Plywood surface finish machining equipment

A surface finishing, plywood technology, used in metal processing equipment, grinding/polishing equipment, devices for applying liquid to surfaces, etc., can solve problems such as inconvenience, and achieve the effect of ensuring normal operation and preventing uneven resin distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

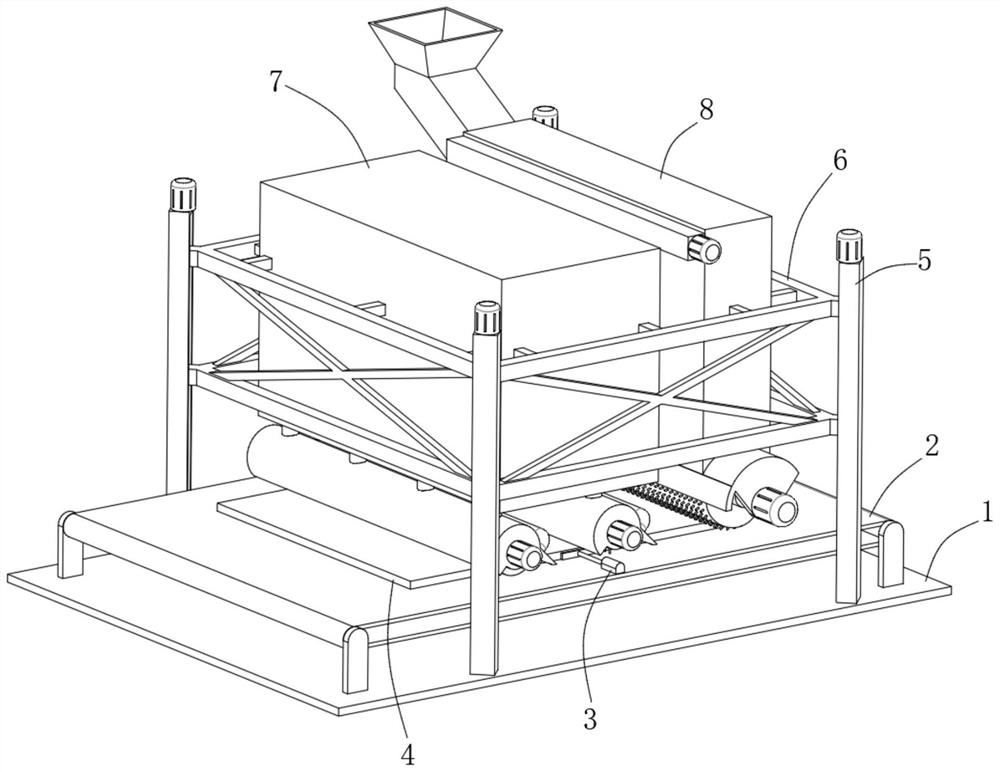

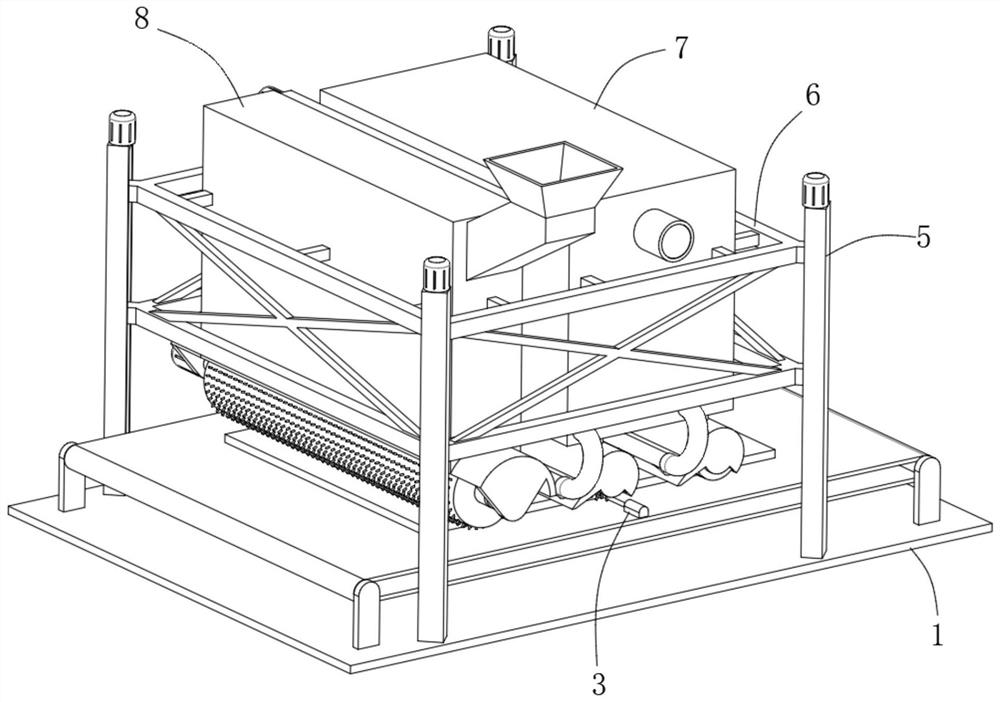

[0032] see Figure 1 to Figure 10 , the invention discloses a plywood surface finishing equipment, comprising: a bottom plate 1, a conveyor