Preparation method of bulk single crystal copper

A single crystal copper and bulk technology is applied in the field of preparation of metal single crystal materials, which can solve the problems of complex preparation process and high cost of high-purity single crystal copper, and achieve the effects of easy large-scale promotion, low cost and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

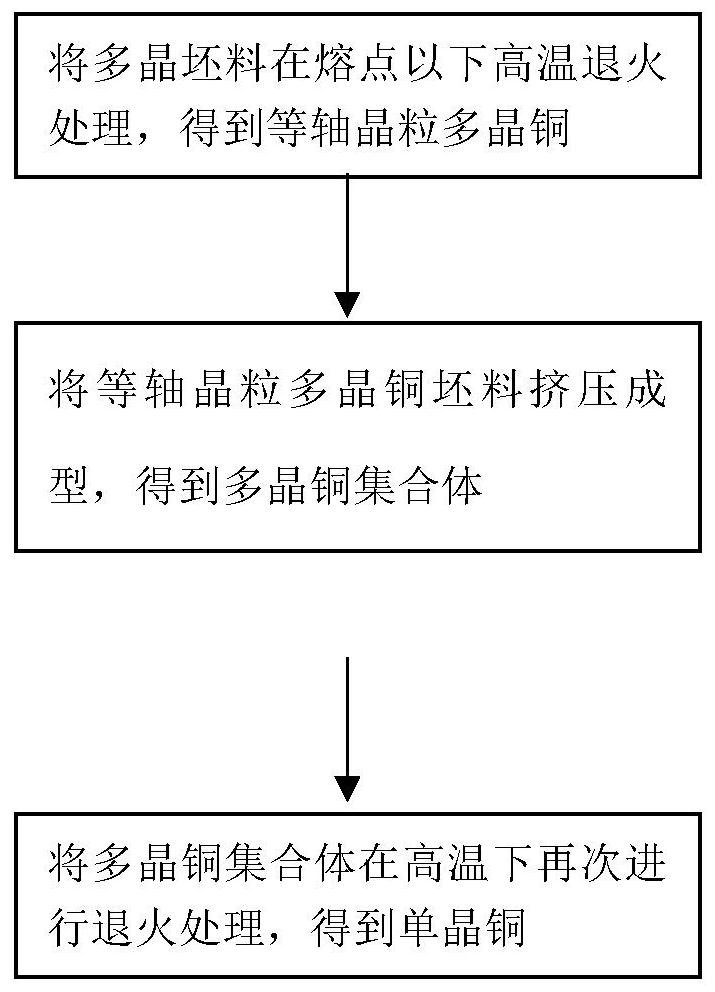

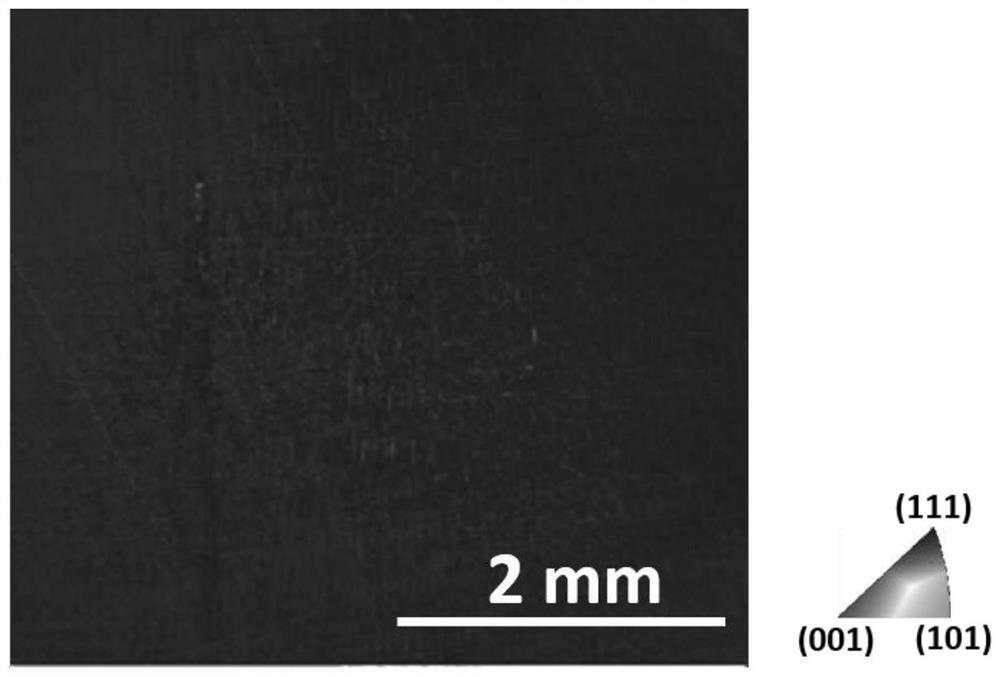

[0026] combine Figure 1 to Figure 4 , to describe this embodiment in detail. A kind of preparation method of bulk single crystal copper involved in the present embodiment, comprises the following steps:

[0027] (1) The polycrystalline copper blank is annealed at a high temperature below the melting point to obtain polycrystalline copper with equiaxed grains; the purity of the used polycrystalline copper blank is 99.9999%.

[0028] In this step, the polycrystalline copper billet after pickling and drying is subjected to high-temperature annealing in a vacuum furnace, and the pressure in the furnace is lower than 1×10 -3 Pa, the temperature is raised to 950-1000°C within 80-90min, and the annealing time is 10 hours.

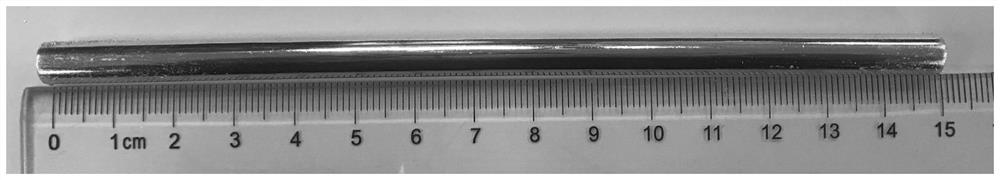

[0029] (2) Extruding the polycrystalline copper blank with equiaxed grains annealed in step (1) to obtain polycrystalline copper aggregates. The cross-section of the polycrystalline copper aggregate can be circular, oval, regular polygon, etc. In this example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com