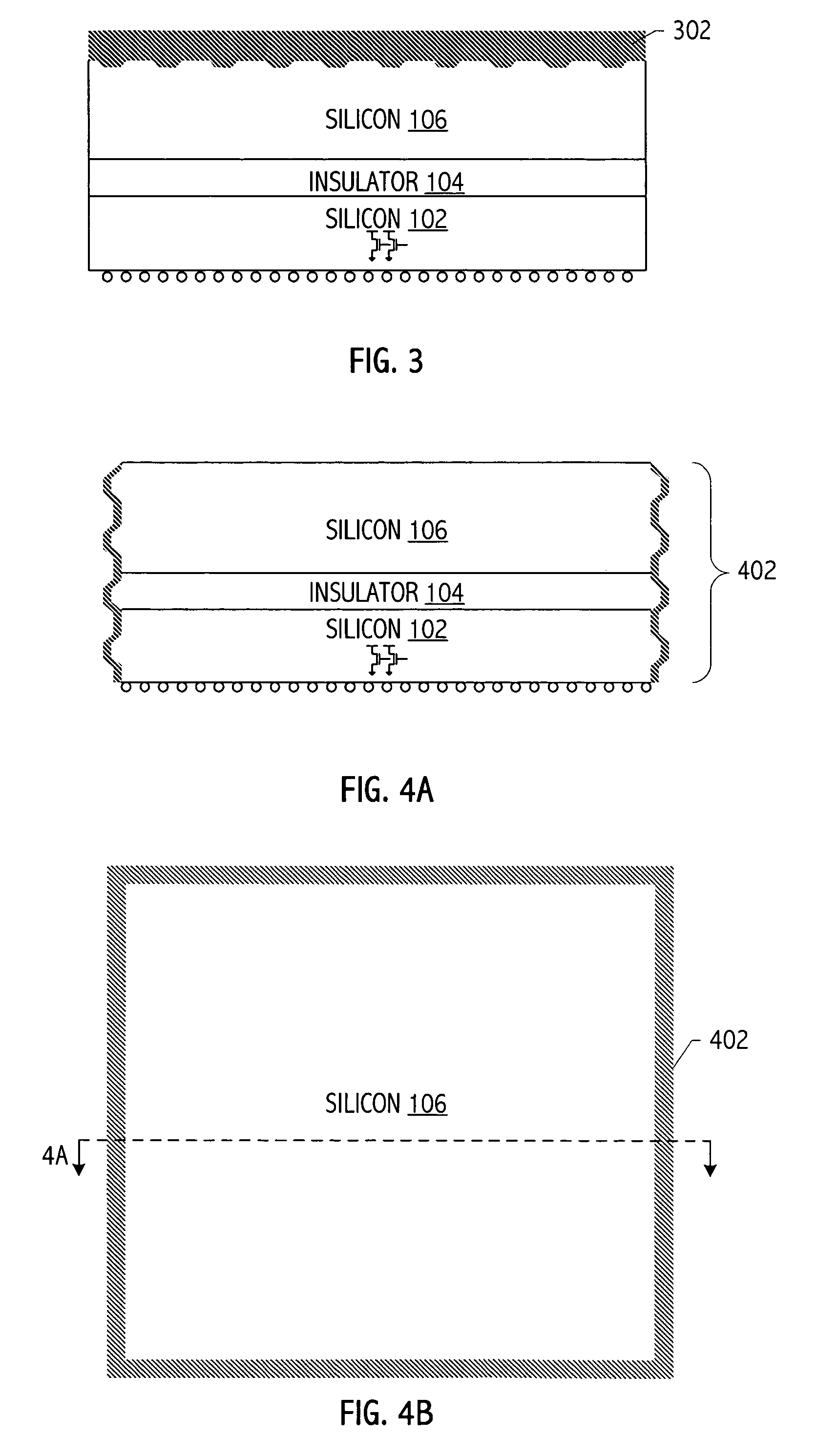

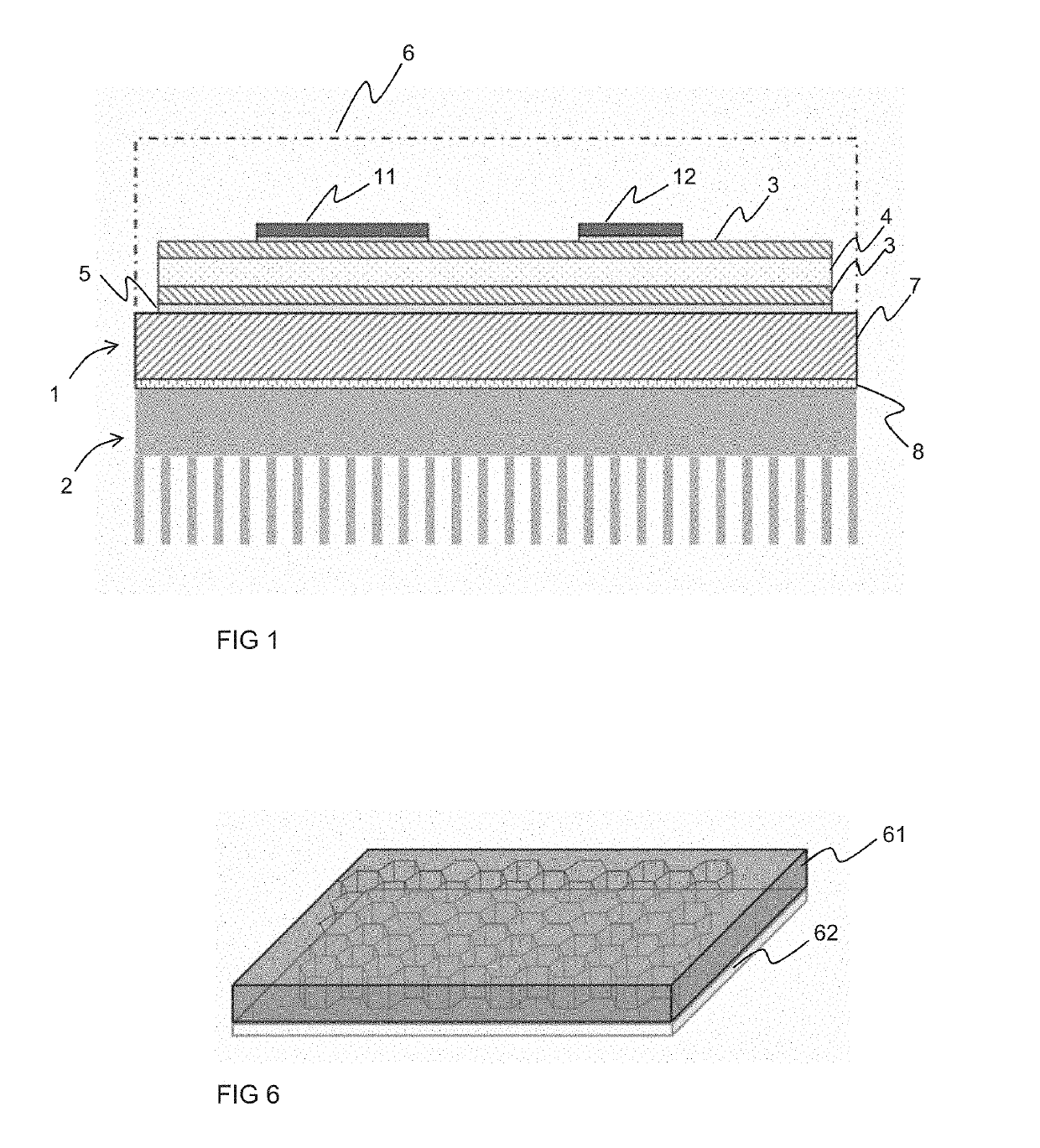

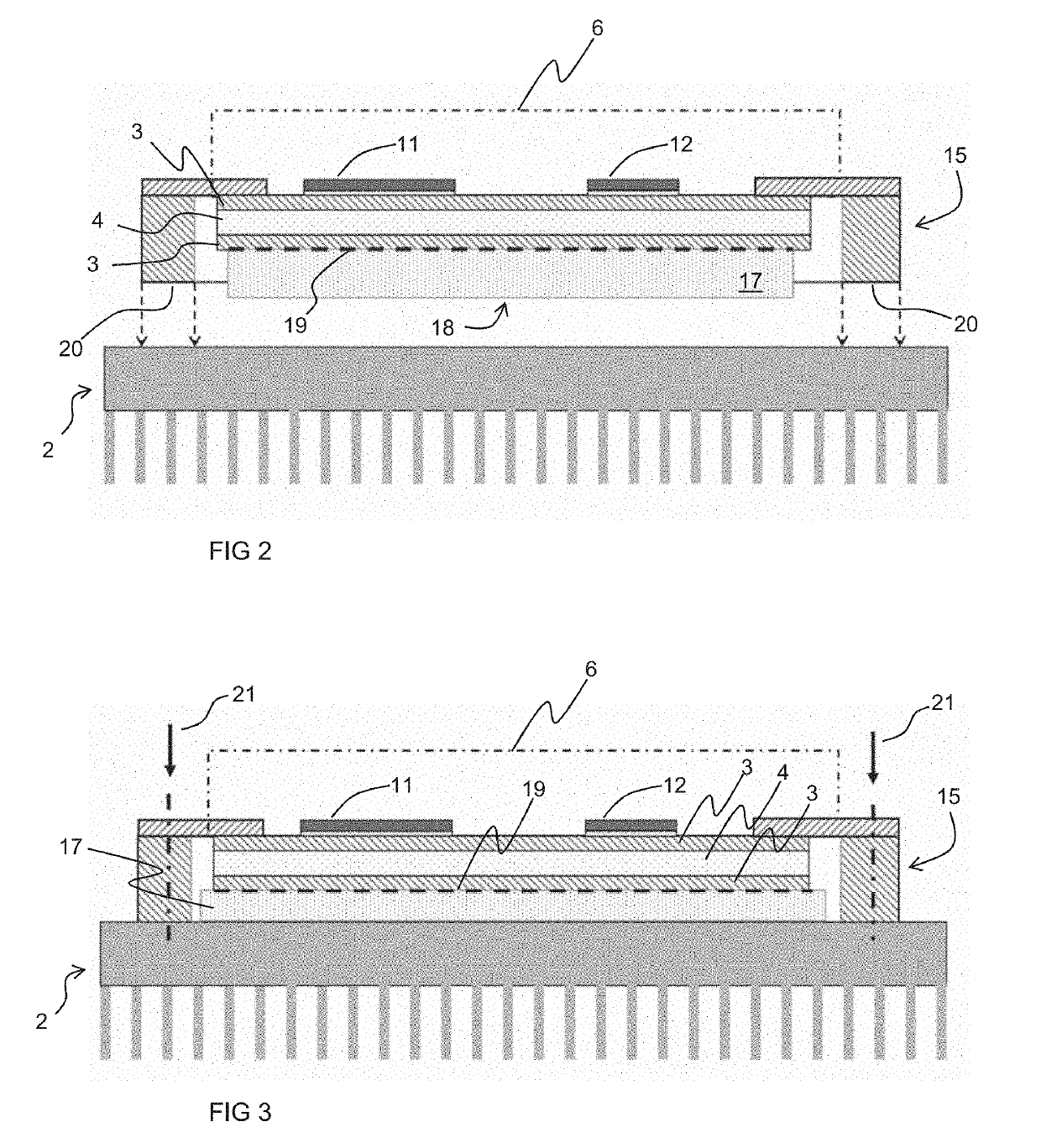

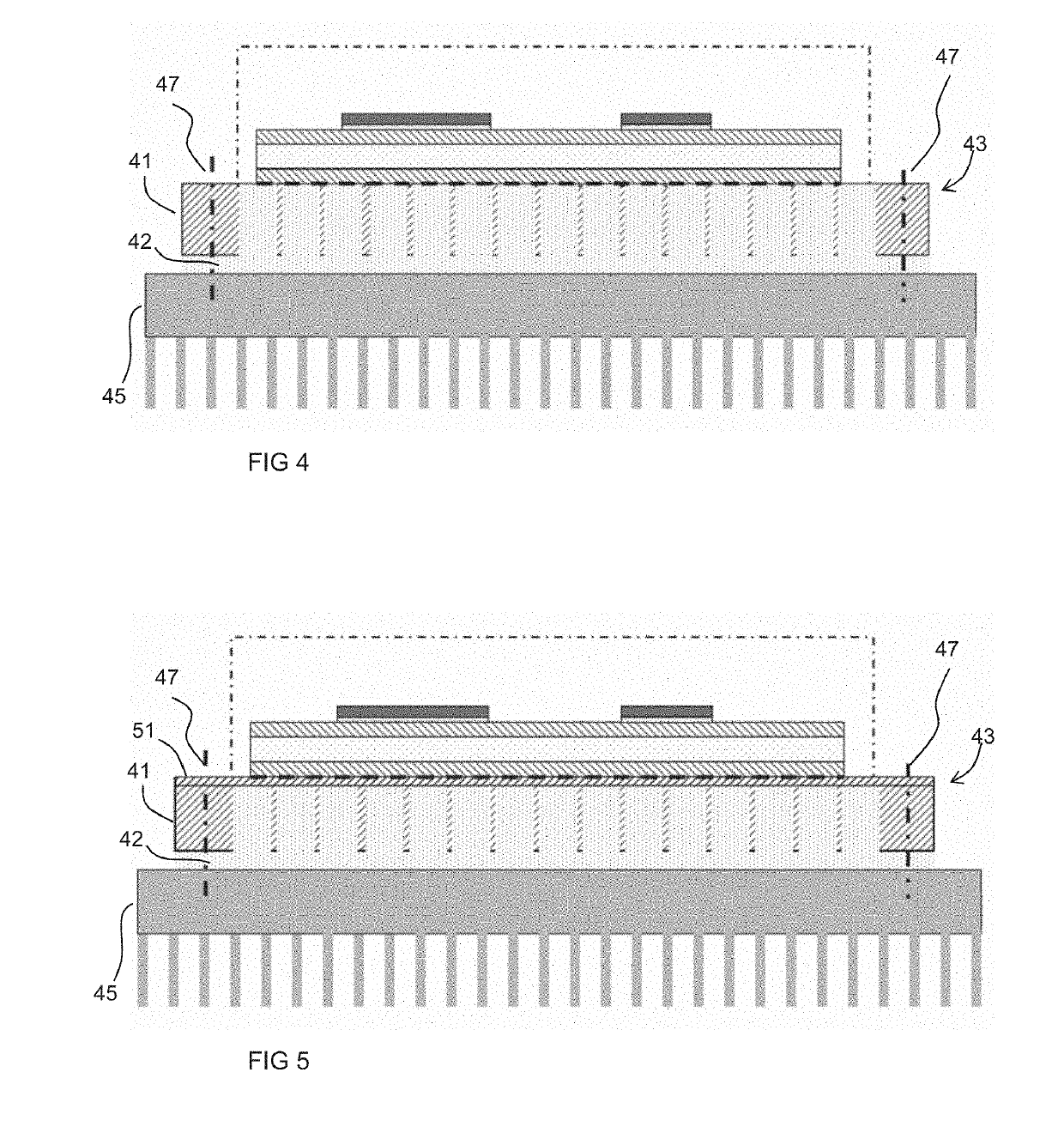

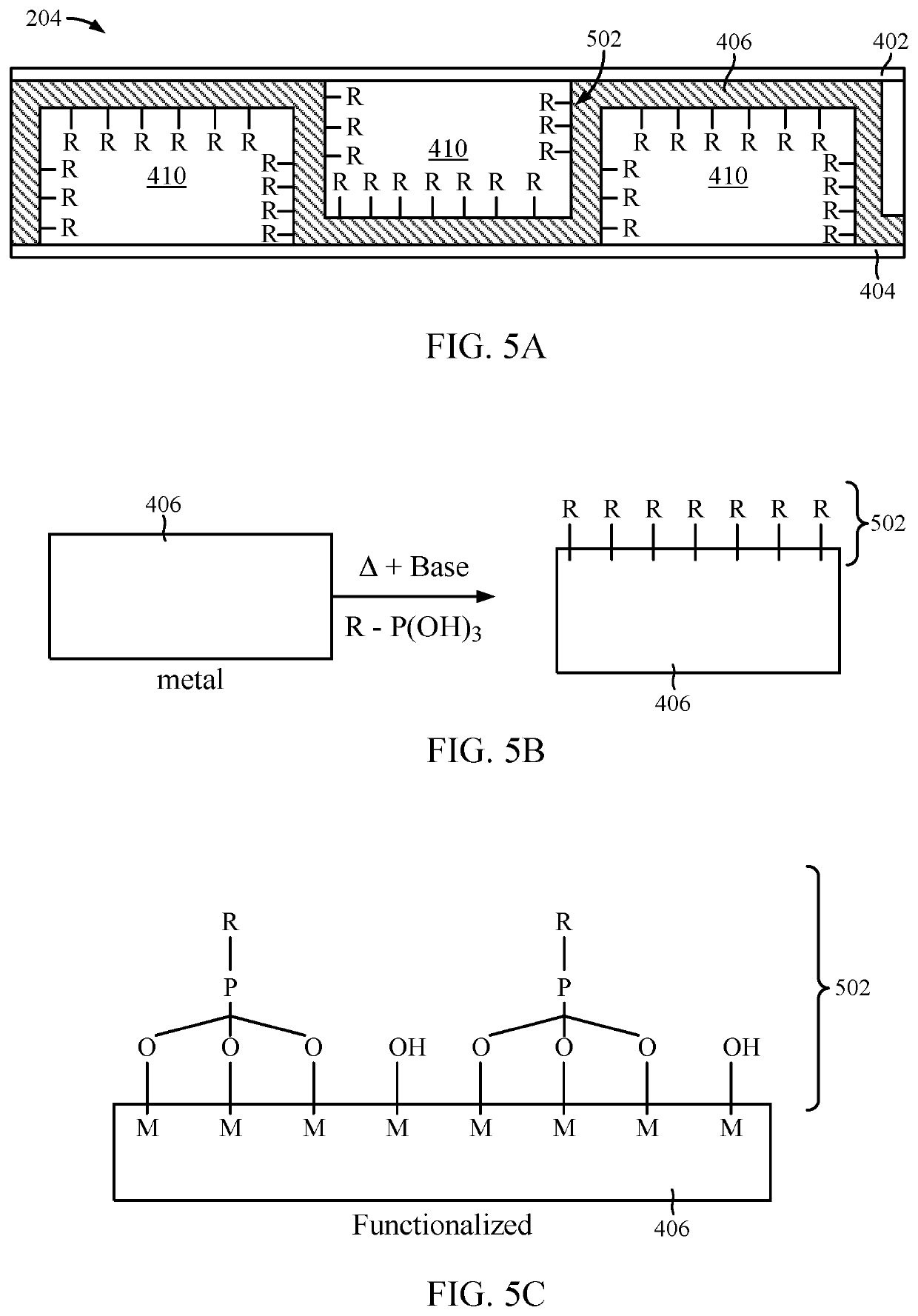

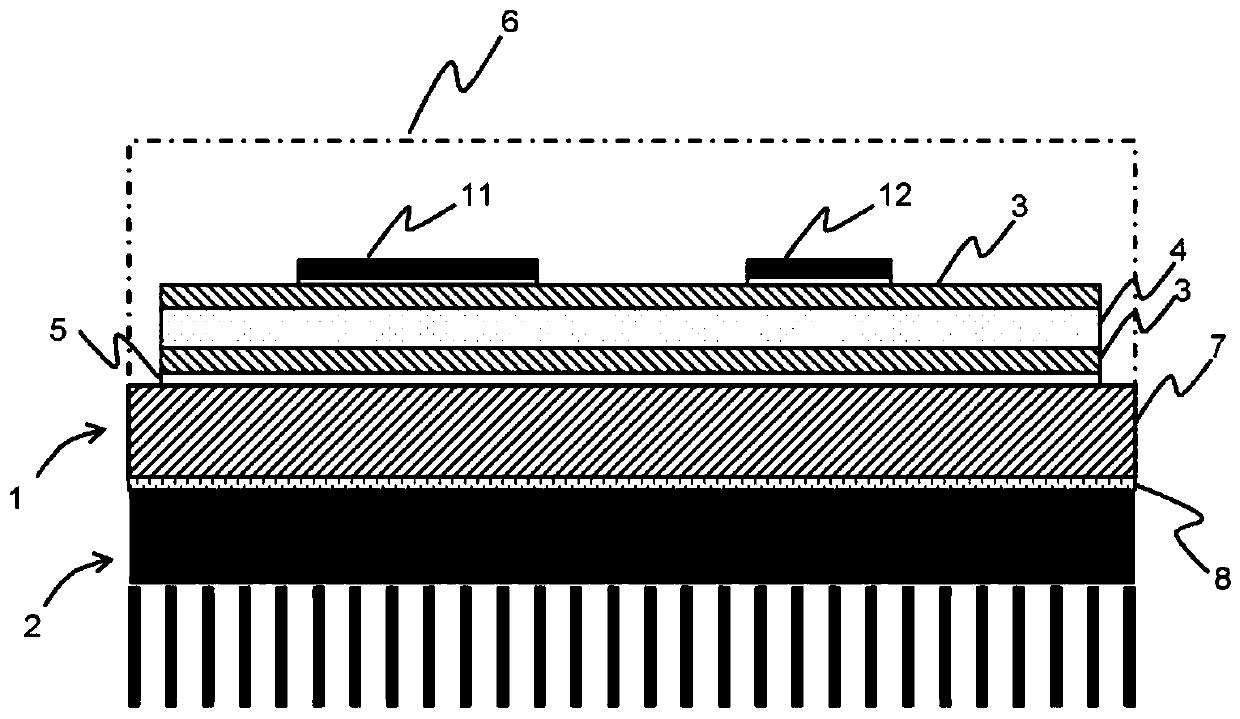

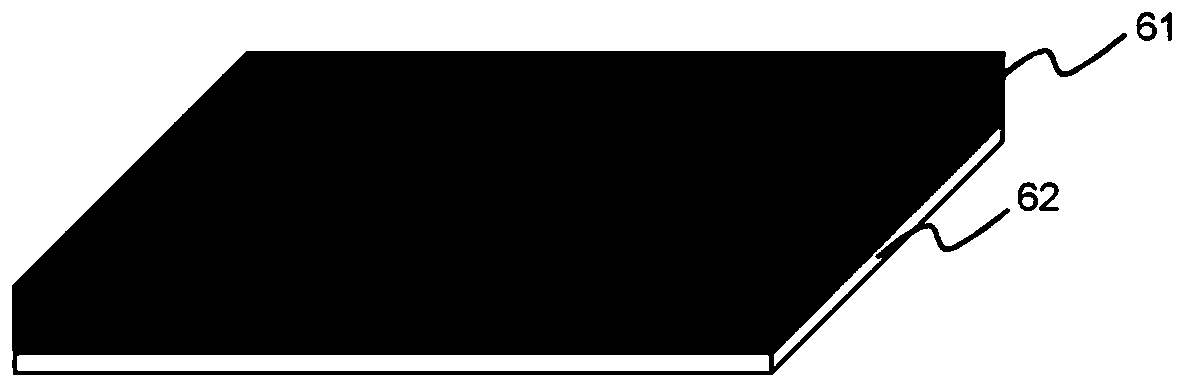

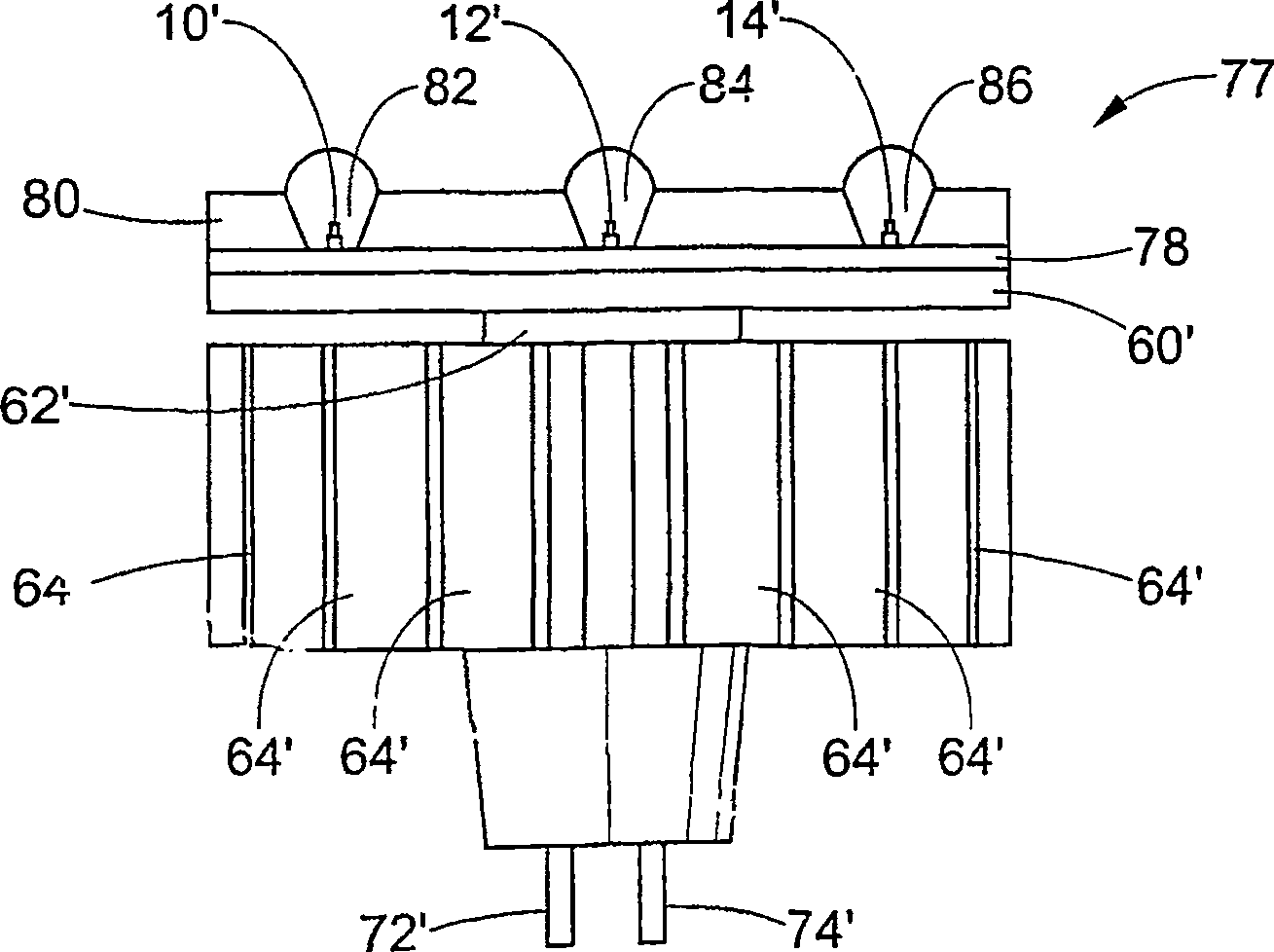

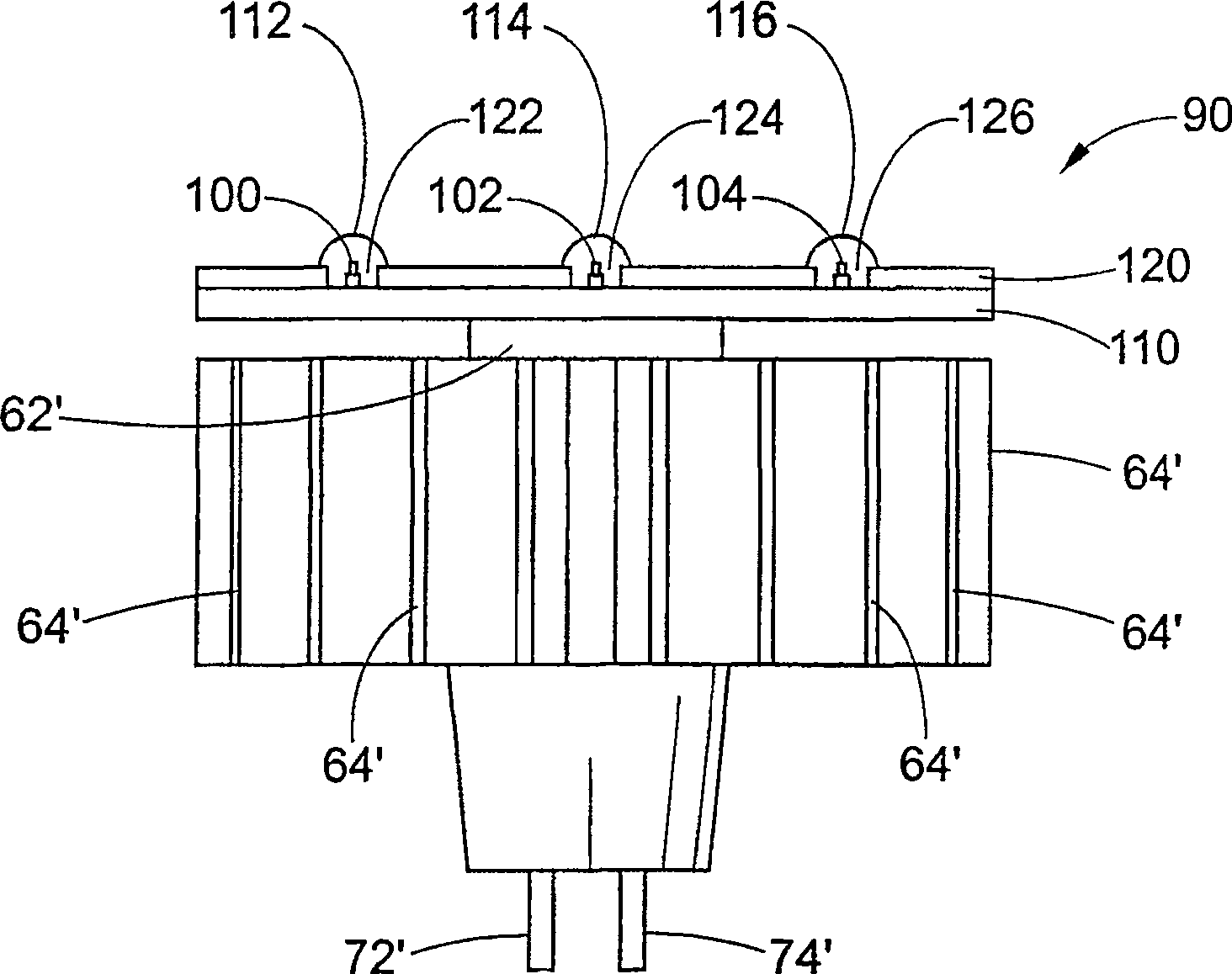

Integrated circuit with increased heat transfer

ActiveUS20060038283A1Increase power consumptionLower thermal resistivitySemiconductor/solid-state device detailsSolid-state devicesMaximum depthHeat power

A technique for improving the thermal power dissipation of an integrated circuit includes reducing the thermal resistivity of the integrated circuit by increasing heat transfer in vertical and / or lateral directions. These results are achieved by increasing the surface area of the backside and / or the surface area of the lateral sides of the integrated circuit die. In some embodiments of the invention, an integrated circuit includes circuit elements formed closer to a first surface of a semiconductor substrate than to a second surface of the semiconductor substrate. The semiconductor substrate has a varying profile that substantially increases the surface area of a thermal interface formed on the second surface as compared to the second surface being substantially planar. A maximum depth of the profile is less than the thickness of the semiconductor substrate.

