Patents

Literature

41 results about "Polycrystalline copper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

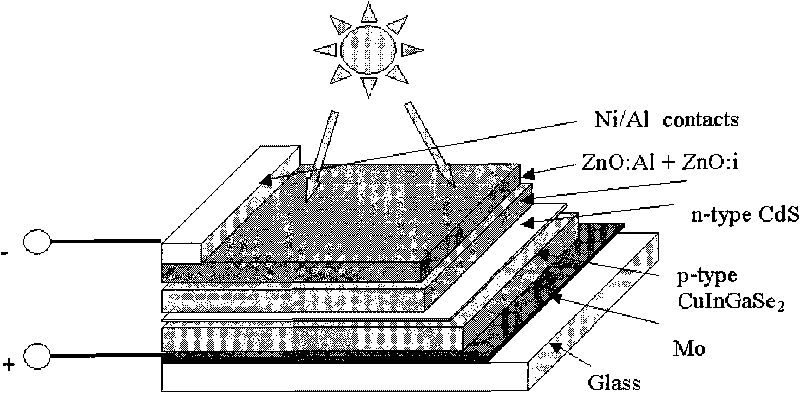

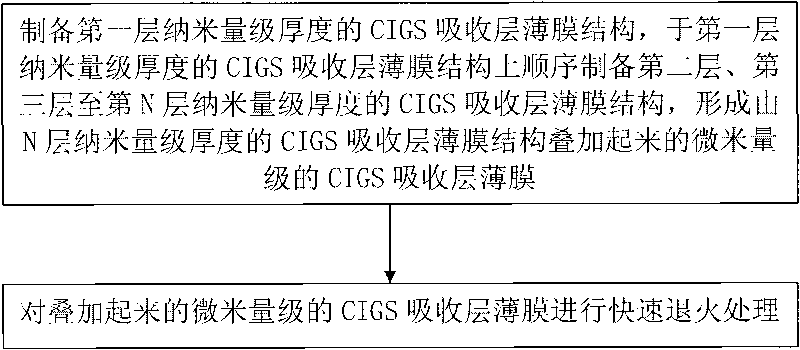

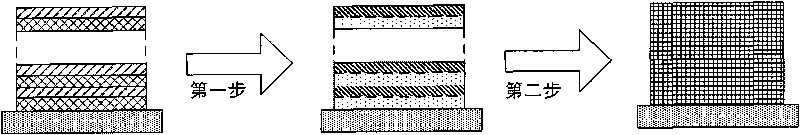

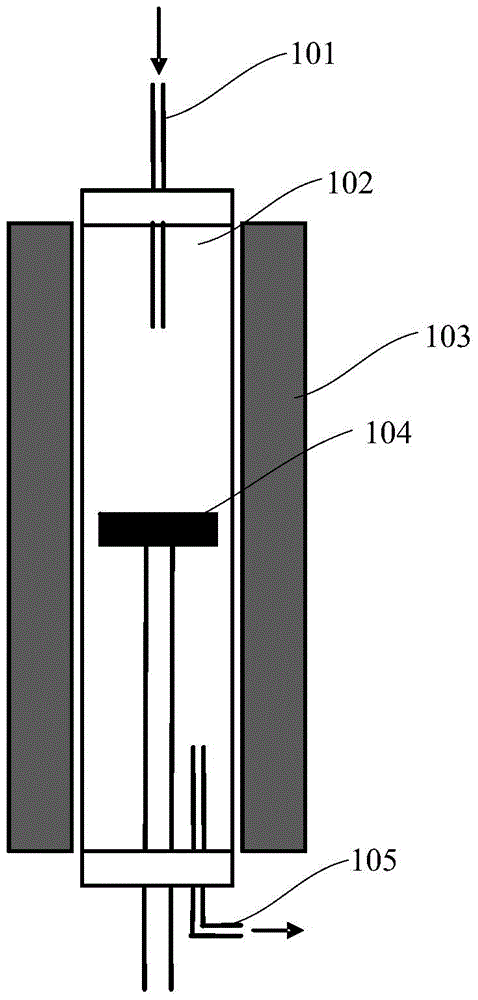

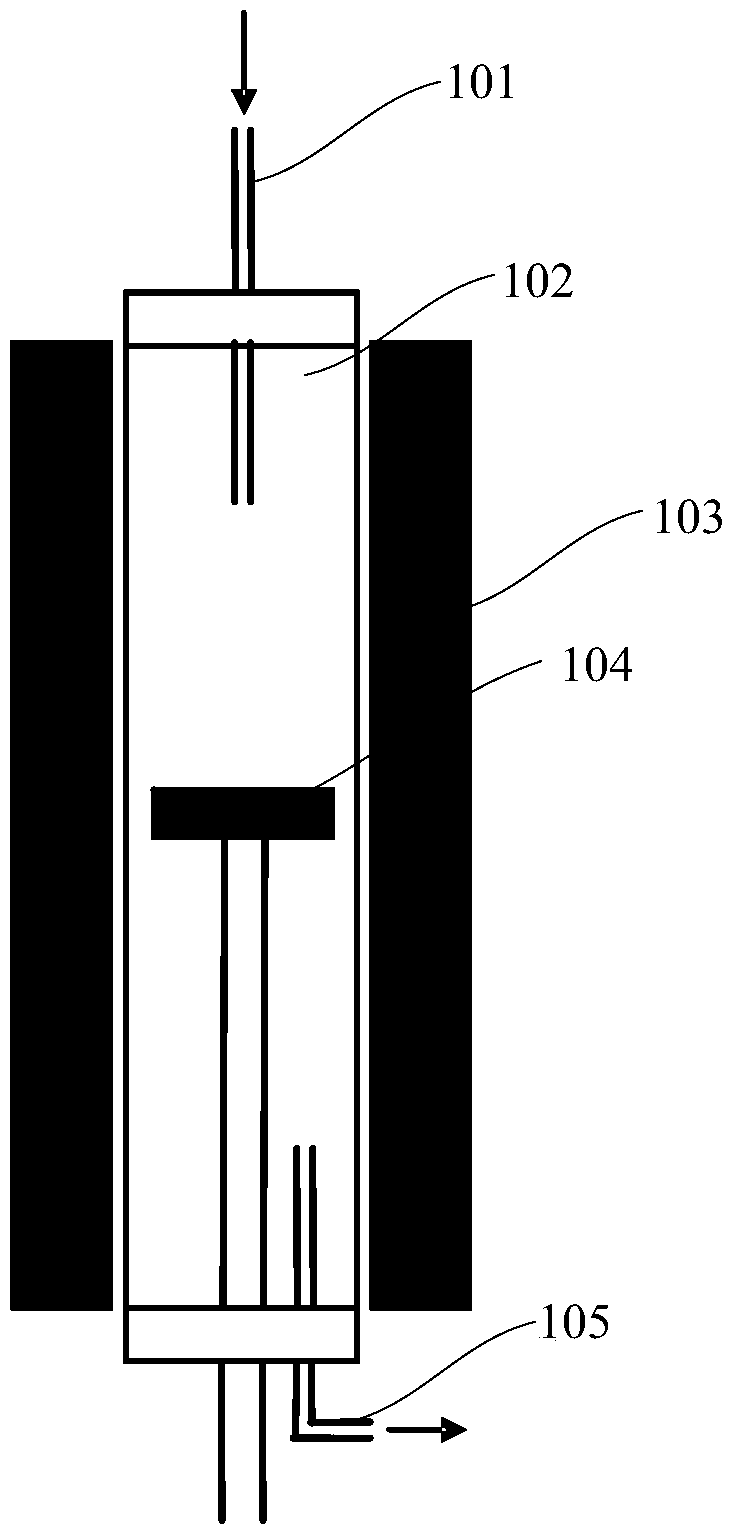

Copper indium gallium selenium (CIGS) solar cell, film of absorbing layer thereof, method and equipment for preparing film

InactiveCN101740660APrevent uneven distributionStop the spreadFinal product manufacturePhotovoltaic energy generationIndiumCopper indium gallium selenide

Owner:北京华仁合创科技有限公司

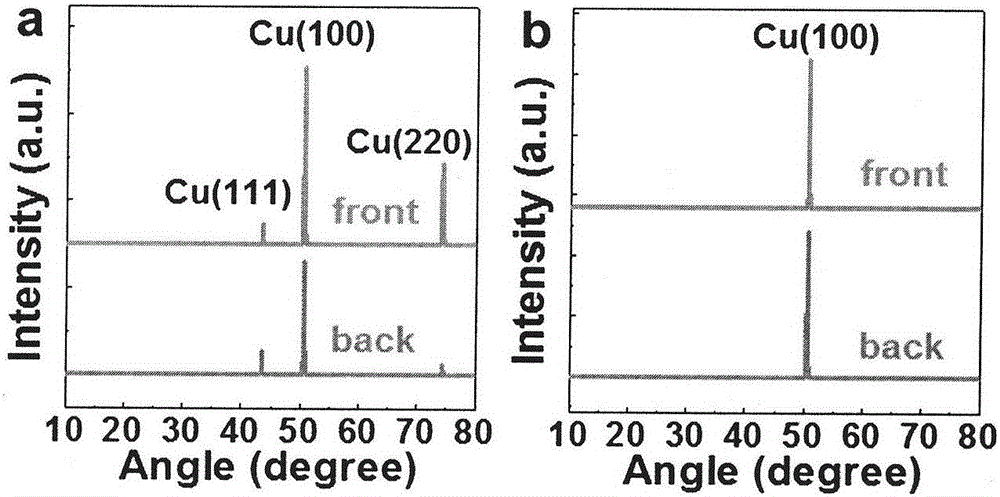

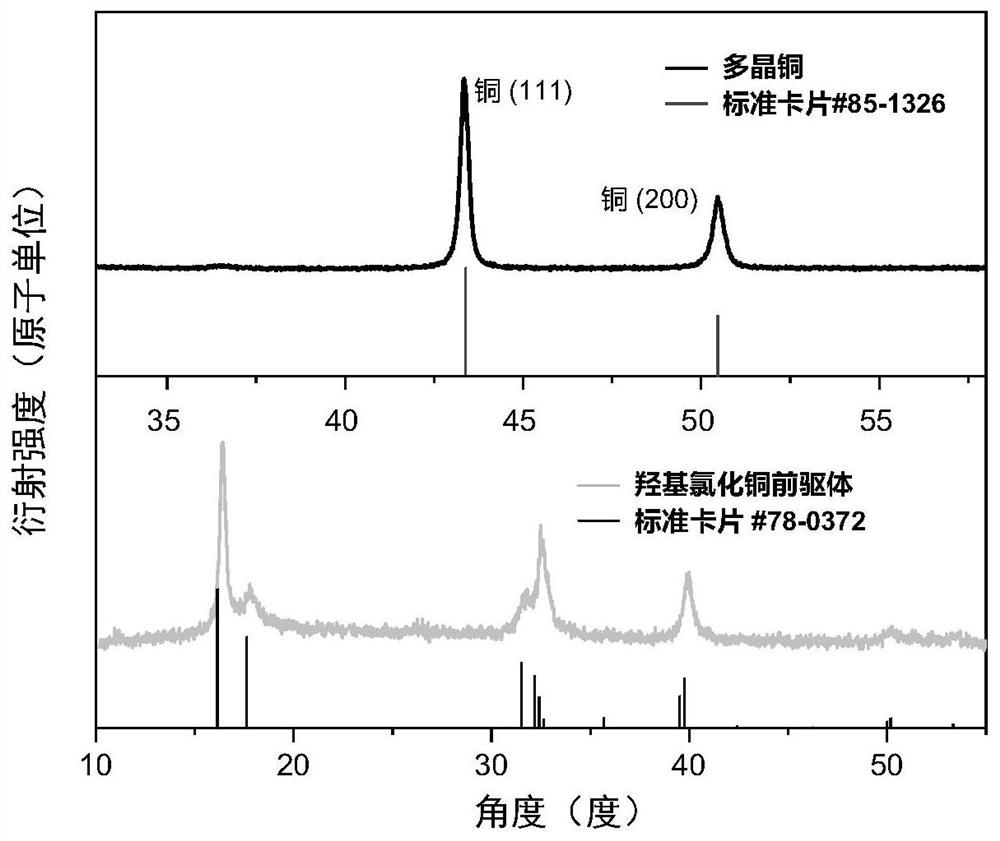

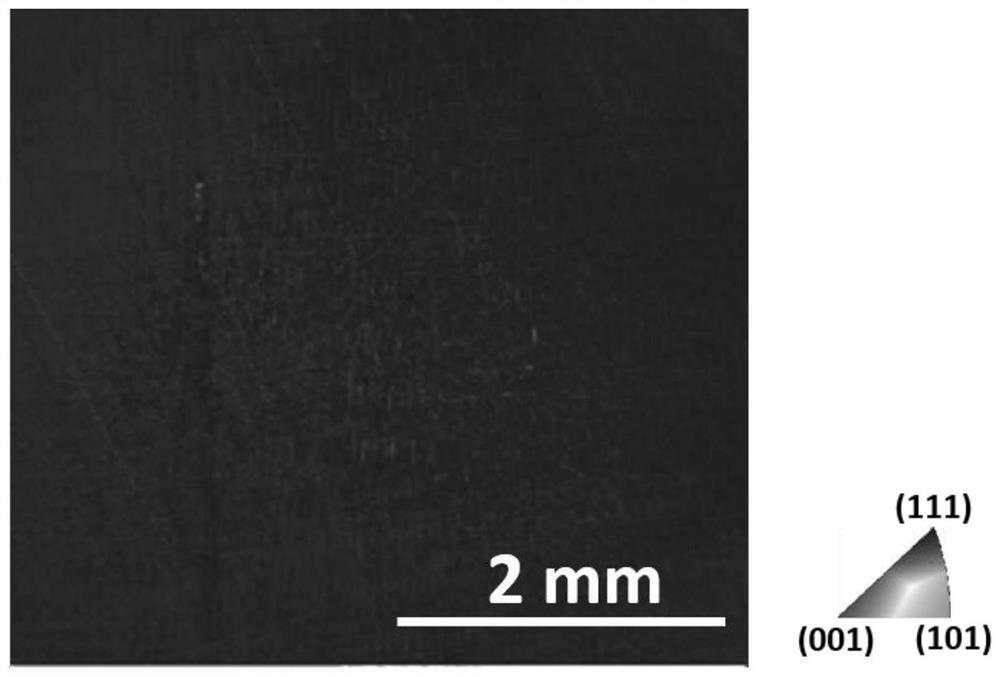

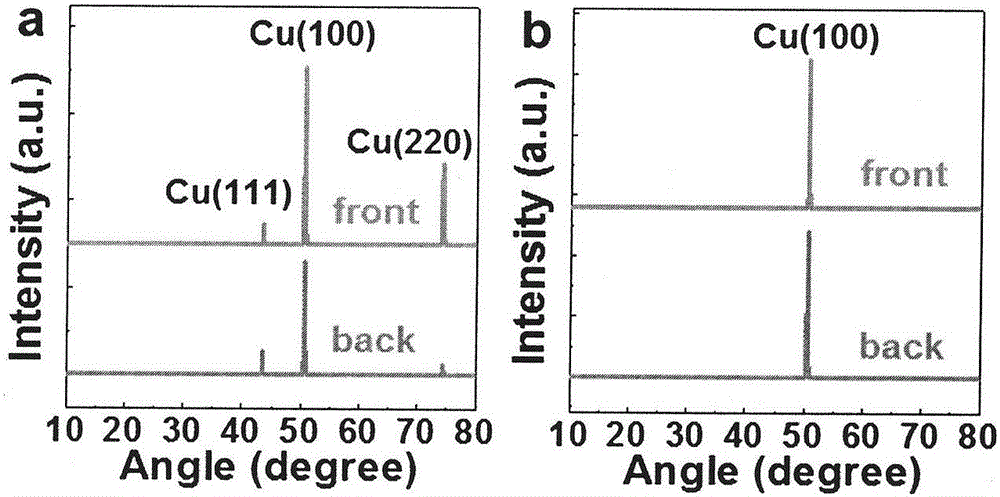

Preparation method of large-size Cu(100) single-crystal copper foil

ActiveCN105714382ASpeed up preparationSolve an extremely expensive problemPolycrystalline material growthFrom solid stateSingle crystalCopper foil

The invention provides a preparation method of a large-size Cu(100) single-crystal copper foil. The method comprises the step that a polycrystalline copper foil doped with metallic elements serves as the raw material, and single-crystal Cu(100) with a super-large size is prepared through a special annealing technology. The preparation method of the large-size Cu(100) single-crystal copper foil solves the problem that the single-crystal Cu(100) is high in price, and preparation of the Cu(100) single-crystal copper foil is achieved through the very simple method.

Owner:PEKING UNIV

Preparation method of absorbing layer of copper-zinc-tin-sulfur film solar cell

InactiveCN101800263AAvoid emissionsImprove securityFinal product manufactureSemiconductor devicesChemical industryHigh absorption

The invention belongs to the technical field of semiconductor photoelectric materials and devices, in particular to a preparation method of an absorbing layer of a copper-zinc-tin-sulfur film solar cell, belonging to the technical field of semiconductor photoelectric materials and devices. The preparation method comprises the following steps: adopting the joint evaporation method to prepare copper, zinc and tin metallic precursors, vulcanizing the precursors in sulfur vapor to obtain copper-zinc-tin-sulfur, and successfully preparing a polycrystalline copper-zinc-tin-sulfur film on a glass substrate under appropriate conditions, wherein the film has a single-phase stannite structure, a direct band gap (1.51eV) which well matches with the solar spectrum and a high absorption coefficient (104cm<-1>) for the visible light, and the resistivity, the carrier mobility and the carrier concentration of the film are respectively up to 1.46 ohm cm, 4.2cm<2> / VS and 2.37*1018cm<-3>. The invention has the advantages of abundant material resources, no toxicity, simple preparation process, tractable film performance and the like, and is applicable to the large-scale chemical industry production.

Owner:ZHANJIANG NORMAL UNIV

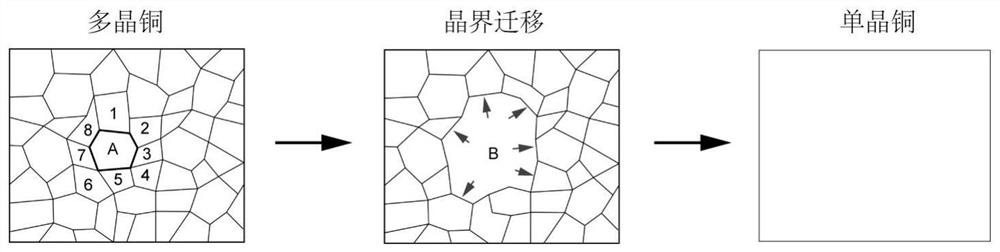

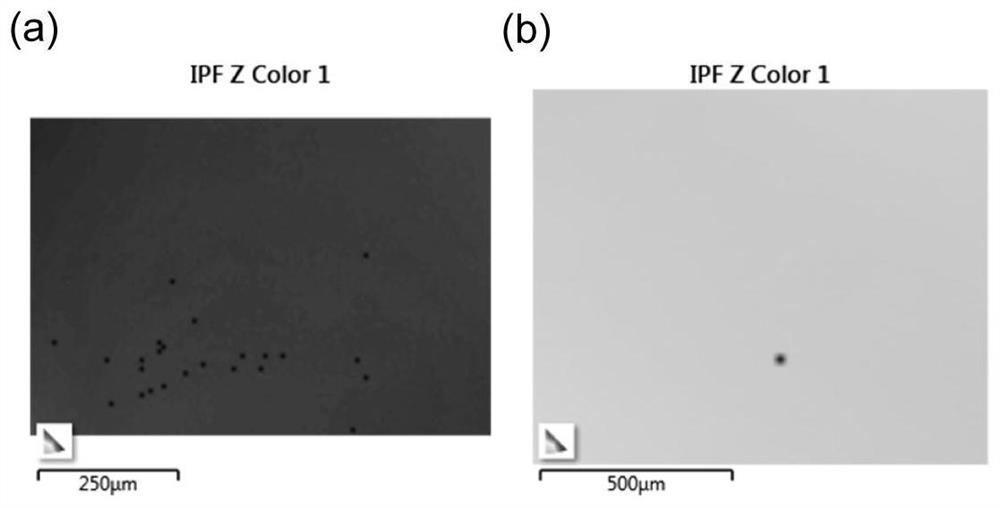

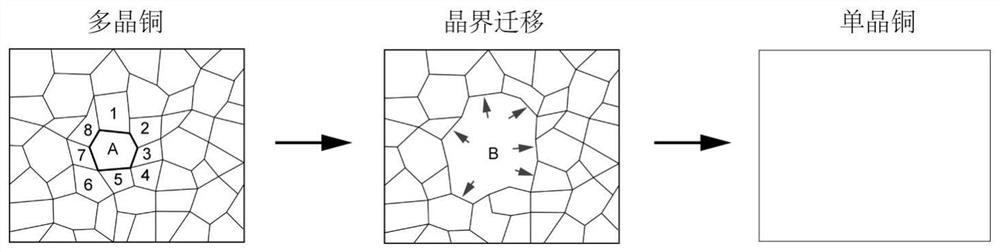

Preparation method of monocrystalline copper strips

The invention relates to monocrystalline copper, and specifically relates to a method utilizing crystal merging growth to prepare monocrystalline copper strips. Utilization of polycrystalline copper strips which can gradually merge and grow at a sufficiently high temperature, grain boundary areas can be gradually centralized together due to the merging growth process, when the grain boundary areas are large enough or two large enough crystals meet each other, an area which cannot be converted into a monocrystalline is formed; through a method of step-by-step continuous heating, the area which is not converted into the monocrystalline always remains relatively small size, at the same time, the part which is not converted into the monocrystalline is avoided from generating anisotropy by an ultrasonic vibration effect, and a continuous single-crystal strip area is eventually obtained by heating to grow for enough time.

