Novel reinforced extra-high-voltage power cable

A power cable and reinforced technology, which is applied in the field of new reinforced ultra-high voltage power cables, can solve the problems of easy breakage of conductors and short cable life, and achieve the effects of not being easy to break, reducing thermal resistance coefficient, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

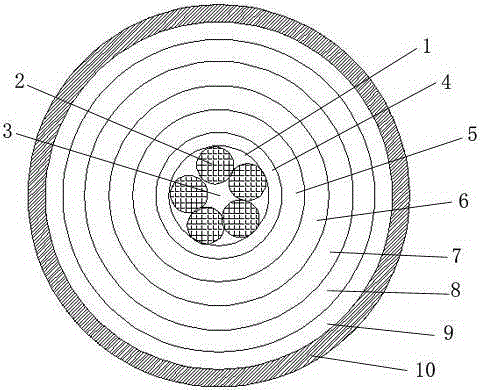

[0012] Such as figure 1 As shown, in a new type of reinforced ultra-high voltage power cable described in the present invention, the conductor 1 is first arranged in the center of the cable, and five circular reinforcing cores 2 are first arranged in the conductor 1 along the inner edge of the conductor, and then There is a five-sided arc-shaped reinforcement core 3 between the five circular reinforcement cores 2; the structure of the existing reinforcement core is changed, and the 5+1 mode is adopted, which makes the reinforcement of the cable 5 times higher than the original one, making the cable It is more difficult to break, so that the service life of the cable is longer. Even if it is artificially damaged, the conductor is not easy to break; Conductive shielding layer 6, then extrude semiconductive buffer layer 7, corrugated aluminum sheath 8, non-metallic sheath 9 outside semiconductive shielding layer 6; extrude graphite coating layer 10 on the outermost layer of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com