Preparation method of millimeter-scale monolayer monocrystalline graphene based on polycrystalline copper foil

A single crystal graphene, millimeter-scale technology, applied in the field of thin film graphene material preparation, can solve the problems of dirty copper foil surface, difficulty in controlling the cleaning degree and cleaning time of copper foil, and affecting the preparation of graphene, etc., to achieve uniform and The effect of uniform growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

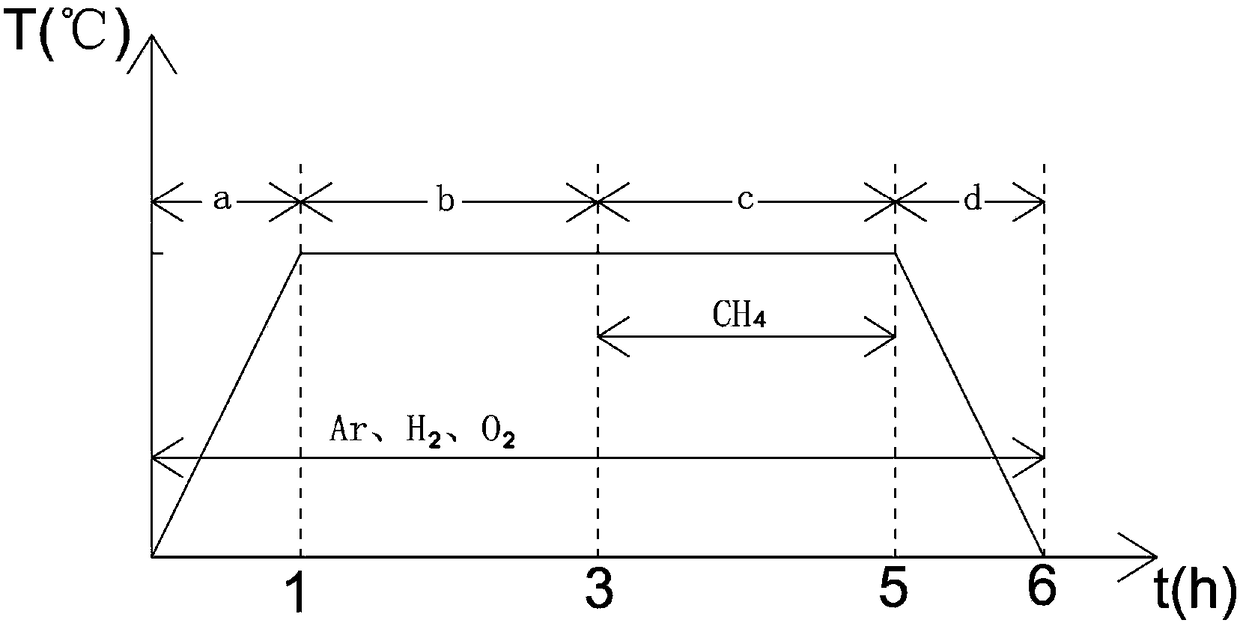

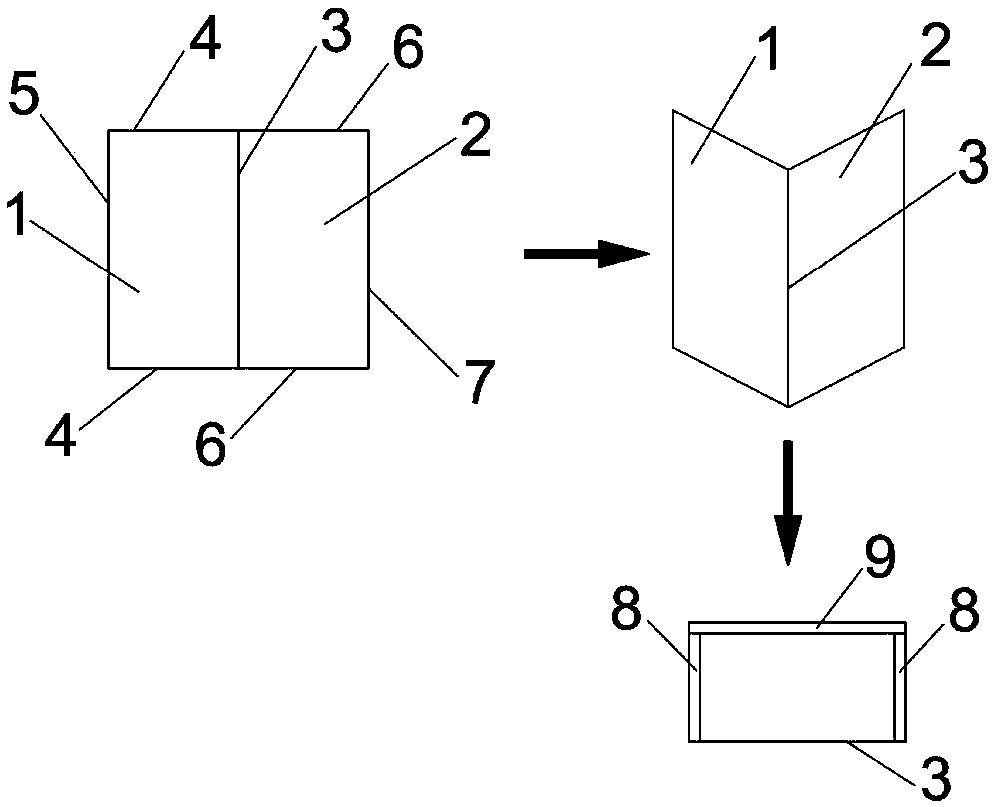

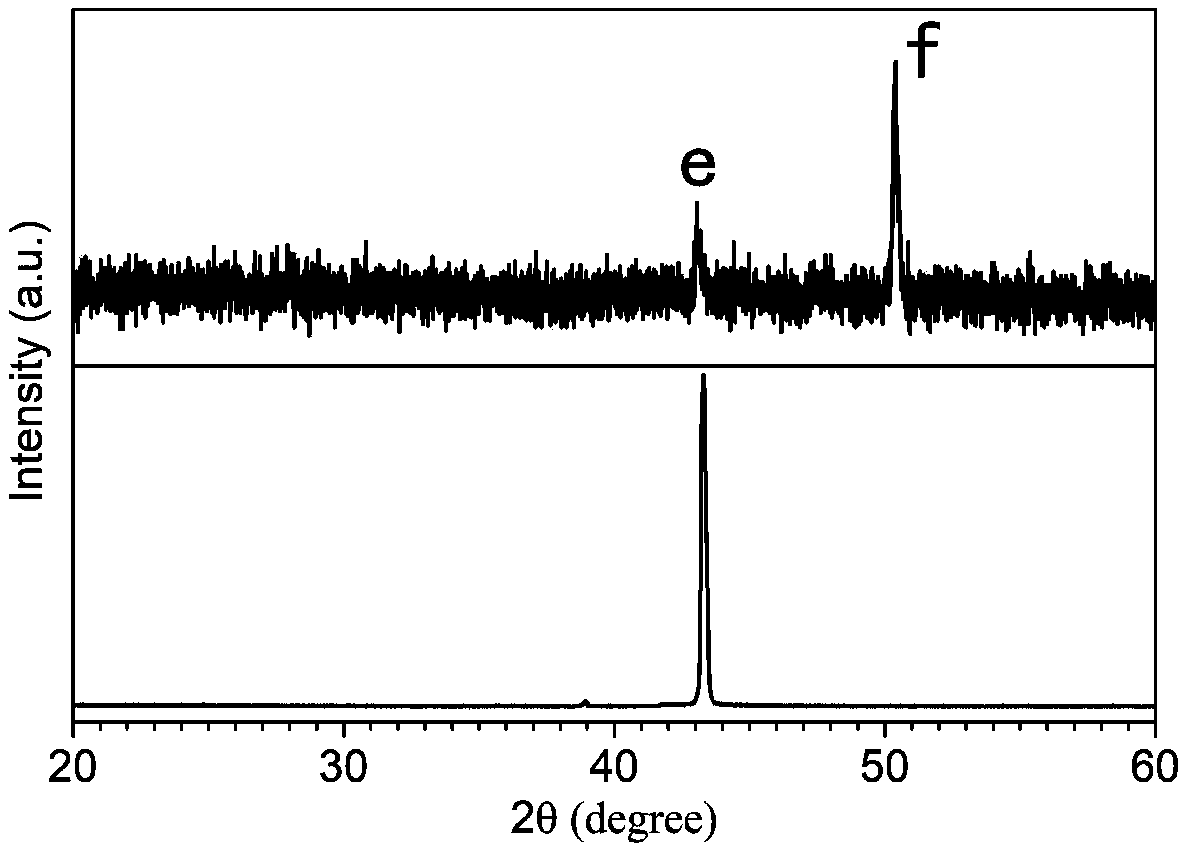

[0034] Embodiment: a kind of preparation method of millimeter-scale single-layer single-crystal graphene based on polycrystalline copper foil, such as figure 1 - As shown in Figure 4, the specific steps are:

[0035] (1) Pretreatment of copper foil:

[0036] Use Alfa Aesar's #46986 copper foil with a thickness of 0.025mm and a purity of 99.8%. At room temperature, clean the surface of the copper foil with absolute ethanol and dry it with dry nitrogen; cut the copper foil with scissors Form a rectangular diaphragm of 6.0cm*5.5cm, fold it into a closed rectangular box; then load the rectangular box into a high-temperature-resistant quartz tube with an inner diameter of 50mm, and place the quartz tube in the CVD reaction chamber. evacuate the body to an approximate vacuum state below 0.05Pa, and then continuously feed 600sccm argon, 100sccm hydrogen and 0.06sccm oxygen into the CVD reaction chamber until the pressure in the CVD reaction chamber reaches 460Pa, and continue to mai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com