Patents

Literature

654results about How to "Increase migration rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

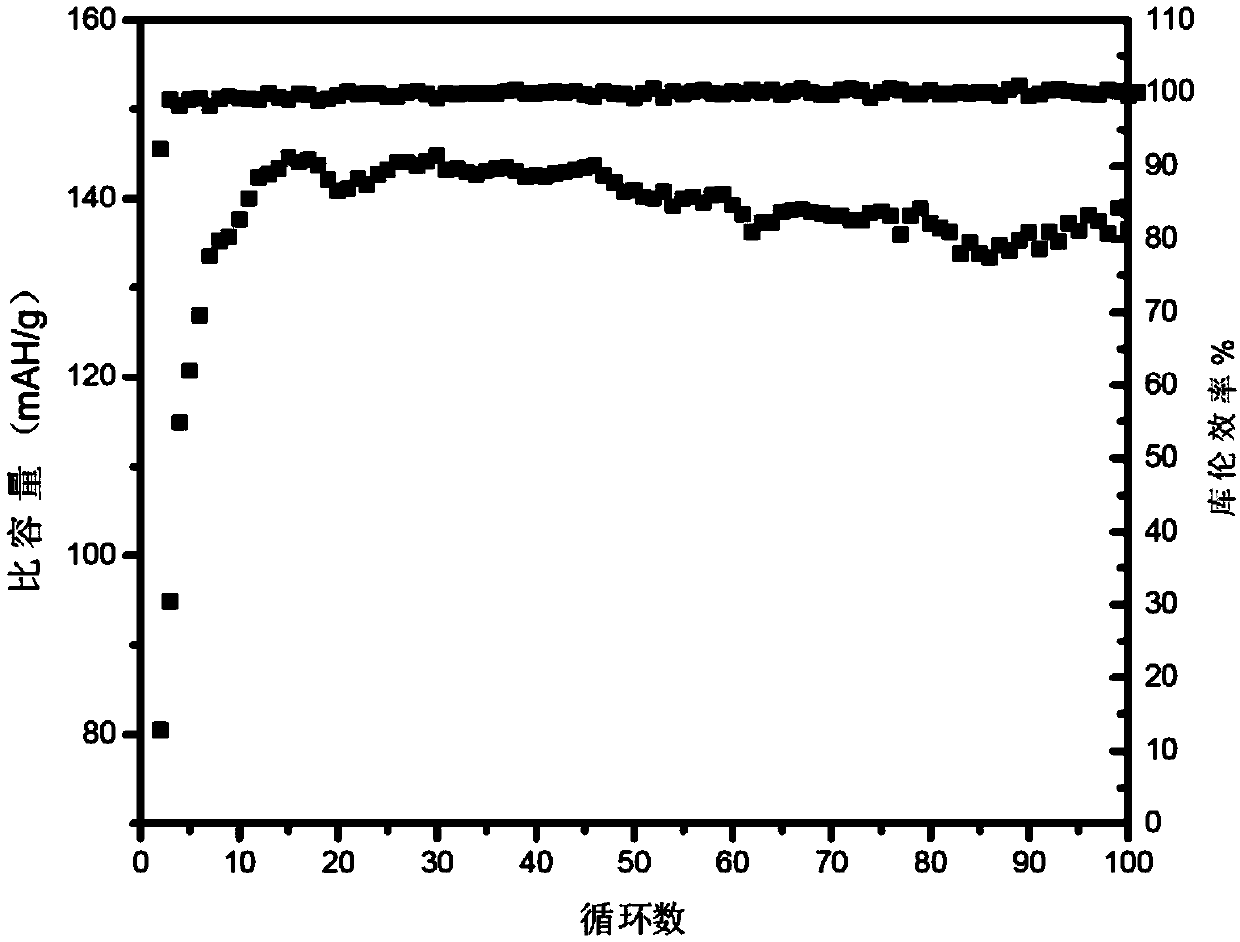

Carbon-coated ternary positive electrode material and preparation method thereof

ActiveCN103474628AImproved magnification performanceImprove conductivityCell electrodesNickel saltManganese

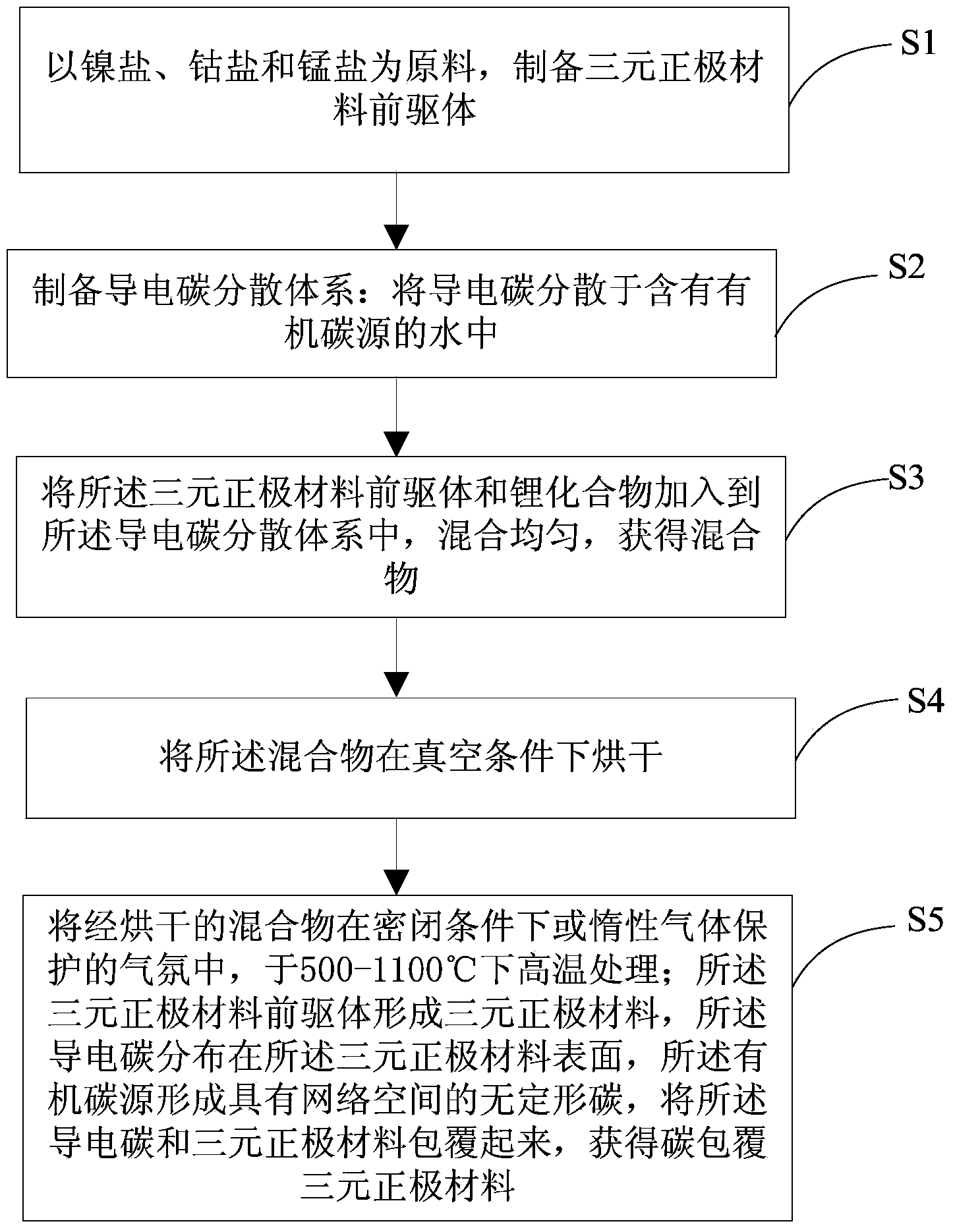

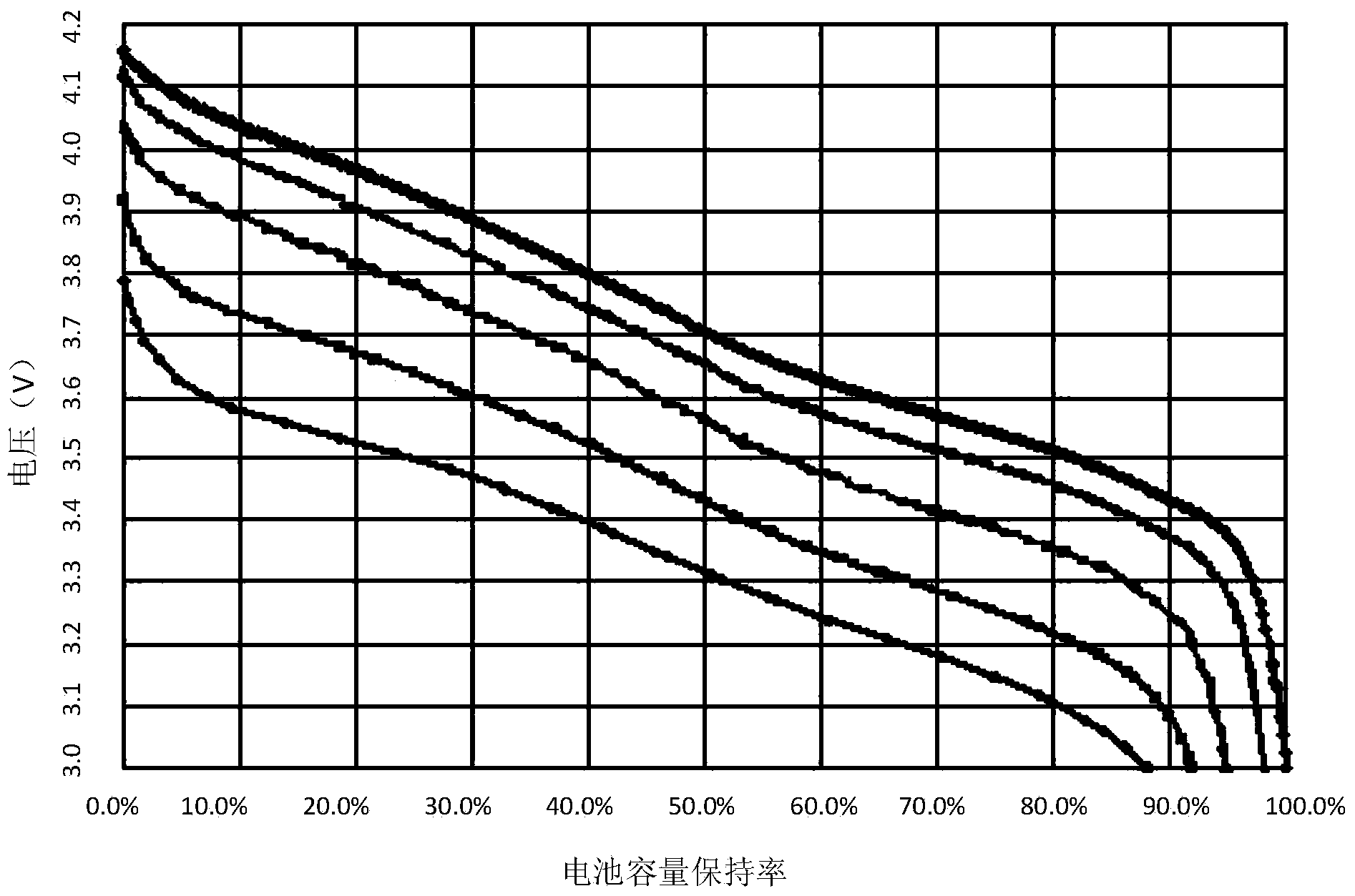

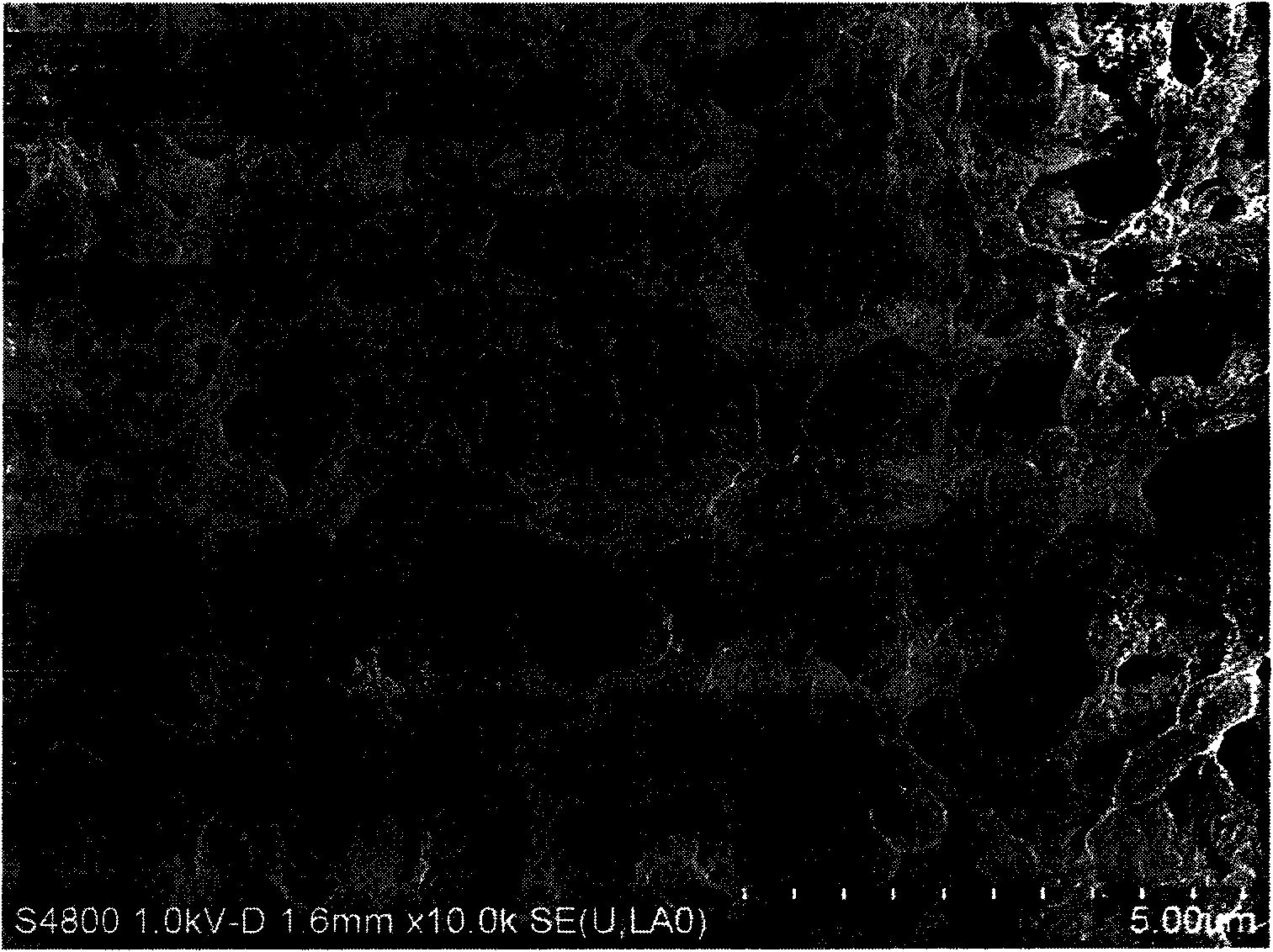

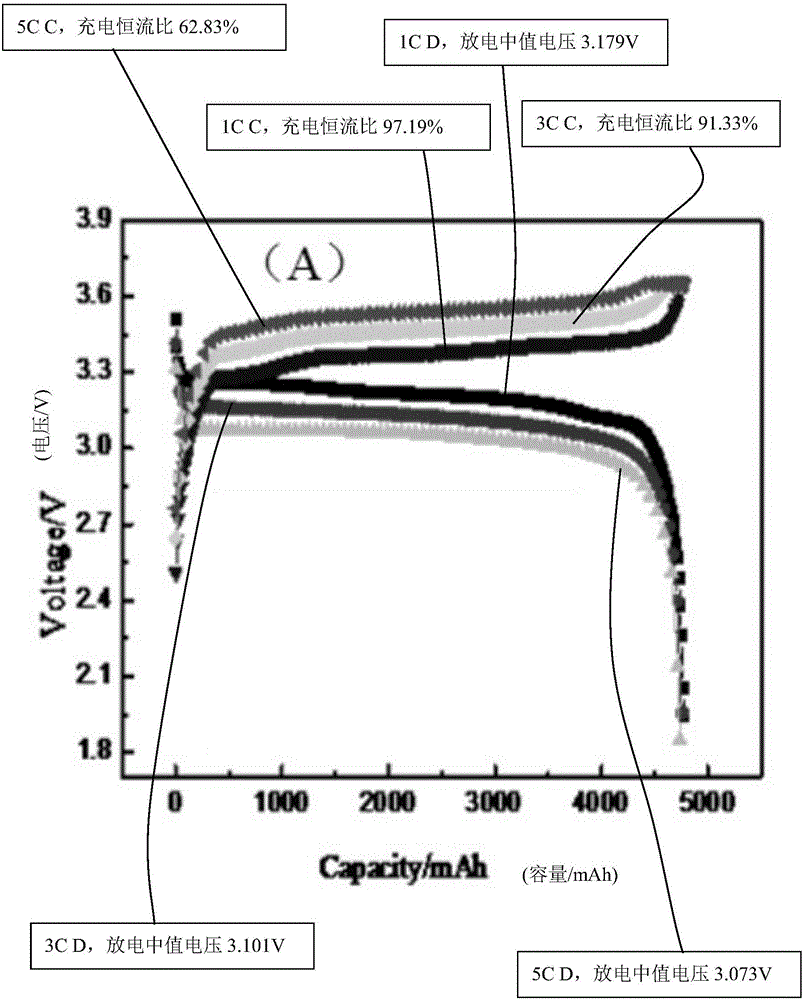

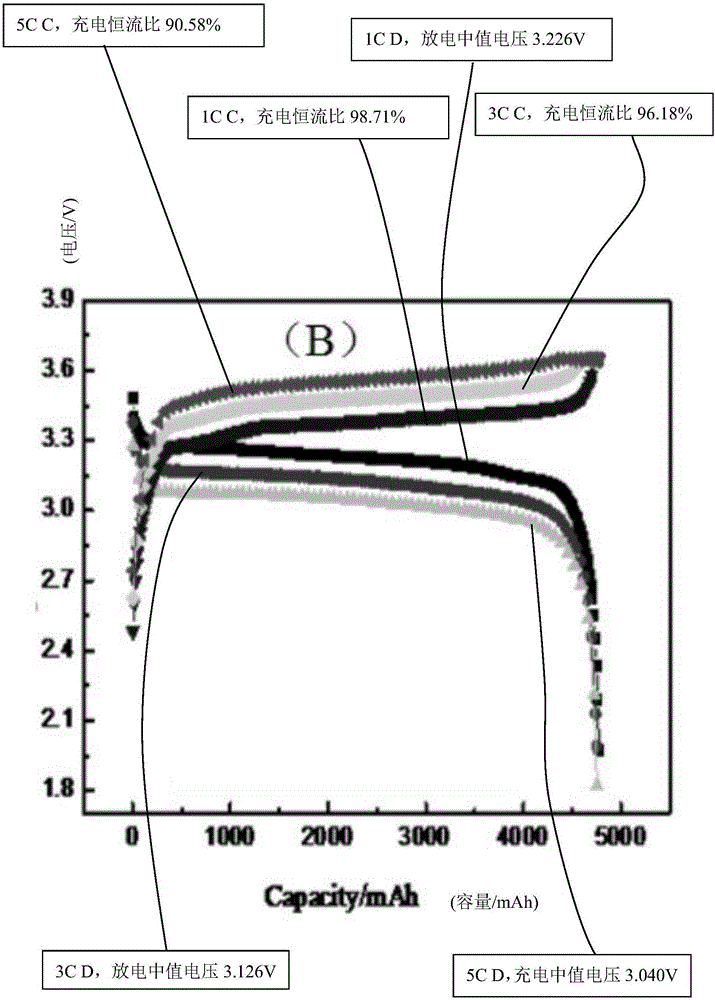

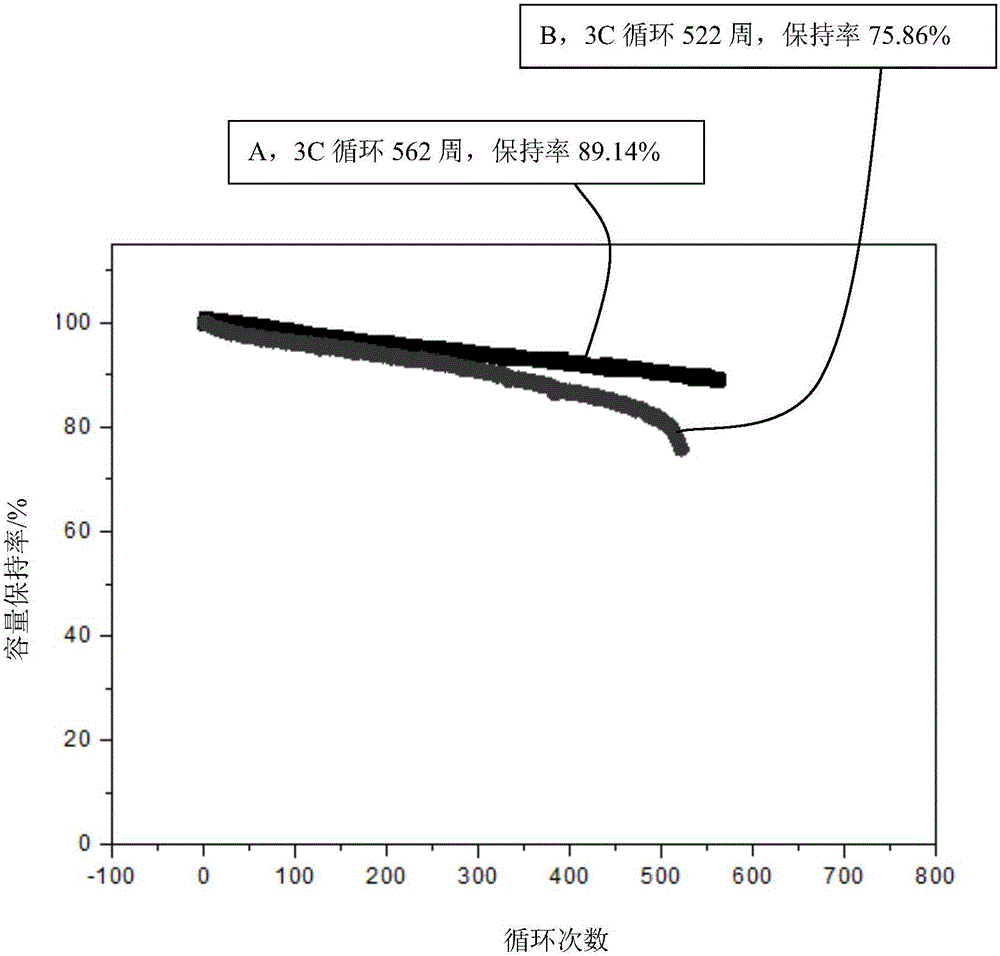

The invention discloses a carbon-coated ternary positive electrode material and a preparation method thereof. The preparation method comprises the following steps: S1, preparing a ternary positive electrode material precursor by taking nickel salt, cobalt salt and manganese salt as raw materials; S2, preparing a conductive carbon dispersion system, wherein conductive carbon is dispersed in water containing an organic carbon source; S3, adding the ternary positive electrode material precursor and a lithium compound into the conductive carbon dispersion system, and mixing uniformly to obtain a mixture; S4, drying the mixture under a vacuum condition; S5, carrying out high temperature treatment on the dried mixture under a closed condition or in an inert gas protection atmosphere so as to obtain the carbon-coated ternary positive electrode material. The carbon-coated ternary positive electrode material is uniform in coating, simple to operate, low in cost and high in efficiency; the conductive carbon and the ternary positive electrode material are simultaneously coated with network-shaped amorphous carbon which serves as a conductive medium or a channel of the conductive carbon and the ternary positive electrode material, thereby greatly improving the rate performance of the ternary positive electrode material.

Owner:SHENZHEN BETTERPOWER BATTERY

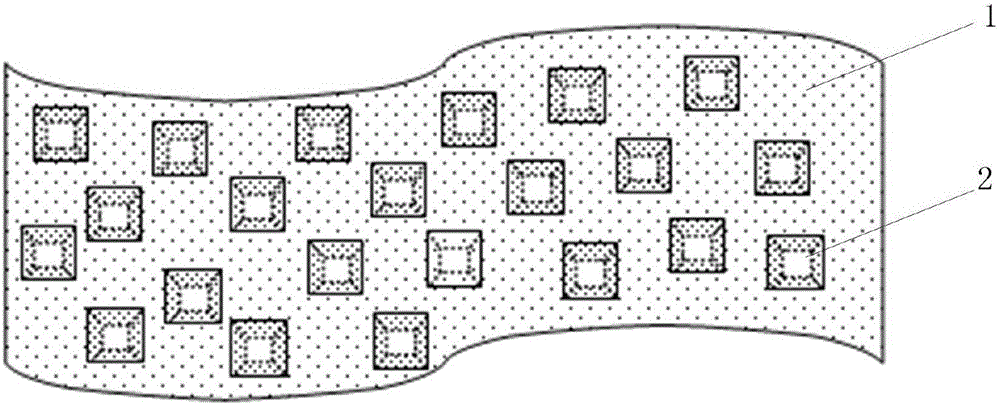

High-liquid absorbing rate micro-nano structure polymer electrolyte membrane and preparation method thereof

InactiveCN101626097AHigh liquid absorptionPromote absorptionSecondary cellsMicro nanoPolymer science

The invention discloses a preparation method of a high-liquid absorbing rate micro-nano structure polymer electrolyte membrane, wherein the membrane is prepared by polymer material being packed on a support frame. The method comprises the following steps of: by being processed, the polymer membrane has a micro-nano structure, forms holes with micron level and nanometer level, and forms a netty distribution hole structure with the nanometer holes of the support frame; and the polymer which is crossly linked layer by layer is packed on the special support frame to form a special netty micro-nano structure polymer electrolyte membrane. The polymer membrane of the micro-nano structure can absorb large numbers of electrolyte, greatly increase liquid-absorption rate, and improve the affinity of diaphragm to the electrolyte; the netty micro-nano structure leads the electrolyte to be kept in the membrane well, leads lithium ion in the polymer electrolyte membrane to be evenly distributed, leads the concentration to be to balanced, and lead the current density in the battery to be evenly when discharging electricity; and the special support frame guarantees the mechanical capability of the membrane. The preparation technology of the polymer electrolyte membrane has simple route and easily obtained raw material, can be operated under a normal condition, and does not need harsh production environment. The polymer lithium ion battery prepared by the membrane has good electrochemistry capability.

Owner:CHANGSHA HIGH TECH INDAL DEV ZONE CAISHENG NEW ENERGY TECH

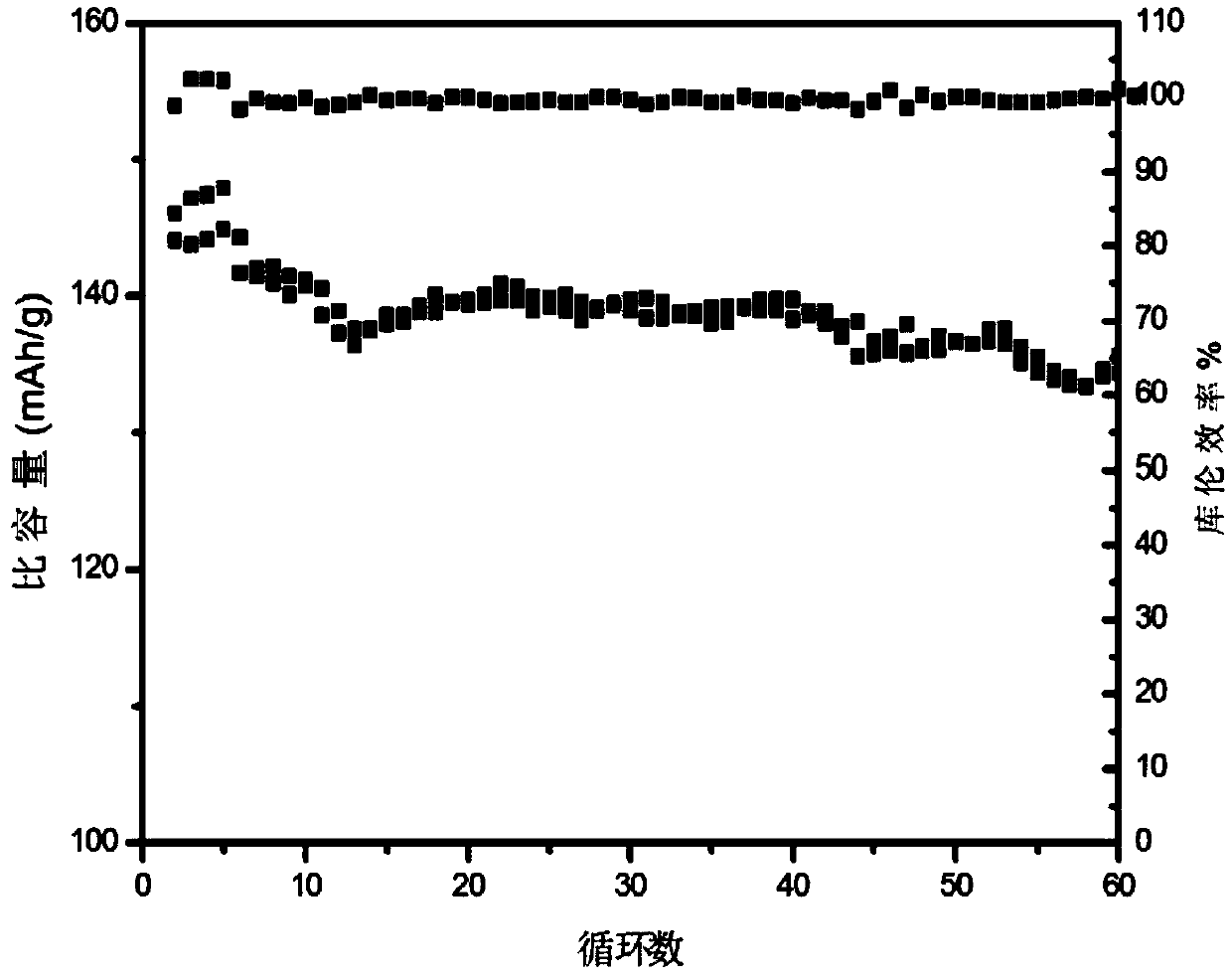

Modified high nickel ternary positive electrode material and its preparation method and lithium ion battery

InactiveCN108206277AImprove the first discharge capacityImprove the first Coulombic efficiencyCell electrodesSecondary cellsAluminium-ion batteryElectrical conductor

The invention discloses a modified high nickel ternary positive electrode material. The surface of a high nickel ternary positive electrode material is coated with a coating layer containing a fast ion conductor. The fast ion conductor has the chemical general formula of Li3x1La2 / 3-x1Ma1TiNz1O3, Li2+2x2Zn1-x2GeO4 or LiM'2(PO4)3, wherein M represents Ba<2+> and / or Sr<2+>, N represents Al<3+> and / orZr<4+>, x1 is greater than or equal to 0.04 and less than or equal to 0.167, a1 is greater than or equal to 0 and less than or equal to 1, z1 is greater than or equal to 0 and less than or equal to 1, x2 is greater than -0.3 and less than 0.8, and M' represents one or more of Zr, Ti, Ge and Hf. Compared with the existing positive electrode material, the modified high nickel ternary positive electrode material is provided with the coating layer containing the fast ion conductor and the coating layer can react with residual lithium on the surface of the material to reduce residual lithium on the surface of the material and inhibit side reactions of the residual lithium and the electrolyte so that material surface stability and cycle performances are improved. The modified high nickel ternary positive electrode material has good lithium ion deintercalation ability, improves the first discharge capacity of the material and first coulombic efficiency and has a good application prospect. The invention also discloses a preparation method of the modified high nickel ternary positive electrode material and a lithium ion battery.