Owner:XINGHUA PRECISION CASTING & FORGING IND RES INST CO LTD

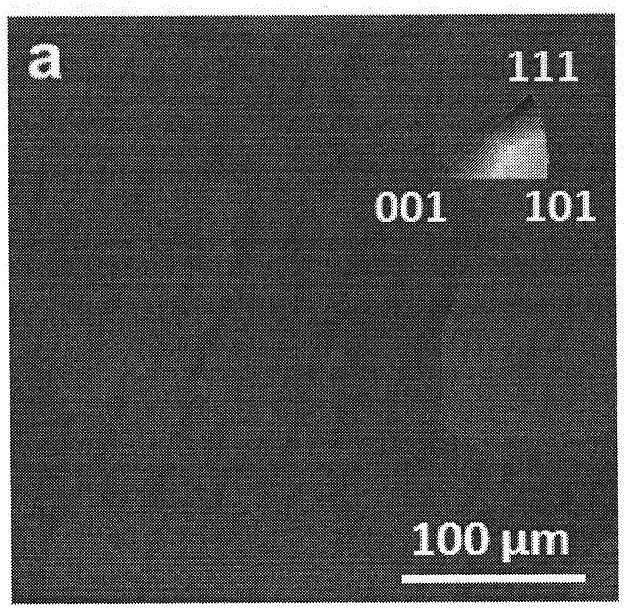

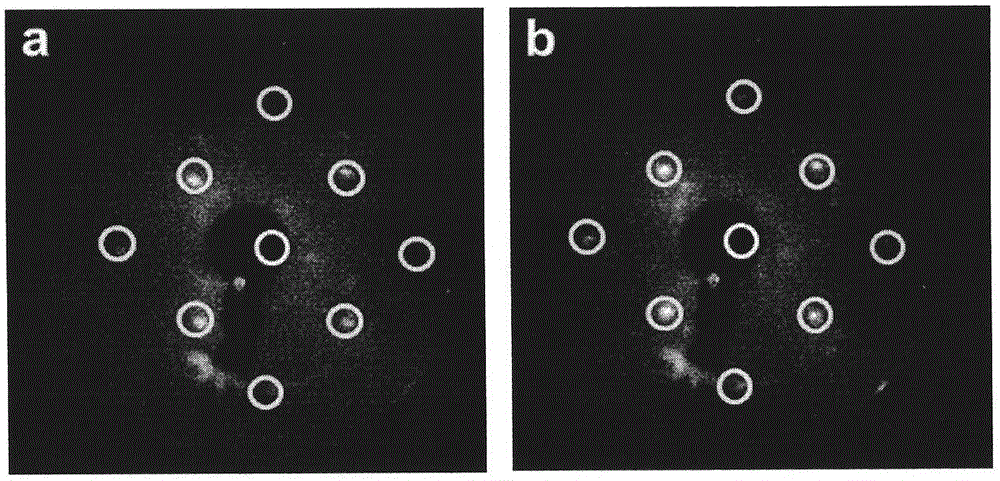

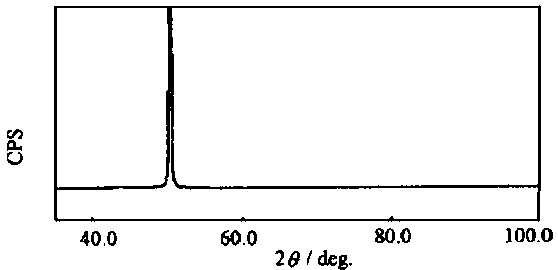

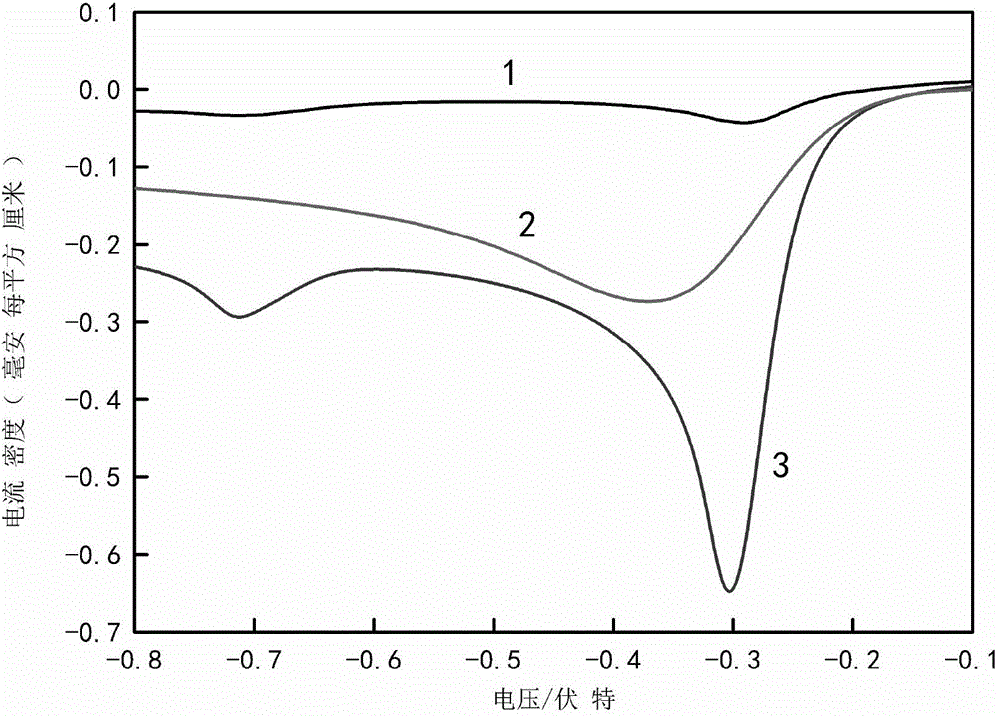

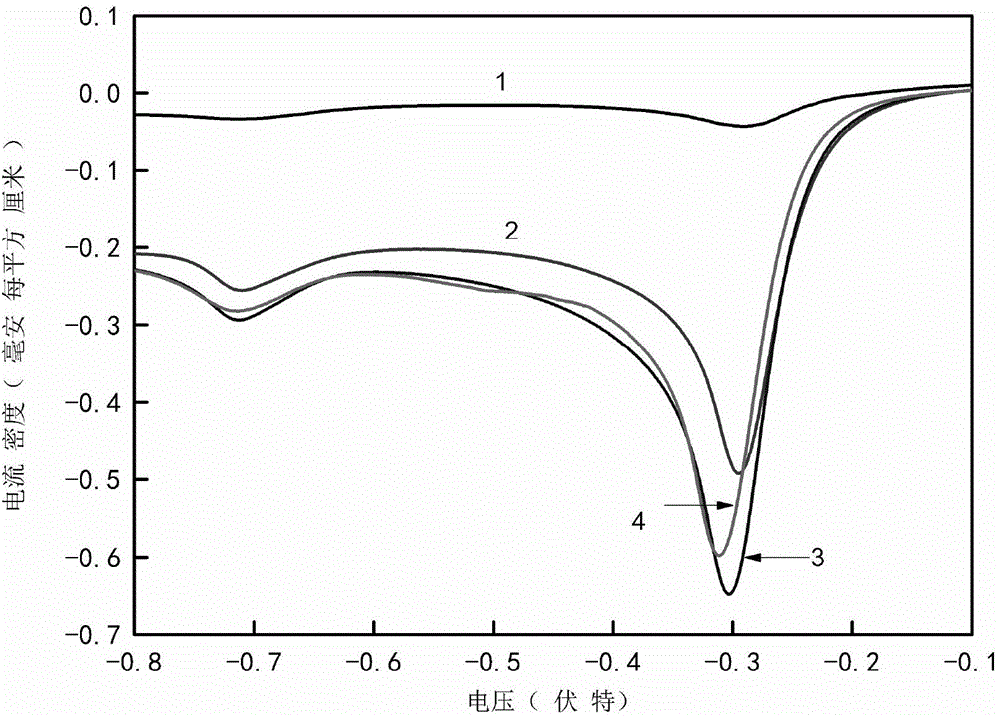

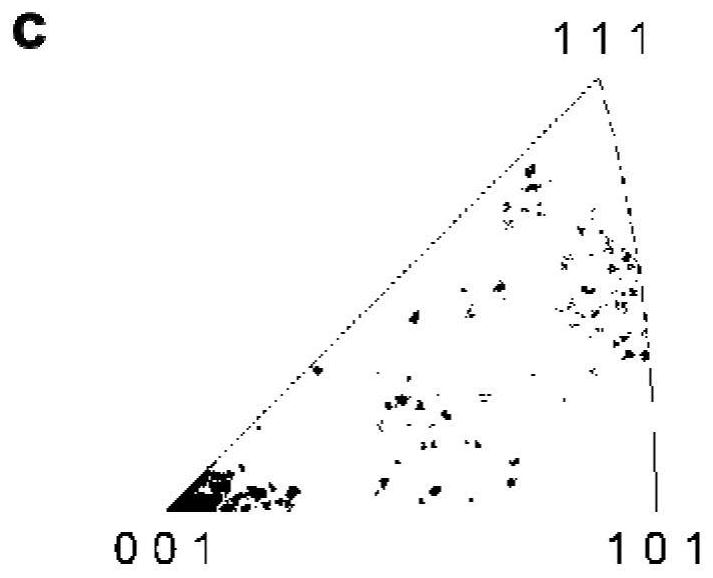

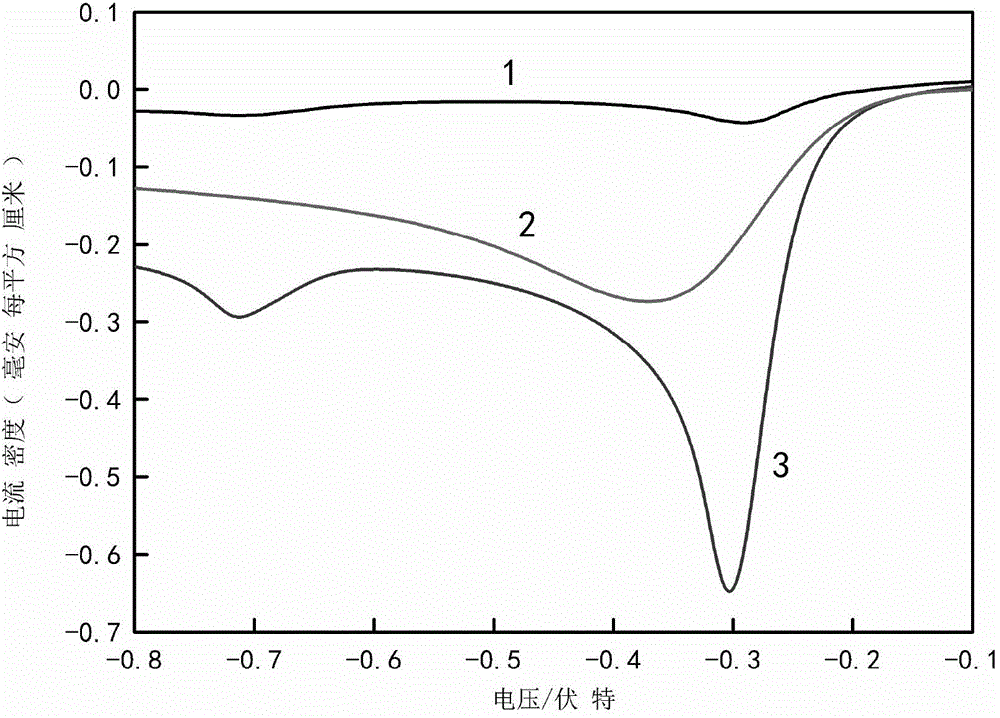

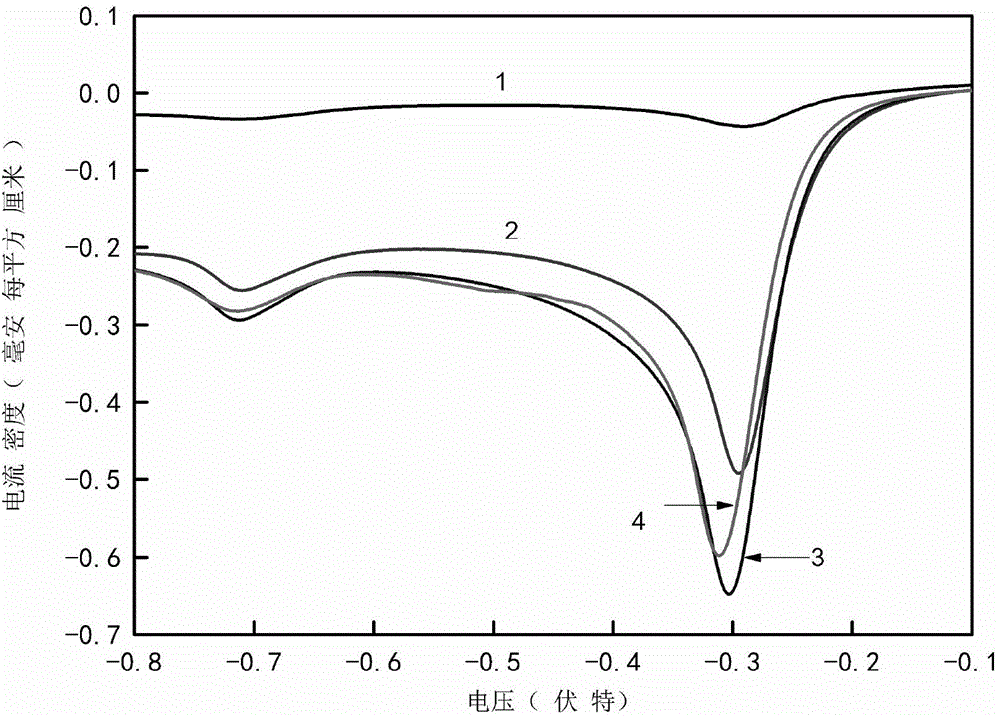

Silver copper nano alloy electro-catalyst and laser gas phase deposition method thereof

ActiveCN104084216ALow costEfficient catalytic performanceMaterial nanotechnologyCell electrodesElectro catalystGas phase

The invention discloses a silver copper nano alloy electro-catalyst and a laser gas phase deposition method thereof. The silver copper nano alloy electro-catalyst is obtained by depositing on a titanium sheet via a laser gas phase deposition method by taking the titanium sheet as a substrate and taking silver copper alloy as a target. The mole ratio of silver to copper in the silver copper nano alloy electro-catalyst is 4 to 1; the structure morphology of the silver copper nano alloy electro-catalyst is nanocrystalline and non-crystalline, and the nanocrystalline is embedded into the non-crystalline; or the structure morphology of the silver copper nano alloy electro-catalyst consists of nanocrystalline or multi-crystalline, wherein the nanocrystalline is a solid solution of a silver and copper face-centered cubic structure, the non-crystalline is metal copper, and the multi-crystalline is multi-crystalline copper. According to the silver copper nano alloy electro-catalyst and the laser gas phase deposition method, the oxygen reduction reaction catalytic effect is superior, and the preparation cost is low.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