Owner:GLOBALFOUNDRIES US INC

Semiconductor device having reduced effective substrate resistivity and associated methods

InactiveUS7098108B1Reducing effective substrate resistivityReducing the effective substrate resistivityTransistorSemiconductor/solid-state device detailsMOSFETElectrical conductor

A semiconductor device includes at least one device active region formed in a first surface of a semiconductor substrate, an electrical contact layer on a second surface of the semiconductor substrate, and at least one resistivity-lowering body positioned in a corresponding recess in the substrate and connected to the electrical contact layer. The body preferably comprises a material having an electrical resistivity lower than an electrical resistivity of the semiconductor substrate to thereby lower an effective electrical resistivity of the substrate. The device active region may be an active region of a power control device, such as a MOSFET or IGBT, for example. The body may preferably comprise an electrical conductor such as copper, aluminum, silver, solder, or doped polysilicon. The at least one recess and associated resistivity-lowering body preferably defines a proportion of the semiconductor substrate area adjacent the device active region greater than about 0.4 percent, and may extend into the semiconductor substrate a distance greater than about 25 percent of a thickness of the substrate.

Owner:FAIRCHILD SEMICON CORP

Light-emitting device having a thinned structure and the manufacturing method thereof

ActiveUS8207539B2Lower thermal resistivityImprove efficiencySemiconductor/solid-state device testing/measurementSolid-state devicesEngineeringLight emitting device

A semiconductor light-emitting device having a thinned structure comprises a thinned structure formed between a semiconductor light-emitting structure and a carrier. The manufacturing method comprises the steps of forming a semiconductor light-emitting structure above a substrate; attaching the semiconductor light-emitting structure to a support; thinning the substrate to form a thinned structure; forming or attaching a carrier to the thinned substrate; and removing the support.

Owner:EPISTAR CORP

Novel low-smoke, halogen-free and fireproof insulated wire and manufacturing method thereof

InactiveCN105355298ABlock deliveryReduce secondary investment costsPlastic/resin/waxes insulatorsCeramicsPolyolefinElectrical conductor

The invention discloses a novel low-smoke, halogen-free and fireproof insulated wire and a manufacturing method thereof. The fireproof insulated wire comprises wire conductors and an insulated layer. The wire conductors are formed by intertwisting one to sixty-one circular annealed copper wires with a diameter of [phi]1.2-4.5mm in a length direction. The insulated layer is disposed outside the wire conductors, and is a ceramic polyolefin material. The manufacturing method comprises the following steps: S1, drawing copper wires: drawing an oxygen-free copper rod with a 8.0mm diameter and resistivity not more than 0.017241[omega]*mm<2> / m into copper wires with a diameter of [phi]1.2-4.5mm through a conventional technology, the output speed of the copper wires being 3-25m / s, preheating the copper wires to 240-260 DEG C after copper wire drawing, introducing nitrogen, heating the copper wires again to 550-560 EDG C for recrystallization, and blow-drying the copper wires by compressed air and cooling the copper wires to 80 DEG C below after watering cooling; S2, intertwisting conductors (except single-core conductors); S3, extruding an insulated layer; and S4, making an insulated wire a roll. The manufacturing method is easy to operate, the quality control difficulty is minimized, the secondary investment cost of the wire can be reduced if people use the fireproof insulated wire, and the service life of the wire can be prolonged.

Owner:BAOJI EVERLASTING LIGHT CABLE CO LTD

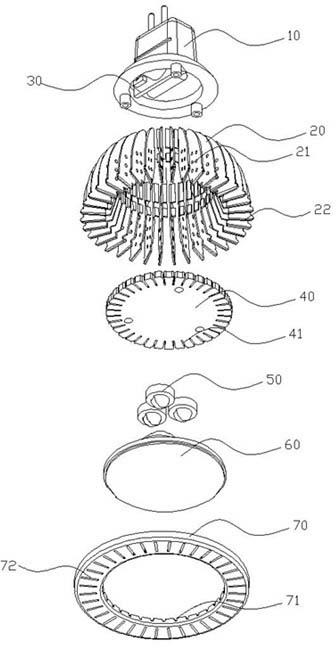

Light emitting diode (LED) lamp

InactiveCN102606897AReduce usageLower thermal resistivityPoint-like light sourceLighting heating/cooling arrangementsLight beamAluminum substrate

The invention discloses a light emitting diode (LED) lamp, which comprises a lamp holder plastic part, an aluminum substrate radiator, a driver, an LED light source, and a light source lens. The plastic part is arranged at the bottom of the substrate radiator. The driver is fixed in the substrate radiator and the plastic part. The LED light source is arranged on the substrate radiator, and is electrically connected with the driver. Light beams generated by the light source after electrifying is converged and refracted through the light source lens. In the invention, the aluminum substrate radiator is a heat dissipation structure formed by an aluminum substrate and a plurality of heat dissipation fins, which reduces heat resistivity of the radiator, and simultaneously lowers the consumption of aluminum raw material due to simple structure, to really achieve effects of energy saving and environmental friendliness.

Owner:李翘英

Integrated circuit with increased heat transfer

ActiveUS7259458B2Increase power consumptionLower thermal resistivitySemiconductor/solid-state device detailsSolid-state devicesMaximum depthHeat power

A technique for improving the thermal power dissipation of an integrated circuit includes reducing the thermal resistivity of the integrated circuit by increasing heat transfer in vertical and / or lateral directions. These results are achieved by increasing the surface area of the backside and / or the surface area of the lateral sides of the integrated circuit die. In some embodiments of the invention, an integrated circuit includes circuit elements formed closer to a first surface of a semiconductor substrate than to a second surface of the semiconductor substrate. The semiconductor substrate has a varying profile that substantially increases the surface area of a thermal interface formed on the second surface as compared to the second surface being substantially planar. A maximum depth of the profile is less than the thickness of the semiconductor substrate.

Owner:GLOBALFOUNDRIES U S INC

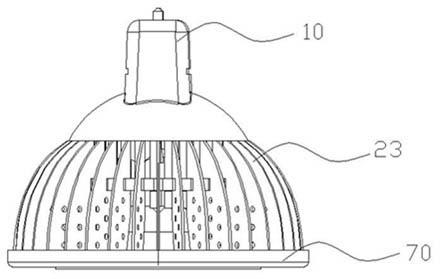

Heat-pipe type LED (light emitting diode) lamp

InactiveCN102606905AHigh light efficiencyExtend your lifePoint-like light sourceElectric circuit arrangementsEngineeringLED lamp

The invention relates to an LED (light emitting diode) lamp, in particular to a heat-pipe type LED lamp. In the prior art, a large-power LED lamp is usually cooled by using a heat pipe, the LED chip can not be directly attached to a radiator, and a base for supporting the LED chip is required between the heat pipe and the LED chip so as to influence heat dissipation of the LED due to the thermal resistance of the base. The heat-pipe type LED lamp is characterized in that the radiator includes a heat pipe, and a substrate connected with the heat pipe, wherein a closed cavity is formed in the middle of the substrate; the heat pipe is communicated with the cavity; an LED light source is arranged on the upper end face of the substrate; the contact surface between the substrate and the LED light source is a plane surface; and a LED chip is directly packaged on the upper end face of the substrate to form the LED light source integrated with the radiator. The substrate keeps plane contact with the LED light source so as to ensure the integrity of the contact, thereby improving welding quality. Additionally, the heat generated by the LED chip can be dissipated by the radiator, thereby reducing thermal resistance coefficient, realizing quick thermal conduction, and improving luminous efficiency and prolonging service life of LED.

Owner:杭州临安新联电器工业有限公司

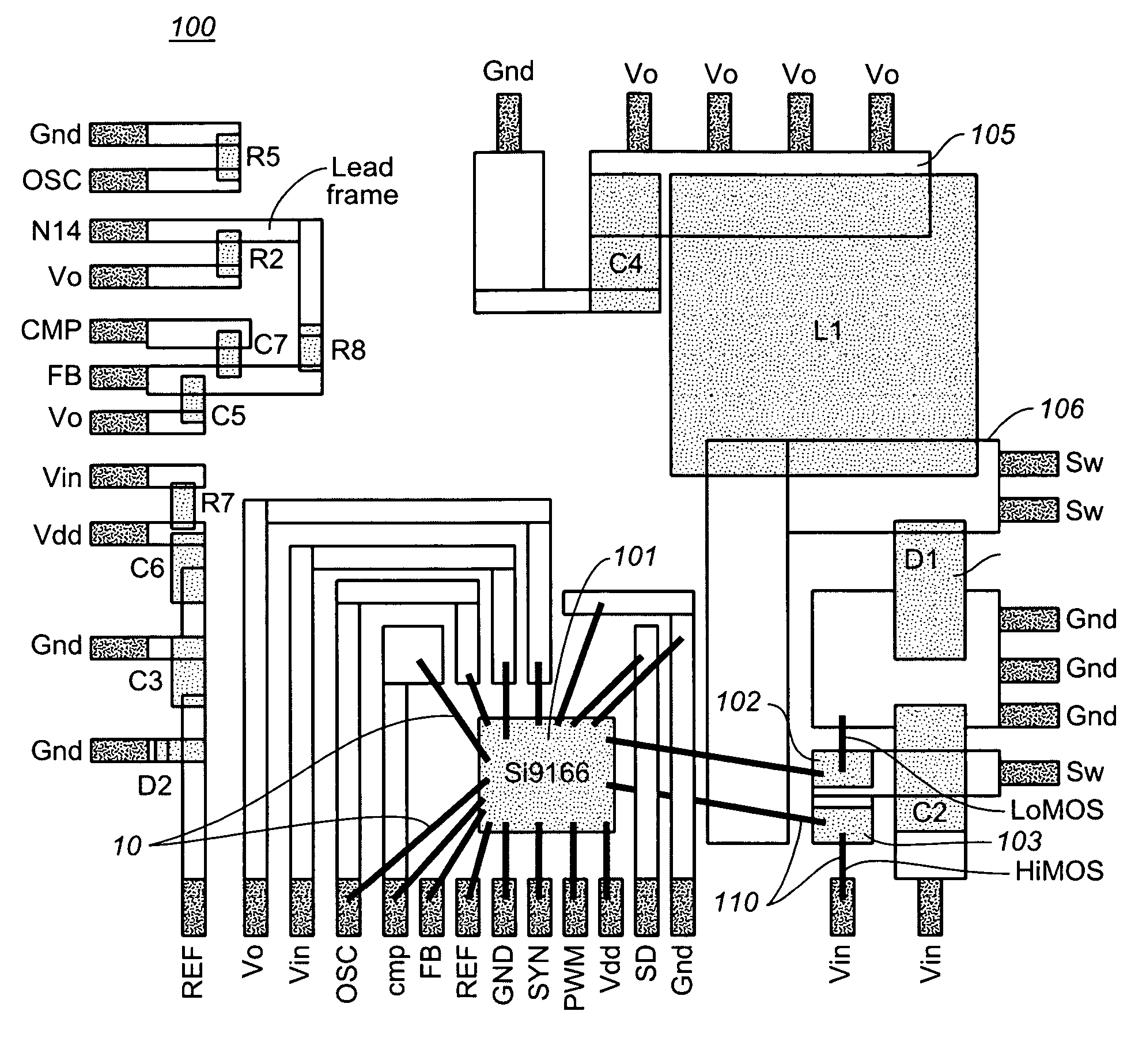

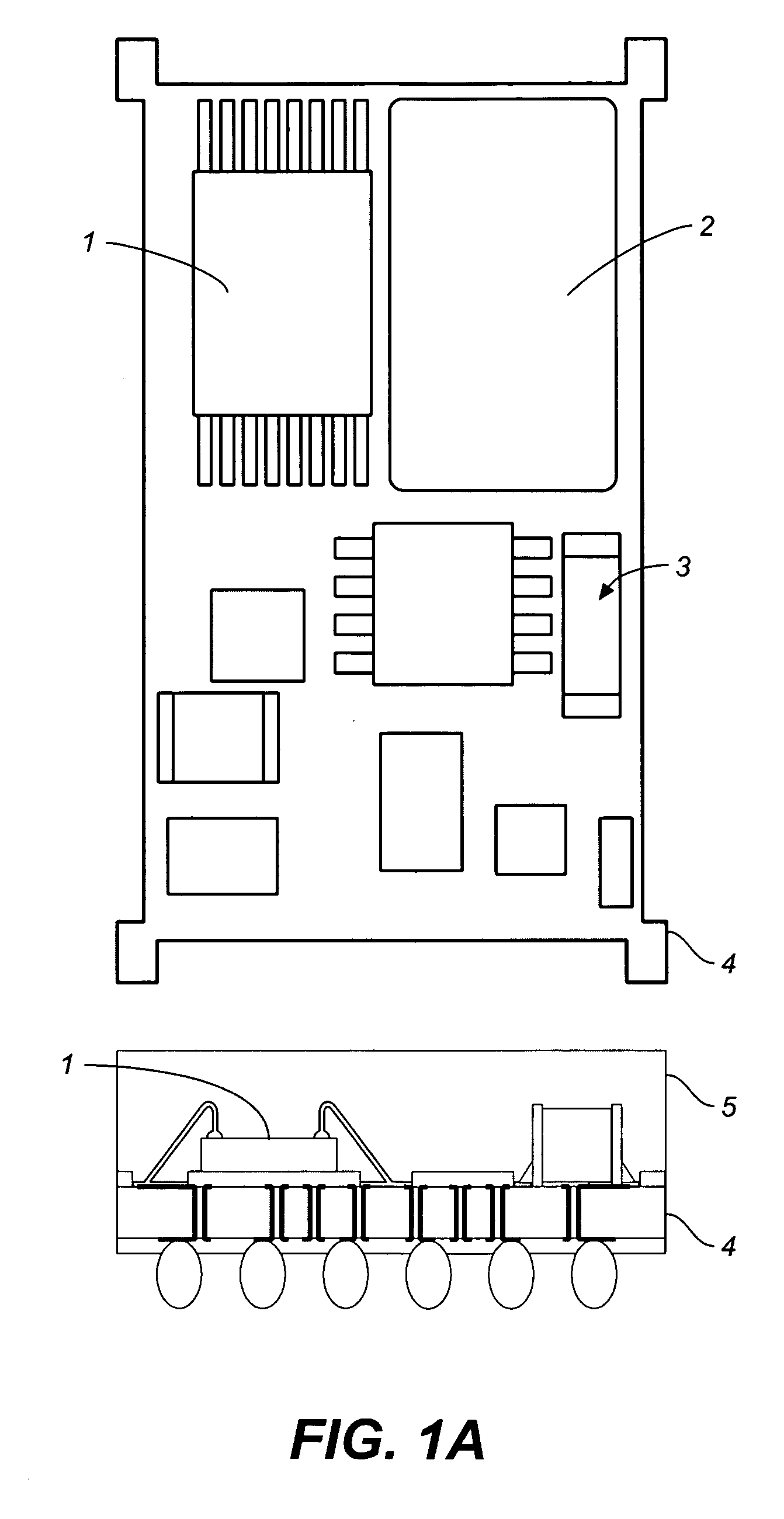

Complete power management system implemented in a single surface mount package

ActiveUS20070063341A1Increase chanceReduce thermal resistanceSemiconductor/solid-state device detailsCross-talk/noise/interference reductionMOSFETEngineering

A complete power management system implemented in a single surface mount package. The system may be drawn to a DC to DC converter system and includes, in a leadless surface mount package, a driver / controller, a MOSFET transistor, passive components (e.g., inductor, capacitor, resistor), and optionally a diode. The MOSFET transistor may be replaced with an insulated gate bipolar transistor, IGBT in various embodiments. The system may also be a power management system, a smart power module or a motion control system. The passive components may be connected between the leadframe connections. The active components may be coupled to the leadframe using metal clip bonding techniques. In one embodiment, an exposed metal bottom may act as an effective heat sink.