Owner:CONTEMPORARY AMPEREX TECH CO

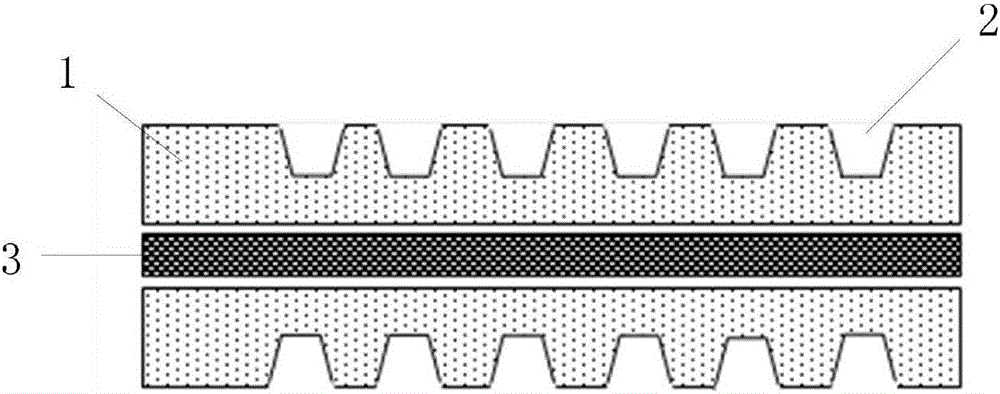

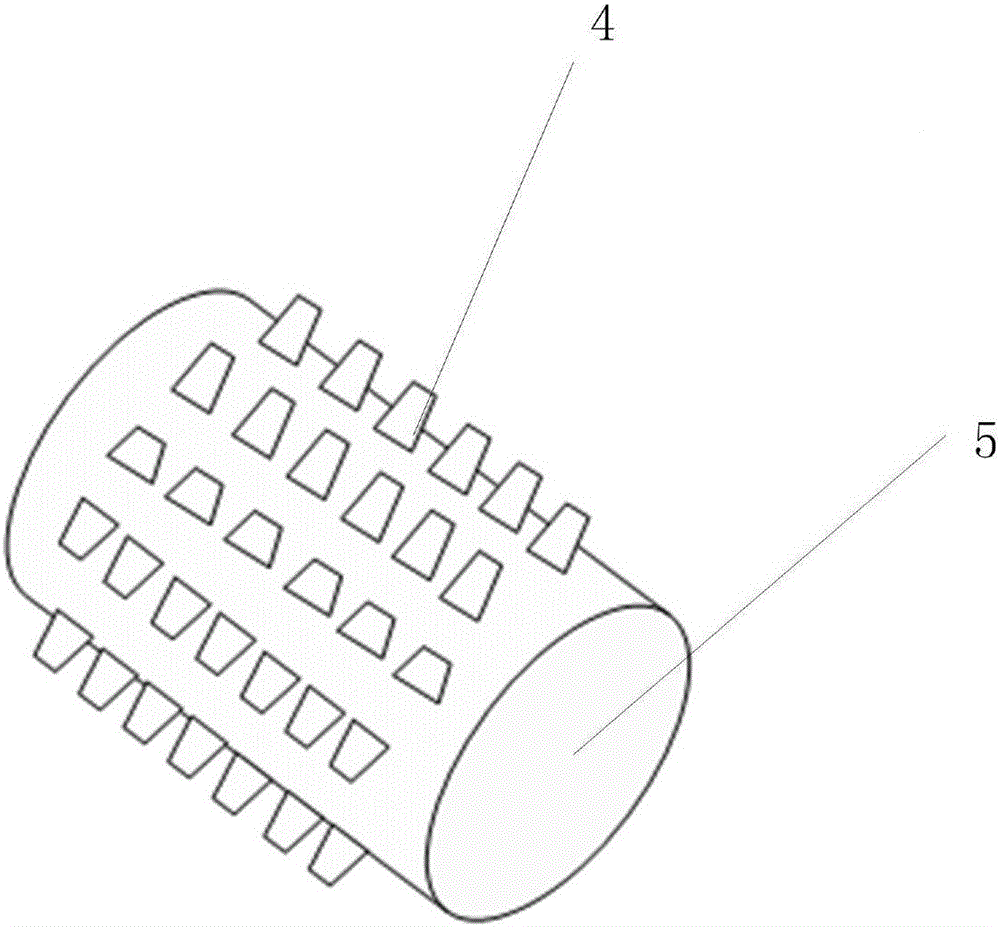

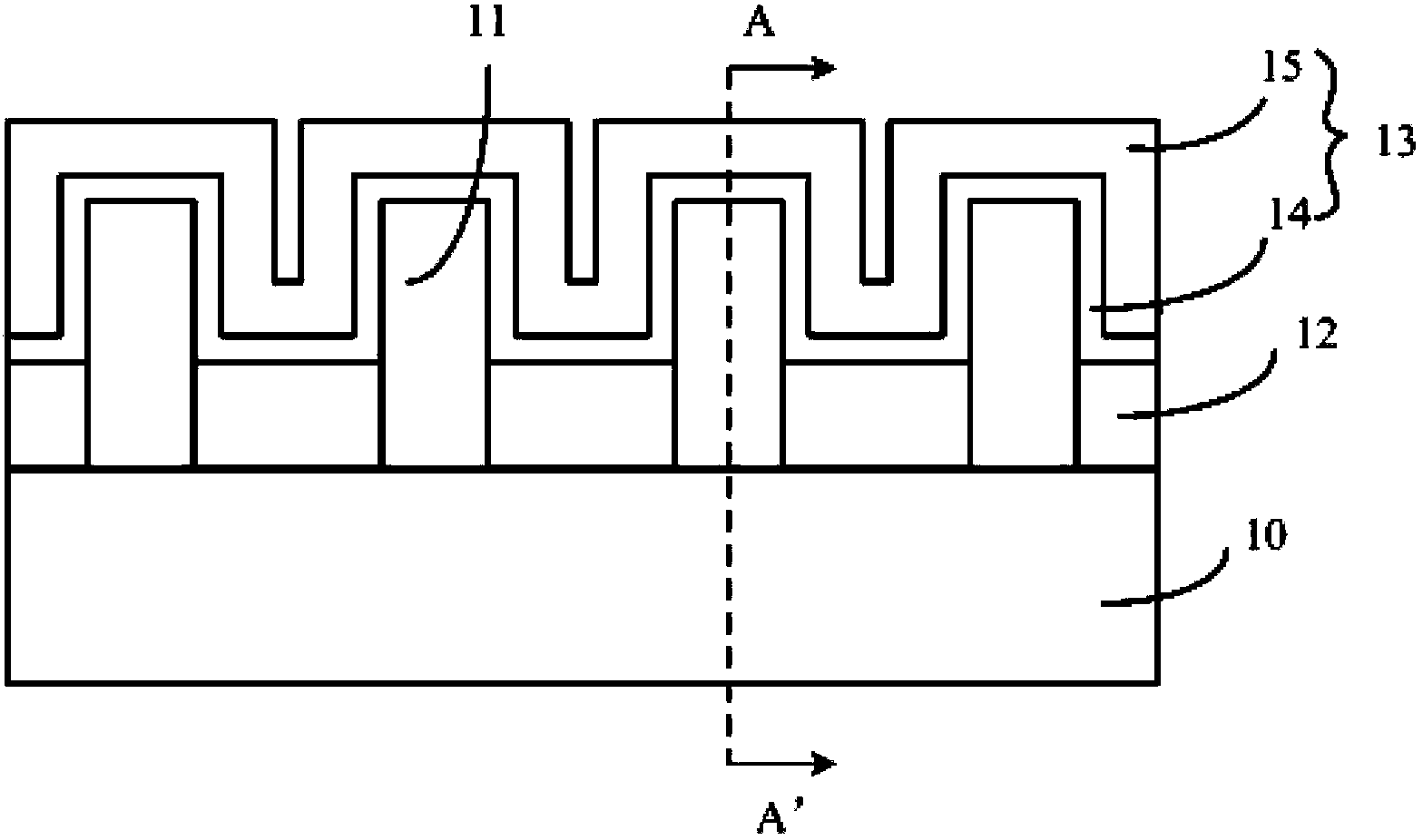

Electrode pole plate of lithium ion battery, pole plate rolling device and lithium ion battery

ActiveCN106531961APromote infiltrationIncrease migration rateElectrode rolling/calenderingSecondary cellsElectrolytic agentCharge discharge

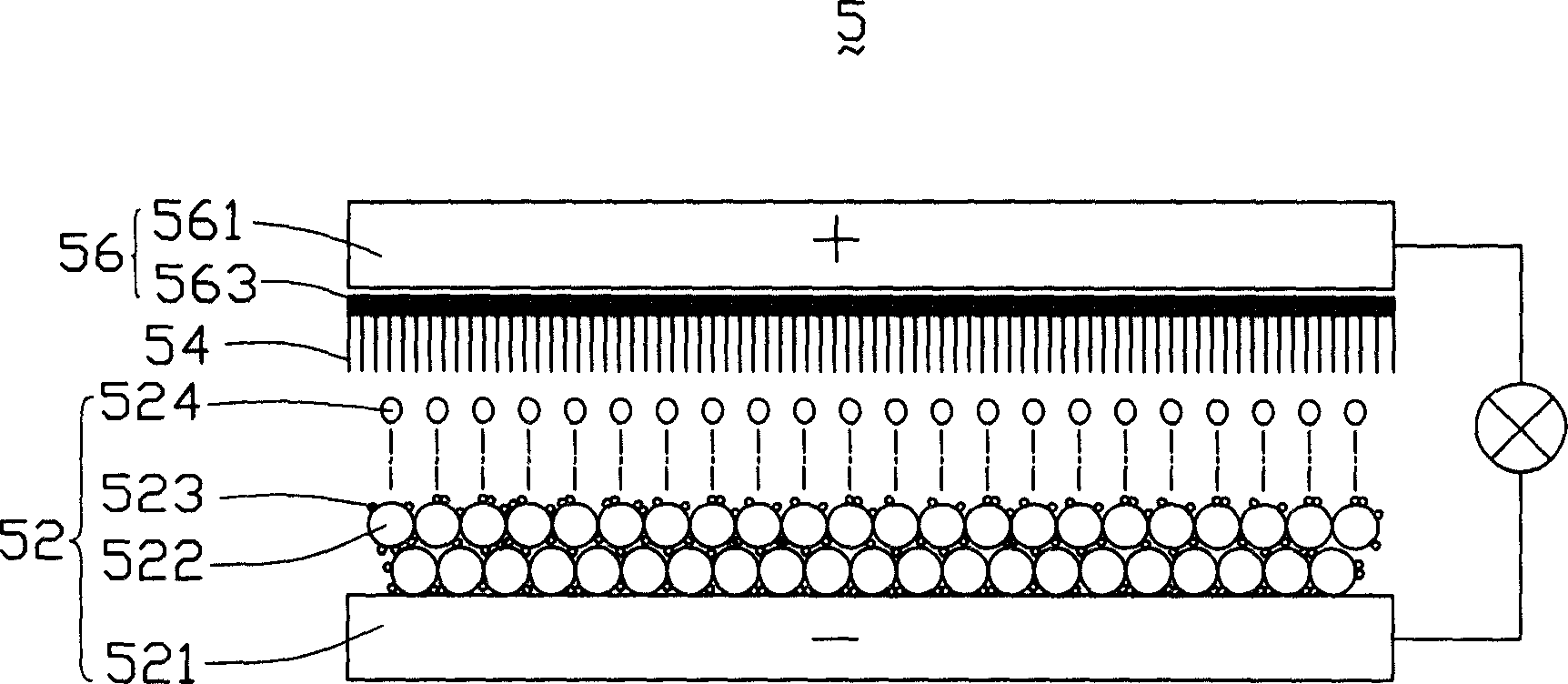

The invention discloses an electrode pole plate of a lithium ion battery. The electrode pole plate comprises a current collector and active substance coating layers, wherein the active substance coating layers are uniformly coated at two sides of the current collector, and grooves are symmetrically and uniformly formed in surfaces of the active substance coating layers at two sides. A thick pole plate with specially-shaped grooves in a surface are prepared, the electrolyte retention quantity in the battery can be remarkably increased, and long-term recycle of the battery is promoted; moreover, the specially-shaped grooves are uniformly formed in the surface of the thick pole plate, electrolyte penetration and diffusion are facilitated, and the rate charge-discharge electrochemical performance of the battery is improved; and meanwhile, the specially-shaped grooves are uniformly formed in the surface of the thick pole plate, thus, the specific area of the pole plate is expanded, the polarization current density of the battery during the charge-discharge process is reduced, a lithium precipitation risk of a large-current charging positive electrode separator is improved, and the application safety of the battery is improved.

Owner:欣旺达惠州动力新能源有限公司

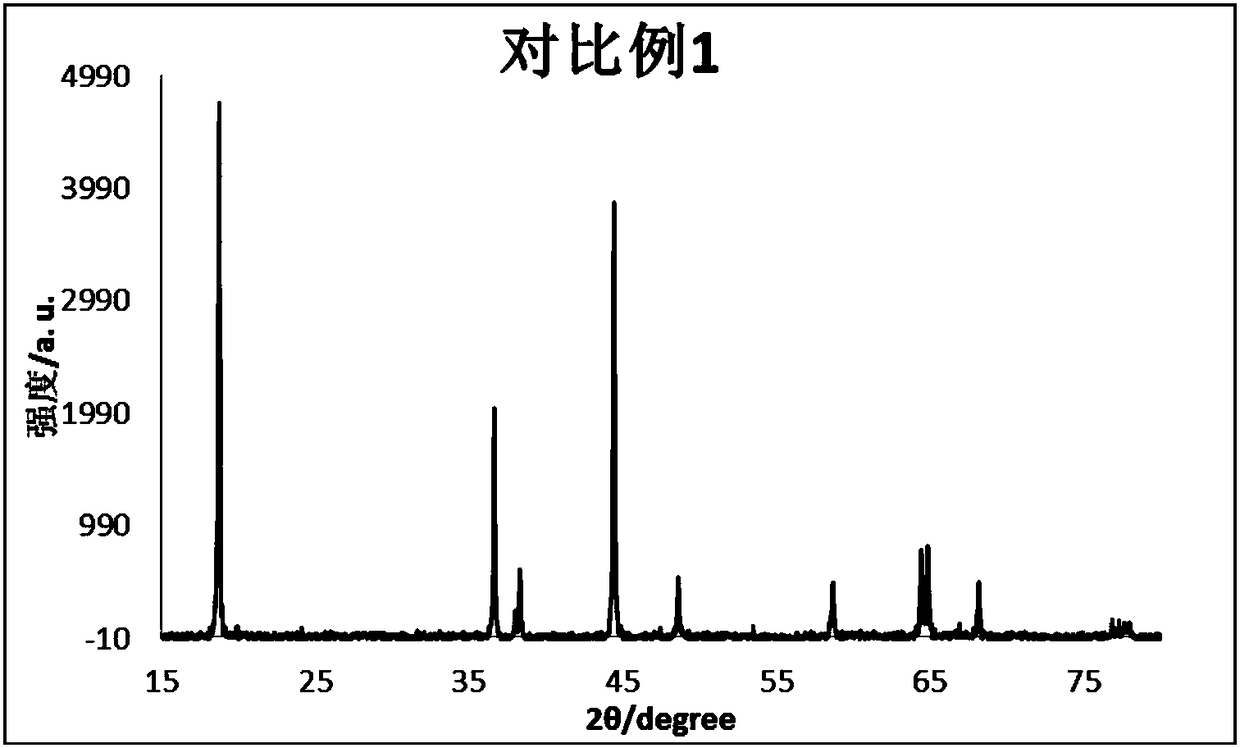

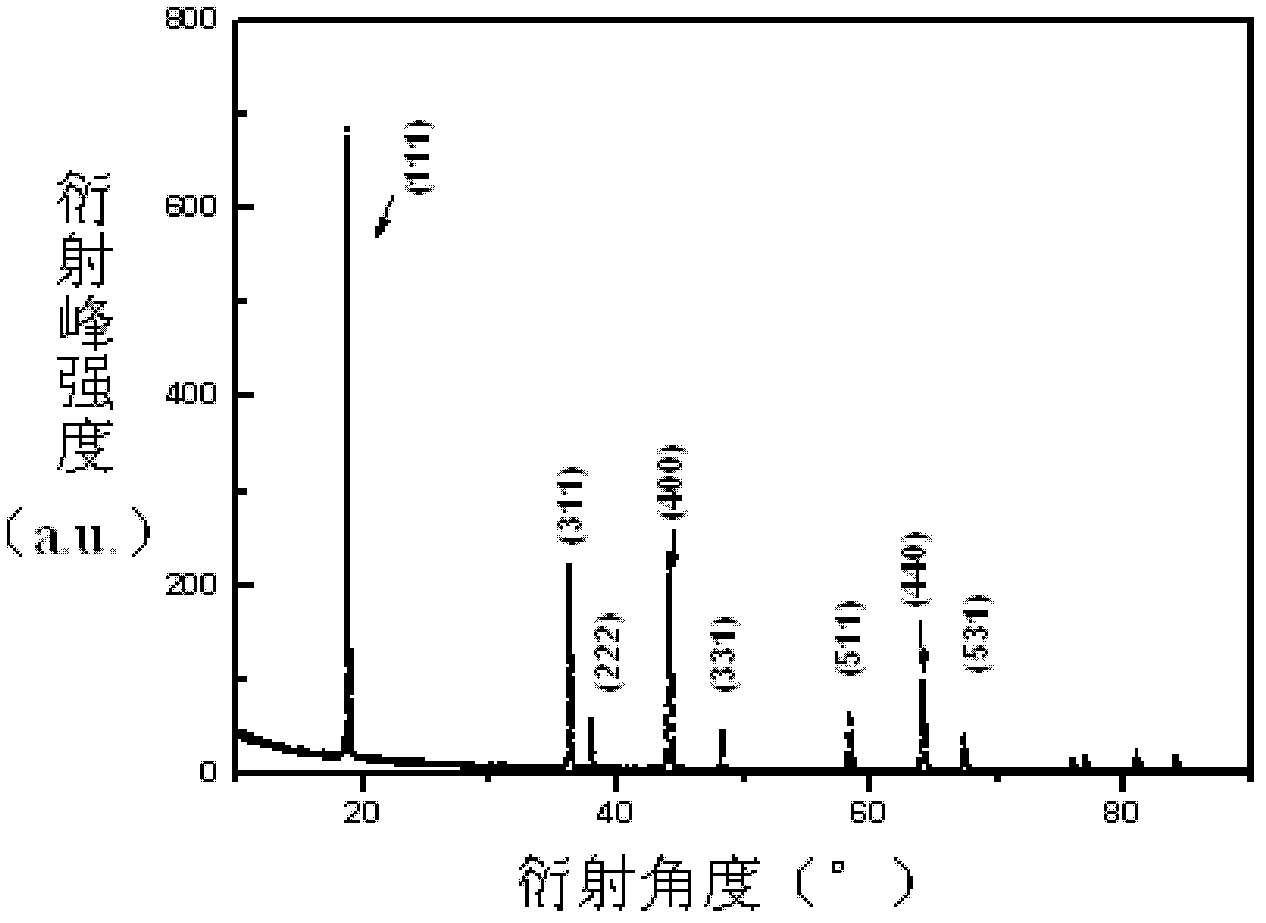

Cathode material of lithium ion battery and preparation method of cathode material

ActiveCN102683669ASmall specific surface areaGood high temperature cycle performanceCell electrodesManganesePhysical chemistry

The invention discloses a cathode material of a lithium ion battery. The cathode material has an atomic ratio of LiaMxMn(2-x)O(4-y)Zy. Primary particles of the cathode material of the lithium ion battery are substantially spherical, and the surface of each primary particle consists of 2 to 120 multilayer crystal dislocation frustums. The invention provides a preparation method of the cathode material of the lithium ion battery. The cathode material of the lithium ion battery is prepared by annealing, cooling and grinding a lithium manganate precursor in a roasting treatment mode of repeatedly changing roasting temperature. The invention has the advantages that by repeatedly changing the roasting temperature in the roasting process, the prepared cathode material of the lithium ion battery has a dislocation structure, and the mobility of ions and electrons from the inner part of the material to the outer part of the material is improved, and the magnification performance of a lithium manganate material is improved. Because the cathode material is substantially spherical, the specific surface area of the lithium manganate material is reduced, and manganese is difficult to dissolve, so the cathode material of the lithium ion battery is high in high-temperature cycle performance.

Owner:宁波富理电池材料科技有限公司

Composite negative electrode of solid-state lithium battery and preparation method of composite negative electrode

PendingCN108110217AImprove wettabilityUniform depositionVapour deposition manufacturingSolid state electrolyteMolten state

The invention relates to the technical field of lithium batteries and in particular relates to a composite negative electrode of a solid-state lithium battery and a preparation method of the compositenegative electrode. The composite negative electrode of the solid-state lithium battery comprises a solid-state electrolyte thin film layer and a lithium negative electrode layer, wherein the lithiumnegative electrode layer comprises a lithium metal negative electrode material; the lithium metal negative electrode material is combined on the solid-state electrolyte thin film layer at a molten state to form the lithium negative electrode layer. The lithium metal negative electrode material is combined on the solid-state electrolyte thin film layer at the molten state to form the lithium negative electrode layer; the wetting performance between the lithium negative electrode layer and the solid-state electrolyte thin film layer can be improved very well and the formation of lithium dendritic crystals is inhibited very well; the safety performance of the lithium battery with a negative electrode structure is improved; meanwhile, the interface impedance between the lithium negative electrode layer and the solid-state electrolyte thin film layer is reduced very well, the migration rate of conductive ions between the lithium negative electrode layer and the solid-state electrolyte thinfilm layer is improved and the conductivity of the lithium negative electrode layer is improved.

