Silver copper nano alloy electro-catalyst and laser gas phase deposition method thereof

A nano-alloy and electrocatalyst technology, which is applied in the field of oxygen reduction reaction electrocatalyst and its preparation, can solve the problems of low catalytic activity, non-nanometerization of alloy metal phase separation, complex preparation process, etc., achieve good catalytic effect, reduce cost, The effect of high catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

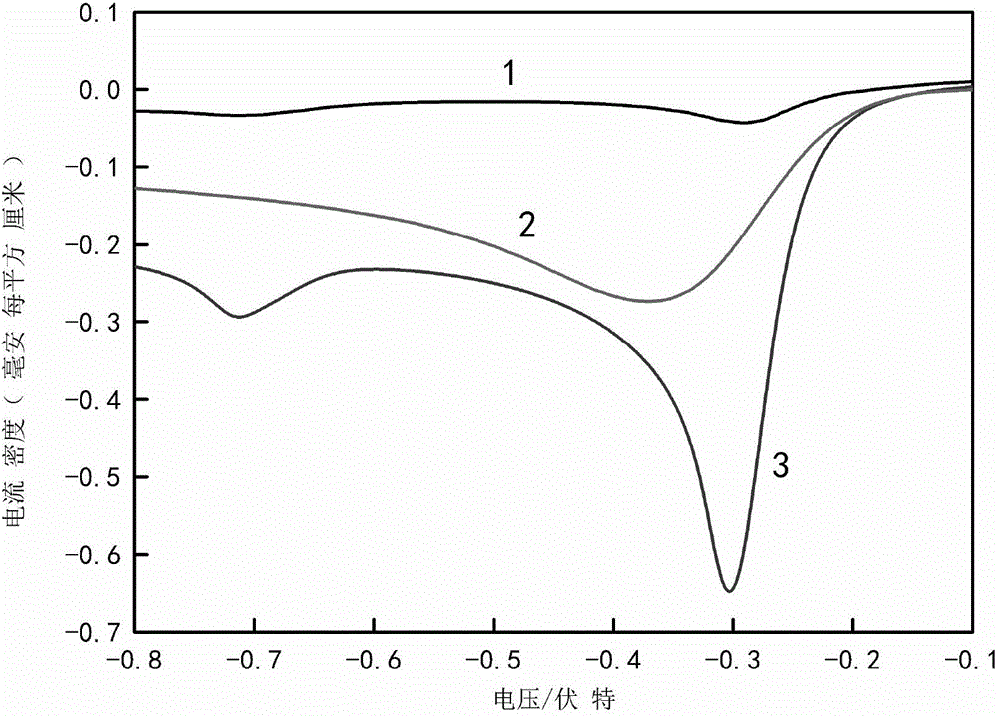

[0044] This embodiment is a silver-copper nano-alloy electrocatalyst, which is obtained by depositing a silver-copper alloy on the titanium sheet by laser vapor deposition with a titanium sheet as a substrate and a silver-copper alloy as a target. The physical state of the silver-copper nano-alloy electrocatalyst is thin film.

[0045] The molar ratio of silver and copper in the silver-copper nano-alloy electrocatalyst component is 4:1. The microscopic appearance of the silver-copper nano-alloy electrocatalyst through a transmission electron microscope is that nano-crystals with a size of 2-5 nanometers are embedded in amorphous, wherein the nano-crystals are silver-copper face-centered cubic solid solution, and the amorphous is metallic copper.

[0046] The preparation process of the silver-copper nano-alloy electrocatalyst described in the present embodiment is as follows:

[0047] Step 1, processing the titanium sheet substrate: use No. 1200 and No. 1500 metallographic san...

Embodiment 4

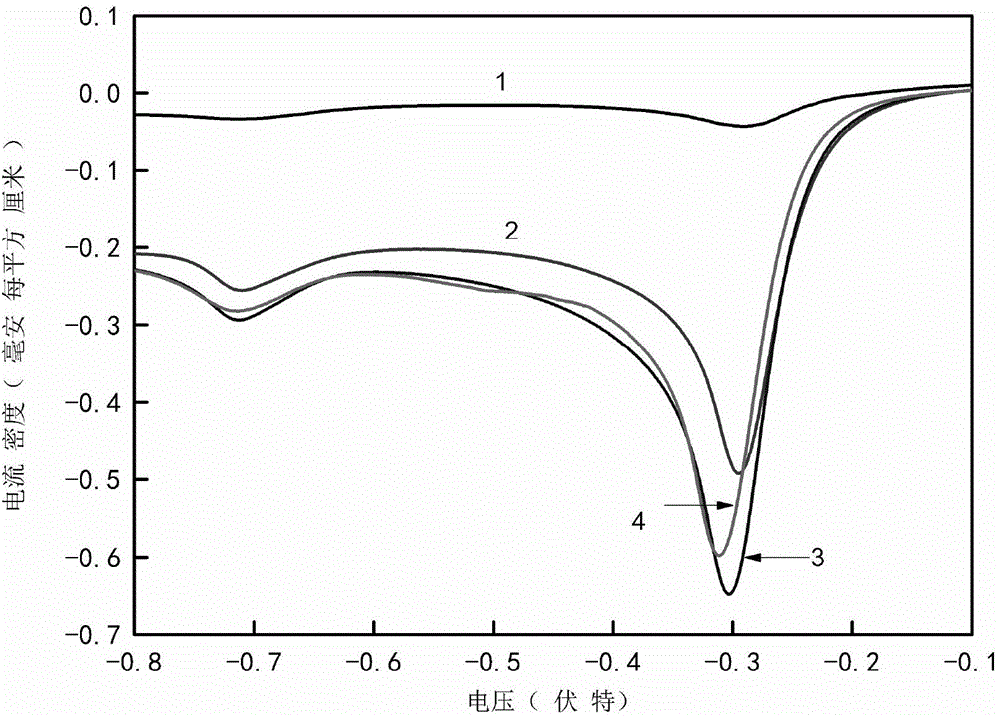

[0061] This embodiment is a silver-copper nano-alloy electrocatalyst, which is obtained by depositing a titanium sheet as a substrate and a silver-copper alloy as a target material on the titanium sheet by physical vapor deposition.

[0062]The molar ratio of silver and copper in the silver-copper nano-alloy electrocatalyst component is 4:1. The microscopic morphology of the silver-copper nano-alloy electrocatalyst is composed of nanocrystals and polycrystals, and the silver-copper face-centered cubic structure solid solution nanocrystals and polycrystal copper are connected into one piece.

[0063] The preparation process of the silver-copper nano-alloy electrocatalyst described in the present embodiment is as follows:

[0064] Step 1: Processing the titanium sheet substrate: the process of processing the titanium sheet substrate is exactly the same as the process of processing the titanium sheet substrate in Embodiment 1.

[0065] Step 2, preparing silver-copper nano-alloy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com