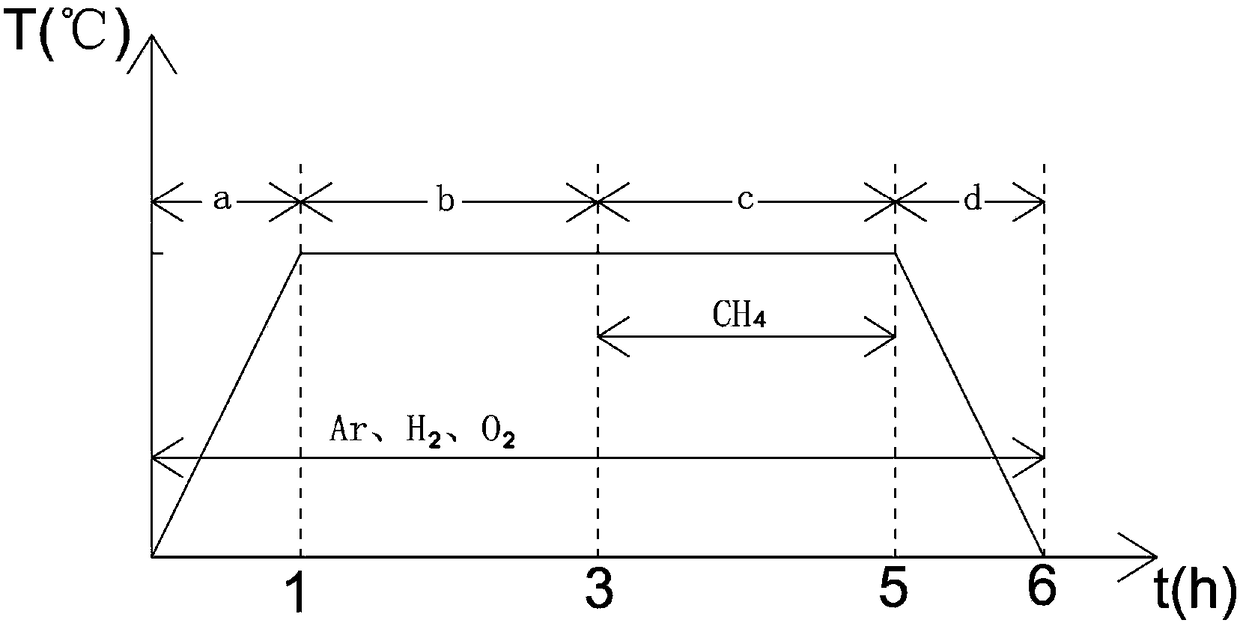

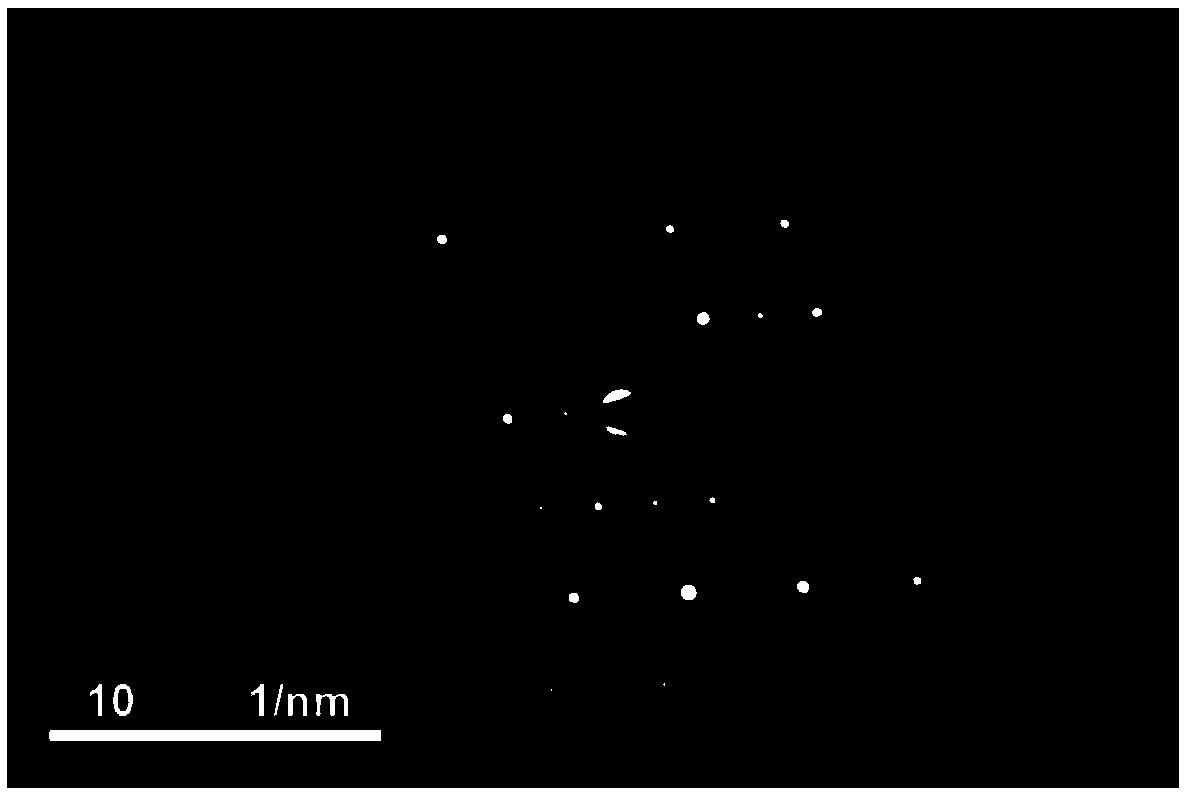

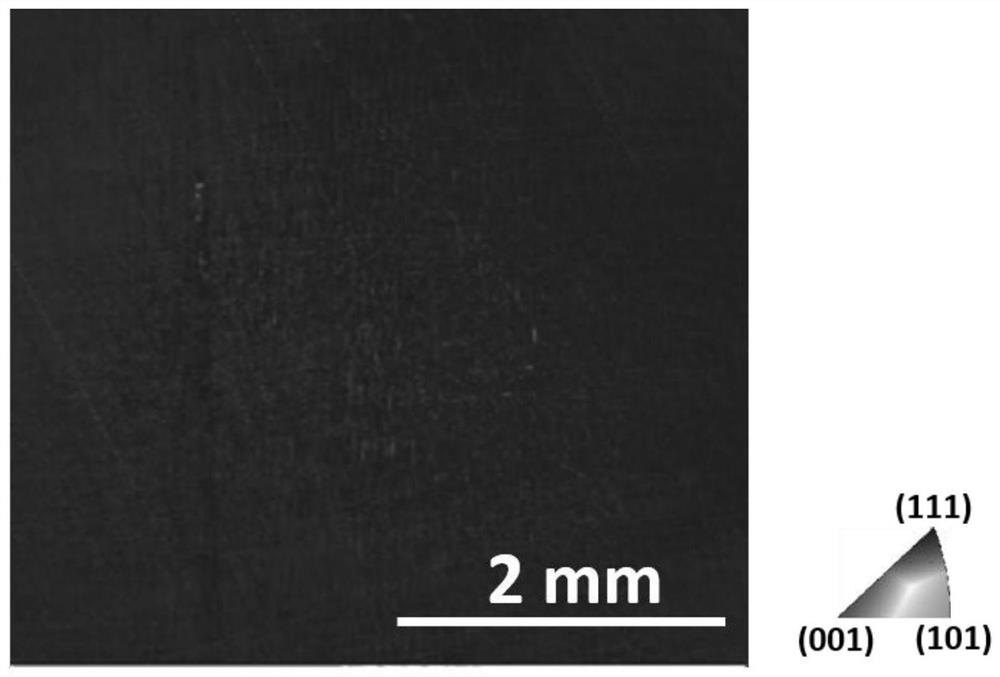

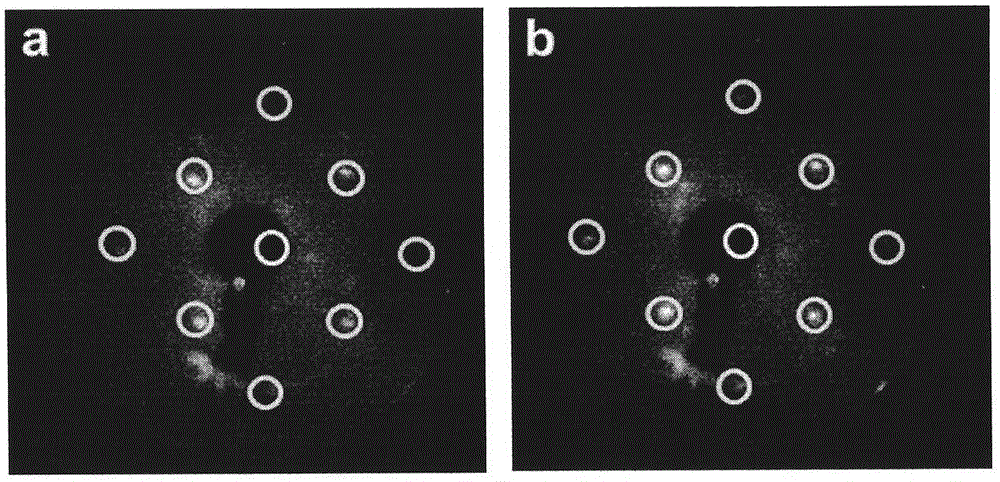

Preparation method of millimeter-scale monolayer monocrystalline graphene based on polycrystalline copper foil

ActiveCN108423659AAffect qualityAchieve single crystal growthSingle layer grapheneSingle crystalCopper foil

The invention discloses a preparation method of millimeter-scale monolayer monocrystalline graphene based on a polycrystalline copper foil and belongs to the technical field of thin film graphene material preparation. The preparation method includes: in an atmosphere with argon, hydrogen and oxygen, heating a copper foil; utilizing methane for catalytic cracking on the surface of the copper foil;growing on the inner wall of a rectangular box to form large-size monolayer monocrystalline graphene. Complex pretreatment of the copper foil is not needed, and the surface of the copper foil can be simply cleaned by only using anhydrous alcohol, so that introduction of new impurities is avoided. Pre-oxidation treatment of the copper foil is not needed, and monocrystalline growth of graphene can be realized by controlling flow of oxygen and pressure intensity in a CVD reaction cavity in the process of preparing graphene. On the premise that optimal oxygen flow parameters are utilized, growth time of monocrystalline graphene is controlled by controlling lasting time of methane to regulate size of monocrystalline graphene.

Owner:SHAOXING UNIVERSITY

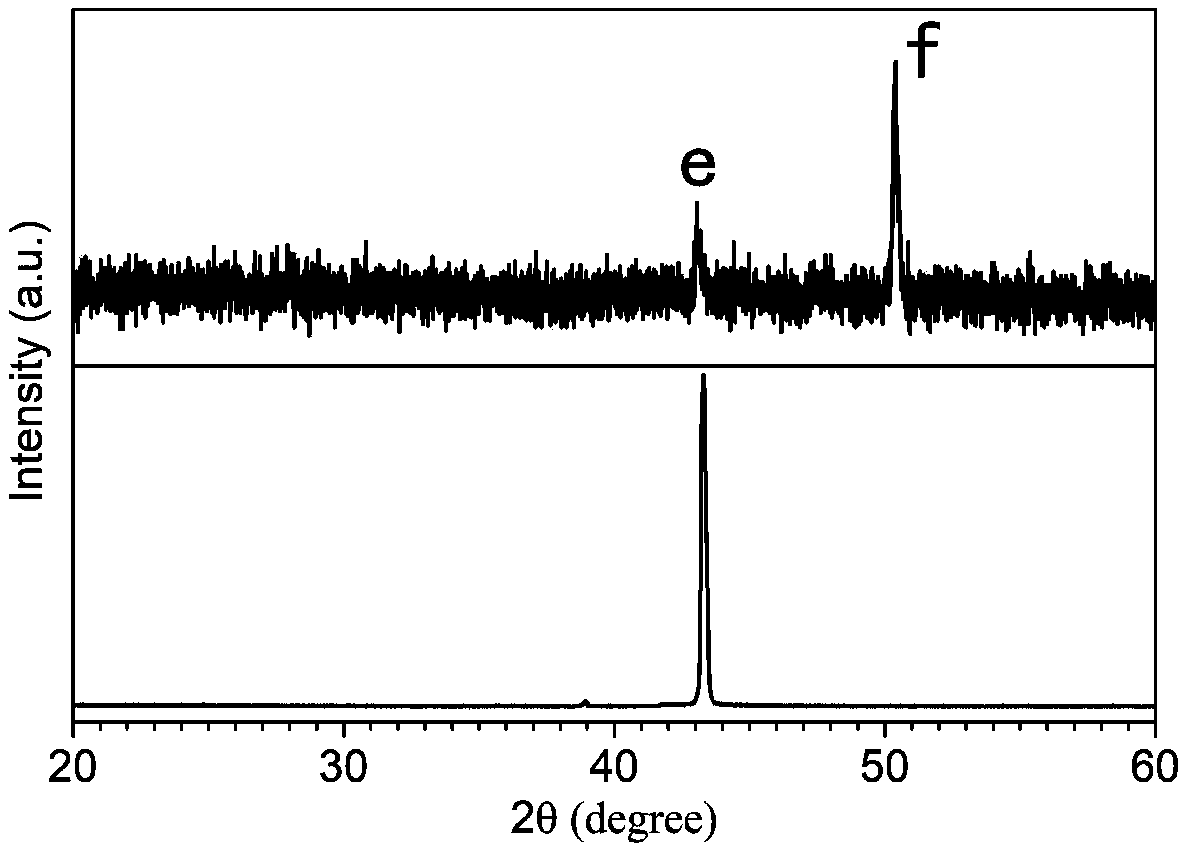

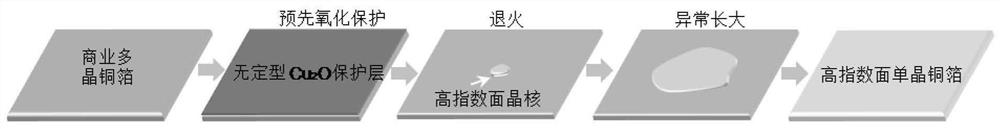

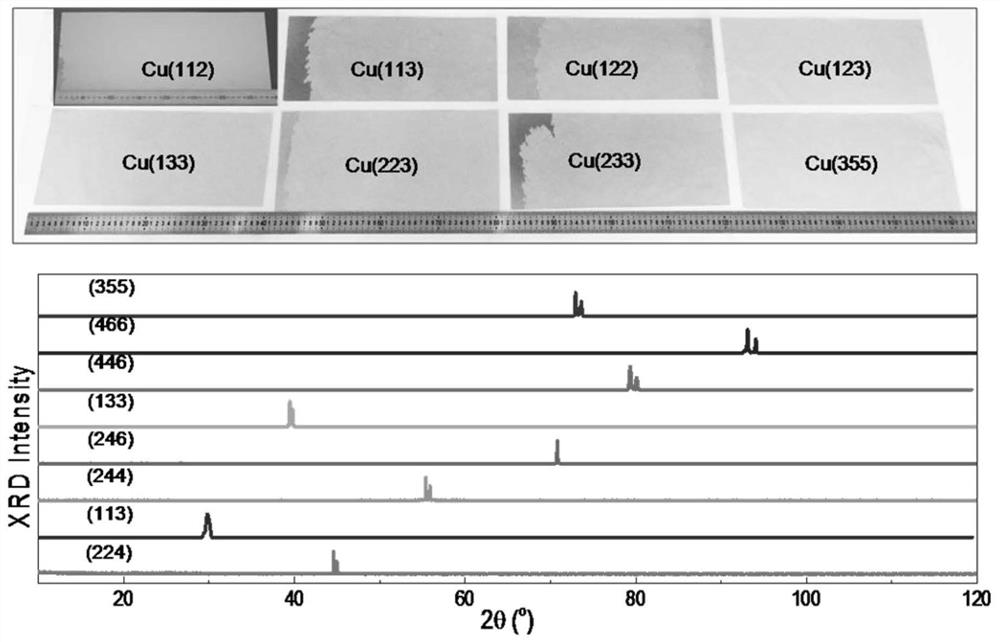

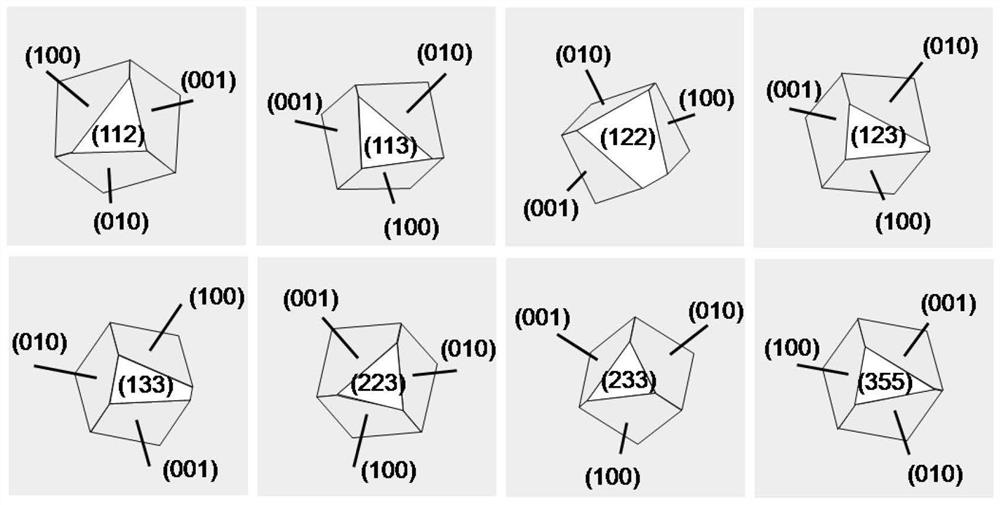

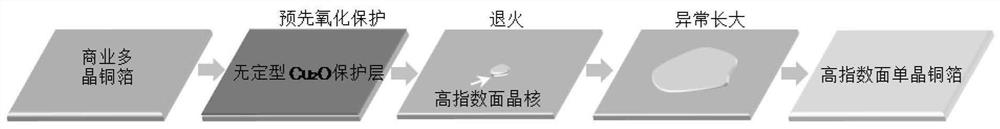

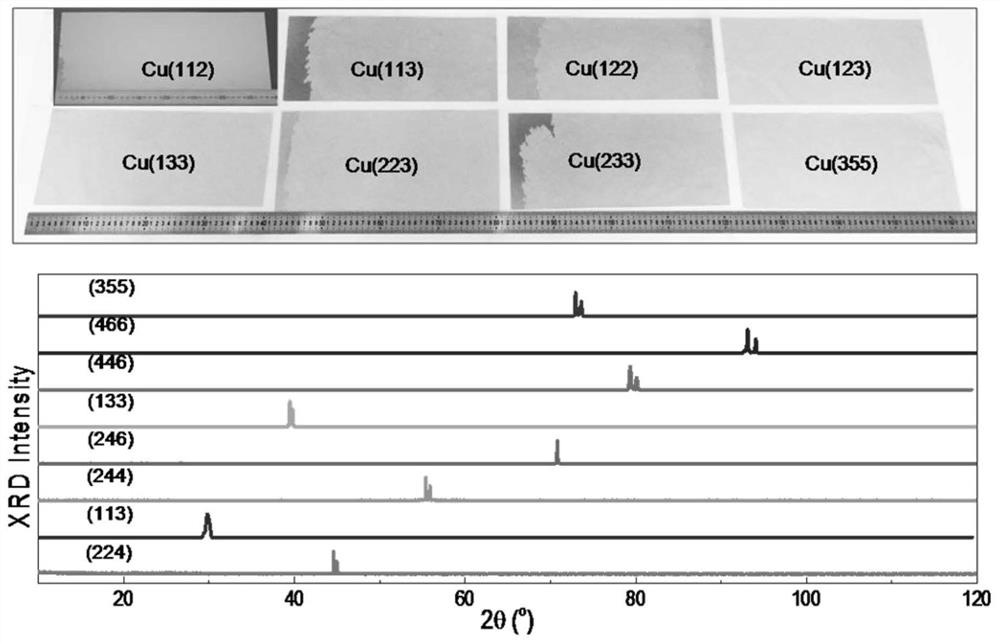

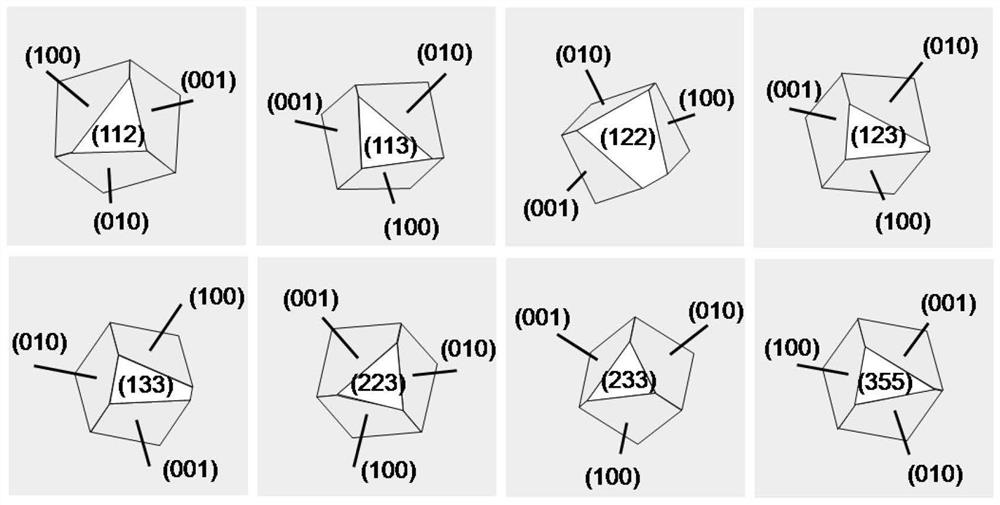

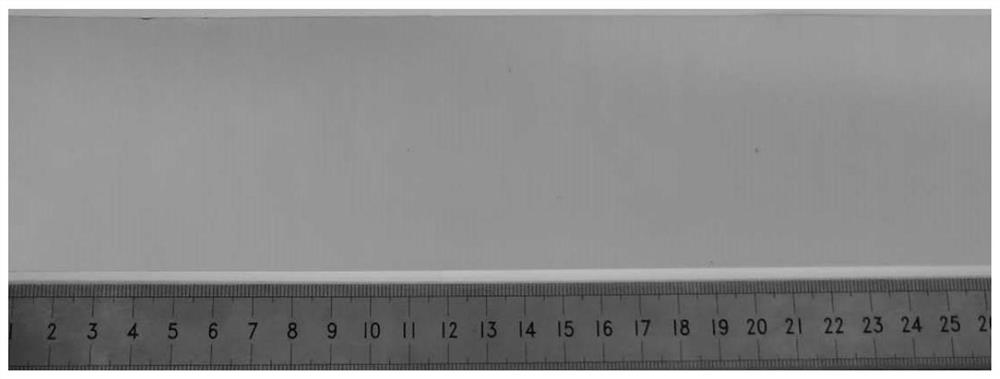

Preparation method of meter-scale large single crystal high-index surface copper foil

ActiveCN111690983ASettle the priceSolve the costPolycrystalline material growthFrom solid stateMetallurgyPhysical chemistry

The invention provides a preparation method of a meter-scale large single crystal high-index surface copper foil. According to the method, commercial polycrystalline copper foil is used as a raw material, and a series of meter-scale large-single-crystal high-index-surface copper foils such as Cu (112), Cu (113), Cu (122), Cu (133), Cu (223), Cu (233), Cu (355) and other high-index surfaces are prepared by using a process of oxidation protection in advance and annealing. The method proposed by the invention can solve the problems that Cu (112), Cu (113), Cu (122), Cu (123), Cu (133), Cu (223),Cu (233), Cu (355) and other high-index surface single crystal copper foils are high in price and preparation cost, and no product is supplied on the market. Macro preparation of high-quality meter-scale large single crystal Cu (112), Cu (113), Cu (122), Cu (123), Cu (133), Cu (223), Cu (233), Cu (355) and other high-index surface copper foils is realized through a very simple method.