Owner:成都大超科技有限公司

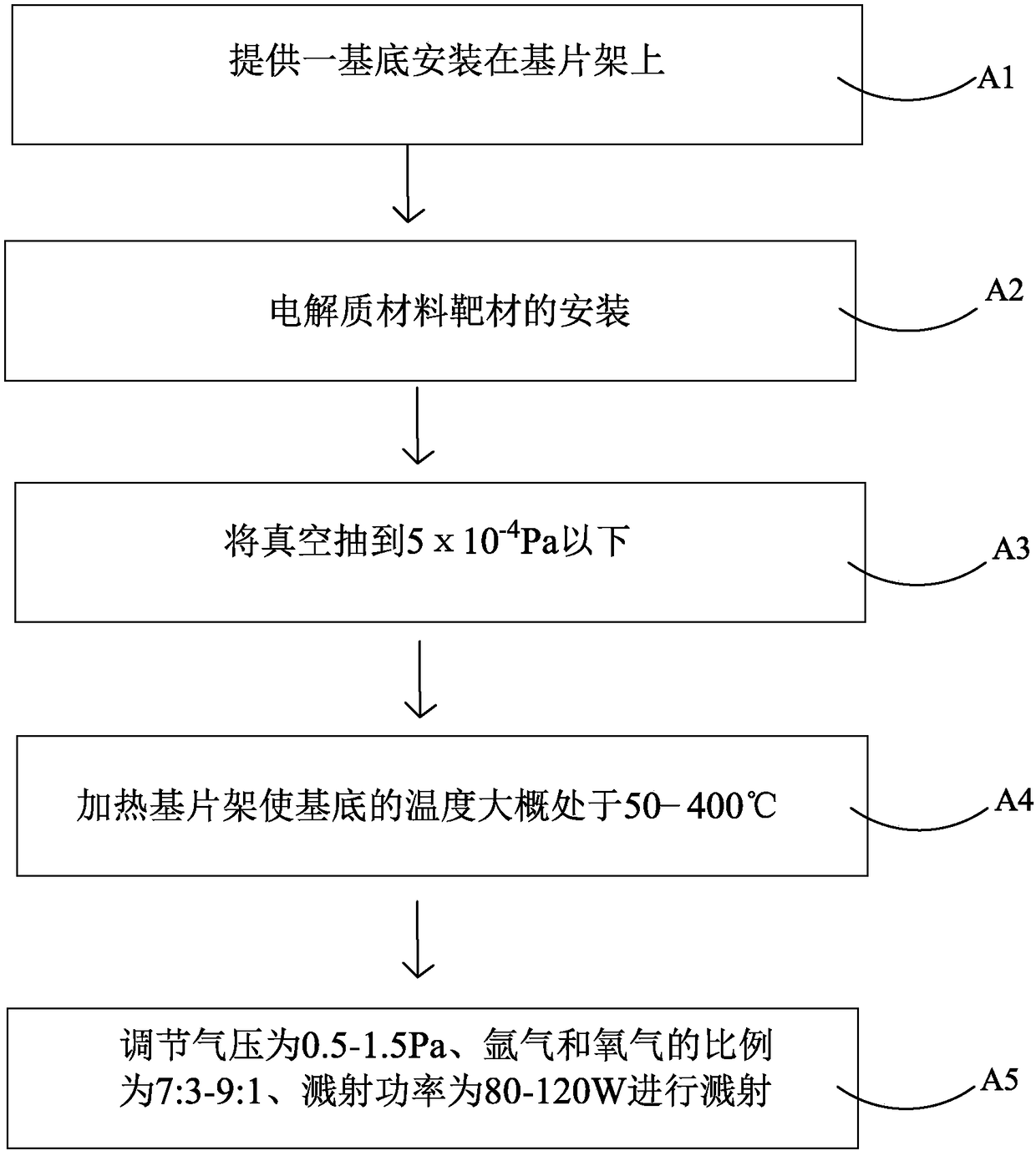

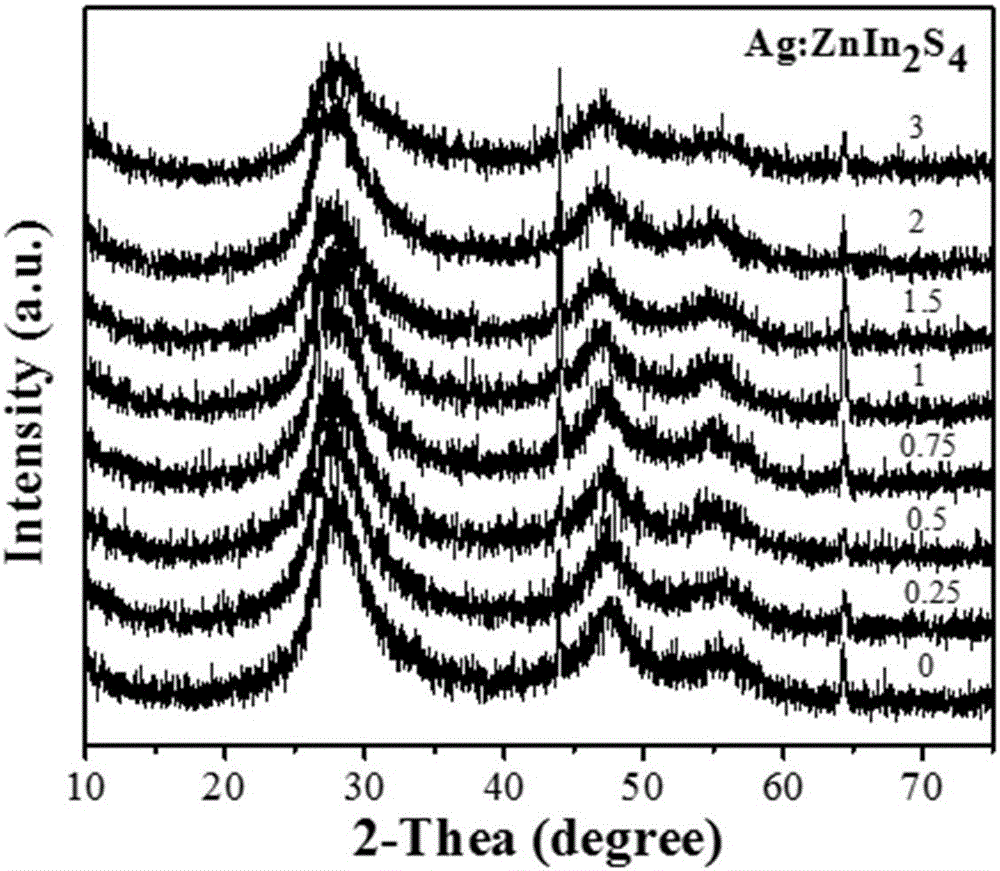

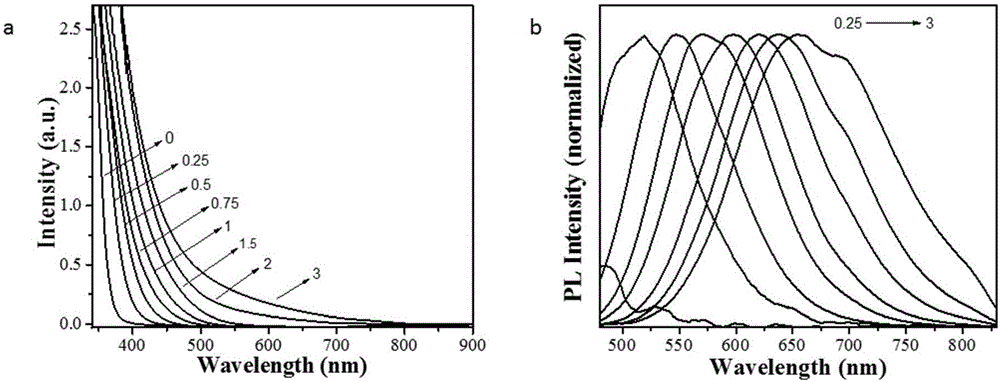

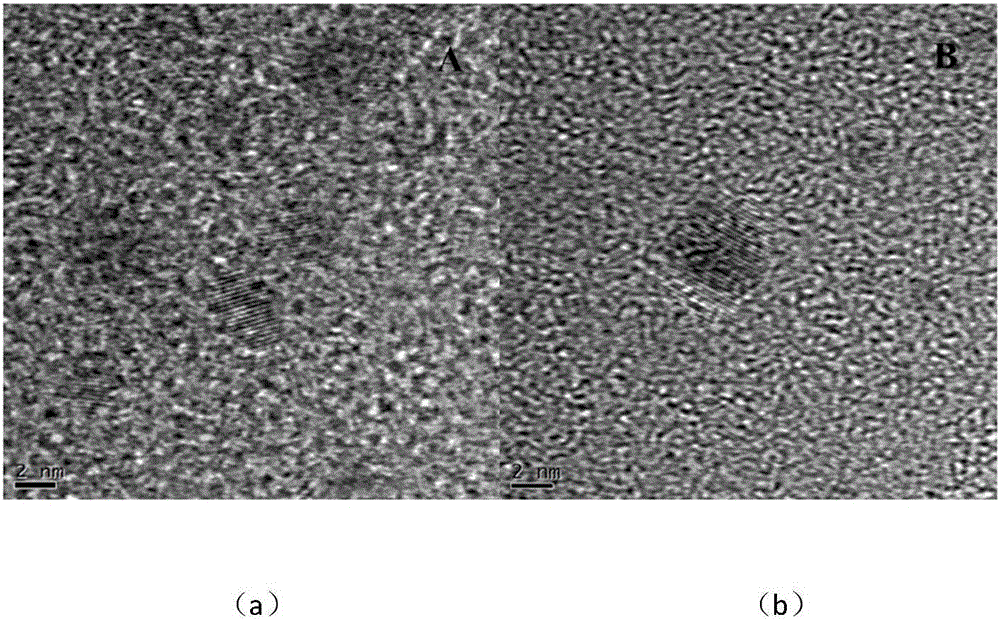

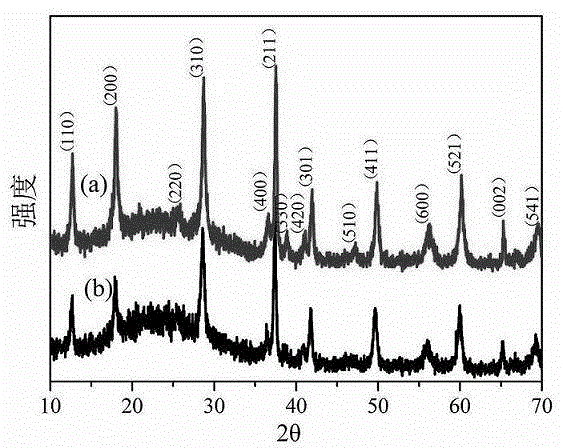

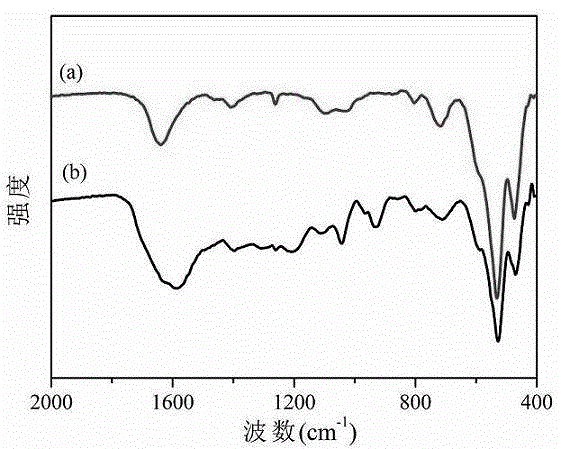

Method for preparing Ag:ZnIn2S4 luminescent quantum dots and photocatalyst

InactiveCN105950140AFully crystallizedGood dispersionMaterial nanotechnologyPhysical/chemical process catalystsFluorescenceZinc Acetate Dihydrate

The invention relates to the field of synthesis of nano-materials and particularly relates to a method for synthesizing a series of Ag:ZnIn2S4 luminescent quantum dots by using a simple and rapid hydrothermal method in one step. Fluorescence is adjustable in the range of 460nm to 830nm, the fluorescent life is relatively long, and the luminescent quantum dots can be applied to water-decomposed hydrogen production under visible light. The method comprises the steps of firstly, mixing and dissolving silver nitrate, indium nitrate, zinc acetate dihydrate and L-cysteine in an aqueous solution, adjusting the pH value of the solution to 8.5 by using NaOH, adding thioacetamide into the solution, carrying out ultrasonic stirring, then, carrying out a hydrothermal reaction for 4 hours at the temperature of 110 DEG C, and carrying out centrifugal drying after the reaction ends, thereby obtaining Ag@ZnIn2S4 nanocrystals of different ratios. Proven by a photocatalytic hydrogen production experiment under the visible light, the prepared composite photocatalyst has good photocatalytic activity.

Owner:JIANGSU UNIV

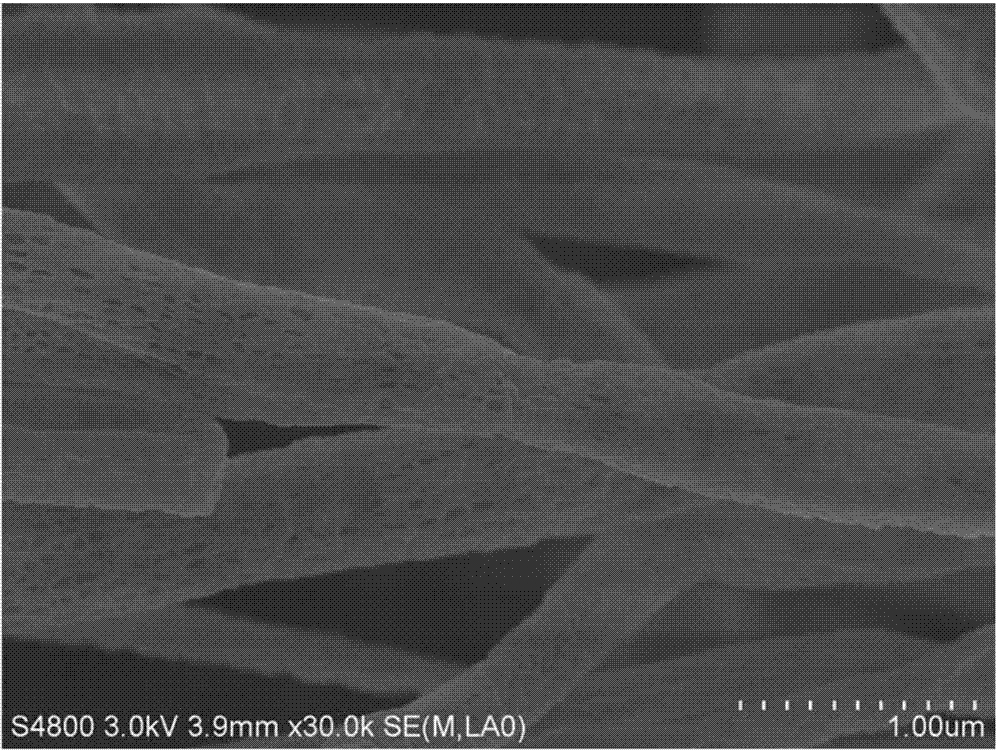

Method for preparing polyimide porous nanofiber electrode diaphragm

ActiveCN104752665AImprove stabilityHigh mechanical strengthHybrid capacitor separatorsCell component detailsMetal oxide nanoparticlesAcid anhydride formation

The invention discloses a method for preparing a polyimide porous nanofiber electrode diaphragm. The method comprises the following steps: carrying out condensation reaction by adopting binary organic amine and binary organic acid anhydride in an organic solvent, thereby obtaining a polyamide acid solution; adding a soluble metal salt to prepare a spinning precursor, preparing a polyamide acid-metal salt electrostatic spinning fiber diaphragm by virtue of high-voltage electrostatic spinning, and performing thermal imidization treatment, thereby obtaining a polyimide-metallic oxide fiber composite diaphragm; and dissolving the composite diaphragm in an inorganic acid aqueous solution for performing acid treatment, so that metallic oxide nanoparticles are converted into soluble metal salts so as to be dissolved in the inorganic acid aqueous solution so as to obtain the polyimide nano / micron porous fiber diaphragm. The method has the advantages that according to the polyimide nano / micron porous fiber diaphragm, the mechanical strength, thermal stability, liquid holdup, permeability, wettability and migration rate of conductive ions of the diaphragm can be effectively improved, and the liquid junction resistance of the diaphragm and electrolyte and the contact resistance of the diaphragm and the electrode can be reduced, so that the electrochemical performance of a supercapacitor is improved.

Owner:锦州凯美能源有限公司

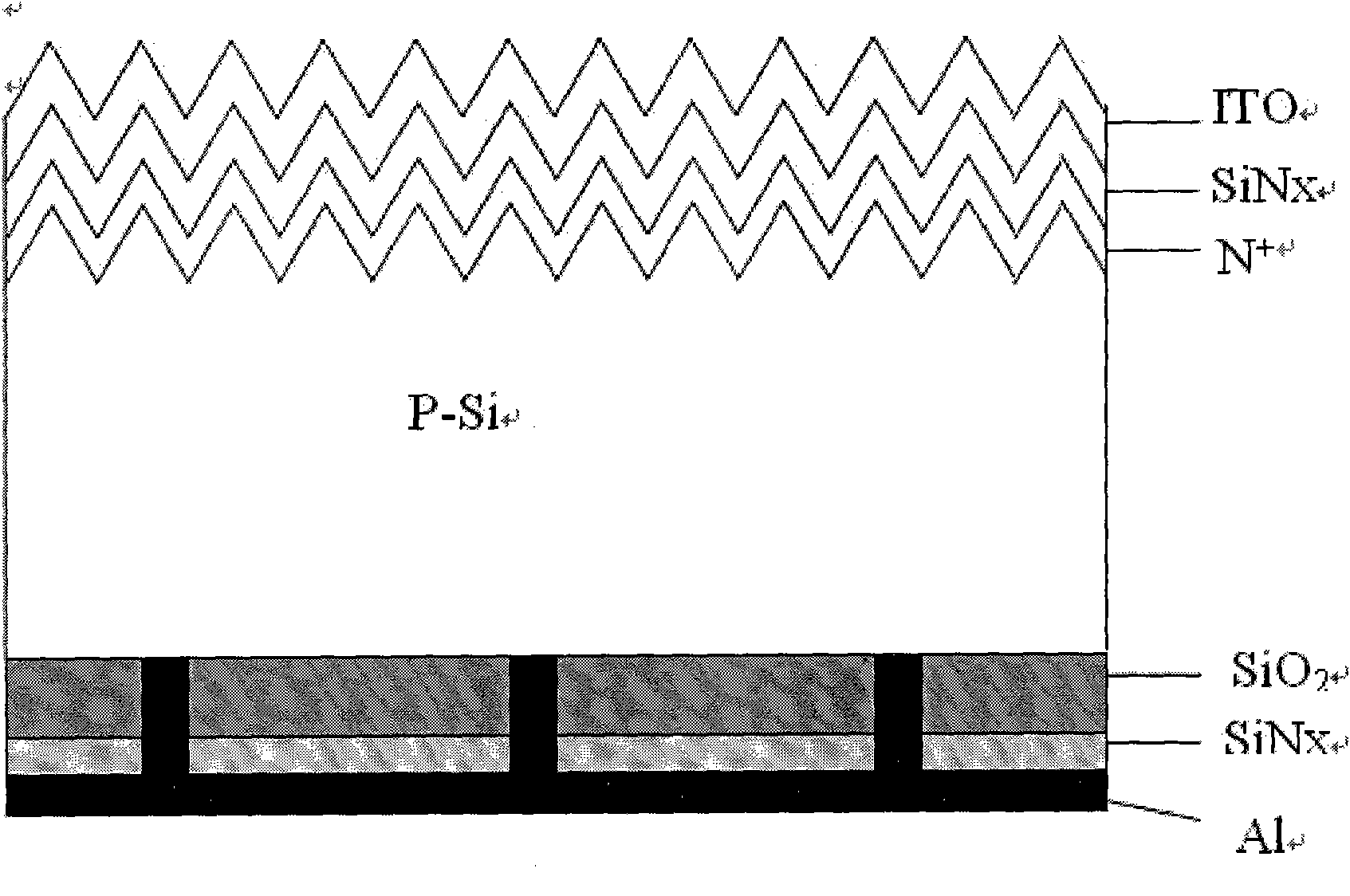

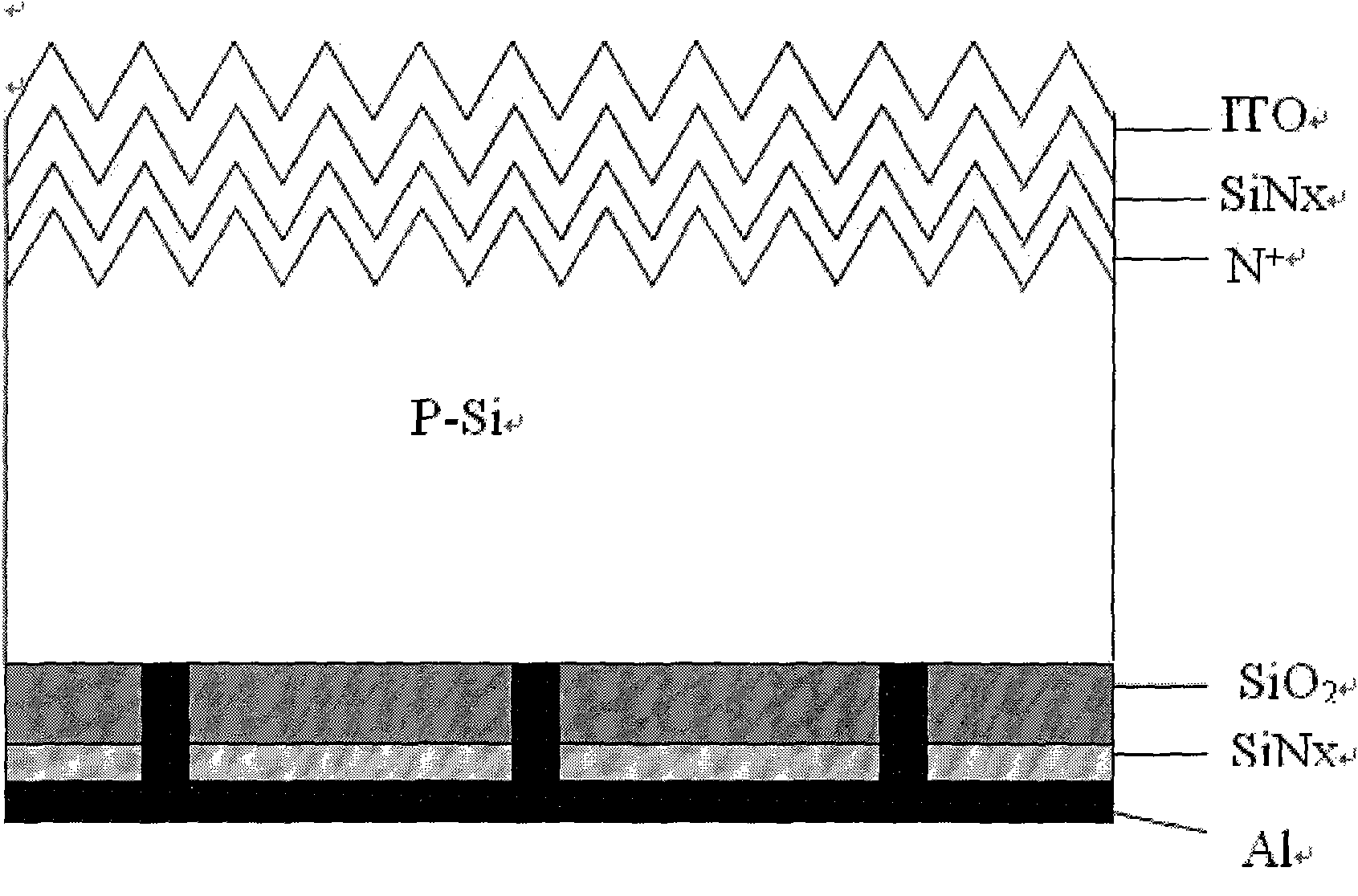

Preparation method of solar cell with buried charge layer

ActiveCN101882650AIncrease short circuit currentAvoid churnFinal product manufactureSemiconductor devicesCharge layerElectrode Contact

The invention relates to a monocrystalline silicon solar cell and a preparation method thereof, in particular to a monocrystalline silicon solar cell with a buried charge layer introduced into a passivating dielectric layer, and belongs to the technical field of the preparation of solar cell devices. The monocrystalline silicon solar cell is developed based on the preparation scheme of the general monocrystalline silicon solar cell and adopts a structure of partial back contact, and the preparation method is characterized by comprising the steps of: growing an SiO2 layer on the back of a solar cell by utilizing a thermal oxidation or atomic layer deposition technology, growing a layer of SiNx thin film by using PECVD (Plasma Enhanced Chemical Vapor Deposition), etching a back electrode contact area by using a laser grooving technology, then injecting electrons with a corona mode, and finally depositing an Al electrode with a vacuum evaporation mode. The invention can effectively improve the solar cell efficiency.

Owner:南通东湖国际商务服务有限公司

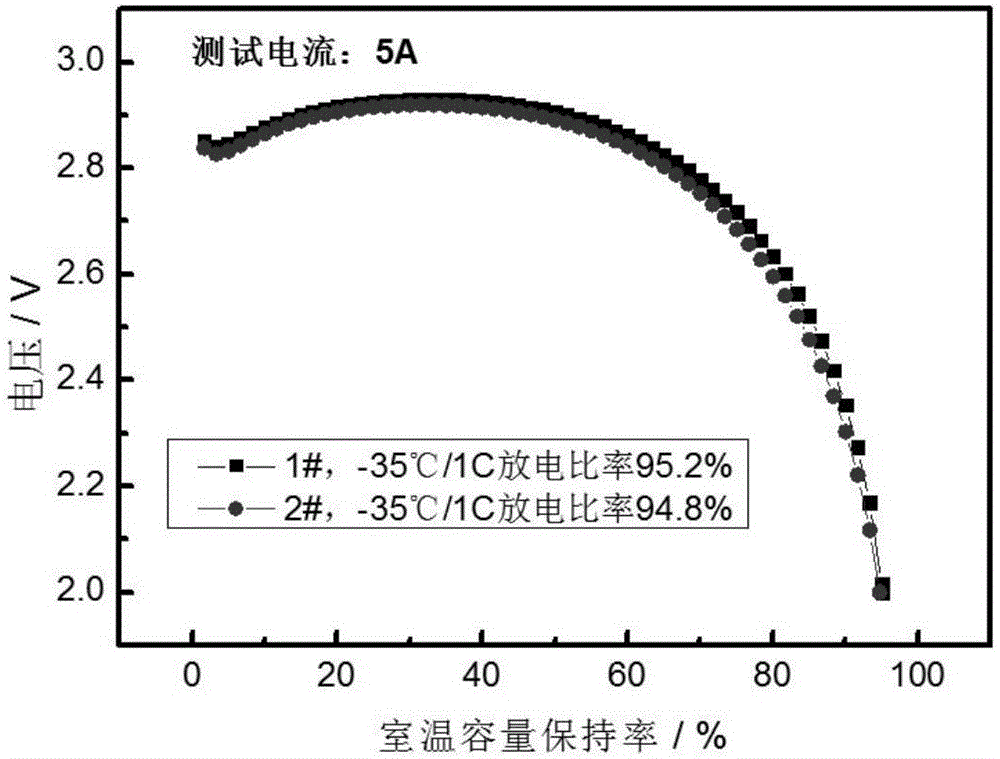

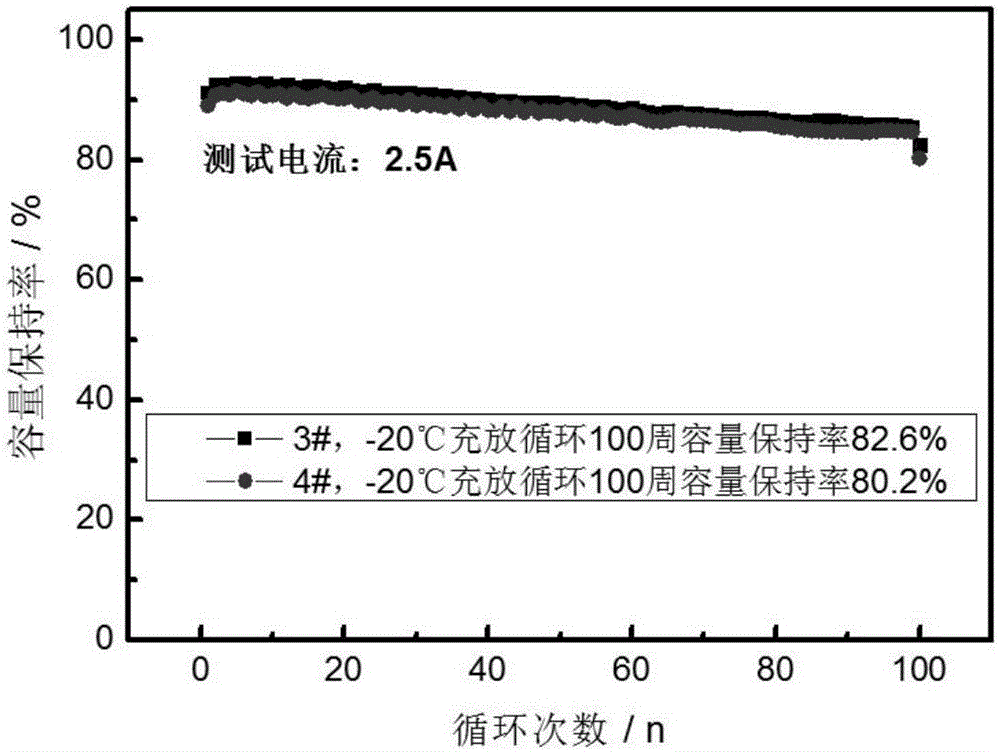

Ultralow temperature lithium iron phosphate power battery and preparation method thereof

InactiveCN106299291AEffective dispersionIncrease migration rateFinal product manufactureCell electrodesPower batteryLithium iron phosphate

The invention provides an ultralow temperature lithium iron phosphate power battery. The ultralow temperature lithium iron phosphate power battery comprises a cathode plate, an anode plate, a diaphragm and a low-temperature electrolyte. The cathode plate comprises a cathode collector piece and nano lithium iron phosphate cathode slurry with which the cathode collector piece is coated. The nano lithium iron phosphate cathode slurry is prepared through the high-speed dispersion process that a glue solution and an active-matter-containing component are beaten separately, in other words, the glue solution and the active-matter-containing component are separately prepared. The glue solution is prepared according to a certain proportion; the active-matter-containing cathode powder raw material and a solvent are mixed according to a certain proportion and dispersed uniformly at high speed to form cathode premixed slurry; the prepared glue solution is added into the cathode premixed slurry step by step, by means of the stirring mode in which revolution and high-speed autorotation are combined, the glue solution and the cathode premixed slurry are fully mixed, stirred and dispersed uniformly, and then the cathode slurry is obtained. The anode plate comprises an anode collector piece and modified graphite anode slurry with which the anode collector piece is coated. The electrolyte is prepared from lithium salt, a solvent and an additive.

Owner:OPTIMUM BATTERY CO LTD

Composite solid polymer electrolyte film and preparation method and application thereof

InactiveCN109546207AReduce the degree of crystallizationHigh mechanical strengthSolid electrolytesSecondary cellsSlurryElectrochemistry

A composite solid polymer electrolyte film and a preparation method and an application thereof are provided. The preparation method includes the following steps: dissolving a polymer in an organic solvent, and stirring the solution evenly after ultrasonic dispersion; adding lithium salt, nano-ceramic particles, ionic liquid and plasticizer, and stirring the mixed solution evenly to form slurry; applying the slurry to a glass plate to form a liquid film; and drying the liquid film to obtain a composite solid polymer electrolyte film. The composite solid polymer electrolyte film of the inventionhas high room-temperature ionic conductivity and mechanical strength, is prepared through a simple process and can be mass-produced. Moreover, the composite solid polymer electrolyte film of the invention has good electrochemical performance when applied to lithium ion batteries.