Owner:VISHAY SILICONIX LLC

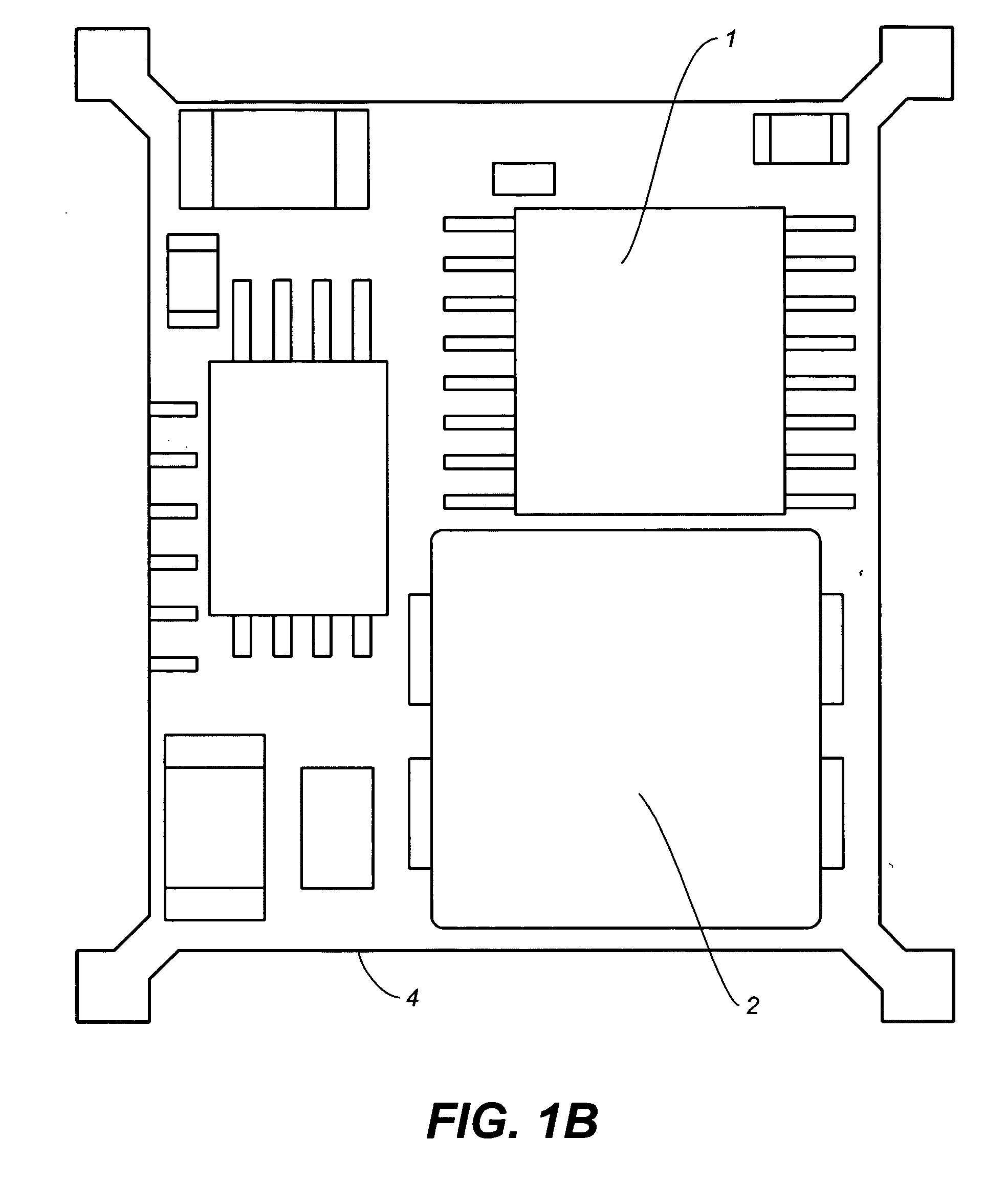

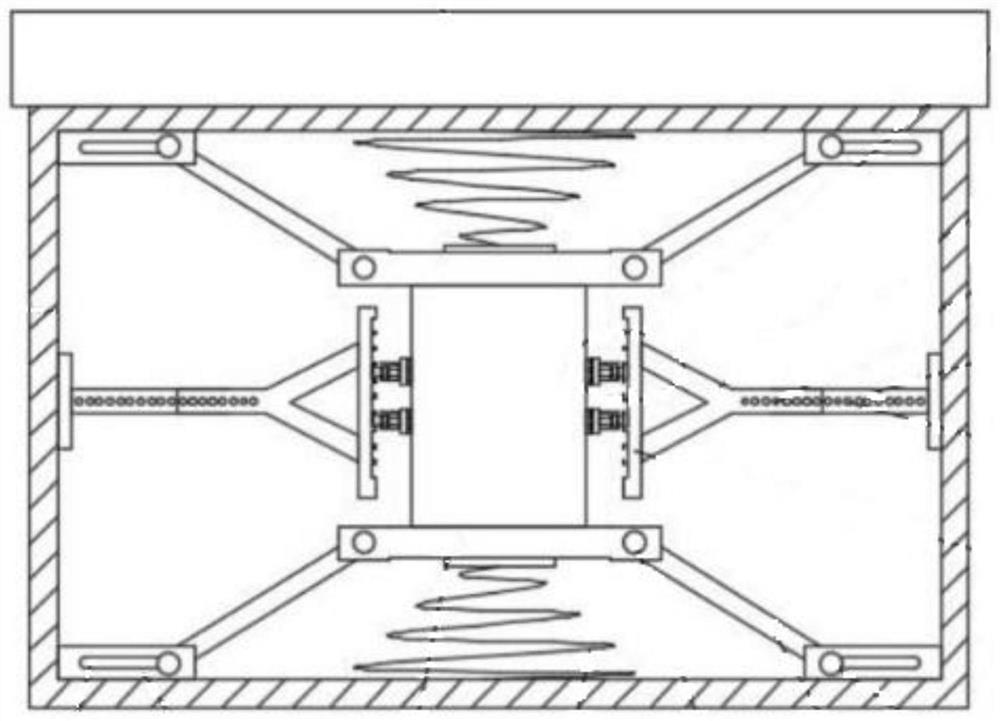

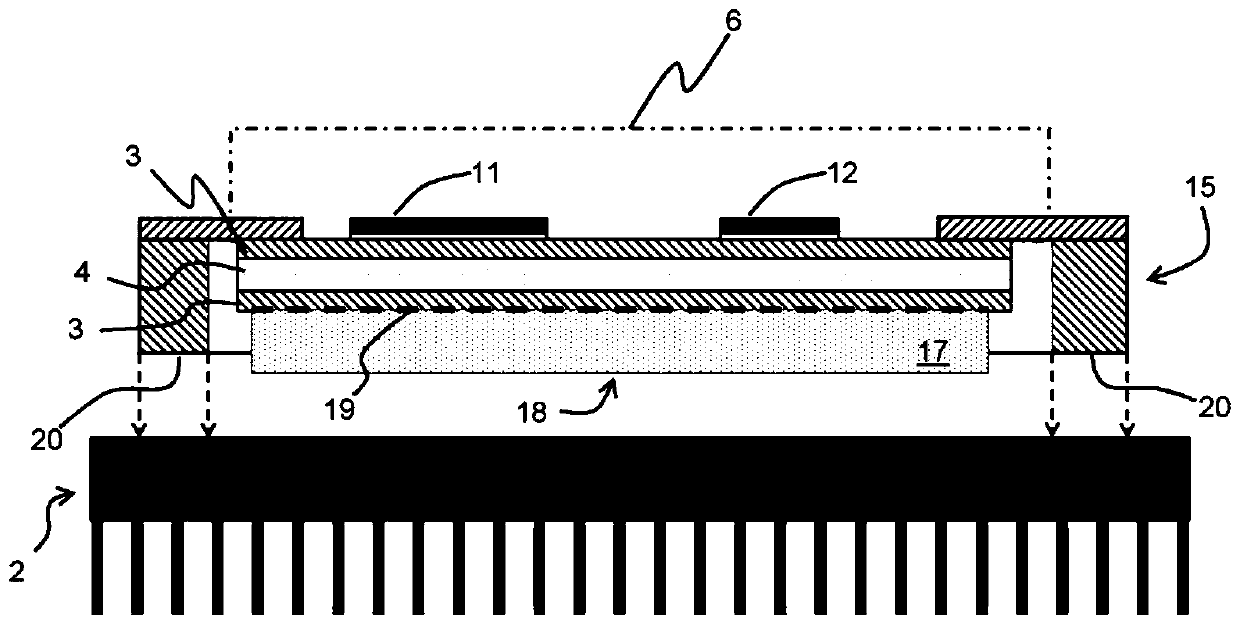

Power electronics module and a method of producing a power electronics module

ActiveUS20190239337A1Stable structureReduce thermal resistancePrinted circuit assemblingSemiconductor/solid-state device detailsComputer moduleSemiconductor chip

A power electronics module and a method of producing a power electronics module. The power electronics module includes multiple of power electronic semiconductor chips incorporated in a housing and attached to a substrate, and a heat transfer structure attached to the substrate and having a bottom surface which forms an outer surface of the module and which is adapted to receive a surface of a cooling device, wherein the heat transfer structure includes a compressible base plate.

Owner:ABB (SCHWEIZ) AG

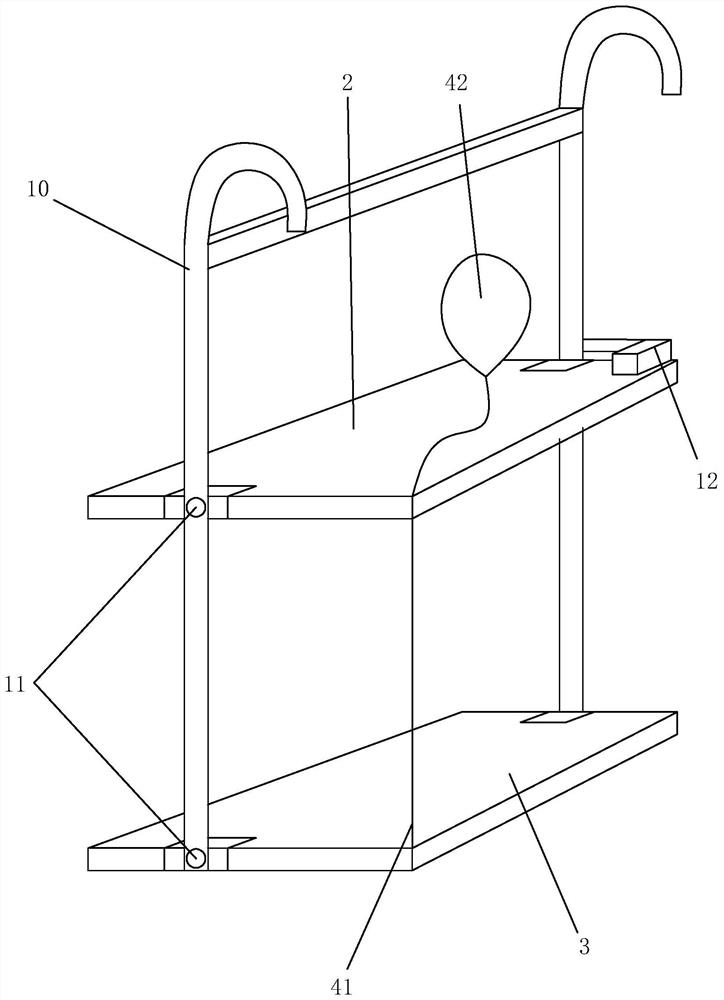

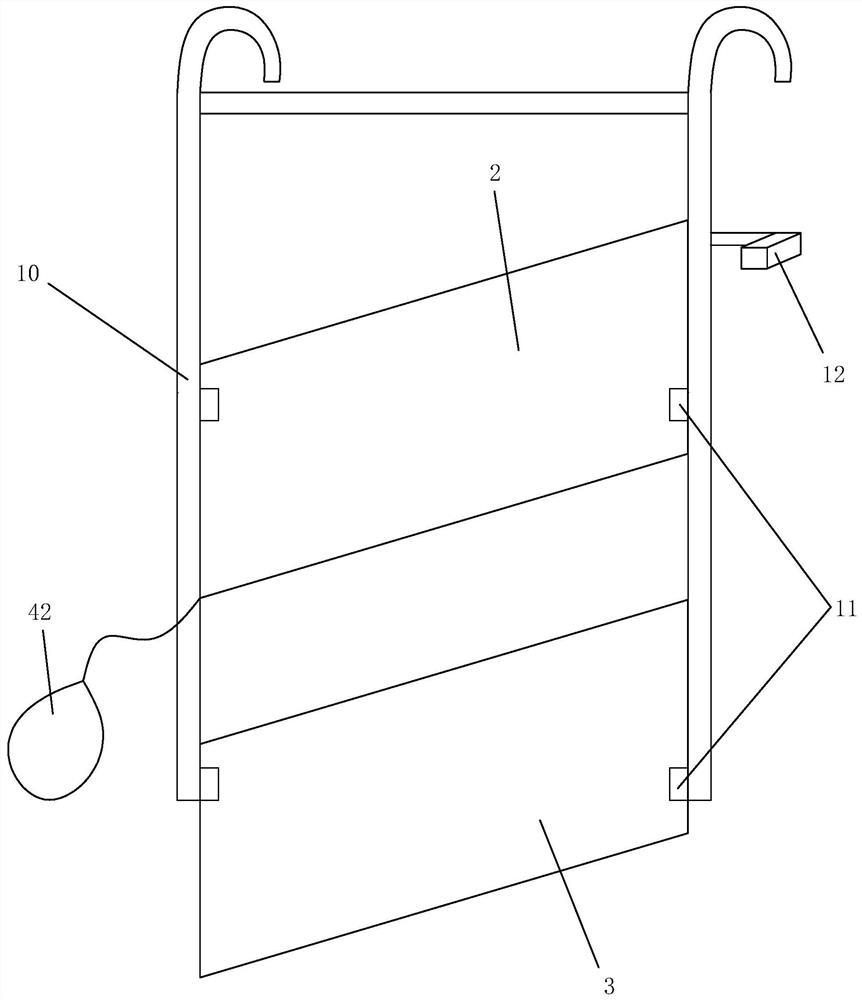

Preparation device of vapor chamber wick and preparation method of wick

PendingCN114855248ALower thermal resistivityReduce equipment costsElectrolysis componentsIndirect heat exchangersElectrolytic agentMechanical engineering

The invention provides a preparation device of a vapor chamber wick, which has the advantages of thin structure, low thermal resistance coefficient, high heat dissipation power, simplified process, stable quality, low equipment and processing cost, reduced reject ratio of manufacture and the like, and is not easy to be damaged due to the overlarge thin plate during electroplating. And upward bending deformation is caused by liquid resistance when the battery is placed in electrolyte.

