Preparation method of large-size Cu(100) single-crystal copper foil

A large-size, copper foil technology, applied in the field of preparation of large-size Cu single crystal copper foil, can solve the problems of reducing grain boundary density, etc., and achieve the effect of reducing preparation cost, low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment one: a kind of method for annealing doped polycrystalline copper to prepare single crystal Cu (100), comprises the following steps:

[0018] (1), place the polycrystalline copper foil doped with the metal element flatly on the high temperature resistant substrate, put it into the chemical vapor deposition equipment, pass inert gas and H 2 Gas, the inert gas flow rate is 300~500sccm, H 2 Flow rate is 20~50sccm, then starts to heat up, and described inert gas is N 2 or Ar;

[0019] (2) When the temperature rises to 800~1100℃, H 2 Gas, H 2 The flow rate is 2-500 sccm, the annealing process is carried out, and the Cu(100) single crystal copper foil is obtained after the annealing is completed.

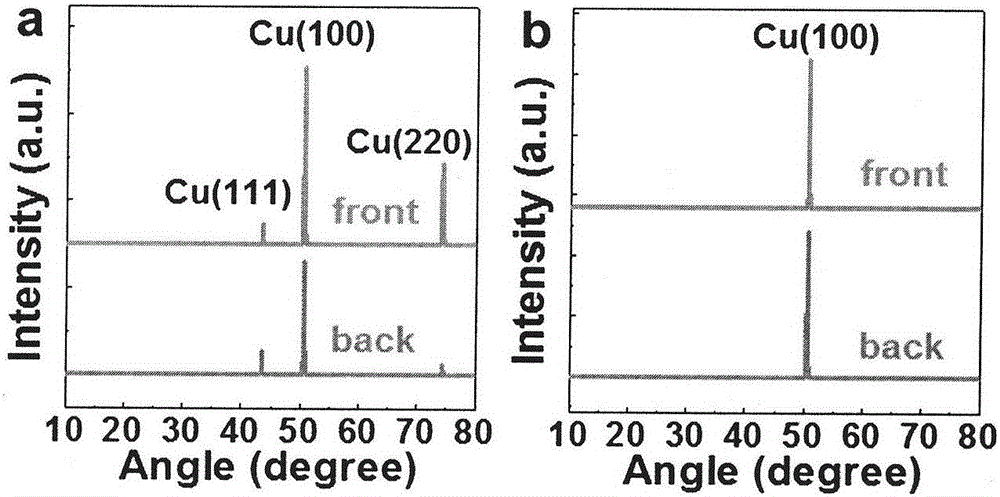

[0020] Carry out XRD characterization to the copper foil after above-mentioned annealing, the result is as follows figure 1 as shown in b. Depend on figure 1 b It can be seen that the front and back of the annealed copper foil have only one direction, that is, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com