Owner:XI AN JIAOTONG UNIV

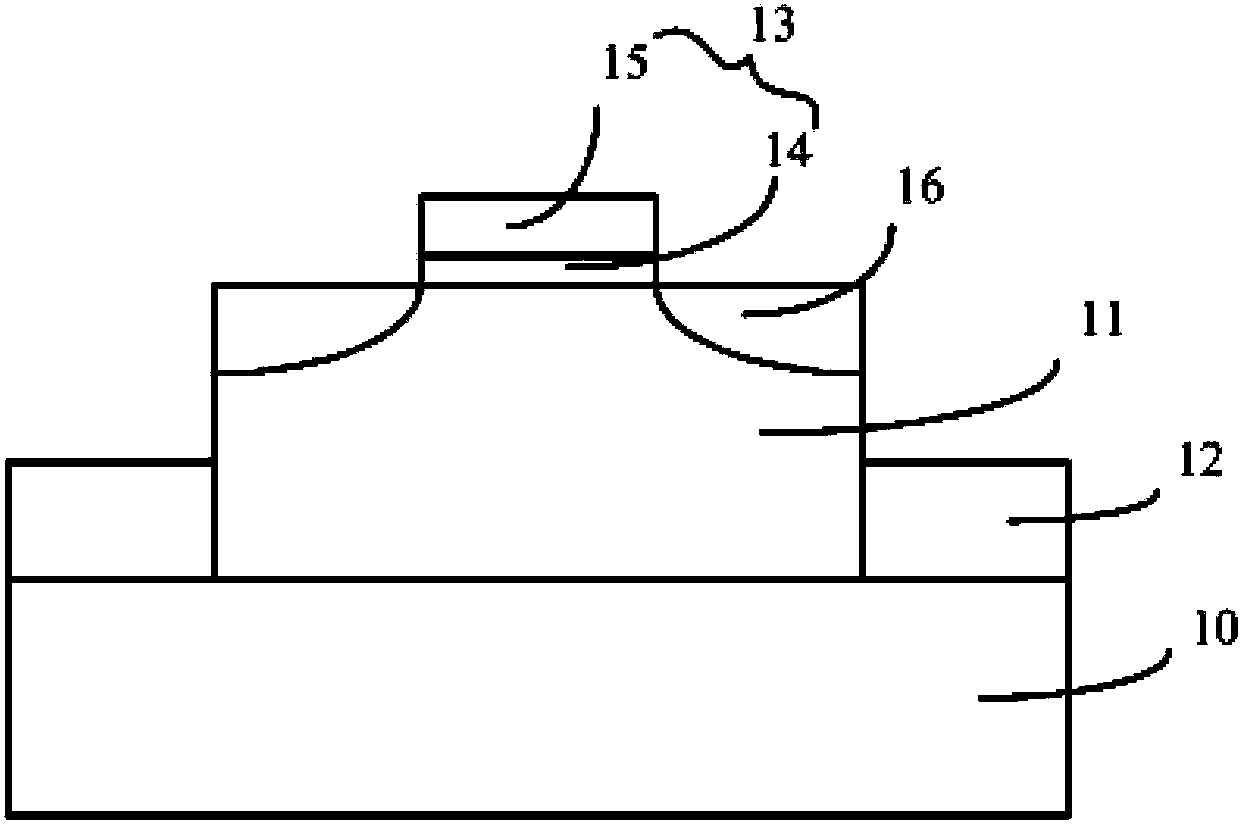

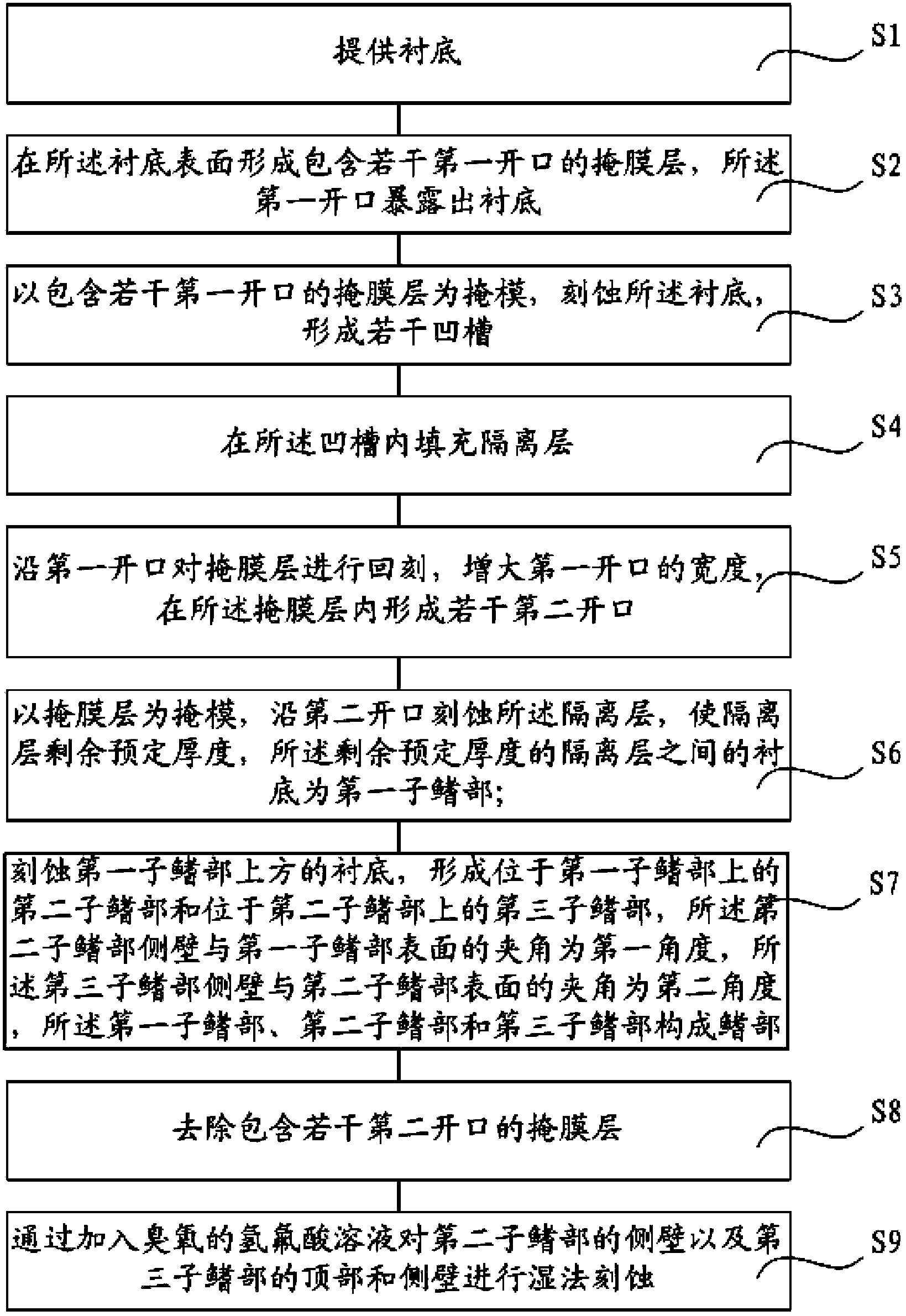

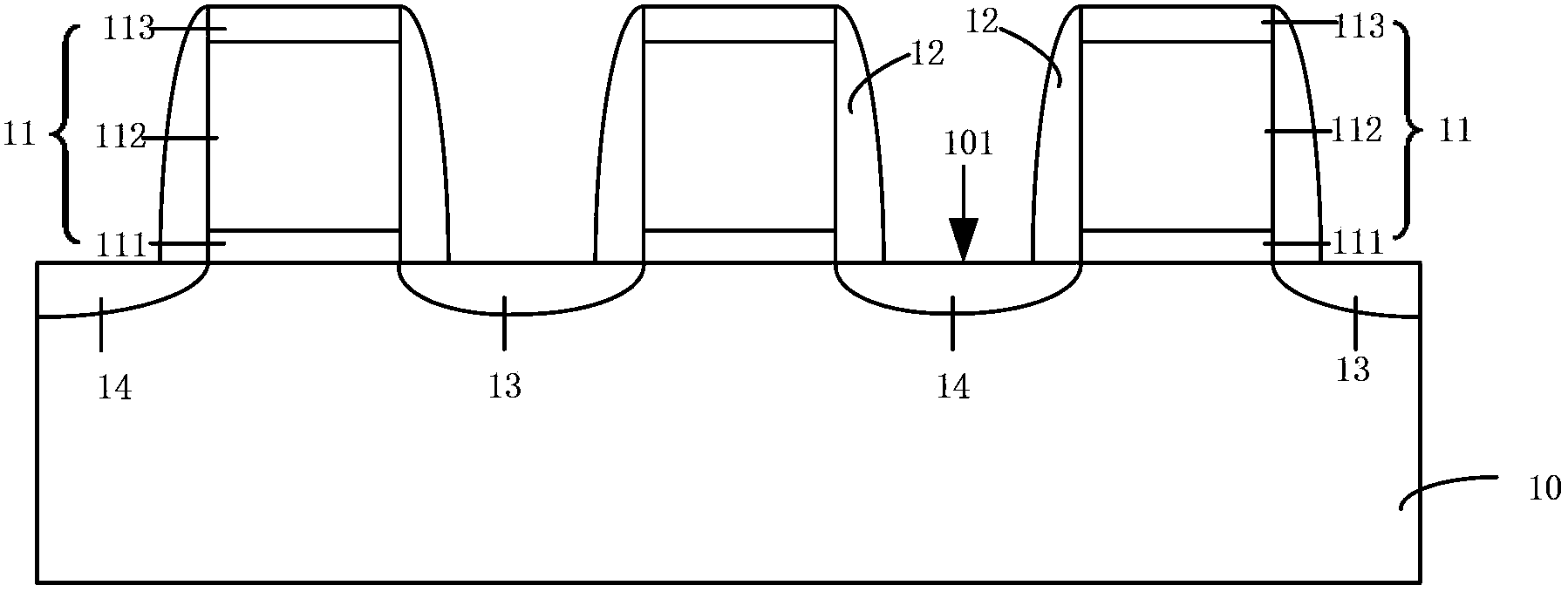

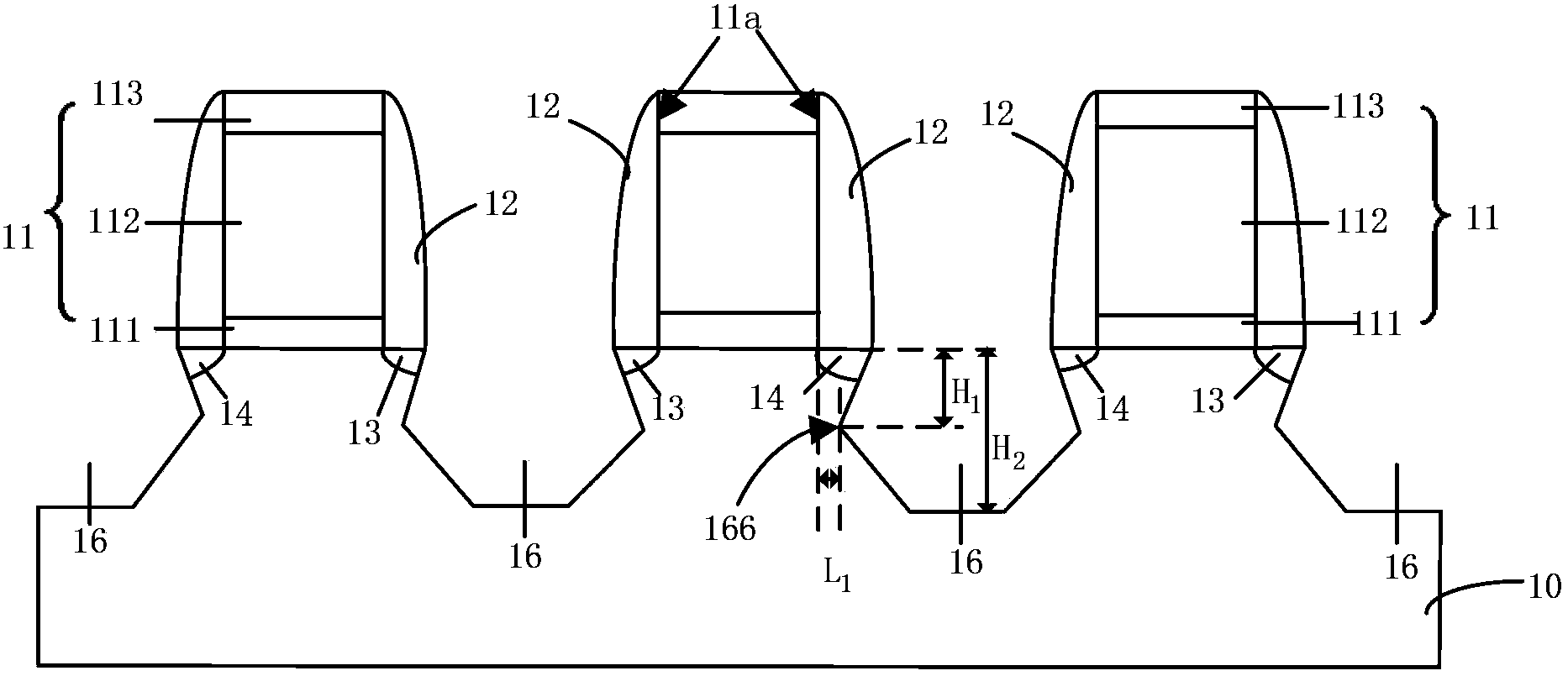

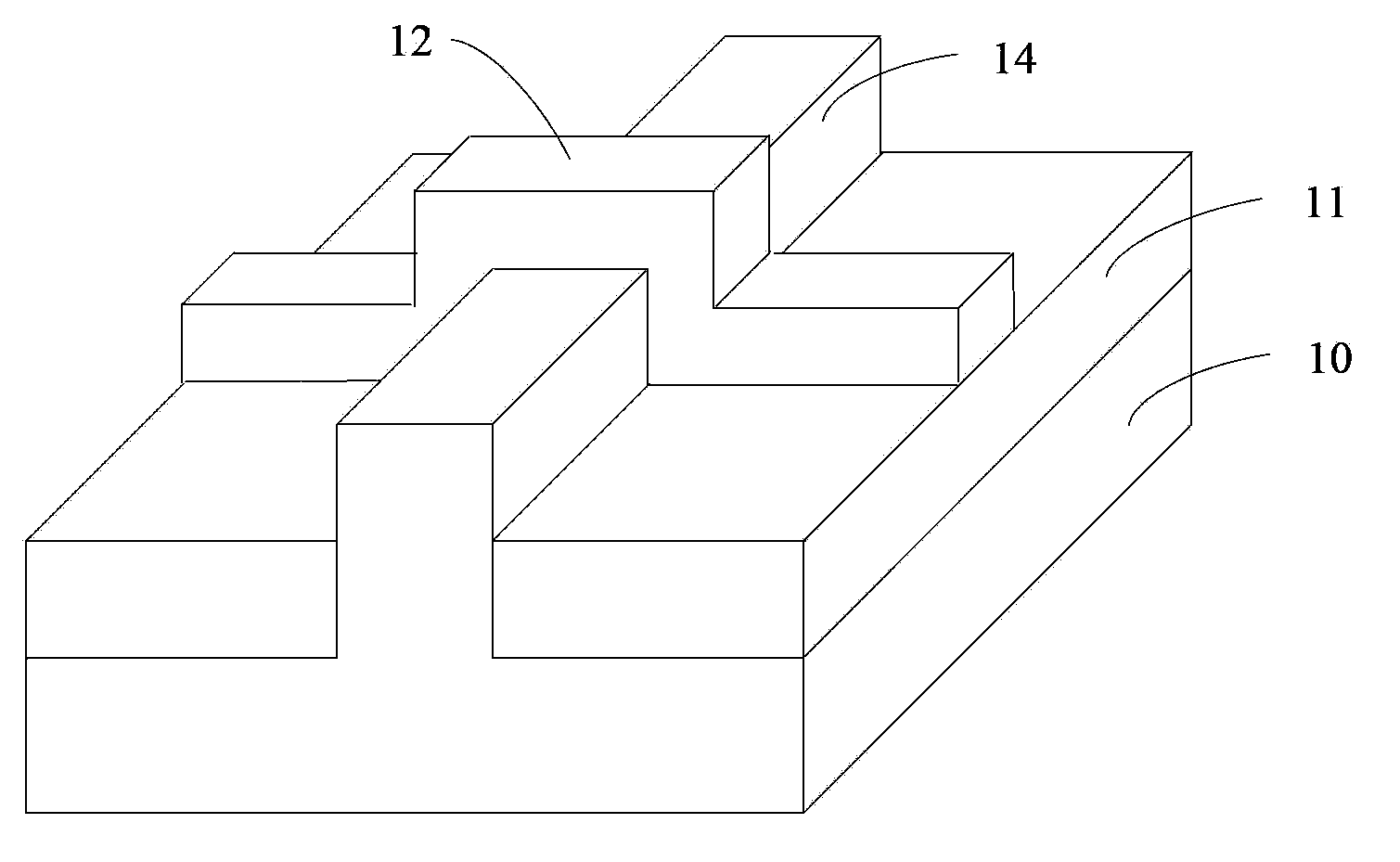

Fin part and finned-type field-effect transistor and forming method thereof

ActiveCN103578988APromote formationIncrease migration rateSemiconductor/solid-state device manufacturingSemiconductor devicesInsulation layerField-effect transistor

The invention discloses a fin part and a finned-type field-effect transistor and a forming method of the fin part and the finned-type field-effect transistor. The forming method of the fin part includes the steps that a substrate is provided; mask layers provided with multiple first openings are formed on the surface of the substrate, and the first openings are exposed out of the substrate; the substrate is etched with the mask layers provided with the first openings as a mask, so that multiple grooves are formed; insulation layers are filled into the grooves; the mask layers are etched back along the first openings, the width of the first openings is increased, and multiple second openings are formed in the mask layers; insulation layers are etched along the second openings with the mask layers as a mask so that the insulation layers can remain with a preset certain thickness, and the substrate among the remaining insulation layers with the preset thickness serves as first auxiliary fin parts; the substrate above the first auxiliary fin parts is etched to form second auxiliary fin parts located on the first auxiliary fin parts and third auxiliary fin parts located on the second auxiliary fin parts. According to the fin part and the finned-type field-effect transistor and the forming method of the fin part and the finned-type field-effect transistor, stability of the finned-type field-effect transistor is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

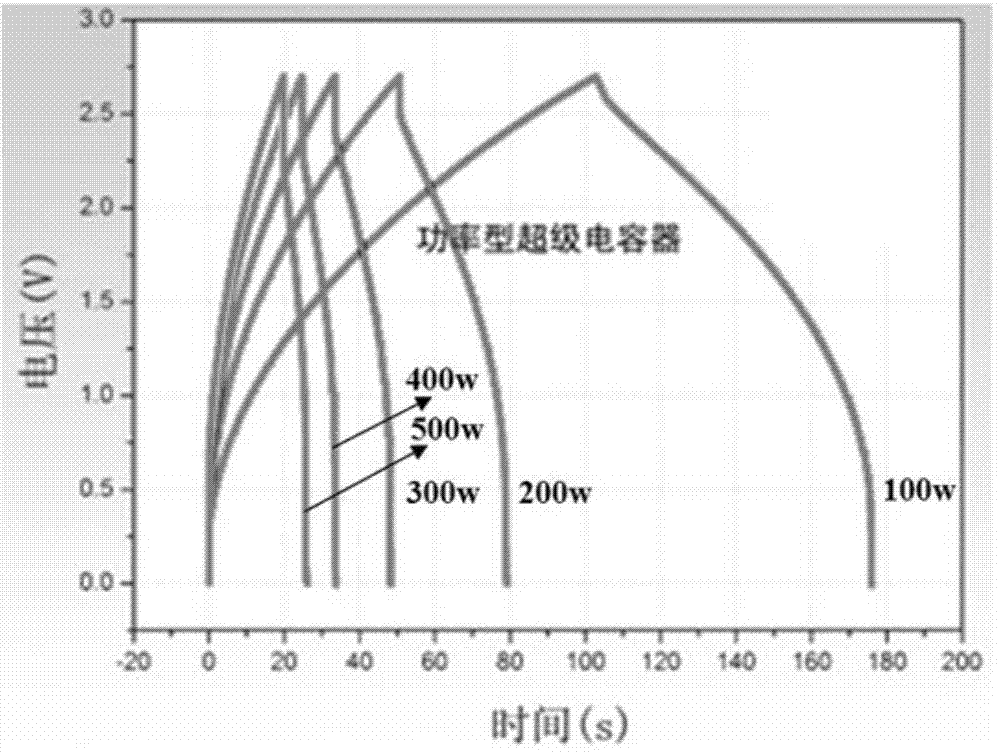

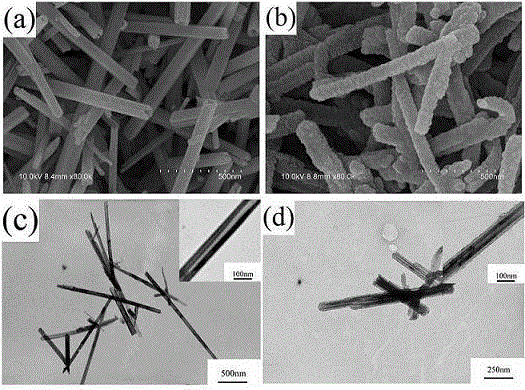

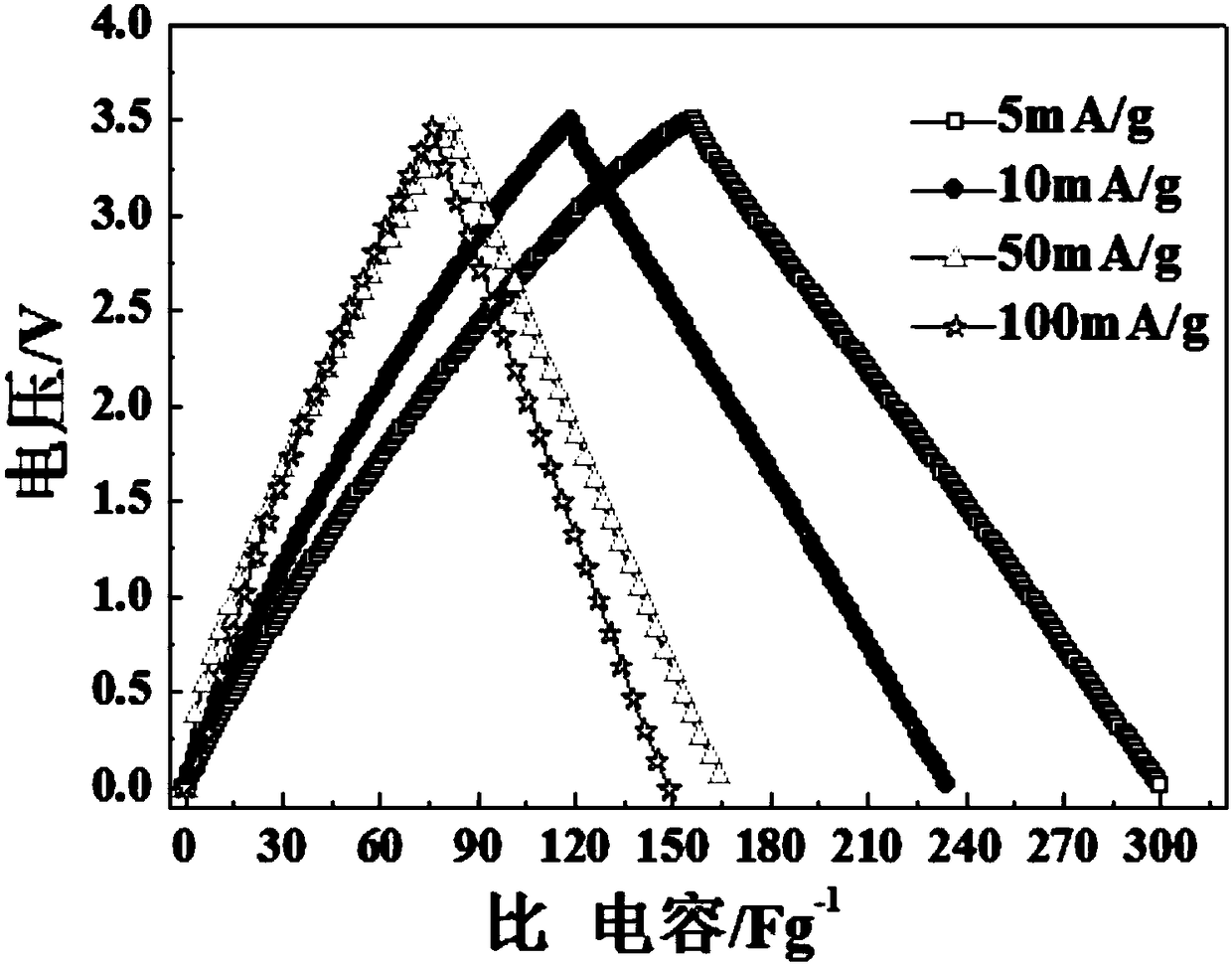

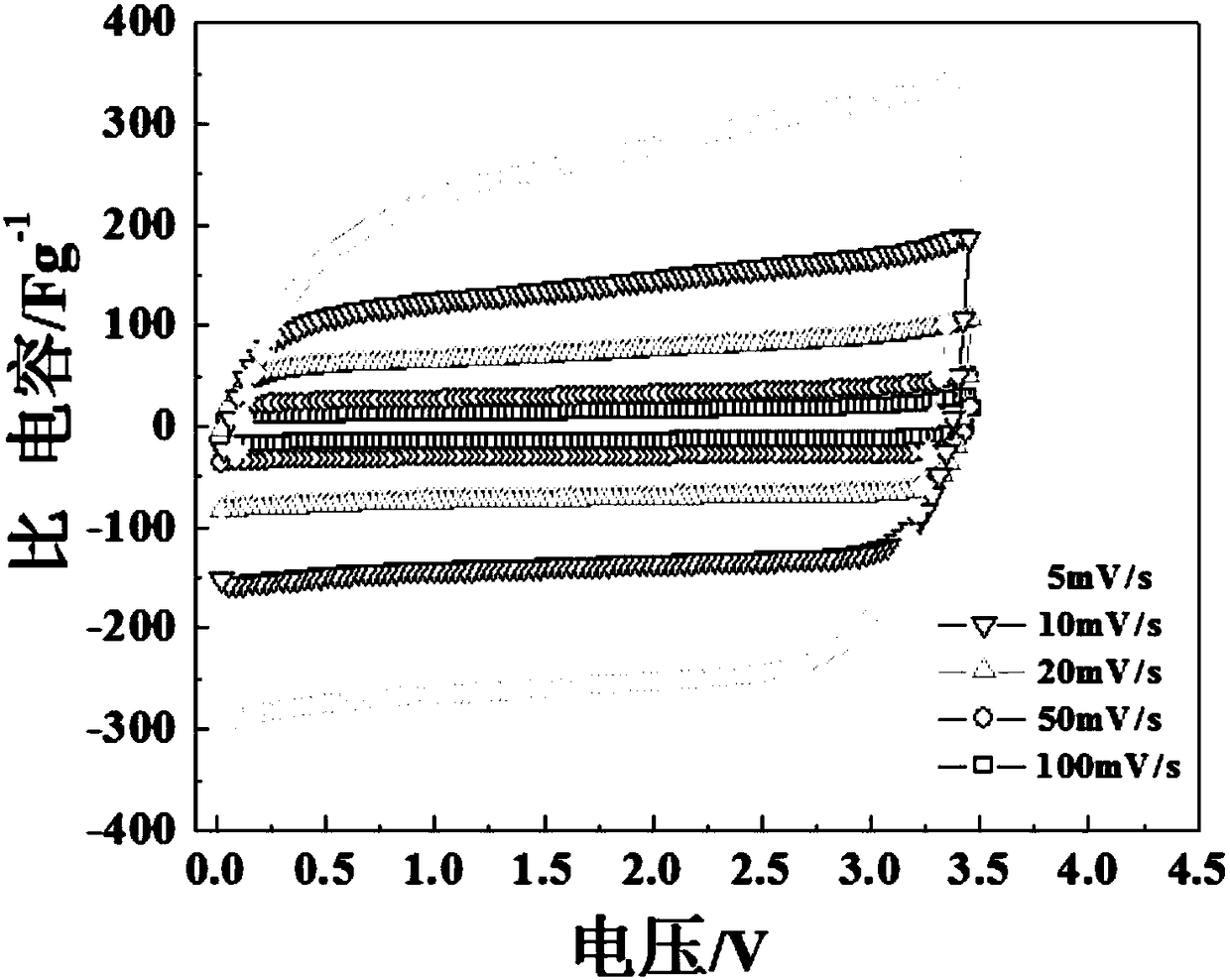

High-specific-capacitance manganese-dioxide conducting polymer composite electrode material with core-shell structure and manufacturing method thereof

InactiveCN103151179AAct as a skeletonHigh specific capacitanceHybrid capacitor electrodesHybrid/EDL manufactureCapacitancePolypyrrole

The invention discloses a manganese-dioxide conducting polymer composite electrode material with a core-shell structure. The manganese-dioxide conducting polymer composite electrode material adopts a manganese-dioxide nano material as a core, adopts conducting polymer as a shell and is a composite nano material with the core-shell structure; the manganese-dioxide nano material is nano balls, nano rods, nano wires or nano tubes; and polyaniline, polypyrrole, polythiophene or poly(3,4-ethylenedioxythiophene) is used as the conducting polymer of the shell, the mass fraction of the manganese dioxide in the composite material is 5-95%, and the mass fraction of the conducting high polymer is 95-5%. The manganese-dioxide conducting polymer composite electrode material disclosed by the invention has the advantages that due to the conducting polymer component, the conductivity of the composite material is increased, and the migration rate of electrons in the charging and discharging process are accelerated, so that the specific capacitance of the composite electrode material is increased; the nano manganese dioxide plays a role in a skeleton, so that the damage of the microstructure of the conducting polymer in the charging and discharging process is avoided, and the cyclic life of the electrode material is greatly prolonged; and the conducting polymer and the nano manganese dioxide both play roles in storing charges. The invention discloses a manufacturing method of the electrode material.

Owner:NANJING UNIV

Lithium ion battery negative electrode MOF material and application thereof

ActiveCN107732248AHigh lithium storage capacityWith lithium storage performanceNon-aqueous electrolyte accumulator electrodesLithiumHigh energy

The invention discloses a lithium ion battery negative electrode MOF material. The MOF material disclosed by the invention is prepared by reacting porphyrin or porphyrin derivative of the porphyrin with transition metal or a transition metal cluster through a solvent thermal or wet chemistry method. When the MOF material is utilized as a lithium ion battery negative electrode material, the MOF material has a series of advantages of high specific capacity, long cycle life, outstanding rate capability and the like. Theoretical calculation proves that an active site of the action between the MOFmaterial disclosed by the invention and metal lithium has excellent performance, and the MOF material can be applied to developing high energy density lithium ion batteries.