Owner:中山市仲德科技有限公司

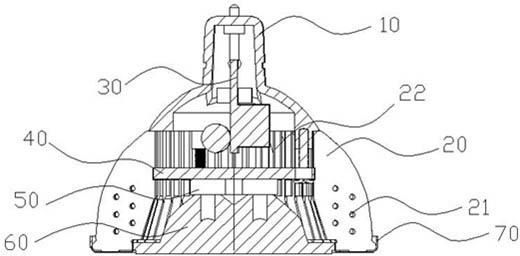

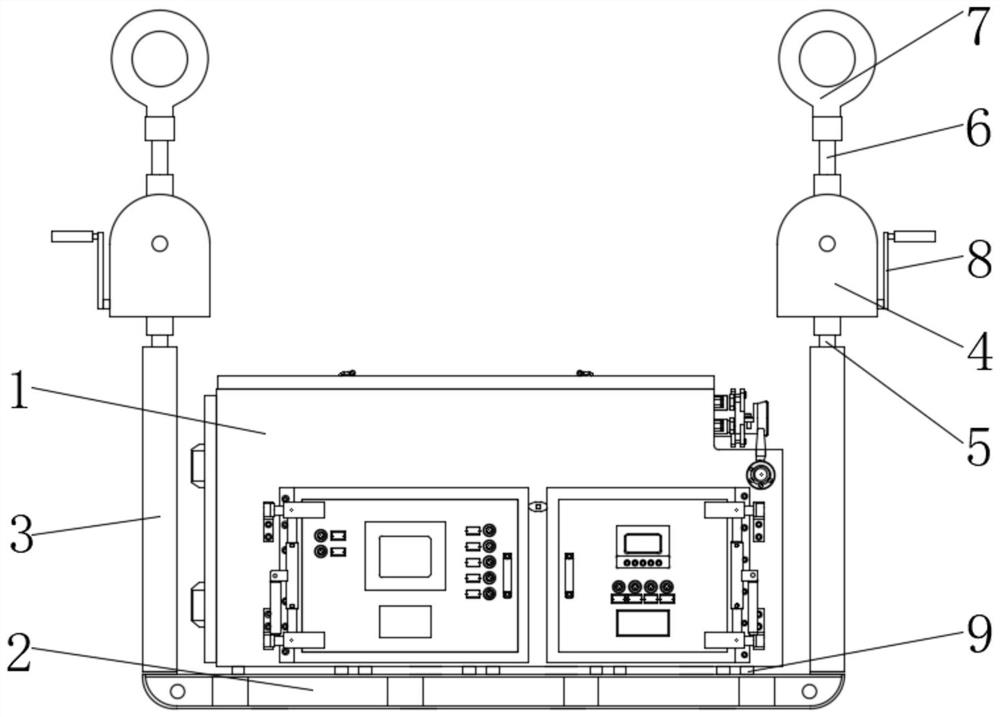

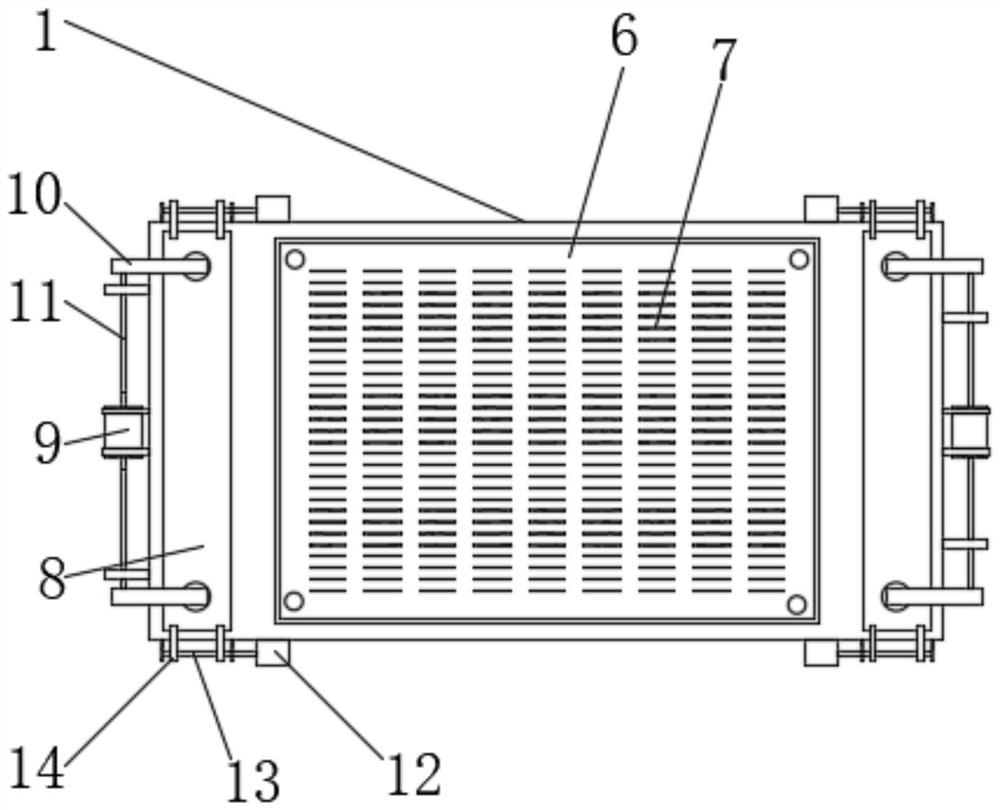

Protection device for mining belt conveyor controller

PendingCN114368602AAvoid damageContinuous workControl devices for conveyorsCooling/ventilation/heating modificationsEngineeringBelt conveyor

The invention relates to a protection device for a mining belt conveyor controller, which comprises a mainframe box, support frames are arranged below two sides of the bottom of the mainframe box, lifting upright posts are mounted above two ends of each support frame, posture adjusting mechanisms are mounted at the tops of the lifting upright posts, gradienters are mounted around the bottom of the mainframe box, and the gradienters are mounted on the periphery of the bottom of the mainframe box. Hanging rings are mounted at the tops of the posture adjusting mechanisms, a shielding plate is mounted at the top of the mainframe box, two cooling fans are embedded in the middles of a top plate and a bottom plate of the mainframe box, and a plurality of supporting plates arranged side by side are mounted in the mainframe box and located between the cooling fans on the two sides; a heat dissipation plate for cooling and heat dissipation of the circuit board is installed on one side of the supporting plate, external low-temperature air is conducted into the mainframe box from the bottom of the mainframe box along with an air channel formed by the heat dissipation fans on the upper side and the lower side, so that heat is rapidly taken away, and rapid heat dissipation is conducted in heat conduction air flow output by the heat dissipation fans through the heat dissipation fins.

