Method for simply and selectively preparing single crystal copper foil

A selective, copper foil technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problem of making full use of unfavorable resources and meet the needs of industrialization, and it is difficult to achieve selective preparation of various single crystal copper foils, The problem of preparing low crystal plane index single crystal copper foil, etc., achieves the effect of large-scale industrial application prospects, short preparation period and good surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

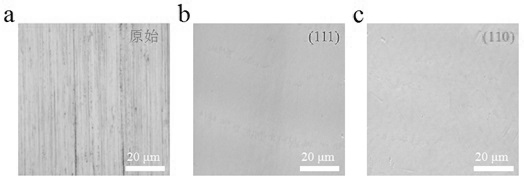

Embodiment 1

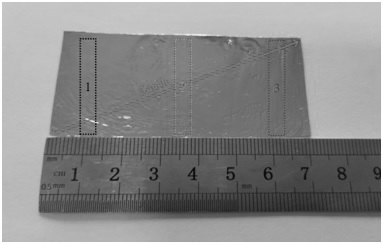

[0035] (1) To clean the copper foil, soak the polycrystalline copper foil with a diagonal size of 3 inches (thickness 25 μm) for 5 minutes with a mixed solution of alcohol, acetic acid, and deionized water with a volume ratio of 1:1:1, and then use pure Rinse with deionized water for 2-3 times, and finally dry the copper foil with nitrogen;

[0036] (2) Sample injection, place the dried copper foil on a flat quartz plate, and slowly push it into the main temperature zone of the tube furnace;

[0037] (3) Wash the air, place the sample properly, tighten the flanges and air valves, turn on the mechanical pump, and after the mechanical pump has been running for a period of time, slowly open the exhaust valve, and close the exhaust valve when the vacuum in the tube is pumped to within 10 Pa , open the inlet valve and fill the quartz tube with argon (500 sccm) up to atmospheric pressure. Repeat the vacuuming-argon filling operation three times to complete the gas washing operation...

Embodiment 2

[0045] (1) To clean the copper foil, soak the polycrystalline copper foil (thickness 25 μm) with a diagonal size of 3 inches in a mixed solution of alcohol, acetic acid and deionized water with a volume ratio of 1:2:2 for 5 minutes, and then use pure Rinse with deionized water for 2-3 times, and finally blow dry with argon;

[0046] (2) Sample injection, place the dried copper foil on a flat silicon wafer, and slowly push it into the main temperature zone of the tube furnace;

[0047] (3) Wash the air, place the sample properly, tighten the flanges and air valves, turn on the mechanical pump, and after the mechanical pump has been running for a period of time, slowly open the exhaust valve, and close the exhaust valve when the vacuum in the tube is pumped to within 10 Pa , open the intake valve and fill the quartz tube with nitrogen (800 sccm) up to atmospheric pressure. Repeat the vacuuming-nitrogen filling operation three times to complete the scrubbing operation;

[0048]...

Embodiment 3

[0056] (1) To clean the copper foil, soak the polycrystalline copper foil with a diagonal size of 3 inches (thickness 25 μm) for 10 minutes in a mixed solution of alcohol, acetic acid, and deionized water with a volume ratio of 1:1:3, and then use pure Rinse with deionized water for 2-3 times, and finally blow dry with nitrogen;

[0057] (2) Sample injection, place the dried copper foil on a flat alumina sheet, and slowly push it into the main temperature zone of the tube furnace;

[0058] (3) Wash the air, place the sample properly, tighten the flanges and air valves, turn on the mechanical pump, and after the mechanical pump has been running for a period of time, slowly open the exhaust valve, and close the exhaust valve when the vacuum in the tube is pumped to within 10 Pa , open the inlet valve and fill the quartz tube with argon (900 sccm) up to atmospheric pressure. Repeat the vacuuming-argon filling operation three times to complete the gas washing operation;

[0059]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com