Owner:南京铁鸣能源科技有限公司

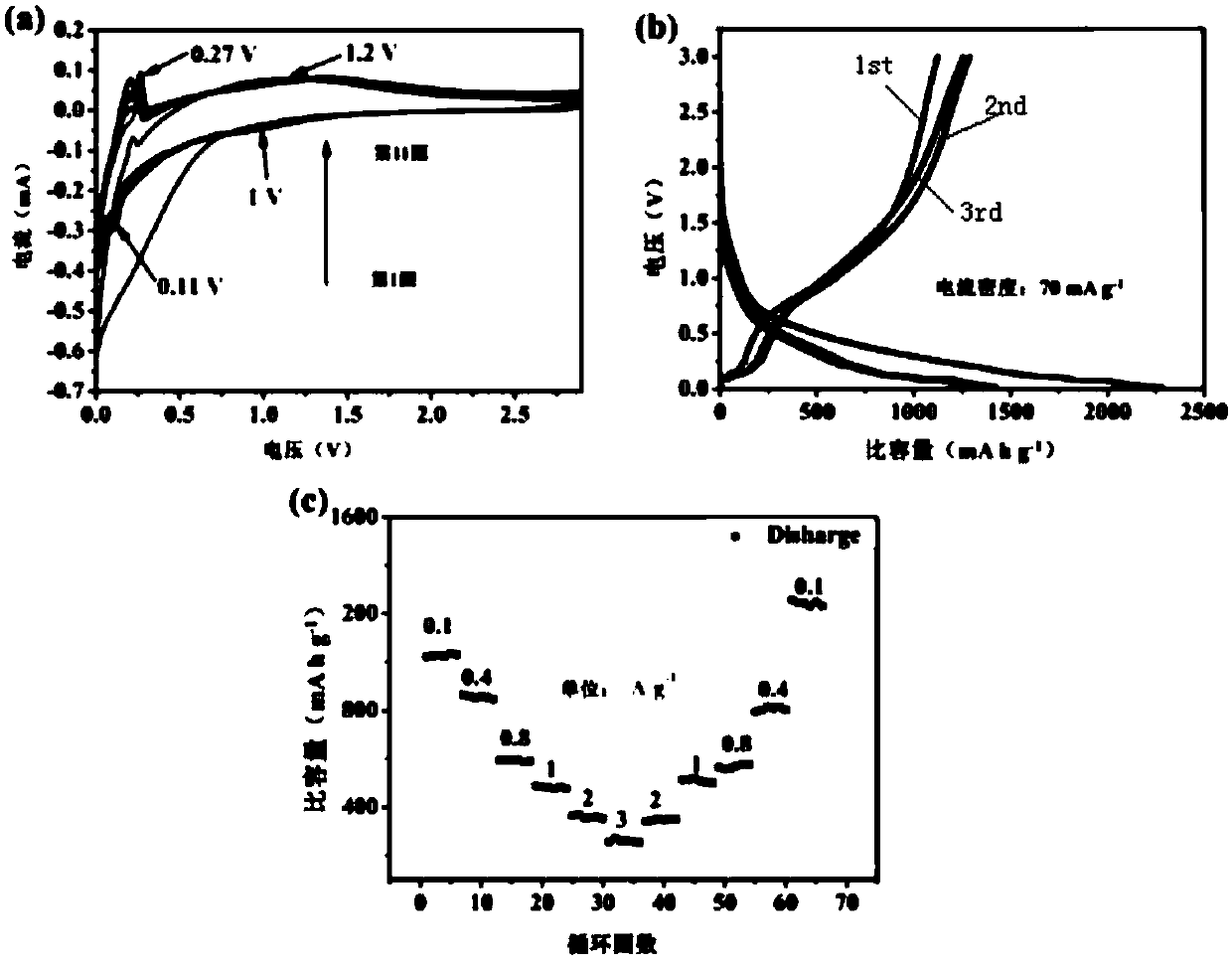

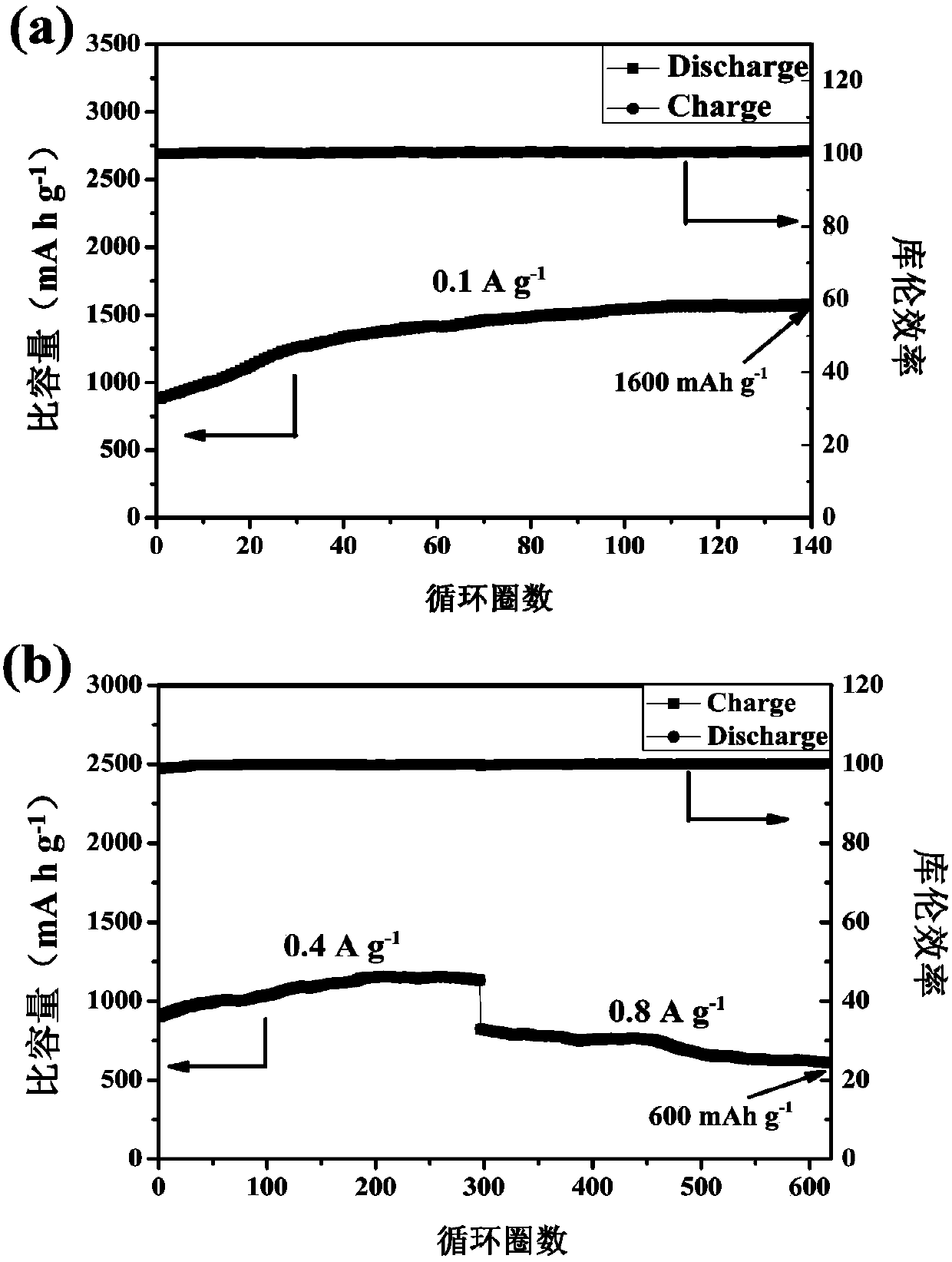

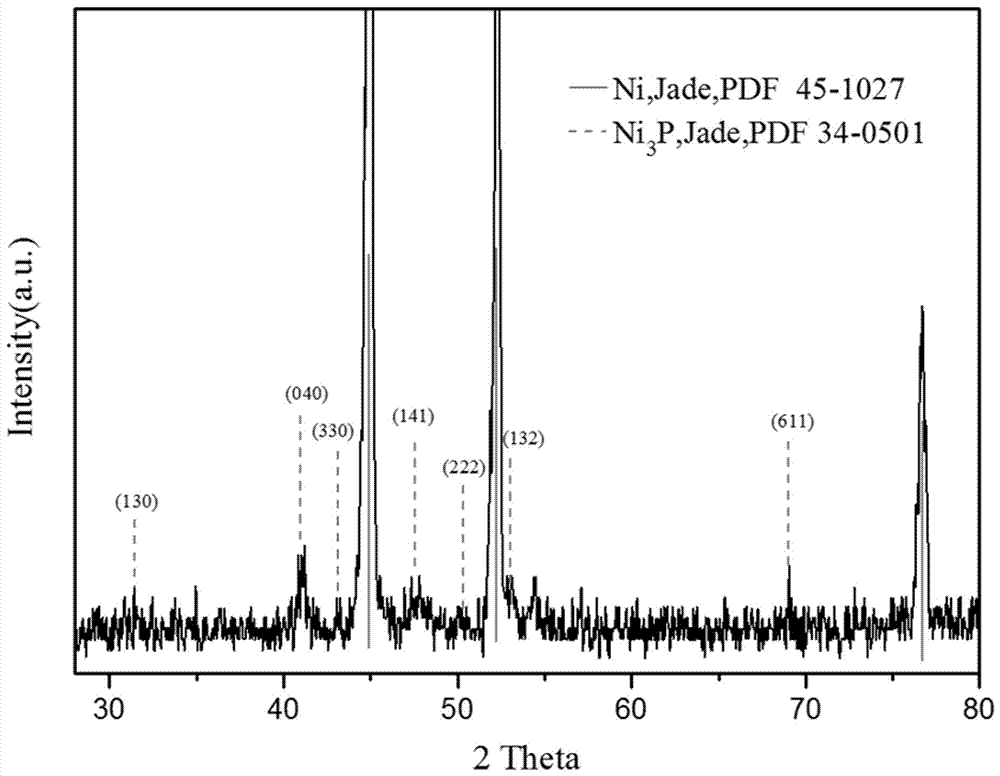

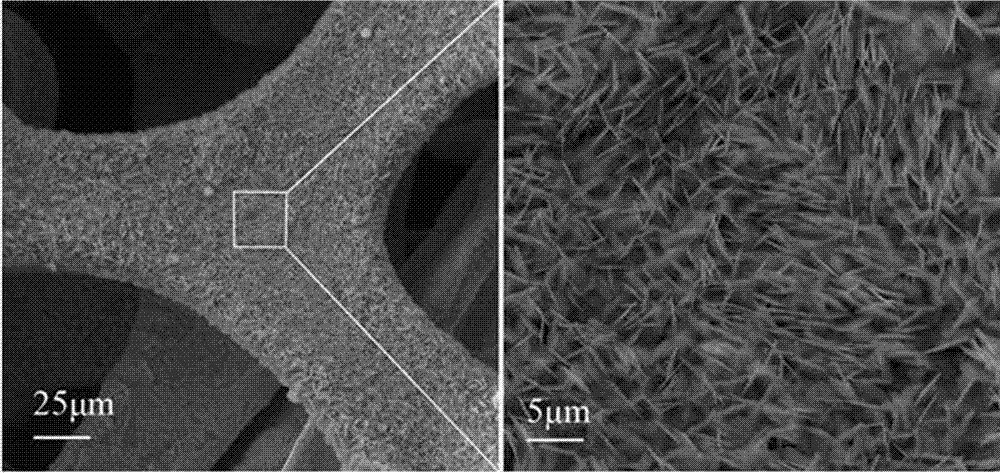

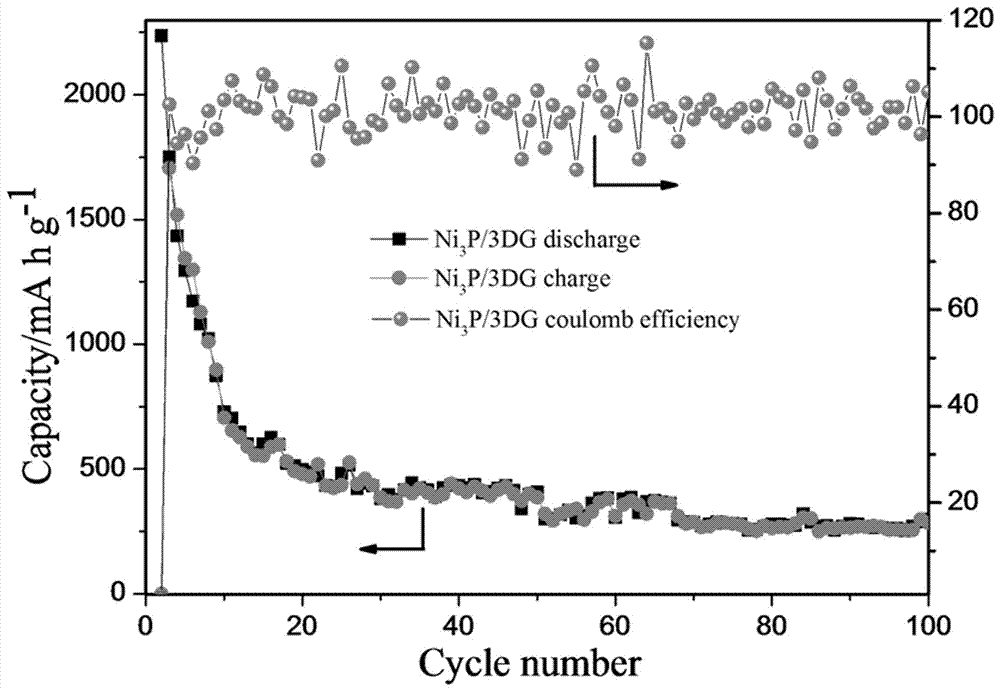

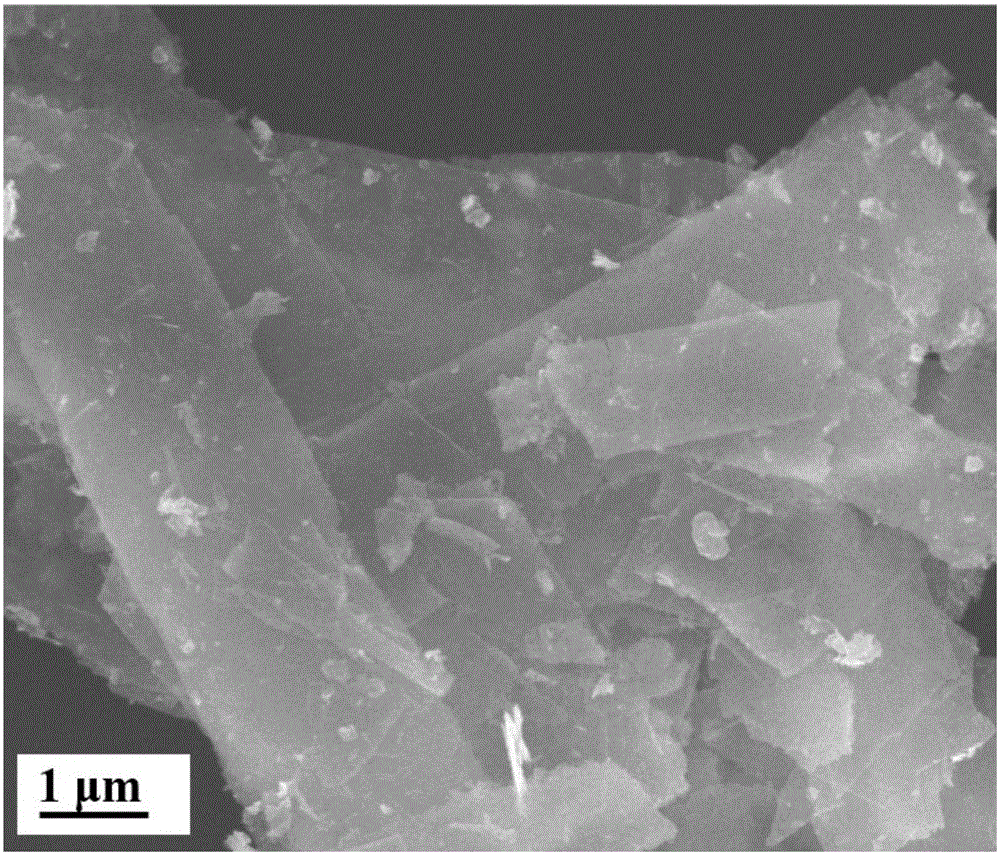

Sodium ion battery nanosheet array nickel phosphide/three-dimensional (3D) graphene composite material and preparation method thereof

ActiveCN107331851AImprove cycle stabilityImproved magnification performanceMaterial nanotechnologyCell electrodesSodium-ion batteryInorganic phosphorus

The invention discloses a sodium ion battery nanosheet array nickel phosphide / three-dimensional (3D) graphene composite material and a preparation method thereof. The preparation method comprises the steps of preparing 3D graphene by using foam nickel and a chemical vapor deposition (CVD) method, enabling the 3D graphene and deionized water having a pH value of 3 to be subjected to a hydrothermal reaction, and generating an Ni(OH)2 nanosheet array structure on a foam nickel substrate loaded with the 3D graphene; respectively placing nanosheet array Ni(OH)2 / 3D graphene composite material and a phosphorus source at the two ends of a tube furnace, heating the tube furnace, replenishing one end of the tube furnace, where the inorganic phosphorus source is placed, with flowing inert gas, and carrying out heat treatment; cooling the product of the reaction to room temperature to obtain the nanosheet array nickel phosphide / 3D graphene composite material. The whole preparation method provided by the invention is simple and environmentally-friendly; nickel phosphide is compounded with the 3D graphene, so that the material performance is improved; when the composite material is used as a self-supported sodium ion battery anode material, a conductive additive is not needed; the sodium ion battery nanosheet array nickel phosphide / 3D graphene composite material has high specific capacity and good rate performance, thus having a wide industrial application prospect.

Owner:TAIYUAN UNIV OF TECH

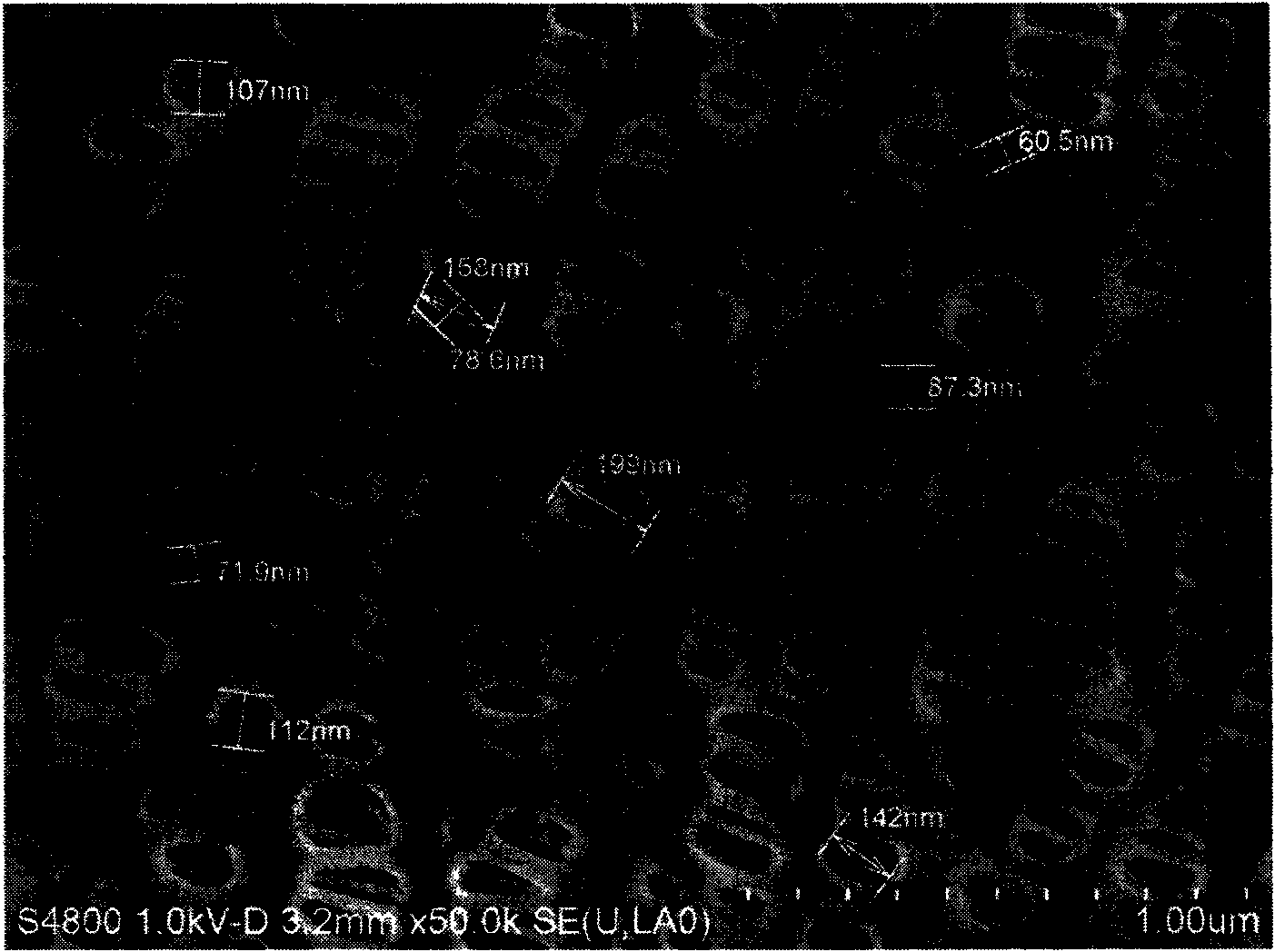

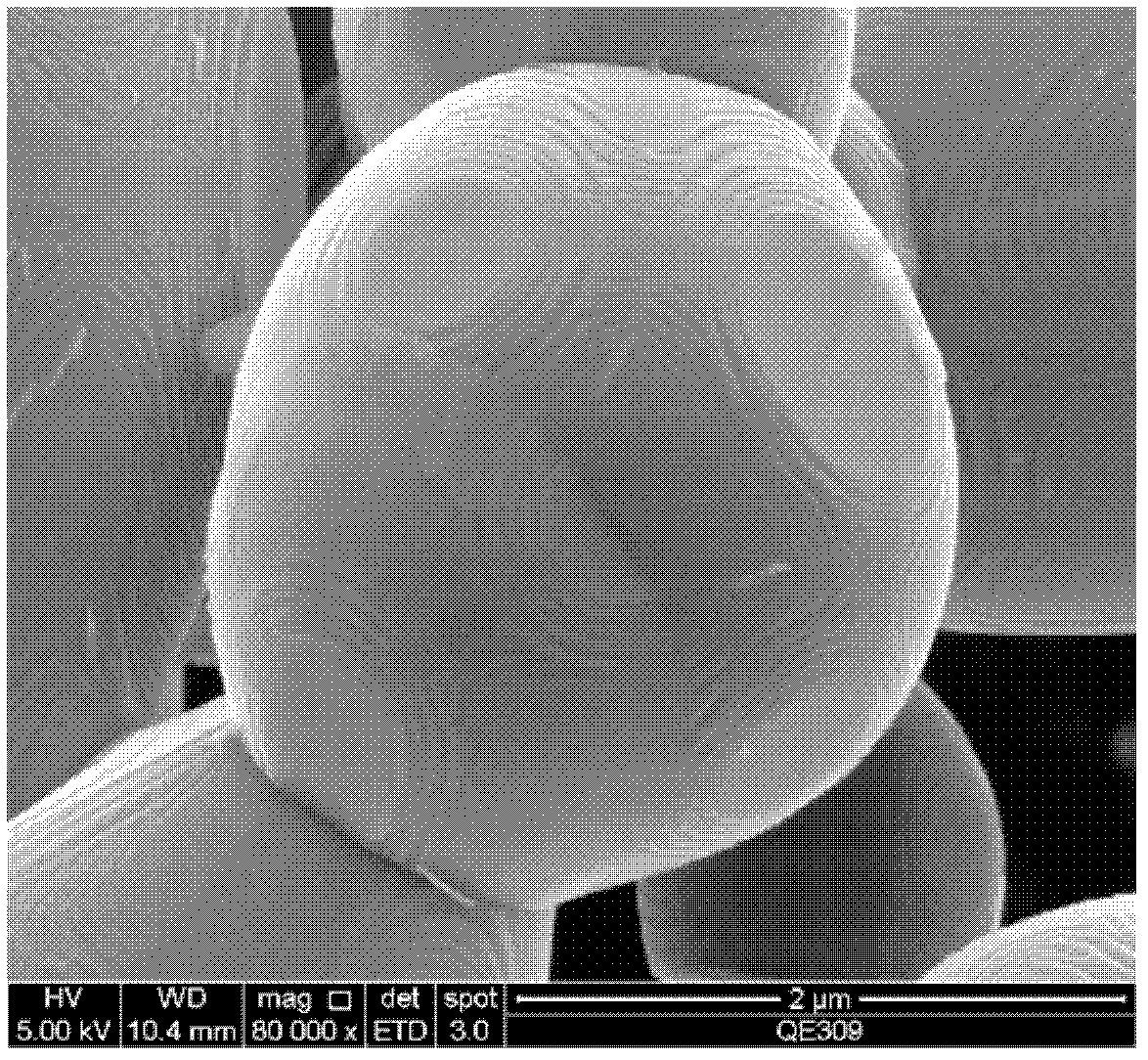

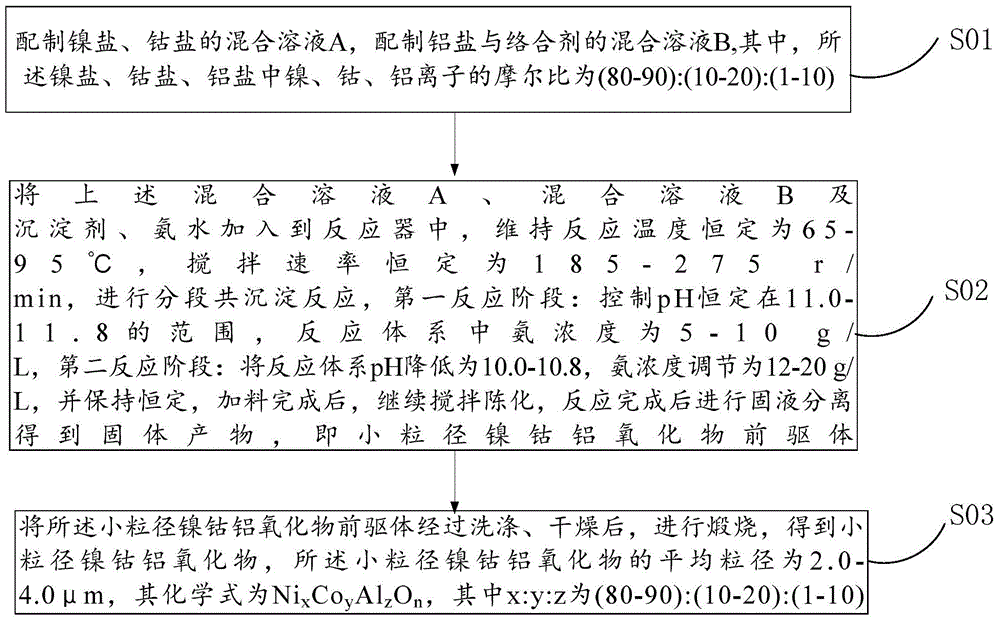

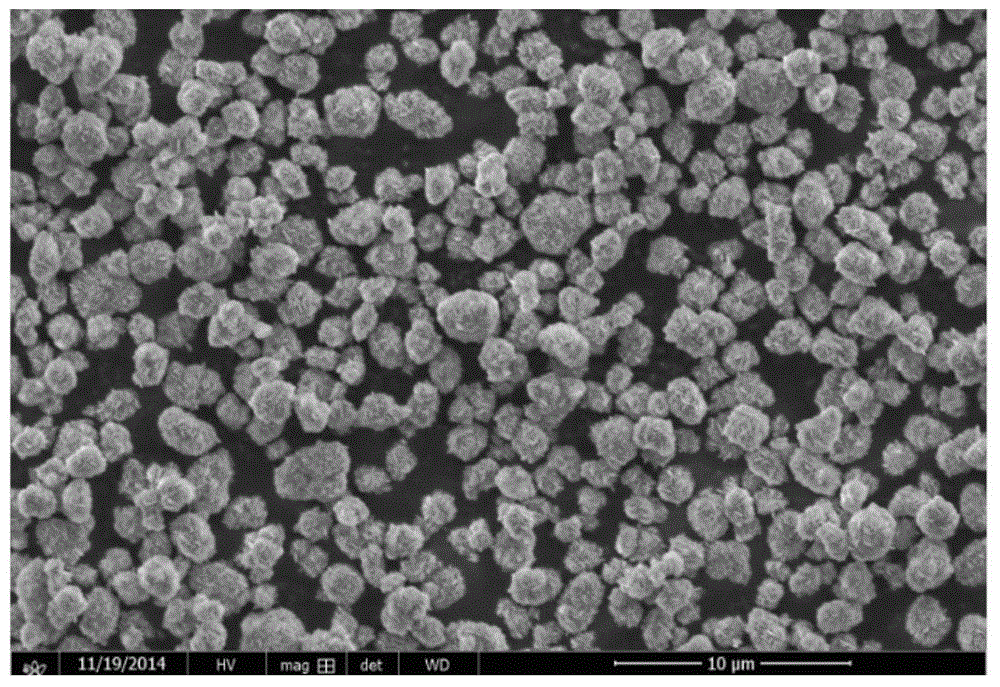

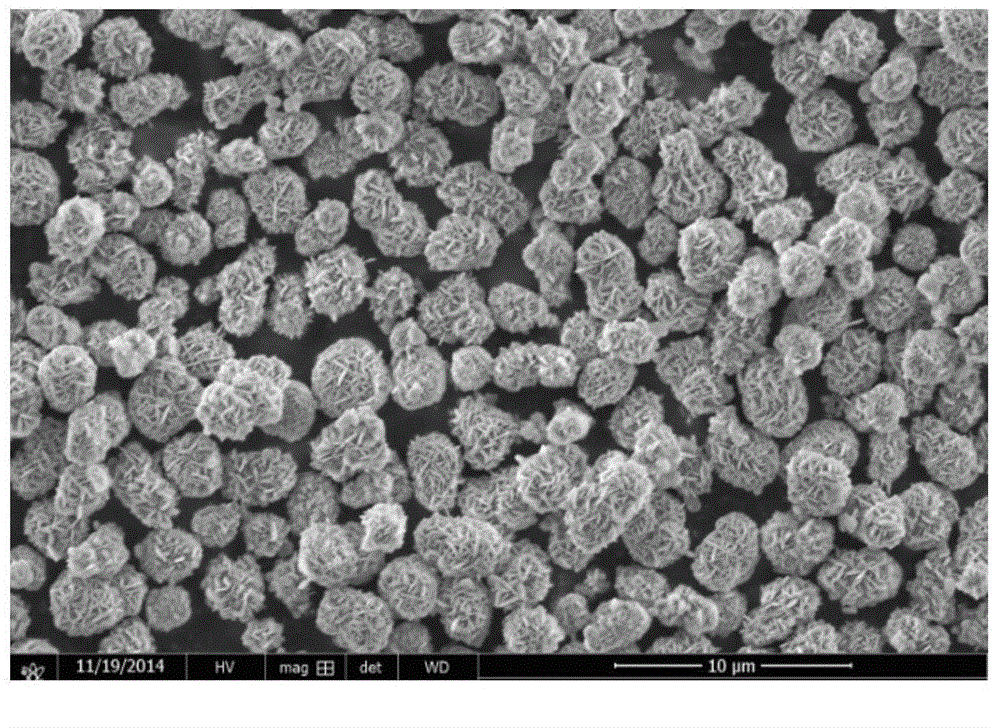

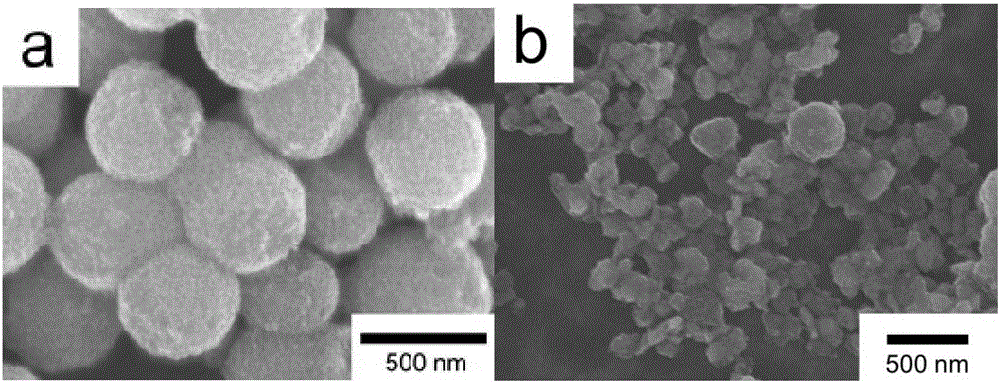

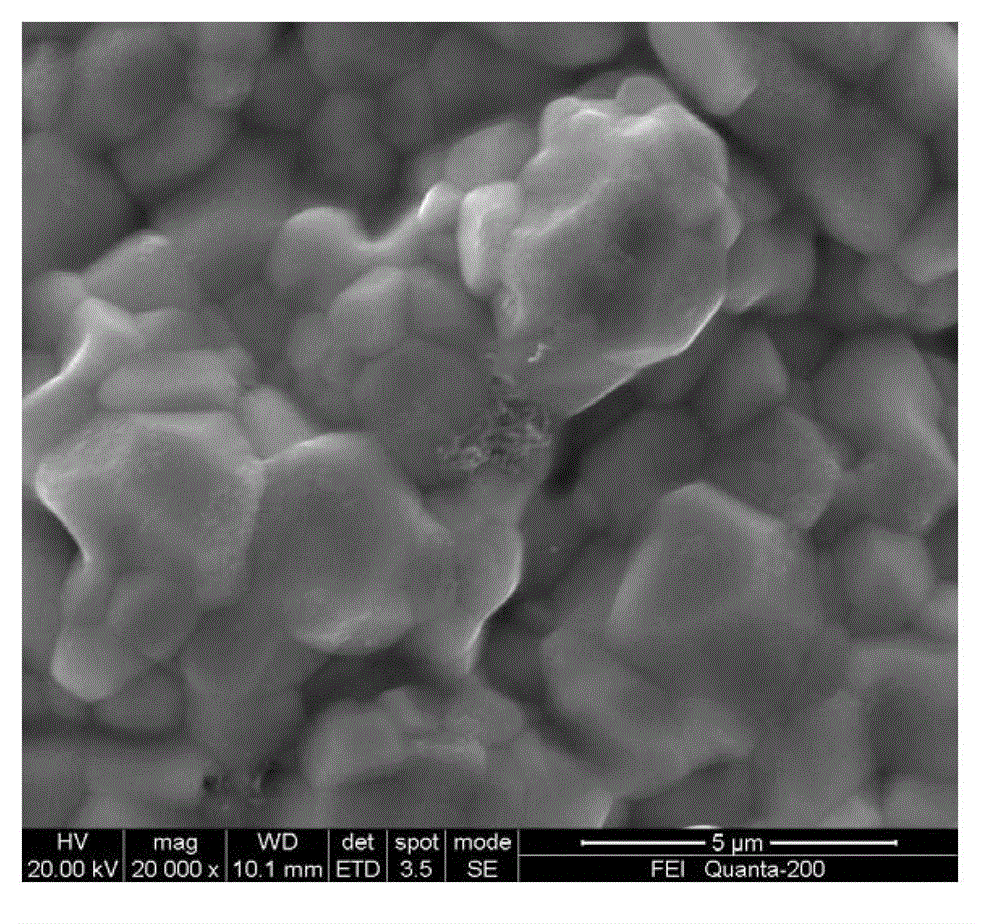

Small-particle-size nickel-cobalt-aluminum oxide and preparation method thereof

The invention provides a small-particle-size nickel-cobalt-aluminum oxide which is regular spherical, relatively good in sphericity degree and uniform in particle size distribution and has the average particle size of 2.0-4.0 [mu]m; the bulk density is greater than 0.8 g / cm<3>, the tap density is greater than 1.2 g / cm<3>, and the small-particle-size nickel-cobalt-aluminum oxide can be used for stacking and filling with a large-particle-size nickel-cobalt-aluminum oxide, so as to solve the application problem of low tap density of a positive electrode material. The invention also provides a preparation method of the small-particle-size nickel-cobalt-aluminum oxide, wherein the preparation method comprises the steps: adding a nickel and cobalt mixed solution, an aluminum-complexing agent mixed solution, a precipitating agent and ammonia water into a reactor in a parallel flow manner, and controlling conditions of high pH and low ammonia concentration during an initial stage of a reaction; in the reaction process, under conditions of low pH and high ammonia concentration, making nucleation and growth of a nickel-cobalt-aluminum precursor implemented separately, preparing a small-particle-size nickel-cobalt-aluminum oxide precursor, and calcining to obtain the small-particle-size nickel-cobalt-aluminum oxide with good sphericity degree and high tap density. The preparation method has the advantages of simple process, high controllability and low cost.