Owner:HUAINAN WANTAI ELECTRONICS

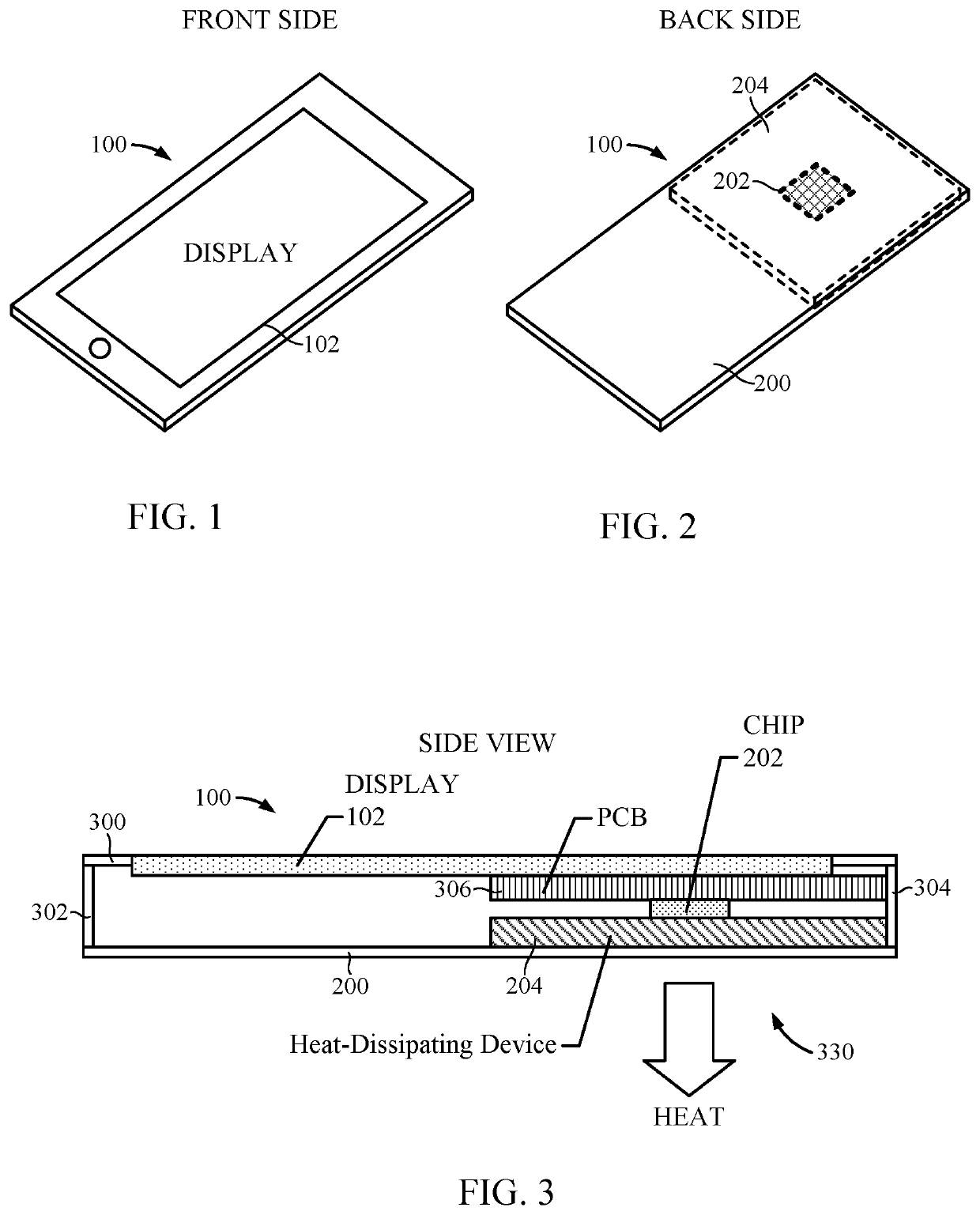

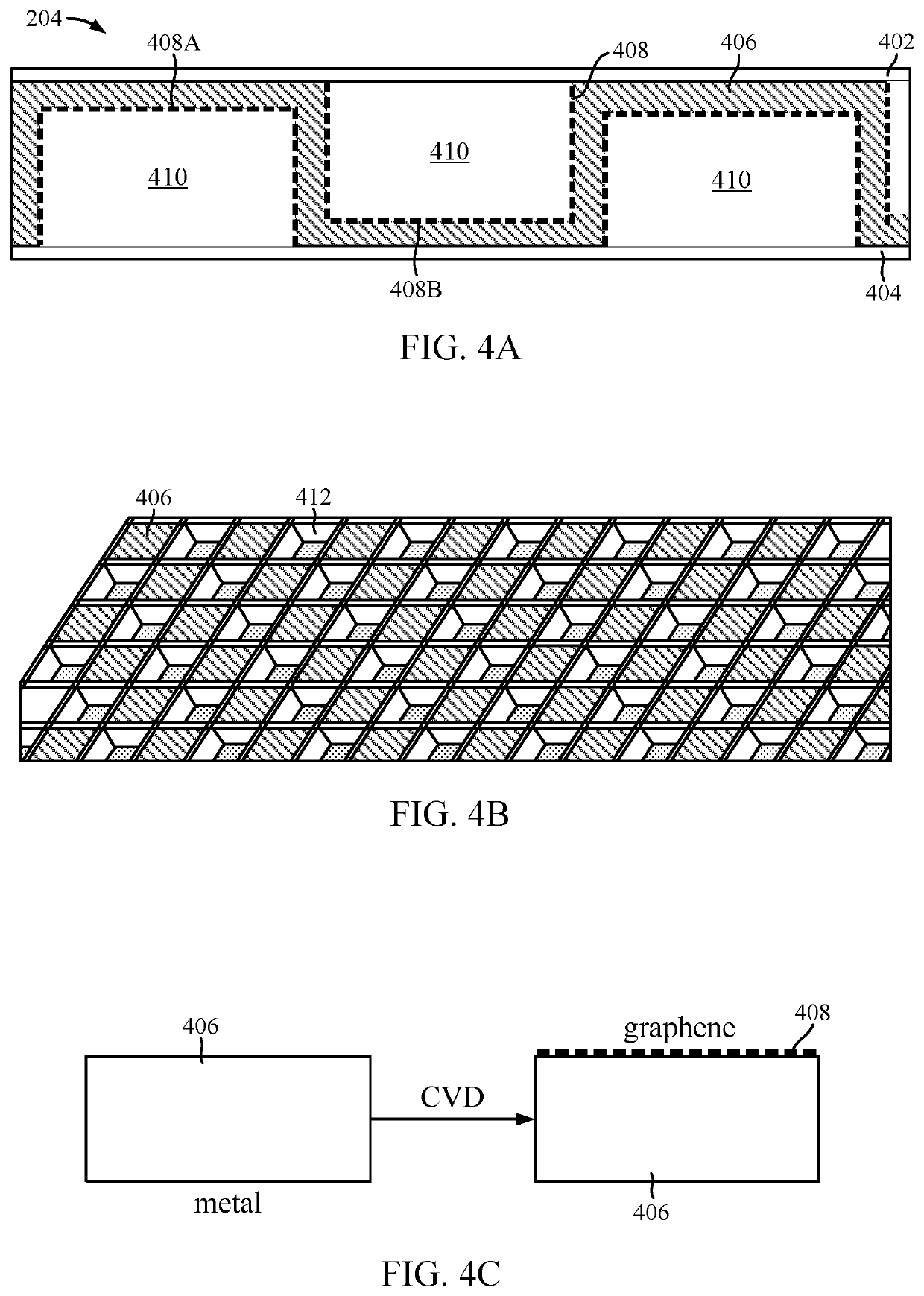

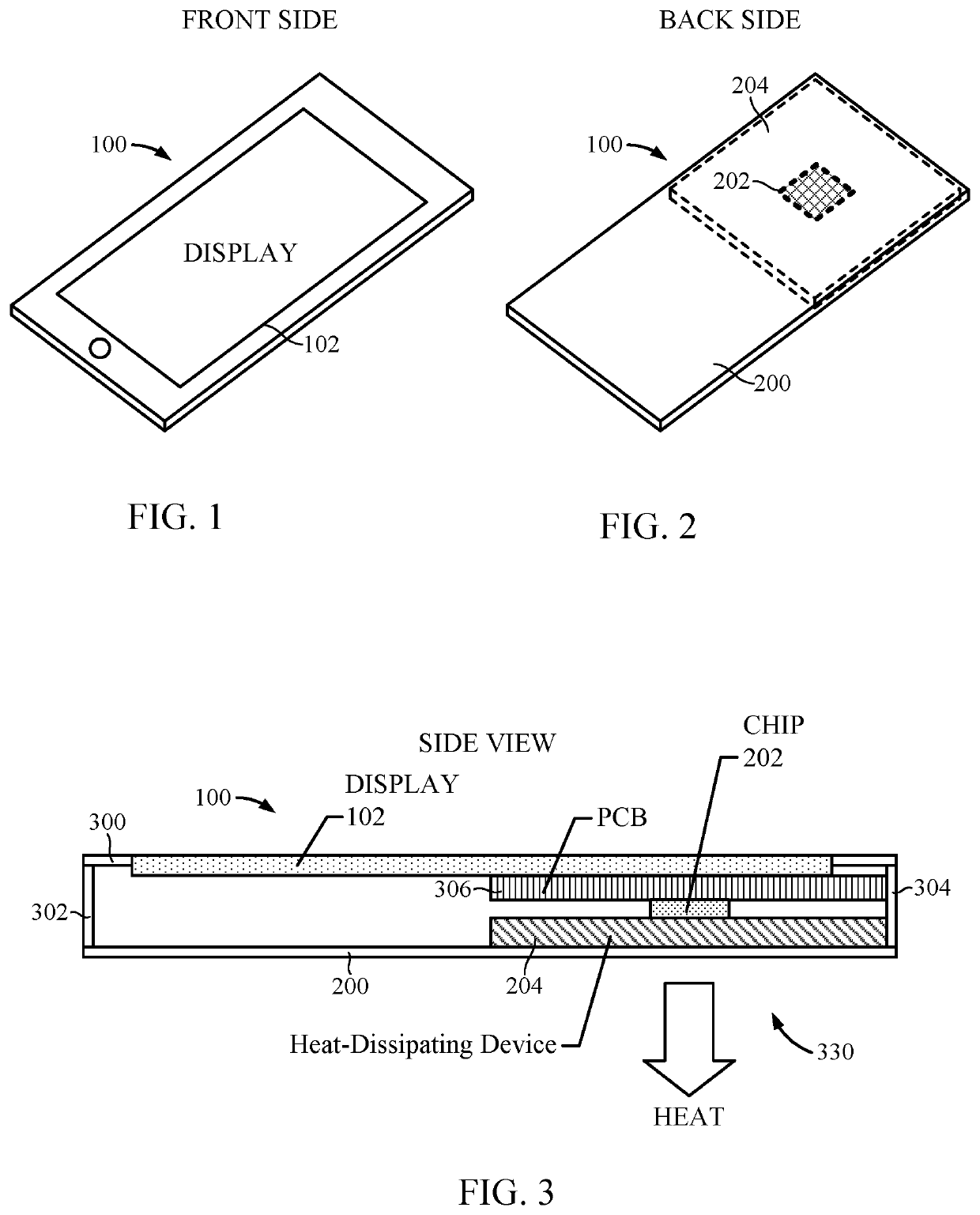

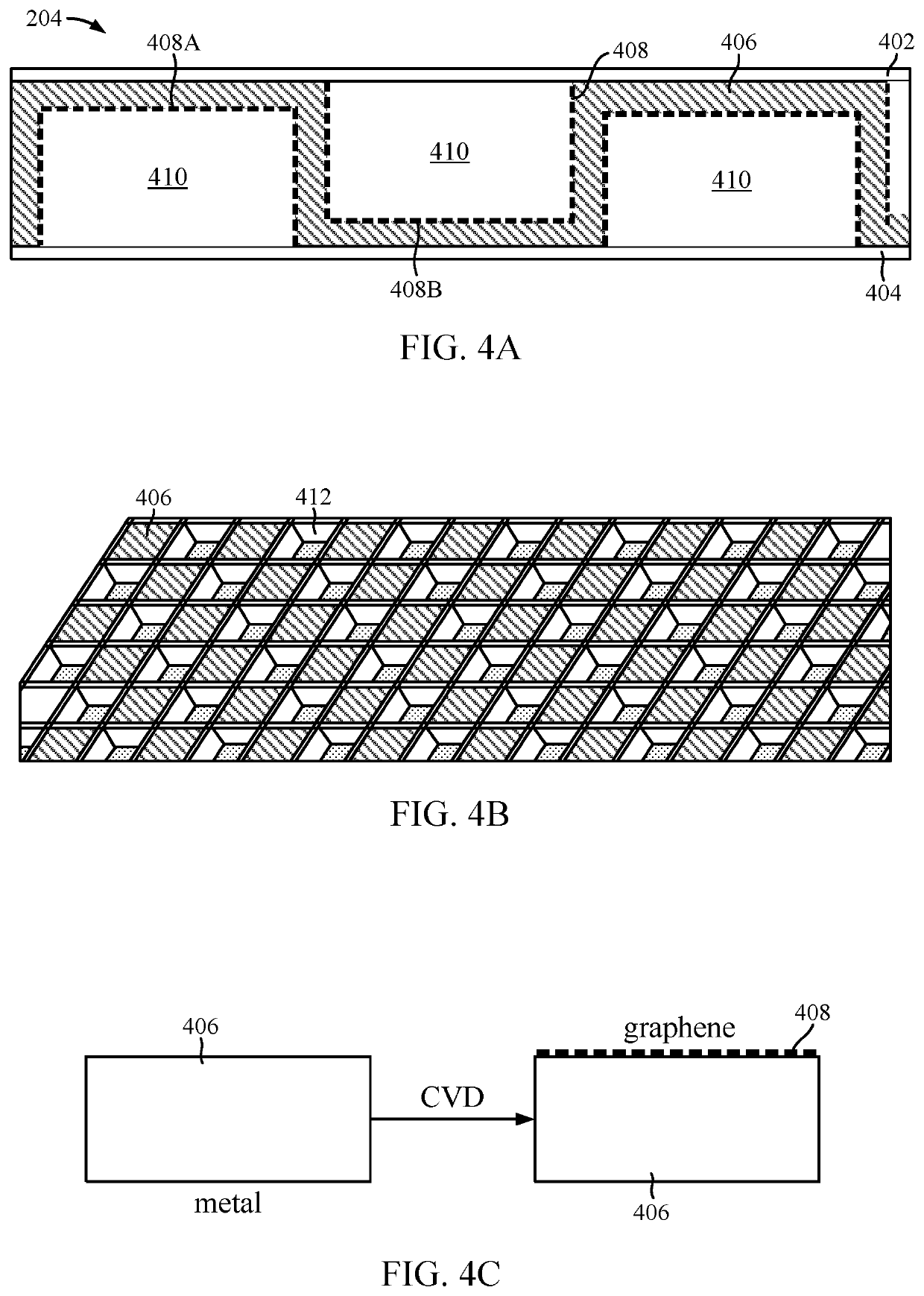

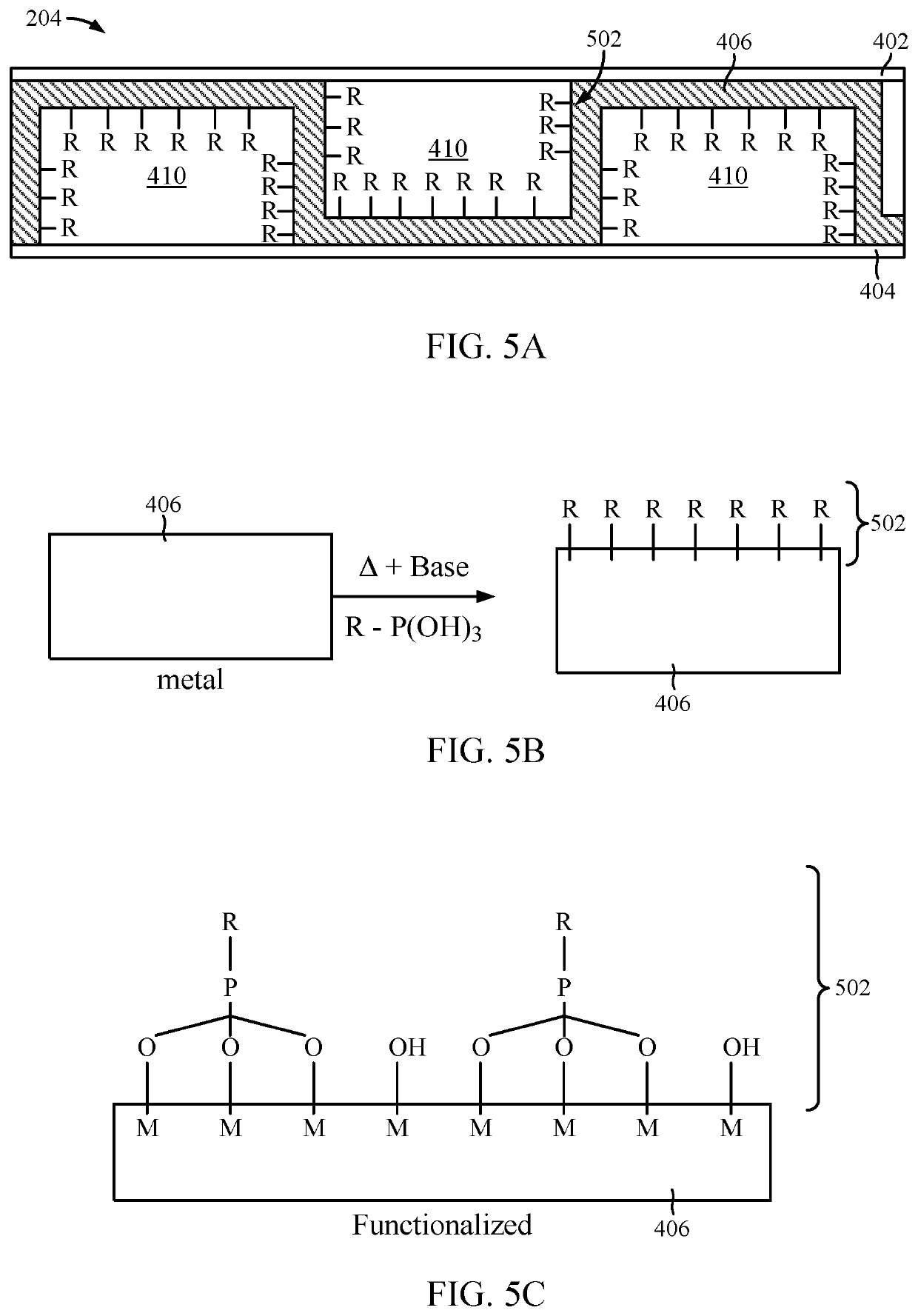

Heat-dissipating device with interfacial enhancements

ActiveUS20200271388A1Lower thermal resistivityHeat storage plantsSemiconductor/solid-state device detailsInterposerEngineering

Certain aspects of the present disclosure provide a heat-dissipating device with enhanced interfacial properties. One example heat-dissipating device generally includes a first heat spreader configured to be thermally coupled to a region configured to generate heat, a second heat spreader, an interposer thermally coupled to at least one of the first heat spreader or the second heat spreader, at least one interfacial layer comprising a graphene material disposed on at least one surface of the interposer, and a phase change material disposed between the at least one interfacial layer and at least one of the first heat spreader or the second heat spreader and thermally coupled to at least one of the first heat spreader or the second heat spreader.

Owner:QUALCOMM INC

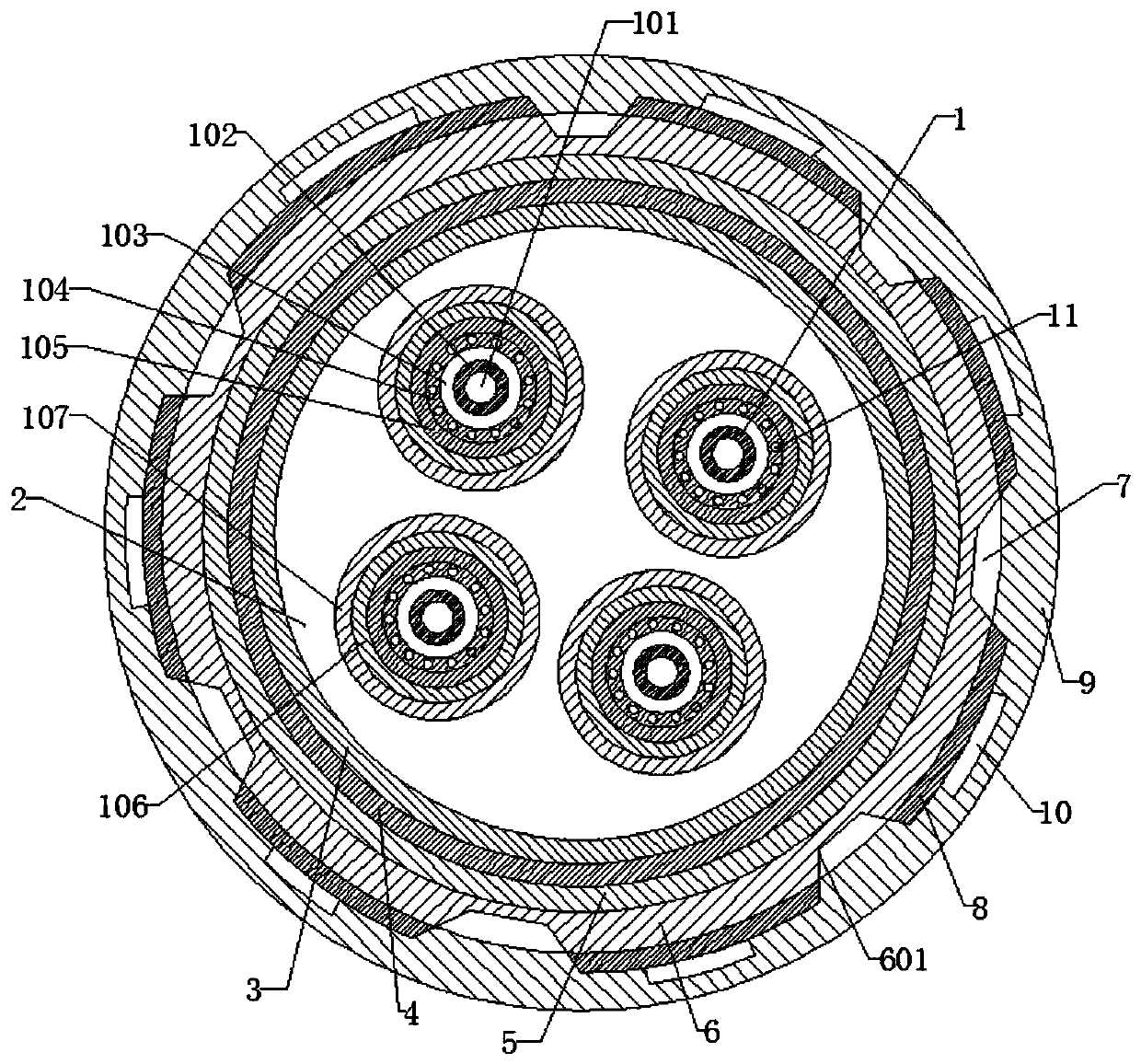

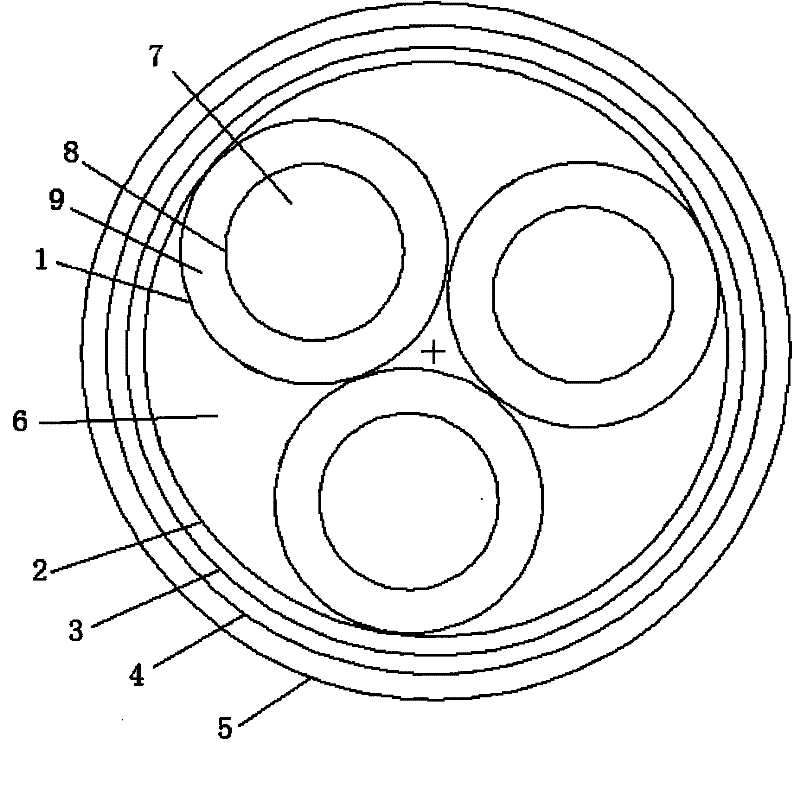

Anti-counterfeiting cable

InactiveCN110718325AImprove cooling effectAvoid overheating and burningInsulated cablesInsulated conductorsEngineeringStructural engineering

The invention discloses an anti-counterfeiting cable, and the cable comprises a cable core, a filling layer, a wrapping tape layer, an inner sheath layer, a steel tape armoring layer, an outer sheathlayer, an anti-counterfeiting annunciator, a colored tape, a light-transmitting anti-counterfeiting film and a QR code anti-counterfeiting pattern; the cable core comprises a conductor, an anti-oxidation layer, a foaming layer, an insulating layer, an inner shielding layer, an outer shielding layer and a copper strip shielding layer. The wrapping tape layer wraps the outer surface of the cable core. The filling layer is filled between the cable core and the wrapping tape layer; the inner protective layer coats the outer surface of the wrapping tape layer; the outer surface of the inner sheathlayer is coated with the steel tape armoring layer; the outer sheath layer wraps the outer surface of the steel tape armor layer, the outer sheath layer is provided with an installation groove, the anti-counterfeiting annunciator is arranged in the installation groove, the outer surface of the outer sheath layer is coated with the colored tape, the QR code anti-counterfeiting pattern is evenly distributed on the colored tape, and the light-transmitting anti-counterfeiting film wraps the outer surfaces of the colored tape and the QR code anti-counterfeiting pattern.