Owner:PEKING UNIV

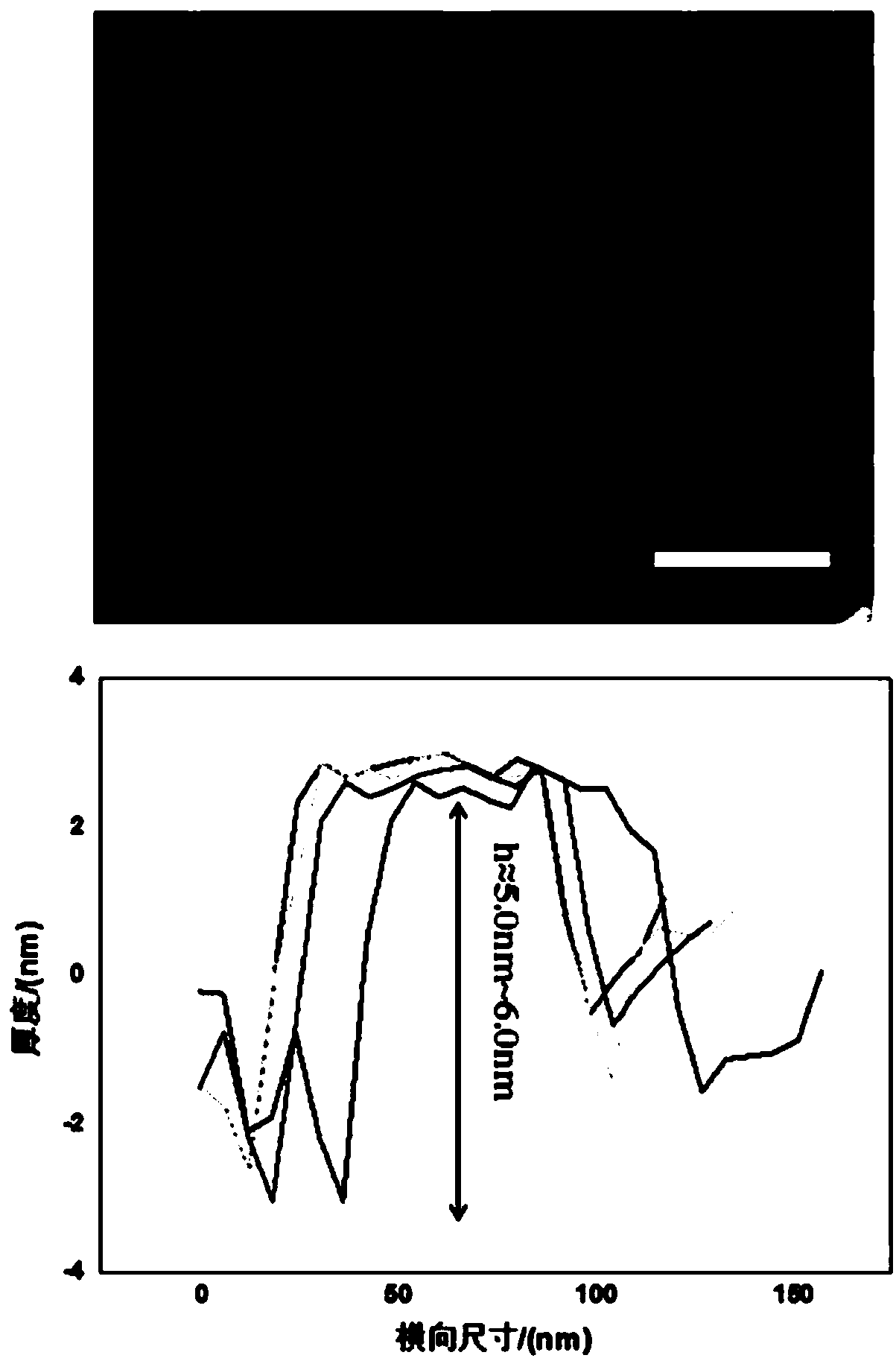

Preparation method of antimonene nanosheet

ActiveCN109607470AEasy to operateQuality improvementDecorative surface effectsCoupling light guidesGas phaseNucleation

The invention discloses a preparation method of an antimonene nanosheet. The method comprises the steps of taking pure antimony powder as a precursor and a polycrystalline copper foil sheet as a substrate; under a normal pressure, setting a gas atmosphere flow ratio to be Ar : H2=100-300 : 10-50 sccm; carrying out physical vapor deposition at a temperature of 640-690 DEG C for 3-19 minutes; enabling the temperature of the substrate to be 150-250 DEG C; and obtaining the triangular or trapezoidal antimonene nanosheet which grows on the polycrystalline copper foil sheet. The method disclosed bythe invention is simple to operate and is carried out under the normal pressure; and the prepared triangular or trapezoidal antimonene nanosheet is high in nucleation density, high in purity and stable in chemical property is stable, the length is 25 nm to 10 microns, and the thickness can be controlled to be 2 nm to 110 nm.