Owner:格林爱科(荆门)新能源材料有限公司

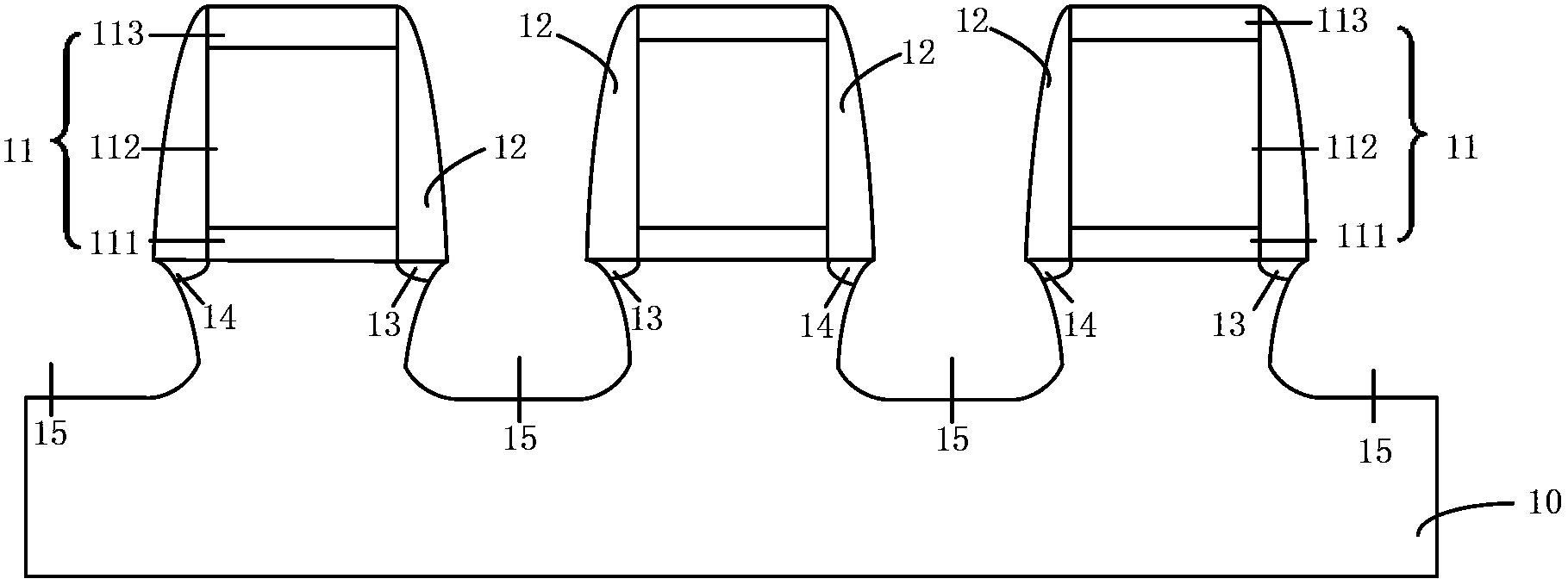

Manufacturing method for PMOS transistor and manufacturing method for NMOS transistor

ActiveCN104103515AIncrease compressive stressIncrease the tensile stressTransistorSemiconductor/solid-state device manufacturingEngineeringElectron

The invention provides a manufacturing method for a PMOS transistor and a manufacturing method for an NMOS transistor. According to the aforementioned manufacturing methods, multiple laminated sigma-shaped grooves (at least two), i.e. stepped sigma-shaped grooves, are formed in source electrode and drain electrode regions in a direction of being perpendicular to the surface of a silicon substrate. In the direction from the surface of the silicon substrate into the silicon substrate, the groove tip, which stretches into a channel, of each sigma-shaped groove presents to be away from the channel gradually. Then a) as for the PMOS transistor, silicon germanium material is filled in the stepped sigma-shaped grooves so that pressure stress is applied to the channel, b) and as for the NMOS transistor, silicon carbide material is filled in the stepped sigma-shaped grooves so that pulling stress is applied to the channel. Therefore, capacity of the stepped sigma-shaped grooves is larger, and more silicon germanium material or silicon carbide material can be accommodated. Correspondingly, pressure stress or pulling stress to the channel is increased so that migration rate of hole carriers or electron carriers is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

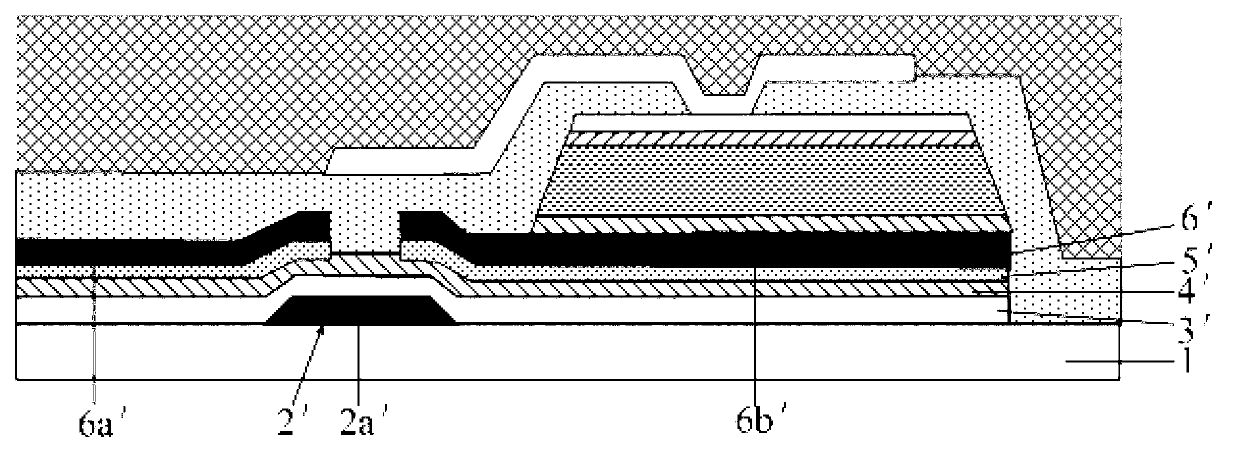

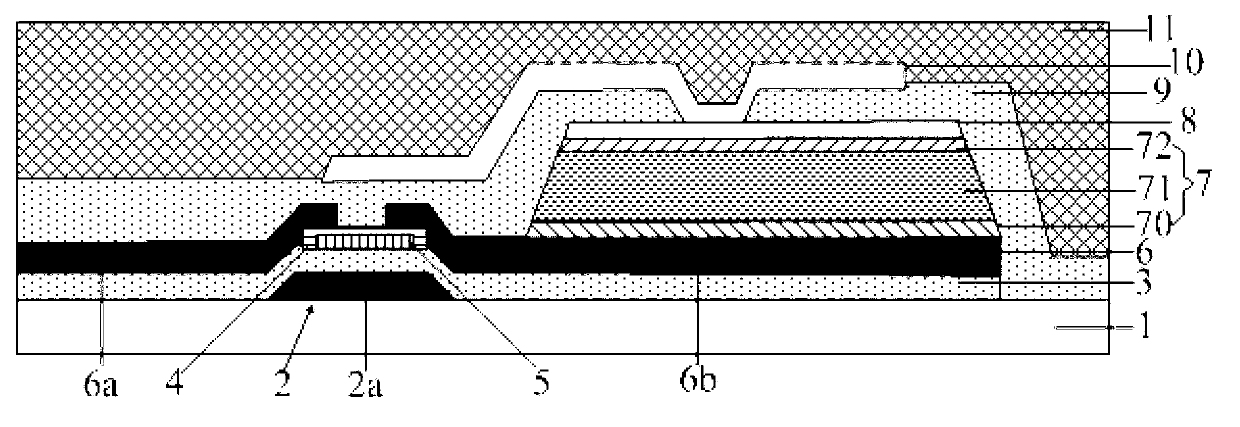

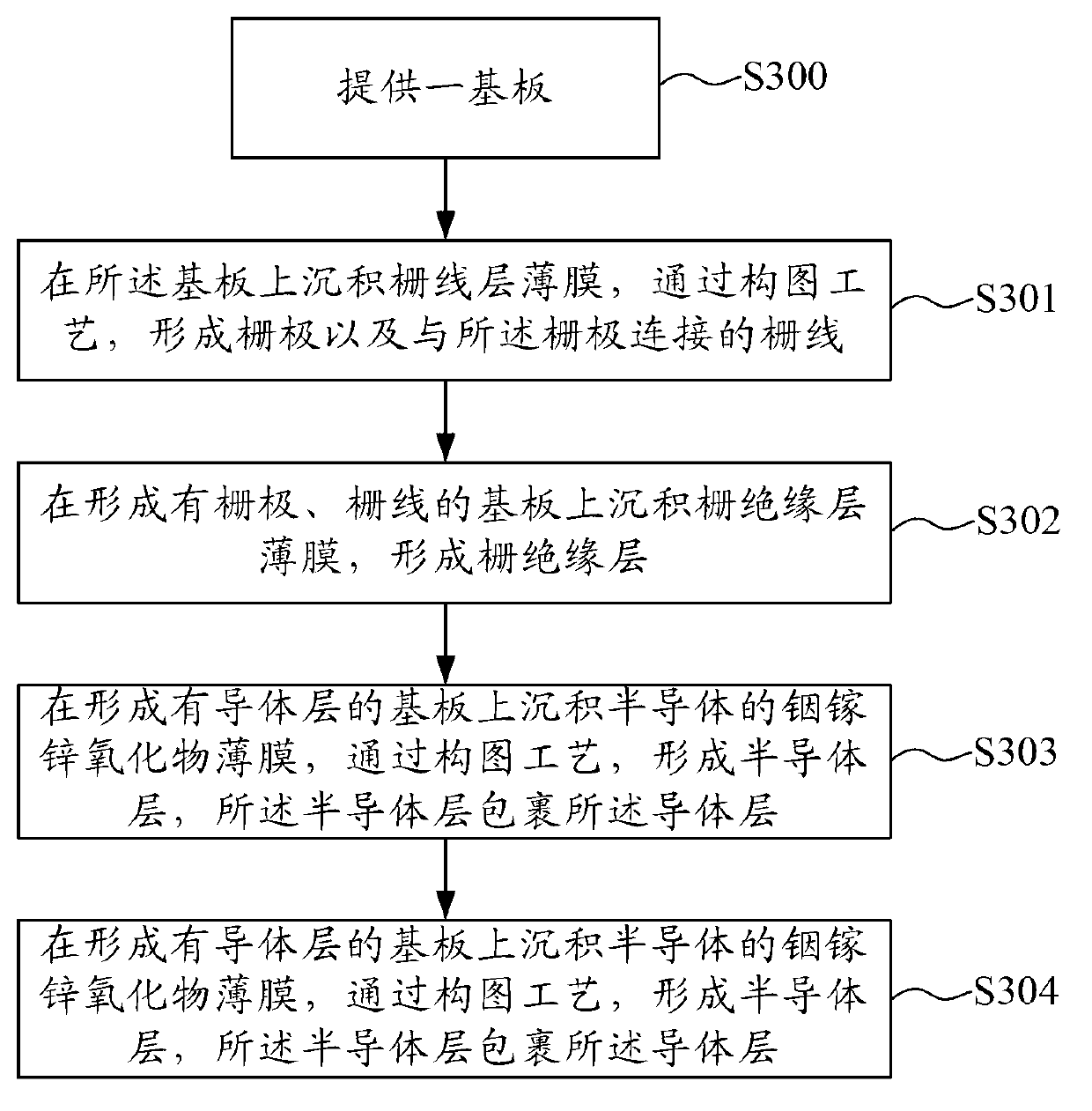

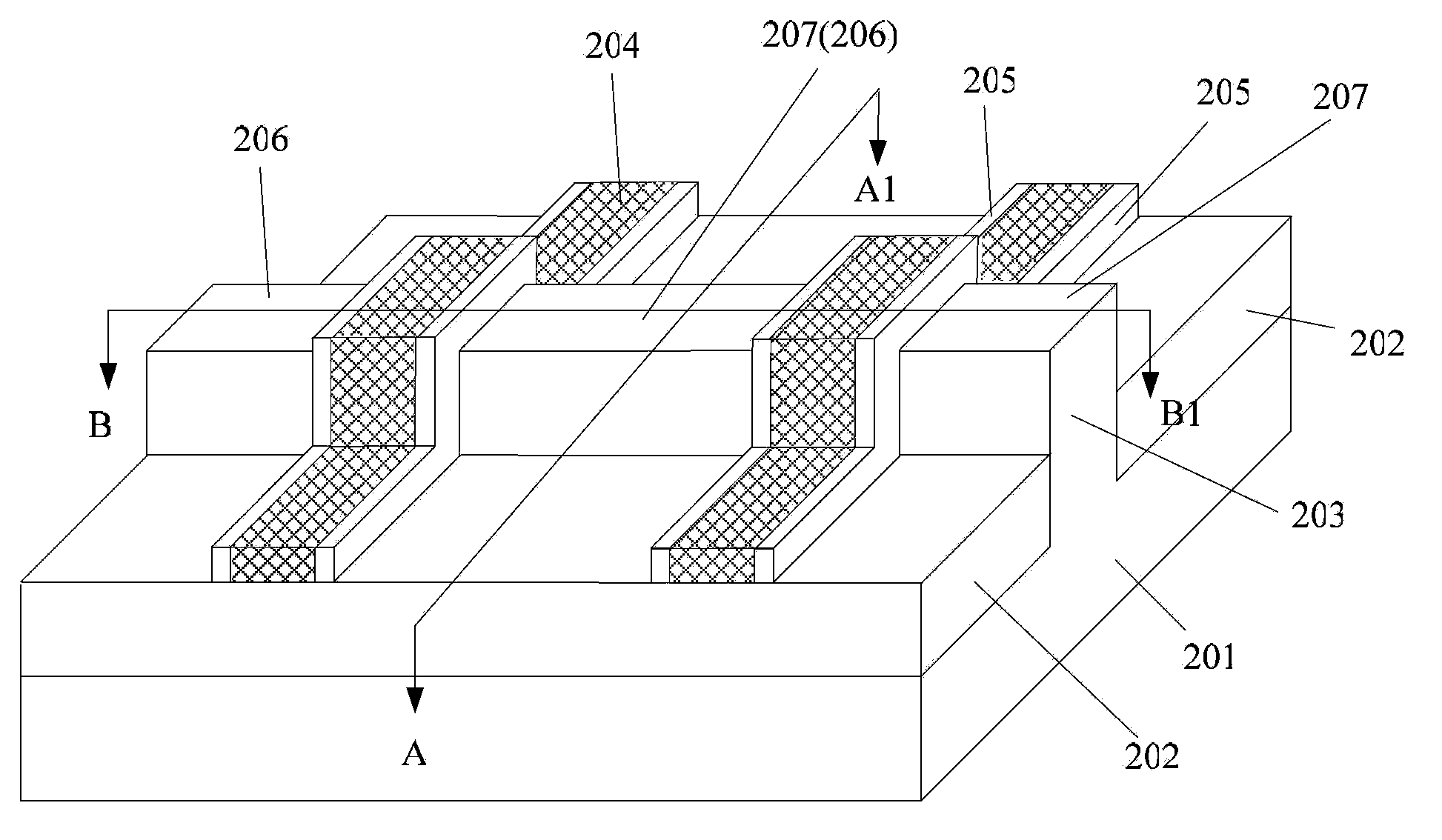

Array substrate and manufacturing method thereof and X ray flat plate detector

ActiveCN103137641AIncrease migration rateIncrease the number ofRadiation controlled devicesElectrical conductorX-ray

The invention discloses an array substrate and a manufacturing method of the array base plate and an X ray flat plate detector. The invention relates to the technical field of photoelectricity. Stability of a thin film transistor is strengthened. The array substrate comprises a base plate, a grid line layer, a grid insulating layer, a source layer and a data line layer. The grid line layer is formed on the substrate. The grid line layer comprises a grid electrode and a grid line connected with the grid electrode. The grid insulating layer is formed above the grid line layer. The source layer is formed above the insulating layer. The data line layer is formed above the source layer. The data line layer comprises a source electrode, a drain electrode and a data line connected with the source electrode. The data line crosses with the grid line. The source layer comprises a conductor layer and a semiconductor layer. The conductor layer is formed above the grid insulating layer. The conductor layer is packed by the semiconductor layer. The array substrate and a manufacturing method of the array substrate are mainly suitable for the X ray flat plate detector.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Porous sulfide/graphene composite electrode material for super capacitor and preparation method thereof

ActiveCN105869911AImprove conductivityLarge specific surface areaMaterial nanotechnologyHybrid capacitor electrodesMaterials scienceGraphite oxide

The invention discloses a porous sulfide / graphene composite electrode material for a super capacitor and a preparation method thereof, and relates to a nanometer strip-shaped porous CuCo2S4 / graphene composite material and a preparation method thereof. The preparation method comprises the following steps: (1) mixing a Cu-containing metal salt, a Co-containing metal salt, oxidized graphene or reduced oxidized graphene or graphene dispersion liquid, a weakly-alkaline substance and amine, and performing a hydrothermal reaction on the mixed solution to obtain a graphene-copper-cobalt hydroxide precursor; (2) heating the graphene-copper-cobalt hydroxide precursor obtained in the step (1) at a high temperature to obtain a graphene-copper-cobalt oxide precursor; (3) dissolving the graphene-copper-cobalt oxide precursor obtained in the step (2) into water, and performing a hydrothermal reaction with NaS.9H2O to obtain a CuCo2S4 / graphene composite material. The composite material is taken as an electrode material of the super capacitor, and has high electrochemical energy-storing performance.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

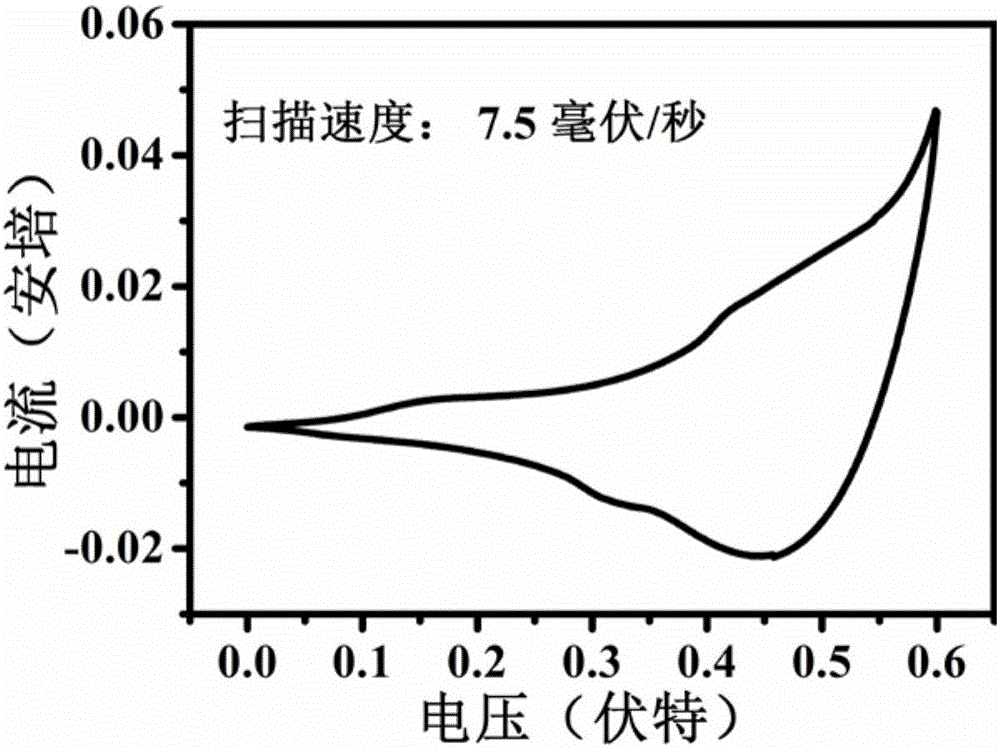

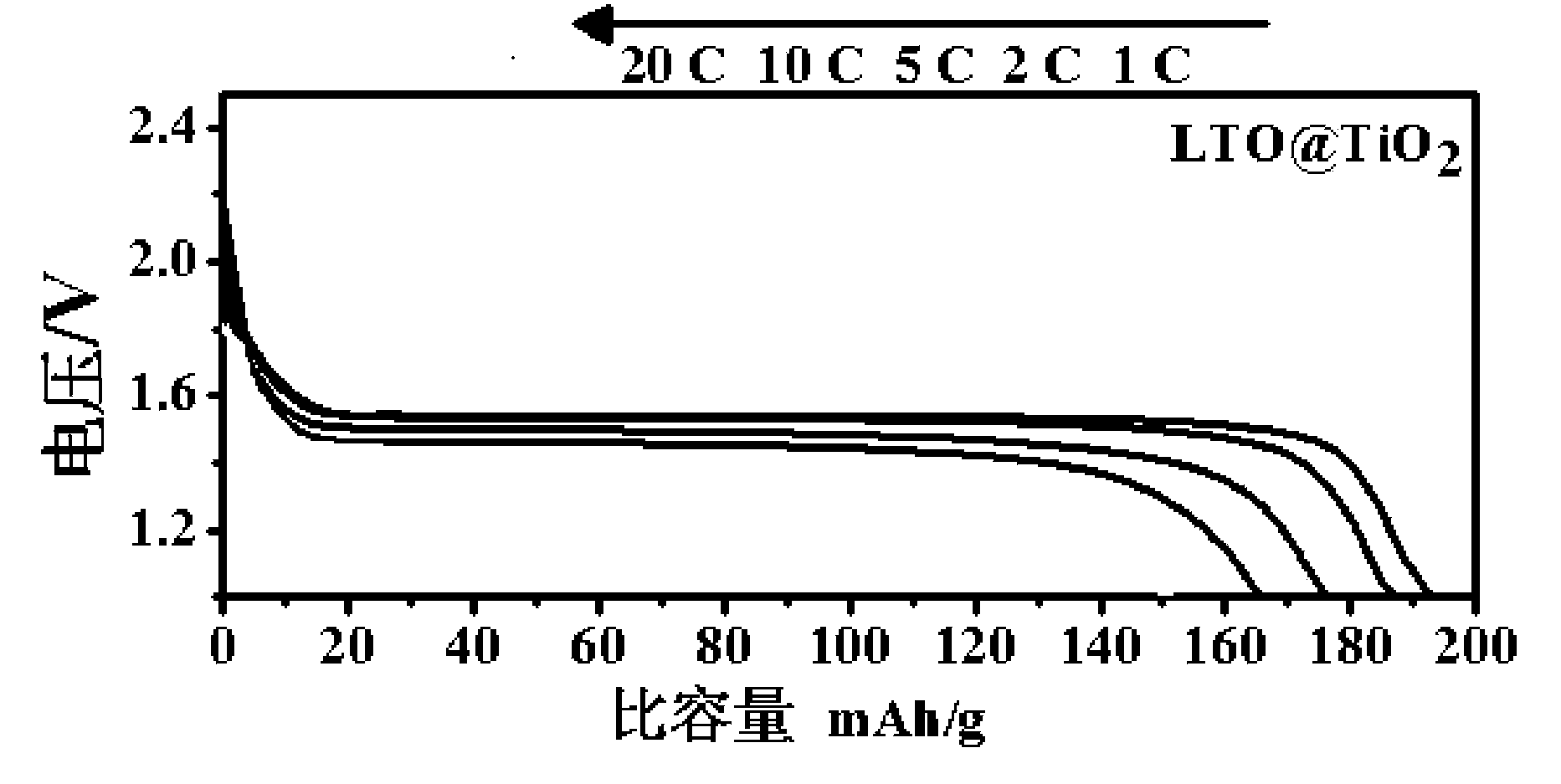

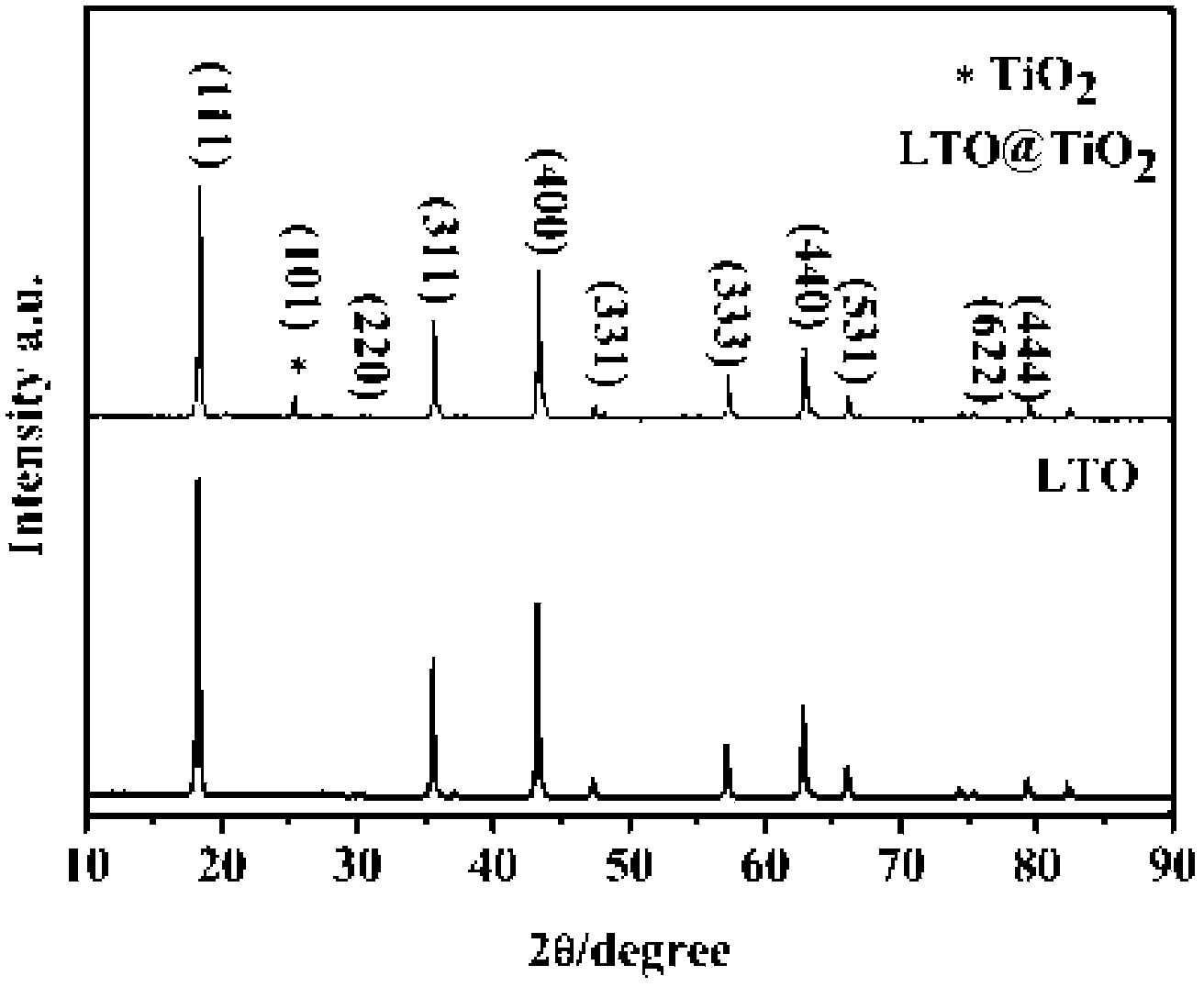

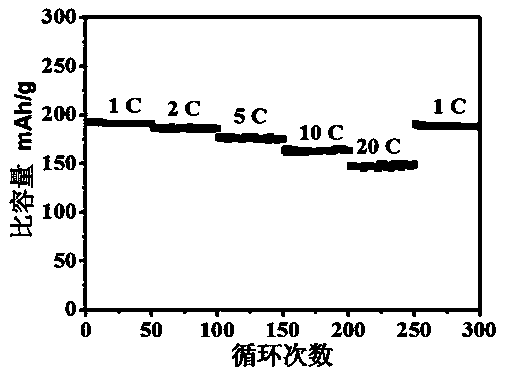

Preparation method for nanoscale lithium titanate material with high specific capacity

ActiveCN103682296AEvenly distributedReduce consumptionMaterial nanotechnologyAlkali titanatesAlcoholRoom temperature

The invention discloses a preparation method for a nanoscale lithium titanate material with high specific capacity. The preparation method comprises the following steps: (1) preparing a liquid A; (2) preparing a liquid B; (3) under a condition of magnetic stirring, slowly adding the liquid B into the liquid A, so as to obtain a mixed dispersion liquid; (4) putting the mixed dispersion liquid into a high-temperature reaction still, then placing the high-temperature reaction still in a drying oven for reaction, after the reaction, naturally cooling to room temperature, leaching, washing with deionized water and absolute ethyl alcohol, and then drying under a condition that the temperature is 60-120 DEG C so as to obtain a precursor; (5) sintering the precursor for 1-5 hours in anitrogen atmosphere under a condition that the temperature is between 400-1000 DEG C, so as to obtain the nanoscale lithium titanate material; (6) immersing the nanoscale lithium titanate material in an acid solution with the hydrogen ion concentration of 0.01-14mol / L under a condition that the temperature is 20-200 DEG C, then leaching, washing with deionized water and absolute ethyl alcohol, and then drying, so as to obtain the nanoscale lithium titanate material with high specific capacity.