Owner:徐州长盛电力设备有限公司

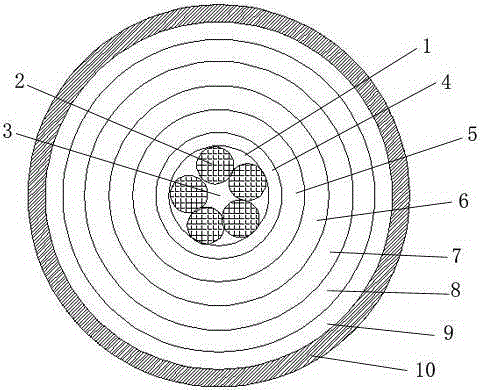

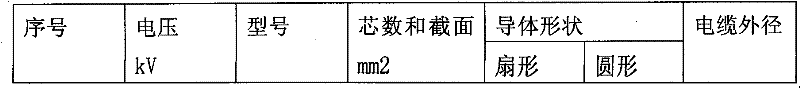

Novel reinforced extra-high-voltage power cable

InactiveCN105280299ALower thermal resistivityIncrease elasticityPower cables with screens/conductive layersInsulated cablesElectrical conductorUltra high voltage

The invention discloses a novel reinforced extra-high-voltage power cable. The power cable comprises a conductor arranged in the center of the cable; the conductor is wrapped with an inner semi-conducting shielding layer, a crosslinked polyethylene insulating layer, and an outer semi-conducting shielding layer in sequence; the outer semi-conducting shielding layer is extruded with a semi-conducting buffering layer, a corrugated aluminum sheath, and a non-metal sheath; the outermost layer of the cable is extruded with a graphite coating layer; five circular reinforced cores are arranged in the conductor along the inner edge of the conductor; and a quinquelateral arc-shaped reinforced core is arranged among the five circular reinforced cores. The semi-conducting buffering layer provided by the invention adopts an extruded semi-conducting silicone rubber structure so as to reduce sealed and stationary air amount in the buffering layer and to ensure the compactness of the cable structure, so that the carrying capacity of the cable can be effectively improved.

Owner:WUXI GREAT WALL ELECTRIC WIRE & CABLE

Directional heat conduction pcb board and electronic equipment

ActiveCN102802347BUniform heat conductionLower thermal resistivityCircuit susbtrate materialsCopperPrinted circuit board

The invention relates to a directional heat conduction PCB (printed circuit board), comprising a first metal layer, a heat conduction dielectric layer, a second metal layer and a copper layer, wherein the copper layer and the heat conduction dielectric layer are respectively arranged on the two sides of the second metal layer, and the first metal layer is arranged on one side of the heat conduction dielectric layer relative to the second metal layer. The electronic equipment adopts the directional heat conduction PCB, and thus heat dissipation of a circuit of the whole electronic equipment is changed into a downward heat conduction manner from a conventional upward heat conduction manner; and heat conduction is uniform, and thermal resistivity is low. The invention also provides electronic equipment applying the directional heat conduction PCB.

Owner:KUANG CHI INST OF ADVANCED TECH

Power electronics module and a method of producing a power electronics module

ActiveCN110098153ALower thermal resistivitySpeed up heat transferSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipPower electronics

The invention discloses a power electronics module and a method of producing a power electronics module. The power electronics module comprising multiple of power electronic semiconductor chips incorporated in a housing and attached to a substrate, and a heat transfer structure attached to the substrate and having a bottom surface which forms an outer surface of the module and which is adapted toreceive a surface of a cooling device, wherein the heat transfer structure comprises a compressible base plate.

Owner:ABB (SCHWEIZ) AG

Fireproofing and heat resistant environmental-friendly power cable

InactiveCN101834029BEvenly distributedReduce the temperaturePlastic/resin/waxes insulatorsPower cables with screens/conductive layersPower cableMaterials science

The invention discloses a power cable which comprises a core wire, an aluminum tape layer lapping outside the core wire and steel-tape armoring arranged outside the aluminum tape layer, wherein the gap between the core wire and the aluminum tape layer is provided with silicon carbide mineral composite fillers, a polyethylene inner sheath is arranged between the aluminum tape layer and the steel-tape armoring, and a polyethylene outer sheath is arranged outside the steel-tape armoring. The invention has the advantages of good heat radiation property, long service life, strong flame retarding property, electricity saving, no toxicity and environmental protection.

Owner:无锡市黄浦电线电缆有限公司

Heat-dissipating device with interfacial enhancements

ActiveUS11181323B2Lower thermal resistivityHeat storage plantsSemiconductor/solid-state device detailsThermodynamicsInterposer

Owner:QUALCOMM INC

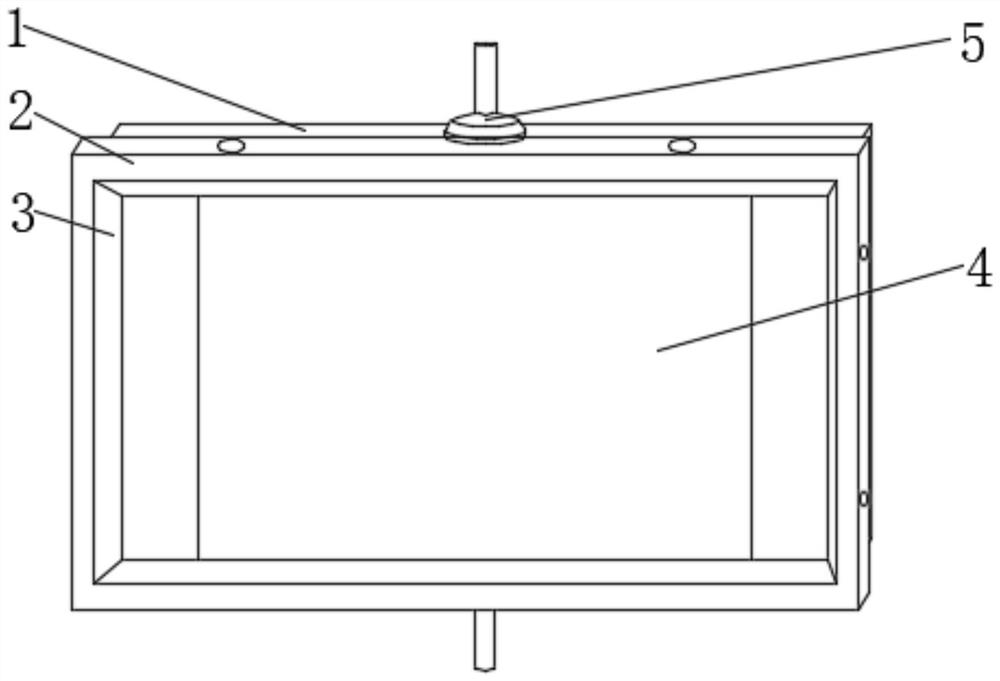

Waterproof fixing device for high-water-resistance HJT photovoltaic cell

ActiveCN114362656AAvoid erosionPrevent penetrationPhotovoltaicsPhotovoltaic energy generationTemperature controlEngineering

The invention relates to a waterproof fixing device for a high-water-resistance HJT photovoltaic cell, and the device comprises a main frame, the middle part of the upper end of the main frame is provided with a photovoltaic cell, the outer surface of the upper end of the main frame is provided with a sealing glass plate, the periphery of the main frame is flush with the periphery of the sealing glass plate, and the periphery of the sealing glass plate is connected with a second sealing frame in a sealing manner. A first sealing frame is installed on the outer surface of the second sealing frame, a heat dissipation plate is installed in the middle of the lower end of the main frame, heat dissipation fans are installed on the two sides, close to the heat dissipation plate, of the lower end face of the main frame, and storage openings used for storing the heat dissipation fans are formed in the two sides, close to the heat dissipation fans, of the lower end face of the main frame. A sealing mechanism used for sealing the storage opening is installed at the storage opening of the main frame, and it is ensured that water is completely isolated. Heat is taken away through the heat conduction plate, the heat dissipation fins and the heat dissipation fan, and temperature control is carried out, so that the service life of the HJT photovoltaic cell is prevented from being shortened due to too high temperature.

Owner:马鞍山中南光电新能源有限公司

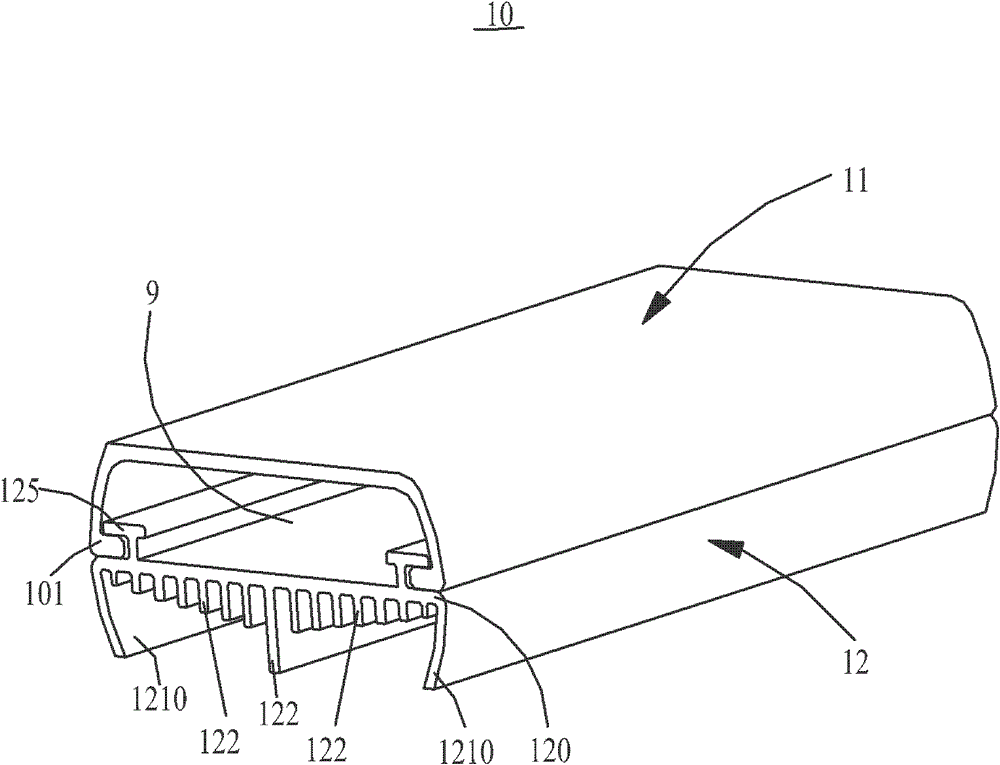

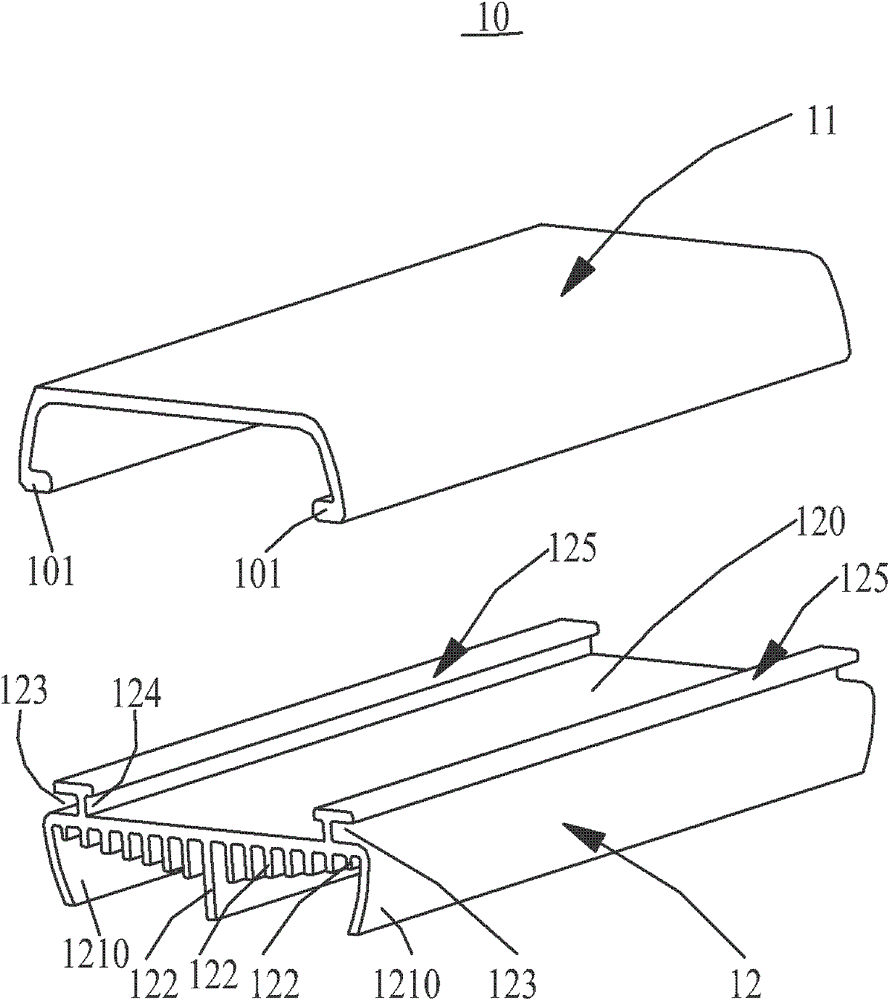

Cooling components and electronic equipment

ActiveCN102802379BFlexible internal structure layoutUniform heat conductionCooling/ventilation/heating modificationsEngineeringPrinted circuit board

The invention discloses a radiation component, which comprises a protective cover and a radiation unit. The radiation unit comprises a plate-like pedestal, and a first clamping part, a second clamping part and fins, which are arranged on the plate-like pedestal. The first and second clamping parts and the fins are arranged on the two opposite surfaces of the plate-like pedestal respectively. A pair of clamping hooks are formed on the protective cover, and are clamped in the first clamping part to buckle the protective cover and the radiation unit to form a cavity. The second clamping part is used for fixing a printed circuit board in the cavity. Heat produced by high-heat devices on the PCB is quickly conducted to the radiation component through the directional heat conduction PCB, and is externally dissipated, so that the temperature of the whole PCB is substantially kept consistent. The invention also provides electronic equipment with the radiation component.

Owner:KUANG CHI INST OF ADVANCED TECH +1

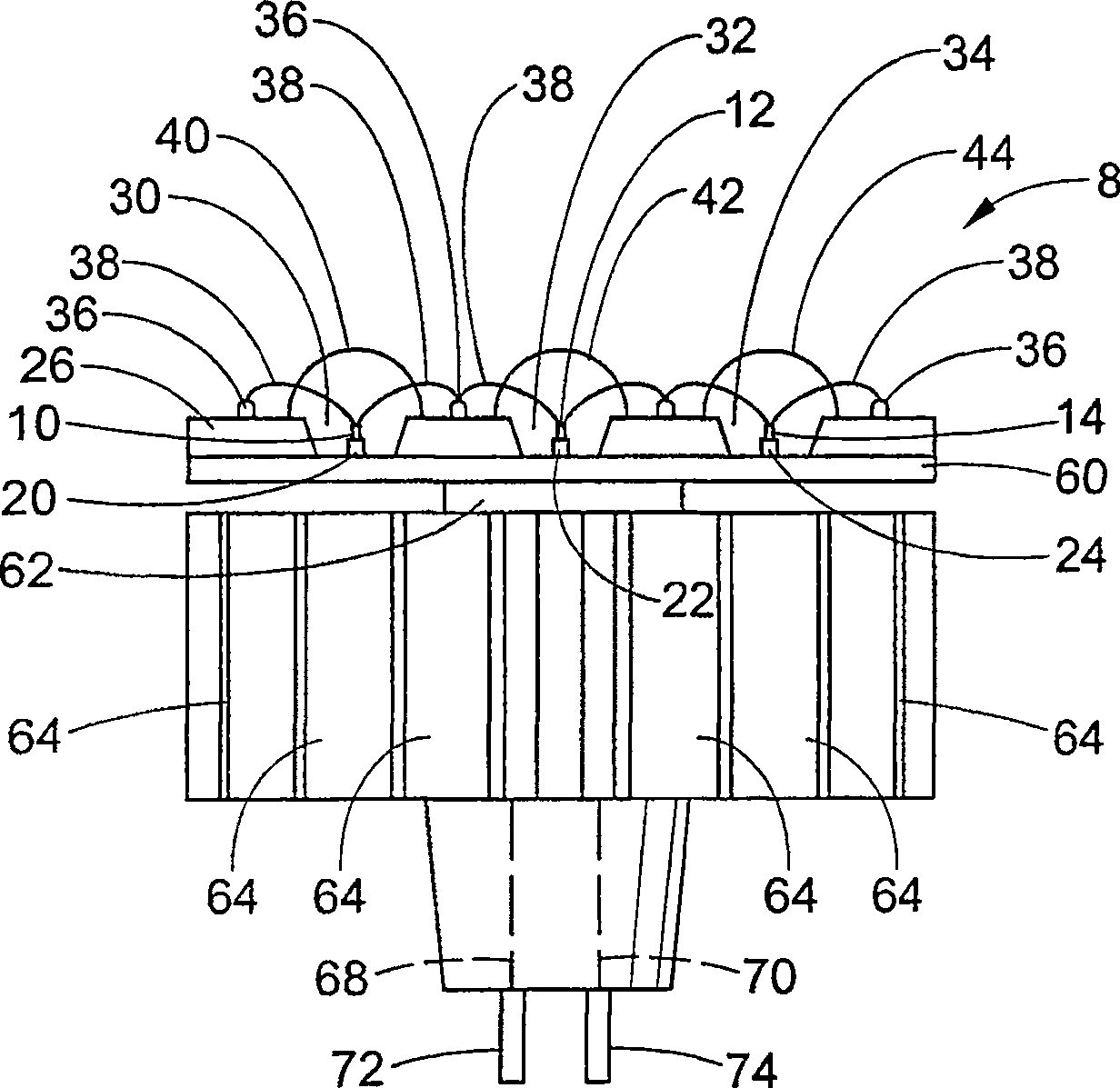

High power LED module for spot illumination

InactiveCN100524746CLower thermal resistivityLower working temperatureLight source combinationsPoint-like light sourceElectrical conductorEngineering

A light-emitting module includes a light-emitting diode assembly, which is provided with a front-side light-emitting diode array and a rear side. The rear side is in thermal communication with a thermally conductive extension sheet, and a thermally conductive core is in thermal communication with the conductive extension sheet. The thermally conductive core includes an electrical conductor in operative communication with the front LED array, and a plurality of appendages positioned around the thermally conductive core so that they are in thermal communication with the conductive extensions.