Owner:NANJING UNIV OF SCI & TECH

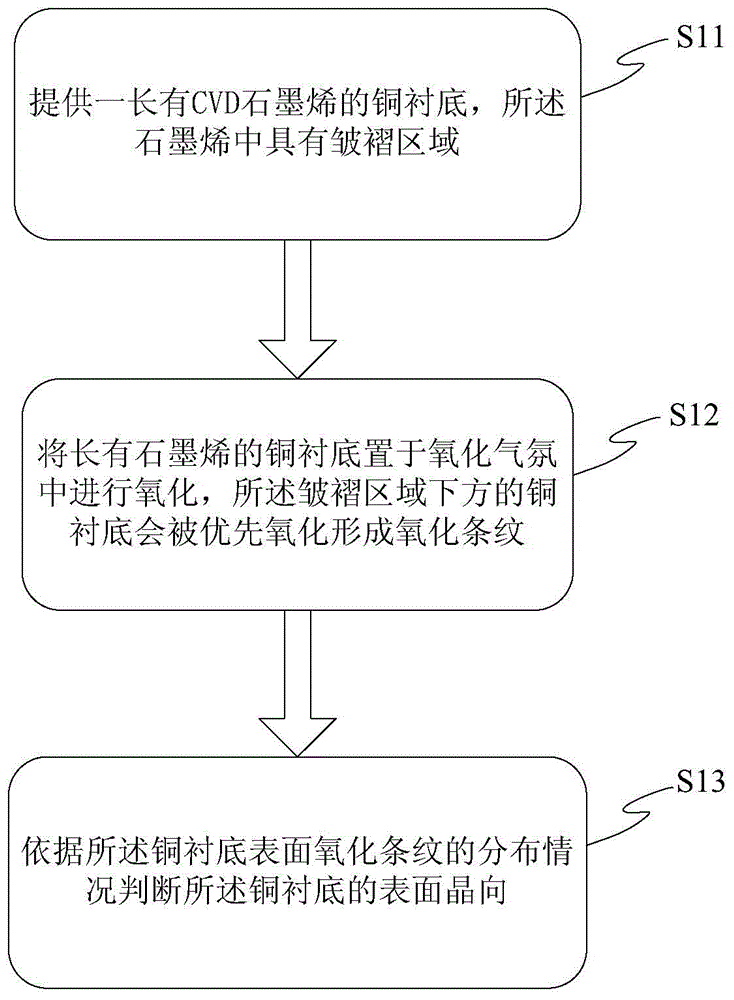

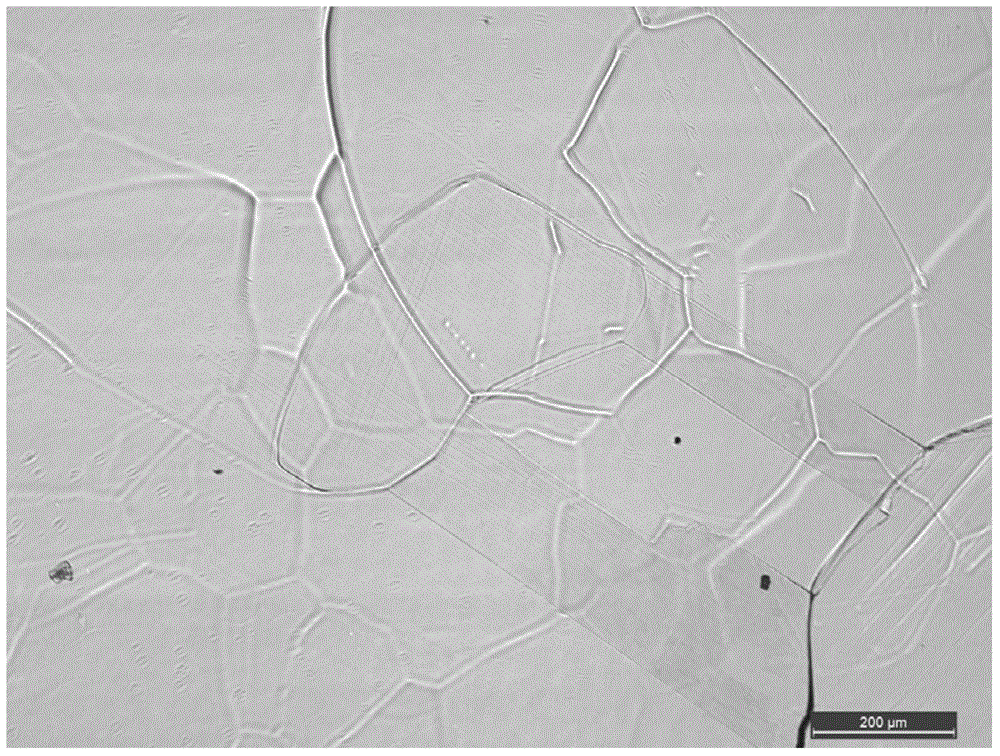

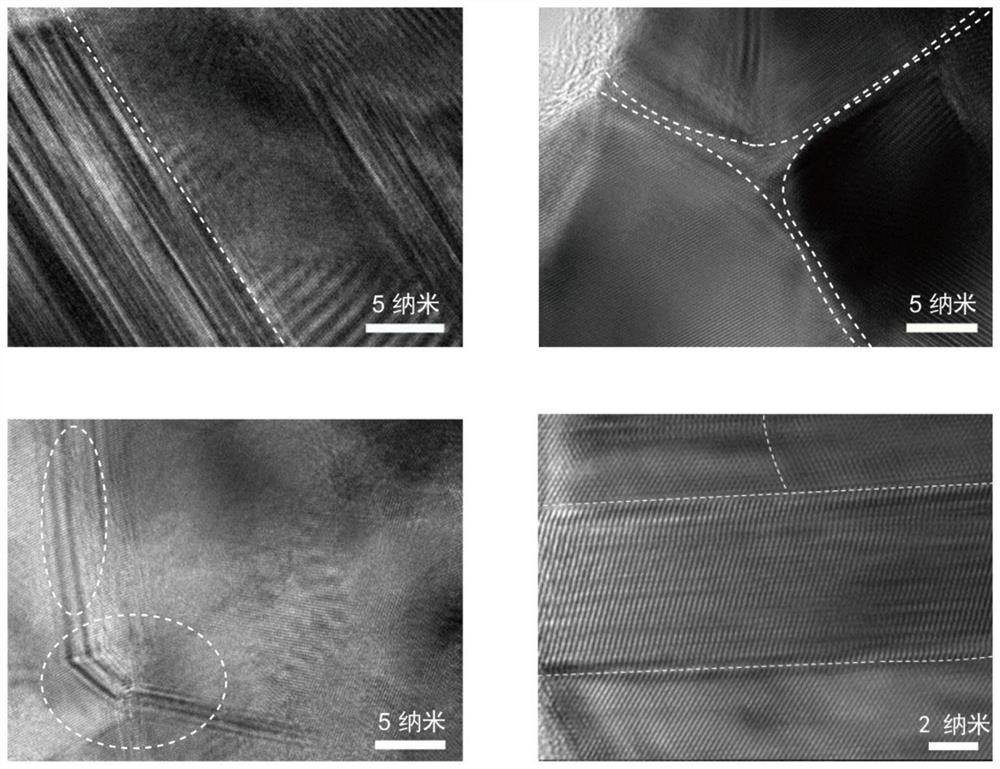

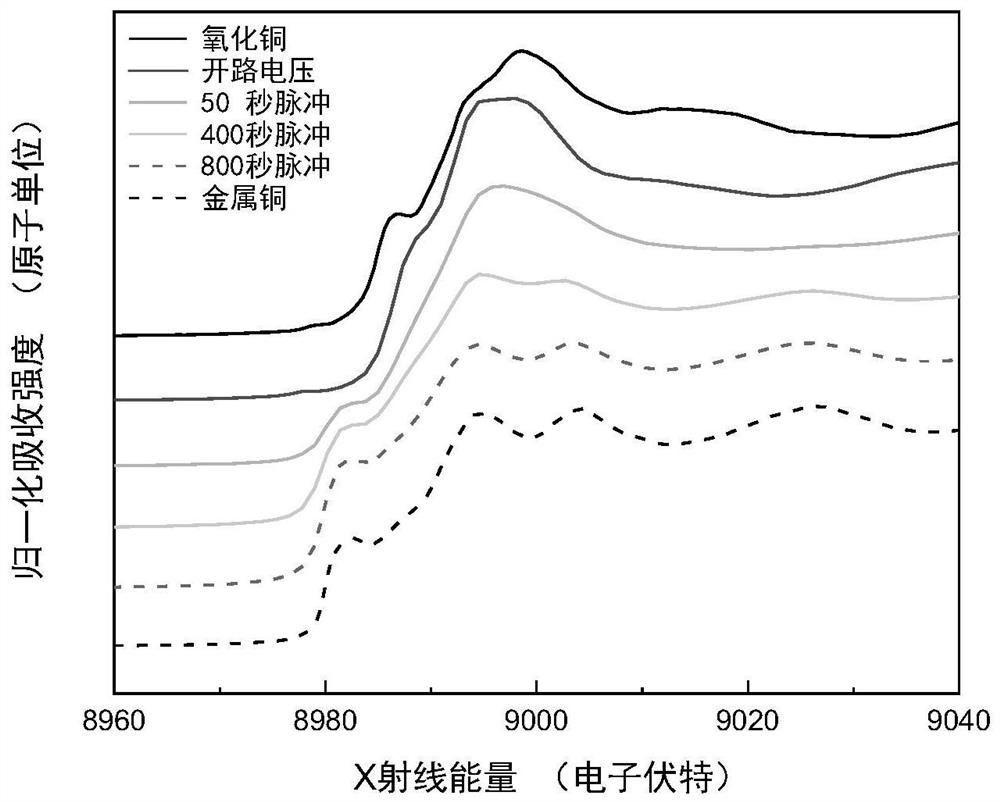

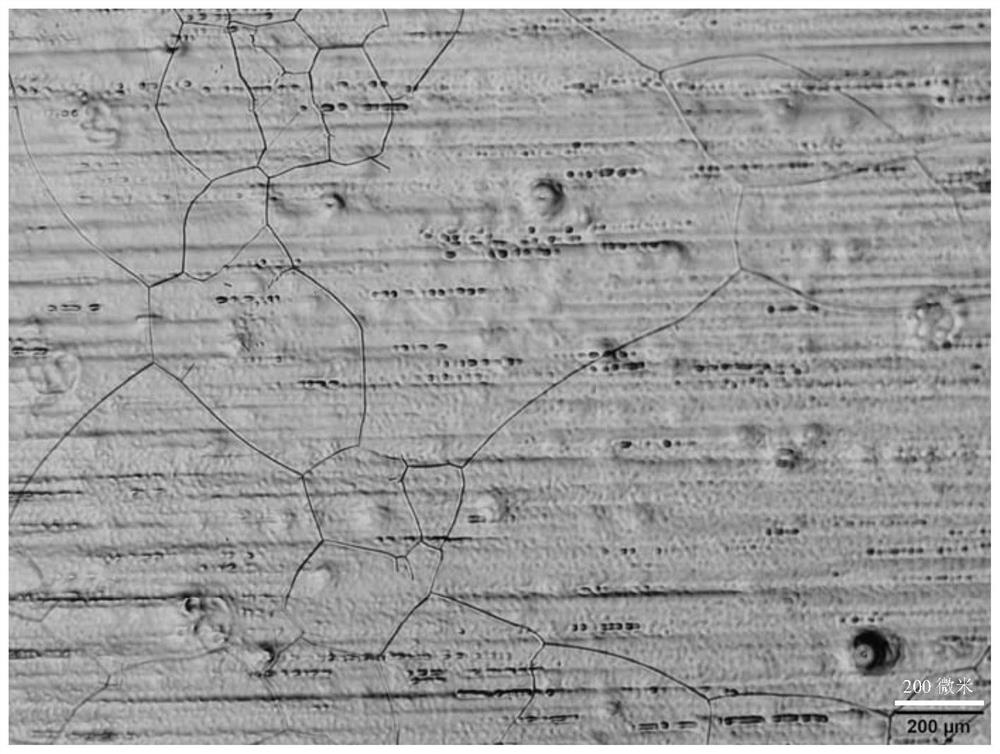

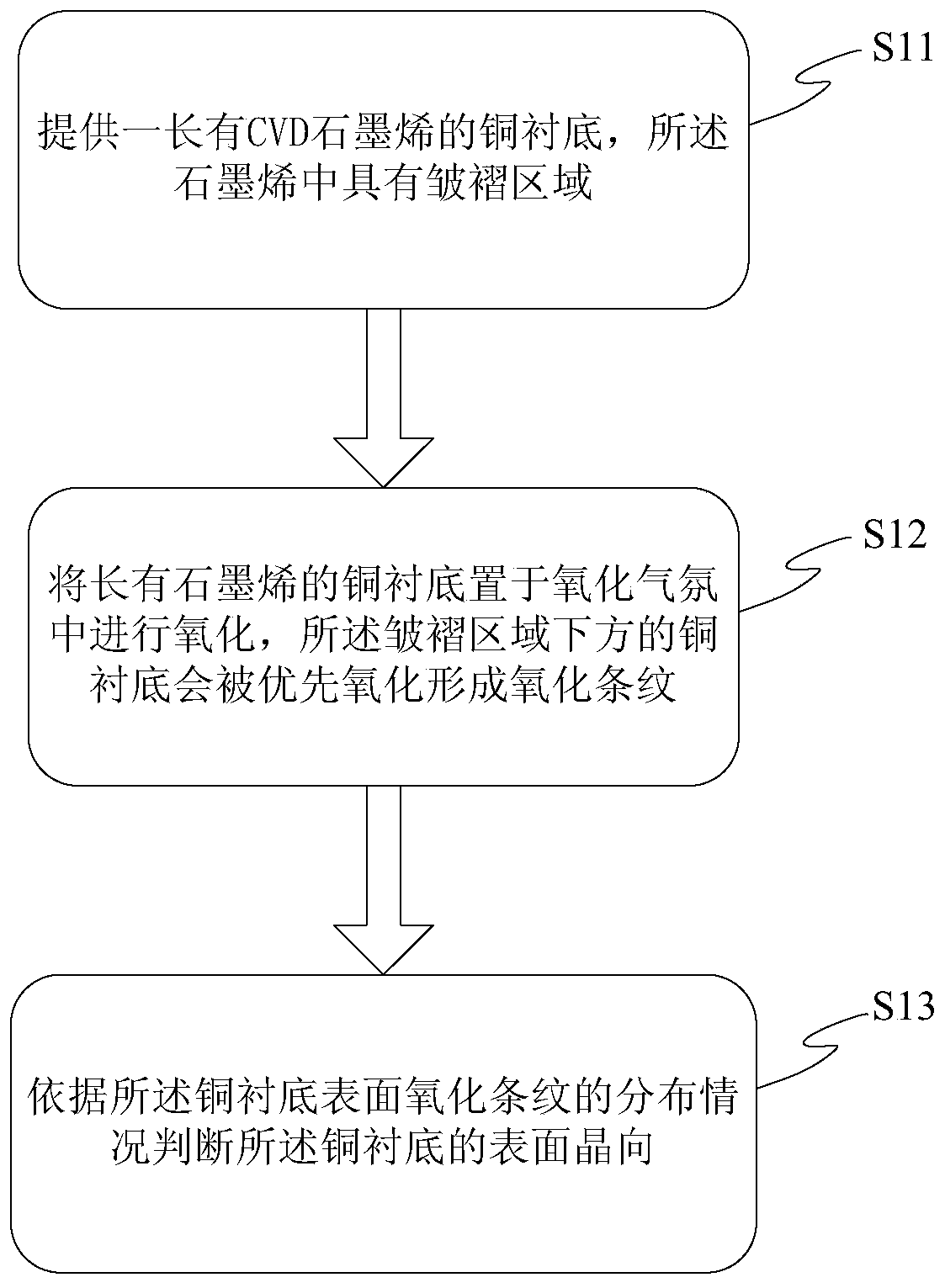

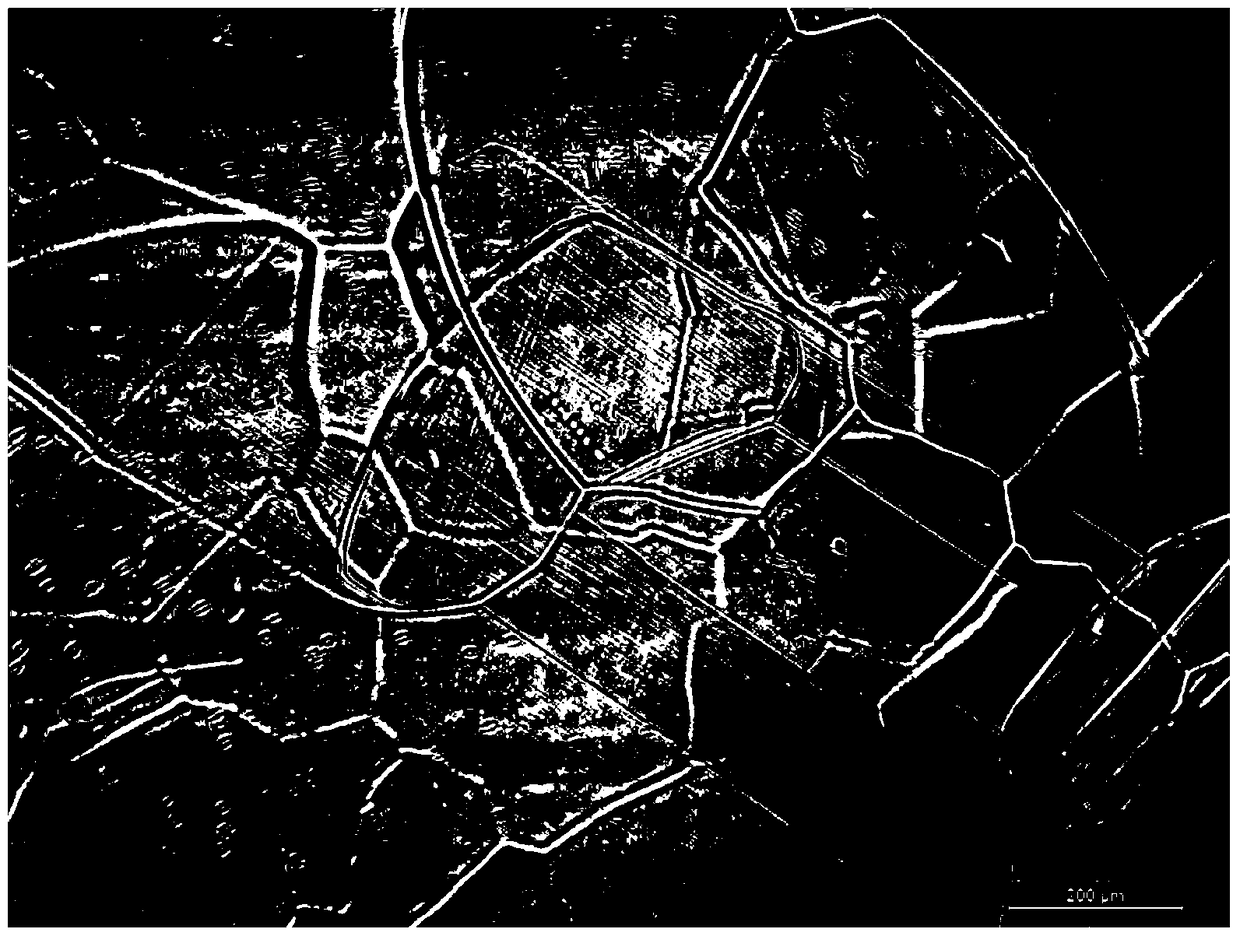

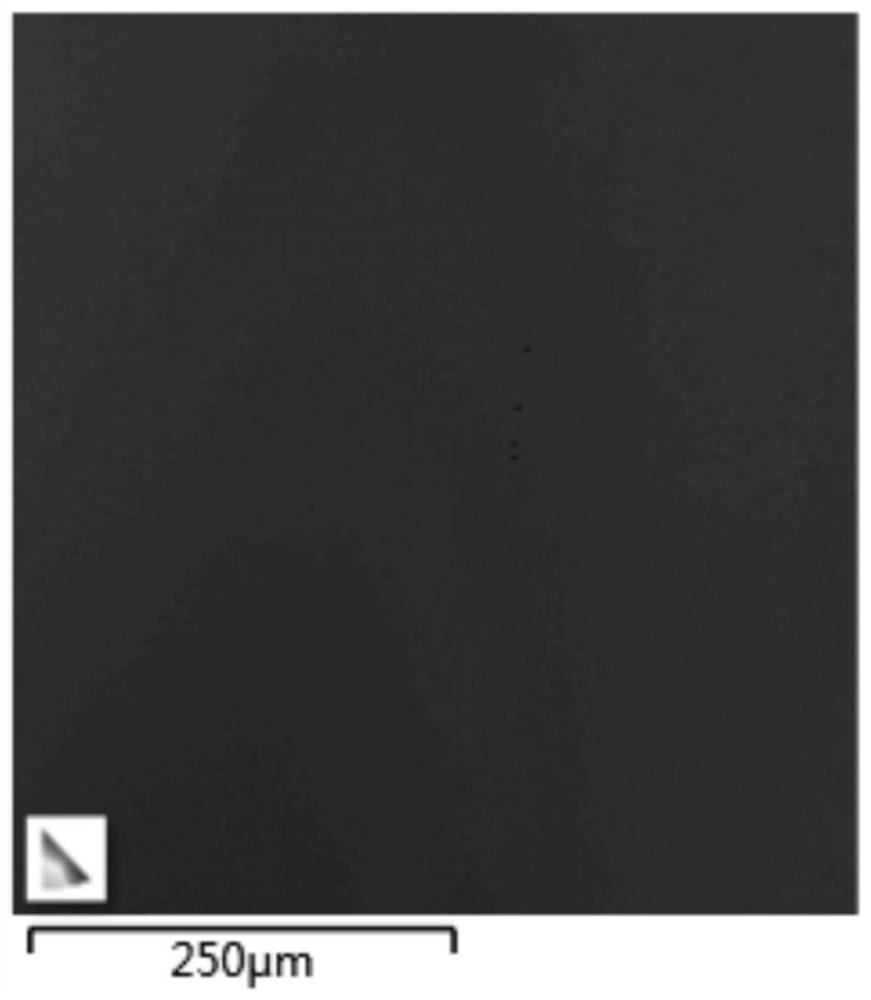

Method for using graphene to determining copper substrate surface crystal orientation

ActiveCN104807810AIt is convenient to understand the distribution of crystal orientation on the surfaceGood repeatabilityAnalysis by subjecting material to chemical reactionWrinkle skinCrystal orientation

The present invention provides a method for using graphene to determining copper substrate surface crystal orientation. The method at least comprises: 1) providing a copper substrate with growing chemical vapor deposition (CVD) graphene, wherein the wrinkle region exists in the graphene; 2) placing the obtained copper substrate in an oxidizing atmosphere to oxidize, wherein the copper substrate positioned below the wrinkle region is preferentially oxidized to form oxidation stripes; and 3) according to the distribution condition of the oxidation stripes on the copper substrate surface, judging the copper substrate surface crystal orientation. According to the present invention, the determination method has characteristics of high repeatability, simpleness, easy performing, and low cost. With the method of the present invention, the surface crystal orientation distribution condition of the polycrystalline copper substrate with the graphene growing through the chemical vapor deposition can be easily known.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

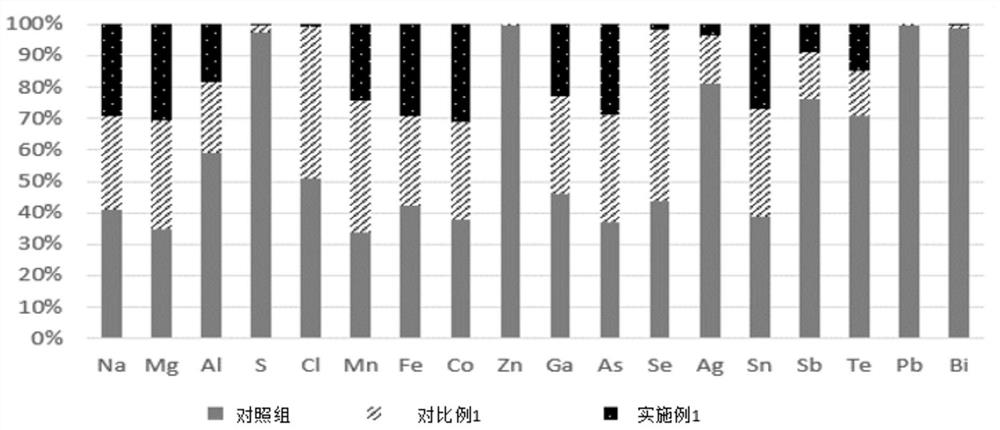

Polycrystalline copper nano material, and preparation method and application thereof

PendingCN113913932ALow CO* protonation barrierHighly Selective Electrocatalytic ReductionMaterial nanotechnologyPolycrystalline material growthPtru catalystFaraday efficiency

The invention provides a polycrystalline copper nano material. Grain boundaries exist on the surface and in the polycrystalline copper nano material. Under the action of a crystal boundary, the polycrystalline copper nano material has a lower CO* protonation energy barrier in the electrocatalytic carbon monoxide reduction process, and a reaction intermediate CHCHO* for generating acetic acid has lower formation energy, so that high-selectivity electrocatalytic reduction from carbon monoxide to acetic acid is realized. Experimental results show that by using the polycrystalline copper nano material provided by the invention as a catalyst, in a traditional gas diffusion electrode flow cell, the Faraday efficiency of acetic acid reaches 52%, and the maximum bias current density of acetic acid reaches 321 mA cm<->. According to a membrane electrode solid electrolyte battery provided by the invention, the performance of the catalyst is stable within continuous 140 hours under the current of 250 mA, the relative purity of the prepared acetic acid solution reaches 98%, and the membrane electrode solid electrolyte battery can be directly applied to commercialization.

Owner:UNIV OF SCI & TECH OF CHINA

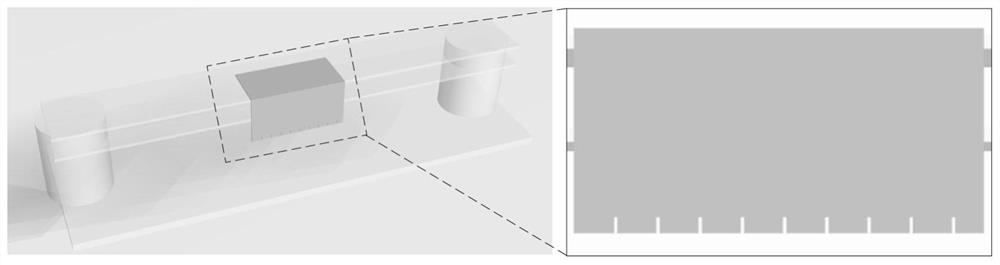

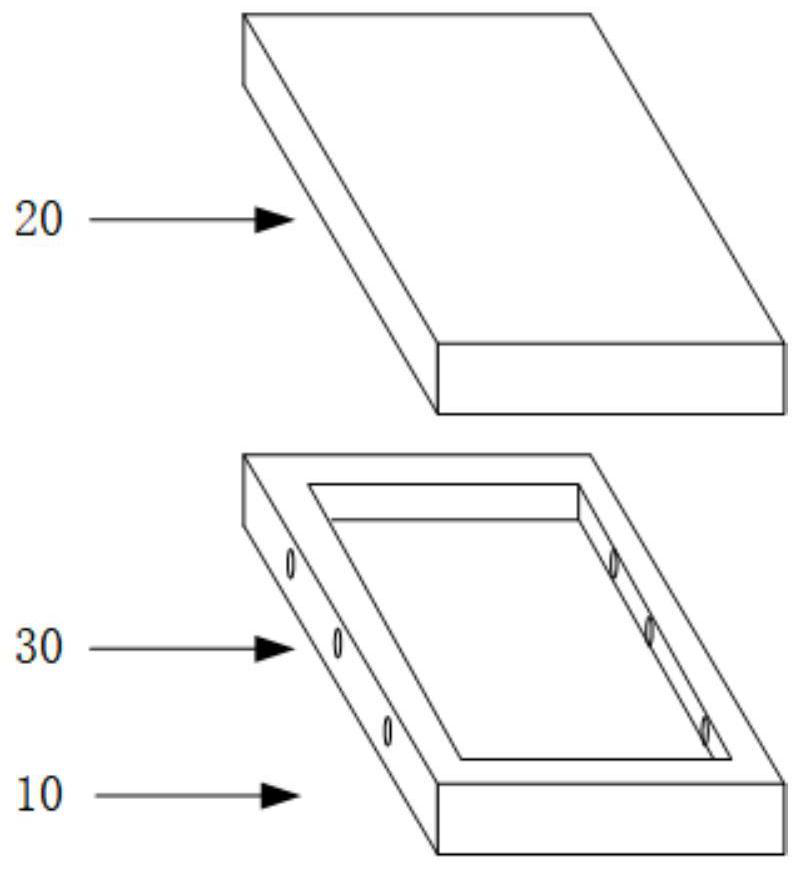

Preparation method of wafer-level single crystal copper foil and preparation method of structured graphene

ActiveCN112522775APrevent oxidationHigh degree of single crystalPolycrystalline material growthFrom solid stateHydrogen atmosphereSingle crystal

The invention discloses a preparation method of a wafer-level single crystal copper foil and a preparation method of structured graphene. The preparation method of the wafer-level single crystal copper foil comprises the steps of carrying out notch treatment on the edge of a polycrystalline copper foil to obtain the polycrystalline copper foil with a notch; and carrying out annealing treatment onthe polycrystalline copper foil with the notch in a hydrogen atmosphere to obtain the single crystal copper foil. The preparation method of the wafer-level single crystal copper foil has the characteristics of simple process, high efficiency, rapidness and energy conservation, and can be used for rapidly preparing single crystal copper with large area, high single crystal degree and high flatness.

Owner:SHENZHEN UNIV

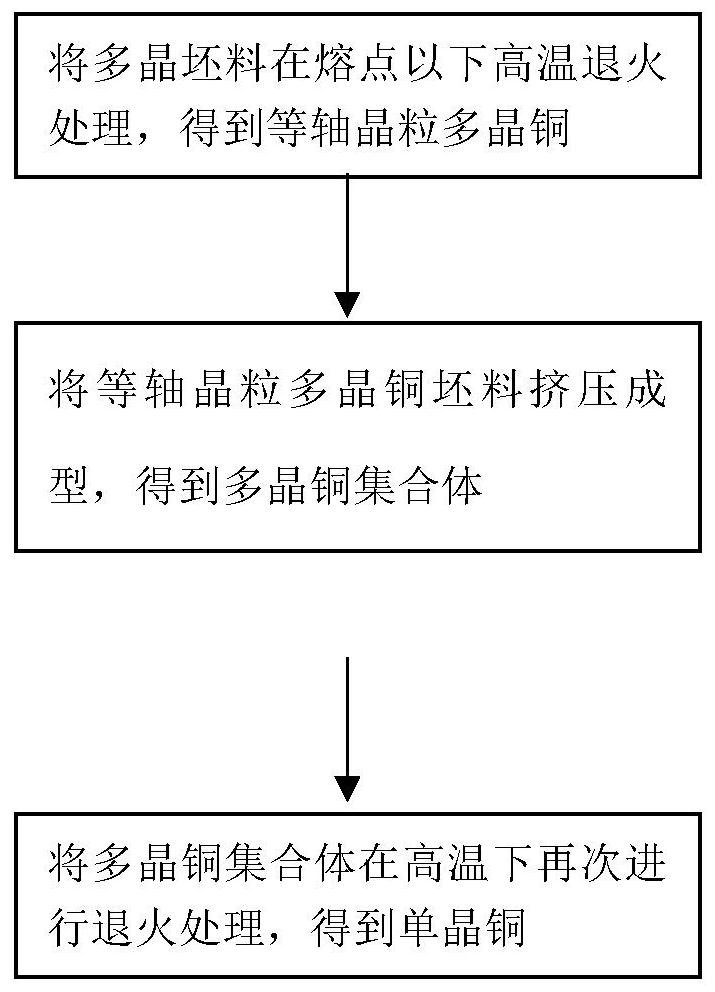

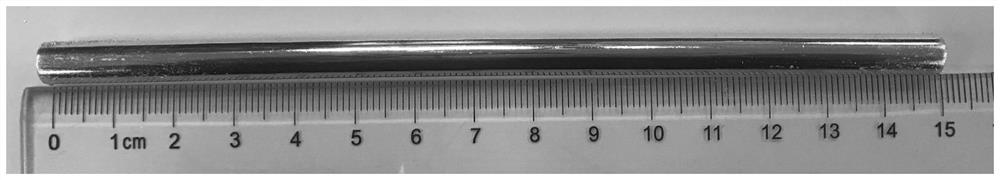

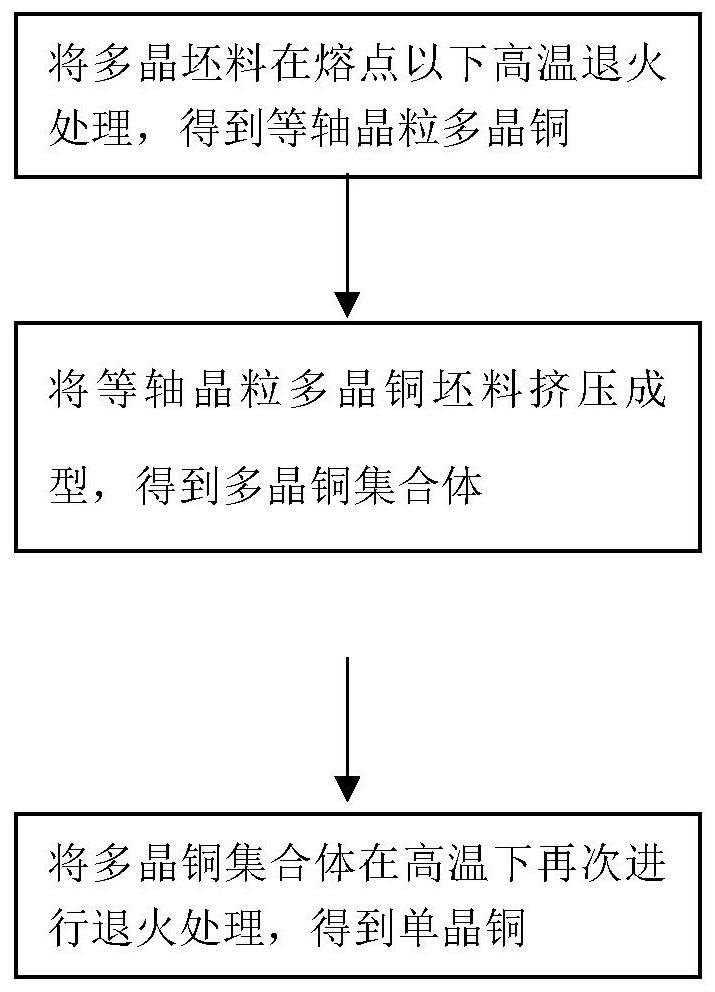

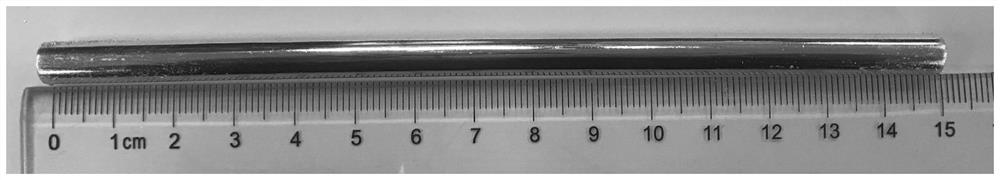

Preparation method of bulk single crystal copper

ActiveCN112553681ASimple processEasy to controlPolycrystalline material growthFrom solid stateSingle crystalPolycrystalline copper

The invention discloses a preparation method of bulk single crystal copper, and the method comprises the following steps of: (1) carrying out high-temperature annealing treatment on a polycrystallinecopper blank below a melting point to obtain equiaxed grain polycrystalline copper; (2) carrying out extrusion molding on the equiaxed grain polycrystalline copper blank annealed in the step (1) to obtain a polycrystalline copper assembly; and (3) carrying out annealing treatment on the polycrystalline copper assembly subjected to extrusion molding in the step (2) again at a high temperature to obtain the bulk single crystal copper. According to the preparation method of the bulk single crystal copper, large-size single crystal copper is prepared through a non-melting method. According to themethod, pre-extrusion treatment is utilized, and then high-temperature annealing is carried out to prepare the bulk single crystal copper bar. The method is simple in process, easy to control, low incost and easy to popularize on a large scale.

