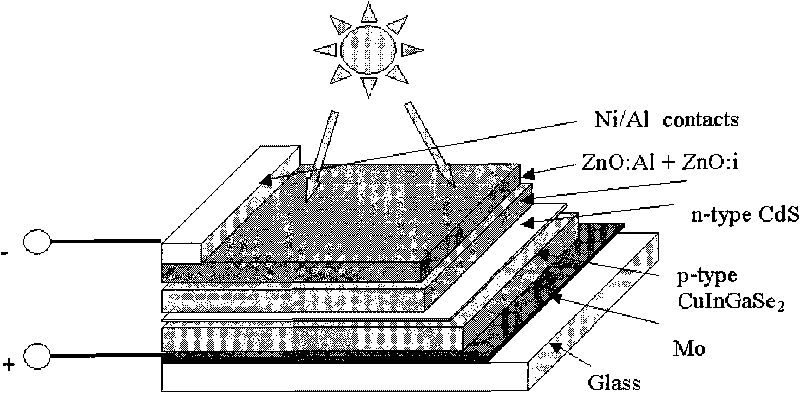

Copper indium gallium selenium (CIGS) solar cell, film of absorbing layer thereof, method and equipment for preparing film

A technology of solar cells and copper indium gallium selenide, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of uneven distribution of In and Ga elements, and achieve the effects of assembly line operation, cost reduction, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

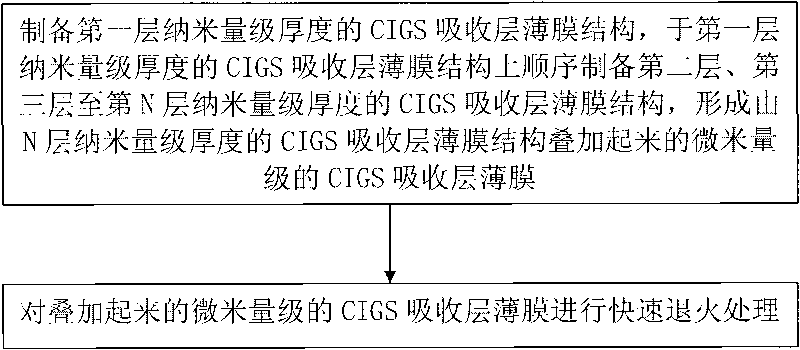

Method used

Image

Examples

example 1

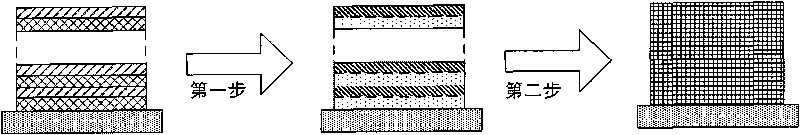

[0043] Example 1: the present invention's process can be as attached Figure 5 implemented in the vacuum apparatus shown. The system consists of three vacuum chambers A, B, and C, and A and B, B and C are isolated by gate valves. The sample is fixed vertically on the sample holder, the side of the sample with the Mo film faces the positive direction of the vacuum chamber, the sample holder is driven by the rack, and can freely move in translation in the three vacuum chambers. In the vacuum chamber A, a Cu / Ga alloy target (Ga atomic content 20% to 40%) and a pure In target are set in the forward direction for sputtering and depositing metal films, and there is a resistance wire heater in the reverse direction, which can Heat the sample. There is a Se evaporation line source in the forward direction of the vacuum chamber B, and a heater in the reverse direction to provide a substrate temperature of 250-400°C, which can complete the evaporation of selenium and selenization. Ch...

example 2

[0044] Example 2: This example is the assembly line of the process of Example 1, and the system is composed of A 1 B 1 A 2 B 2 ......A n B n C, as attached Figure 6 , where A 1 、A 2 ~A n structure and attached Figure 5 The vacuum chambers A are identical to those of B 1 , B 2 ~B n with attached Figure 5 Vacuum chamber B is consistent. In this way, the sample can move in one direction in the system to realize the pipeline.

[0045] The effect of the preparation method of the present invention: the core technology of the present invention is to adopt partial selenization and then unified annealing. Compared with other techniques for preparing copper indium gallium selenide (CIGS) thin films, it mainly has the following advantages: first, micron-scale The copper indium gallium selenide (CIGS) absorbing layer film of the company is formed by stacking multiple nanoscale copper indium gallium selenide (CIGS) film structures, which can effectively prevent the uneven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com