Novel low-smoke, halogen-free and fireproof insulated wire and manufacturing method thereof

A manufacturing method and technology of refractory cloth, applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of difficult quality control, high cost, low output, etc., to reduce secondary investment costs and low difficulty in quality control , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

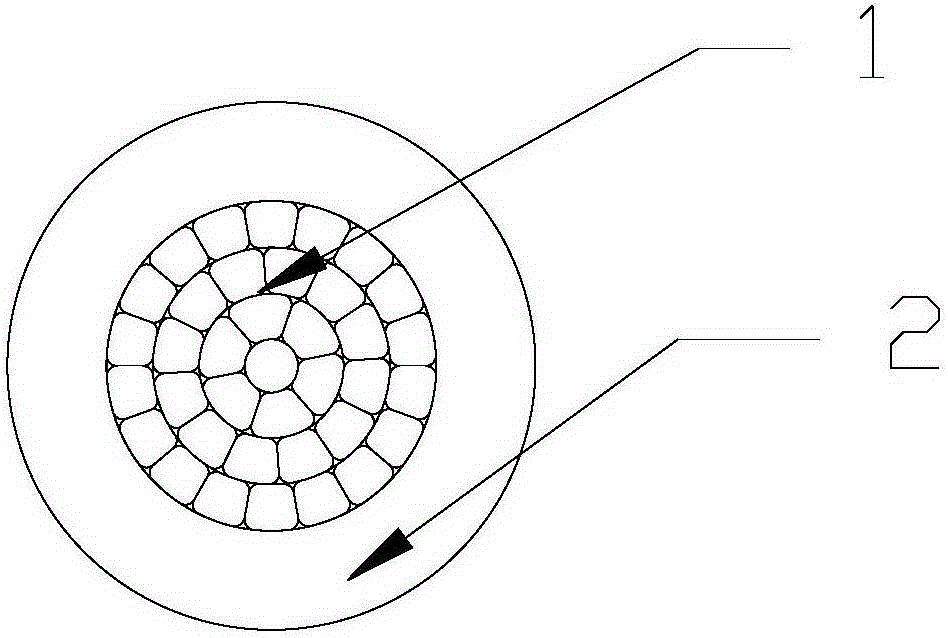

[0022] refer to figure 1 , the manufacture method of a kind of novel low-smoke halogen-free refractory wire that the present invention proposes, comprises the following steps (conductor nominal section 10mm 2 ):

[0023] S1, drawn copper wire: the diameter is 3mm, and the resistivity is not greater than 0.017241Ω·mm 2 / m annealed annealed copper wire is drawn into a copper wire with a diameter of φ1.35mm by the existing technology. , and then heat the copper wire to 550°C for recrystallization, after cooling with water, dry it with compressed air and cool it down to below 80°C to obtain a round annealed copper wire;

[0024] S2, stranded conductor: 7 circular annealed copper wires are twisted into a conductor, the conductor outlet speed is 20m / min, the pneumatic tension of the pay-off reel is controlled at 1.8bar, and the take-up tension is 500N;

[0025] S3, extrude the insulating layer: extrude the refractory ceramic polyolefin material through the extruder, the temperatu...

Embodiment 2

[0028] refer to figure 1 , the manufacture method of a kind of novel low-smoke halogen-free refractory electric wire that the present invention proposes, comprises the following steps (conductor nominal section 185mm 2 ):

[0029] S1, drawing copper wire: drawing an oxygen-free round copper rod with a diameter of 8 mm into a round copper single wire of 2.52 mm, with a deviation of +0.02 mm to 0 mm. The 2.58mm copper wire drawing production equipment is continuous annealing, 9-mode sliding high-speed copper drawing machine, the mold matching molds in the wire drawing box are: the first mold size: 7.0mm, the second mold size: 5.75mm, the second mold size: The third mold size: 4.8mm, the fourth mold size: 4.03mm, the fifth mold size: 3.43mm, the sixth mold size: 2.95mm, the seventh mold size: 2.54mm; the mold is made of polycrystalline copper The slip coefficient between each wire drawing die is controlled between 1.01 and 1.015; the copper wire annealing adopts the direct curr...

Embodiment 3

[0034] refer to figure 1 , the manufacture method of a kind of novel low-smoke halogen-free refractory wire that the present invention proposes, comprises the following steps (conductor nominal section 400mm 2 ):

[0035] S1, drawn copper wire: the diameter is 8.0mm, and the resistivity is not greater than 0.017241Ω·mm 2 The / m oxygen-free copper rod is drawn into a copper wire with a diameter of φ2.85mm by the existing technology, and the copper wire outlet speed is 15m / s. After the copper wire is drawn, the copper wire is preheated to 250°C, and then nitrogen gas is introduced , and then heat the copper wire to 550°C for recrystallization, after cooling with water, dry it with compressed air and cool it down to below 80°C to obtain a round annealed copper wire;

[0036] S2, stranded conductor: 61 circular annealed copper wires are twisted into a conductor, the conductor outlet speed is 20m / min, the pneumatic tension of the pay-off reel is controlled at 2.0bar, and the take...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com