Light emitting diode (LED) lamp

A technology of LED lights and LED light sources, applied in the field of lighting, can solve the problems of high production cost, high application of aluminum raw materials, and difficulty in improving heat dissipation efficiency, and achieve the effect of improving heat dissipation efficiency and reducing thermal resistance coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

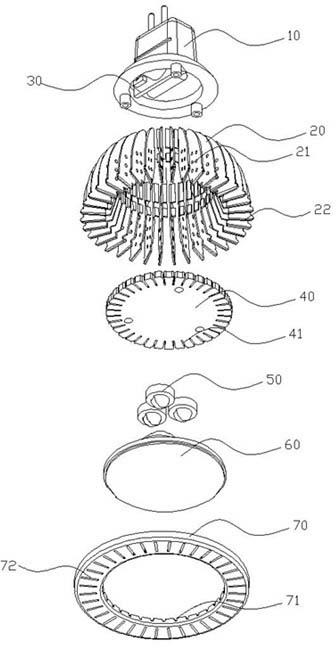

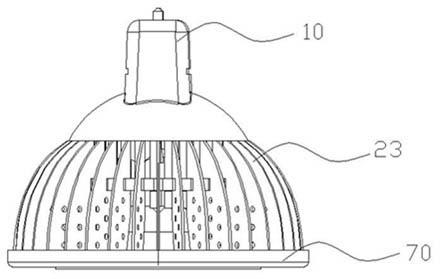

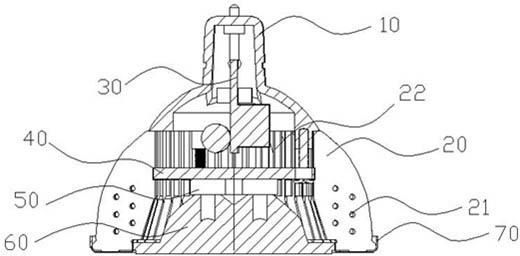

[0029] The structure of the present invention will be described in detail below with specific embodiments in conjunction with the accompanying drawings.

[0030] refer to figure 1 and figure 2 As shown, an LED lamp provided by the present invention includes a lamp base plastic part 10 , a driver 30 , a substrate radiator 23 , an LED light source 50 , a light source lens 60 and a cover sheet 70 . The integrated substrate radiator 23 composed of heat dissipation fins 20 and aluminum substrate 40 is a bowl-shaped structure approximately semi-spherical, with a hollow accommodation space inside. The plastic part 10 is located at the bottom of the base radiator 23: the driver 30 is located at the plastic In the accommodating space of the component 10, the LED light source 5 is fixed on the upper part of the substrate heat sink 23, and is electrically connected with the driver 30, and emits light under the control of the driver 30, and the emitted light beam is converged and refrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com