Owner:嘉兴固美科技有限公司

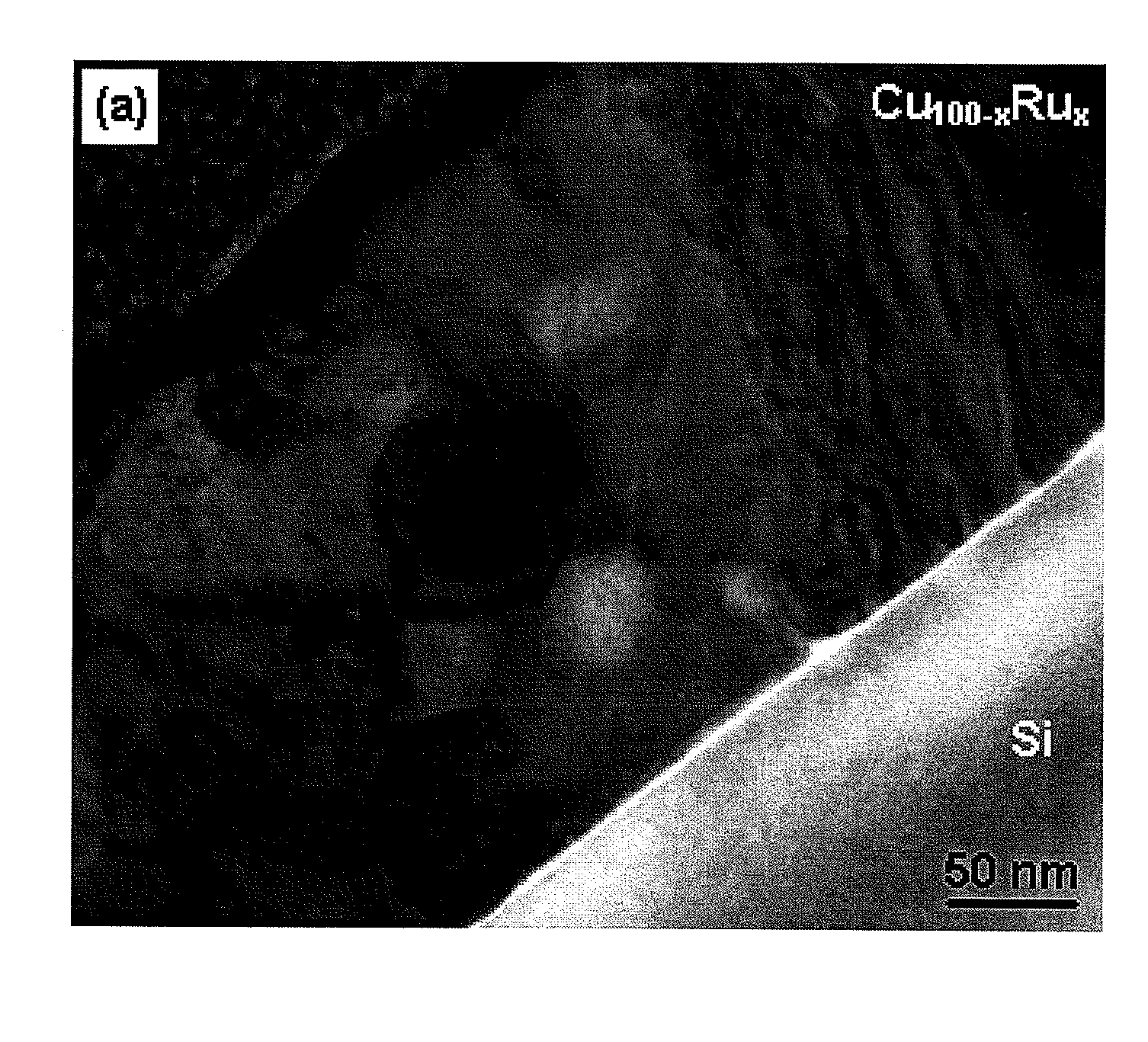

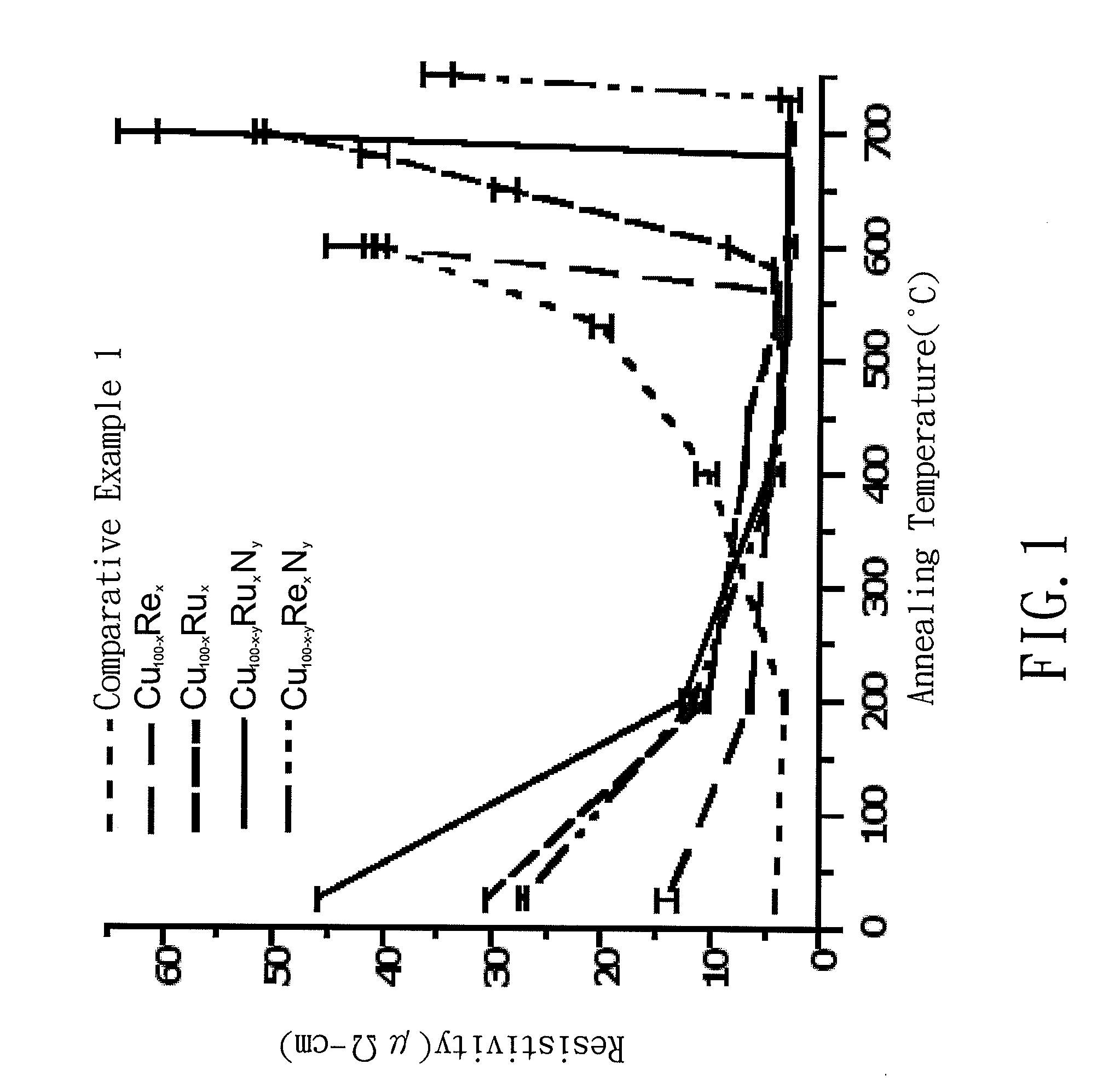

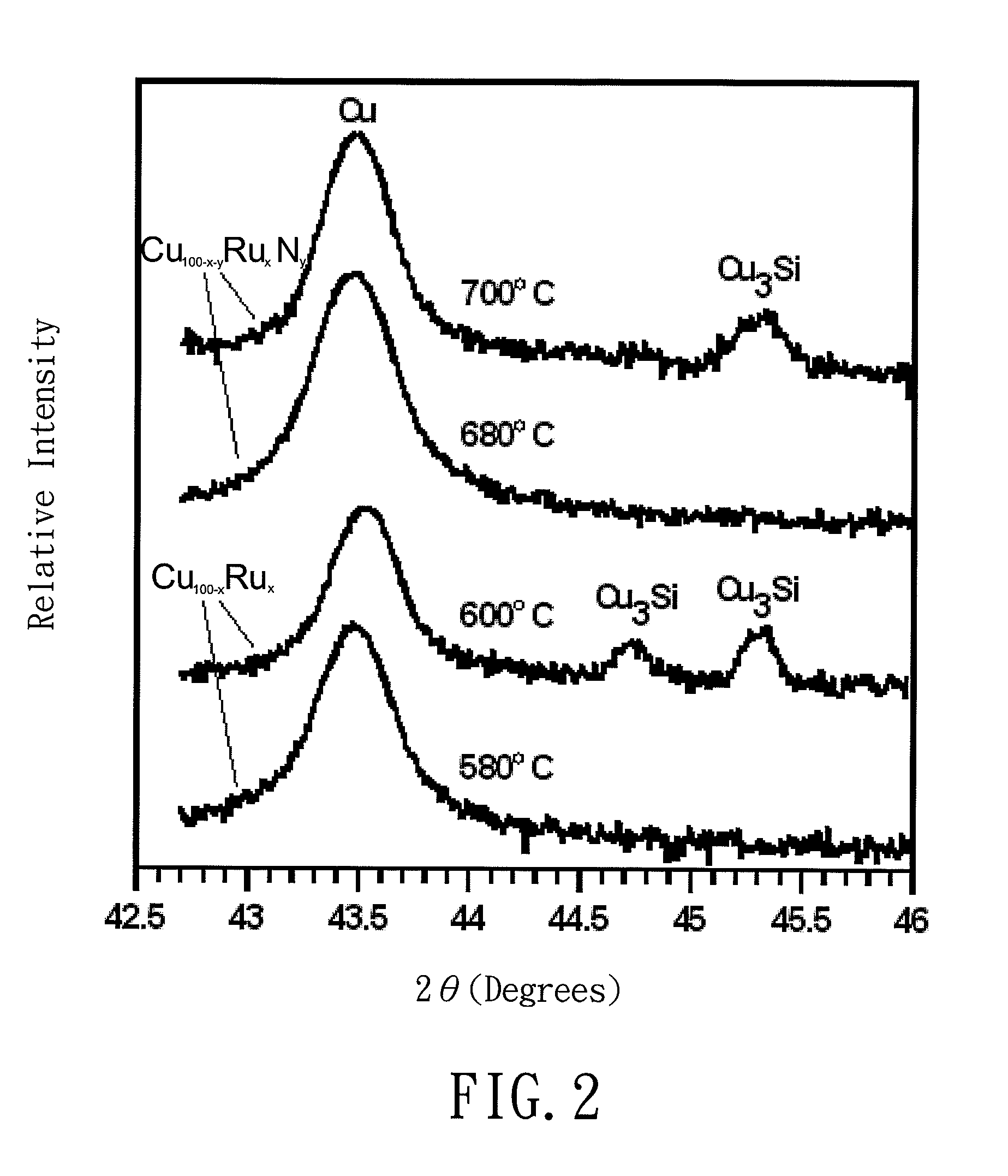

Electrically Conductive Material

An electrically conductive material includes: a supersaturated solid solution of a polycrystalline copper alloy having a composition represented by the formula: Cu100-x-yMxNy; wherein x and y are atomic ratios; wherein 0<x≦2.0 and 0≦y≦2.0; wherein M is selected from Ru, Re, Ho, and combinations thereof; and wherein the supersaturated solid solution includes M precipitates formed at grain boundaries of the polycrystalline copper alloy when y is equal to zero, and includes M precipitates and MN particles formed at the grain boundaries of the polycrystalline copper alloy when y is not zero.

Owner:CHU JINN

A kind of preparation method of bulk single crystal copper

ActiveCN112553681BSimple processEasy to controlPolycrystalline material growthFrom solid statePhysical chemistrySingle crystal

The invention discloses a method for preparing bulk monocrystalline copper, which comprises the following steps: (1) annealing a polycrystalline copper blank at a high temperature below the melting point to obtain polycrystalline copper with equiaxed grains; (2) performing the step ( 1) extruding equiaxed grain polycrystalline copper billets after annealing to obtain polycrystalline copper aggregates; (3) annealing the polycrystalline copper aggregates extruded in step (2) at high temperature again to obtain Bulk single crystal copper. The invention discloses a method for preparing large block single crystal copper, which prepares large size single crystal copper through a non-melting method. The method utilizes pre-extrusion treatment, followed by high-temperature annealing to prepare bulk single-crystal copper rods. The invention has the advantages of simple process, easy control, low cost and easy large-scale popularization.

Owner:嘉兴固美科技有限公司

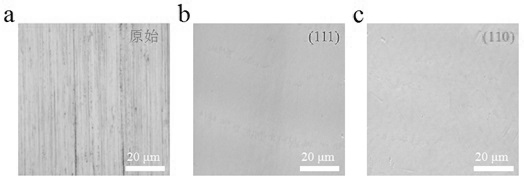

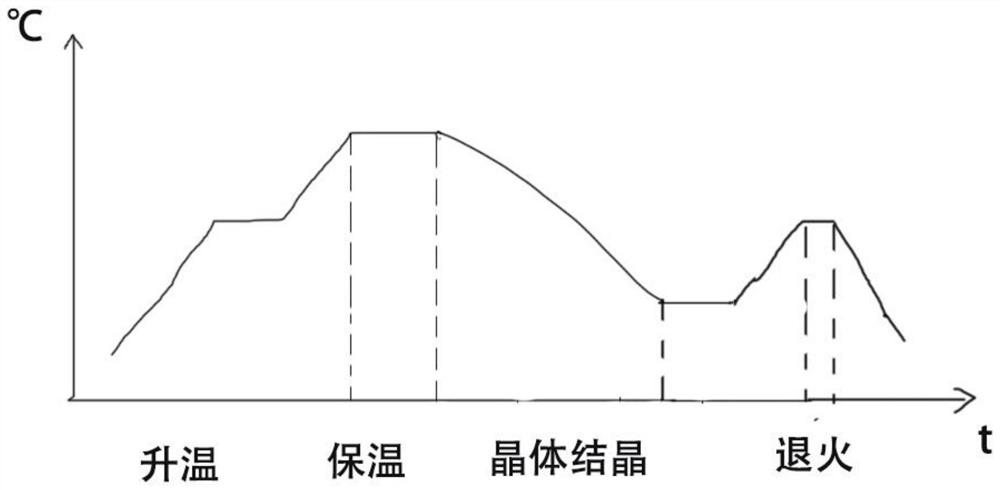

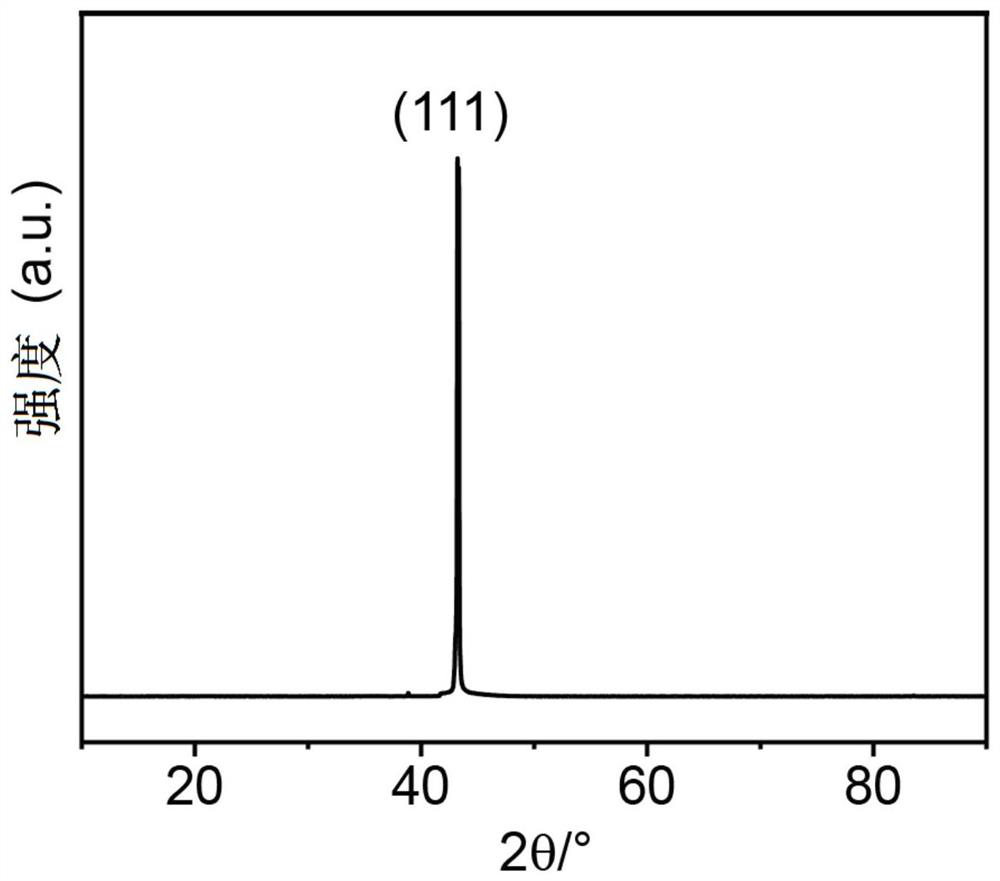

Method for simply and selectively preparing single crystal copper foil

ActiveCN112144116AHigh crystallinityGood surface smoothnessPolycrystalline material growthFrom solid stateMetallurgySingle crystal

The invention belongs to the technical field of single crystal copper foil preparation, and particularly relates to a method for simply and selectively preparing single crystal copper foil. The methodcomprises the following steps: cleaning cheap polycrystalline copper foil by using a mixed solution, putting the copper foil into an annealing furnace, keeping the temperature for a period of time ata temperature close to the melting point of the copper foil to melt the surface of the copper foil, conducting cooling to a certain temperature within a certain period of time, and carrying out annealing treatment. By controlling the cooling rate from the surface melting temperature to the annealing temperature, the (111) or (110) single crystal copper foil can be finally prepared selectively. According to the method, the preparation process of the single crystal copper foil is integrated to a certain extent, resource waste is reduced, and the method has a great industrial application prospect.

Owner:ZHENGZHOU UNIV

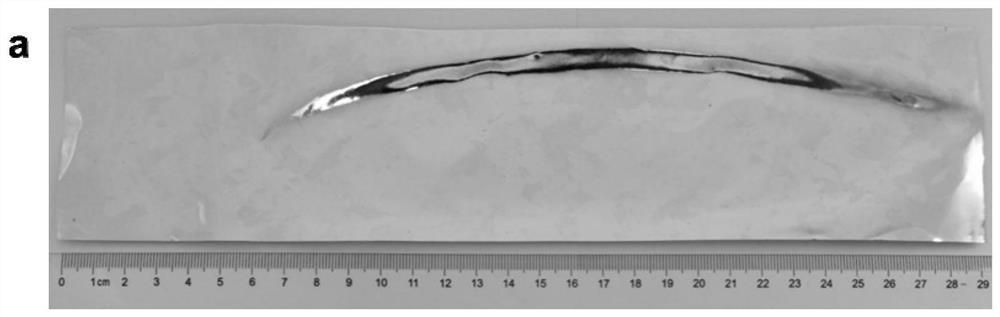

Method for preparing large-area single crystal copper foil

ActiveCN112442729AImprove the lubrication effectReduce interactionPolycrystalline material growthFrom solid stateHexagonal boron nitridePhysical chemistry

The invention provides a method for preparing a large-area single crystal copper foil. The method provided by the invention comprises the following steps: providing a polycrystalline copper foil; providing a carrier made of graphite or hexagonal boron nitride; placing the polycrystalline copper foil on the carrier; and annealing the polycrystalline copper foil on the carrier under a certain temperature gradient to obtain the single crystal copper foil. Due to the fact that the carrier made of the graphite or the hexagonal boron nitride has excellent lubricity, the interaction between copper and the graphite or the hexagonal boron nitride is weak at high temperature, the carrier made of the material can greatly reduce the interaction between the carrier and copper foil above the carrier inthe annealing process, and external stress generated by the carrier on the copper foil is reduced at high temperature, so that not only is a good single crystallization effect ensured, but also the regular and flat appearance of the copper foil can be maintained.