Owner:上海大学浙江嘉兴新兴产业研究院

High-nickel positive electrode material with uniform coating layer and preparation method thereof

InactiveCN109950498AAvoid excessive churnHigh specific capacityMaterial nanotechnologyCell electrodesPhase mixingLithium

The invention discloses a high-nickel positive electrode material with a uniform coating layer and a preparation method thereof. The preparation method comprises the steps of (1) performing fixed-phase mixing on a high-nickel positive electrode material, a lithium source and a nano coating material to be uniform and screening to obtain a mixture, and (2) placing the mixture in step (1) in a saggarand performing high-temperature sintering, cooling, crushing and sieving in a preheated muffle furnace oxygen atmosphere to obtain a uniform coating layer. According to the invention, the surface ofthe high-nickel positive electrode material is coated with an oxide coating layer, then an additional lithium source is added, and the positive electrode material with good stability and high specificcapacity is obtained through high-temperature sintering. According to the invention, the fixed-phase mixing of the coating material, the high-nickel positive electrode material and the lithium sourceis carried out, the operation is simple, the cost is low, and the mass production is easy to realize.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

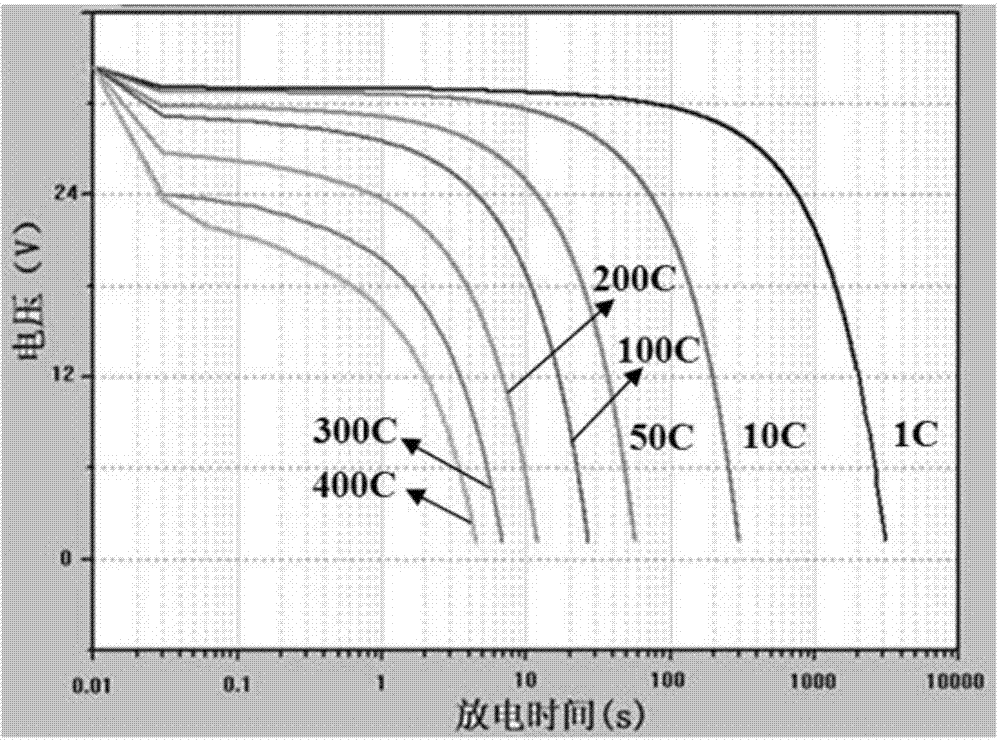

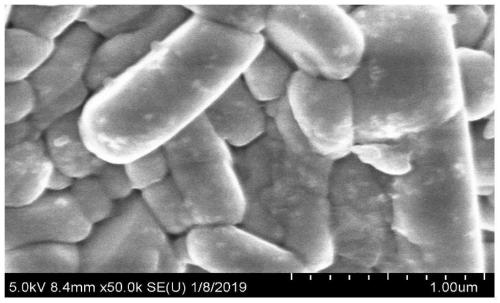

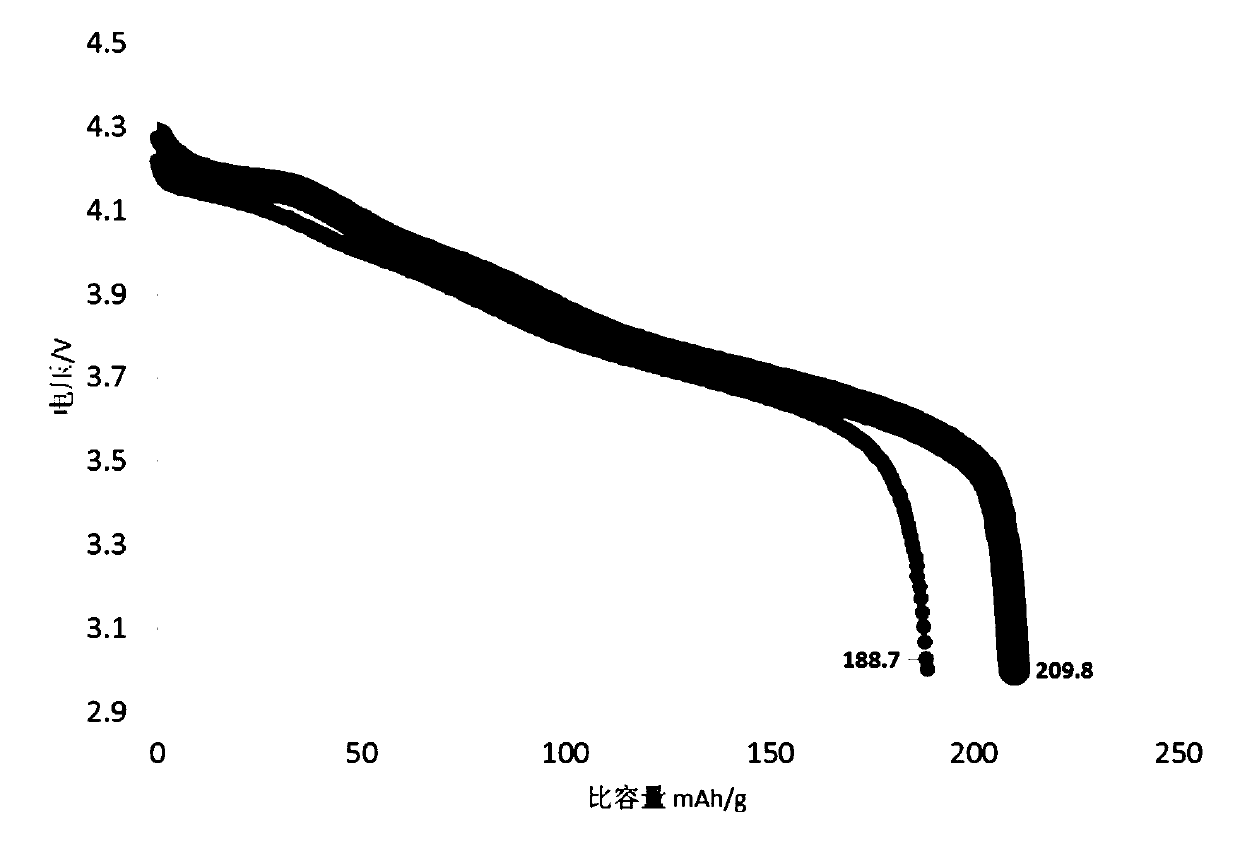

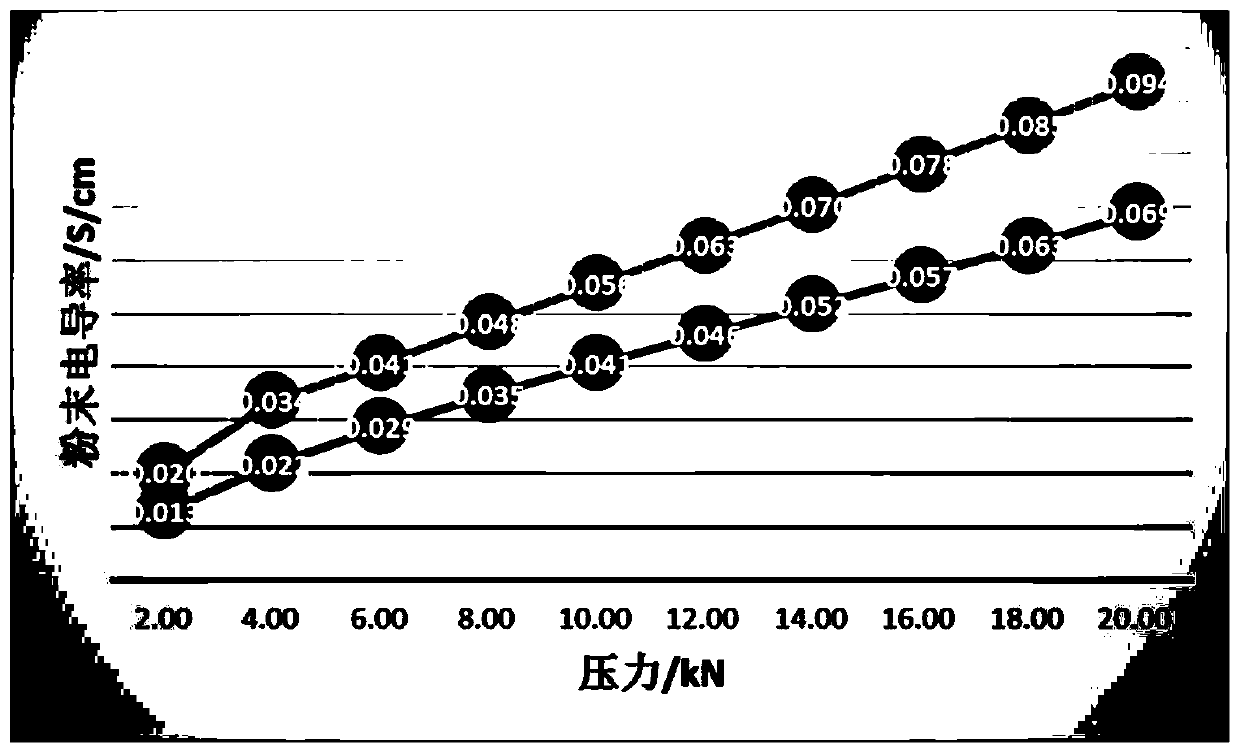

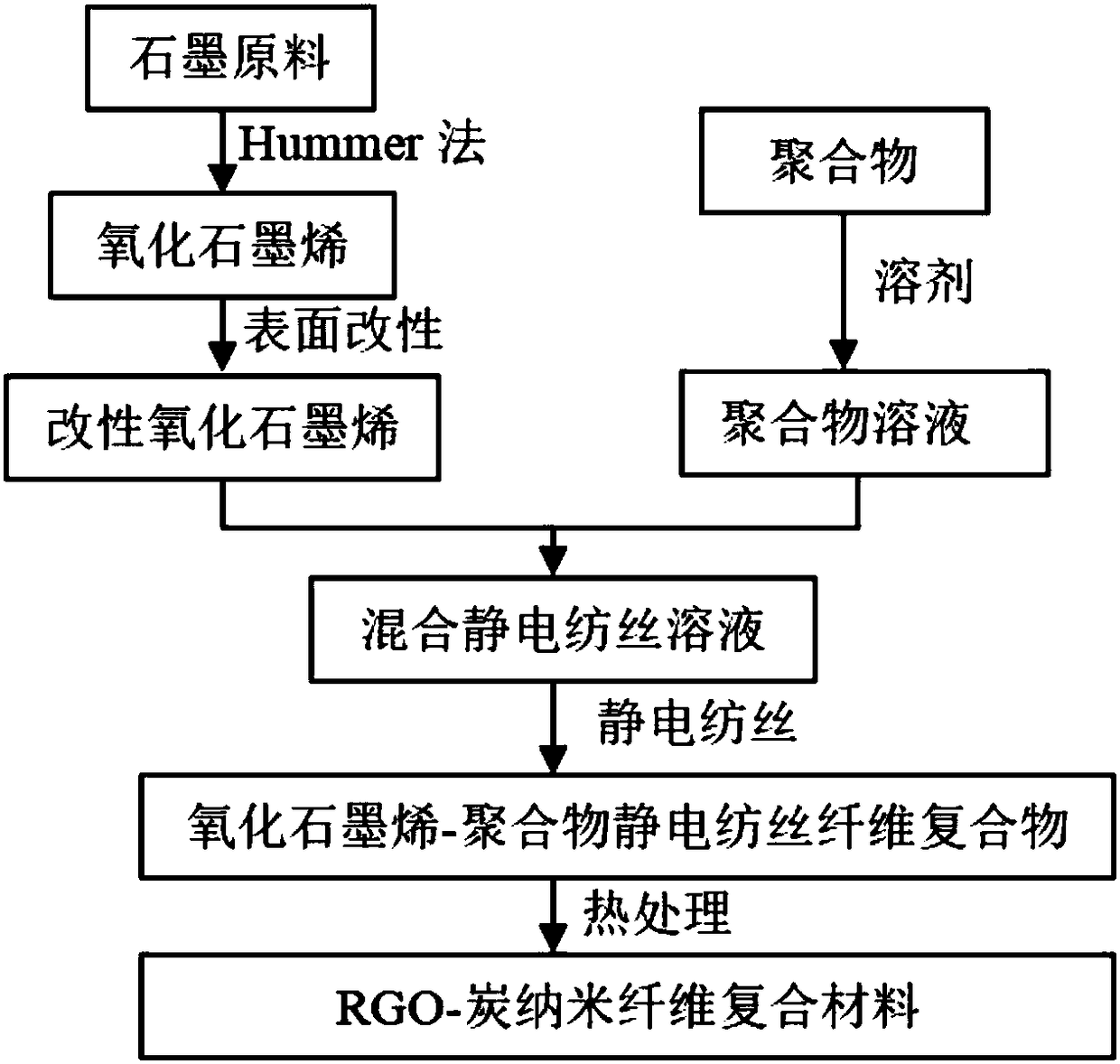

Carbon nanofiber supported orderly-arranged reduced graphene oxide (RGO) electrode material

ActiveCN108335917AAchieve reductionAchieve strippingCarbon compoundsHybrid capacitor electrodesFiberUltrasound - action

The invention discloses a preparation method of a carbon nanofiber supported orderly-arranged reduced graphene oxide (RGO) electrode material. The preparation method comprises the following steps: preparing graphene oxide from flake graphite by a Hummer method, performing surface modification on the graphene oxide by ionic liquid to obtain ionic liquid surface-modified graphene oxide, adding a polymer into a solvent, and stirred strongly under the action of ultrasonic waves to form an electrostatic spinning solution; and performing electrostatic spinning on the electrostatic spinning solution,and performing heat treatment on graphene oxide-polymer electrostatic spinning fibers obtained on an electrostatic spinning receiver to obtain a composite material in which RGO is arranged verticallyand orderly on the surfaces of the carbon nanofibers in an embedded manner. The preparation method has the advantages of reasonable process and stable performance, can prevent RGO agglomeration, increase the specific surface area and increase the charge storage density and charge transfer rate, is taken as an electrode of a high-capacity power supercapacitor, and can be up to 99.5 to 99.7 percentin charging and discharging efficiency.

Owner:锦州凯美能源有限公司

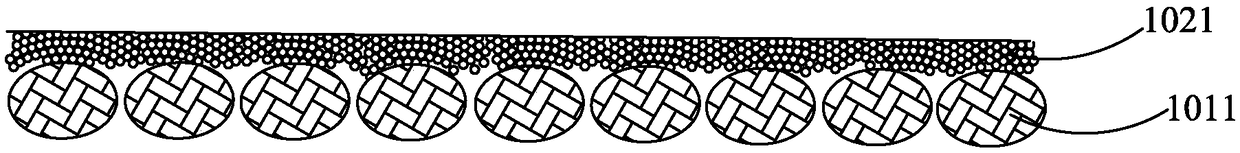

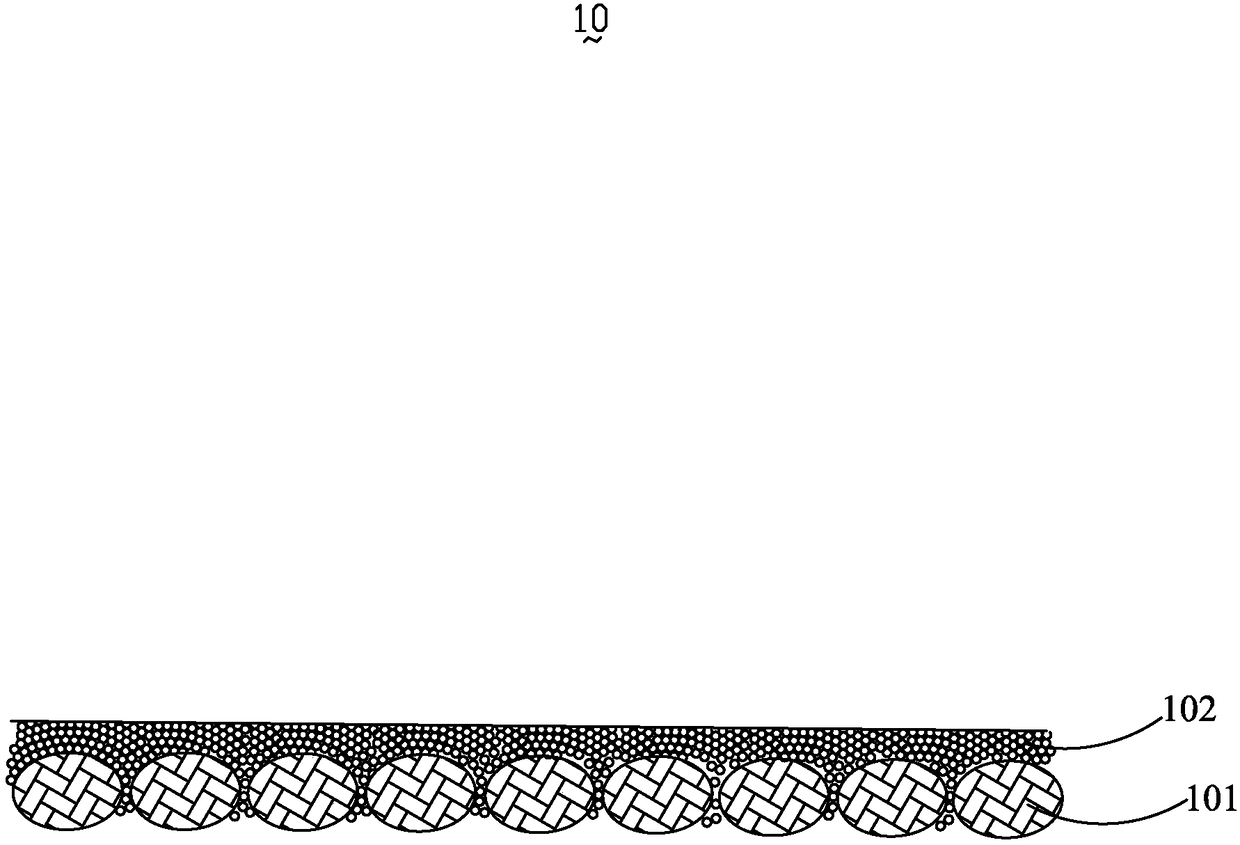

Composite material and preparation method thereof

ActiveCN108079934ALarge specific surface areaIncrease loadOther chemical processesAluminium silicatesCarbon filmMicrosphere

The invention relates to a composite material and a preparation method thereof, and can be widely applied to the fields of batteries, environmental protection, adsorptive dehumidification, air conditioning, refrigeration, heat pumps, pressure-variable separation purification, hydrogen storage production and the like. The composite material comprises a supporting framework material, carbon microspheres and / or a carbon film and a loading material, the loading material comprises salt, an electrode material and a physical adsorbent, the carbon microspheres and / or the carbon film are / is firmly attached to the wall surfaces of pores in the supporting framework material, and the loading material is uniformly distributed inside the carbon microspheres and / or the carbon film, so that direct embedment of the loading material between carbon atoms is achieved, the anti-agglomeration inactivation capacity is obviously enhanced, and the service life is effectively prolonged; the composite material breaks through a limitation of the specific surface area of the original skeleton material, so that the specific surface area of the composite material can be effectively increased under the premise ofincreasing the loading capacity, and the adsorption, reaction or electron migration rate can be increased; the composite material conveniently achieves close contact between the adsorbent and a heat-exchanging wall surface by an extruding, bonding or brazing method, so that the contact heat resistance between the two is effectively reduced.

Owner:SHANDONG UNIV

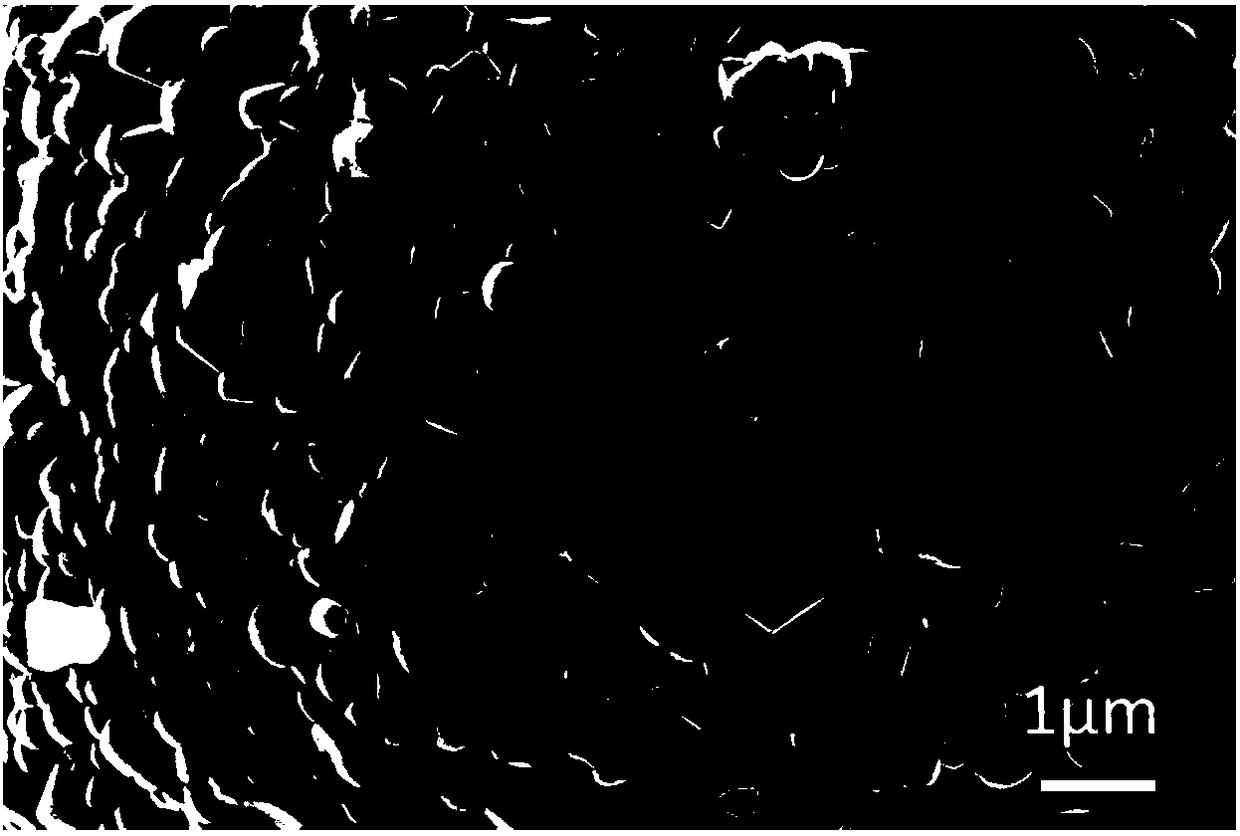

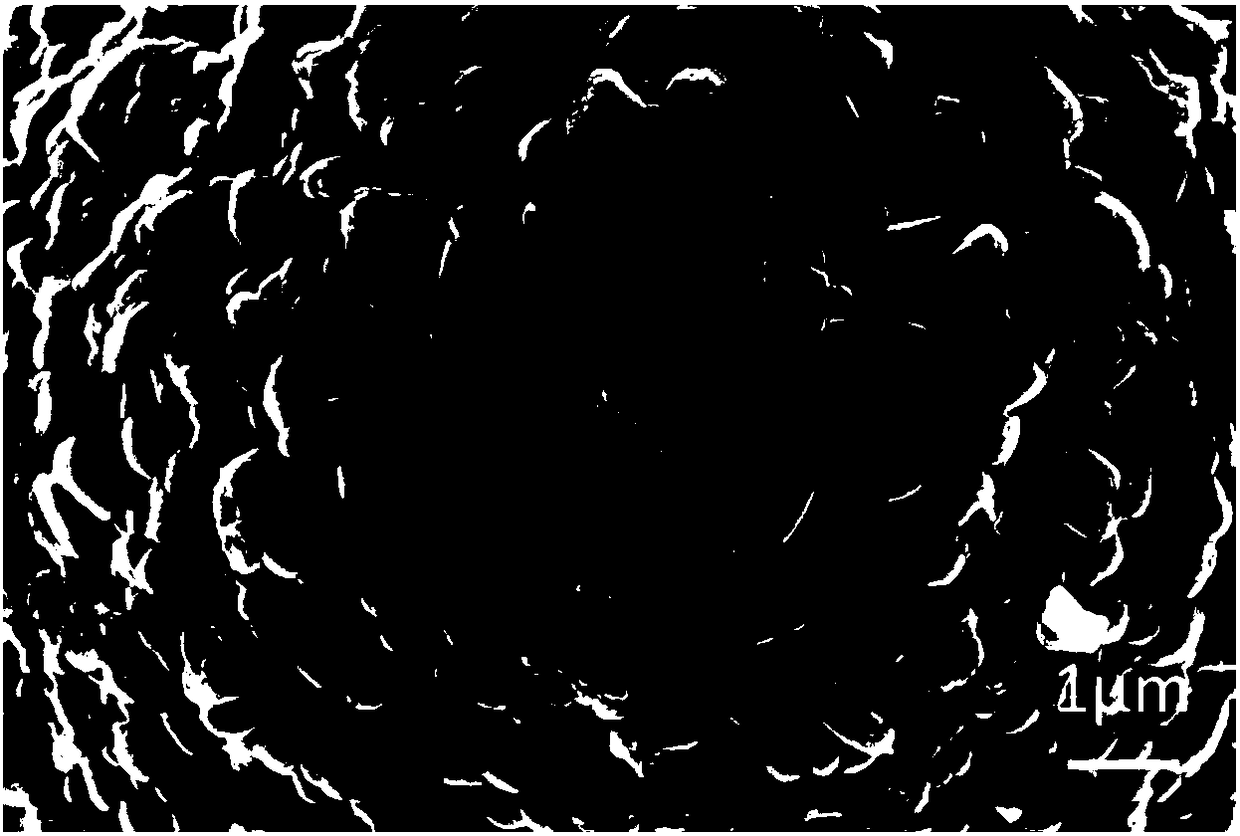

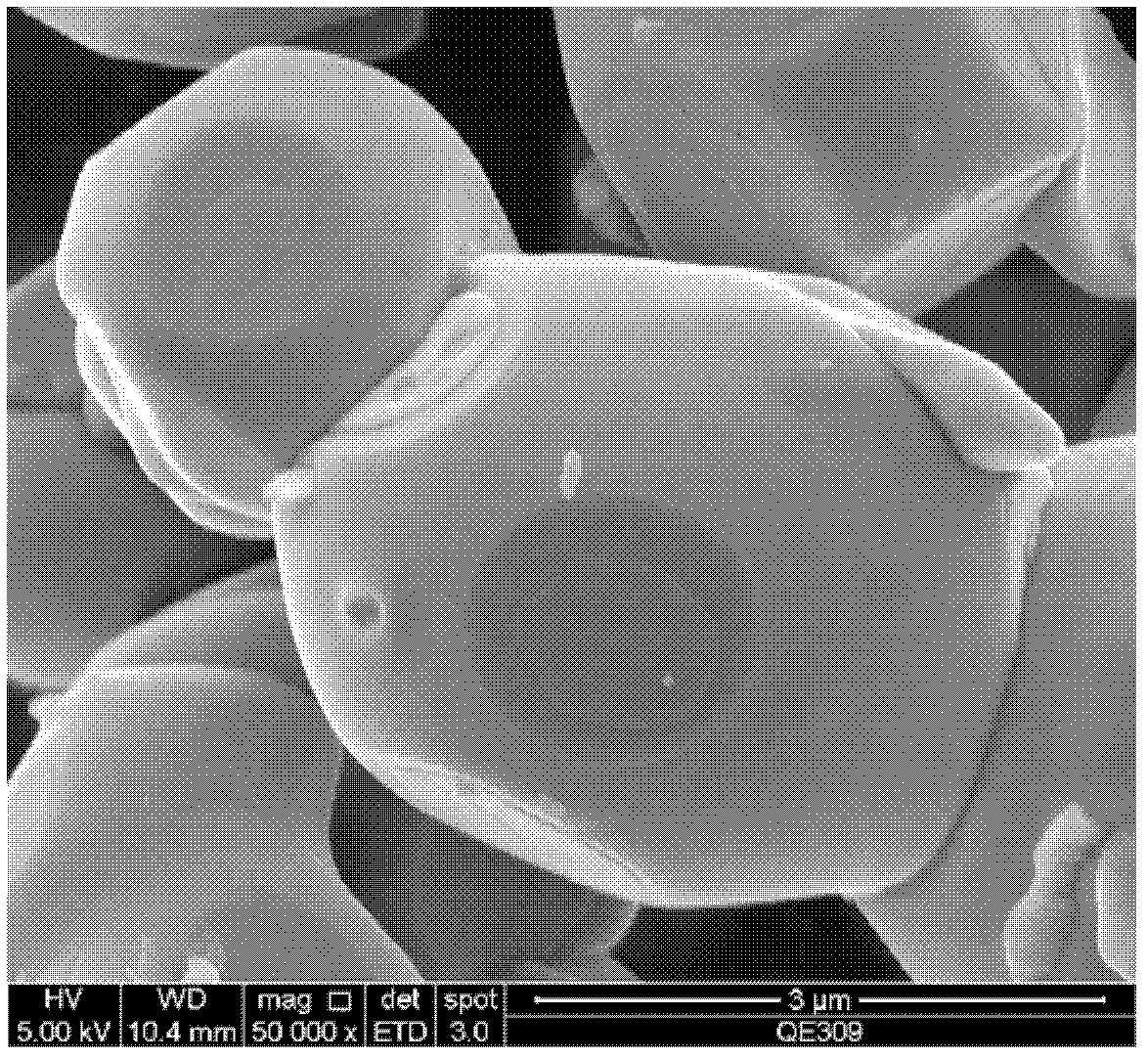

Ternary anode material precursors, synthesis method thereof and lithium ion battery

ActiveCN106784786ALow S contentImprove cycle lifeCell electrodesSecondary cellsSynthesis methodsDivalent metal

The invention discloses a ternary anode material precursor, a synthesis method thereof and a lithium ion battery. The precursor has the formula of NixCoyMn1-x-y-zMez (OH) <2>, wherein X is greater than 0.33 and less than 0.51, Y is greater than 0.3 and less than 0.33, Z is greater than 0 and less than 0.02, and Me is a mixture of divalent metal and tetravalent metal. In the scheme, the ternary anode material has a ball-shaped morphology of flaky stacks. The crystal preferentialy grows along the 001 crystal plane, exposes the crystal surface which easily makes the lithium ion diffuse, and accelerates the rate of lithium ion detachment. The specific ball-shaped morphology of flaky stacks is capable of increasing the contact surface of the anode with the electrolyte, so that the power performance of the material is excellent. Furthermore, the specific ball-shaped morphology of flaky stacks ensures that the S-content of the ternary anode material precursor is obviously lower than that of ordinary process. The crystallinity of the material is improved and the stability of the material is further enhanced.

