Preparation method of monocrystalline copper strips

A copper strip and single crystal technology, applied in the field of single crystal copper, can solve the problems such as the production and use of single crystal copper strip, and achieve the effect of avoiding single crystal to polycrystalline transformation, continuous production, and controllable thickness range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

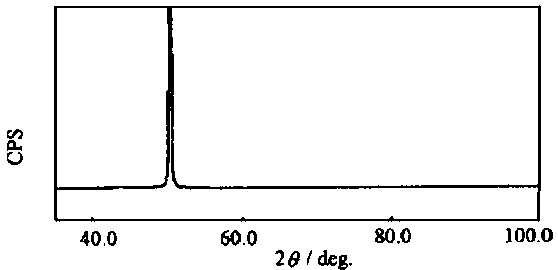

Embodiment 1

[0018] This embodiment specifically implements a method for preparing a single crystal copper strip. Under the protection of a mixed gas of argon and hydrogen containing 1.0% hydrogen by volume, the polycrystalline copper strip with a thickness of 0.005mm and a width of 100mm obtained by cold rolling The copper strip is continuously fed into a closed holding furnace with a temperature of 1000°C. The polycrystalline copper strip enters the holding furnace with an effective heating length of 100cm at a speed of 5mm / min. Starting from the position of the ultrasonic horn, through three ultrasonic horns with a distance of 10 mm, under the protection of inert gas, ultrasonic action is performed on the continuously moving polycrystalline copper strip. The temperature of the polycrystalline copper strip is controlled at 900°C, the ultrasonic vibration frequency is 20kHz, and the power is 200W / mm 2 ; Next, continue to keep warm at 1000 ° C for 100 min under the protection of inert gas,...

Embodiment 2

[0020] This embodiment specifically implements a method for preparing a single crystal copper strip. Under the protection of a mixed gas of argon and hydrogen containing 0.8% hydrogen by volume, the polycrystalline copper strip with a thickness of 0.010mm and a width of 300mm obtained by cold rolling The copper strip is continuously fed into a closed holding furnace with a temperature of 1020°C; the polycrystalline copper strip enters a holding furnace with an effective heating length of 100cm at a speed of 10mm / min, and is kept in the furnace for 100min, and then the effective heating length is 50mm from the holding furnace Starting from the position, through three ultrasonic horns separated by 10 mm, ultrasonic action is performed on the continuously moving polycrystalline copper strip under the protection of inert gas. The temperature of the polycrystalline copper strip is controlled at 950°C, the ultrasonic vibration frequency is 30kHz, and the power is 250W / mm 2 ; Next, c...

Embodiment 3

[0022] This embodiment specifically implements a method for preparing a single crystal copper strip. Under the protection of a mixed gas of argon and hydrogen containing 0.5% hydrogen by volume, the polycrystalline copper strip with a thickness of 0.030mm and a width of 500mm obtained by cold rolling The copper strip is continuously fed into a closed holding furnace with a temperature of 1040°C; the polycrystalline copper strip enters a holding furnace with an effective heating length of 80cm at a speed of 8mm / min, and is kept in the furnace for 100min, and then the effective heating length is 50mm from the holding furnace Starting from the position, through three ultrasonic horns separated by 10 mm, ultrasonic action is performed on the continuously moving polycrystalline copper strip under the protection of inert gas. The temperature of the polycrystalline copper strip is controlled at 920°C, the ultrasonic vibration frequency is 20kHz, and the power is 300W / mm 2 ; Then, con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com