Owner:BEIJING GRAPHENE INST +1

A kind of silver-copper nano-alloy electrocatalyst and its laser vapor deposition method

The invention discloses a silver copper nano alloy electro-catalyst and a laser gas phase deposition method thereof. The silver copper nano alloy electro-catalyst is obtained by depositing on a titanium sheet via a laser gas phase deposition method by taking the titanium sheet as a substrate and taking silver copper alloy as a target. The mole ratio of silver to copper in the silver copper nano alloy electro-catalyst is 4 to 1; the structure morphology of the silver copper nano alloy electro-catalyst is nanocrystalline and non-crystalline, and the nanocrystalline is embedded into the non-crystalline; or the structure morphology of the silver copper nano alloy electro-catalyst consists of nanocrystalline or multi-crystalline, wherein the nanocrystalline is a solid solution of a silver and copper face-centered cubic structure, the non-crystalline is metal copper, and the multi-crystalline is multi-crystalline copper. According to the silver copper nano alloy electro-catalyst and the laser gas phase deposition method, the oxygen reduction reaction catalytic effect is superior, and the preparation cost is low.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

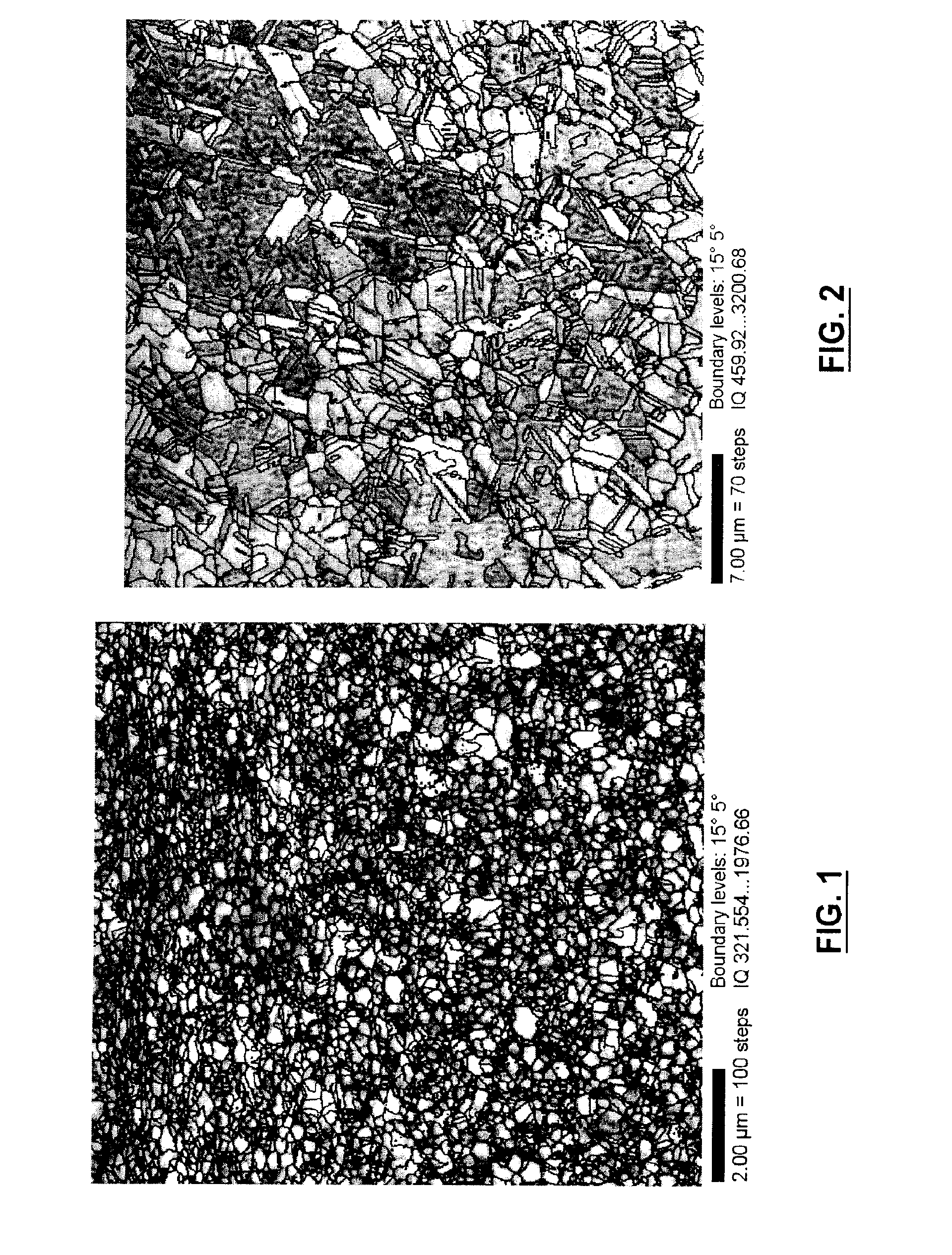

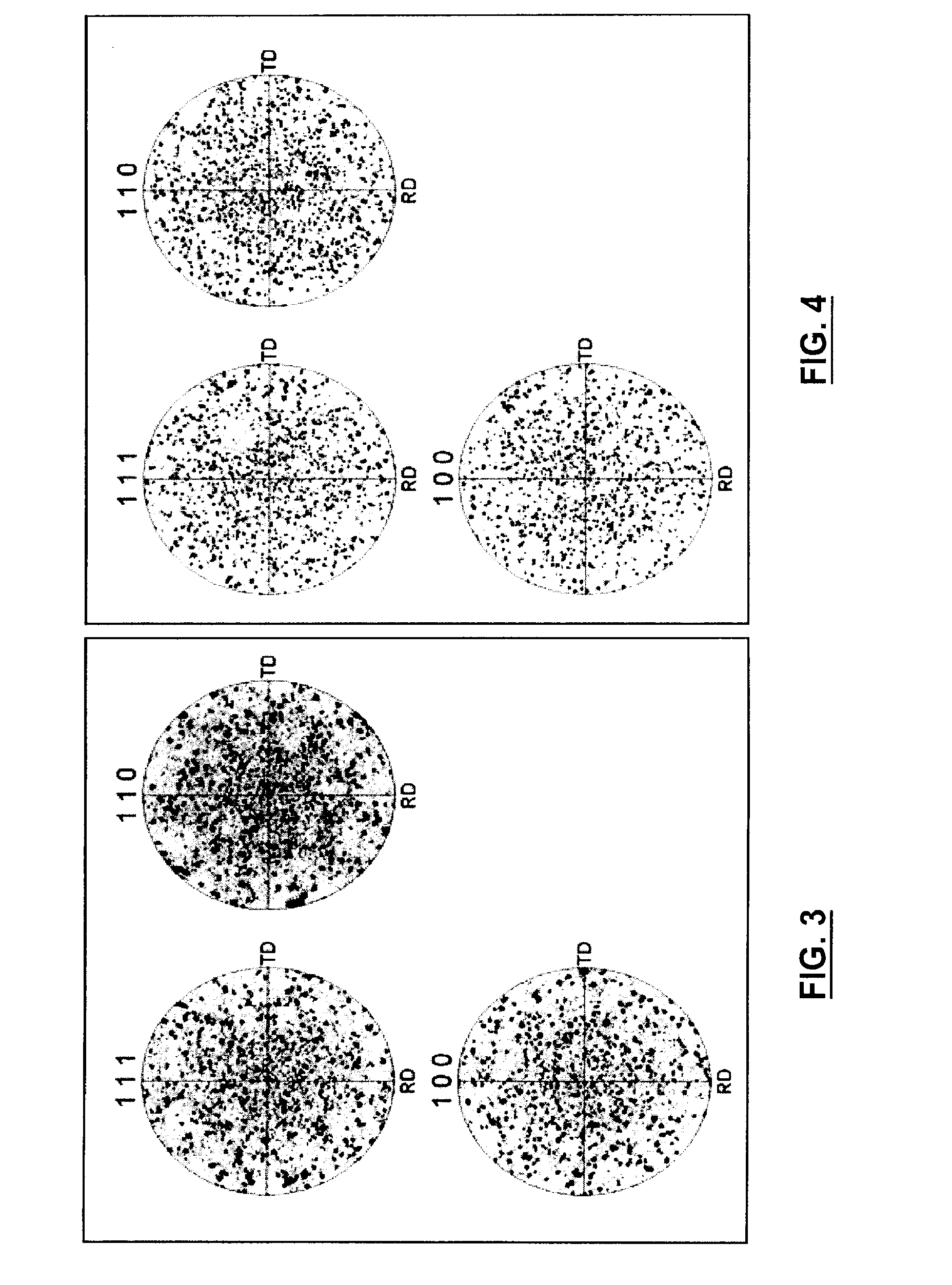

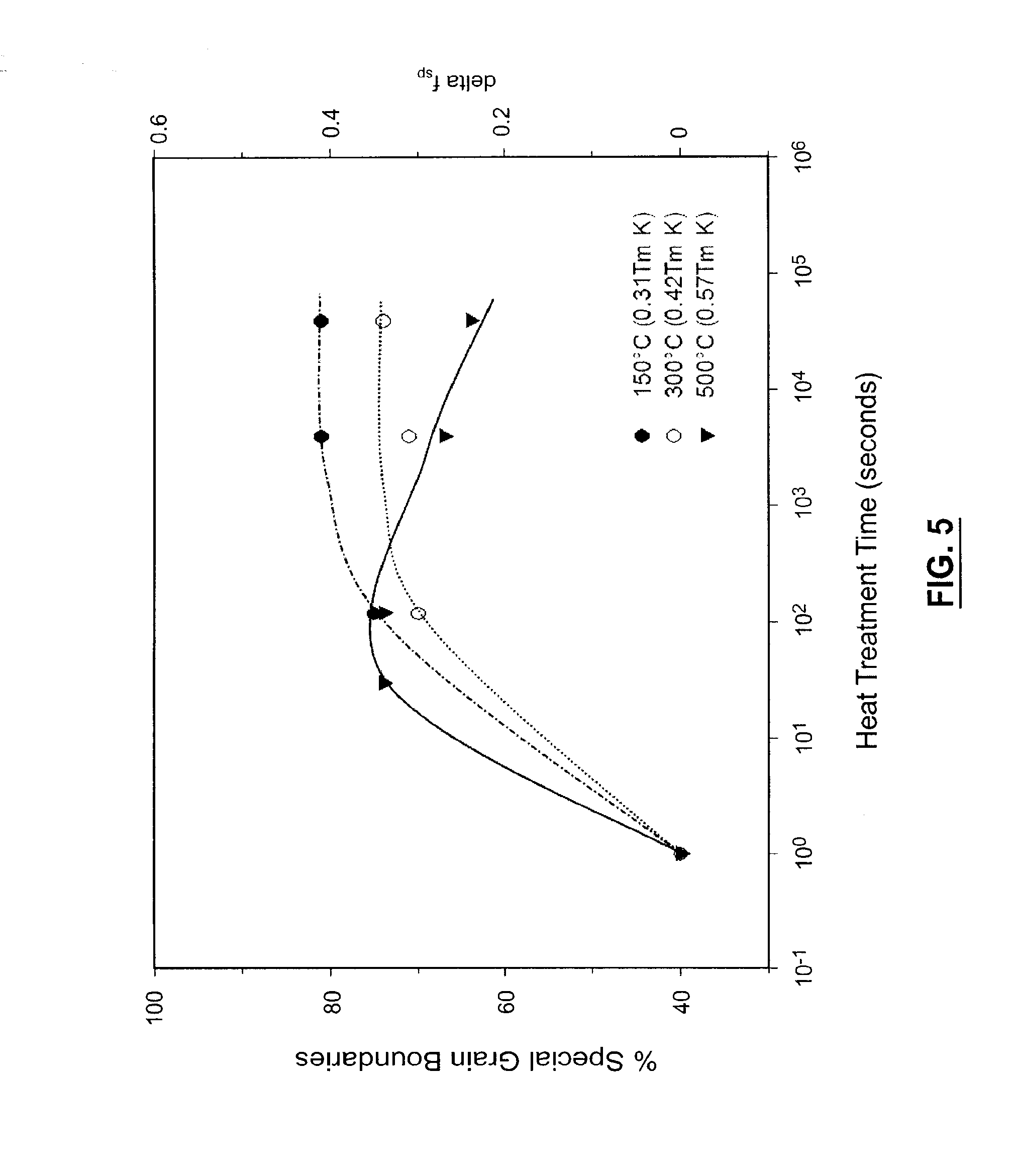

Electrodeposition method for preparing polycrystalline copper having improved mechanical and physical properties

ActiveUS20160208369A1Surface reaction electrolytic coatingVacuum evaporation coatingCrystal structurePolycrystalline material

Owner:INTEGRAN TECH

Preparation method of large-size cu(100) single crystal copper foil

ActiveCN105714382BSpeed up preparationReduce manufacturing costPolycrystalline material growthFrom solid stateSingle crystalCopper foil

The invention provides a preparation method of a large-size Cu(100) single-crystal copper foil. The method comprises the step that a polycrystalline copper foil doped with metallic elements serves as the raw material, and single-crystal Cu(100) with a super-large size is prepared through a special annealing technology. The preparation method of the large-size Cu(100) single-crystal copper foil solves the problem that the single-crystal Cu(100) is high in price, and preparation of the Cu(100) single-crystal copper foil is achieved through the very simple method.

Owner:PEKING UNIV

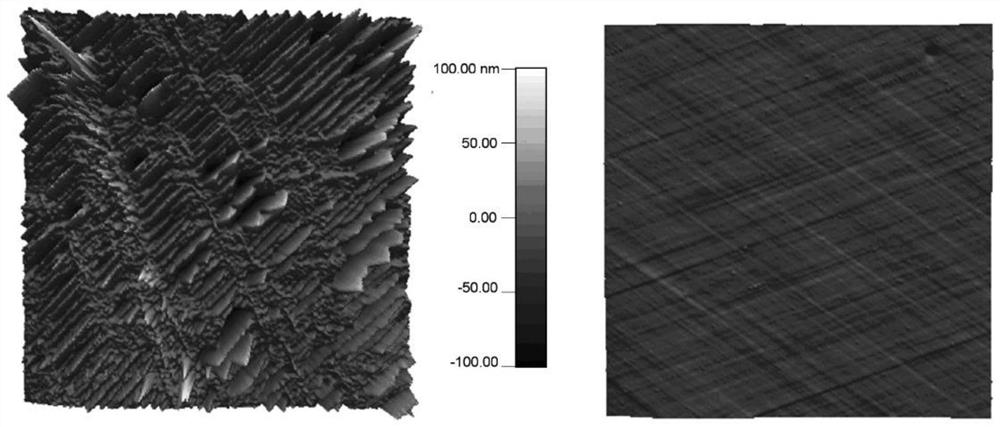

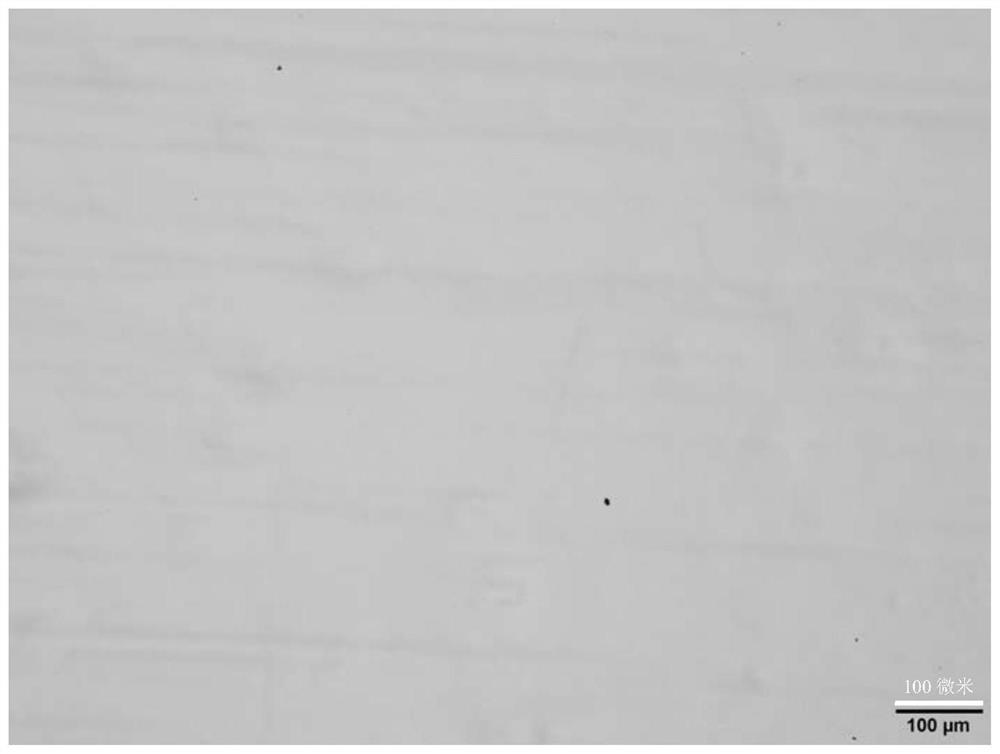

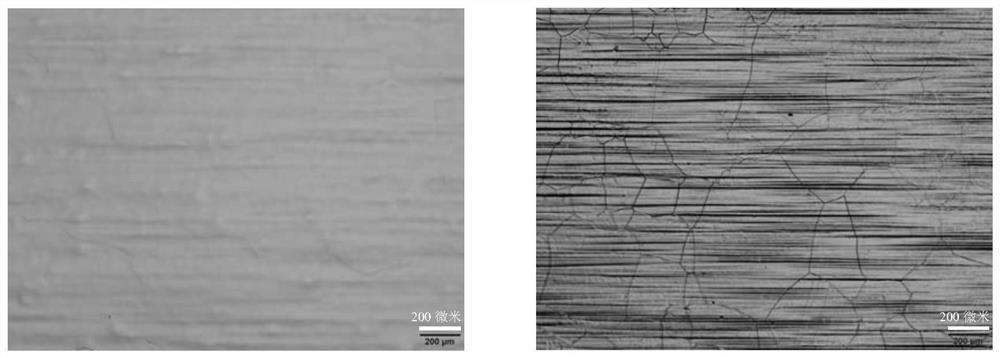

Method for reducing roughness of copper foil and copper foil product thereof

The invention discloses a method for reducing the roughness of a copper foil and a copper foil product thereof. The method comprises the following steps: 1) preparing a polishing solution; 2) treating the copper foil to be polished; 3) performing electrochemical polishing; and 4) performing cleaning, specifically, cleaning the large-grain-size copper foil subjected to electrochemical polishing, and then performing drying treatment to obtain the copper foil product with reduced roughness. The method for reducing the roughness of the copper foil provided by the invention is simple in process and simple and effective to operate; the large-grain-size copper foil formed by annealing a polycrystalline copper foil is polished by an electrochemical polishing technology; and the polishing solution is formed by mixing strong phosphoric acid and ethylene glycol, so that the used raw materials are few in variety, low in cost, small in environmental pollution and good in polishing effect. The copper foil product obtained by polishing by the method for reducing the roughness of the copper foil has the surface roughness of 1-2 nm, which is reduced by more than 10 times compared with that before treatment, has high finish degree and a good mirror effect, and meets the application of the ultra-smooth copper foil market.

Owner:SONGSHAN LAKE MATERIALS LAB

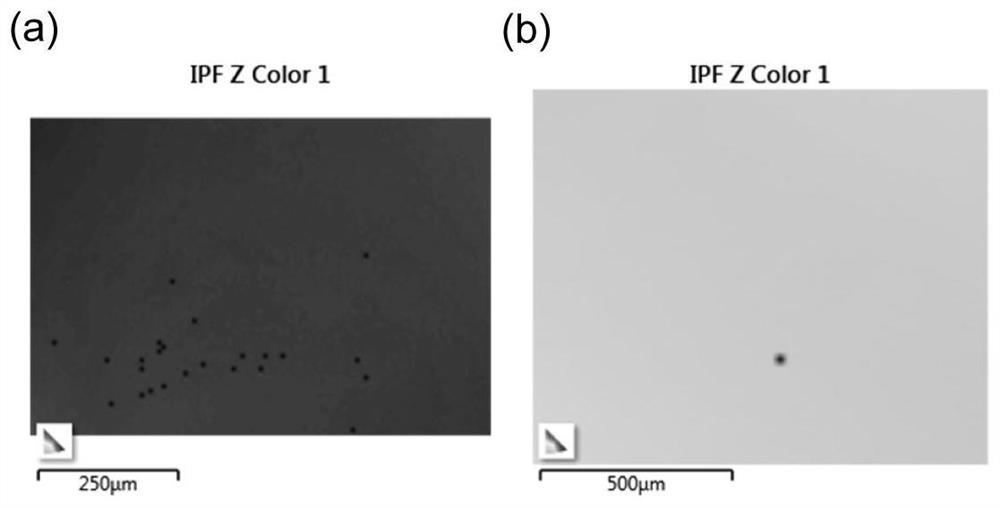

A method for preparing large-area copper Cu(111) single crystals

ActiveCN110273176BLower the barrierIncrease exercisePolycrystalline material growthAfter-treatment detailsPhysical chemistrySingle crystal

The invention discloses a method for preparing a large-area monocrystal Cu (111). The method comprises is characterized in that a polycrystalline copper foil is treated several times to obtain the monocrystal Cu (111); every treatment successively comprises polishing and annealing; and the treatment frequency is not less than 3, and specifically is 3 or 4. The crystal faces of the copper foil obtained by the method are all (111) faces, and the area of the monocrystal Cu (111) is limited only by the size of a preparation container, so the method realizes large-area preparation of the monocrystal Cu, and has great application values.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

