Preparation method of wafer-level single crystal copper foil and preparation method of structured graphene

A wafer-level, copper foil technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

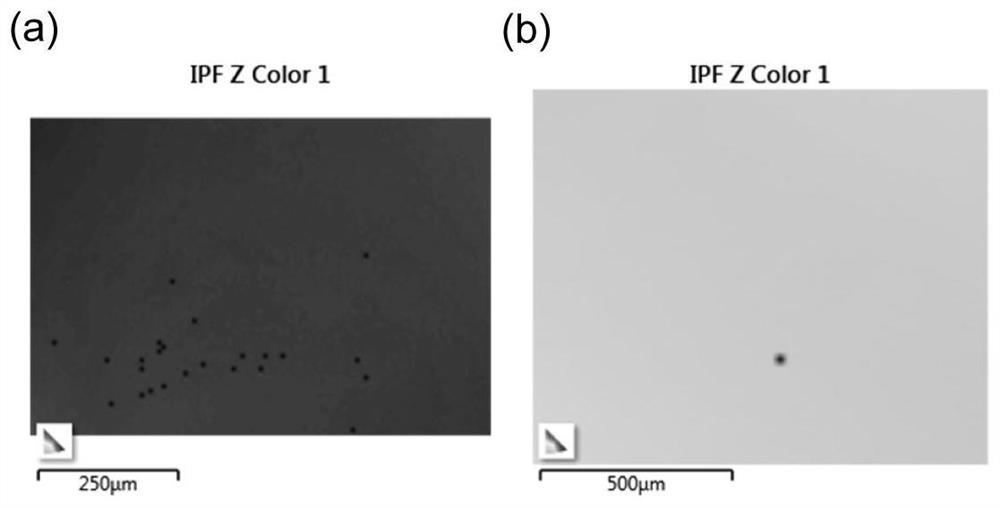

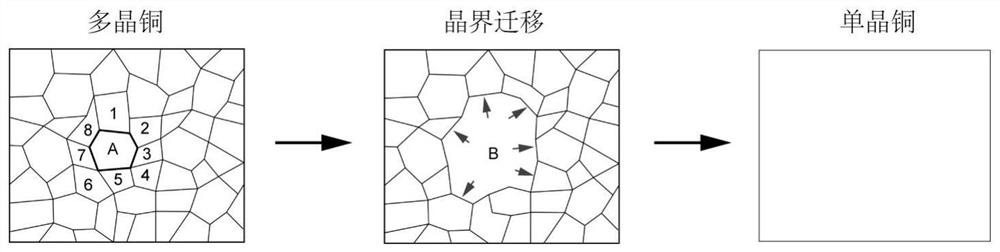

[0065] This embodiment provides a method for rapidly preparing single-crystal copper foil and highly regular graphene from suspended polycrystalline copper foil with notches through high-temperature annealing.

[0066] 1), the preparation method of described Cu(111), comprises the steps:

[0067] Select polycrystalline copper foil with a size of 6cm*3cm and a thickness of 0.08mm.

[0068] Make a cut at the suspended boundary of the polycrystalline copper foil with a depth of 3mm and a width of 20mm.

[0069] Soak the cut polycrystalline copper foil in acetic acid for 10 minutes, rinse thoroughly with deionized water at least three times, and blow dry with a nitrogen gun.

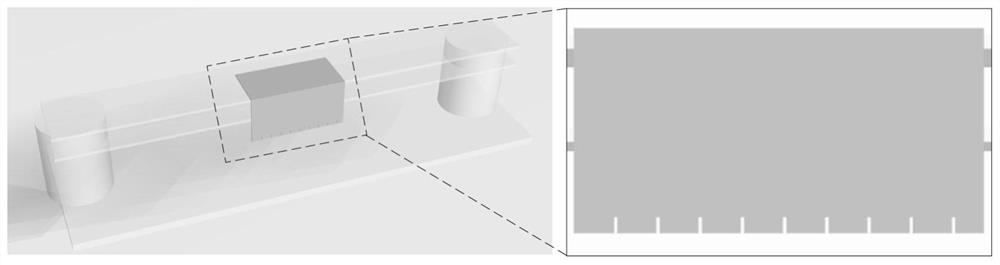

[0070] Select the quartz support, the upper surface of which is a plane with a width of 1.5mm and a length of 15mm, and the height of the support is 25mm; place the folded half of the polycrystalline copper foil on the plane of the quartz support, and hang the other half of the polycrystalline copper foil w...

Embodiment 2

[0080] A method for rapidly preparing single-crystal copper foil and highly regular graphene from suspended polycrystalline copper foil with cutouts through high-temperature annealing.

[0081] 1), taking the Cu(146) preparation method as an example, comprising the following steps:

[0082] Select polycrystalline copper foil with a size of 6cm*3cm and a thickness of 0.08mm.

[0083] Make a cut at the suspended boundary of the polycrystalline copper foil with a depth of 3 mm and a width of 10 mm.

[0084] Soak the cut polycrystalline copper foil in acetic acid for 10 minutes, rinse thoroughly with deionized water at least three times, and blow dry with a nitrogen gun.

[0085] Select the quartz support, the upper surface of which is 1.5mm wide, 15mm long, and the height of the support is 25mm; half of the folded polycrystalline copper foil with a cut is placed flat on the plane of the quartz support to support the copper foil, and the polycrystalline copper with a cut The oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com