Power electronics module and a method of producing a power electronics module

A power electronic module, power electronic technology, applied in the direction of printed circuit manufacturing, circuits, electrical components, etc., can solve the problems of foil layer rupture, grease or paste material pumping, etc., to achieve increased heat transfer capacity, simple installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

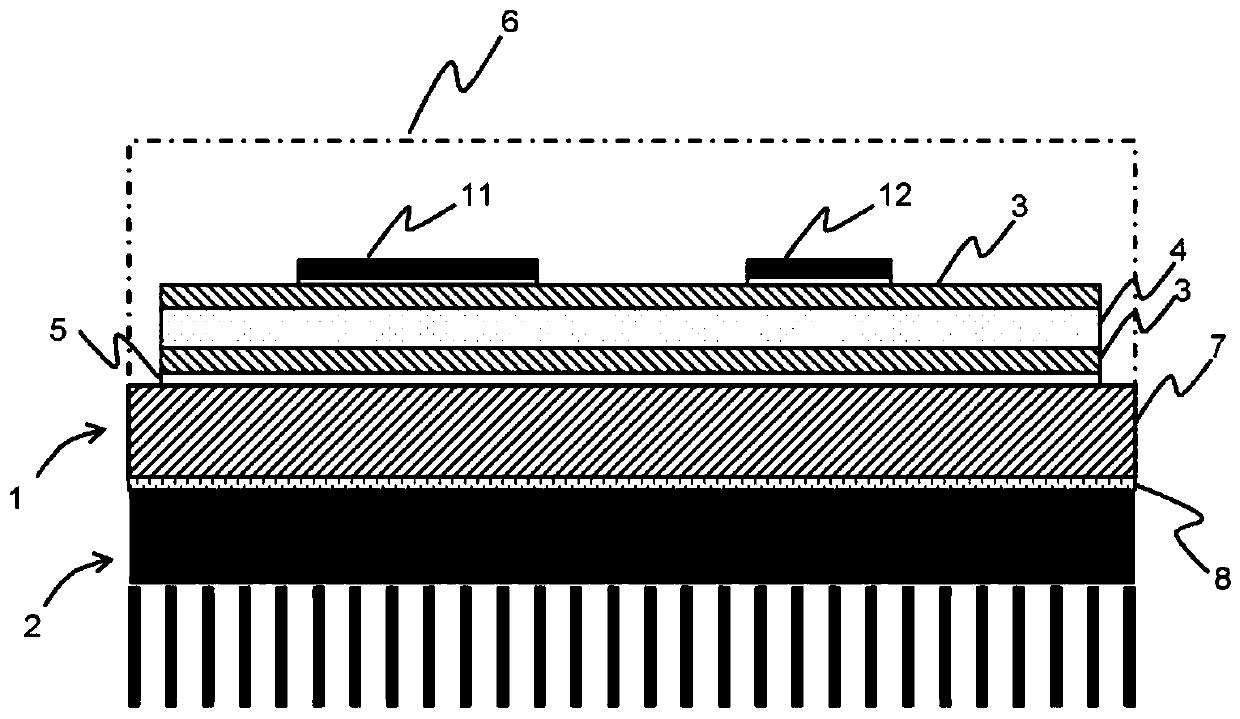

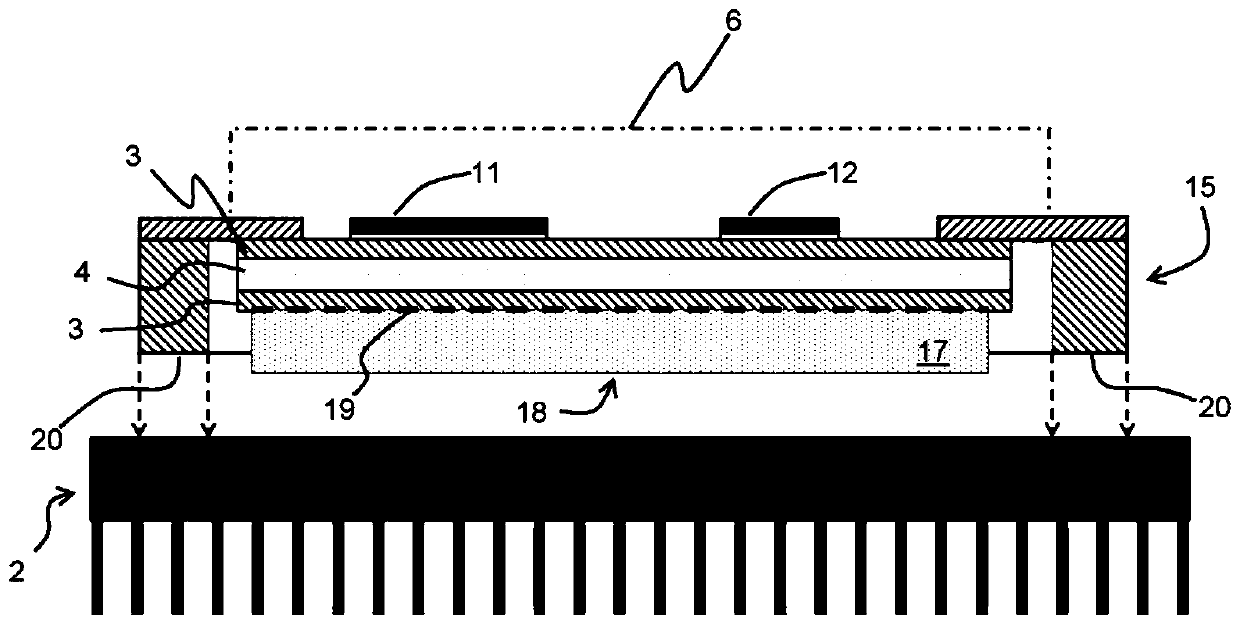

[0038] figure 2 A cross-section of a power electronics module according to an embodiment of the invention is shown. figure 2 The cross-section of FIG. 1 shows power semiconductor chips 11 , 12 soldered to a substrate such as a DBC structure 3 , 4 . According to the invention, a power electronics module comprises a plurality of power electronics semiconductor chips incorporated into a housing and attached to a substrate. In the description and drawings, specific reference is made to a direct bonded copper structure as an example of a substrate. figure 2 The section of FIG. 1 shows only two semiconductor chips 11 , 12 . However, the number of chips is not limited to any specific number.

[0039] The power electronics module also includes a heat transfer structure attached to the substrate and having a bottom surface forming an outer surface of the module and adapted to receive a surface of the cooling device. It is well known that heat from semiconductor chips is usually ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com