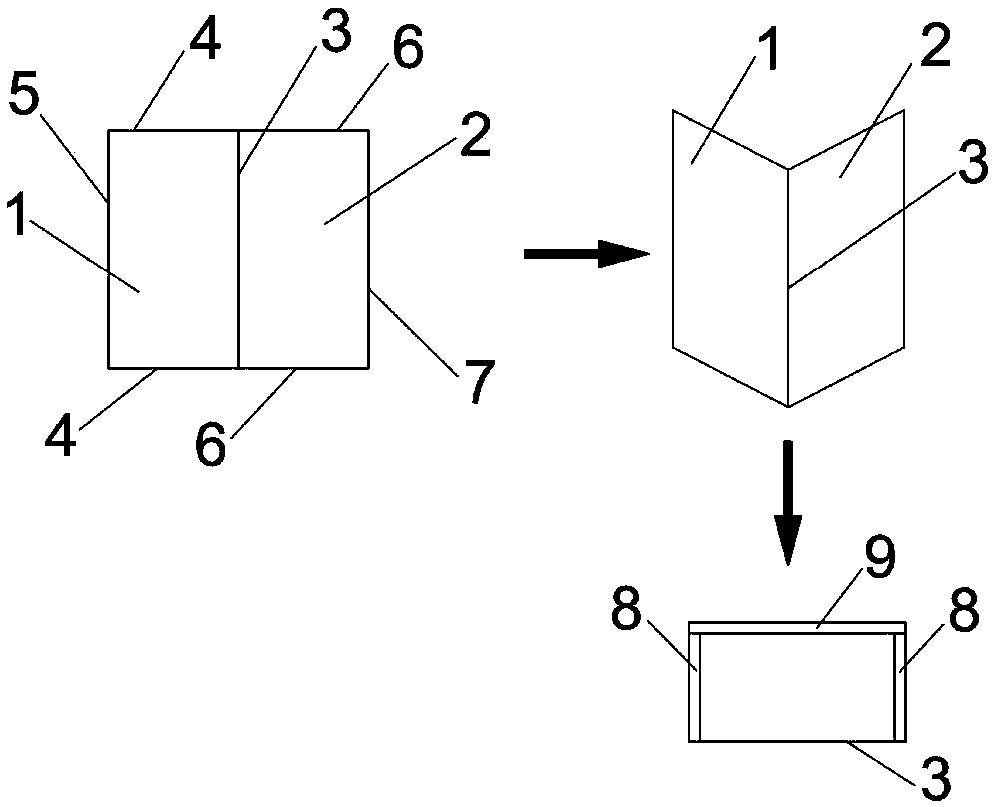

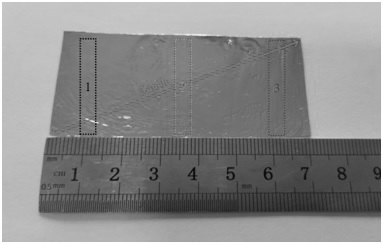

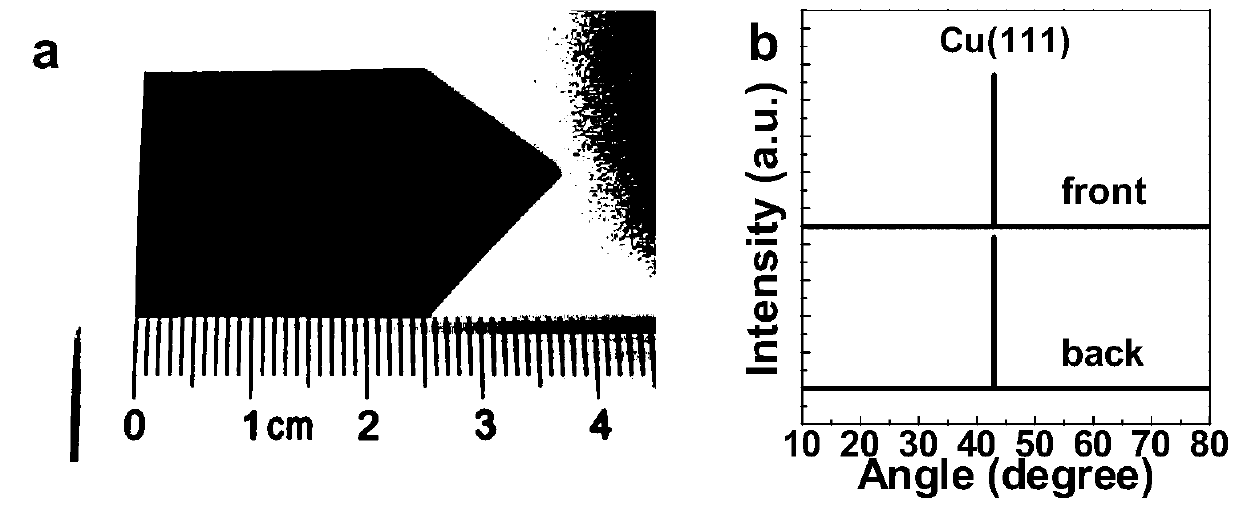

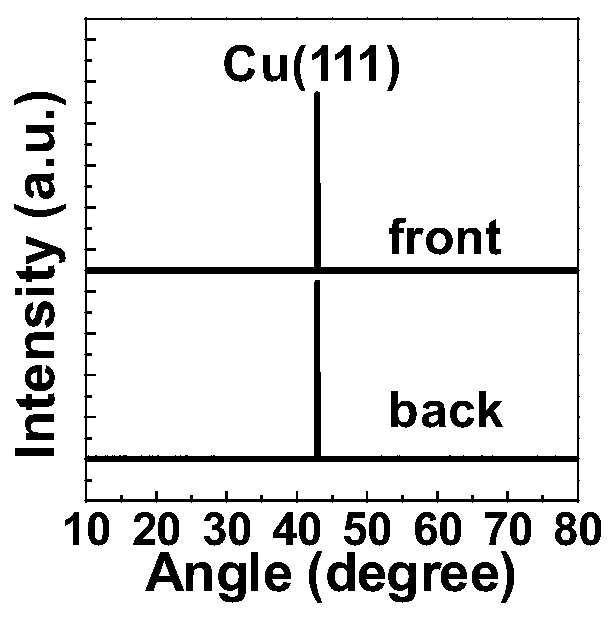

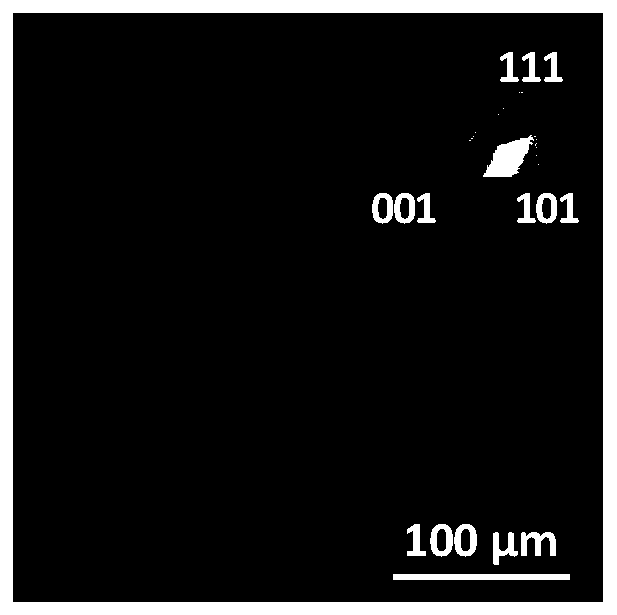

A kind of preparation method of large size single crystal copper foil

ActiveCN107904654BAchieve preparationReduce manufacturing costPolycrystalline material growthFrom solid stateMetallurgySingle crystal

The invention provides a large-size single crystal copper foil preparation method, wherein a polycrystalline copper foil is used as a raw material, one end is cut into a tip, and the large-size singlecrystal copper foil is prepared by using a special annealing process. According to the present invention, with the method, the problem of the high price of the single crystal copper foil is solved; and the preparation of the large-size single crystal copper foil is achieved through the simple method.

Owner:PEKING UNIV

Single crystal copper growth process

InactiveCN113802176AHigh purityLow costPolycrystalline material growthAfter-treatment detailsCrucibleSingle crystal

The invention belongs to the technical field of single crystal copper production, and particularly relates to a single crystal copper growth process which comprises the steps of heating, specifically, taking 4-6 parts of polycrystalline copper, pressing 4-6 parts of polycrystalline copper through a pressing tool, placing the pressed polycrystalline copper in a crucible, putting the crucible filled with the polycrystalline copper into a high-temperature descending furnace, continuously heating the high-temperature descending furnace until the temperature of the high-temperature descending furnace is increased to 1150-1350 DEG C, and then vacuumizing the interior of the high-temperature descending furnace until the pressure of the interior of the high-temperature descending furnace is 0.001-0.002 Pa; and conducting heat preservation, specifically, and when the temperature reaches the range of 1150-1350 DEG C, injecting inert protective gas into the high-temperature descending furnace. According to the specific production method of the single crystal copper, in the heat preservation process, protection is conducted through the inert protective gas, a temperature field is simulated through a computer, descending is controlled through a parameter program, sequential crystallization is conducted through a Bridgman-Stockbarger method, not only is the production cost reduced, but also the difficulty is reduced, and the preparation purity of the single crystal is increased.

Owner:HUAIAN HONGXIANG PHOTOELECTRIC TECH

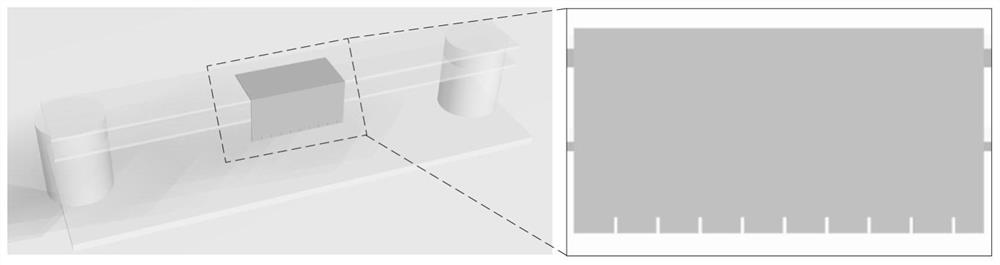

Preparation method of single crystal copper

ActiveCN112899768AImprove surface cleanlinessImprove production efficiencyPolycrystalline material growthFrom solid stateSlagPhysical chemistry

The invention belongs to the technical field of materials, and particularly relates to a preparation method of single crystal copper. According to the preparation method of the single crystal copper, polycrystalline copper is placed in a graphite container to be subjected to annealing treatment, various impurities such as quartz slag and dust particles in the annealing treatment process are isolated outside the graphite container through the confinement space effect of the graphite container, and therefore impurity pollution caused by the impurities to the obtained single crystal copper is avoided; the surface cleanliness and the preparation efficiency of the obtained single crystal copper are greatly improved, the large-size single crystal copper can be obtained, and the obtained single crystal copper has more excellent performance. The preparation method provided by the invention is simple to operate, does not need to carry out complex and diverse surface pretreatment on the polycrystalline copper, and is favorable for realizing industrial preparation of the single crystal copper.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

A preparation method of wafer-level single crystal copper foil and a preparation method of structured graphene

ActiveCN112522775BPrevent oxidationHigh degree of single crystalPolycrystalline material growthFrom solid stateSingle crystalCopper foil

The invention discloses a method for preparing wafer-level single crystal copper foil and a method for preparing regular graphene. The preparation method of the wafer-level single crystal copper foil includes: performing notching treatment on the edge of the polycrystalline copper foil to obtain a polycrystalline copper foil with a notch; performing the polycrystalline copper foil with a notch under a hydrogen atmosphere Annealing treatment to obtain the single crystal copper foil. The preparation method of the wafer-level single crystal copper foil of the present invention has the characteristics of simple process, high efficiency, fast energy saving, and can rapidly prepare single crystal copper with large area, high single crystal degree and high flatness.

Owner:SHENZHEN UNIV

A method of using graphene to determine the crystal orientation of copper substrate surface

ActiveCN104807810BIt is convenient to understand the distribution of crystal orientation on the surfaceGood repeatabilityAnalysis by subjecting material to chemical reactionWrinkle skinCrystal orientation

The present invention provides a method for using graphene to determining copper substrate surface crystal orientation. The method at least comprises: 1) providing a copper substrate with growing chemical vapor deposition (CVD) graphene, wherein the wrinkle region exists in the graphene; 2) placing the obtained copper substrate in an oxidizing atmosphere to oxidize, wherein the copper substrate positioned below the wrinkle region is preferentially oxidized to form oxidation stripes; and 3) according to the distribution condition of the oxidation stripes on the copper substrate surface, judging the copper substrate surface crystal orientation. According to the present invention, the determination method has characteristics of high repeatability, simpleness, easy performing, and low cost. With the method of the present invention, the surface crystal orientation distribution condition of the polycrystalline copper substrate with the graphene growing through the chemical vapor deposition can be easily known.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

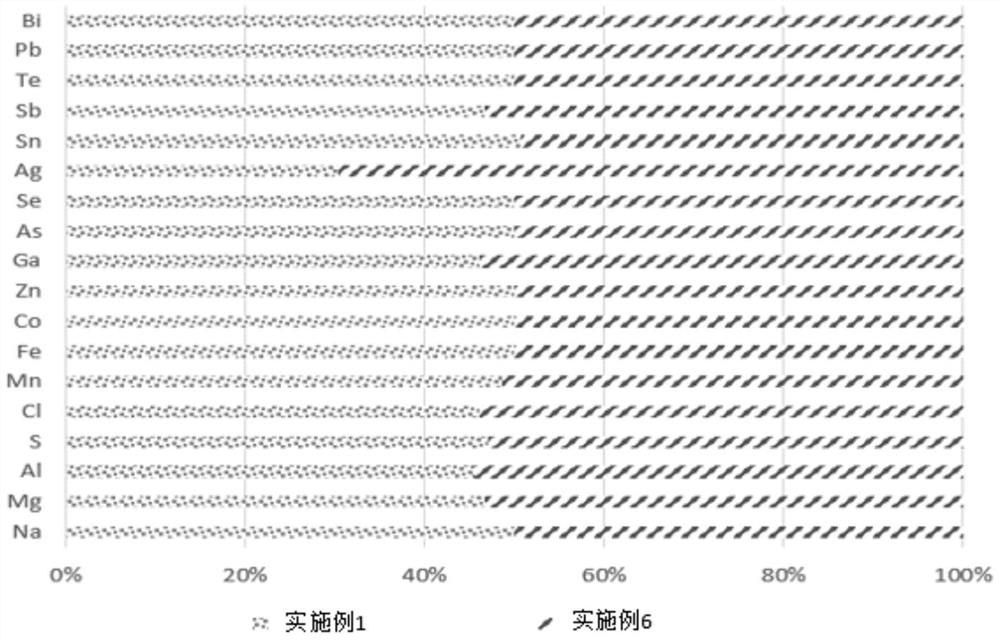

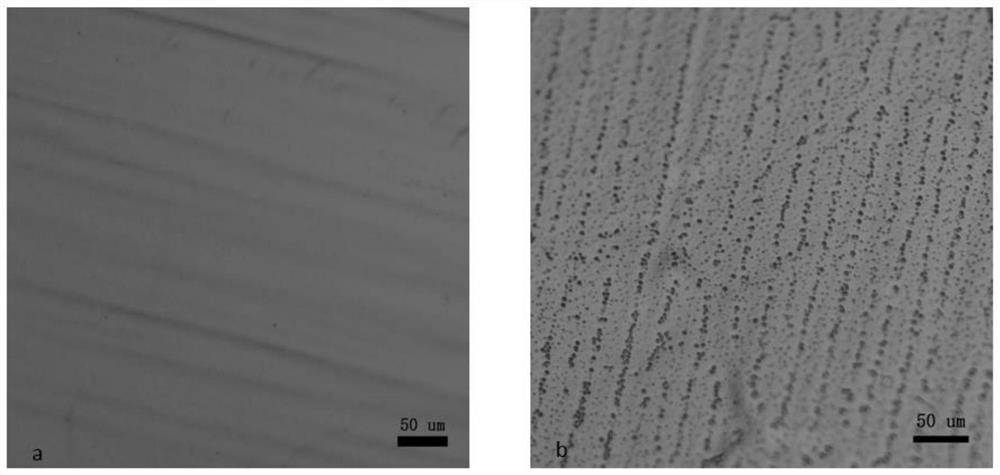

Method for purifying copper foil

The invention discloses a copper foil purification method and belongs to the field of material purification. The purification method of the copper foil comprises the steps that an assembly is placed in a central temperature zone of a tubular furnace, annealing is conducted for at least 5 h under the mixed atmosphere of inert gas and hydrogen under the condition that the temperature of the central temperature zone is kept at 1050-1070 DEG C, purified single crystal copper foil is obtained, and the assembly is composed of polycrystalline copper foil containing impurities and a carrier supporting the polycrystalline copper foil. The polycrystalline copper foil is a rolled copper foil, the flow of the inert gas is 500-600 sccm, and the flow of the hydrogen is 30-100 sccm. According to the purification method, the industrial polycrystalline copper foil can be directly purified, the problems that an existing purification method is large in energy consumption and high in preparation difficulty are solved, meanwhile, the industrial polycrystalline copper foil can be subjected to single crystallization, and the product performance is improved.

Owner:SONGSHAN LAKE MATERIALS LAB +1

A preparation method of meter-scale large single crystal high-index surface copper foil

ActiveCN111690983BSpeed up preparationReduce manufacturing costPolycrystalline material growthFrom solid stateMetallurgyPhysical chemistry

The invention provides a preparation method of meter-scale large single crystal high-index copper foil. The method uses commercial polycrystalline copper foil as a raw material, and prepares Cu(112) and Cu(113) by using a process of pre-oxidation protection and then annealing. , Cu(122), Cu(123), Cu(133), Cu(223), Cu(233), Cu(355) and other high-index surfaces and a series of meter-scale large single crystal high-index surface copper foils. The method proposed by the present invention solves the problems of Cu(112), Cu(113), Cu(122), Cu(123), Cu(133), Cu(223), Cu(233), Cu(355) and other high Due to the high price and preparation cost of index-faced single crystal copper foil and the lack of product supply in the market, through a very simple method, high-quality meter-level large single crystal Cu(112), Cu(113), Cu(122), Macro-production of Cu(123), Cu(133), Cu(223), Cu(233), Cu(355) and other high-index copper foils.

Owner:PEKING UNIV

A kind of preparation method of single crystal copper foil

ActiveCN110438556BEasy to getHigh degree of single crystalPolycrystalline material growthFrom solid stateMetallurgyPhysical chemistry

The invention provides a preparation method of single crystal copper foil. The preparation method comprises the steps that polycrystalline copper foil is placed in an area with multiple temperature zones for annealing, and the single crystal copper foil is prepared; and in the area with the multiple temperature zones, the temperature difference between the adjacent temperature zones is 5-200 DEG C. According to the preparation method, the process is simple, and a cooper single crystal with large area, high single crystal degree and high flatness can be conveniently obtained.

Owner:BEIJING GRAPHENE INST +1

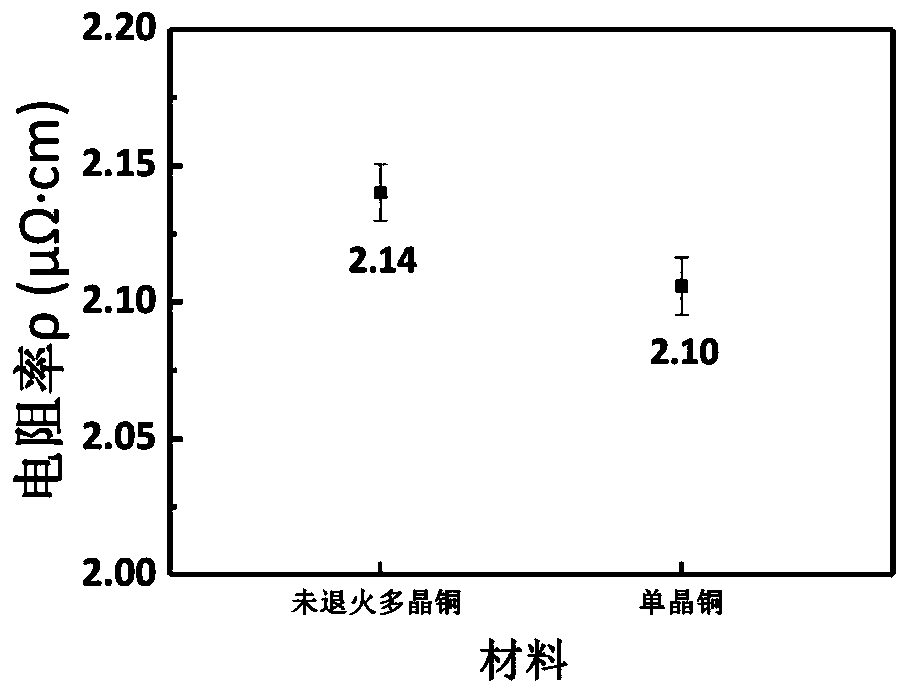

Method for reducing circuit losses based on single crystal copper

InactiveCN109949964AImprove conductivityReduce lossPolycrystalline material growthMetal/alloy conductorsSingle crystalTransmission loss

The invention provides a method for reducing circuit losses based on single crystal copper. The single crystal copper is formed by the growth of one grain and thus has no grain boundary and less lattice imperfection. Compared to polycrystalline copper, the single crystal copper has better electrical conductivity and transmission characteristics, and thus has an excellent effect of reducing energyloss. The method for reducing circuit loss based on single crystal copper, includes, but not limited to, using the single crystal copper as a material for manufacturing high-frequency cables, wires and integrated circuits, so as to reduce energy loss and high-frequency signal transmission loss of the circuit.

Owner:PEKING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com