Owner:SUNWODA ELECTRIC VEHICLE BATTERY CO LTD

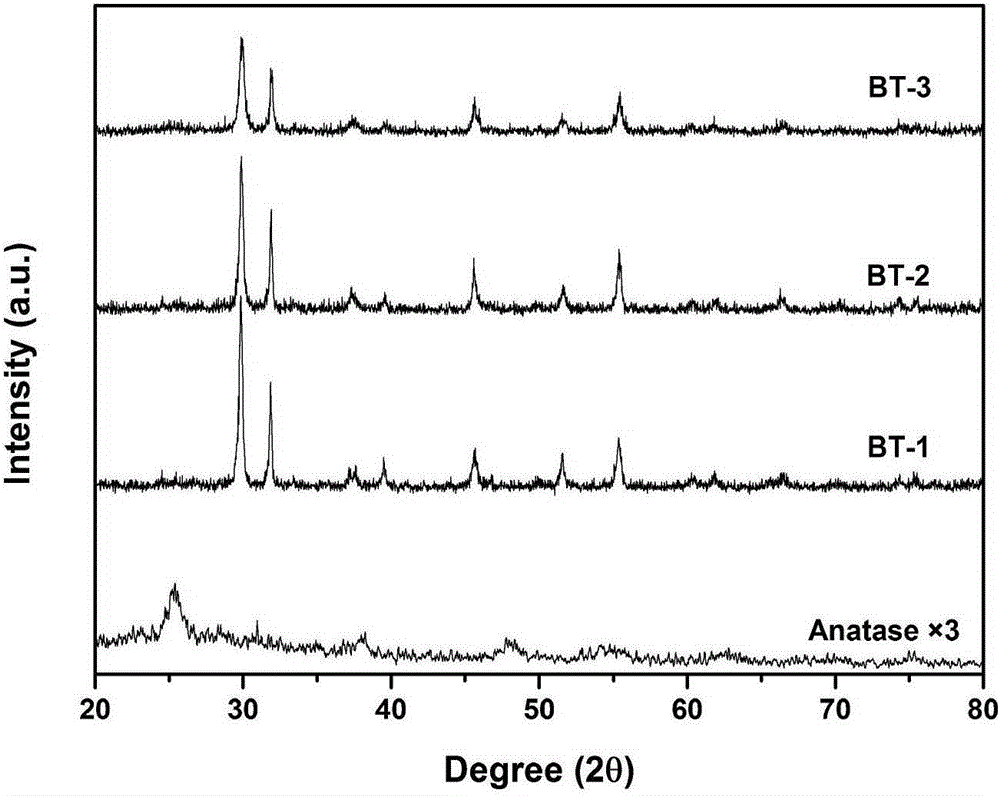

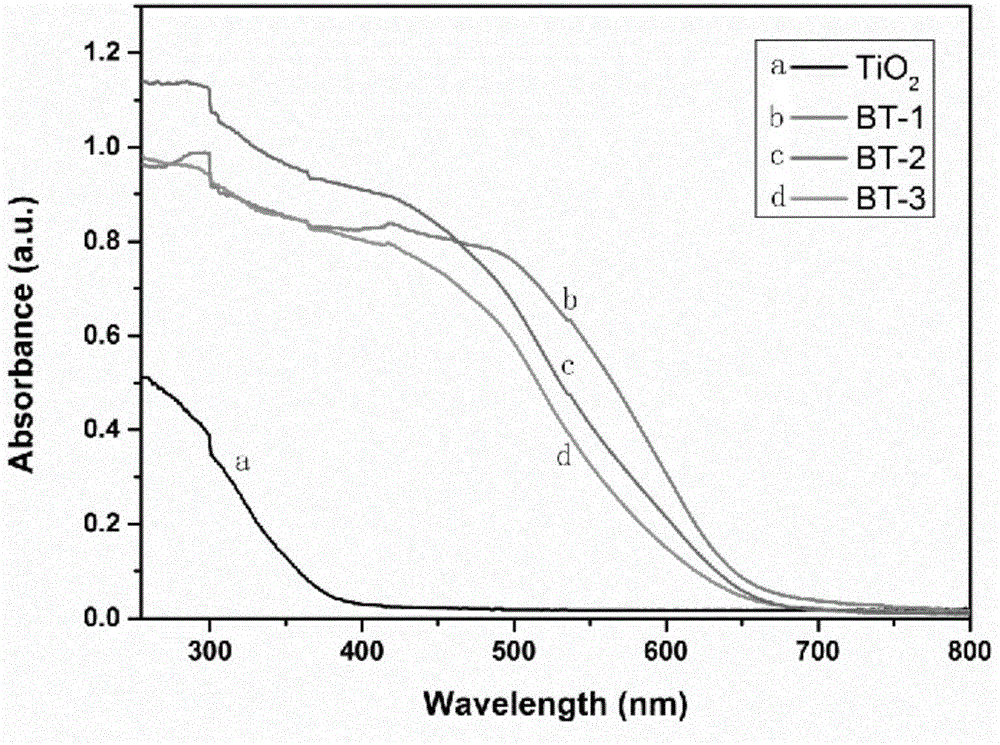

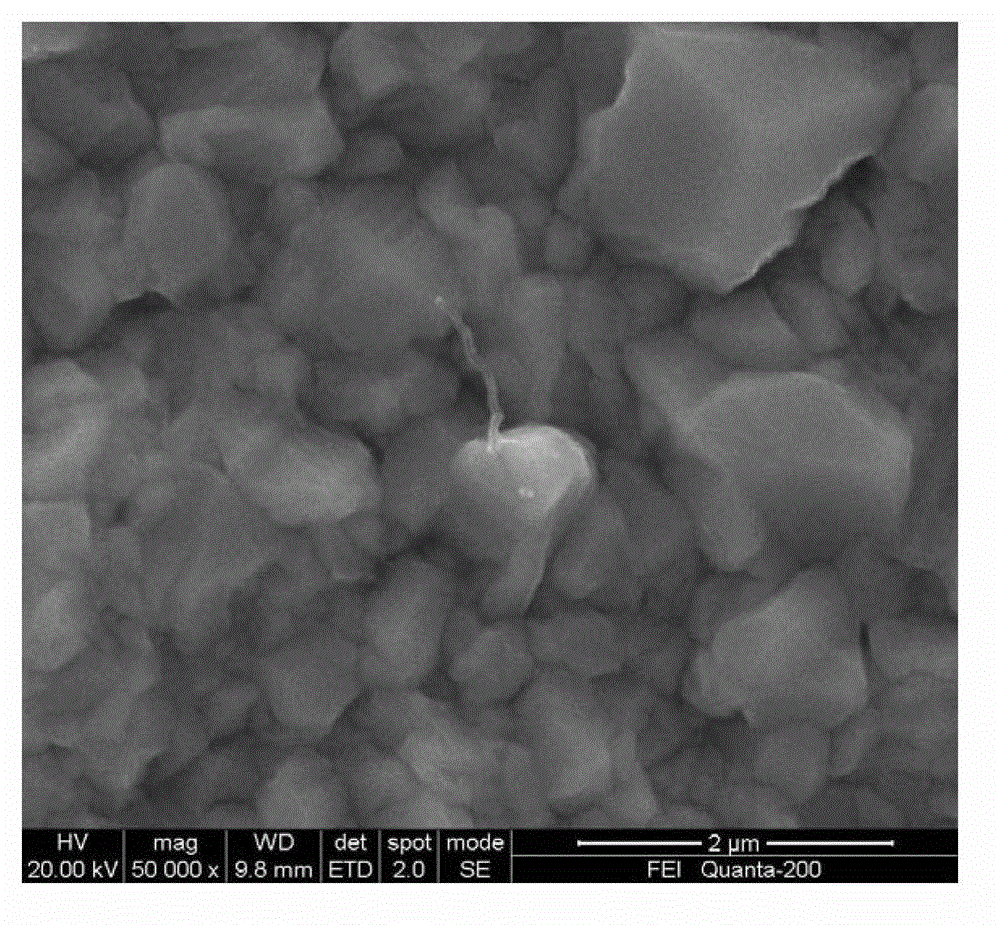

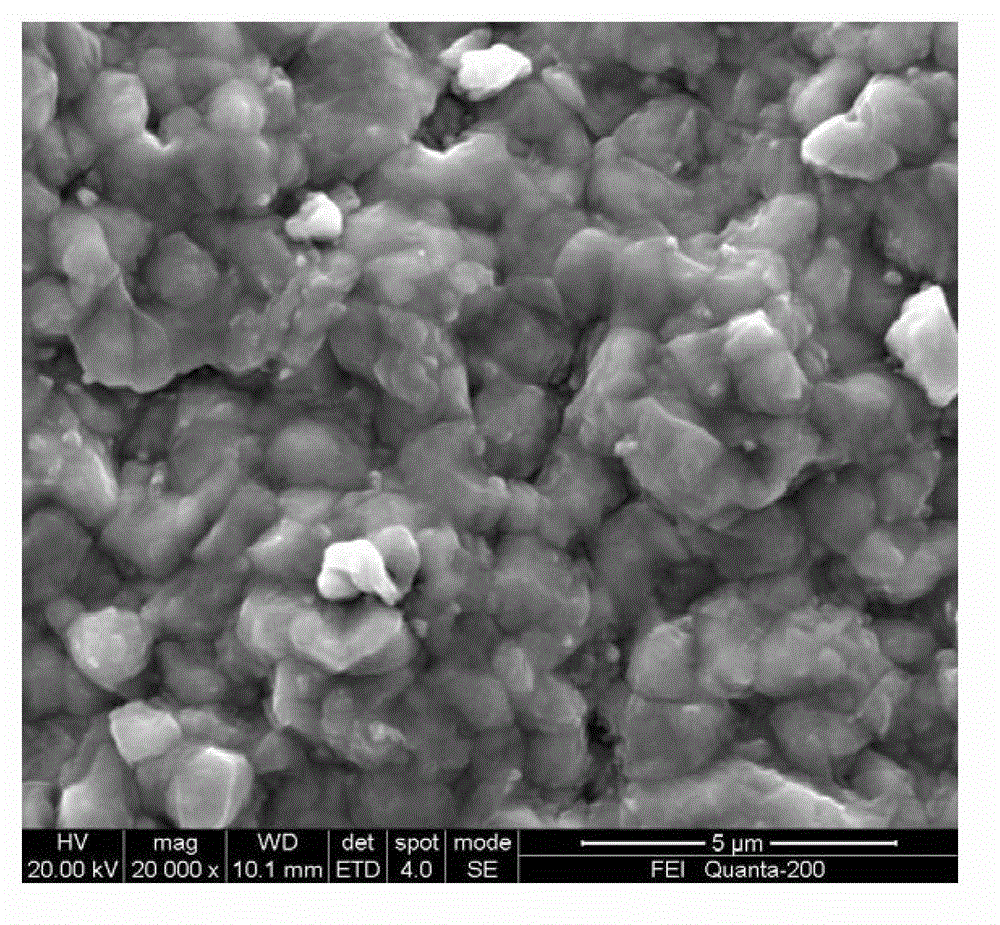

Bismuth oxyiodide/porous titanium dioxide compound photocatalyst as well as preparation method and application thereof

ActiveCN105214693AWide spectral response rangeEfficient photocatalytic activityPhysical/chemical process catalystsWater/sewage treatment by irradiationSpectral responseMicrosphere

The invention relates to a bismuth oxyiodide / porous titanium dioxide compound photocatalyst as well as a preparation method and an application thereof and belongs to the field of photocatalysis. The technical scheme is as follows: bismuth nitrate is dispersed in ethylene glycol, potassium iodide is added, stirring is performed continuously, then porous titanium dioxide microspheres are added, ultrapure water is added, stirring is continuously performed at the room temperature for 1-3 h, an obtained product is washed and dried, and the bismuth oxyiodide / porous titanium dioxide compound photocatalyst is obtained. Porous titanium dioxide microspheres are synthesized with a simple hydrothermal method, and are large in specific surface area, uniform in size and beneficial to light scattering. The bismuth oxyiodide / porous titanium dioxide compound photocatalyst synthesized with the microspheres has the wider spectral response range, has efficient photocatalystic activity under visible light and has characteristics of wide application range and good stability, the technology is simple, operation is easy, and the cost is low.

Owner:辽宁蓝水化学品制造有限公司

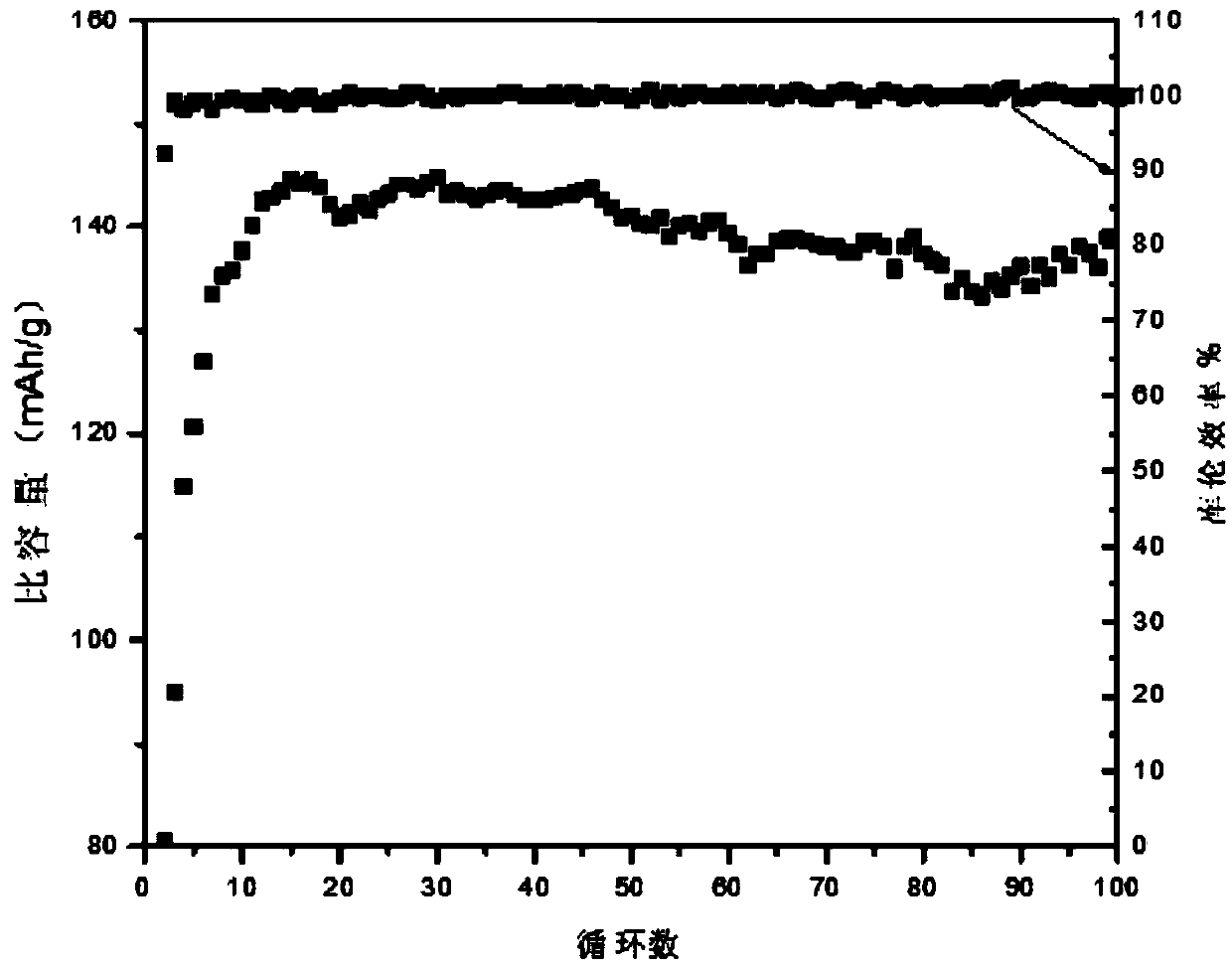

Carbon-Cu6Sn5 alloy negative electrode materials and preparation method thereof

InactiveCN103066252AReduce the likelihood of sheddingIncrease migration rateElectrolytic coatingsCell electrodesCarbon nanotubeAlloy

The invention discloses carbon-Cu6Sn5 alloy negative electrode materials and a preparation method thereof. The carbon-Cu6Sn5 alloy negative electrode materials and the preparation method thereof combine carbon nanometer tubes and graphene into electrodes and add a Cu-CNTs connecting layer between active materials and current collectors. Therefore, cyclic perforce of an alloy negative electrode is improved greatly. The carbon-Cu6Sn5 alloy negative electrode materials and the preparation method thereof use copper foils as the current collectors (electroplating substrates). The copper foils are plated by a Cu-CNTs composite plating and a composite plating of stannum-carbon nanometer tubes or stannum- graphene or stannum-carbon nanometer tubes- graphenes in sequence, wherein the thickness of the Cu-CNTs composite plating is 1-5 micrometers and the thickness of the composite plating of the stannum-carbon nanometer tubes or the stannum- graphene or the stannum-carbon nanometer tubes- graphene is 1-4 micrometers. The carbon-Cu6Sn5 alloy negative electrode materials can be obtained finally through thermal treatments. First specific discharge capacity of lithium ion battery alloy cathodes prepared by the method can achieve 613 m AH / g and specific capacity attenuation of the lithium ion battery alloy cathodes is only 4%-6% after 100 cycles. The carbon-Cu6Sn5 alloy negative electrode materials and the preparation method thereof are simple in technique, good in prepared alloy cathode performance and suitable for large-scale industrial production.

Owner:XIANGTAN UNIV

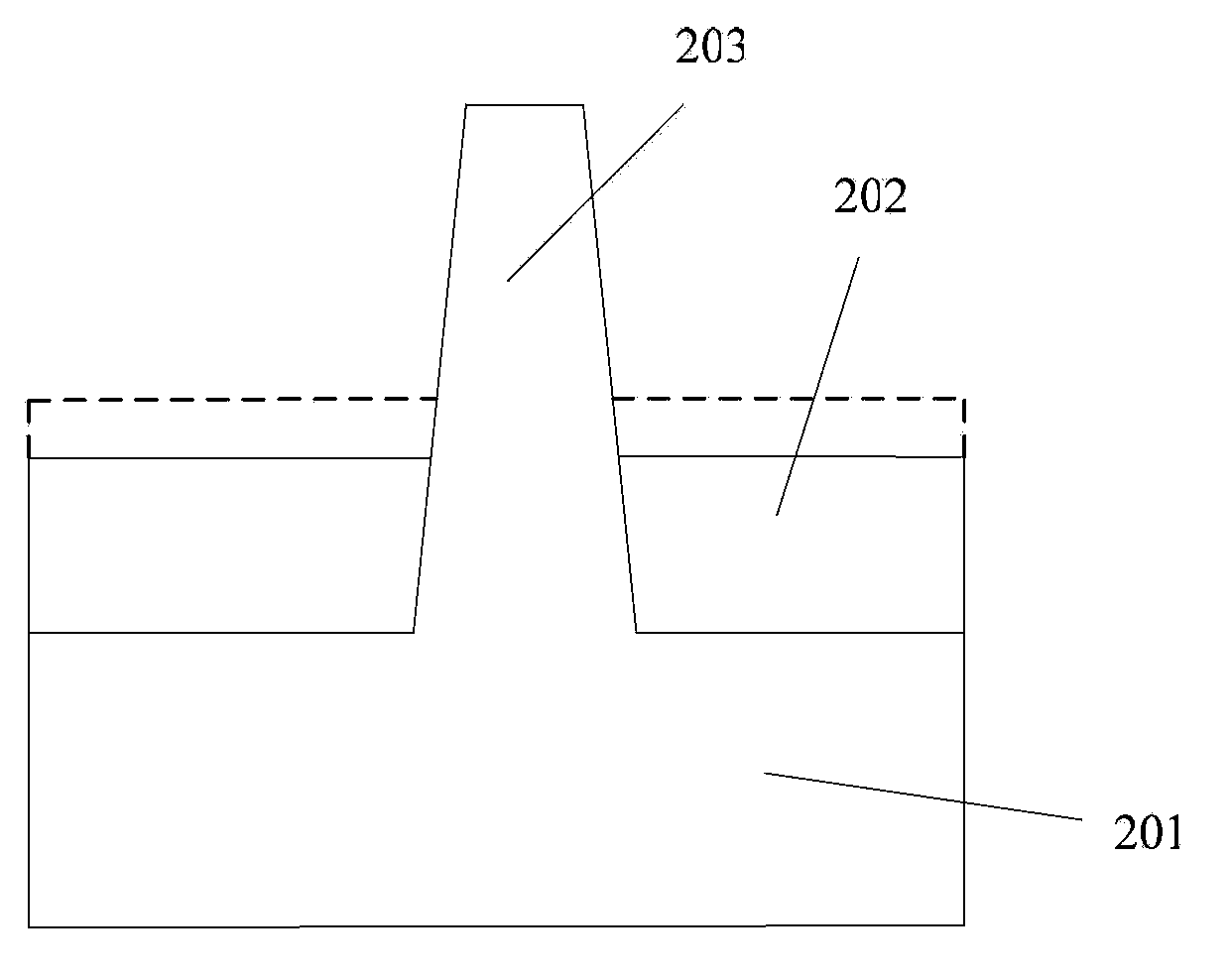

Fin type field effect transistor and forming method thereof

ActiveCN103681337AIncrease drive currentIncrease migration rateSemiconductor/solid-state device manufacturingSemiconductor devicesCharge carrier mobilityField-effect transistor

The invention relates to a fin type field effect transistor and a forming method thereof. The fin type field effect transistor comprises a semiconductor substrate, a fin part, first dielectric layers, a gate structure, a source region, a drain region and contact metal layers, wherein the fin part is positioned on the surface of the semiconductor substrate; the first dielectric layers are positioned on two sides of the fin part, and the surfaces of the first dielectric layers are lower than the top of the fin part; the gate structure is positioned on the fin part and covers parts of the top and the side wall of the fin part; the source region and the drain region are positioned on two sides of the gate structure; the contact metal layers are positioned on the surfaces of the source region and the drain region and have stretching stress. The carrier mobility of the fin type field effect transistor is high.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Composite conductive agent preparation method, lithium battery positive plate preparation method and lithium battery preparation method

The invention discloses a composite conductive agent preparation method which includes the steps: firstly, respectively weighing carbon nano-tubes, graphene and acetylene black according to the weight ratio of 5:5:90, adding the carbon nano-tubes, the graphene and the acetylene black into 15% of ethanol solution, adjusting a pH (potential of hydrogen) value of the solution, and enabling the pH value to be 6; secondly, enabling the carbon nano-tubes, the graphene and the acetylene black to organically combine by the aid of assist vibration process of high-speed dispersion and intense ultrasound, and synthesizing mixture by the aid of action of pi-pi bonds between material molecules and Vander Wale force to obtain uniformly-dispersed three-dimensional hybridization conductive agent solution of the carbon nano-tubes, the graphene and the acetylene black; thirdly, drying the hybridization conductive agent solution obtained in the step 2 for 24 hours in a vacuum drying oven at the temperature of 85 DEG C, and sufficiently grinding dried solid matters into powder to form the composite conductive agent. The invention further provides a lithium battery positive plate and a lithium battery preparation method.

Owner:OPTIMUM BATTERY CO LTD

Dye sensitized solar batter and its electrode

InactiveCN1624935AImprove photoelectric conversion performanceImprove conductivityLight-sensitive devicesCell electrodesMetal particleSolar battery

A dye sensitization solar battery electrode, including a conducting substrate, a semiconductor nanometer crystal film formed on the substrate and the dye layer formed on the crystal film. The semiconductor nanometer crystal film contains umpty conductive particles. This invention also provides the dye sensitization solar battery adopting the above electrode. This invention adds umpty conductive particles such as metal particles, carbon nanometer materials and etc into the semiconductor nanometer crystal film of the dye sensitization solar battery electrode, and solves the problem of low conducting ratio of the present semiconductor nanometer crystal film of the dye sensitization solar battery.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

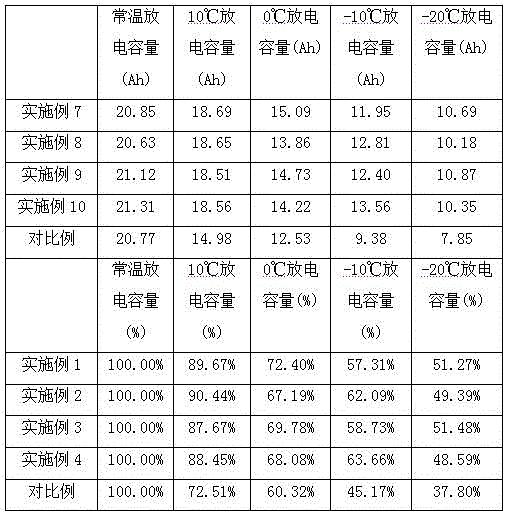

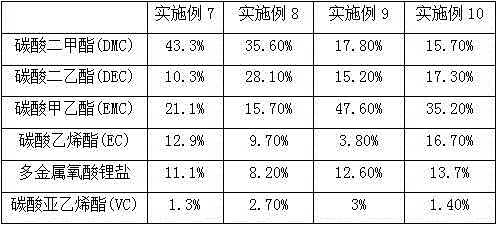

Low-temperature electrolyte for LiFePO4 (lithium iron phosphate) lithium-ion batteries

InactiveCN102983362AIncrease migration rateGood low temperature characteristicsSecondary cellsElectrolytic agentPhosphomolybdic acid

The invention relates to a low-temperature electrolyte for LiFePO4 (lithium iron phosphate) lithium-ion batteries, belonging to the technical field of low-temperature electrolytes for lithium batteries. The electrolyte comprises dimethyl carbonate, diethyl carbonate, ethyl methyl carbonate, ethylene carbonate, a film-forming additive and lithium polyoxometallate, wherein the lithium polyoxometallate refers to lithium phosphomolybdate Li3PMo12O40, lithium phosphotungstate Li3PW12O40, lithium silicotungstate Li4SiW12O40 or lithium silicomolybdenate Li4SiMo12O40. For solving the problems that in the prior art, the lithium ion transport of an electrolyte is blocked, slow in speed and low in efficiency and the electrolyte is poor in low-temperature performance, the invention provides a novel fluoride-free low-temperature electrolyte for LiFePO4 lithium-ion batteries; and by taking the non-fluoride lithium polyoxometallate with a three-dimensional skeleton structure as an electrolytic lithium salt and selectively adopting a low-viscosity carbonate solvent, through optimized proportioning, the migration rate of lithium ions is increased, and the low temperature properties of LiFePO4 batteries can be significantly improved.

Owner:中国东方电气集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com