belt 2 arranged on the bottom plate 1, and a plywood 4 is clamped and fixed on the conveyor belt 2 by an electric push rod 3. In actual use, the plywood 4 After being placed on the conveyor belt 2, the plywood 4 is clamped and fixed by the electric push rod 3.

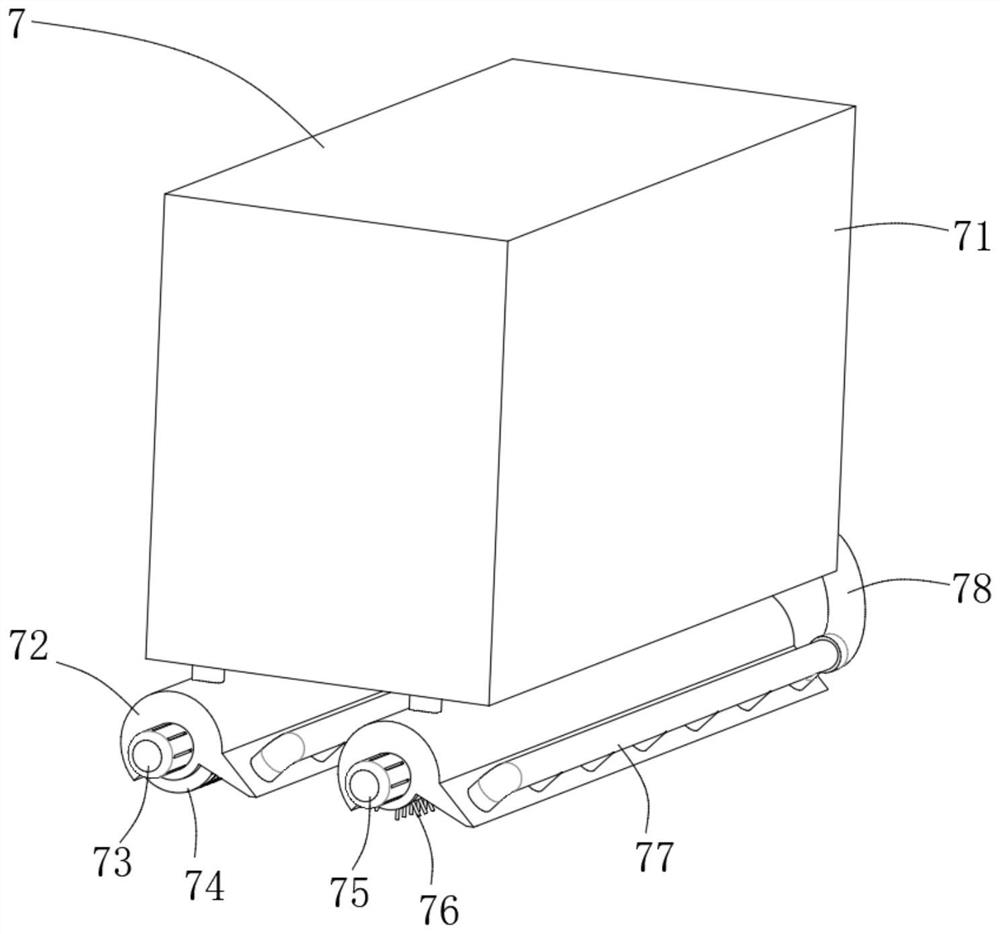

[0033] The bottom plate 1 is connected with a fixed frame 6 through a lead screw adjustment mechanism 5, and the fixed frame 6 is respectively provided with a grinding treatment mechanism 7 for grinding the surface of the plywood 4, and a roller c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com