Owner:GELCORE LLC (US)

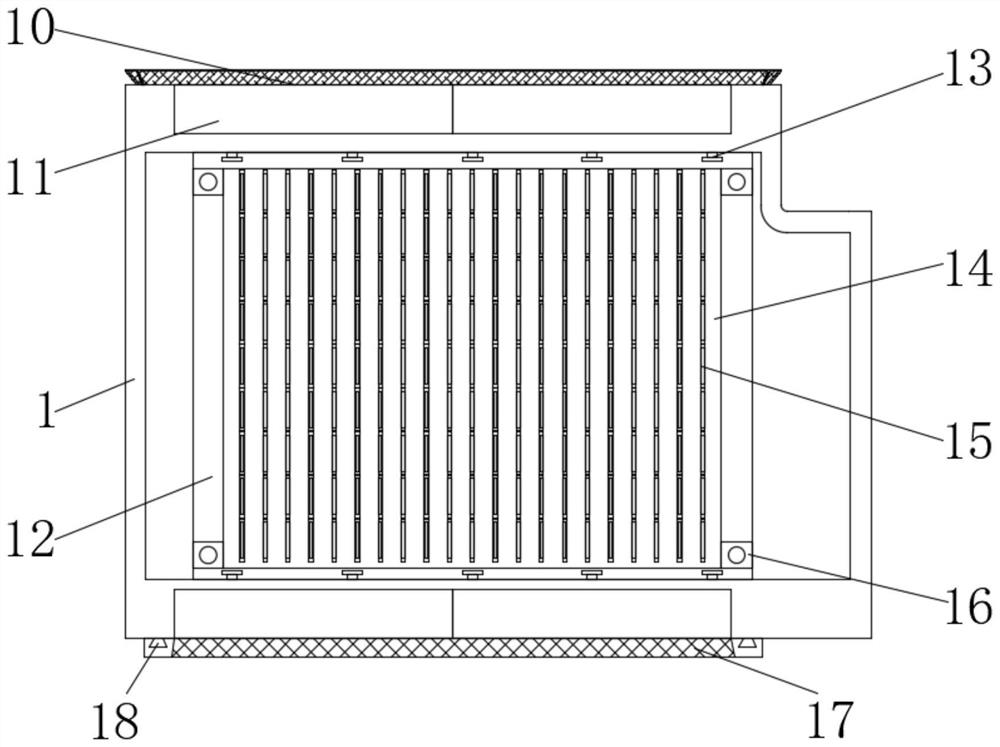

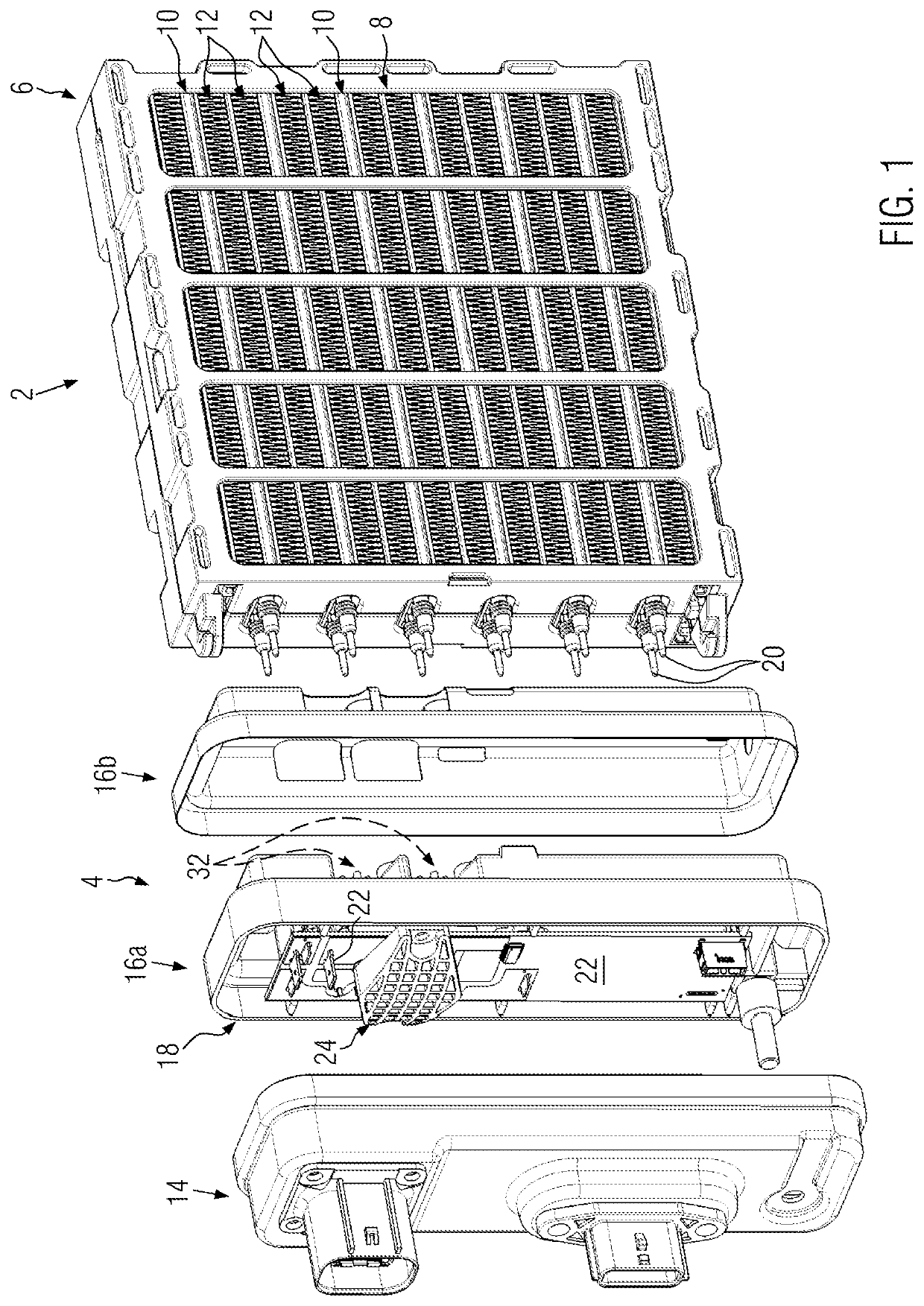

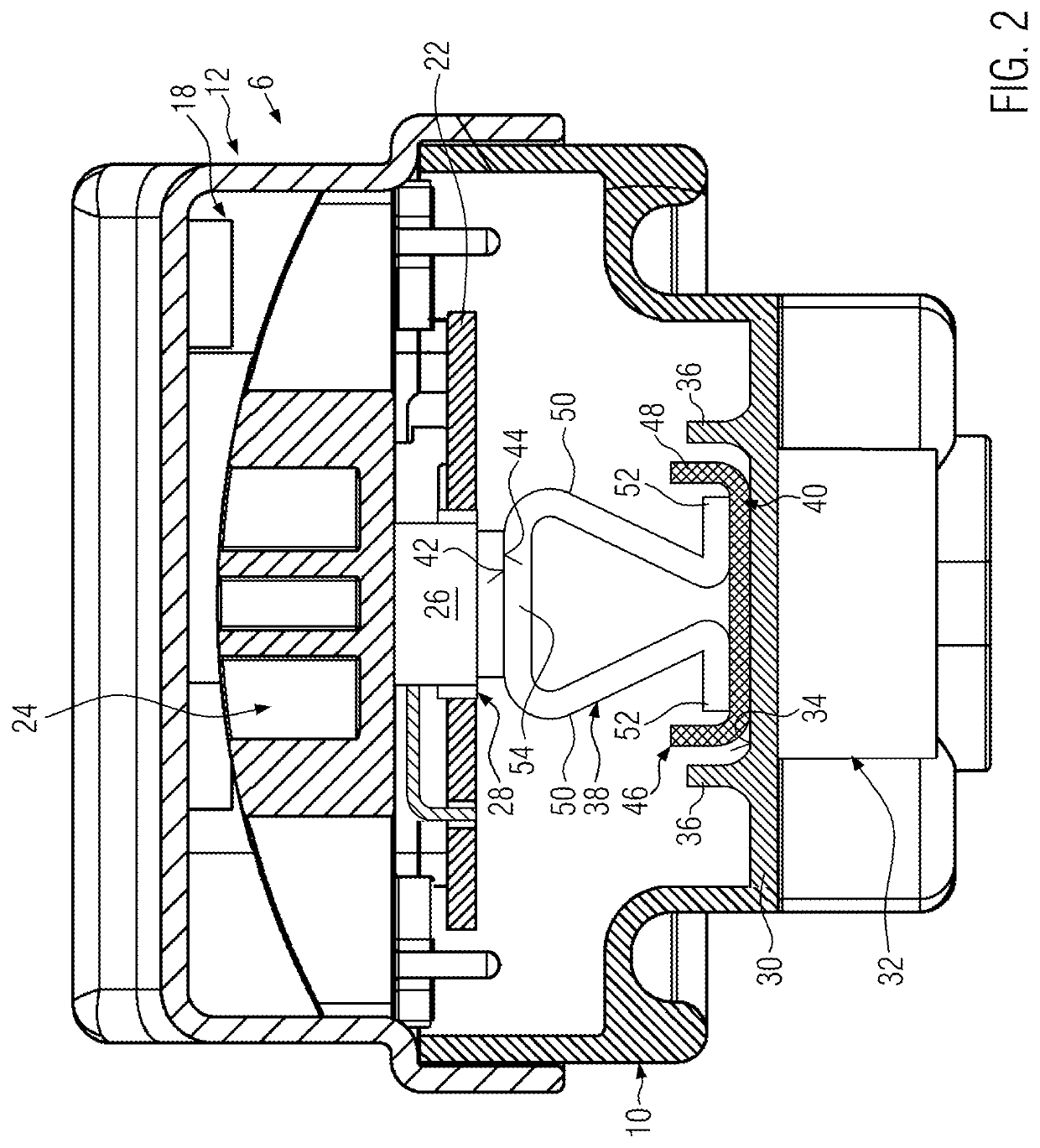

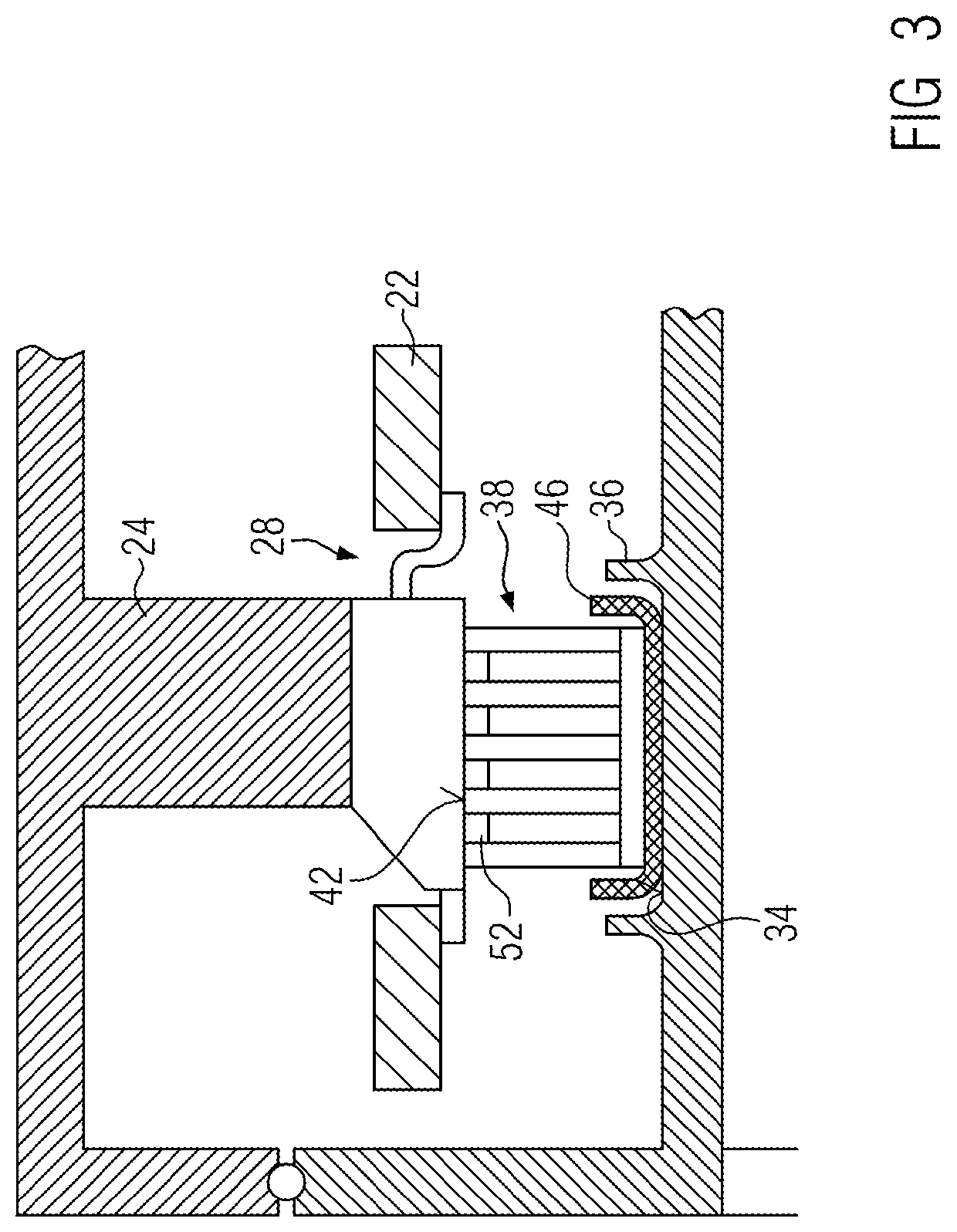

Electric Heating Device

PendingUS20220007465A1Reliably ensures dissipation of power lossLower thermal resistivityHeater elementsAir heatersElectrical conductorPower switching

An electric heating device includes an electric control device with a control housing that is in structural unity with a housing of a power section. The power section has a frame forming a heating chamber. At least one PTC heating device with at least one PTC element and conductor elements is provided in the heating chamber. The control housing forms a chamber which is separated from the frame by a partition wall. A heat sink projects from the partition wall into the power section. The electric control device has a printed circuit board and at least one power switch which generates a power loss and which is connected in a heat-conducting manner to a surface of a heat sink. An electrically insulating layer and a spring element, which holds the power switch applied under pretension against the surface of the heat sink, are provided between the power switch and the heat sink.

Owner:EBERSPACHER CATEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com